Page 1

INSTRUCTIONS

Welcome to the world of Ultimate flying! Now that you're an experienced R/C pilot, you're ready to step up to

a higher level of aerobatic flying. And we've made sure this ARF version won't disappoint. With just the same

flight characteristics as the kitted version, you'll soon know why the Carl Goldberg Products Ultimate has

been America's favorite sport biplane since 1990.

WARNING

A radio-controlled model is not a toy and is not intended for persons under 16 years old. Keep

this kit out of the reach of younger children, as it contains parts that could be dangerous. A radiocontrolled model is capable of causing serious bodily injury and property damage. It is the buyer's

responsibility to assemble this aircraft correctly and to properly install the motor, radio, and all other

equipment. Test and fly the finished model only in the presence and with the assistance of another

experienced R/C flyer. The model must always be operated and flown using great care and common

sense, as well as in accordance with the Safety Code of the Academy of Model Aeronautics

(www.modelaircraft.org). We suggest you join the AMA and become properly insured prior to flying this

model. Also, consult with the AMA or your local hobby dealer to find an experienced instructor in your

area. Per the Federal Communications Commission, you are required to use only those radio frequencies specified "for Model Aircraft."

LIMITED WARRANTY

Carl Goldberg Products, Ltd. has inspected and certified the components of this aircraft. The company urges the buyer to perform his own inspection, prior to assembly, and to immediately request a replacement of any parts he believes to be defective for

their intended use. The company warrants replacement of any such components, provided the buyer requests such replacement

within a period of 90 days from the date of purchase and provided the defective part is returned, if so requested by the company.

No other warranty, expressed or implied, is made by the company with respect to this kit. The buyer acknowledges and understands that it is his responsibility to carefully assemble the finished flying model airplane and to fly it safely. The buyer hereby

assumes full responsibility for the risk and all liability for personal or property damage or injury arising out of the buyer's use of

the components of this kit.

1

PT. #2045 6/03

The Ultimate ARF

CARL GOLDBERG PRODUCTS, LTD.

P.O. Box 818 Oakwood GA 30566 Phone #678-450-0085 Fax # 770-532-2163 www.carlgoldbergproducts.com

© Copyright 2000 Carl Goldberg Products LTD.

Page 2

ITEMS NEEDED TO COMPLETE THIS AIRCRAFT

1 RADIO GUIDANCE SYSTEM (4 CHANNEL

MINIMUM REQUIRED)

2 12” AILERON SERVO EXTENSION WIRES

1 Y-HARNESS

1 ENGINE .60-.90 2-CYCLE, .90-1.20 4-

CYCLE AND MUFFLER

1 2 OZ. BOTTLE CA GLUE

1 1/2 OZ. BOTTLE CA GLUE

1 EPOXY

1 8 x 12 FOAM RUBBER

OPTIONAL:

1 PILOT FIGURE

1 SWITCH HARNESS

*

NOTE: The Ultimate ARF covering matiches

Bright Yellow(#872), Deep Blue(#873)

UltraCote®.

UltraCote® is a registered trademark of Horizon Hobby Distributors

TOOLS AND SUPPLIES FOR ASSEMBLY.

MODELING OR UTILITY KNIFE

WORK SURFACE (24" X70")

ELECTRIC DRILL

1/16”, 3/32”,1/8", 3/16”, 5/32”, 1/4”, 5/64”

7/32” DRILL BITS

SMALL STANDARD & PHILLIPS SCREW-

DRIVERS

MASKING TAPE

NEEDLE NOSE PLIERS

MOTO TOOL

24” RULER

FLEXIBLE STRAIGHT-EDGE

30-60-90° x 6" TRIANGLE

SOFT PENCIL

A FEW STRAIGHT OR "T" PINS

ADJUSTABLE WRENCH

WIRE CUTTER (DYKES)

OPTIONAL HEAT GUN/COVERING IRON

ACID BRUSH

ELECTRICAL TAPE

SOLDERING IRON, FLUX, SOLDER

PIECE OF MEDIUM SANDPAPER

5 FT. LENGTH OF STRING

2

Page 3

INTRODUCTION

USING THIS INSTRUCTION MANUAL

Before you begin assembling your ULTIMATE ARF, take

some time to read through this entire instruction book. It

is designed to take you step-by-step through the process

and to give you added information on engine and radio

selection and set-up, balancing your aircraft, and flying

your model. The time you spend will speed the assembly process and help you avoid problems.

PREPARING FOR ASSEMBLY

You will need a work area of approximately 24 x 70" which has

been covered to protect it from adhesive, as well as c uts and

other damage. Many people cover their work area with a

sheet of dry wall (sheet rock) and/or waxed paper t o

prevent CAglue and Epoxy from ruining the work surface.

CONSTRUCTION TIPS

IMPORTANT: ALWAYS READ A FEW STEPS AHEAD.

This will alert you to coming instructions and will help you

plan accordingly.

Using the Parts Identification section, familiarize yourself

with the various items included in your kit box.

As you work, CHECK OFF EACH STEP in the box provided, so that you are sure you do not forget anything.

Do not hesitate to ask questions. Your local hobby dealer and area flyers will most likely by happy to help, as

they want you to have a successful flying experience.

You may also receive technical assistance from Carl

Goldberg Models via e-mail (questions@carlgoldbergproducts.com) or by telephone 1-678-532-0085.

tCAUTION

Some people may experience an allergic reaction when

exposed to fumes from CA glue or epoxy. As with paints,

thinners, and solvents, it is always important to use glues

only where there is adequate ventilation to carry fumes

away. A fan is recommended. Also, special care must be

taken when using CA, as it will bond skin as well as other

surfaces. Before using any CA, carefully read all label precautions. When using CA, protective eye-wear and care in

keeping the glue away from the face is highly recommended. If CA does happen to get into the eye, hold lid

open and flush with water only. Seek immediate medical

attention.

COVERING

The Ultimate ARF is covered in genuine a premium polyester film chosen by many of the world's top flyers for its

beauty, toughness, and ease of application and repair. It

is not uncommon for ARF's to develop a few wrinkles in

transit. If this is true of your model, the situation is easily corrected. Before you begin putting the pieces together, run over the surface of each section with an iron

(either specially designed for airplane use or the more

cumbersome household iron) or use a modeling heat

gun. Apply the heat (set at about 350° F), following

along with a soft cloth and pressing down on the covering as you go around. This will more firmly set the covering adhesive into the wood and keep your aircraft covering tight and smooth in the future.

3

Page 4

1. Collect the following parts:

(1) Top Wing

(1) Bottom Wing

(4) Ailerons

(16) Jet Hinges

WING CONSTRUCTION

Aileron Installation

2. Locate the pre-cut aileron hinge slots in both

the top and the bottom wings. Using a hobby

knife (#11 blade), slide the blade into each of

the slots to make sure they are cleanly cut.

Repeat this process with the ailerons, mak-

ing sure all hinge slots are clean.

3.

Place a straight pin into the center of each of

four Jet Hinges.

3.

Slide four hinges into the hinge slots on one

side of a wing The straight pin will prevent

the hinges from going further than halfway

into the wing.

4.

Select one of the ailerons and insert the

exposed half of each hinge into the aileron

slots. Slide the aileron toward the wing until

no gap remains between the aileron and the

wing.

When satisfied with the alignment, remove

the straight pins, being sure to keep the

aileron tight to the wing. You may wish to

apply a few pieces of masking tape to keep

the pieces in place.

6.

Keeping the aileron and wing in position,

apply 3 or 4 drops of Instant thin CA to the

small exposed area of each hinge.

Turn the wing assembly over and again

apply 3 or 4 drops of thin CA to the exposed

hing surface.

Allow to dry for 10 minutes before flexing the

aileron.

7.

Repeat the above steps for each of the other

ailerons.

NOTE: Remember that the following pictures may

not exactly match the hardware you are using.

Always check the manufacturer’s instructions when

installing radio equipment.

5. Carefully check the alignment of the aileron,

making sure it is flush with the end of the

wing.

1. Collect the following parts:

(1) Aileron servo door

(2) 3/8 x 3/4 x 3/4"servo mounting block

(4) 1/8 x 3/4 x 3/4 aileron door mounting plate

(4) Servo mounting screw (supplied with radio)

(4) #2 Washer

(4) #2 x 3/8" screw

(1) Servo with rubber grommet

Aileron Servo Installation (Bottom Wing)

4

Page 5

8. Place the servo door on the wing and drill a

1/16” hole on each corner. Screw the door to

the plate, using the #2 x 3/8” screw and the

#2 washer supplied with the kit.

Repeating the above steps, mount the sec-

ond aileron servo.

3. Remove the servo from the door. Spread

epoxy on the servo mounting blocks and

glue them in place along the line just drawn,

making sure the wood grain runs vertically.

4.

When the epoxy is dry, drill 1/16” holes and

mount the servo onto the blocks with the

mounting screws supplied with the radio.

Repeat these steps to mount the other

aileron servo.

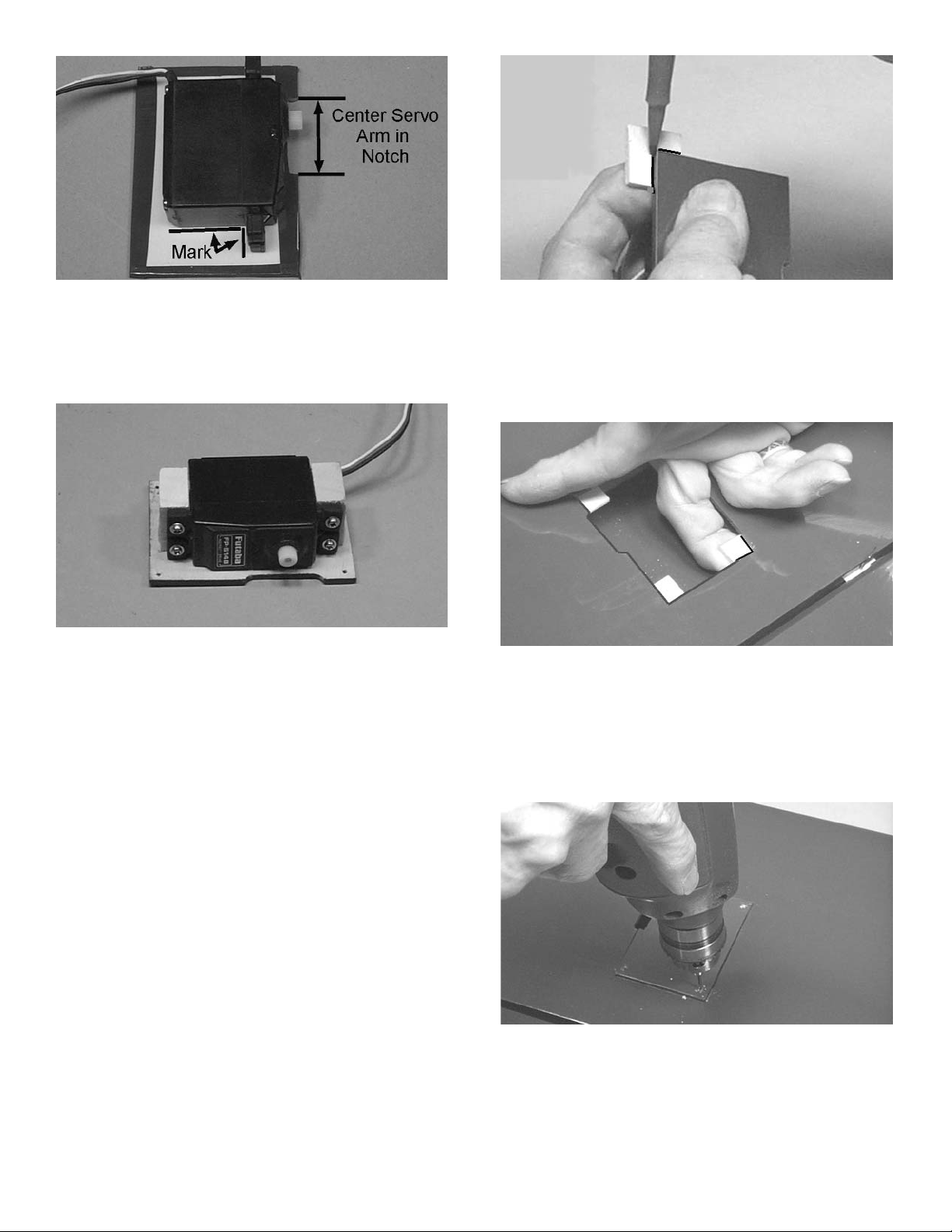

2. With the servo door upside down on the

work surface, place the servo on top of the

door with the servo arm post centered vertically and horizontally with the servo door

notch. Mark the location of the servo, as

above.

6. Hold one of the servo plates in place against

one corner of the servo door, locating it in

such a way that the tab does not interfere

with the servo.

Mark the servo door-edge location on the

plate.

7. CA glue the plate to the corresponding cor-

ner of the servo hole in the wing.

Follow the same procedure with each of the

other three plates.

NOTE: Plates will fit into the corner differently,

depending on the servo used.

5

Page 6

Aileron Extension Installation

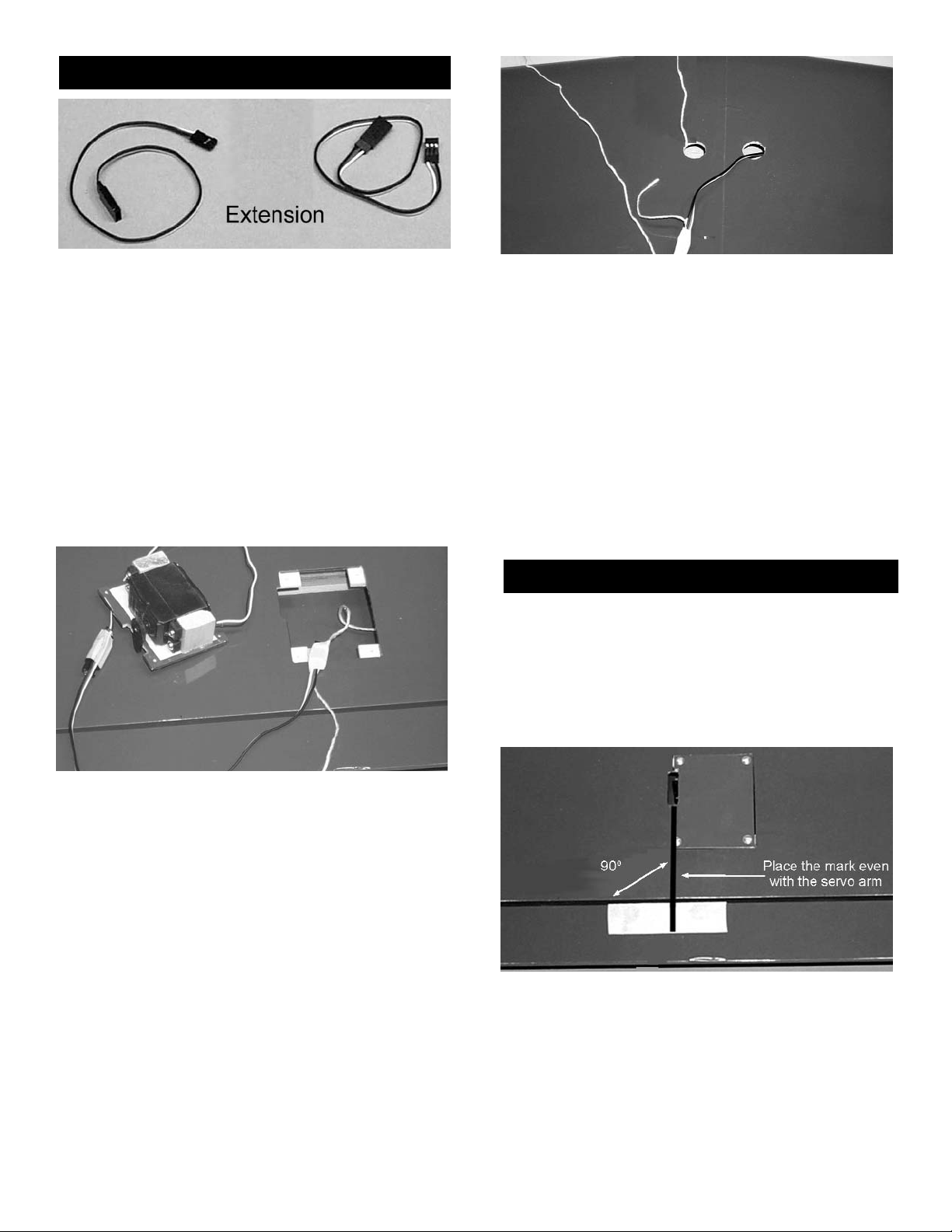

1. Gather the following items.

(2) 12” extension wires

NOTE: Before starting, remove the servo door and

make sure the length of one servo wire, when

plugged into the 12” extension, is long enough

to reach to the center of the wing. If necessary, add

an additional extension to reach the center of the

wing.

IMPORTANT! To ensure that any connections

located inside the wing will not come loose, either

when the wires are pulled, or during flying, always

tape them securely together with electrical tape.

2. Remove servo door and, making sure to use

the correct servo for the opening, attach the

servo wire to the12” extension and securely

tape connection.

NOTE: Before continuing, make sure the other end

of the string inside the wing, next to the second

aileron hole, is taped firmly to the wing, so that it is

not pulled out by mistake. (If it becomes necessary

to reinsert this string into the wing, tie a 6-32 nut to

the end of the string and feed it back into the wing.

The nut will easily fall through the wing rib holes.

Tie the other end of the extension to the

string that exits the servo opening and tape

this connection, also.

3. Grasping the string in the hole in the center

of the wing, SLOWLY pull until the end of the

12” extension comes out of the hole. Work

the string back and forth to get the extension

plug to go through the cutouts in each rib.

Pull gently and have patience.

4.

Tape the extension securely to the wing, so

that it will not slide back in while you are

working.

Repeat these steps for the other half of the

wing, so that both servo extensions are exiting the holes in the center of the wing..

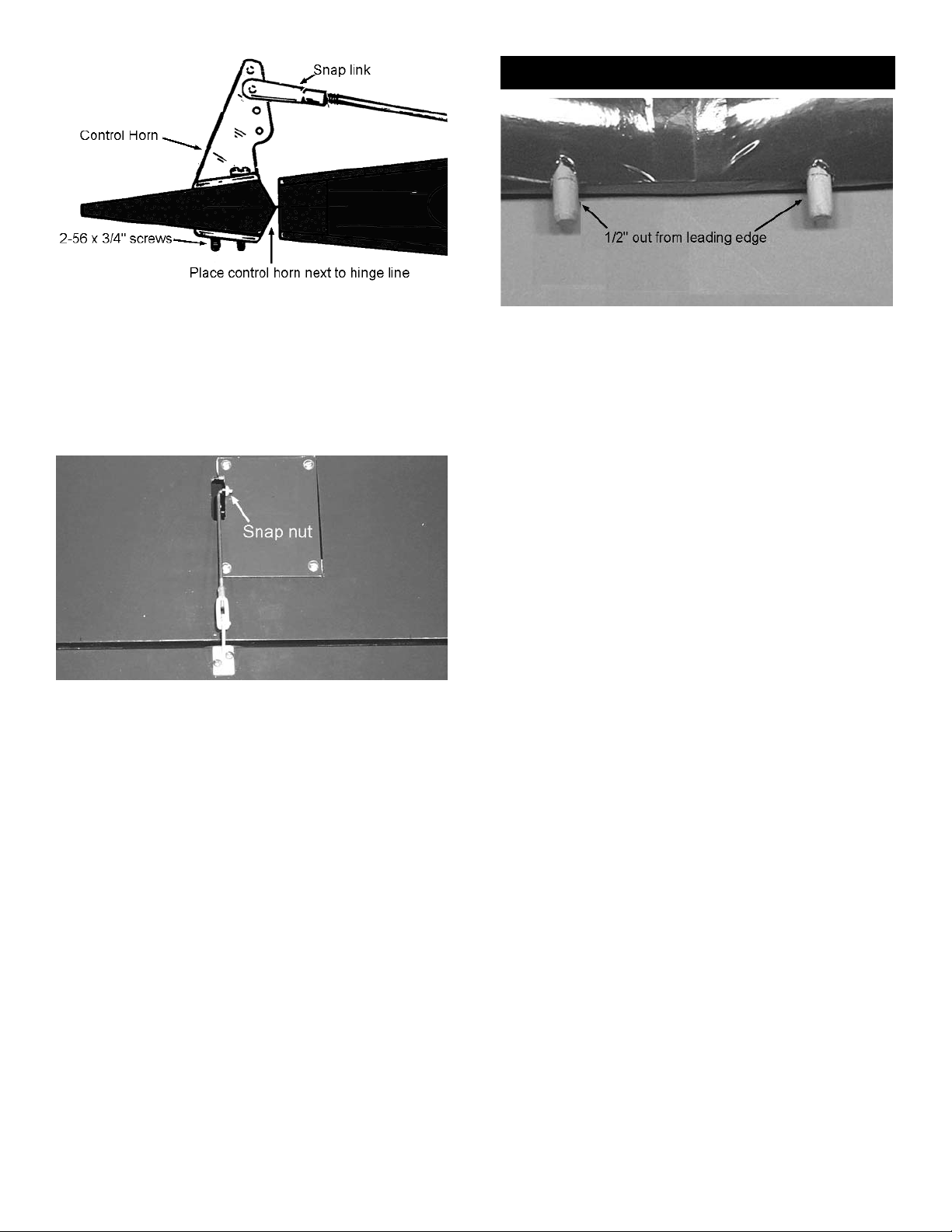

Control Horn Installation

1. Collect the following items:

(2) Large control horn with back plate

(4) 2-56 x 3/4” screw

(2) 1/16 x 7” threaded wire

(2) Snap-link

(2) Nylon snap nut (molded 6-up - see photo in

Engine Pushrod Installation)

2. Replace the servo door and screw it down

onto the wing.

3.

Make a mark at a 90º angle to the trailing

edge and in line with the servo arm.

6

Page 7

Wing Dowel Installation

5. Thread a snap-link on the end of one of the

1/16 x 7” threaded rods.

Place the snap-link in the second-from-the-

top hole on the control horn.

6.

Making sure the aileron is in neutral position,

mark where the wire meets the hole on the

servo arm.

Put a 90º bend (or a z-bend, if preferred) in

the wire, as shown above, and then attach

the wire to the servo arm with a snap nut.

Finally, put a drop of glue on the snap nut.

Repeat these steps for the other aileron.

4. Position the control horn so that the snap

link holes are right next to the hinge line.

Using a 3/32” drill bit, make a pilot hole in

each screw location, and then mount the

control horn, using the 2-56 x 3/4” screws.

1. Using epoxy, mount the 5/16 x 1-3/4” dowels

into the holes in the leading edge of the bottom wing. Make sure to leave about 1/2” of

dowel sticking out of the front of the wing.

You may wish to slighly taper the exposed

dowel ends for ease of insertion into the fuse

holes.

Now set the bottom wing aside until later.

7

Page 8

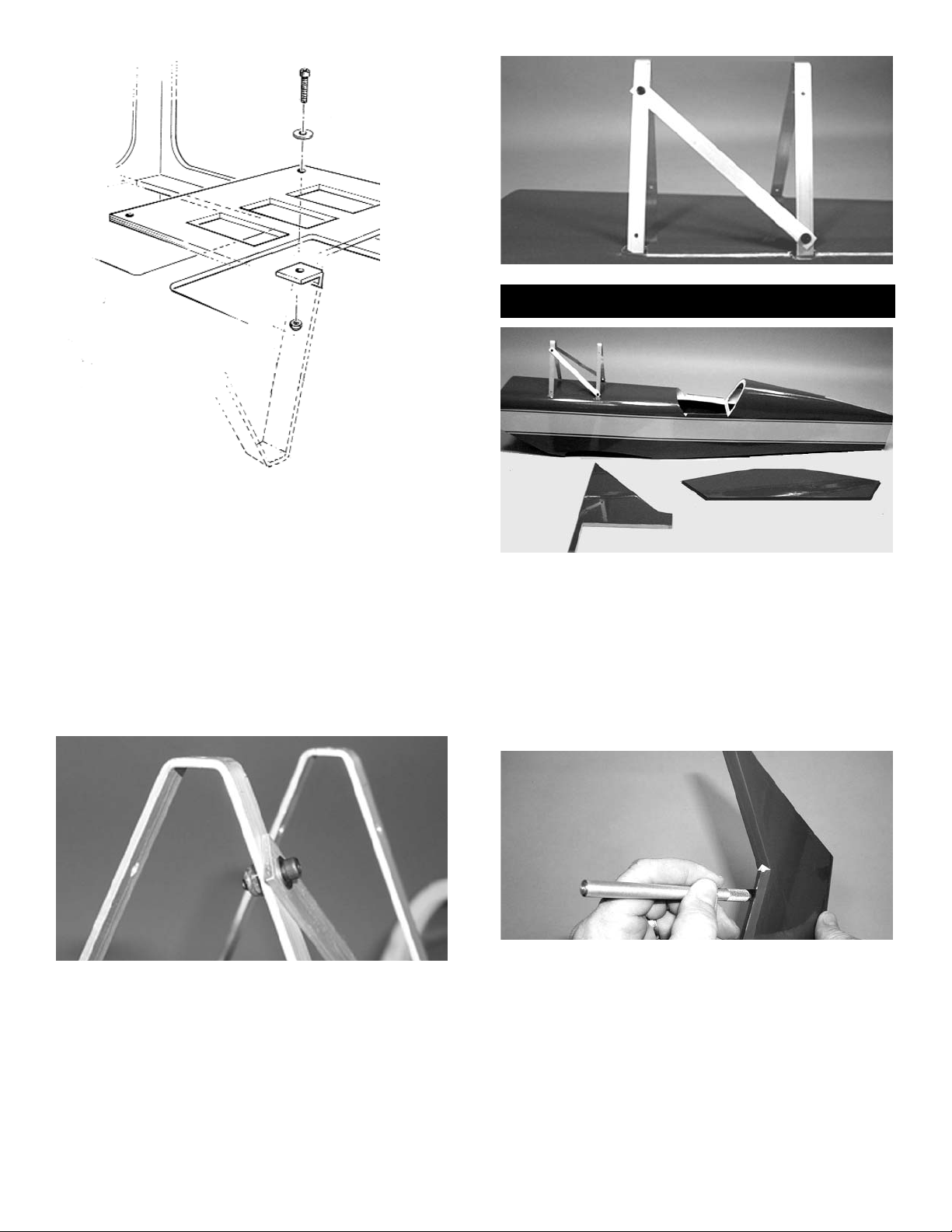

1. Collect the following parts.

(1) Fuselage

(1) Servo tray

(2) Front cabane doubler

(2) Cabanes

(2) Cross brace

(4) 4-40 x 1/2” Socket head screw

(4) 4-40 x 3/8” Socket head screw

(4) #4 x 7/16” washer

(4) #4 washer (smaller)

(8) 4-40 lock nut

2. Being careful to align the holes and the

servo cutouts, CA glue the servo tray doubler into the fuselage.

4. Beginning at the front of the fuselage, make

a mark at 5” and at 9-3/4”. This will help

locate the pre-cut cabane slots on the

curved top of the fuse, behind the firewall.

5. Using a hobby knife, make a horizontal slit

from front to back, in the middle of the

cutout, as shown.

Slit all four cutouts in the same way.

FUSELAGE ASSEMBLY

Cabane Installation

3. Glue the front cabane doublers over the

holes in front of the fuselage former. Again,

make sure the holes in both the doubler and

the fuselage are aligned.

6. Gently push one side of the cabane into the

front fuselage slot, until it falls inside.

7. Slip the other side of the cabane into the cut

on the opposite side of the fuselage.

8

Page 9

2. Locate the pre-cut hinge slots and, using a

hobby knife, make sure all slots in the stabilizer, elevators, rudder, and fin are cleanly

cut.

Test the size of each slot by sliding a hinge

halfway into the opening. Then set the rudder and elevators aside until later.

8. Turn the fuselage over and, working from

the inside, insert a 4-40 x 1/2” screw with

a #4 x 7/16” washer into the fuselage hole in

the cabane doubler and then through the

cabane hole. This is somewhat tricky, so

have patience.

When the screw protrudes through the

cabane hole, cap it with a 4-40 locking nut

and tighten.

Repeat these steps at each of the three

mounting points to complete the cabane

installation.

9. Insert a 4-40 x 3/8” screw and washer into

the cross brace in the top side hole of the

front cabane and secure with a 4-40 locking

nut.

Then, mount the other end of the cross

brace into the rear cabane, as shown below.

Repeat with the other cross brace.

Stabilizer/Fin Installation

1. Collect the following items.

(1) Fuselage

(1) Horizontal stabilizer

(1) Vertical fin

(2) Elevators

(1) Rudder

(1) 5ft. Length of string (not included in kit)

9

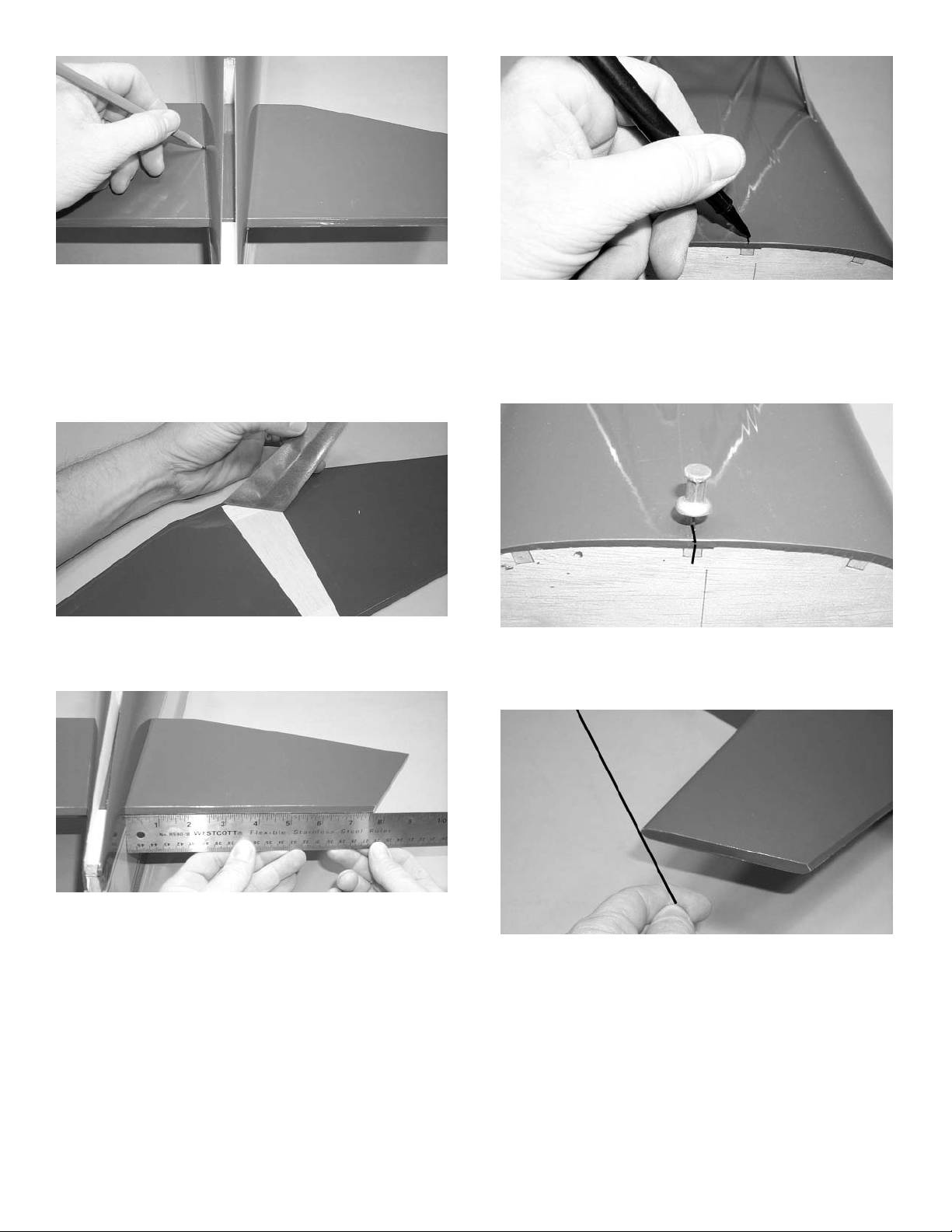

Page 10

3. Locate the pre-cut stab cutout by feeling

along the fuse side in the area where the

stab should go.

Remove the covering over the stab slot on

both sides of the fuselage.

4. Mark the center of the stab on both the trail-

ing and leading edge.

5. Slide the stab into the back of the fuselage,

using the center marks as a guide. Measure

the stab, as shown, to make sure it is properly centered.

NOTE: It is also possible to see the centermarks

through the fin cutout.

6. Turn the fuse around, and determine the

vertical centerline of the fuse top front.

Measure to the center point on the top of the

fuselage. DO NOT CENTER ON THE FIREWALL THRUST LINE.

7. Place a pushpin on the center mark and tie

a string around the pushpin.

8. Stretch the string back until it touches the

outer tip of the stabilizer leading edge. Mark

the string and then measure back to the

other outer L.E. tip, making sure the distance

is the same.

10

Page 11

9. When the stab is correctly aligned, outline on

both the top and bottom of the stab where it

meets the fuse, as shown.

10. Remove the stab from the fuselage. Being

careful to not cut into the wood, and work-

ing about 1/8” inside the outline on the stab,

lightly cut away the covering on both the bottom and top of the stab.

Replace the stab on the fuselage, but DO

NOT GLUE AT THIS TIME.

11. Slide the fin into the back slot and push the

fin front down into the top slot.

When the fin is all the way down and flush to

the fuselage, mark a line on both sides of the

fin where it meets the fuselage.

12. Locate the solid wood area under the cover-

ing and place marks on the line where the

wood ends. Make sure not to mark any open

frame areas.

13. Staying at least 1/4” away from the open

frame, carefully remove the covering on

those areas of the fin (both sides) that are

inside the fuselage.

14. Replace the fin on the fuselage and check to

see that the fit is good and the alignment

square.

When you are satisfied with the fit, remove

the fin.

Mix 2-3 tablespoons of epoxy and, using a

stick or an acid brush, spread epoxy down

inside the fin slot, along the walls of the slot,

and on top of the stab.

Glue the stabilizer and the fin to the fuselage

and, using the measuring string and a 90º triaangle, check to see that the tail assembly is

square. Allow to dry thoroughly.

11

Page 12

15. When dry, turn the fuse over and wick a few

drops of thin CA gluet along the stab/fuse

joint.

Control Horn Installation

1. Collect the following parts:

(2) Elevator

(2) Large control horn with backplate

(4) 2-56 x 3/4” Pan head screw

(1) Rudder

(1) Double-sided control horn

(1) 2-56 x 1/2 Phillips head screw

NOTE: You will be making both a LEFT and a

RIGHT elevator.

2. Mark 1” in from the inside edge along the

hinge line of the elevator.

3. Place the control horn as shown, with the

center aligned on the 1” mark and the snaplink holes directly above the hinge line.

On the elevator, mark the location of the

mounting holes on the base of the control

horn and drill, using a 3/32” bit. Then mount

the control horn as shown, using 2-56 x

3/4” screws.

Remembering that you are making both a

lef

t and a right elevator, repeat the previ-

ous steps to mount the control horn on the

other elevator.

NOTE: The double-sided control horn is two control

horns screwed together back to back.

4. Place the control horn on the rudder as

shown. The control horn must be even with

the hinge line. When you are satisfied with

the fit, mark the location of the screw hole

and drill, using a 3/32” bit through the rudder.

Place the two control horns together and

mark the bolt location on the second control

horn base.

Drill the second control horn using a 1/16”

bit.

Mount the control horn, using the 2-56 x 3/4”

screw.

Elevator/Rudder Hinge Installation

1. Collect the following items.

(1) Fuselage/Tail Assembly

(2) Elevators

(1) Rudder

(9) Jet hinges

12

Page 13

Landing Gear Installation

1. Collect the following items:

(1) Landing gear

(3) 6-32 x 3/4” socket head screws

(3) 6-32 blind nuts

(3) #6 washers

(1) Fuselage

2. Place the main gear on the bottom of the

fuselage, as shown.

Locate the center of the fuselage and mark

it. Then mark the center of the gear and line

up both center marks.

3.

Move the gear back until it touches the stop on the

back of the gear block. Then mark the hole locations and drill a 5/32” hole at each location.

4.

With the screws and the washers through

the gear, pull the blind nuts up tight inside

the fuselage.

2. Take three hinges and, as with the aileron

hinge installation, insert the hinge into the

elevator, using straight pins to ensure the

hinge stays centered between the stabilizer

and the elevator.

Slide the exposed side of the hinge into the

slots in the stab until the pins touch both the

stab and the elevator.

3. Holding the elevator and stab together, place

a straight pin between the stab and the elevator, at the elevator tip. This pin will create

a 1/32” gap between the elevator and the

stab.

Remove the pins in each hinge and, keeping

the elevator/stab assembly in position, apply

3 or 4 drops of thin CA to each hinge, on

both the top and bottom sides of the stab.

Allow ten minutes for the CA to cure before

flexing the elevator. Then install the second

elevator.

4. When the elevators have cured, install the

hinges and mount the rudder, using the

same techniques used for the other hinged

surfaces.

NOTE: Before gluing, make sure the top of the rud-

der is even with the top of the fin.

13

Page 14

Tailwheel Installation

1. Collect the following items:

(1) Tailwheel bracket

(1) Tailwheel

(2) Springs

(2) 2-56 x 1/2” Philips head screw

2. Locate the three holes under the covering on

the bottom rear of the fuselage. Remove the

covering from all three holes.

NOTE: The hole nearest to the nose of the model is

the exit hole for the receiver antenna. The other two

holes are for the tailwheel assembly.

14

5. One of the bracket collars has two holes

threaded into it, one on each side. This one

is the top one.

Put the bottom bracket collar on the axle and

insert it through the spring bracket.

Put the top collar bracket on top and tight-

ened the two set screws.

6.

Screw one of the two threaded rods on each-

side of the top bracket collar.

Screw the nylon horn fittings on each end of

the threaded rod.

7.

Put the tail wheel on the axle and retain with

the wheel collar.

9. Mount the tail wheel assembly on the rear of

the fuselage using the two 4-40 screws.

3. Mount the tailwheel using the 4-40 x 1/2”

phillips head screws, as shown above. Hook

the springs between the rudder control horn

and the tailwheel bellcrank. It may be necessary to open the end of the springs in order

to connect them to the control horns and the

bellcrank.

1. Collect the following items:

(1) Engine

(1) Motor mount

(4) 6-32 x 3/4” socket head screw

(4) 6-32 blind nut

(4) #6 washer

(4) #8 x 1” pan head screw

Motor Mount/Engine Installation

Page 15

Align Marks

REMEMBER, the following pictures and instruc-

tions may vary slightly, depending on the equipment

you are using.

2. Using the alignment marks, center the motor

mount on the firewall and tack glue.

3. Drill a pilot hole through the motor mount,

using a 1/8” drill bit.

Remove the motor mount and re-drill the

holes, using a 5/32” drill bit.

4. Install the motor mount blind nuts into the the

back of the firewall with the 6-32 x 3/4” socket head screws and the #6 washer.

NOTE: The top left blind nut may rub on the hori-

zontal former. When the motor mount is

installed, tighten this blind nut down last.

5.

Using the 6-32 x 3/4” socket head screws,

install the motor mount onto the firewall.

Check to see that all of the alignment marks

on the motor mount match the marks on the

firewall.

You may wish to put thread lock on the

screws at this time.

7. Using the drill, lightly mark the locations of

the engine mounting holes.

Set the engine aside and, using the 5/32”

drill bit, finish drilling the holes.

6. Place the engine on the motor mount, mak-

ing sure the propeller drive plate is 5-5/8”

away from the firewall.

8. Replace the engine on the motor mount and

install the engine using the #8 x 1” screws.

Elevator Servo Installation

1. Collect the following items:

(2) 2-1/4 x 3/8 x 1” servo block

(3) Radio servo

(12) Servo mounting screw

2.

Make sure the servos fit snuggly in the servo

tray.

3. Glue the servo blocks at each end of the

middle servo hole.

15

Page 16

16

Elevator Pushrod Installation

1. Collect the following items:

(3) .072 x 10” threaded wire

(3) Nylon snap link

(1) Single-hole pushrod plug

(1) Double-hole pushrod plug

(1) 36” fiberglass pushrod tube

(2) 1/8 x 24” nylon guide tube

(1) Elevator wire drawing(Back of booklet)

2. Using a fine-tooth saw or modeling knife, cut

the fiberglass pushrod to a length of 16-1/2.”

This may be accomplished by rolling the

tube under the blade.

3.

Measure 1” back from one end of the

pushrod and drill a 5/64” hole completely

through both sides. This hole will hold the

elevator wires.

4. Measure 1” from the other end of the

pushrod and drill a 5/64” hole HALFWAY

THROUGH the pushrod. TAKE CARE TO

DRILL ONLY THROUGH ONE SIDE.

5. Using the 5/64” drill, and holding a pushrod

plug, as shown, drill out the center of the plug

to form a tube. Repeat for the other plug.

6. Using the Elevator Wire Drawing, place a

threaded 10” wire over Drawing #1, as

shown.

Starting at the threaded end, measure back

to the first bend and mark the wire. Then,

carefully bend the wire to match the drawing.

7. Mark the second bend and then bend the

wire accordingly.

Repeat this process for a second threaded

wire.

Page 17

12. When the bent tip is exiting the hole in the

pushrod and the plug tightly meets the

pushrod, apply CA glue to the joint.

13. Insert both of the nylon guide tubes into the

exit holes located closest to the stab on each

side of the model.

Look through the cockpit to see the guide

holes in the former. Then, thread the guide

tubes through the guide holes.

14. When the nylon tubes have been pushed

through the fuselage, insert the two wires

from the end of the pushrod into the tubes.

Then, slide the pushrod back down through

the fuselage, allowing the nylon tubes to

guide the way until the two ends of the

pushrod come out of the exit holes on either

side of the airplane.

11. Place the single-hole plug onto the wire and

then bend the wire, as shown.

Referring to the drawing, cut the wire after the

bend and slide the end of the wire into the

single-hole end of the pushrod.

15. Once the wire has exited the fuselage,

remove the nylon tubing from the end of the

wires.

8. With the pointed end of the plug facing the

threaded end of the wired, slide the doublehole plug onto the non-threaded end of the

wires.

Measure 2-3/8” down from the second bend

and make a 90º bend. Then, cut the wire

after the bend, so that it will fit in the

pushrod.

9. Insert the two wires into the double-hole end

of the pushrod until the bent ends slide into

the holes.

Slide the plug as far as it will go down into

the pushrod. Then, CA glue the plug to the

pushrod.

10. Using Drawing #2 as a template, mark the

location of the bend on the third threaded

wire.

17

Page 18

16. Thread the snap-links onto each of the wires,

until the the wire shows in the middle of the

snap-link.

17.

Connect the snap-link to the second hole of

control horn.

18. Thread a snap-link onto the servo-end of the

pushrod and attach to the elevator servo.

Rudder Cable Installation

1. Collect the following items:

(2) 34” stranded cable

(4) 1/16 threaded couplers

(4) Snap-links

)2) 1/8 x 24” nylon tubing

2. Using flux and silver solder, solder a thread-

ed coupler onto the end of the cable.

3.

From the coupler end, and including the cou-

pler itself, measure 30 inches and mark the

cable. Then cut it with a wire cutter.

Now, making sure the cable is all the way

into another threaded coupler, solder it to the

cut end. The total length of the finished cable

should be 31”.

Repeat the above steps to make a second

cable to the same length.

4.

Install the cables by using the guide tubing

and threading them through the fuselage, as

was done with the elevator pushrod.

Wash the soldered coupler/cable assembly

with soap and water.

5.

Place a snap link on each end of each cable.

6. Connect two snap links to the center servo,

as shown, and the other two snap links to

the rudder control horn.

18

Page 19

5. Place the cockpit insert on the fuselage and,

while pressing down on the insert, tape the

cockpit insert down.

6.

Using a 1/16” bit, drill four holes 1/4” up from

the cockpit bottom and along the centerline

that extends from under the insert.

7. Place the canopy over the cockpit insert and,

making sure it is straight on the fuselage,

tape it securely.

Drill four holes in the canopy at the same

locations as those drilled in the cockpit insert.

8. Remove both the canopy and the cockpit

insert, and then remove the tape from the

side of the fuselage.

Replace the insert on the fuselage and put the

canopy in place over it. Screw down both parts

with the #2 x 3/8” screws and #2 washers.

Engine Pushrod Installation

1. Collect the following items:

(1) .063 x 16-3/4” wire

(1) 1/8 x 24” nylon guide tubing

(1) Snap nut wheel

(1) Pushrod connector

(1) 4-40 x 1/4” socket head screw

(1) 20” length of fuel tubing

NOTE: The following photos and instructions are for

mounting a 4-cycle engine. Other engines might

require different steps for installations.

Canopy & Cockpit Installation

Make sure the cables are tight and that the

rudder does not move without moving the

servo.

NOTE: This servo works best if it has ball bearings.

1. Collect the following items:

(1) Cockpit insert

(1) Canopy

(4) #2 x 3/8” sheeet metal screw

(4) # 2 washer

2. Carefully cut the cockpit along the scribe

line.

3.

Place a strip of masking tape along both

sides of the fuselage cockpit opening.

4. Find the center of the cockpit doubler and

make a mark on the tape at the center point.

19

Page 20

2. Mark 1/4” from the end of the .063 wire and

make a 90º bend.

3.

Cut the wire to a length of 12-3/8”.

4. Cut off a piece of nylon guide tube 9-1/2”

long.

5. With the engine in place on the motor mount,

mark the location for the throttle pushrod on

the firewall.

6. Remove the engine and drill a 1/8” hole for

the pushrod in the firewall.

7.

Next, drill two 1/4” holes for the fuel tubing.

Take the 20” length of fuel tubing and pass

equal amounts of the tube into each of the

holes, so that equal lengths of tubing are

inside the fuselage.

8. Insert the 9-1/2” guide tube through the front

of the firewall back to the throttle servo.

Make sure the tube goes through the hole in

the former, as shown above.

NOTE: A short length of guide tubing should extend

out the front of the firewall.

9. Holding the engine in your hand, take the

bent end of the .063 wire and place it on the

throttle arm of the engine. Then, slide the

other end of the wire into the guide tube.

Make sure the throttle wire goes through the

tubing in the fuselage and over the top of the

throttle servo.

10. Place the throttle wire through the hole in the

pushrod connector and slide the servo arm

on the wire to the top of the servo, as shown.

NOTE: It may be necessary to bend the wire to pre-

vent any binding.

11.

Twist the servo until the arm is pointing

towards the engine and then push the wire

forward until it stops moving.

Tighten the setscrew on top of the pushrod

connector. Final adjustment can be made

later, when the rest of the radio is installed.

20

Page 21

2. Check to see if any part of the engine muffler

or exhaust header will interfere with the fuselage. If necessary to create clearance,

remove a portion or the entire tab that

extends beyond the firewall.

3. Place the piece of clear plastic over the top

of the engine. The end of the plastic should

extend just past the cylinder head.

4.

Mark where the engine contacts the plastic.

Remove the plastic and, using the moto tool,

cut out the engine area until the plastic fits

over the top of the motor and lies flat on the

fuse side. Then, tape the edges of the plastic to one side of the fuselage.

Using the moto tool, cut away the bottom of

the cowl at the point where it hits the landing gear. Take off small amounts at a time

and keep measuring the cowl until it will slide

back to a point that is 1/16” behind the

engine drive washer.

NOTE: If using the engine pictured in these instruc-

tions, the measurement from the firewall to

the front of the cowl will be 5-3/8”.

7. Securely tape the cowl to the fuselage, so

that it will not move. Once taped, measure

the cowl again to make certain its position

has not shifted.

8.

Place a piece of masking tape on the side of

the fuselage just above the landing gear and

long enough so that it extends 3” onto the

cowl and behind the landing gear.

Placing the plane on its side, measure 1-1/4

above the landing gear and make a mark on

the tape.

From the mark, on a plane parallel to the yel-

low striping, measure 1-3/8” and make a

second mark.

Drill a 1/16” hole on the second mark for the

lower cowl screw.

Turn the aircraft over and repeat the above

steps, drilling a bottom hole on the other

side.

6. Slide the cowl under the plastic.

CAUTION! WHEN CUTTING THE COWL, ALWAYS

WEAR PROTECTIVE EYE GEAR AND A LONGSLEEVE SHIRT. CHANGE CLOTHES AND WASH

AFTER CUTTING.

Cowl Installation

1. Collect the following items:

(1) Fiberglass cowl

(4) #4 x 3/8 sheet metal screws

(4) #4 washers

(1) 4 x 12” clear plastic

5. Lift up the untaped side of the plastic and

remove the engine.

21

Page 22

. Place a piece of masking tape down the cen-

ter of the wide yellow trim stripe.

Measuring up 1-3/8” from the bottom of the

yellow stripe, make two marks and draw a

line on the tape, parallel to the yellow stripe.

Make a third mark on the tape, even with the

back of the landing gear. From this point,

measure forward 5-7/8”.

Drill a 1/16” hole at this location for the top

cowl screw.

10. With the fuselage on its left side, trace the

cutout for the engine onto the cowl.

Remove the cowl and, with a moto tool, slow-

ly remove the fiberglass INSIDE the cutout

outline. Work slowly and carefully, until the

cowl matches the clear plastic piece.

Remember, if the fiberglass is damaged dur-

ing this process, it can be repaired only with

epoxy glue.

NOTE:You may wish to make a cutout in the front of

the cowl, at the point where the engine prop washer

sticks out, that is large enough to allow the engine to

vibrate without touching the cowl.

Fuel Tank Installation

1. Collect the following items:

(1) Fuel tank

(1) Fuel tank platform

(2) #30 rubber bands

(2) Brass tube

(1) Large nylon cap

(1) Small nylon washer

(1) Rubber stopper

(1) #4 x 1” screw

(1) Fuel tank klunk

(1) 6” length of white fuel tubing

(1) 1/4 x 3/8 x 2-1/2” fuel tank stop

(1) 1/4 x 3/8 x 5-1/2” fuel tank support

CAUTION! The white neprene stopper and the fuel

tubing provided with this kit are FOR GLOW FUEL

ONLY; DO NOT USE THESE PARTS FOR GASOLINE.

2. Insert both brass tubes through the wide end

of the rubber stopper. Leave 1/2” extending

out the front of the tank.

Place the small nylon washer on both tubes,

as shown, making sure that one of the tubes

extends 1” past the washer. This tube will be

for the klunk pickup.

Cut tube as necessary.

22

Page 23

10. Measure 2-7/8” from the landing gear block

on both sides of the front former. Glue the

fuel tank support stick across the opening the

former.

3. Bend the other tube, at the angle shown,

until it nearly reaches to the fuel tank wall.

This is the vent/overflow tube.

4.

Insert the stopper assembly into the fuel tank

until the vent tube is up inside the “bubble” in

the fuel tank wall. Remove the assembly

and trim the vent tube, if necessary.

5. Install the klunk on the white fuel tubing.

Mount the other end of the fuel tubing onto

the brass outlet tube in the stopper.

6. Again place the stopper assembly into the

fuel tank. If the klunk is touching the back

wall of the tank, trim it as needed.

7.

Place the large nylon cap onto the two brass

tubes.

When satisfied with the fit of the entire stop-

per assembly, tighten the #4 x 1” screw into

the center of the stopper. Take care to not

over-tighten the screw.

8. Referring to the above photo, place the fuel

tank on the fuel tank platform.

Secure the tank to the platform with the rub-

ber bands.

9.

Glue the 1/4 x 3/8 x 2-1/2” balsa stop in front

of the tank, as shown. When the glue has

set, replace the rubber bands with electrial

tape, so that the tank is well-secured to the

platform.

23

Page 24

11. Reach into the fuselage and place the fuel

tubing onto the brass fuel tank tubes. Note

which tube is the vent and which is the outlet.

12.

From the front of the firewall, pull on the fuel

lines to remove any slack.

13. Complete the fuel tank installation by gluing

the rear of the fuel tank platform onto the support stick.

Receiver Installation

1. Insert the Y-harness in the aileron plug in the

receiver and then wrap both the receiver and

the battery in the !/4” foam included in this

kit. Secure with rubber bands.

24

Foam Not

Included

2. Plug the switch into both the battery and the

receiver.

Next, plug the elevator, rudder, and throttle

servo wires into the receiver.

3.

Place the battery and the receiver into the

compartment in front of the servos. Remember to keep the antenna and the Y-harness

outside of the compartment so that the

aileron servo wire can be easily plugged into

the receiver.

Place a piece of scrap wood across the

receiver and battery pack to keep them in

place.

4.

Insert the receiver antenna into the pre-

installed tube in the left side of the fuselage

and slide the antenna down the tube until it

exits out the hole at the rear of the fuselage,

just in front of the tailwheel.

5. Turn on the receiver and transmitter and put

all control surfaces in neutral position. Then

insert the center screw into each of the servos.

CAUTION: Make sure all servo arms are tightened

onto the servos.

1. Collect the following items:

(2) 3” wheel

(2) Axle

(2) Axle locking nut

(4) 3/16” wheel collar

(4) 6-32 x 1/8” set screw

(2) Wheel pant (right and left)

(4) #2 x 7/16” sheet metal screw

Wheel & Wheel Pant Installation

Page 25

NOTE: There are several ways to mount wheel

pants. Following are two different methods.

4.

Place the wheel pant against the back of the

axle, next to the landing gear. Make a mark

on the axle where the outside of the axle hits

the wheel pant.

Check to make sure that the wheel and both

the inside and outside wheel collars will fit on

the axle. If the fit is right, cut the axle at the

point of the mark.

Alternatively, mark the wheel pant where the axle

strikes the wheel pant and drill a 3/32” hole at that

location on the outside of the wheel pant. Let the

axle exit from inside the wheel pant through this

hole. This will help support the wheel pant when flying off a grass or rough field.

2. Insert the threaded part of the axle through

both sides of the landing gear and tighten

the locking nut on each axle.

Thread the 6-32 x 1/8” set screw into each of

the four 3/16” wheel collars and place one

wheel collar onto each axle.

3. Slide the wheel pant over the axle and up

against the landing gear. Make a mark on

the wheel pant where it hits the axle.

25

5. When satisfied with the fit of all the compo-

nents, mount the wheelpants, wheels and

the remaining (outside) wheel collars onto

the axle.

Turn the aircraft right-side up and level the

stabilizer.

When the wheel pant is level, drill a 1/16”

hole through both of the landing gear holes

and into the wheel pant.

Secure the wheel pant to the landing gear

with #2x 3/8” sheet metal screws.

6. Make sure the wheel pant is horizontal to the

tabletop by measuring from center of the

front tip and the center of the back tip, as

shown above.

Page 26

1. Collect the following items:

(1) Bottom wing

(1) Top wing

(1) Bottom wing bolt plate

(2) I-struts

(8) 4-40 x 1/2” sock head screw

(8) 4-40 blind nut

(8) #4 washer

(1) 6-32 x 1” socket head screw

(1) 6-32 blind nut

(1) #6 x 3/34” washer

(2) 4-40 x 1” socket head screw

(2) 4-40 locking nut

(2) #4 x 7/16” washer

(10) #4 washer

FINAL WING INSTALLATION

2. Take the bottom wing and locate the hole in

the center of the wing close to the trailing

edge. Carefully remove the covering from

over the hole on both the top and the bot-

tom of the wing.

Next, find the hole in the center of the wing

bolt plate and, again, remove the covering.

3.

Align the hole in the wing bolt plate over the

hole in the bottom of the bottom wing.

Draw the outline of the plate on the wing

and, taking care to work 1/4” inside the

outline, remove the covering on the wing in

the area where the plate will rest.

Making sure the holes are aligned, CA glue

the plate onto the wing bottom.

4. Working from inside of the fuselage wing

opening, push the 6-32 blind nut in the hole

in the center of the wing block until it will go

no further.

Take the 6-32 x 1” screw and the #6 x3/4”

washer and screw them through the block

into the blind nut. Tighten until the blind nut

is seated well up into the wing block.

5.

Now, temporarily remove the 6-32 screw and

washer and place the bottom wing onto the

fuselage.

Plug the servo extensions from the wing into

the Y-harness.

Insert the two front wing dowels into the bot-

tom of the wing saddle. Then, using the 6-32

screw and washer, screw the back of the

wing to the fuselage

6. With the plane right side up, place the cutout

in the top wing onto the center cabanes.

Next, slide the tabs on both the lower wing

and the top wing into the slots of the I-struts.

The curve of the wing will match the curve of

the bottom of the I-strut.

Wing/I-strut Installation

26

Page 27

4. Connect the aileron coupler assembly to the

aileron control horns, as shown.

7. Working from the outside (towards the fuse-

lage) insert the 4-40 x 1/2” socket head

screws with #4 washers through the holes in

the I-strut.

Attach a 4-40 blind nut to the screw and

tighten until the blind nut is flush with the

back of the I-strut.

Repeat with the other I-strut.

CAUTION: Do not over-tighten these screws, as

doing so will crush the I-strut onto the tab and make

it difficult to remove it from the wing.

8. Referring to the above drawing, bolt down

the center and then the rear of the top wing.

Aileron Coupler Installation

1. Collect the following items:

(4) Small control horn

(8) 2-56 x 1/2” pan head machine screw

(2) .072 x 10-1/2” double threaded wire

(4) Mini snap link

2. Mark locations for the control horns on the

outer edge of each aileron (top and bottom

wing) by measuring 8” in from the aileron tip.

With a wire cutter, remove the top of the con-

trol horns, so that only one hole remains on

each horn.

Thread a mini-snap link to each end of the

double-threaded wire.

3. Using the pan head screws, mount two con-

trol horns on the top of the bottom wing and

two on the bottom of the top wing.

27

Page 28

Decal Installation

Spinner Assembly

1. Clean model surfaces thoroughly before

applying decals.

2.

Cut decal sheets apart in sections, as need-

ed.

Fold decal in half, front to rear. Open at fold

and lay decal out straight. The protective

backing will bubble away from the decal at

the fold. Using a scissors, cut the backing

along the bubble, removing a strip of backing

about 1" wide. Carefully position the decal

on the model and stick in place. Then, working from the center, rub the decal down while

peeling off the backing.

28

A 3" CGP 4-Pin Snap-On Spinner is included with

your Ultimate ARF. It is a rugged precision molded

spinner that does not require any special mounting

nuts or screws. CAREFULLY READ THE SPINNER

INSTRUCTIONS AND WARNINGS INCLUDED

WITH THE SPINNER. Although a spinner helps

reduce the chance of injury from a rotating prop,

extreme caution always must be used when the

engine is running.

Balancing the Model

IMPORTANT: NEVER NEGLECT THIS STEP

WITH ANY AIRPLANE. If you try to fly a plane with

the balance point behind the recommended range,

you run the risk of having an unstable aircraft and

the strong likelihood of a crash. TAKE THE TIME

TO PROPERLY BALANCE YOUR MODEL!

To determine the Center of Gravity, measure back

on the fuselage 2-3/8” from the leading edge of

the bottom wing. The C.G. range for this aircraft

is 1-7/8” to 2-7/8”. It is recommended that you balance this model upside down. Add weight if necessary to achieve the proper balance.

Page 29

Fully-charged flight batteries

Radio transmitter

1 ½ volt starting battery & glo-plug clip

Fuel bulb or pump

Tools for tightening any parts that can vibrate

and loosen

Paper toweling for clean up

Extra props and an extra spinner

Prop wrench

Bottle of CA glue

Field Kit Checklist

Pre-Flight Activities

see that no signals are missed until you are at least

100 feet away. Only if the equipment works perfectly should any flights be attempted. Again, be

careful to not use your transmitter when anyone

else at the field is flying or testing on the same frequency!

After the range check, stand behind the model and

make sure the control responses are correct.

Moving the control stick to the right should give right

rudder (on a 3-channel set-up) or the right aileron

should go up (on a 4-channel set-up). Moving the

stick back or down on the Tx should move the elevator up, and vice versa.

Check also to see that your wheels operate properly Your throttle should open to permit full power

when the stick or tab is moved forward or up. Finally,

make sure that everything on your aircraft is neatly

and firmly in place-motor fastened down, servos

snugged down, receiver and battery wrapped in

foam rubber, tank properly supported, etc. Prop and

spinner must be tight. The receiver antenna must

be extended, not coiled up inside the model.

Nothing should be loose, or unfinished, or

unchecked.

With everything ready, the engine should be started

and broken in for a least a tank or two at no more

than moderate speed. While the engine is running,

make sure the control surfaces do not jitter or move

until you command them and that the throttle also

responds properly to your command.

Prior to going to the flying field, with radio batteries

fully charged, turn on both receiver (Rx) and trans

mitter (Tx) and actuate all controls many times until

you are satisfied with all functions.

Before beginning each day's flying, make a range

check of your equipment in accordance with the

manufacturer's instructions. In general, with transmitter antenna collapsed to 6"-8", you should have

an at least 100 foot range on the ground. To check

this, turn on both the transmitter and the receiver

switches, set the model heading away from you,

and walk away while transmitting signals. Watch to

29

Setting Control Surface Travels

SETTINGS

Gentle

Aerobatic

AILERON: 10º 12º

ELEVATOR: 12º 14º

RUDDER: 15º 23º

When beginning to fly your ULTIMATE, we encour-

age you to start out with the gentle settings,

regardless of your flying ability. Then, after you

have become familiar with the aircraft, move to the

aerobatic settings.

NOTE: Always use the furthest hole on all control

surfaces and adjust at the servo for proper throw.

Do not use the transmitter adjustment to set up the

control travels. The transmitter should be used only

for fine tuning.

It is not recommended that you fly this model with

the dual rate control HIGH RATES set at the “aerobatic settings” and the LOW RATES set at the “gentle settings.” The initial flights should be set up with

the “gentle settings” at the HIGH RATE and the

LOW RATES at 75% of the “gentle settings.” The full

F3A schedule can be flown very well with this setup.

Once the model is trimmed out, if a more “hot dog”

style of flying is desired, increase the control travels

with the same percent of LOW RATE.

Take-Off & Landing

Though the ULTIMATE is not difficult to control dur-

ing take-off and landing, it is important to not overcontrol. Make small smooth corrections until you

become familiar with the feel of your model. When

taking off, you will need to add a bit of right rudder.

Wait until there is plenty of airspeed and gently

rotate (about 1/8-1/4 up elevator), keeping the

wings level.

On landings, you will find that the ULTIMATE glides

better than most bi-planes. However, no bipe glides

as well do monoplanes. For the best landings,

approach the runway at high idle and go to low idle

about one foot above the ground, flaring to a 3-point

landing as you gently touch done.

Page 30

Developing your flying skills to include more varied

maneuvers is exciting and rewarding.. The ULTI-

MATE is an extremely capable aircraft and is able to

do advanced stunts. Here are a few you might try.

ADVANCED AEROBATICS

KNIFE-EDGE LOOP

This maneuver requires a powerful engine

LOMCEVAC

Roll to the left or right and hold a bit (10%) of top

rudder. When ready to start the loop, add more rudder.

Start out in a 45º climbing knife-edge. If you are

using left rudder for the knife-edge, snap-roll left (full

left rudder, left ailerons, and up elevator) 1-1/2 turns.

Then, holding full left rudder, give full down and right

aileron. Timing is the key, as well as power and

climb angle. Try it and hold on!.

30

Page 31

Loading...

Loading...