Page 1

WARNING

A radio-controlled model is not a toy and is not intended for persons under 16 years old. Keep

this kit out of the reach of younger children, as it contains parts that could be dangerous. A radiocontrolled model is capable of causing serious bodily injury and property damage. It is the buyer's

responsibility to assemble this aircraft correctly and to properly install the motor, radio, and all other

equipment. Test and fly the finished model only in the presence and with the assistance of another

experienced R/C flyer. The model must always be operated and flown using great care and common

sense, as well as in accordance with the Safety Code of the Academy of Model Aeronautics (5151

Memorial Drive, Muncie, IN 47302, 1-800-435-9262). We suggest you join the AMA and become properly insured prior to flying this model. Also, consult with the AMA or your local hobby dealer to find an

experienced instructor in your area. Per the Federal Communications Commission, you are required

to use only those radio frequencies specified "for Model Aircraft."

LIMITED WARRANTY

Carl Goldberg Products, Ltd. has inspected and certified the components of this aircraft. The company urges the buyer to perform

his own inspection, prior to assembly, and to immediately request a replacement of any parts he believes to be defective for their

intended use. The company warrants replacement of any such components, provided the buyer requests such replacement within a period of 90 days from the date of purchase and provided the defective part is returned, if so requested by the company.

No other warranty, expressed or implied, is made by the company with respect to this kit. The buyer acknowledges and understands that it is his responsibility to carefully assemble the finished flying model airplane and to fly it safely. The buyer hereby

assumes full responsibility for the risk and all liability for personal or property damage or injury arising out of the buyer's use of the

components of this kit.

CARL GOLDBERG PRODUCTS, LTD.

P.O. Box 818 Oakwood GA 30566 Phone #678-450-0085 Fax # 770-532-2163 www.carlgoldbergproducts.com

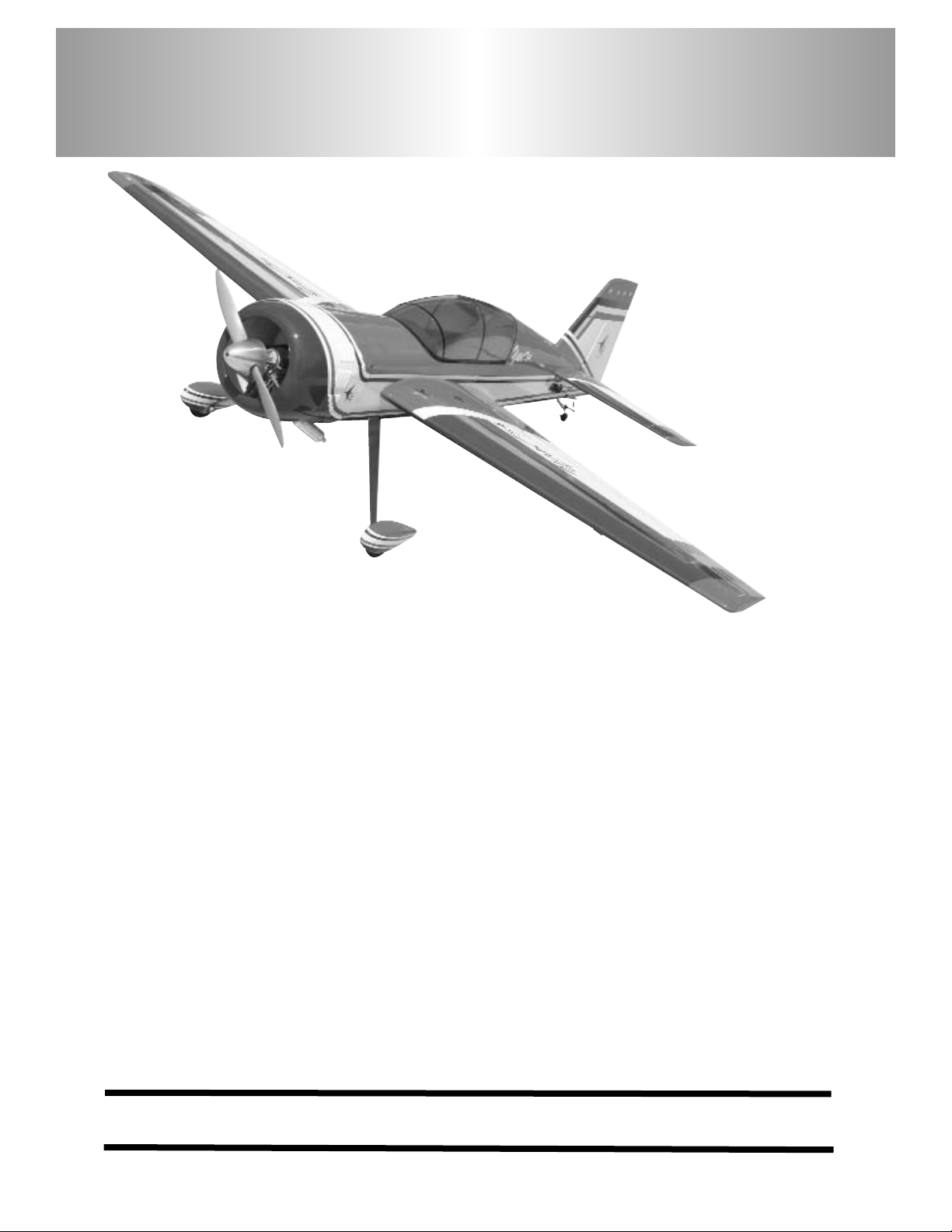

Aerobatic flying just doesn't get any better than this Yak54. The classic lines of a world class aerobatic plane

coupled with the radial cowl, add excitement to the maneuvers you love, knife edge, split S, lumcevac, torque

rolls, snaps, and ground-hugging inverted flight. What's more, we've engineered this ARF to get you into the

air with a minimum of fuss. So take a few minutes to carefully read the introductory material and then get to

work. You'll soon be out at the field with a classic aerobatic champion!

Y

Y

a

a

k

k

5

5

4

4

©copyright 2005 Carl Goldberg Products, Ltd.

Page 2

2

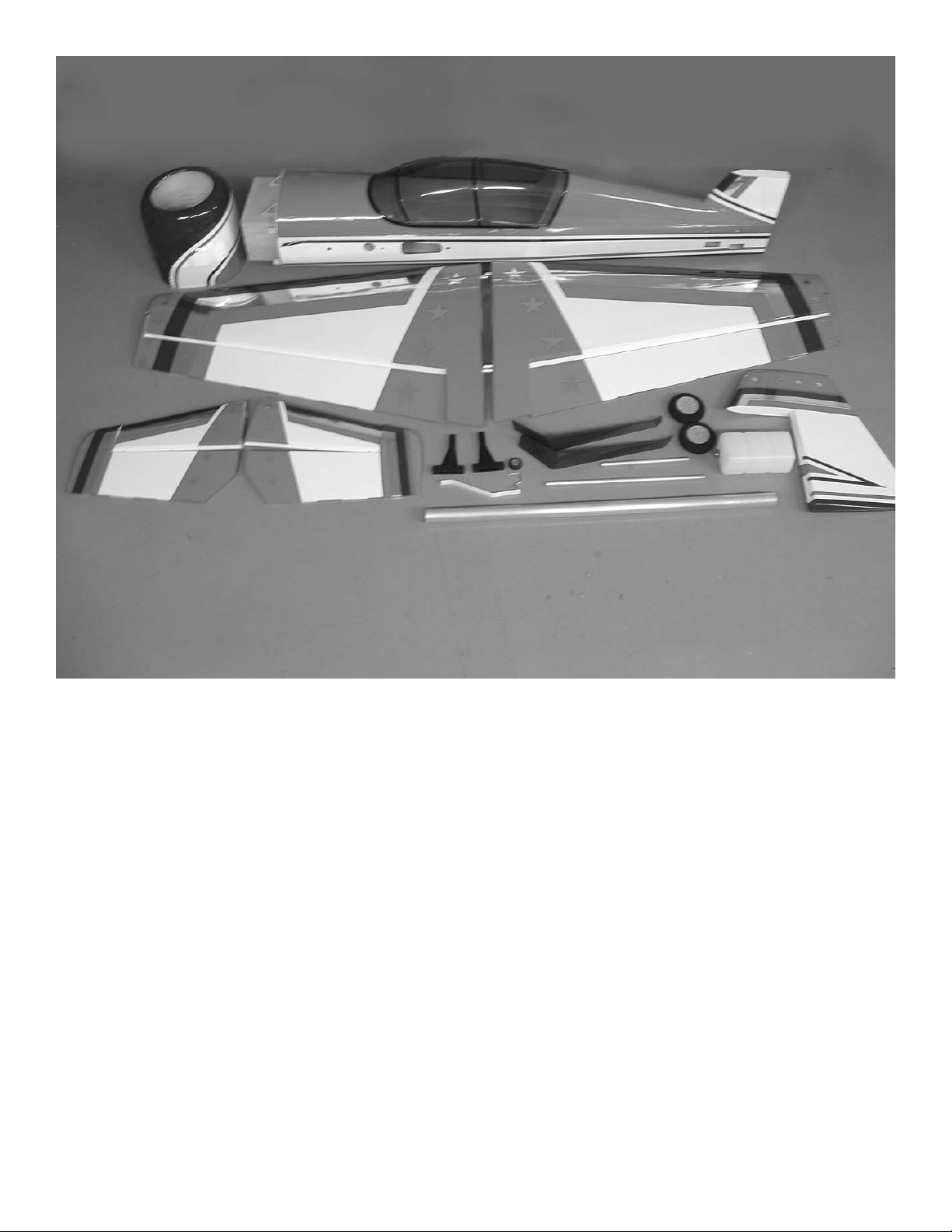

Cowl

Fuselage

Clear canopy

Left wing panel with aileron

Right wing panel with aileron

Stab half left

Stab half right

Elevator left

Elevator right

Motor mounts

Tail wheel bracket

Main gear

Wheels

Stab spars(aluminum tubes)

Wing tube (aluminum tube)

Fuel tank

Rudder

Page 3

3

Before you begin assembling your Yak 54 ARF, take some

time to read through this entire instruction book. It is

designed to take you step-by-step through the process and

to give you added information on engine and radio selection

and set-up, balancing your aircraft, and flying your model.

The time you spend will speed the assembly process and

help you avoid problems.

PREPARING FOR ASSEMBLY

You will need a work area of approximately 24 x 70" which has been

covered to protect it from adhesive, as well as cuts and other

damage. Many people cover their work area with a sheet of

dry wall (sheet rock) and/or waxed paper t o prevent CA

Glue and Epoxy from ruining the work surface.

CONSTRUCTION TIPS

IMPORTANT: ALWAYS READ A FEW STEPS AHEAD.

This will alert you to coming instructions and will help you

plan accordingly.

Using the Parts Identification section, familiarize yourself

with the various items included in your kit box.

As you work, CHECK OFF EACH STEP in the box provided, so that you are sure you do not forget anything.

Do not hesitate to ask questions. Your local hobby dealer

and area flyers will most likely be happy to help, as they

want you to have a successful flying experience. You may

also receive technical assistance from Carl Goldberg

Products, Ltd. by telephone 1-678-450-0085.

ADHESIVES & GLUING TECHNIQUES

CA adhesives are specially formulated to firmly glue the plywood, hardwood, and balsa used in your model and to withstand the vibration and stresses of high performance flight.

However, there are times, such as when you are installing

the stabilizer and fin on the fuselage and want more setup time for careful alignment and positioning, then you

should use epoxy.. Occasionally, you also will want to use

thin CA, which "wicks" into the surrounding areas. Aliphatic

resin glue or similar water-based glues can also be used,

but they will add to the assembly time because they dry so

much more slowly than CA glue. Remember, when ever

using any CA, you must be careful to read instructions thoroughly, as you will have only seconds for positioning of

parts. Be sure to trial fit parts together before gluing. Also,

never use watery THIN type CA glue for gluing plywood and

hardwood parts. Thin CA's do not adequately bond these

areas.

CAUTION

Some people may experience an allergic reaction when

exposed to fumes from CA glue or epoxy. As with paints,

thinners, and solvents, it is always important to use glues

only where there is adequate ventilation to carry fumes

away. A fan is recommended. Also, special care must be

taken when using CA, as it will bond skin as well as other

surfaces. Before using any CA, carefully read all label precautions. When using CA, protective eye-wear and care in

keeping the glue away from the face is highly recommended. If CA does happen to get into the eye, hold lid open and

flush with water only. Seek immediate medical attention.

COVERING

The Yak 54 ARF is covered in a premium polyester film

chosen by many of the world's top flyers for its beauty,

toughness, and ease of application and repair. It is not

uncommon for ARF's to develop a few wrinkles in transit. If

this is true of your model, the situation is easily corrected.

Before you begin putting the pieces together, run over the

surface of each section with an iron (either specially

designed for airplane use or the more cumbersome household iron) or use a modeling heat gun. Apply the heat (set

at about 350° F), following along with a soft cloth and pressing down on the covering as you go around. This will more

firmly set the covering adhesive into the wood and keep

your aircraft covering tight and smooth in the future.

One of the great advantages of polyester film is that it can

be applied over itself without causing gas bubbles. This

allows you to repair your aircraft, as well as to customize it

in a number of ways. If, due to a flight mishap, you get a

hole or similar covering damage, simply trim away the

ragged edges and then apply a patch, following the directions that come with your covering , which is available at

your hobby dealer.

Important Information

Covering coming loose is not COVERED UNDER WARRANTY. Due to

temperature changes the plane may

develop some wrinkles in the covering that you will need to remove with

an iron. Be sure to seal the edges

down first so that you do not cause

the covering to shrink and leave

exposed areas of wood. Please

inspect the plane before beginning

to assemble to make sure you are

happy with it. After assembly has

begun you cannot return the kit. If

you find a problem before beginning

to assemble the plane you must

contact us, please do not return it to

the dealer.

Page 4

4

ITEMS NEEDED TO COMPLETE THIS AIRCRAFT

1 RADIO GUIDANCE SYSTEM (4 CHANNEL

MINIMUM REQUIRED WITH 8 SERVOS)

2 12” AILERON SERVO EXTENSION WIRES

2 24” ELEVATOR SERVO EXTENSION WIRES

3 Y-HARNESS

1 ENGINE and PROP

1 CA ACCELERATOR

1 2 OZ. BOTTLE CA MEDIUM GLUE

1 1/2 OZ. BOTTLE CA THIN GLUE

1 20 MINUET EPOXY

1 1/4” FOAM RUBBER

OPTIONAL:

1 1/5 PILOT FIGURE

1 SPINNER 2-1/2” to 3-1/2”

NOTE: The Yak ARF covering matches Midnight

blue #885, Flame red #883, and White

,#870.

TOOLS AND SUPPLIES FOR ASSEMBLY.

MODELING OR UTILITY KNIFE

WORK SURFACE (24" X70")

ELECTRIC DRILL

1/16”, 3/32”,1/8", 3/16”, 5/32”, 1/4”, 5/64”

7/32” DRILL BITS

SMALL STANDARD & PHILLIPS SCREW-

DRIVERS

MASKING TAPE

NEEDLE NOSE PLIERS

MOTO TOOL

24” RULER

FLEXIBLE STRAIGHT-EDGE

30-60-90° x 6" TRIANGLE

SOFT PENCIL

A FEW STRAIGHT OR "T" PINS

ADJUSTABLE WRENCH

WIRE CUTTER (DYKES)

OPTIONAL HEAT GUN/COVERING IRON

ACID BRUSH

ELECTRICAL TAPE

PIECE OF MEDIUM SANDPAPER

5 FT. LENGTH OF STRING

Caution:

Before starting, carefully go over all high

stress areas with an epoxy or wood glue to

confirm all areas are well glued.

Page 5

5

WING ASSEMBLY

AILERON INSTALLATION

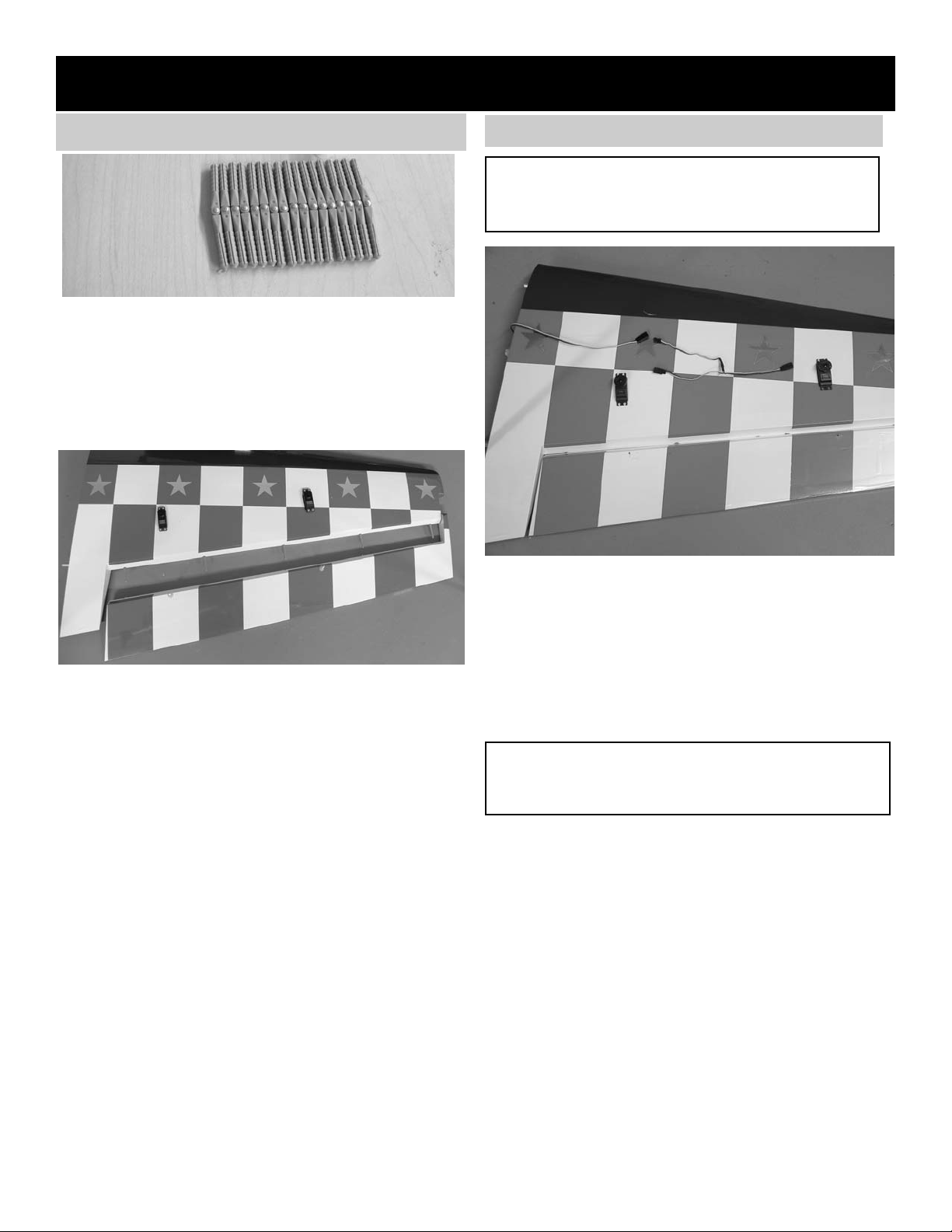

2 Start with one wing panel. Locate the ailerons

and trial fit them on the wing. Make sure all the

hinges are aligned.

Now locate the other aileron and wing panel

and fit the aileron. When you are satisfied with

the fit, remove the ailerons and lay them

behind the wing in the correct position. The pin

style hinges work best if installed in both wing

and aileron at the same time. Apply a drop of

oil in the hinge.Use 30 minute epoxy to glue

them in.

Note: A syringe works great, if you have one

use a 1/8” dowel or piece of 3/32” wire to get

the epoxy into the holes. With glue in the

holes, push the hinges in wing up to the pin.

Apply glue in the holes on the aileron and slide

aileron into place. Work the aileron up and

down several times and the pin hinges will

rotate into position. Make sure you have a tight

fit between the wing trailing edge and aileron

leading edge.

Set aside to dry and install the other aileron.

AILERON SERVO INSTALLATION

Note: The following pictures may not exactly match

the hardware you are using. Always check the

radio manufacturer's instructions when installing

radio equipment.

1. Collect the following items:

(4)Servo mounting screw (supplied with

radio)

(1)Servo with rubber grommet (supplied with

radio)

(2) Servo extensions 12”

(2) y-connectors

IMPORTANT! To ensure that any connections locat-

ed inside the wing will not come loose, either when

the wires are pulled, or during flying, always tape

them securely together with electrical tape.

2. Making sure to use the correct servo for the

opening, attach the servo wire to the y-con-

nector and securely tape the connection.

Push the y-connector wire into the wing until it

comes out the other servo hole near the cen-

ter of the wing.

3.

Connect the other servo and and the 12”

extension to the end of the y-connector.

Install the servo with the output arm forward.

4.

Grasping the extension in the hole, SLOWLY

pull until the end of the extension comes out

of the hole at the center of the wing..

Tape the extension securely to the wing, so

that it will not slide back in while you are work-

ing.

1. Collect the following parts:

(1) Left wing

(1) Right wing

(1) Left aileron

(1) Right aileron

(10) pin hinges

Page 6

6

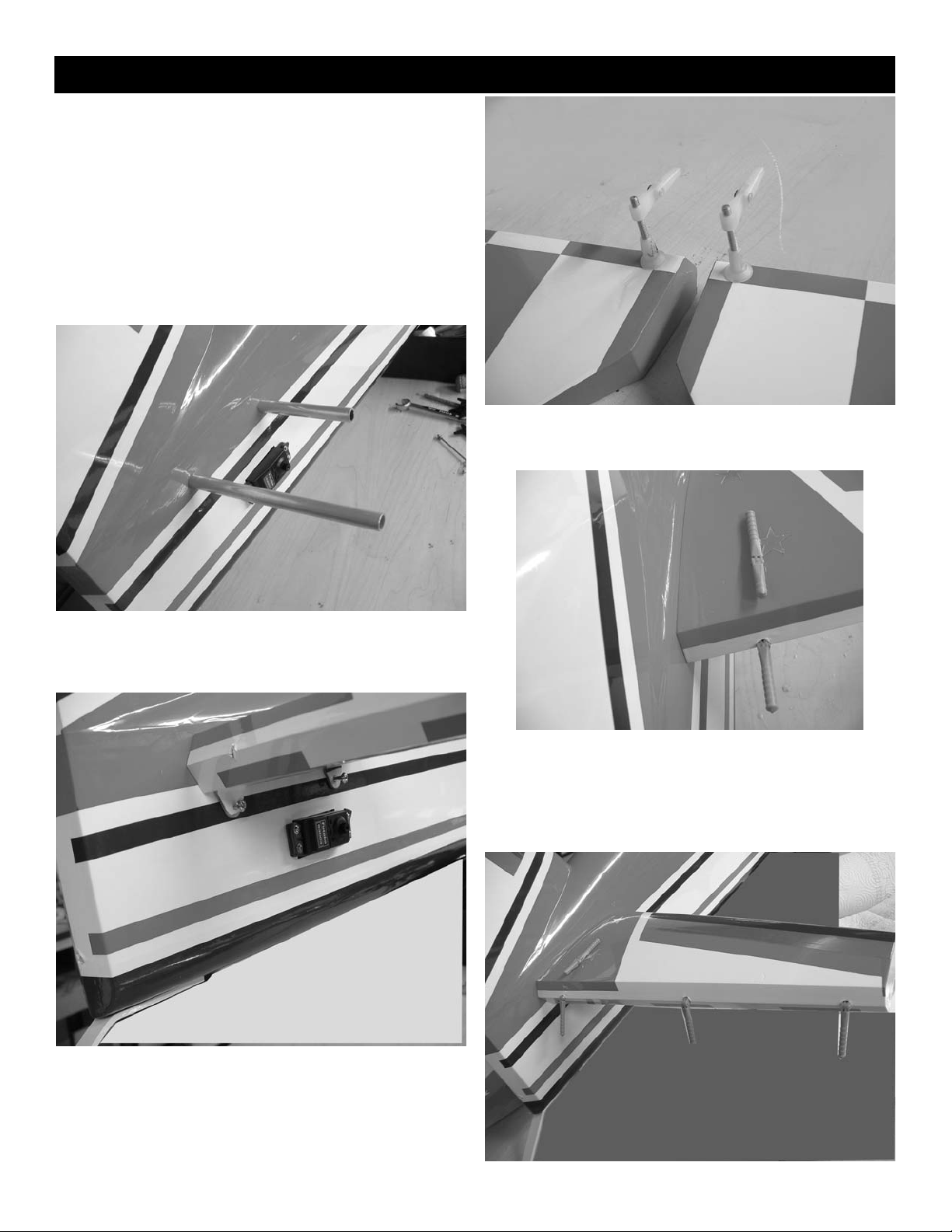

AILERON CONTROL HORN INSTALLATION

1. Collect the following items

(4) Nylon clevis assemblies

(4) nylon ball nuts

(4) 6-32 x 3” Bolt

(4) nylon washers

(4) 4-40 x 4” pushrods

(4) 4-40 clevis

(4) clevis keepers

2. With the aileron servo in place, make a mark

at a 90º degree angle to the trailing edge and

in line with the servo arm.

3.

Use the mark to locate the hard point installed

in the aileron( dowel with hole in middle).

4. Using a 9/64" drill bit, open the hole in the

aileron through to the top side.

HINT: Drill the hole from the bottom half way. Then

drill down to the hole from the top of the

aileron.

5. Insert the 6-32 x 3” screw from the top through

the aileron.

Place the nylon washer and the nylon ball nut

on the bolt and tighten.

Screw the adjustable clevis assemble on the

bolt.

6. Thread on to one end of a 4-40 x 4” pushrod

a nut and clevis.

Mount the pushrod onto the nylon clevis

assemble on the aileron.

With the servo centered, connect the pushrod

to the control horn.

With one servo connected and the radio on,

connect the other servo pushrod making sure

that there is no pressure on the other servo.

Install the clevis keepers.

Repeat the above steps for the other two

aileron servos.

Page 7

7

Collect the following items

(1) Stab

(1) Fuselage

(1) Stab halves

(6) pin style hinges

(4) 4-40 x 1/2” bolts

(2) aluminum stab tube

(2) 6-32 x 3” bolts (control horns)

(2) nylon ball washers

(2) nylon ball nuts

(2) nylon clevis assemblies

Tail Construction.

1. Install the two aluminum stab tubes in the fuse-

lage with the longer one in the rear.

2. Slide the stab half onto the tubes and tightly

against the fuselage side. Install the two 4-40

x 1/2” bolts into the mounting tabs on the bottom of fuselage. Blind nuts are pre-mounted in

the fuselage. Be sure to use lock-tite on the

bolts. Repeat for the other stab half.

3. Install the control horns on the elevators in the

same manner as you did the ailerons.

4. Because of the location of the stab tube, the

inboard elevator hinge will have to be cut off at

the end of the second serration, cut off 1/2”.

Make sure hinge will go into stab up the hinge

pin.

Page 8

8

5. Install the other two hinges. Trial fit the eleva-

tors in place making sure they will fit tightly

against the trailing edge of the stab and work

smoothly.

When satisfied with the fit, remove elevator

and apply epoxy in the holes the same as with

the ailerons. Work the elevators up and down

several time and set aside to dry..

1. Collect the following items:

(1) Rudder

(1) 6-32 x 4” threaded rod

(2) nylon ball washers

(2) nylon ball nuts

(2) nylon clevis assemblies

(2) nylon pushrod connectors

(3) Pin style hinges

1. Insert the three hinges in the fin until the hinge

pin is on the hinge line. Fit the rudder in place

on the hinges.

2. Locate the exit hole in the side of thefuselage

for the rudder pull-pull cable. Using a straight

edge, mark the location of the control horn on

the rudder in line with the hole

3.

Drill a 9/64” hole at the location you just

marked. Drill half way from each side as you

did on the ailerons.

1. Collect the following items.

(2) Landing gear legs

(6) 6-32X3/4” Socket head screws

(6) #6 flat washers

(2) Wheel pants, one left one right

(2) 4mm axels with lock nuts

(4) 4mm wheel collars

(2) 3-1/4” wheels

(2) 4-40 x t-nuts

(2) 4-40 x 1/2” socket head bolts

2. Slide gear leg into slot on side of fuselage and

install retaining bolts through the gear legs

from the inside of the fuselage.Be sure to use

thread lock on the bolts. The blind nut are

already installed.

Rudder Installation

4. Install the 4” threaded rod with a ball washer

and ball nut on each side. Center the bolt in the

rudder. Install the nylon pushrod connector for

the tail wheel steering springs and then the

nylon clevis assemblies. Repeat for the other

side.

5. Trial fit the rudder in place making sure the

hinge line is tight against the fin. When satisfied with the fit glue the hinges in place using

the same procedure you did with the ailerons.

Landing Gear Installation

Page 9

9

3. Install each axel using the locking nut. Be

careful not to over tighten the nut, it looks like

a large bolt but it has been drilled out for the

axel and can be broken if too much torque is

applied.

4. Install one wheel collar on each axel with 3/16”

between the collar and the axel nut. This will

space the wheel in the center of the wheel

pant.

5. The wheel pants have the 1/2” hole predrilled

in each pant. The 1/8” hole for the mounting

bolt must be drilled.

7. Remove the wheel pant and drill a 5/32” hole

at the location you marked. Insert the blind nut

on the inside and pull it tight using the 4-40

mounting bolt. Lock in place with CA glue

being careful not to get it in the threads.

6. Block the tail of the plane up so that the fuse-

lage is sitting level. Put the wheel inside the

pant and slide both on the axel together.

While holding the wheel pant level, mark the

location of the mounting bolt by using a 1/8”

drill and inserting it through the predrilled hole

on the landing gear leg

Page 10

10

8. Reinstall the wheel and wheel pant and retain

with the other 4mm wheel collar. Align the

wheel pant on the gear leg with the hole you

drilled for the blind nut. Install the 4-40 x 1/2”

socket head screw.

Don’t forget to use locktite to make sure it does

not come loose.

Repeat for other wheel pant.

Tail wheel Mounting

1. * Collect the following parts:

(1) tail wheel bracket

(1) tail wheel

(1) 1/8” wheel collars

(2) tail wheel springs

(2) 3mm x 1/2” sheet metal screws\

(2) bracket collars

(2) nylon horn brackets(2) 3mm x 1-1/2” threaded rod

2. Build up the tail wheel assembly by putting the

tail wheel on the axel and retaining with the

1/8” wheel collar. Install the bracket collar

(without holes on each side) on the shaft.

Insert the shaft through the mounting bracket

and install the bracket collar. Screw the threaded rods into the bracket on each side. Make

sure the tiller arms are square to the tail wheel

and tighten the screw. Use locktite on the

screw.

Install the nylon horn brackets on each end of

the threaded rod.

Bracket collars

3. Install the tail wheel bracket on the fuselage by

drilling a .050 hole at each locations and

mounting with the two 3mm x 1/2” screws.

4. Install the tail wheel springs between the rud-

der horn bracket and tail wheel horn bracket.

Page 11

11

Elevator Servos

1. Collect the following parts:

(2) 4-40 x 2-3/4” threaded pushrods

(2) metal clevis

(2) 4-40 nuts

(2) clevis retainers

2. Install the elevator servos in the fuselage side

with the output arm forward.

3. Be sure and use the forward hole for the elevators. There is an optional rudder servo hole.

Do not remove covering from this opening if

using the pull-pull rudder servo setup. The rudder servo can be mounted in the tail if a heavy

motor is used and weight is need in the rear.

The 1.2 to 1.6 two and four stroke motors are

not heavy enough to mount the servos in the

tail.

4. Thread the 2-3/4” pushrod into the clevis

assembly on the rudder horn. Install the nut

and metal clevis on the other end and attach to

servo. arm. Install the clevis keeper. Repeat

for the other elevator servo.

Rudder Servo Tray Installation

1. Locate the servo tray, front bulkhead, and rear

bulkhead.

front bulkhead

rear bulkhead

servo tray

Page 12

12

2. Epoxy the rear bulkhead in place with the

notch on the bottom fitting over the receiver tray

and flush against the bulkhead.

3. Epoxy the servo tray to the rear bulkhead

making sure the servo cutout is to the rear of the

wing tube.

4. Epoxy the front bulkhead in place sitting on

the cockpit floor and back against the bulkhead.

5. If you are using a large motor you may want

to install a piece of tri-stock (not included) along

the front side of the servo tray and the bottom of

the wing tube. This will add strength to the servo

tray.

Rudder Servo

1. * Collect the following parts:

(2) braided steel cable

(2) metal clevis

(2) 4-40 nuts

(2) clevis retainers

(4) threaded cable couplers

(4) cable swages

2. Mount the rudder servo in the tray supplied just

behind the wing tube.

Page 13

13

2. Thread the cable through one of the swages

then through the hole in the end of the threaded coupler and back through the swage.

3. Loop the cable back through the swage then

crimp the swage with a pair of pliers.

4. Screw the threaded coupler with cable

attached into the nylon clevis assembly on the

rudder horn.

5. Thread the cable into the access hole in the

side of the fuselage.

Repeat for the other cable.

rudder cable access hole

threaded coupler with cable

6. Take the other two threaded couplers and

install a nut and clevis on each.

7. Install the two clevis assemblies on a double

control arm.

Center the servo and attach the control arm.

Tape the rudder in place centered.

Page 14

14

8. Pull the rudder cables to the servo and thread

a swage on each. Fit cable through hole in

threaded coupler and back through the swage.

Do both cables at the same time and pull both

tight before crimping swage. Make sure servo

is centered and rudder is centered. Pull both

cables tight and crimp swage.

Engine Installation

1. Collect the following items:

(2) Motor mounts

(4) 4 mm bolts

(4) 4mm blind nuts

(4) flat washers

(4) 3.5mm x18mm screws

2. Draw a line across the firewall in the center.

Draw a line down the firewall offset 3/16” to the

left side of the plane. The 3/16” will compensate for the 2 degrees of right thrust built into

the firewall. Note: The firewall will have a 1“

hole in the center not shown on the photo.

3. Clamp your motor between the beams of the

two mounts and set flat on the work bench.

Make sure the motor is square to the table and

both mounts sit flat.

Put a scrap piece of wood in the prop mount

and measure both sides to make sure it is

square. The distance from the table to the front

of the thrust washer (scrap wood ) will have to

be at least 6-1/4” to clear the front of the cowl.

If you cannot get this much by moving the

engine to the front of the mounts, you will have

to shim the mounts out. Our OS 1.20 fit all the

way to the end of the mounts.

4. With the motor clamped in place, mark the

location of the mounting holes. Drill a 1/8” hole

and screw the motor in place using the 3.5mm

screws. Be careful and don’t over torque the

screws or they will break.

Page 15

15

6. Seat the blind nut by using one of the 4mm

bolts and a flat washer without the mounts.

Pull the blind nut firmly into the firewall using

the screw. Repeat for the other 3 screws.

7. Bolt the engine in place being sure to use lock-

tite on all the screws.

8. Drill a 9/64” hole in line with the throttle output

arm on your engine and insert the nylon tube for the

throttle pushrod.

Throttle Servo

1. Collect the following items:

(1) e-z servo connector

(1) Laser cut plywood mount

(1) 2-56 threaded one end pushrod

(1) 2-56 clevis

(1) clevis retainer

5. With the motor on the mounts, center the

mounts on the two line you drew on the firewall.

Mark the location of the holes and drill a .160

diameter hole at each location.

Open the hole up with a .200 diameter drill (the

shoulder of the blind nut is .200)

Page 16

16

3. Mount the servo to the mount using the hardware supplied with the servo.

4. The throttle servo mount can now be mounted

in a position to match your engine.

5. Locate the e-z pushrod connector and install on

your servo arm.

6. Thread the 2-56 clevis on the pushrod and

insert into the plastic tube. Connect the clevis

to the throttle arm on the motor. Connect the

other end of the pushrod to the e-z connector

on the throttle servo and adjust.

2. Assemble the throttle servo mount by gluing

the 3/8” square rails in the corners of the 1/8”

plate and gluing the triangle gussets under the

rails.

Page 17

17

Fuel Tank

1. Collect the following items

(1) fuel tank

(1) rubber tank stopper

(1) clunk

(1) 3mm x 25mm screw

(1) cap washer large

(1) cap washer small

(2) 3mm x 40mm brass tube

(1) 3mm x 60mm brass tube

2. Insert the 3mm screw through the center hole

in the large washer, through the center hole in

the rubber washer against the large side, and

screw the small washer on the back side.

3. Insert the brass tubes through three of the

holes. They should be arranged so as the long

one will be on the right side of the plane and

the short one on the left side.

The tubes should extend out the front of the

cap 5/8”. Bend the long tube up at about a 20

degree angle. This should be adjusted so the

end of the tube almost touches the top of the

tank when installed.

4. Install the 4mm silicone tube to the short brass

tube and install the clunk to the other end of

the silicone tube. This is the fuel pickup and

must be free to“flop” around in the tank so it

can pick up fuel in any attitude.

(note: If you use gasoline you must use

neoprene fuel line, glow fuel use

silicone fuel line.)

5. Install the assembly into the tank so the vent

tube is turned up to the top of the tank. Tighten

the screw to expand the rubber cap.

Don’t over tighten or you could split the tank.

Page 18

18

6. Install the tank with the cap in the hole in the

firewall. A tank support is provided to hold the

tank in place. Locate the 1/4” x 3/4” x 7-1/2”

piece of plywood and glue across the fuselage

behind the tank to hold the tank in place. It will

fit just above the throttle servo .

tank support

Cowl Mounting

1. * Collect the following items:

(1)Cowl

(4) 4-40 x 1/2” bolts

(4) #4 flat washers

(1) silicone tubing 1/4” long

3. Fit the cowl in place under the pieces of paper

making sure the stripes line up and cowl is

straight. Use masking tape to hold the cowl in

place.

Transfer the holes from the paper to the cowl.

Drill a 7/32” hole at the four locations. The

blind nuts are pre-installed in the mounting

blocks. Fit the 1/4” long pieces of silicone tubing in the holes and insert the 4-40 x1/2”

screws with a flat washer on top. The silicone

tubing will act as a grommet and protect the

fiberglass.

2. Cut two pieces of scrap paper about 1”: wide

and 6” long and tape to the side of the fuselage

so the end of the paper is over the mounting

hole for the cowl.

Mark the location of the holes in the paper.

Page 19

19

4. Remove the cowl and mount the muffler on the

engine. Use another piece of paper and cut to

fit around the muffler. Mark the location of the

paper on the fuselage so you can relocate it

after the cowl is reinstall..

5. Reinstall the cowl and fit the paper in place on

the fuselage and mark the location of the hole

for the muffler. Repeat for the other holes in

the cowl.

6. When mounting the cowl for flight, use locktite

on all the bolts.

Page 20

20

Canopy and Hatch Mounting

1. Collect the following items:

(1)Hatch

(1)Canopy

(2)4-40 screws

2. Fit the hatch in place with the dowels in front

and the tabs in the rear.

3.

Use the two 4-40 screws through the side of

the fuselage to hold in place.

mounting screw

Page 21

21

4. Install pilot and cockpit detail if desired (not

included).

5.

Glue the canopy in place using Zap canopy

glue. Do not glue the canopy in place without

the hatch cover mounted on fuselage and

screwed in place. It is easy to distort the hatch

and it will not fit properly if not mounted while

gluing the canopy on.

Switch and Battery Mounting

1. The prototype balanced with an OS 1.2 four

stroke with no added weight by putting the battery pack on top of the motor box under the

cowl.

2. The switch can be mounted in the balsa sheeting under the wing on either side.

Balance and Control Throws

CG Balancing

Balancing the Yak is very important, you

might need to use weight depending on

the servos and engine that you use. Start

out with the balance point at 6-1/4”. This

balance point is a safe place for you to fly

the Yak at. As you get comfortable you

can move the CG back further. The further you move the CG the more wild the

aerobatics will become, BUT the more

unstable the Yak will become

Throws

We have provided two sets of throws.

Use the lower throws on the first flights

then work your way up to the higher

throws. Do not use the higher throws till

you are ready.

LOW HIGH

Elevator 1” UP& Down All you can get

Ailerons 3/4” Up & Down All you can get

Rudder 1-1/2” Right & Left All you can get

When you have gotten comfortable

flying the YAK slowly increase the throws

while still staying within your flying ability.

Flutter Problems

Any model with large control surfaces such as the

Yak can experience flutter. It is your responsibility to

make sure all linkage is in good order and very tight.

Servos must be in good shape with control arm that

are not worn. You must fly the plane in a manner

that does not cause it to over speed , you must use

throttle management. Flutter is not covered under

warranty.

Loading...

Loading...