Page 1

CARL GOLDBERG PRODUCTS

EX-TREME 330 3-D

© 2002 Carl Goldberg Products, Inc.

Page 2

WARNING! THIS IS NOT A TOY!

THIS IS NOT A BEGINNERS AIRPLANE

This R/C kit and the model you will build from it is not a toy! It is capable of serious bodily harm and property damage.

It is your responsibility, and yours alone - to build this kit correctly, properly install all R/C components and flying gear

(engine, tank, radio, pushrods, etc. and to test the model and fly it only with experienced, competent help, using commonsense

and in accordance with all safety standards as set forth in the Academy of Model Aeronautics Safety Code. It is suggested that

you join the AMA and become properly insured before attempting to fly this model. If you are just starting R/C modeling,

consult your local hobby dealer or write to the Academy of Model Aeronautics to find an experienced instructor in your area.

Write to: Academy of Model Aeronautics, 5151 Memorial Dr. Muncie, IN 47302

LIMITED WARRANTY

Carl Goldberg Products is proud of the care and attention that goes into the manufacture of parts for its model kits. The company

warrants that for a period of 90 days, it will replace, at the buyers request, any part or material shown to the company’s

satisfaction to have been defective in workmanship or material at the time of purchase.

No other warranty of any kind, expressed or implied, is made with respect to the merchandise sold by the company. The buyer

acknowledges and understands that he is purchasing only a component kit from which the buyer will himself construct a finished

flying model airplane. The company is neither the manufacturer of such a flying model airplane, nor a seller of it. The buyer

hereby assumes the risk and all liability for personal or property damage or injury arising out of the buyers use of the components

or the finished flying model airplane, whenever any such damage or injury shall occur.

Any action brought forth against the company, based on the breach of the contract of sale to the buyer, or on any alleged warranty

there under, must be brought within one year of the date of such sale, or there after be barred. This one-year limitation is imposed

by agreement of the parties as permitted by the laws of the state of Georgia.

Important Information

Covering coming loose is not COVERED UNDER WARRANTY. Due to

temperature changes the plane may develop some wrinkles in the covering that

you will need to remove with an iron. Be sure to seal the edges down first so

that you do not cause the covering to shrink and leave exposed areas of wood.

Please inspect the plane before beginning to assemble to make sure you are

happy with it. After assembly has begun you cannot return the kit. If you find

a problem before beginning to assemble the plane you must contact us, please

do not return it to the dealer.

© 2002 Carl Goldberg Products, Inc.

Page 3

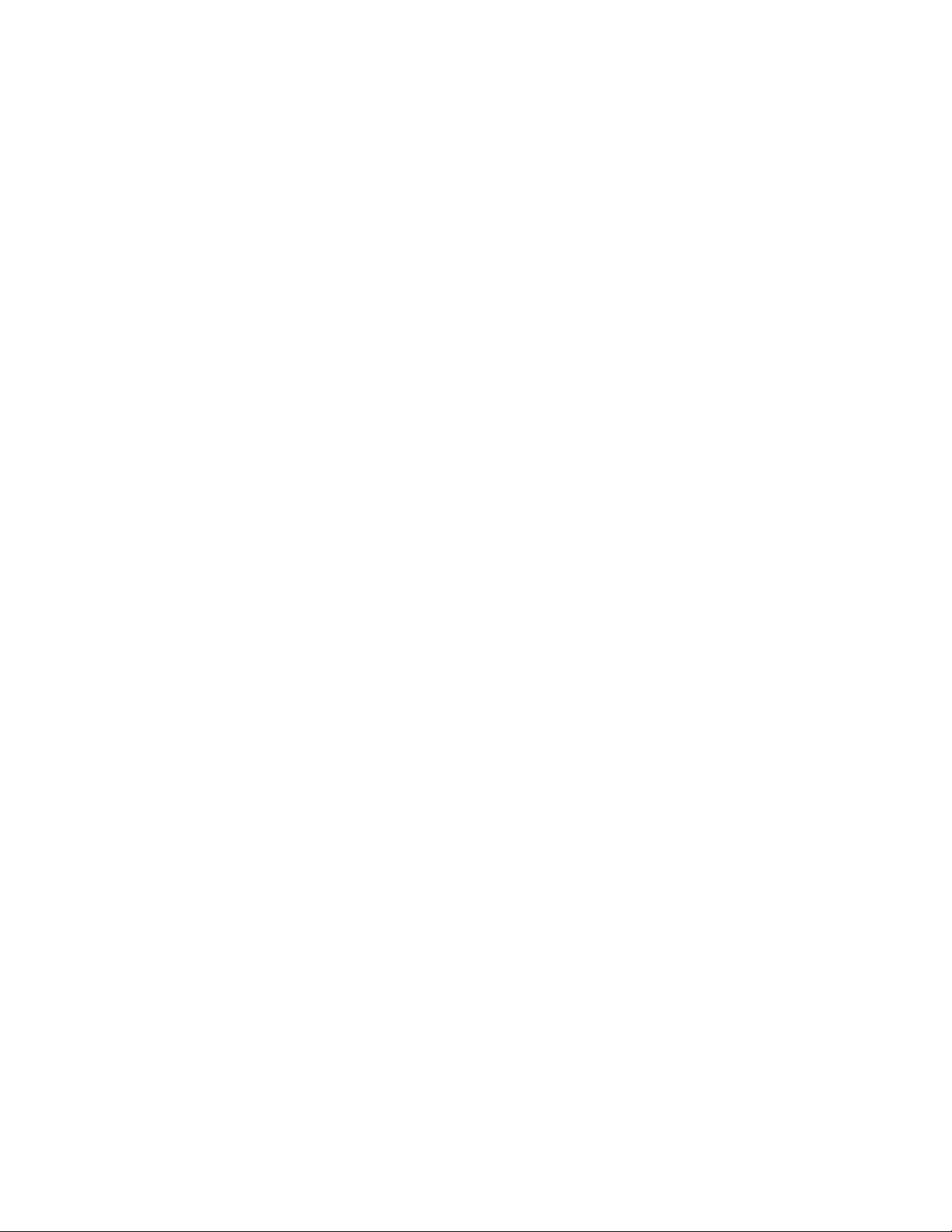

EX-TREME 330 3-D ARF

R udder

V ert ical St ab

PARTS LAYOUT

H ardw ood Engine M ount

Fue l Tank

A lim inum Landing G ear

M ai n W heel s

Elevator

Fuselage

H orizontal St ab

A ilerons

O ne P i ece W i ng

© 2002 Carl Goldberg Products, Inc.

Page - 3

Page 4

EX-TREME 330 3-D ARF

BUILDING INSTRUCTIONS

Before starting to build this kit, we urge you to read

through these instructions. They contain some

important building sequences as well as instructions

and warnings concerning the assembly and use of the

model.

We expect that you have some building experience to

take on this model. However, every minute detail is

not covered. This is not a basic trainer. The

instructions together with the simplicity of this kit

will allow you to produce a first class EX-TREME

330 3-D.

BUILDING SUPPLIES NEEDED

Hobby knife w/ #11 blade

Thin Zap CA

30 Minute Z-poxy

Thread lock

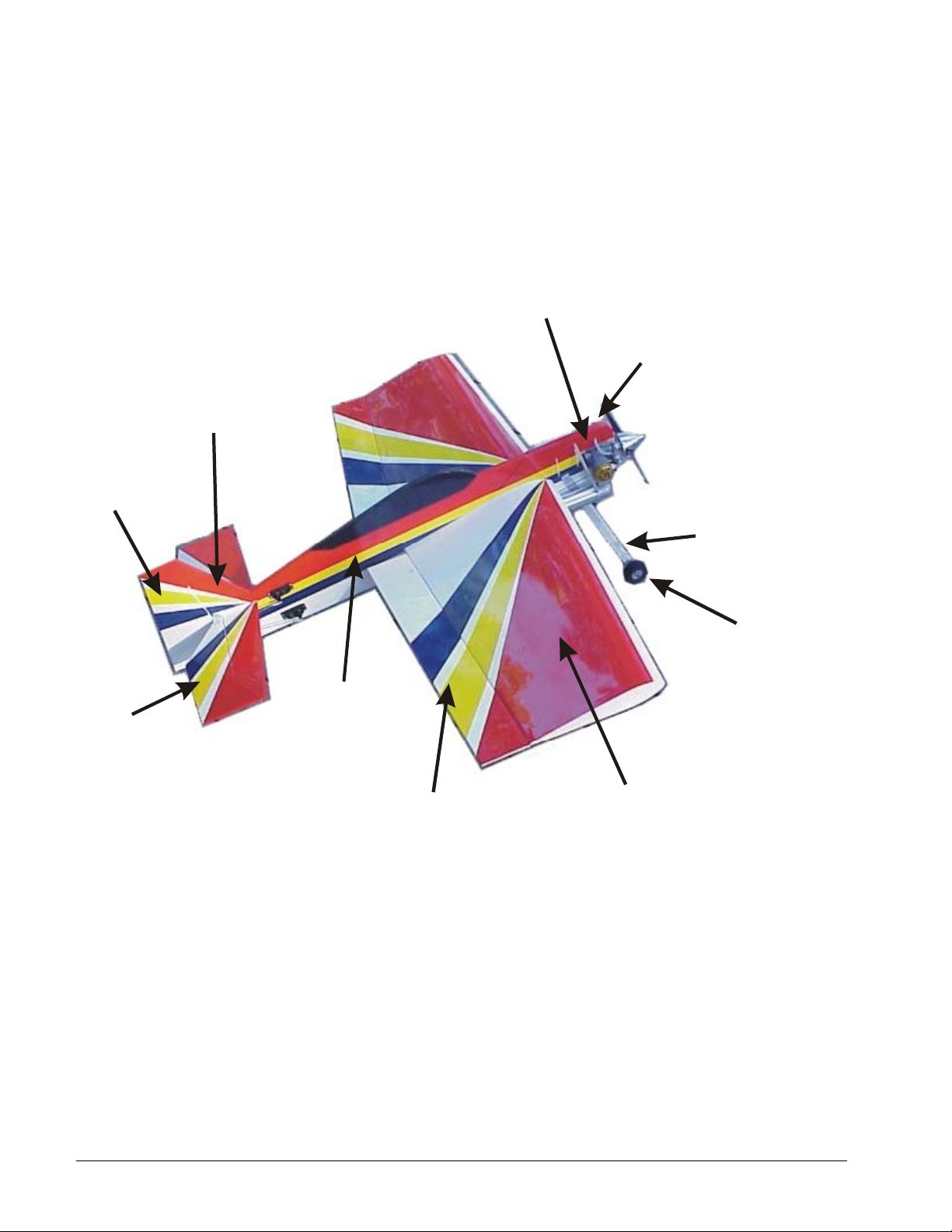

Test fit the wing in the fuse. Make any

1.

adjustments needed with a sanding block or

round file. Try to keep the fit as tight as possible.

Use a ruler to measure to make sure distance A B and C – D are equal. This is important to make

sure the plane tracks straight and predictably.

Wire cutters

Pliers

Drill with bits: 1/8”, 5/32”

Phillips and standard screwdriver

Small clamps

Masking tape

Tape measure

Washable marker

Paper towels

Rubbing alcohol

See the list at the end of the instruction book for a

list of additional R/C equipment you will need to

complete the EX-TREME 330 3-D.

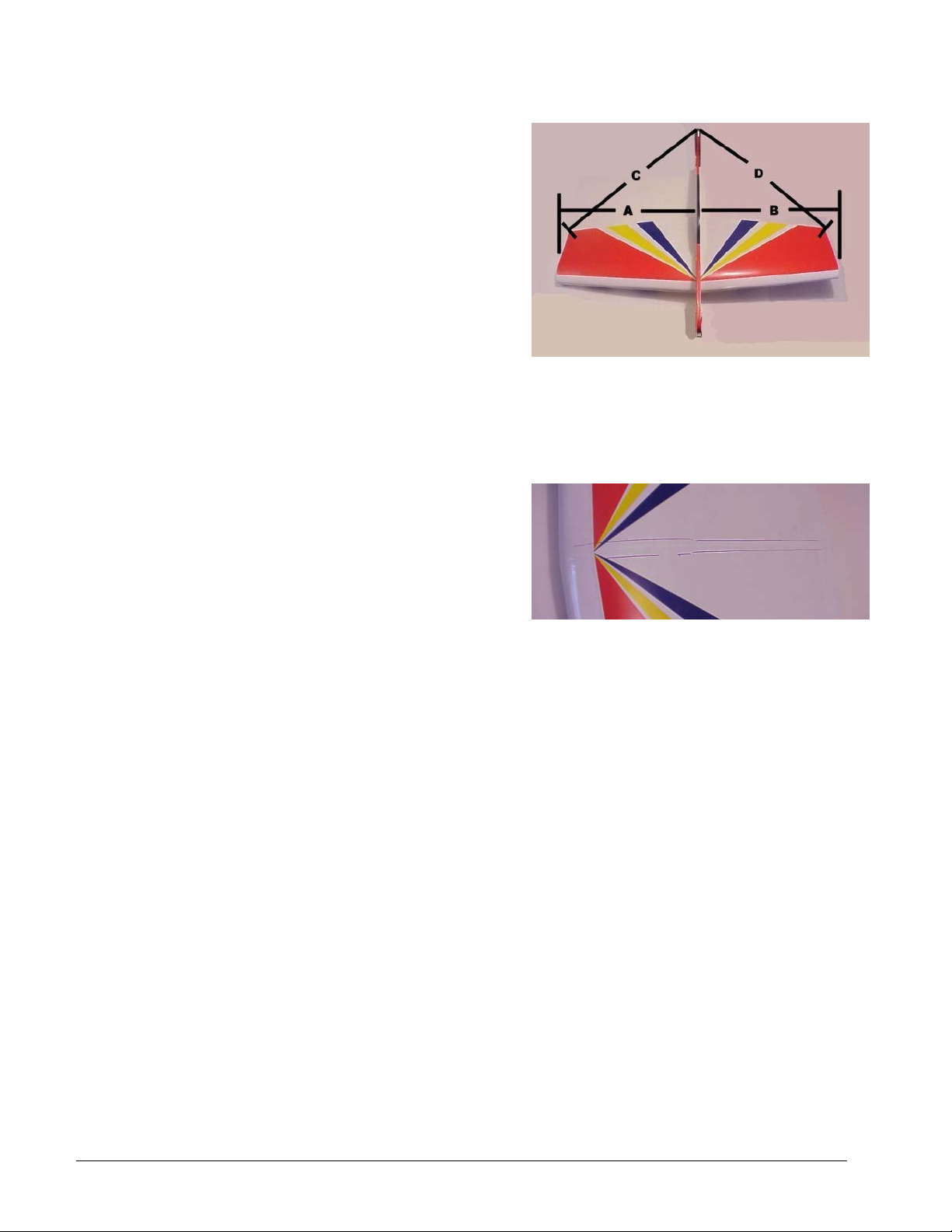

Use a washable marker to mark the location of

2.

the wing in the fuse on both sides, then remove

the wing. Remove the covering from the wing

joint with a sharp hobby blade, being careful to

only cut the covering and not the balsa.

3. Slide the wing back in the fuse, almost to the

wing joint. Coat the bare balsa at the joint with

30 minute z poxy and slide the wing in the rest of

the way. Use your marks to realign the wing,

then remeasure A to B, and C to D. Clean up any

zpoxy that squeezed out with a paper towel and

alcohol. Block the entire assembly on your

workbench until cured.

© 2002 Carl Goldberg Products, Inc.

Page - 4

Page 5

EX-TREME 330 3-D ARF

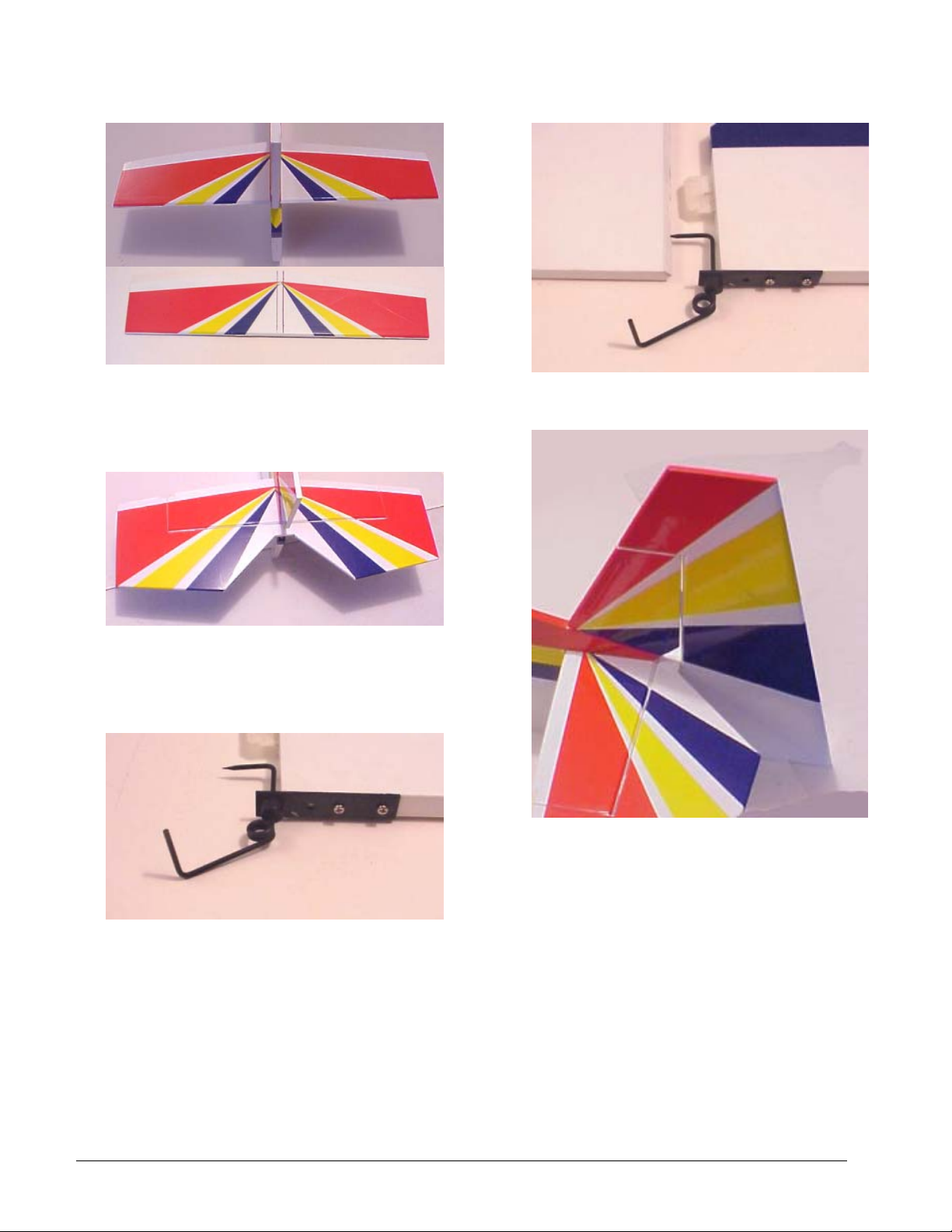

Test fit the horizontal stab in the rear of the fuse.

4.

Center it the same way you did the wing using a

ruler and make sure it square to the wing, then

mark and trim the covering from the joint. Glue

in place with 30 minute z poxy.

Test fit the elevator on the stab with 4 CA hinges,

5.

then glue in place with 1 or 2 drops of thin Zap

on each side of each hinge. Clean any CA runs

with

acetone.

Recess the bottom of the tail wheel bracket to

7.

accept the steering arm for the wheel.

Install the tail wheel bracket on the bottom of the

6.

fuse with two 2mm x10mm screws. Align the

wire with the back of the fuse.

© 2002 Carl Goldberg Products, Inc.

Page - 5

Install the rudder on the fuse with 30 minute

8.

zpoxy on the tail wheel bracket, then 2 CA

hinges and pink zap.

Page 6

EX-TREME 330 3-D ARF

Install the tail wheel on the bracket using a small

9.

inner diameter wheel collar and set screw on each

side of the wheel. Use thread lock on each set

screw.

Trial fit, then install an aileron on each side of

10.

the wing with 4 CA hinges and pink zap. Make

sure the wing tip and aileron tip are aligned

before you glue.

12. Position the aileron control rods off the servos,

toward the ailerons, keeping the rods 90 degrees

to the ailerons. Mark the position of the aileron

control horns, then install them with the 2mm x

20mm machine screws and backing plates.

Trim a hole using a sharp hobby blade, just

13.

behind the radio hatch on each side of the wing,

aligned with the servo, for the aileron control rod.

Install two aileron servos and one throttle servo

11.

in the wing. You may need to open the servo

trays to accept the size of your servos. Use a

hobby blade or razor saw to open the servo trays.

The aileron servos should be located to the

outside of the servo trays from the fuse, the

throttle servo needs to be close to the fuse.

© 2002 Carl Goldberg Products, Inc.

Page - 6

Use a clevis on the threaded end of the control

14.

rod and install one on each control horn. Lay the

rod across the servo arm, then make an “L” bend

at each intersection. Trim each rod to ¼” from

the bend, install in the horn, and secure with an

“L” keeper. Place a small piece of fuel tubing on

each clevis to lock in place.

Page 7

EX-TREME 330 3-D ARF

Install the control horns with the small machine

19.

screws, then install clevis and rod on each horn.

Trim 3 arms from a 4 arm servo wheel. Center

15.

your aileron servos with your radio, then install

the trimmed servo arms on the aileron servos.

Locate the servo positions in the rear of the fuse

16.

and remove the covering with a sharp hobby

blade.

Install your rudder and elevator servos in the

17.

openings, keeping the servo tops on the left side

of the fuse. Center the servos with your radio.

Trim two more 4 arm servo wheels and install on

18.

the servos, then locate the control horn positions

as was done for the ailerons, for the elevator and

rudder, trying to keep the rod positions 90

degrees to the control surface.

Position the rods across the servo horns, mark,

20.

make an “L” bend, then trim as before. Secure

the rod on the servo wheel with an “L” keeper.

21. Use the included wire tube , two brackets, and 4- 2mm

x10mm screws to hold the wires down the length of

the fuse

Cut the tube at an 11degree angle on one end.

22.

23.

Lay the angle cut on the tube on the bottom of

24.

the wing next to the fuselage with the back end of

the tube just in front of the bottom servo. Mark

the position for the hole and cut a notch in the

bottom of the wing next to the fuselage 3/16"

wide and 1/2" long for the rudder and elevator

servo leads

to exit the wing into the

© 2002 Carl Goldberg Products, Inc.

Page - 7

Page 8

EX-TREME 330 3-D ARF

tube.

25. Attach the tube to the side of the fuselage with

the two brackets and 4 sheet metal screws. You

can now run you wires from the rear servos

through the tube into the wing.

Mount your engine to the fuse with 3mm x

27.

20mm bolts, washers, and lock nuts. There is no

need to add any washers under the motor as the

right thrust is built into the motor mounts.

Trial fit your engine on the right side of the fuse.

26.

You can open the rails up slightly if needed.

Slide the engine forward so you have at least ¼”

clearance from the front of the prop hub to the

front of the fuse. Mark the location, remove your

motor, then drill for the 3mm engine mounting

bolts.

Prepare and install a servo wheel on the throttle

28.

servo as was done with the control surfaces.

Make sure your servo is at low position and the

travel matches up with the travel of the

© 2002 Carl Goldberg Products, Inc.

Page - 8

Page 9

EX-TREME 330 3-D ARF

carburetor.

Drill a small hole in the leading edge of the wing

29.

for the throttle control rod to exit, then slide a

control rod to the servo, with the threaded end at

the carb. Use a clevis on the threaded end to

mount to the carb.

Install an “EZ” connector on the outside position

30.

of the servo wheel, then adjust and secure the

throttle rod in the connector. Adjust the position

of the rod and connector to achieve the proper

throw on the carburetor.

Secure the servo with the screws supplied.

32.

33. Use a servo horn as is described above.

As an option, you can use a micro servo on the

31.

throttle. Remove the covering from the area just

behind the engine with a sharp hobby blade.

Position the landing gear on the side of the fuse

34.

with the top of the gear approximately 1” from

the LE of wing and the first bend of the gear just

above the bottom of the fuse. Angle the gear

approximately 15 degrees and mark through the

holes.

© 2002 Carl Goldberg Products, Inc.

Page - 9

Page 10

EX-TREME 330 3-D ARF

Drill the holes for the gear, then install the gear

35.

using the 3mm x 30mm bolts and lock nuts.

Install the axles in the end of the landing gear

36.

using the 4mm lock nuts.

screws.

Lay out the parts for the fuel tank assembly.

39.

Check the tank for any debris inside, then check

the fit of the stopper. You may need to remove

some flash with a sharp hobby knife.

Install the first collar and set screw on the axle.

37.

Install the large wheel, then the second collar and

38.

set screw to secure the wheel. Leave a small

amount of space from the wheel hub to allow the

wheel to turn freely. Use thread lock on the set

Bend the long fuel tube so 1/3 of it is bent up at

40.

45 degrees.

Assemble the stopper as shown, with the small

41.

washer to the inside of the stopper, then the

stopper, and the large washer. Secure with the

machine screw. Just start the screw for now.

© 2002 Carl Goldberg Products, Inc.

Page - 10

Page 11

EX-TREME 330 3-D ARF

Insert the bent tube through the stopper and one

42.

of the shorter tubes. (a 3 tube is supplied if you

would like to use a fill line to the tank, remember

to cap this line for flight).

Insert the fuel tubing on straight line, then trim to

43.

length so the clunk installed on the end does not

interfere with the back of the tank, then insert the

stopper in the tank and secure with the screw.

DO NOT OVERTIGHTEN THE STOPPER

SCREW. It just needs to be tight enough to seal

the opening.

Secure the tank to the fuse using the included

48.

wire ties, then trim the excess with a pair of wire

cutters.

49. Cut two pieces of fuel line with a sharp hobby

blade to run from the tank to the engine, you can

drill two ¼” holes to pass the fuel line through

the fuse if you like. Secure the fuel lines to the

tank with wire ties.

Twist the bent line in the tank so it faces the top

44.

of the tank.

Position your tank on the left side of the fuse,

45.

directly behind the motor, with the center of the

tank level with the upper engine rail. This height

is important for the proper location of the tank to

the carburetor.

Mark the location of the top and bottom

46.

indentions of the tank on the side of the fuse with

a felt marker, then drill four 3/16” holes.

Cut a piece of latex foam the approximate size of

47.

the tank.

Install your muffler using your engine’s included

50.

hardware. Secure your fuel and vent lines on the

proper fastener.

Install your radio switch in the bottom of the

51.

wing, on the side opposite the muffler. Use a

© 2002 Carl Goldberg Products, Inc.

Page - 11

Page 12

EX-TREME 330 3-D ARF

sharp hobby knife to cut through the balsa.

Position the two radio hatches in the radio

52.

openings and temporarily hold in place with

masking tape. Drill a pilot hole in each corner,

through the plywood corner plates. Install the

two radio hatches with the 2mm x8mm screws

and a phillips screw driver. Tighten the screws

until the just contact the balsa, as to not crush it.

Set the cg to 5-1/4 to 5-3/4 from the leading

56.

edge, measured at the fuse side. Keep the cg to

the front for the initial flights, then adjust as

needed.

Double check that all bolts are tight and use

57.

locktite where needed, and double check the cg,

then charge your planes batteries.

Have fun.

58.

Install your spinner back plate, balanced prop,

53.

and prop nut. Tighten it securely.

Install the spinner cone and tighten just snug.

54.

Set the control throws initially to +/- 3/8” for all

55.

surfaces. (After flight testing, adjust as needed.)

© 2002 Carl Goldberg Products, Inc.

Page - 12

Page 13

EX-TREME 330 3-D ARF

ADDITIONAL EQUIPMENT NEEDED TO

COMPLETE YOUR EX-TREME 330 3-D

General

.32 - .47 Size two stroke, or .40 to .63 four stroke R/C

engine and muffler

Minimum of 4 channel radio set required

(5) Standard servos - 70 oz servos recommended for high

horsepower engines.

(2) servo extensions

30 minute Z-poxy

Thin Zap CA (pink)

Dubro #222 Medium fuel tubing

Dubro #514 ½” Foam rubber

Ailerons and CA hinges

Horizontal Stabilizer, Elevator, and CA hinges

Rudder and CA hinges

Profile Fuselage

One Piece Wing

Included Hardware

EX-TREME 330 3-D PARTS LIST

Quantity Description

1 Profile Fuse

1 Elevator

1 Horizontal stabilizer

1 Wing

2 Aileron

2 Aluminum landing gear

2 Landing gear screws and nuts

3mm x 30mm

8 2mmx8mm machine screw

1 Ez connector

4 Control horn

8 2mm x20mm control horn

screws

4 L bend connectors

5 Clevis

5 Push rod

4 Large wheel collars

2 Wheels

2 Axle nut w/screw

1 Fuel tank

1 Fuel tank hardware

1 Tail wheel bracket

1 Tail wheel

4 4 3mm x 20mmscrews

3mm lock nuts

2 Small wheel collars

4 Long wire ties

© 2002 Carl Goldberg Products, Inc.

Page - 13

Page 14

14 CA hinges

1 Wire tube

2 Wire tube brackets

4 2mm x 10mm screws for tube

brackets

1 Decal set

EX-TREME 330 3-D ARF

© 2002 Carl Goldberg Products, Inc.

Page - 14

Page 15

Optional Landing Gear

Available

Make your Extreme 330 different from the crowed!

Our new # 257 Profile Nylon Landing Gear will fit you Extreme 300 and look great too. This

Landing gear also includes our new

# 302 5/32 x 1-1/2” Polished Nickel Landing Gear

axles to give you extra value.

1. Mount the nylon gear in the same location

as the aluminum gear.

2. Use (4) 4-40 x 1-1/2” bolts with washers

and locking nuts.

Caution: Make sure that you center the gear

between the lighting holes in the fuselage

sides.

Page 16

EX-TREME 330 3-D ARF

The Elevator

This maneuver has your plane drop vertically in a nose

high attitude, depending on wind conditions any where

from a 45 degree angle in low wind to almost backwards

in higher wind conditions. To perform it, at a high altitude

with high rates on, pull your throttle back and feed in the

elevator until you have the full high rate applied. Use the

rudder to guide the plane, and adjust attitude with minor

throttle inputs. You will loose altitude quickly, to recover,

apply full power and fly out level. Watch out for getting

too low or applying too much rudder, it could cause the

plane to snap.

The Harrier

This maneuver has your plane in very slow forward flight

in a nose high 45 degree attitude. To perform it, enter the

same way as you would an elevator, then feed in power

until the plane maintains altitude and starts to fly forward

at a nose high attitude. Maintain it by holding up elevator

and adjusting power, use the rudder to change direction.

Using ailerons may cause the plane to snap and should be

avoided. Add power and push the nose back over to

recover.

© 2002 Carl Goldberg Products, Inc.

Page - 15

Page 17

EX-TREME 330 3-D ARF

The Waterfall

This maneuver has your plane flipping around the axis of

the wing, while dropping. Starting from a high altitude, go

to low throttle and gradually pull the nose up to near

vertical. Just when the plane is about the stall, give it full

down elevator and full power. Make attitude corrections

with the rudder and ailerons to keep the plane flipping on

axis. Cut the throttle and hold full down elevator as the

plane flips around to nose high again, add power to flip it

over again. Watch your altitude as to not get too close to

the ground. Neutralize the elevator and add power to

recover.

The Blender

This is a violent maneuver that starts with a vertical rolling

dive that stops the descent as it changes into a flat spin.

Start at a good high altitude, go to low throttle and push

the nose down into a straight dive. Feed in full left aileron

and complete 3 rolls, then immediately move your

transmitter sticks to an inverted snap position, down

elevator, left aileron, right rudder, all full throw. Now

feed in high throttle to flatten the spin and stop the altitude

loss. Recover by neutralizing the rudder and ailerons, and

holding a little down elevator. After you gain some

airspeed you can roll out to upright. Use caution as this is

a violent and high G mauver that will put a great deal of

stress on the airframe.

© 2002 Carl Goldberg Products, Inc.

Page - 16

Loading...

Loading...