Page 1

When it was introduced, the outstanding Russian SUKHOI took the aerobatic world by storm! Never before have

aerobatic enthusiasts had a machine so capable that it appears to have no limits. It enables the pilot not only to execute maneuvers with exceptional precision, but allows him to invent new maneuvers, as well! We have so completely

captured the essence of this extraordinary, competition-worthy aircraft that any good sport flyer will be able to experience the thrill of true unlimited aerobatics with his GOLDBERG SUKHOI. IMPORTANT: When selecting a power

plant for your SU-26, do not put in a larger-than-recommended engine. This will cause undo stress to the airframe

and may result in structural failure. Remember, a bigger engine does not necessarily mean better performance.

WARNING! THIS IS NOT A TOY!

A radio-controlled model is not a toy and is not intended for persons under 16 years old. Keep this kit out of the

reach of younger children, as it contains parts that could be dangerous. A radio-controlled model is capable of causing serious bodily injury and property damage. It is the buyer's responsibility to build this kit correctly and to properly install the motor, radio, and all other equipment. Test and fly the finished model only in the presence and with the

assistance of another experienced R/C flyer. The model must always be operated and flown using great care and

common sense, as well as in accordance with the safety standards of the Academy of Model Aeronautics (5151

Memorial Drive, Muncie, IN 47302, 1-800-435-9262). We suggest you join the AMA and become properly insured

prior to flying this model. Also, consult with the AMA or your local hobby dealer to find an experienced instructor in

your area. Per the Federal Communications Commission, you are required to use only those radio frequencies specified "for Model Aircraft."

LIMI TED WARRANTY

Carl Goldberg Products takes pride in the care and attention given to the manufacture of components for its model airplane kits. The

company warrants replacement of any materials found to be defective for their intended use, prior to their use in construction of the aircraft, provided the buyer requests such replacement within one year from the date of purchase and provided the defective part is

returned, if so requested by the company.

No other warranty, expressed or implied, is made by the company with respect to this kit. The buyer acknowledges and understands

that it is his responsibility to carefully construct a finished flying model airplane and to fly it safely. The buyer hereby assumes full responsibility for the risk and all liability for personal or property damage or injury arising out of the buyer's use of the components of this kit.

Pt. #2097 2/03

INSTRUCTIONS

SUKHOI SU-26

©Copyright 1993

Page 2

ITEMS NEEDED TO COMPLETE THIS KIT

1 RADIO GUIDANCE SYSTEM (4 CHANNEL MINIMUM REQUIRED)

1 ENGINE .90 2-CYCLE OR 1.20 4-CYCLE

(NO BIGGER!)

1 PROPELLER (SIZE DEPENDS ON

ENGINE)

1 12-16 OZ. FUEL TANK

1 12" SILICONE FUEL LINE

2 3-1/2" DIAMETER WHEELS

1 1-1/4" DIAMETER WHEEL

3 ROLLS IRON ON COVERING FLIM

1 CGP 3" DIAMETER SPINNER

3 2 OZ. BOTTLE CA GLUE

1 EPOXY 6 OR EPOXY 20 MINUTE

1 TUB JET MODEL MATE

1 CGP 1/4" FOAM PADDING

4 CGP 3/16" WHEEL COLLAR

1 TUBE CLEAR CANOPY GLUE

1 CGP 3/32" WHEEL COLLAR

OPTIONAL

PILOT: 1/5 SCALE

TOOLS AND SUPPLIES

REQUIRED FOR ASSEMBLY

MISCELLANEOUS RUBBER BANDS

(INCLUDING #64)

ROLL OF WAXED PAPER

SANDPAPER (ASSORTED GRITS, INCLUD-

ING COARSE (80), MEDIUM (150) AND

FINE (220)

SANDING BLOCK

"T" PINS (at least 100)

X-ACTO MODELING KNIFE

SINGLE EDGE RAZOR BLADE

RAZOR SAW

BUILDING BOARD (24" x 74")

36" STEEL STRAIGHT EDGE

ELECTRIC DRILL

1/8" DRILL BIT

5/16" DRILL BIT

5/32" DRILL BIT

SMALL SCREWDRIVER

SOLDERING IRON AND FLUX

COVERING IRON AND HEAT GUN

MASKING TAPE

6" RULER

10" 30-60-90 DRAFTING TRIANGLE

SPRAY BOTTLE

2

Page 3

INTRODUCTION

USING THIS INSTRUCTION MANUAL

Before you start gluing and sanding, take some time

becoming familiar with the plans and looking through this

entire Instruction Booklet. It is designed to guide you

through the construction process step by step, so build in

the order given in this book. Building options, as well as

balancing, set- up, and flying the model are covered.

Like a full-size airplane, the SUKHOI is built from

basic structures (stabilizer, fin, wing, etc.), which are then

assembled into the complete airplane.

Special procedures or comments will usually be

explained before a step, so you will be prepared. If a step

begins with a statement like "Note," "Warning," or

"Important," it is a good idea to read through the step

before doing it.

A check-off box appears at the beginning of each

step. Check these boxes as you build, so you can tell at

a glance what steps you have completed. Some steps

are repeated and must be marked twice, as in the case of

the left and right wing panel.

Some of the instructions deal with general procedures. Boxes are not needed for these sections.

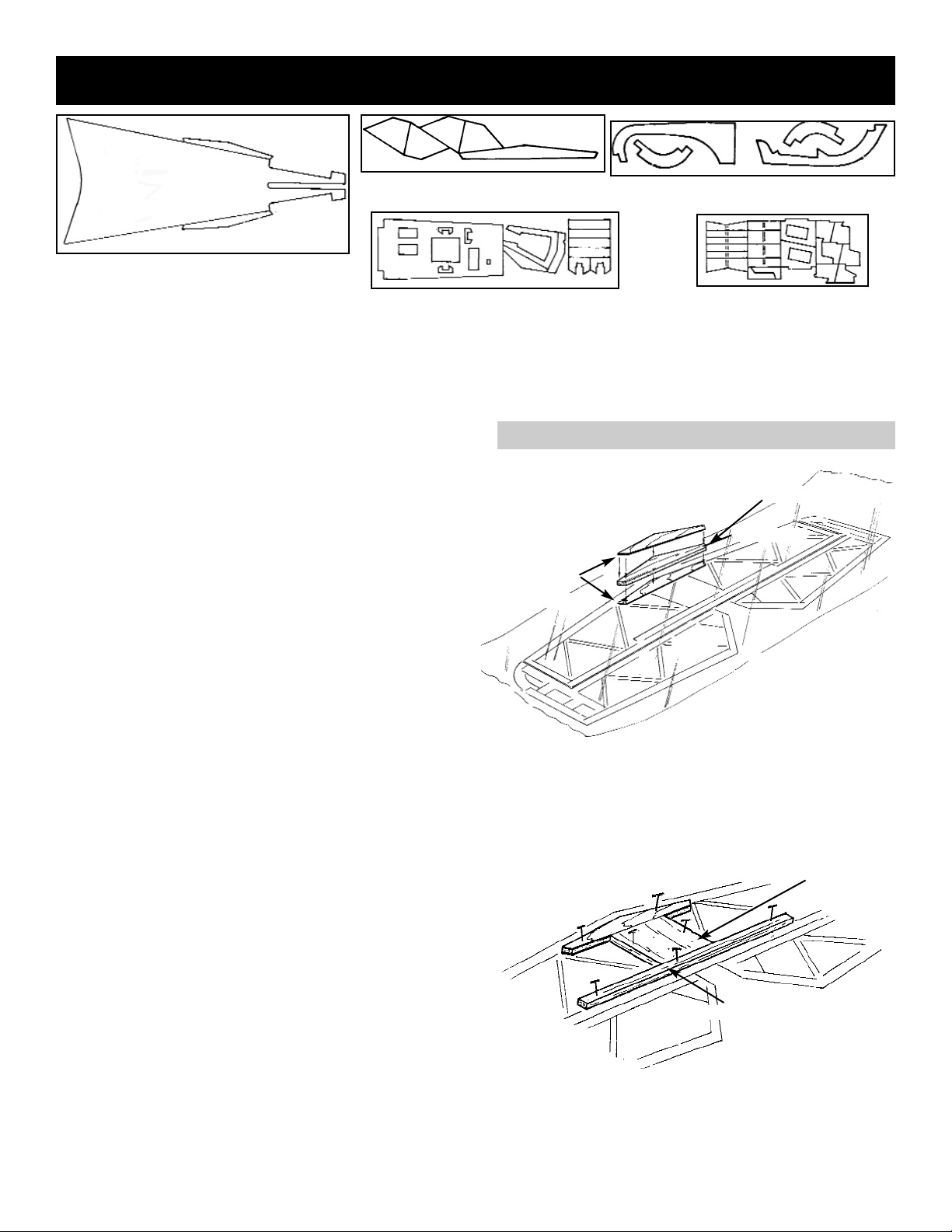

HOW TO READ THE PLAN

There are two plan sheets in this kit, showing the

Fuselage (Body), the Wing, and the Tail Parts.

Everything on the plan is drawn to full-size and shape and

shows how the finished parts fit together.

The plan is drawn to show the model completely

assembled, but as a result, the areas inside or underneath are covered up, making it hard to understand how

these parts fit together. Therefore, for clarity, some parts

are drawn with hidden lines, others with breakaway

views, and some are entirely removed from the structure

and shown separately.

For example, on the fuselage, the left side of the completed model has been removed to show the details

inside. Sometimes a surface is broken away to reveal the

detail behind or underneath. Dashed lines indicate details

that are hidden behind or under another part of the surface.

The model is made from four varieties of wood: balsa,

bass, birch, and various plywoods. Each kind of wood

has its own characteristic end grain pattern (as viewed

from the end) which has been drawn in this book. You

can easily use these end grain patterns to identify what

kind of wood is shown for a part, if you are in doubt.

HOW TO USE THE PLAN

The plan is used in several ways. The wings, stabilizer,

and fin are assembled directly over the plan. Each wood

part is matched over its corresponding location printed on

the plan and pinned in place. To prevent ruining your plan

from gluing your wings, etc. to it, cover the area you are

working on with waxed paper.

The paper the plan is printed on can expand or

contract slightly with changes in temperature or

humidity. Because of this, a preformed part such as

the notched wing trailing edge may not exactly match

the plan. This is no problem, as slight deviations in the

outline or size will not noticeably affect flight performance.

Because the fuselage plugs together and is selfaligning, it is not built directly over the plan. As you

assemble the fuselage, you will find the plan helpful in

identifying parts and how things fit together. The plan

also shows the installation of a typical radio, battery and

all remaining equipment and hardware needed to complete the model. By referring to the examples shown,

you should be able to install your own radio, etc., even if

it is not the same as what is shown on the plan.

IDENTIFYING PARTS

Parts for the wing are bundled together; likewise, parts

for the tail assembly are also grouped. Die-cut plywood and

balsa sheets of common sizes are bundled together, so they

are less likely to be damaged during shipping and handling.

The various screws, hinges, and fittings are packaged

in plastic bags.

PREPARING FOR ASSEMBLY

Set a flat, warp-free pinning board on your work

bench. Any material that accepts pins, such as insulation

board, soft plywood, or dry-wall (sheet rock) will work.

Important: any warps or bends in the pinning board will

result in wings or tail surfaces that are also warped or

bent, making your model more difficult to fly. Make sure

that the pinning board is flat by laying a straight edge

across it. You may be able to correct a warped board by

shimming its low areas.

Position the area of the plan (such as the stabilizer)

on which you are going to build over the pinning board

and tape it in place so the plan lays flat and wrinkle free.

Place a sheet of waxed paper or plastic kitchen wrap

over the work area to prevent Super Jet from sticking to

your plan and ruining it.

CONSTRUCTION TIPS

In assembling your model, the following tips will

prove helpful.

IMPORTANT: ALWAYS READ A FEW STEPS

AHEAD. This will alert you to coming instructions and

will help you plan accordingly.

You may find it convenient to empty all of the small

parts from the hardware bags into a common container,

such as a margarine tub. This will help you find items

quickly.

When drilling any 1/16" holes in balsa, you may find

it easier to twist the drill between your thumb and index

finger. This procedure allows more control in positioning

the drill on the center mark.

Punch out only the laser-cut parts you need as you

proceed. This will help you keep track of parts, especially the small ones.

Sometimes you will be asked to “tack cement” a

piece of wood that will later be taken apart. To provide

for easy removal without damage, use only a small drop

of glue.

After completing each section of the aircraft, you may

want to go back and reglue the joints, just in case some

area has been missed. Be careful not to use too little

glue, which will leave the model weak, or too much glue,

which can make the model heavy. Properly glued joints

are important to the overall strength of the model. CA

glue is recommended for most parts of the assembly,

although epoxy glue may be used when more time is

needed for careful placement.

3

Page 4

WOOD PARTS

Be careful when removing parts (such as fuselage formers) from the laser-cut sheets. Long parts are fragile

until glued into a structural unit. If necessary, use a

razor knife or razor saw to assist in the removal of

parts from the sheet. Sometimes a little trimming and

sanding can improve parts, where desired. Save scrap

until the model is completed, in case a part is missing

or damaged. Also, scrap is used in some building

steps.

ABOUT THE WOOD IN THE KIT

We strive to supply good quality materials in your kit.

Wood parts are inspected with regard to the function

they will serve. If an imperfection is spotted in a scrap

corner of a laser-cut sheet and doesn't affect actual

parts, the sheet is considered acceptable. Also, internal stresses in wood are relieved as it is cut into parts.

These relieved stresses may cause some parts to

bow. Bows in wood parts (such as leading edges)

readily straighten out as they are CA glued into a

structural unit

4

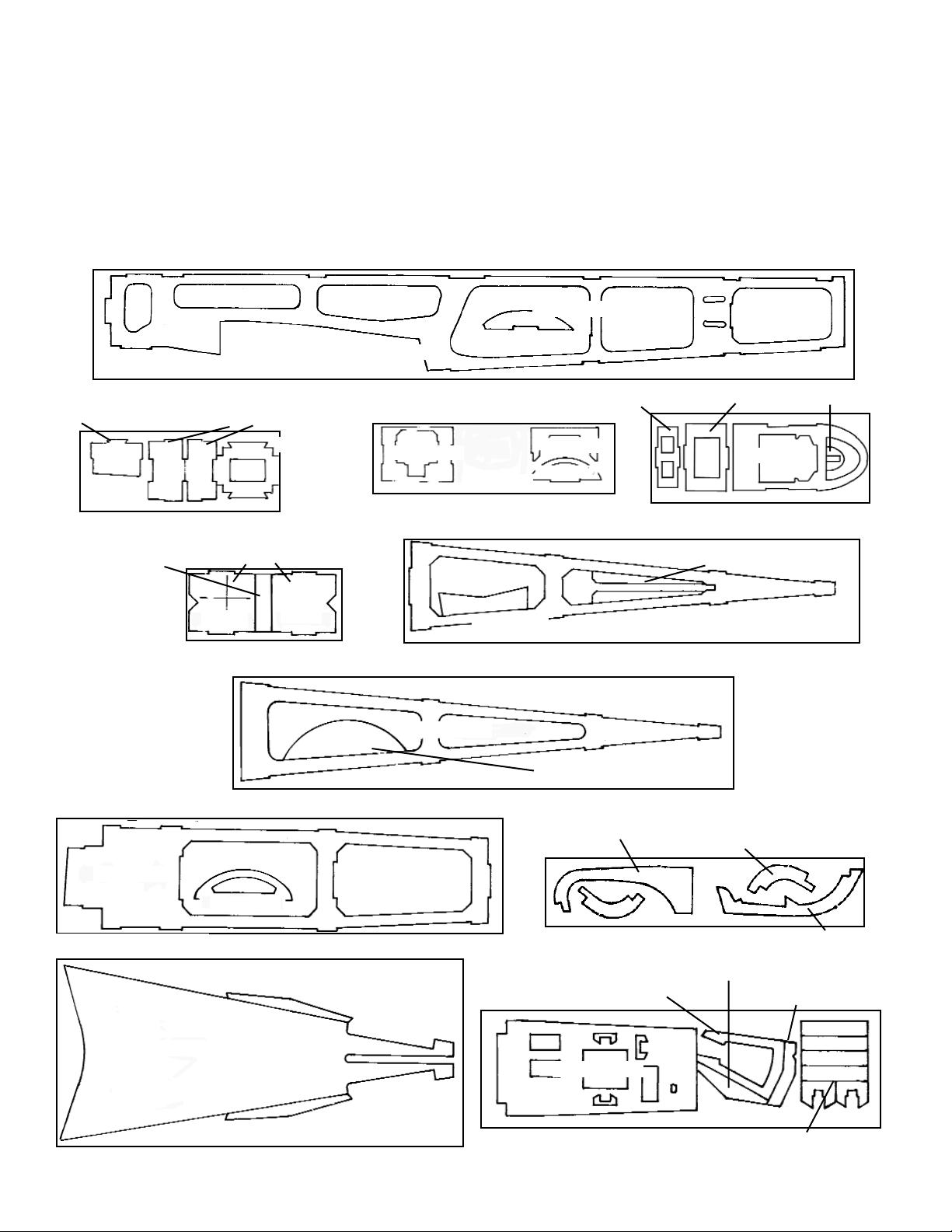

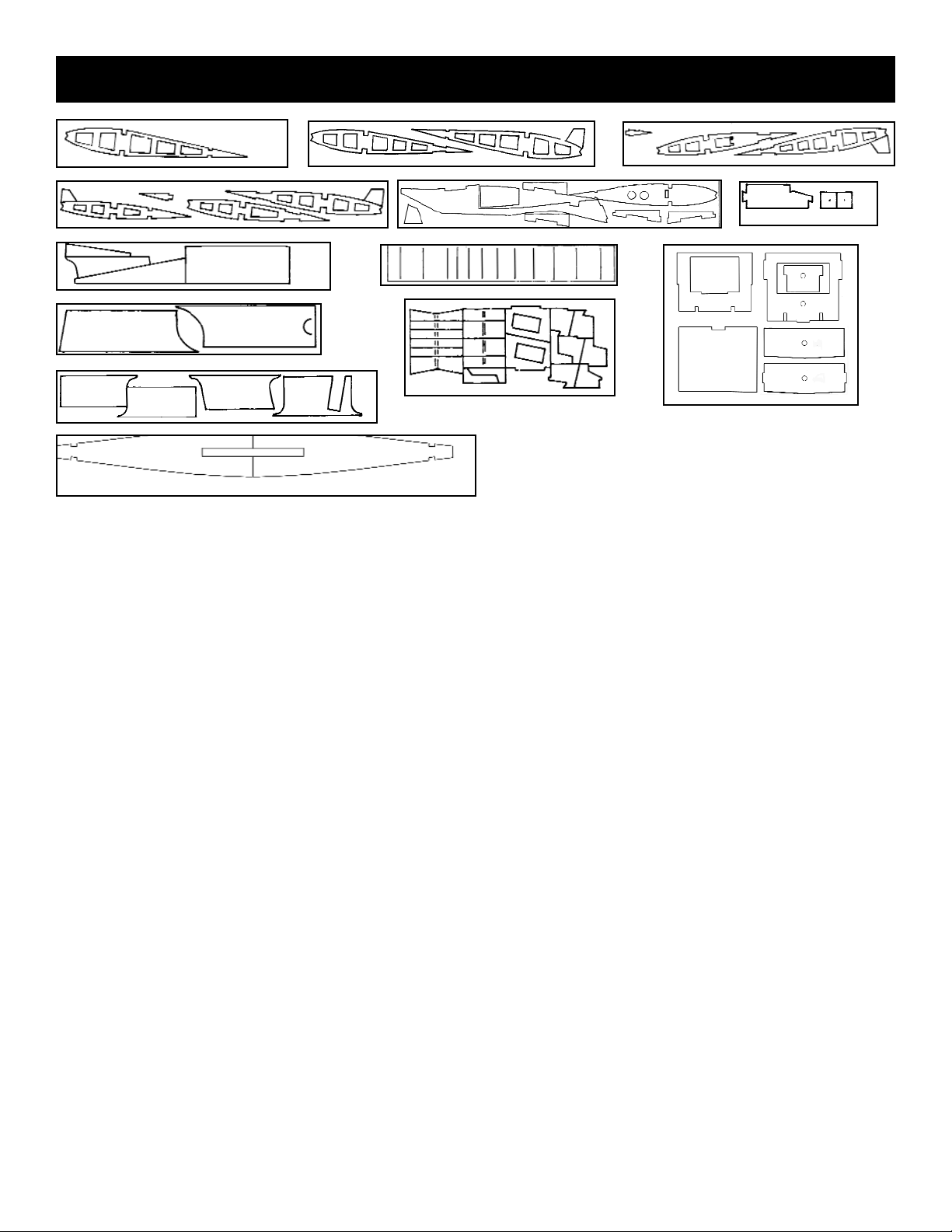

D/C SHT. 6728 2 REQ’D

D/C SHT. 6703 1 REQ’D

D/C SHT. 6704 1 REQ’D

D/C SHT. 6705 1 REQ’D

WING PIN

DOUBLER

D/C SHT. 6707 1 REQ’D

D/C SHT. 6708 1 REQ’D

D/C SHT. 6709 1 REQ’D

D/C SHT. 6710 1 REQ’D

D/C SHT. 6712 1 REQ’D

D/C SHT. 6711 2 REQ’D

D/C SHT. 6706 1 REQ’D

MOTOR MOUNT SIDES

FUSELAGE SIDE

FORMER H

FORMER JFORMER G

TANK TRAY

COWL SIDE SUPPORT

WIND STOP

FRONT

BACK

FORMER E

FORMER E

FORMER C

FORMER D

TOP FRONT

TURTLEDECK

RUDDER BOTTOM

RUDDER TOP

SERVO TRAY

RUDDER GAUGE

AILERON GAUGE

ELEVATOR GAUGE

ROUNDING TOOL PARTS

ELEVATOR AIRBALANCE L.E.

COWL SUPPORT-TOP

BOTTOM AFT

TOP AFT

FIREWALL

MOTOR MOUNT FRONT

TURTLEDECK BACK-UP

FORMER F

Page 5

5

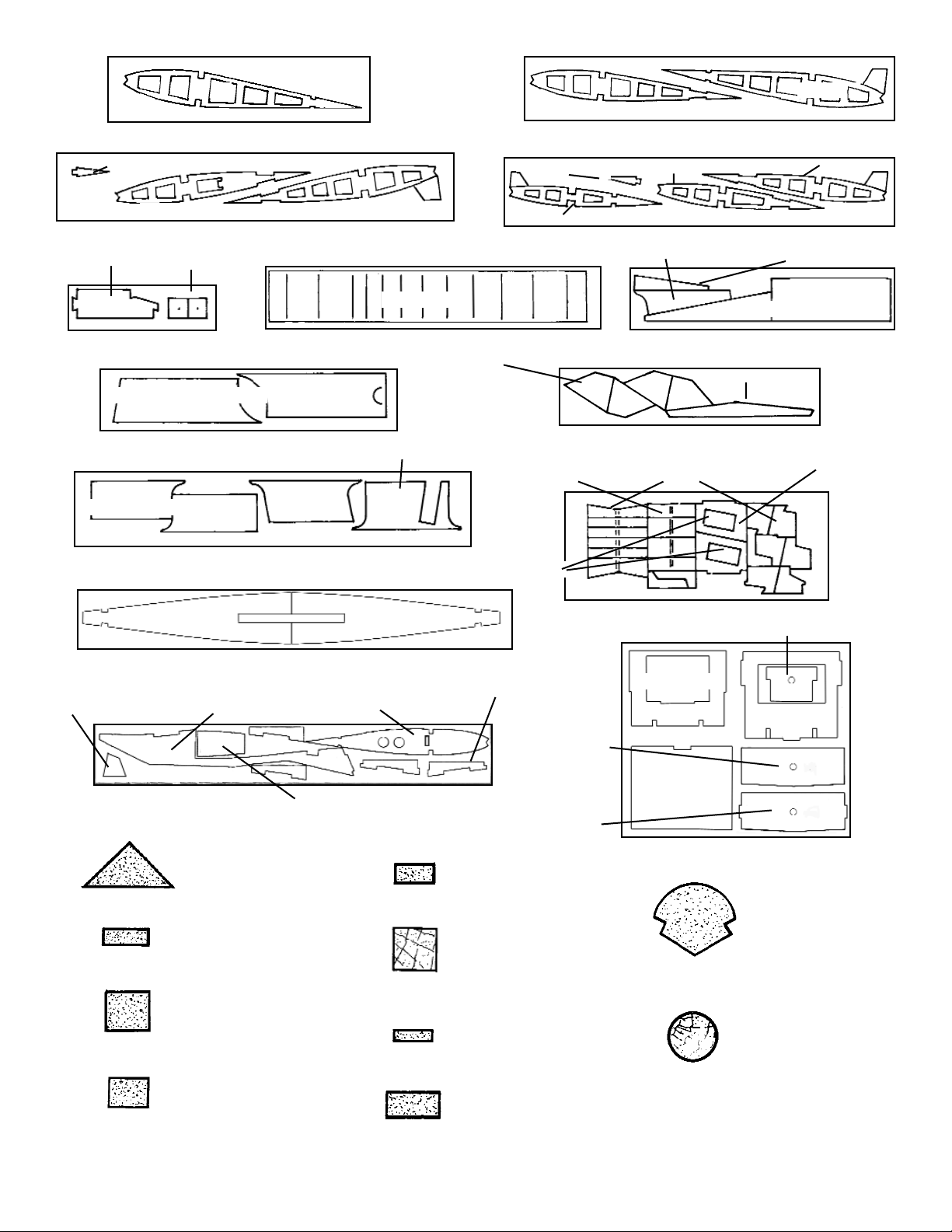

D/C SHT. 6720 4 REQ’D

L/C SHT. 6730 1 REQ’D

D/C SHT. 6723 1 REQ’D

D/C SHT. 6722 2 REQ’D

D/C SHT. 6727 1 REQ’D

L/C SHT. 6731 2 REQ’D

L/C SHT. 6732 1 REQ’D

D/C SHT. 6719 4 REQ’D

D/C SHT. 6718 2 REQ’D

D/C SHT. 6726 1 REQ’D

D/C SHT. 6716 2 REQ’D

D/C SHT. 6715 2 REQ’D

D/C SHT. 6714 2 REQ’D

RIB #2

LANDING GEAR DOUBLER

L. G. COVER

PLATE

WING CENTER DOUBLER

WING DOWEL SCAB PLATE

FORMER B

FORMER B2

WING SADDLE DOUBLER

CENTER RIB

WING JOINER

FRONT

WING JOINER

REAR

RIB #2 TEM-

PORARY TAB

STAB JOINER

ELEVATOR HORN MOUNT

AILERON HORN BACK-UP

AILERON SERVO

MOUNT

BEVEL GAUGE

DIHEDRAL FIXTURE

AILERON COVER SHEET

CENTER SHEET

RIB SPACER

GAUGE

TIP SHEET

SHEAR WEB

WING BOLT PAD

WING CENTER SHEETING

WING TIP SHEETING

AILERON SERVO SHEETING

AILERON RIB

AILERON RIB

RIB #6

RIB #7

RIB #5

RIB #4

RIB #8

RIB #9

RIB #10

RIB #3

D/C SHT. 6725 2 REQ’D

1/2” BALSA TRI

STOCK 3 REQ’D

5/16 x 3/8 x 14”

BALSA 1 REQ’D

1/8 x 3/8 x 12”

BALSA 4 REQ’D

1/4 x 5/16 BALSA

12” 1 REQ’D

16” 2 REQ’D

24” 3 REQ’D

3/16 x 3/8 x 20”

BALSA 2 REQ’D

SHAPED L.E. x 36”

2 REQ’D

5/16 DIA. x 4-1/2”

DOWEL 1 REQ’D

3/8 SQ. BASS

12” 8 REQ’D

15” 1 REQ’D

18” 4 REQ’D

35-1/8” 4 REQ’D

5/64 x 1/4 x 22”

BALSA 5 REQ’D

1/8 x 1/4 BALSA

20” 3 REQ’D

36” 4 REQ’D

Page 6

TAIL CONSTRUCTION

1. Collect the following items:

(1) D/C SHT. 6711 BALSA PT. # 3670

CONTAINS:

(4) ELEVATOR AIR BALANCE L.E.

(2) RUDDER BOTTOM

(2) RUDDER TOP

(1) D/C SHT. 6712 PLY PT. #3671

CONTAINS ROUNDING TOOL

(1) D/C SHT. 6727 BALSA PT. #3657

CONTAINS:

(1) STAB JOINER

(4) ELEVATOR HORN MOUNT

(1) D/C SHT. 6723 PLY PT. #3697

CONTAINS BEVEL TOOL

(1) D/C SHT. 6710 PLY PT. #3669

CONTAINS:

(2) STAB JOINER DOUBLER

(3) TRUSSING STICKS PT. #3675

1/4 x 1/8 x 20” BALSA

(4) RUDDER TRUSSING PT. #3676

1/8 x 3/8 x 12” BALSA

(1) STAB T.E. DOUBLER PT. #3677

1/4 x 5/16 x 12” BALSA

(2) STAB L.E. & TIP PT. #3678

1/4 x 5/16 x 16” BALSA

(3) PERIMETER STICKS PT. #3679

1/4 x 5/16 x 24” BALSA

(2) ELEVATOR TRUSSING PT. #3680

3/16 x 3/8 x 20” BALSA

(1) RUDDER TRAILING EDGE PT. #3681

5/16 x 3/8 x 20” BALSA

(8) ELEVATOR PERIMETER STICK PT. #3682

3/8” SQ. x 12” BALSA

(1) RUDDER LEADING EDGE PT. #3683

3/8” SQ. x 18” BALSA

(1) STAB PLATFORM PT. #3684

1/4 x 2-1/2 x 3-3/4” BALSA

(4) STAB/FIN SHEETING PT. #3685

5/64 x 3 x 24” BALSA

(2) FIN SHEETING PT. #3686

5/64 x 3 x 18” BALSA

(1) CENTERLINE MARKING TOOL PT. #1425

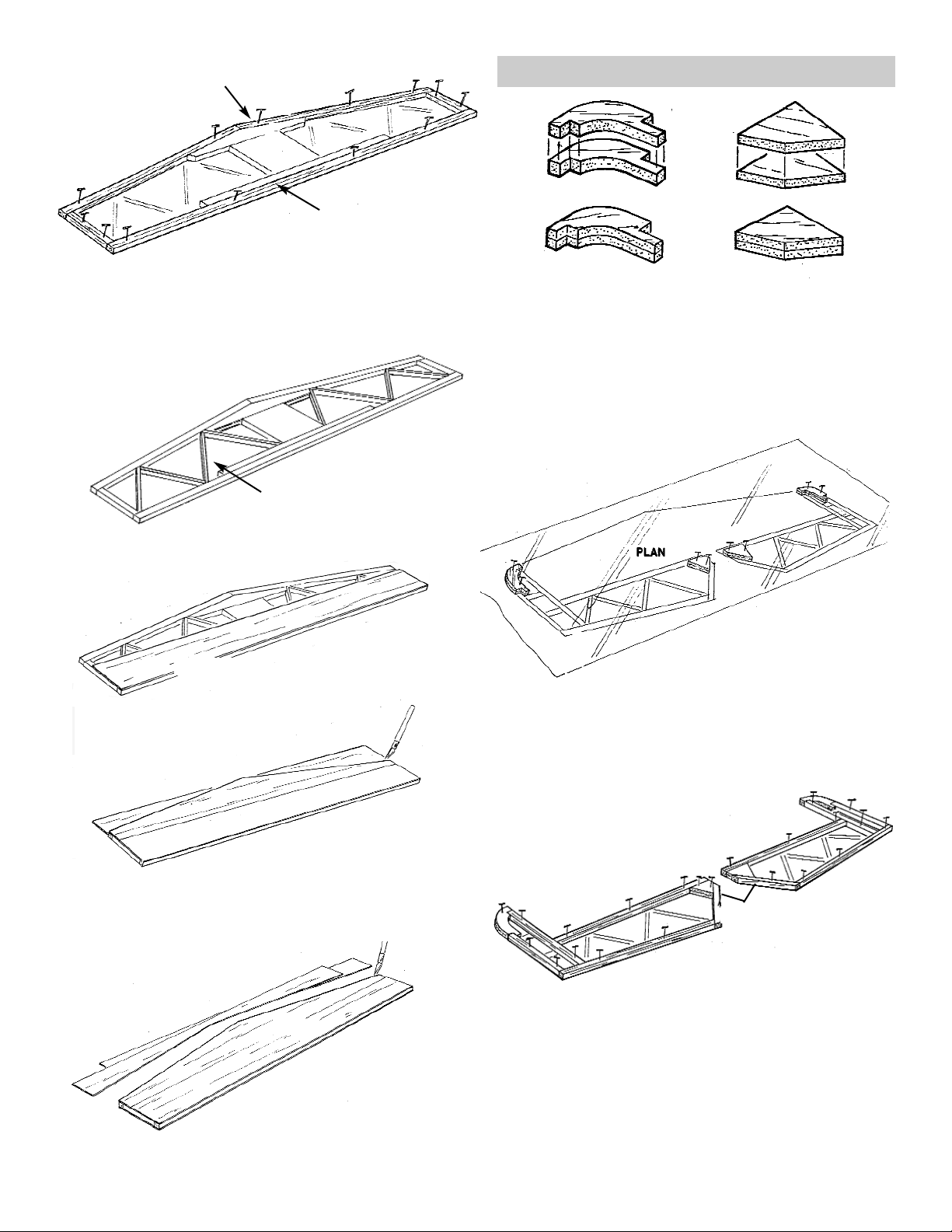

HORIZONTAL STABILIZER

2. Place the WING PLAN on the building board

and cover the horizontal stabilizer portion of

the plan with waxed paper.

3. Glue a STAB JOINER DOUBLERS to each

side of the STAB JOINER, as shown above.

4. Glue and pin the JOINER ASSEMBLY, STAB

PLATFORM and T.E. DOUBLER over the plan.

(10) LARGE FLEX POINT HINGE PT. #1449

(1) WING PLAN PT. #2124

(1) FUSELAGE PLAN PT. #2123

6

3/16" BALSA

1/32" PLY

PLAN

1/4 x 2-1/2 x 3-3/4" BALSA

1/4 x 5/16 x 12"

Page 7

7. Trimming as needed, prefit the SHEETING

onto the stab. When satisfied with the fit, CA

glue in place.

8. Flip the stab over and sheet the other side.

ELEVATOR

1. Laminate the two sets of ELEVATOR AIR BAL-

ANCE L.E.s and ELEVATOR HORN MOUNTS.

2. Place waxed paper over the elevator portion of

the plan.

3. Working over the plan, glue and pin the ELE-

VATOR AIR BALANCE L.E.s and the ELEVATOR HORN MOUNTS in place.

4. Trim each PERIMETER STICK, as needed,

and glue and pin in place over the plan.

6. Trim and glue the TRUSSING in place.

5. Trim the STAB LEADING EDGES and TIPS to

fit.

Pin in place and glue.

7

1/4 x 5/16 x 16"

1/4 x 5/16x24"

1/8 x 1/4 x 20"

3/8" SQ. BALSA

5/64” BALSA

Page 8

6. From scrap 3/16” balsa, cut a piece 1/2”x 1/2”

triangle to form a gusset.

Glue in place, as shown.

VERTICAL FIN

RUDDER

1. After covering the fin portion of the FUSE-

LAGE PLAN with waxed paper, begin trimming, gluing, and pinning the 1/4 x 5/16 balsa

PERIMETER STICKS in place.

Next, trim and glue the 1/8 x 1/4 TRUSS

STICK pieces in place.

2. Trim the SHEETING to fit the fin framework.

When satisfied with the fit, glue in place.

Turn the fin over and sheet the other side of the

fin structure.

NOTE: When covering the fin, DO NOT cover posts

and bottom where the structure is to be

glued to the fuse.

5. Trim and glue the 3/16 x 3/8” TRUSS STICKS.

1. Laminate the two RUDDER TOPS and RUD-

DER BOTTOMS.

8

1/2"

1/2"

1/4 x 5/16" BALSA

RUDDER BOTTOM

RUDDER TOP

ELEVATOR

1/8 x 1/4" BALSA

GUSSET

Page 9

2. Working over the rudder portion of the plan,

place the laminated RUDDER TOP over the

plan and trim, if needed. When satisfied with

the fit pin in place.

Follow the same procedure for the laminated

RUDDER BOTTOM.

3. Using 3/8” square balsa, glue the rudder L.E.

to the rudder top.

4. Use 1/8 x 3/8” balsa sticks, as shown, to form

the trussing.

5. Complete the trussing. Then use 5/16 x 3/8”

balsa to form the rudder trailing edge.

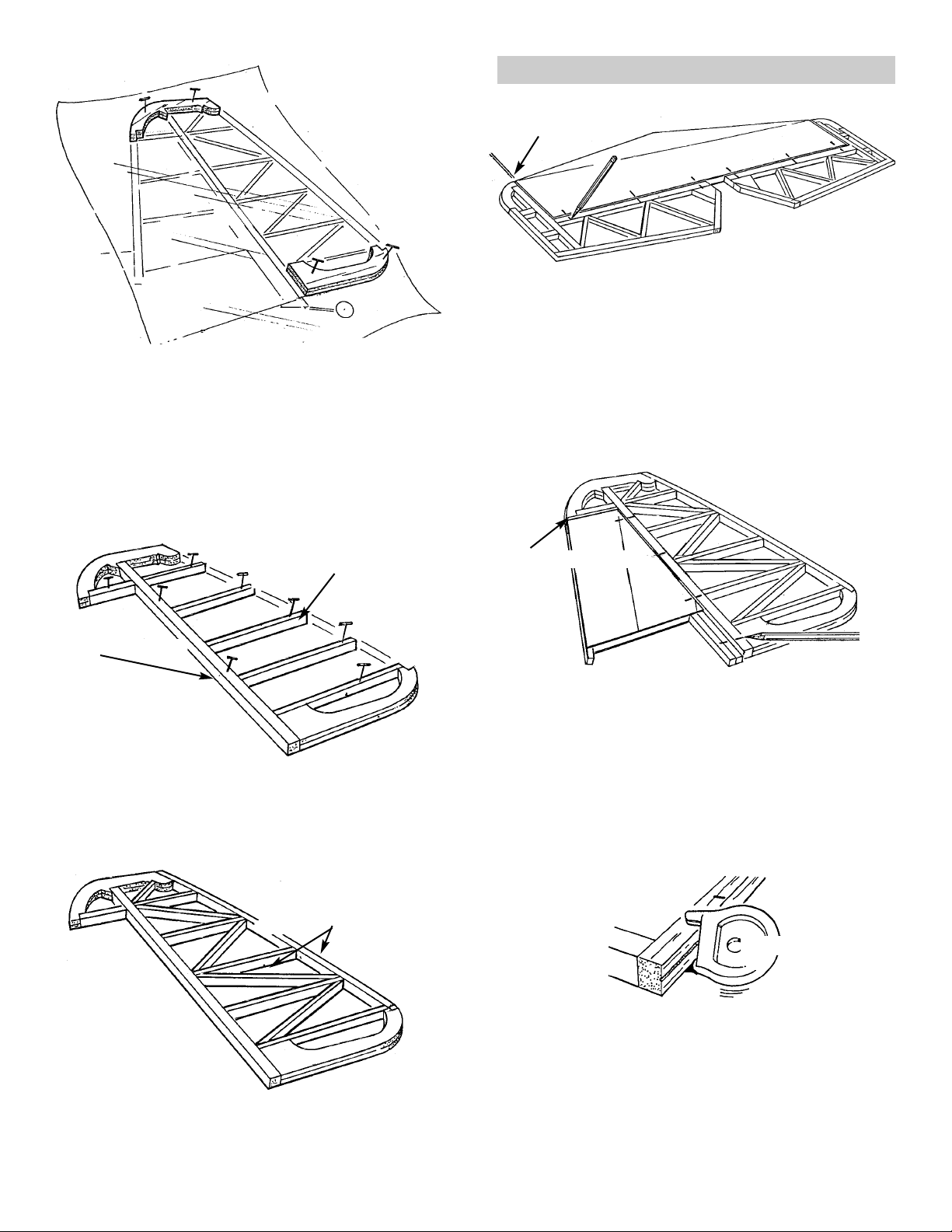

HINGING AND ROUNDING

1. Referring to the plans, mark the hinge locations

onto the elevator.

2. Fit the stab and the elevator together and, use

balsa sheeting scrap to make a 5/64” spacer

between the elevator air balance and the stab.

Then, transfer the hinge locations from the ele-

vator to the stab.

3. Again referring to the plans, mark the hinge

locations onto the rudder.

As in the previous step, make a 5/64” scrap

balsa spacer between the fin and the rudder air

balance.

Transfer the hinge locations from the rudder to

the fin.

4. Using the CGP CENTERLINE MARKER,

scribe a centerline onto the elevator L.E.

Next, scrib a line onto the stab T.E.

Repeat this process with the rudder L.E. and

the fin T.E.

9

3/8" SQ. BALSA

5/16 x 3/8" BALSA

MARK

MARK

5/64" BALSA SPACER

5/64" BALSA SPACER

CGM CENTERLINE TOOL

1/8 x 3/8" BALSA

AIR BALANCE

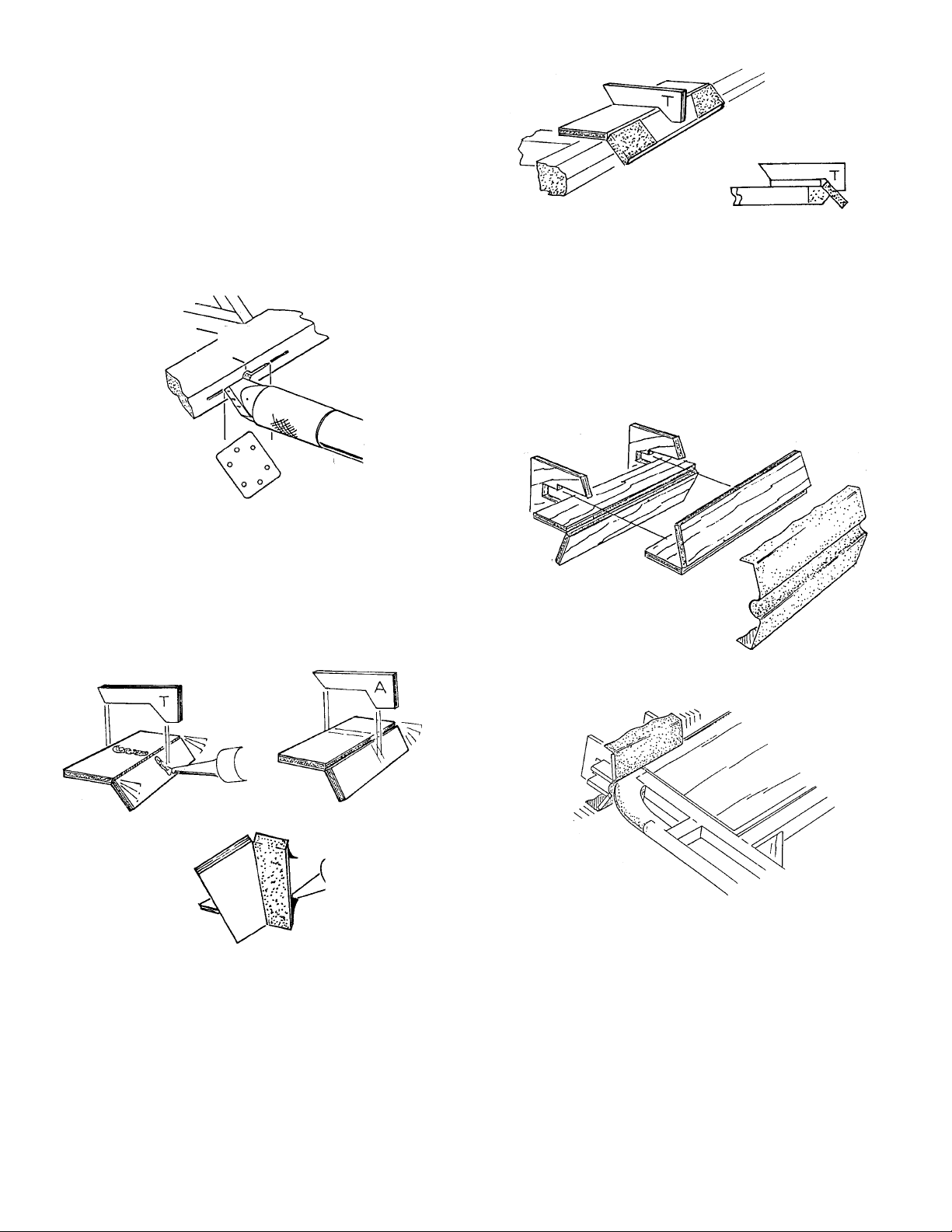

Page 10

5. Use a knife to make an slot on on the center-

line for each hinge.

6. Test fit each hinge, as you proceed.

NOTE: DO NOT GLUE THE HINGES IN PLACE AT

THIS TIME.

7. From D/C sheet 6723, assemble the two

BEVELING TOOLS.

Tack glue a piece of medium sandpaper onto

each tool.

8. Using the tool marked “T,” bevel the rudder

L.E. and the elevator L.E. to a point at the

scribed centerline. Use a knife to bevel near

the air balances, as the tool cannot get into the

corner.

9. Temporarily hinge the rudder/fin assembly and

the elevator/stab assembly, in order to check

the alignment and round the perimeter of the

assembles. You may wish to use masking tape

to help hold the pieces together.

10. Assemble the ROUNDING TOOL and insert,

but do not glue, a piece of medium sandpaper

11. Use the tool to round the perimeter of the

fin/rudder assembly and the elevator/stab

assembly.

When satisfied with the shape, change the

sandpaper to fine git and repeat Step 10 to

smooth the rough surface.

12. Finish sand the entire surface of both assem-

blies, using a sanding block with fine grit sandpaper. Then separate the fudder from the fin

and the stab from the elevator.

THIS COMPLETES THE TAIL OF THE AIRCRAFT.

SET THE PARTS ASIDE UNTIL LATER.

10

SLOT

HINGE

LIKE THIS

FOR AILERON BEVEL

Page 11

WING CONSTRUCTION

1. Gather the parts needed to construct the wing:

(2) D/C SHT. 6725 5/64” BALSA PT. # 3656

CONTAINS WING RIB #3

(2) D/C SHT. 6714 5/64” BALSA PT. #3688

CONTAINS WING RIB #4 & #5

(2) D/C SHT. 6715 5/64” BALSA PT. #3689

CONTAINS: WING RIB #6 & 7,

AND AILERON RIB

(2) D/C SHT. 6716 5/64” BALSA PT. #3690

CONTAINS: WING RIB #8, #9,

#10, AND AILERON RIB

(1) L/C SHT. 6732 PLY PT. #3652

CONTAINS: WING JOINER FRONT

WING JOINER REAR,

WING DOWEL SCAB PLATE

(1) L/C SHT. 6730 BALSA PT. #3654

WING CENTER RIB

(2) L/C SHT. 6731 PLY PT. #3653

CONTAINS: RIB #2, RIB #2 TAB,

WING CENTER DOUBLER

(1) D/C SHT. 6726 PLY PT. #3658

CONTAINS :

(1) RIB SPACING GAUGE

(2) WING BOLT PADS

(2) D.C SHT. 6718 BALSA PT. #3692

CONTAINS:(8)SHEAR WEB

(4) D/C SHT. 6719 5/64” BALSA PT. #3693

CONTAINS:

(2) WING TIP SHEETING

(1) AILERON SERVO COVER SHEETING

(4) WING CENTER SHEETING

(4) D/C SHT. 6720 5/64” BALSA PT. #3694

CONTAINS:

(2) WING CENTER SHEETING

(2) D/C SHT. 6722 5/64” BALSA PT. #3695

CONTAINS:

(2) WING TIP SHEETING

(2) AILERON SERVO COVER SHEETING

(1) D/C SHT. 6723 PLY PT. #3697

CONTAINS:

(2) AILERON SERVO MOUNT

(8) DIHEDRAL FIXTURES

(5) MAIN SPARS PT. #3700

(3/8 x 3/8 x 35-1/8" BASS)

(8) AFT SPARS PT. #3701

(1/8 x 1/4 x 35-3/4" BALSA

(4) HINGE STICK PT. #3702

(1/4 x 1 x 25-1/2" BALSA)

(2) WING TIP BLOCK PT. #3703

(1-1/4 SQ x 10" BALSA)

(1) T.E. BACK-UP PT. #3704

(1-3/4 TAPERED x 7" BALSA)

(2) SHAPED L.E. PT. #3705

(12) WING SHEETING PT. #3706

(4) CAPSTRIPS PT. #3707

(5/64 X 1/4 X 22" BALSA)

(1) LANDING GEAR PLATE PT. #3708

(1/4 x 2-1/4 x 6-1/4" PLY)

(1) NYLON TAPE PT. #3709

(4) #6-32 x 1" SOCKET HD. SCREW PT. #1023

(4) #6 WASHER PT. #1140

(10) LARGE FLEX-POINT HINGE PT. #1449

(1) WING DOWEL PT. #1750

(5/16 x 4-1/2" ASH)

(1) BEVEL TOOL “A” PREVIOUSLY CON-

STRUCTED.

11

Page 12

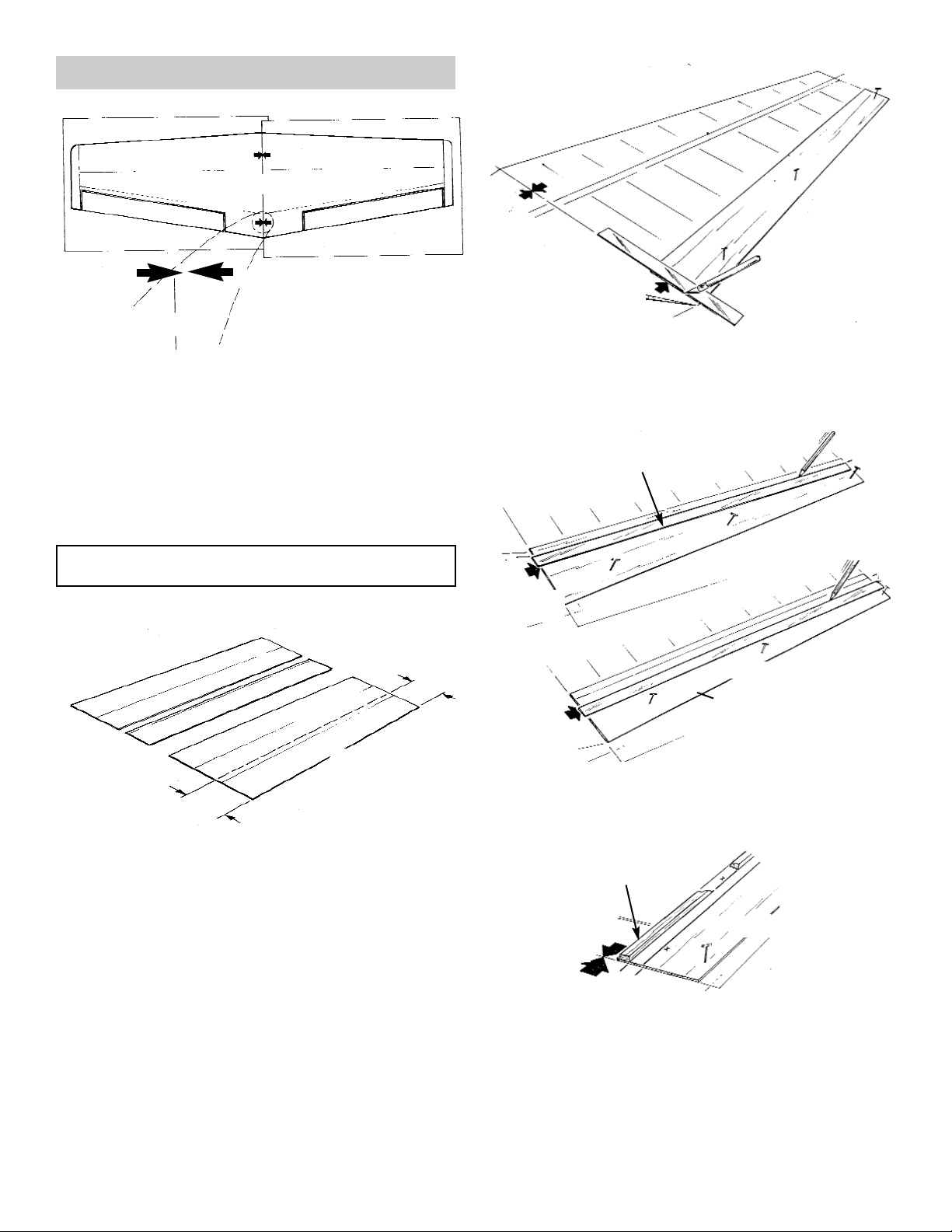

2. Cut the plan along the dotted line.

Position the left wing plan over the right wing

plan, aligning the arrows and main spar lines,

as shown.

Pin or tape the plan to the building board and

place a sheet of waxed paper over the entire

wing plan.

START THE WING CONSTRUCTION BY FIRST

BUILDING THE RIGHT WING HALF.

3. Edge-glue two assembllies of three 5/64 x 3 x

36” balsa.

Measure 3-1/4” from each end of both assem-

blies and cut, as shown, to makeT.E. SHEETS.

NOTE: The remainder of the sheeting will be used later

for the leading edge.

4. Pin a T.E. sheet over the plan.

Align a straight-edge with the wing centerline

and trim the sheet even with the centerline.

5. Align a straight-edge with the aft spar marks on

the plan and draw lines on the sheeting to

locate the spars.

WING

12

MATCH ARROWS

LEFT

RIGHT

PLAN

T.E. SHEET

T.E. SHEET

T.E. SHEET

T.E. SHEET

3-1/4"

3-1/4"

STRAIGHT-EDGE

STRAIGHT-EDGE

AFT SPAR

MARKS

MARKS

MARKS

MARKS

SPAR MARKS

FORWARD AFT SPAR

TRIM

6. Position the 1/8 x 1/4 x 36” FORWARD AFT

SPAR on the T.E. sheet, in front of the front

line.

NOTE: Make sure the spar end is flush with the cen-

terline edge of the T.E. sheet.

Glue the spar in place.

CENTERLINE

T.E. SHEETING

Page 13

7. Tape both sides of the tab break-off line on all

of the tabbed ribs.

9. Locate Rib #2 over the plan and glue it to the

T.E. sheet.

10. Angle-cut the T.E. BACK-UP to fit tight against

Rib 2.

With the back-up flush with the top of the rib,

glue the back-up to the trailing edge sheet.

Cut off the back-up flush with the wing center-

line.

11. Use the Plan to locate the distance between Rib

#3 and and Rib #2.

NOTE: Because the plan paper can stretch somewhat, due to variations in humidity, the plan is not

always an accurate representation of the desired

results. Therefore, to guarantee the ribs are spaced

correctly, a rib spacing gauge is provided. Use this

gauge to measure the distance from the previously

installed rib to the next, making sure that all ribs are

parallel.

12. Use the long side of the rib spacing gauge to

position Rib #4 from Rib #3.

13

TAPE BOTH SIDES

PLAN

T.E. BACK-UP

RIB SPACING GAUGE

RIB SPACING GAUGE

T.E. BACK-UP

CENTERLINE

Page 14

13. Using the wing-tip side of Rib #4 as a guide, cut

through the trailing edge sheeting.

14. Cut a 1/8 x 1/4” balsa aft spar to a 10-3/4” length

and butt one end against Rib #4.

Glue to the T.E. sheeting along the edge of the

rear line, as shown.

15. Using 5/64” scrap balsa as a spacer, glue an

AILERON RIB to the aft spar and the T.E. sheet.

16. From D/C sheet 6723, take an AILERON HORN

BACK-UP, marked “D” an glue it to the T.E.

sheeting, in line with the aft spar.

17. Using the long side of the rib spacing gauge,

locate ribs #5 through #9, gluing each of them to

the T.E. sheet.

NOTE: Make sure that the ribs are parallel to the

ribs on the plan, before gluing.

18. With the long side of the rib gauge, locate the

cut-off mark on the back of the aft spar, and cut.

Install Rib #10.

14

RIB #3

RIB #3

RIB #4

RIB #4

STARTING HERE

WING TIP

WING TIP

RIB SPACING GAUGE

AFT SPAR

5/64" SCRAP

CUT

AFT SPAR

10-3/4"

Page 15

Again using the 5/64” scrap spacer, locate and

glue the aileron rib to the trailing edge sheeting.

19. Using Rib #10 as a guide, cut through the T.E.

sheeting along the wing center side of the rib.

20. With the end flush with the centerline of the

wing, insert the TOP MAIN SPAR into the rib

notches and glue at each rib.

Again with the spar flush with the centerline,

insert the FORWARD AFT SPAR and glue in

place.

21. Trim the rear aft spar to fit and glue to the ribs.

22. Position the SHAPED LEADING EDGE on the

wing centerline and then glue the L.E. to each

rib.

23. Using fine grit sandpaper, flat sand the tops of

the ribs flush with the aft spars.

15

WING CENTERLINE

1/8 x 1/4 x36" BALSA

REAR AFT SPAR

TRIM

STARTING HERE

FORWARD AFT SPAR

MAIN SPAR

AILERON RIB

5/64" SCRAP

Page 16

24. Glue the top T.E. SHEETING to the spars, ribs,

and the bottom T.E. sheet.

25. From the remainder of the edge-glued sheeting

used for the T.E., measure a width of 5-3/8” from

one end and 3-7/8” at the other end.

With a straight-edge, draw a line from one mark

to the other. Then cut the sheeting along the

line, creating two tapered pieces.

26. Glue and pin the L.E. sheet to the shoulder on

the leading edge, the rib camber, and the spar.

27. Making sure the servo wire knock-out hole is on

the piece closest o the L.E., glue the three large

pieces of CENTER SHEETING to the ribs, the

L.E. and the T.E..

Pre-fit a wedge-shaped piece of sheeting to fill

the center area.

When satisfied with the fit, apply glue and slide

the piece into place, as shown.

28. Use a flexible straight-edge to trim the sheeting

flush with the wing centerline.

Punch out the knock-out hole in the sheeting to

provide access for the servo wire.

16

T.E. SHEETING

L.E. SHEETING

L.E. SHEETING

5-3/8"

3-7/8"

FLUSH WITH T.E.

SLIDE

ON CENTERLINE

BREAK OUT

Page 17

29. Trim and then glue the WING TIP SHEETING

and the 5/64” balsa capstrips in place.

THIS COMPLETES THE RIGHT WING HALF. SET IT

ASIDE AND PLACE THE LEFT WING HALF OF THE

PLAN IN THE CENTER OF THE BUILDING BOARD.

Begin building the left wing at Step 3.

DO NOT BUILD THE SECOND WING PANEL OVER

THE SAME PORTION OF THE PLAN!

WHEN THE SECOND WING PANEL IS COMPLETE,

REMOVE IT FROM THE BOARD AND CONTINUE TO

THE NEXT STEP.

30. Assemble the DIHEDRAL FIXTURES, as

shown. Note that one is offset. This fixture will

not be needed in construction of this second edition Sukhoi.

31. Working over the full waxed-paper-covered wing

plan, pin or glue the fixtures in place, as shown

above.

32. Place the wing panels onto the fixtures with the

bottom (open framework) facing up.

Check the centerline fit and, if necessary, sand

to improve fit.

When satisfied with the fit, you may wish to

anchor in place with pins and rubber bands, as

shown.

33. Carefully remove the reinforcing tape and crack

off all of the wing support tabs.

34. Test fit and then glue the MAIN SPARS to each

wing rib.

17

OFFSET

"S"

"S"

CRACK

"T"

"T"

"R"

WING IS BOTTOM-SIDE UP

Page 18

35. Test fit the front and rear WING JOINERS

between the two #2 ribs, as shown. Note the

rear joiner tabs which fit into the rib slots.

Sand any parts, as necessary, to improve the fit

of the two wing halves.

36. When satisfied with the fit, apply JET Epoxy 20

along the centerline of both wing panels and

spars and glue them together.

Epoxy the wing joiners securely in place.

After making sure all elements are correctly

aligned, allow epoxy to thoroughly cure before

proceeding. You may wish to use clamps to hold

the assembly tightly together.

37. Beginning at the wing tips, use Super Jet to glue

the corresponding SHEAR WEBS to the front side

of the top and bottom main spars in each rib bay.

NOTE: The web that goes between Rib #2 and Rib #3

must be trimmed to fit.

Center the Rib #2/3 web between the two ribs

and glue in place.

38. Test fit the L.E. sheeting. When satisfied with

the fit, apply glue to the top of the L.E., the front

rib tops, and the top of the main spar.

Install the sheeting and pin in place, as shown.

Allow to dry thoroughly.

39. When dry, determine the two Rib #2 locations

and make a mark on the leading edge.

Make a second mark at the location of the wing

joiner/spar assembly.

Referring to the above diagram, and taking

care not to cut into the ribs or the wing joiner, use a razor saw and/or a hobby knife to cut

the L.E. and the L.E. sheeting back to the wing

joiner/spar assembly between the two #2 Ribs.

40. Take one of the WING CENTER RIBS and lam-

inate a WING CENTER DOUBLER to the outboard side.

18

SHEAR WEBS

WING CENTER DOUBLER

WING CENTER RIB

WING JOINER

RIB #2

RIB #2

FRONT WING JOINER

Page 19

Take the second center rib and repeat the above

lamination, taking care to make a right center

rib and a left center rib.

41. Laminate the two center ribs together, creating a

single four-ply center rib with the doublers facing

the wing tips.

42. Insert the center rib assembly, as shown, and

then test fit the dowel, making sure it slides

through the hole in the wing joiner and into the

center of the rib assembly.

When satisfied with the fit, glue the rib assembly

and then the dowel in place.

43. Test fit and then install the CENTER SECTION

SHEETING.

44. Glue the AILERON SERVO MOUNT into the

upper slot of Rib #7 and onto the top of the spar.

Repeat for the other wing panel.

45. Temporarily mount the servo, and mark the

AILERON SERVO COVER SHEETING accordingly.

Make a cut-out for the servo.

46. Install the capstrips and the wing tip sheeting.

47. Remove the wing from the fixtures and flat sand

the end ribs, as shown.

48. Cut the 1-1/4” square WING TIP BLOCK in two

equal pieces and glue each piece to the end

ribs.

Rough carve the tips to the shape of the rib.

19

WING TIP

WING TIP

RIB #7

AILERON SERVO MOUNT

AILERON SERVO CUT-OUT

CAPSTRIPS

WING TIP

SHEETING

CARVE TO SHAPE

SAND

CENTER SHEETING

Page 20

Using first medium grit, and then fine, sandpa-

per, sand the both wing tips to a rounded and

tapered final shape.

49. Finish sand the entire wing surface, top and bot-

tom.

50. WORKING IN A WELL-VENTILATED AREA

and with plastic wrap or a plastic bag covering your finger, completely wrap the center

joint of the wing (top and bottom) with 2-1/2 “

nylon tape, smoothing a liberal amount of glue

into the fabric, as you go.

Cut a hole for the dowel and, when the wing is

fully wrapped, trim off any excess tape.

AILERON

1. Referring to the plan, determine the aileron cut

lines and transfer onto the bottom sheeting of

the wing trailing edge.

Then, carefully cut through the sheeting, as

shown.

2. Using a straight-edge, remove a strip of sheet-

ing between the two aft spars, as shown.

3. Using a razor saw, cut through the ribs and the

T.E., between the two aft spars, to separate

the ailerons from the wing.

Mark “top right” and “top left” on the root end

of each aileron, so that you will know which

piece fits into the left wing half and right right

wing half.

4. Trim the sheeting back flush with the aft spars

on both the aileron and the wing.

Flat sand along the entire length of the spar.

20

WORK IN A WELLVENTILATED AREA!

STRAIGHT-EDGE

REMOVE STRIPS OF SHEETING

ROOT END

R

L

MARK RIGHT AND LEFT

SAND FLUSH

MARK AND CUT

TRIM

Page 21

5. Trim to fit and then glue a 1/4” balsa HINGE

SHEETING onto both the ailerons and the

wing.

Sand flush to the wing and to the aileron airfoil

profile.

6. Using the CGP centerline marker, scribe a cen-

terline onto both the aileron and the wing.

Transfer the hinge locations from the plan onto

the wing and the aileron.

7. Following the same procedure used when con-

structing the control surfaces on the tail. Slot

each of the hinge locations.

8. Using the previously constructed Bevel Tool

“A”, bevel both sides of the ailerons.

Test fit the ailerons to the wing, but do not per-

manently install until after they have been

covered.

NOTE: MAKE SURE YOU CAN IDENTIFY THE

LEFT AND THE RIGHT AILERON. YOU WILL NEED

TO SCREW THE CONTROL HORN INTO THE PLY

BACKUP LOCATED INSIDE.

9. Carefully check the wing for any nicks and

deep scratches and fill with CGP Model

Mate™. Finish sand any areas that will detract

from the appearance of your model after it is

covered.

THIS COMPLETES CONSTRUCTION OF THE

WING. SET IT ASIDE UNTIL IT IS NEEDED.

21

SLOT

AILERON BEVEL

GAUGE

CHECK AILERON MOVEMENT

HINGE SHEETING

LIKE THIS

Page 22

FUSELAGE CONSTRUCTION

1. Gather the parts needed to construct the fuselage.

(2) D/C SHT.6728 LITE PLY PT. #3655

FUSE. SIDE/COWL SIDE SUPPORT

(1) D/C SHT. 6729 LITE PLY PT. #3651

FORMER "A", "C" & "D"

(1) D/C SHT. 6704 LITE PLY PT .#3663

FORMER "F","G","H" & "J"

(1) D/C SHT.6724 LITE PLY PT. #3659

CONTAINS:

(1) FUEL TANK TRAY

(1) MOTOR MOUNT BOTTOM

(1) LEFT MOTOR MOUNT SIDE

(1) RIGHT MOTOR MOUNT SIDE

(1) D/C SHT. 6706 BIRCH PLY PT. #3665

CONTAINS:

(1) FIREWALL FRONT

(1) FIREWALL AFT

(1) D/C SHT. 6707 LITE PLY PT. #3666

CONTAINS:

(1) TOP AFT

(1) WIND STOP

(2) TURTLE-DECK BACK-UP

(1) D/C SHT. 6708 PT. #3667

CONTAINS:

(1) BOTTOM AFT

(1) COWL SUPPORT-TOP

(1) D/C SHT.6709 LITE PLY PT. #3668

CONTAINS:

(1) TOP-FRONT

(1) FORMER "E"

(1) D/C SHT. 6710 BIRCH PLY PT. #3669

(1) TURTLEDECK

(2) L/C SHT. 6731 LITE PLY PT. #3653

CONTAINS:

(1) WING SADDLE DOUBLER

(1) L/C SHT. 6732 LITE PLY PT. # 3652

CONTAINS: (1) FORMER B

(1) FORMER B2

(1) LANDING GEAR PLATE

(1) WING MOUNTING BLOCK PT. #3672

7/16" TAPER x 5-1/8" BASS

(1) FRONT TOP SHEET PT. #3673

1/32 x 8 x 9-1/2" BIRCH PLY

(3) GUSSET PT. #4217

1/2" TRI x 8" BALSA

(1) .078 x 13-5/8” THREADED ROD PT. #1281

(2) ENGINE MOUNT PT. #1466

(6) 6-32 BLIND NUTS PT .#1124

(2) 6-32 x 1" SOCKET HEAD SCREW PT. #1023

(2) #6 FLAT WASHER PT. #1140

(2) #6 x 3/4" O.D. FLAT WASHER PT. #1144

(1) FUSELAGE PLAN PT. #2123

2. Making sure the marking lines are facing out

and that the perimeter is lined up, laminate the

two 1/8” birch plywood FIREWALL parts with

SUPER JET.

22

MARKING LINES FACING UP

Page 23

3. When the firewall has thoroughly dried, tack-

glue the motor you intend to use to the

ENGINE MOUNTS.

Align the marks on the engine mounts with the

vertical marking line on the firewall.

Center the engine mounts on the horizontal

marking line, as shown, and mark all four hole

locations.

Mark the location of the throttle pushrod exit in

line with the throttle control.

4. Drill a 5/32” diameter hole at each hole loca-

tion.

Flip the firewall over and insert four 6-32

BLIND NUTS. Seat them with a soft hammer

blow.

Making sure that the glue does not get into the

threads, coat the edges of each blind nut with

CA glue. Then, set the firewall aside.

NOTE: Flying the Sukhoi with one of the larger

recommended engines will produce spectacular

results. However, these larger 4-stroke engines

generate a lot of vibration. Therefore, you may

wish to install two elevator servos. If you choose

this option, refer to the following instructions.

(a) Do not punch out the elevator exit. Instead, glue it

permanently in place.

(b) Cut a hole for the servo on each side of the fuse-

lage, as shown.

(c) Make two doublers from scrap 1/8 x 1/4 x 1-1/4"

ply and glue the forward doubler to the INSIDE of

the fuselage. Glue the rear doubler to the OUTSIDE of the fuselage. This helps to position the

servo more parallel to the elevator pushrod.

(d) From the fuse side punch-out, cut off about a 1”

piece from the end and glue this strip back into the

fuse.

(e) When mounting the servos, it is essential that one

of the servos be reversed. The easiest way to

accomplish this is to use a special Y- harness

that will reverse one servo from the other.

Alternatively, "mix" your elevator channel into an

exta channel in your radio, and then reverse to

achieve proper direction. Consult your radio manual for details.

(f) Using the elevator pushrod wire supplied in the kit,

trim to fit, making sure there are no bends. When

adjusting throws, try to get both elevators to move

equally.

TWO SERVO OPTION

Tape together and place under a weight until

dry.

23

1/2 ENGINE WIDTH

ALIGN MARKS

PLY DOUBLER

SERVO CUT-OUT

DO NOT REMOVE

FROM PUNCH-OUT

1”

FORMER J

Page 24

7. Positon, but DO NOT GLUE, FORMERS A, B,

B2, C, F, G, and H. Use a rubber band at each

former location to hold the fuselage together.

8. Slide the TOP FRONT (note slant) and the

TOP AFT under the rubber bands and into the

alignment notches. DO NOT GLUE.

9. Invert the fuse and slide the BOTTOM AFT and

the LANDING GEAR COVER PLATE into the

notches provided. Again, DO NOT GLUE.

10. Position the fuselage assembly over the bottom

view of the plan and check the alignment.

Secure the assembly with small pieces of mask-

ing tape, as shown.

Sight check along the fuselage to ensure that

the fuse is straight, not twisted.

5. Lay the FUSELAGE SIDES on a flat surface

side-by-side, in a mirror-image configuration.

This will ensure that you build a left and a right

fuselage side.

Aligning the front and rear points for correct

positioning, glue a WING SADDLE DOUBLER

to each fuse side.

6. With the doublers face-to-face, rubber band

the fuse sides together at the rudderpost location.

24

ALIGN

ALIGN

TAPE IN PLACE

PLAN

LIKE THIS

NOT LIKE THIS

SLANT

Page 25

11. When the fuselage is perfectly aligned, glue all

of the areas where the sides, top, bottom, and

formers join.

12. Insert the remaining 6-32 blind nuts into the pre-

drilled holes in the WING MOUNTING BLOCK.

NOTE: Make sure the blind nuts are inserted into the

side of the mounting block where the holes are

centered.

Tap with a hammer to ensure the spurs are fully

set into the wood.

13. With the blind nuts on the inside the fuse, place

the mounting block into the cut-outs in the wing

saddle doubler and the fuselage sides. Trim, if

necessary, to achieve a good fit. Then, using

epoxy, glue in place.

NOTE: THIS IS A HIGH STRESS AREA. THE BETTER THE MOUNTING BLOCK FITS INTO THE

SOCKET, THE STRONGER THE JOINT WILL BE.

14. Form four 2-ply assemblies from the four LAND-

ING GEAR DOUBLERS.

When the laminated assembles are dry, test fit

in position. The assemblies with the tabs fit at

the slotted locations between Former B and

Former B2. The assemblies without the tabs

go along the fuse sides.

Epoxy securely in place.

15. Epoxy the 1/4 x 2-1/4 x 5-11/16” ply landing gear

plate between the fuse sides and into landing

gear doublers.

Now get the wing, which will be needed for the next

few steps.

16. Place the fuselage, bottom up, on a flat surface.

Glue the WIND STOP to the fuse sides and the

doublers.

Insert the wing dowel through the slightly over-

sized hole in Former B2. Slide the wing as far

forward as it will go. Make sure that the wing fits

tightly all along the wing saddle.

17. True the wing to the fuselage by adjusting the

distance from the wing-tip to the tail until both

dimensions are equal. Mark the wing for reference and tape in place.

25

HOLE IS CENTERED

TABBED DOUBLERS

UNTABBED DOUBLERS

MARK WITH TAPE

WIND STOP

L.G. PLATE

GLUE ALL SEAMS

WING DOWEL

Page 26

20. Drill a 5/32” hole at the centermark on each

WING BOLT PAD.

Place each pad on a 6/32 x 1” socket head

screw and screw part way down into the blind

nut.

21. Install the MOTOR MOUNT BOTTOM and both

MOTOR MOUNT SIDES to the fuse,as shown.

Use a generous amount of glue, as this is a high

stress area.

22. Using the 1/2” balsa tri stock, trim and fit the

FIREWALL GUSSETS in place. They should be

located 1/4” back from the edge of the motor

mount, as shown.

23. With the blind nuts to the inside and the V-notch

on top, epoxy the FIREWALL into the fuse. Use

plenty of epoxy and let dry thoroughly.

18. Carefully turn the wing/fuselage assembly to an

upright position.

Cut the threaded segment from one of the .078

x 13-5/8” threaded rods and use as a drill bit.

Don’t use anything larger than 7/64”

(.109/2.7mm) in diameter.

Using the blind nuts as locators, drill a pilot hole

through the bottom of the wing.

Remove the wing from the fuselage and, using

the pilot hole as a guide,

19. Test bolt the wing to the fuse and, following the

procedure used before, again check the alignment by making sure the dimensions from wing

tip to tail are still equal on each side of the

model.

Being careful not to get glue on the dowel, glue

the WING DOWEL SCAB PLATE over the wing

dowel and to the front side of Former B2.

Glue the LANDING GEAR COVER PLATE in

position.

Make sure the holes are aligned. Then, taking

care to not get glue in the hole or on the

screw, apply CA glue to the bottom of the

wing bolt pad and glue to the wing.

NOTE: Brush On™ Super Jet is excellent for this job.

26

1/14" BACK FROM

FRONT EDGE

1"

"V" NOTCH AT TOP

NO LARGER THAN 7/64"

5/32" HOLE

WING DOWEL SCAB

PLATE

Page 27

24. Trim and glue the remaining firewall gussets in

place, as shown.

25. Glue FORMER D and FORMER E into the

notches in the fuselage top.

26. Overlapping the side 3/16”, as shown, glue one

edge of the 1/32” ply FRONT TOP SHEET to

the fuselage.

When the glue is dry, use a spray bottle to soak

the sheet with water. Then SLOWLY roll the

sheeting to the opposite side of the fuse, gluing

to the formers as you go.

Bevel-sand the plywood edge at the fuselage

overlap.

Fill the joint area with JET MODEL MATE™ and

sand smooth.

27. Glue FORMER J directly over FORMER H.

28. Mark the centerline onto the horizontal stabilizer

and onto the stab platform on the fuselage.

Position the stab on the stab platform, making

sure to locate it on the centerlines and against

former J.

Using epoxy, glue the stab to the stab platform.

27

3/16" OVERLAP

JET MODEL MATE

FILLER

ALIGN

STABILIZER

FUSLAGE

MATCH THE CENTERLINES

DIRECTLY ABOVE

WATER SPRAY

FORMER D

FORMER E

Page 28

29. Insert the vertical fin L.E. into the slot in Former

J and slide the rudder post into the fuselage.

Check to make sure the fin is at a 90º angle to

the stab and then glue in place.

Glue the two TURTLEDECK BACK-UPS, as

shown.

30. Slide the 1/32” ply TURTLEDECK back around

the fin.

Again using the spray bottle and water, soak the

top center of the turtledeck.

31. When satisfied with the fit, apply glue to the for-

mers, fuselage, fin and stab.

Immediately wrap the turtledeck down onto the

fuse and tape in place until dry.

When thoroughly dry, bevel-sand the plywood

edge where it overlaps the fuse. Also sand the

turtledeck front flush with Former F.

As with the top front sheeting, fill the step with

JET Model Mate™ and sand smooth.

32. Go over the fuselage, sanding all seams and

joints.

Then, finish sand the entire fuse assembly with

fine grit sandpaper to provide a smooth surface

for covering.

THIS COMPLETES THE BUILDING PORTION OF

YOUR MODEL. MAKE SURE ALL PARTS ARE WELLSANDED AND ALL NICKS ARE FILLED. THEN PROCEED TO THE “GENERAL INFORMATION BOOK”,

COVERING SECTION. AFTER COVERING THE

MODEL, RETURN TO THE FINISHING SECTION IN

THIS BOOK AND CONTINUE.

Before the glue has set and with the fuse sitting

flat on the work surface, check to make certain

the stab is parallel to the building board.

SLOWLY wrap the plywood around the form-

ers and down onto the fuselage sides.

Check the fit and trim, if necessary.

28

EQUAL OVERLAP

FILL STEP

LIKE THIS

NOT LIKE THIS

Page 29

FINISHING THE MODEL

CANOPY INSTALLATION

1. You will need the canopy and paint or covering.

2. Cover the cockpit interior with black or gray

iron on film or paint, as preferred.

3. Trim the canopy around the perimeter, along

the trim line.

4. Using epoxy or a clear canopy glue, glue the

canopy overlap to the fuselage sides and

around the front and back of the cockpit.

FUEL TANK INSTALLATION

1. Gather the following items:

(1) D/C SHT. 6724 PT. #3659

TANK TRAY

(1) FUEL TANK NOT INCLUDED

(1) 12” LENGTH OF FUEL LINE NOT INCLUDED

(2) #64 RUBBER BANDS NOT INCLUDED

(1) FOAM PADDING NOT INCLUDED

2. Rubber band the foam pad and the fuel tank to

the tank tray.

3. Thread the fuel line through the “V” notch in the

firewall and attach them to the tank.

Pull the line forward and glue the tank assem-

bly onto the locating shoulders on Former A

and Former B, inside the fuselage.

Connect the fuel lines when you mount the

engine.

TAILWHEEL ASSEMBLY

1. Collect the following items:

(1) TAILWHEEL ASSEMBLY PT. #5819

(1) ADJUSTABLE HORN BRACKET PT. #1424

(2) #2 x 3/8” SHT. METAL SCREW PT. #1084

(1) 1-1/4” TAILWHEEL NOT INCLUDED

(2) CGP 3/32” WHEEL COLLAR NOT INCLUDED

2. Cut a narrow slot through the fuse bottom and

secure the tailwheel brack assembly with the

#2 x 3/8” screws.

3. Notch the bottom of the rudder to mount the

horn bracket.

Slide the bracket into the wire and glue into the

notch. DO NOT GLUE BRACKET TO WIRE.

4. Trim the wire and install tailwheel, as shown.

29

#2 x 3/8" SCREW

HORN BRACKET

CUT SLOT

NOTCH

FUEL TANK TRAY

Page 30

CONTROL SURFACE/RADIO INSTALLATION ENGINE PUSHROD INSTALLATION

1. Collect the following items:

(1) 3/8" x 3/8" x 16" BASS PT.#3674

PUSHROD

(2) LONG CONTROL HORNS PT.#1407

(4) 2-56 x 3/4" PAN HEAD SCREWS PT.#1042

(3) SNAP LINKS PT.#1405

(2) HOODED PUSHROD EXITS PT.#1453

(1) .078 x 10" THREADED ROD PT.#1272

(2) .078 x 13-5/8" THREADED ROD PT.#1281

1. If you did not do so immediately after covering

the model, thin CA glue the hinges in place,

permanently attaching the elevator to the stab

and the rudder to the fin.

Permanently install the ailerons on the wings.

2. Referring to the GENERAL INFORMATION

BOOK and to the specific details and guidelines that came with your radio system, install

the radio, servos, and battery. A servo tray is

provided in this kit; however, it may be necessary to modify it to suit your equipment.

ELEVATOR PUSHROD INSTALLATION

2. Cut 3-1/2” off the end of the basswood

pushrod. Set this piece aside, as it will be

need for attaching the cowling and for elevating the rudder servo.

3. Using the TOP VIEW of the fuse plan as a tem-

plate, bend the two 13-5/8” threaded rods in

the correct configuration.

Glue the rods to the bass pushrod and wrap

with a strong thread. Coat the thread with

more glue.

4. Referring to the plan, cut the 10” threaded rod

to size. Attach to the other end of the bass

pushrod, wrapping with string and coating with

glue.

1. Gather the necessary parts.

(4) 6-32 x 3/4" SOCKET HEAD SCREW P T.#1022

(4) #6 M.S. WASHER PT.#1140

(1) .034 I.D. x 18" NYLON TUBE PT.#1657

(1) .030 x 34" CABLE PT.#1289

(2) P.R. CONNECTOR BODY PT.#1375

(2) 4-40 x 3/16" SOCKET HEAD SCREW PT.#1003

(1) NYLON SNAP-NUT (6/set) PT.#1461

(4) #6 x 3/4" SHT. METAL SCREW PT.#1082

2. Bolt the MOTOR MOUNTS to the firewall,

using four 6-32 x 3/4” SOCKET HEAD

SCREWS and #6 washers.

3. Referring to the plan for correct engine/cowl

position, screw the engine to the mounts with

four #6 x 3/4” SHEET METAL SCREWS.

4. Insert the NYLON GUIDE TUBE in the previ-

ously drilled hole in the firewall. Glue in place.

5. Install the CONNECTOR BODIES to the

engine throttle arm and the throttle servo arm.

Secure with the NYLON SNAP-NUT.

6. Thread the .030 x 34” CABLE through the

nylon tube and into the connector bodies.

With the servo at low motor position, and the

carburetor closed, lock both ends of the cable

with two 4-40 x 3/16” SOCKET HEAD

SCREWS.

7. Attach the fuel lines and install the muffler.

30

3-1/2"

PLAN

ELEVATOR SERVO

BEND WIRE PER PLAN

3/32" DRILL

CONNECTOR BODY

GUIDE TUBE

4-40 x 3/16" SOCKET

HEAD SCREW

Page 31

AILERON SERVO CONNECTION LANDING GEAR INSTALLATION

RUDDER CABLE INSTALLATION

1. Collect the following items:

(4) #2 x 5/16" SHT. METAL SCREWS PT.#1086

(2) .078 x 10" THREADED ROD PT.#1272

(2) SNAP LINKS PT.#1405

(2) LONG CONTROL HORNS PT.#1407

(2) SERVOS NOT INCLUDED

(2) 18" SERVO EXTENSIONS NOT INCLUDED

2. Install the aileron servos, if you have not

alreeady done so.

3. Lay the triangle along the hinge line and over

the last hole on the servo arm to locate the

control horn.

Attach the control horns by screwing two #2 x

3/8” screws into the plywood back-up inside

the ailerons.

4. With the ailerons and the servos in the neutral

position, connect the pushrods.

1. Collect the following items:

(1) FORMED ALUMINUM GEAR PT.# 1367

(2) THREADED AXLE PT.# 1369

(4) #6 x3/4” SHT. METAL SCREW PT. #1082

(4) #6 WASHER PT. #1140

(2) 3-1/2" WHEEL (NOT INCLUDED)

( 4) C.G.P 3/16" WHEEL COLLAR (NOT INCLUDED)

2. Mark the centerpoint of the landing gear cover

plate and the formed LANDING GEAR, making

sure they are aligned.

3. Using four #6 x 3/4” sheet metal screws, per-

manently mount the landing gear through the

cover plate into the 1/4” ply landing gear

mount.

4. Bolt the AXLES to the landing gear and install

the wheels.

NOTE

The SUKHOI uses a pull-pull system. Therefore, the

rudder servo must be located as shown on the plan to

ensure the correct cable alignment with the cable exits.

This feature was designed into the fixtured placement

of the servo tray supplied in this kit. If you decide not

to use the tray, make sure that you place the servo as

shown on the plan.

1. Collect the following items:

(1) D/C SHT. 6712 PLY PT. #3671

CONTAINS RADIO TRAY

(2) .030 x 34" CABLES PT.#1289

(4) THREADED COUPLERS PT.#1192

(2) LONG CONTROL HORNS PT.#1407

(2) 2-56 x 3/4" PAN HEAD SCREWS PT.#1042

(4) SNAP LINKS PT.#1405

(2) HOODED P.R. EXITS PT.#1453

(1) 3/8" SQ. x 2" BASS

CUT FROM PT.#3674

31

#2 x 5/16" SCREW

ALIGN WITH HOLE IN

SERVO ARM

"Z"BEND

.078 WIRE

#6 x 3/4" SCREW

Page 32

2. Solder a threaded coupler to one end of each

cable.

Lay the cable over the plan and cut to length.

Solder a threaded coupler to the cut end of

each cable.

3. Glue the hooded exits to the fuselage and

thread the cable assemblies from the rudder

servo opening to the control horns.

4. Install a CONTROL HORN on each side of the

rudder, directly opposite from one another.

Drill two 1/16” holes into one of the horn and

thread the two 2-56 screws into the horn.

5 Thread the SNAP LINKS onto the threaded

couplers and attach the links onto the rudder

control horns.

5. Cut the remaining 3/8 sq. piece of bass from

the elevtor pushrod into a 2” length. Then, cut

this piece into two equal pieces.

Glue the two small blocks to the servo tray to

raise the rudder servo, as shown on the plan.

Mount the servo (a ball-bearing servo is rec-

ommended) and, with the servo in the neutral

position, attach and adjust the cables until the

rudder is centered.

NOTE: Cables need only be tight enough to eliminate

slack.

32

RUDDER SERVO

SERVO TRAY

2-56 x 3/4"

SCREW

1/16" DRILL

SOLDER

1"

Page 33

33

Assembling The Engine Cowling & Belly Pan

Page 34

343536

Page 35

Page 36

Page 37

SETTING CONTROL SURFACE TRAVEL

Use the control surface travel gauges to correctly set

up the surface deflections. The gauges provide you

with two setting: a gentle response setting and a more

aerobatic setting. Even if you are an experienced pilot,

we encourage you to start out at the gentle setting and

then move to the aerobatic mode after you become

more familiar with the characteristics of this aircraft.

AILERON GAUGE

ELEVATOR GAUGE

RUDDER GAUGE

1. Place the gauge anywhere along the wing.

Align the center of the aileron to the mark in the

neutral position.

With the control stick full left and full right,

match the center of the aileron to the mark.

2. Adjust the horn bracket up or down along the

hole selection to achieve the correct travel setting.

NOTE: This is a good time to make sure the control

surfaces are responding correctly. You would

not want to correct a left bank with more left, so

check it now!

1. Place the elevator gauge anywhere along the

elevator hinge line.

2. Adjust the servo arm hole along with the con-

trol horn hole to achieve the desired setting.

Check each elevator.

1. Position the rudder gauge at the top of the fin at

the hinge line. Follow the same procedure

used for the elevator to achieve the desired

travel.

37

HIGH THROW

LOW THROW

HIGH THROW

LOW THROW

HIGH THROW

LOW THROW

UP ELEVATOR

NOTCH POINTS UP

NOTCH POINTS

DOWN

3/16"

3/8"

1/4"

LEFT AND RIGHT RUDDER

DOWN ELEVATOR

Page 38

FLYING THE SUKHOI

The CARL GOLDBERG PRODUCTS SU-26 probably

flies more like its full-size cousin than any other kit on

the market. We have designed it deliberately to make

unlimited aerobatics practical for the average pilot. In

fact, if you are comfortable with a low-wing sport aircraft, you should have no difficulty in being successful

with the GOLDBERG SUKHOI. Take great care in

building and setting up your aircraft and the SU-26 will

reward you with many hours of exciting aerobatics.

THROWS

We have provided two sets of throws. It is highly recommended that you start with the lower throws and,

after a few flights, work your way up to the higher settings, if you desire. If you are using a computerized

radio, always use the highest percentage possible and

then mechanically adjust for the proper throw. Also,

because of the high deflection and generous area of

the control surfaces, it is recommended that you use

exponential to soften the feel around neutral. At the

lower control settings, little, if any, expo is needed. Try

15-20% at first and, for the higher settings, try about

40% for all controls. These settings are only suggestions and may be modified "to taste."

ENGINES

This SUKHOI was designed around the .90 two-stroke

and the 1.20 four-stroke engines, which will yield

excellent performance. . The secret is to not build too

heavy. Remember, a bigger engine is not better, as it

adds weight, vibration, etc. Therefore, DO NOT use a

larger-than-recommended engine, which could result

in structural failure of the aircraft. As for props, we

have found that a 15-8 to 16-8 propeller and a properly sized spinner seem to work well on these engines.

FIRST FLIGHT

Double and triple check that all is in order...extra time

here is always well spent! When satisfied with controls, engine response, etc., you're ready.

When taxiing, we recommend you always maintain full

up elevator, especially when flying off grass. Point the

nose into the wind and gradually apply full power. As

the SUKHOI accelerates, reduce the elevator setting

so that, when the aircraft is ready to fly, you will have

just enough up elevator to rotate and climb out at a

shallow angle. Also, during the application of power,

due to engine torque, the SUKHOI will veer to the left,

so be prepared to hold some right rudder. In all probability, no more than 10-20% rudder input will be needed, and this should be maintained during the initial

climb-out. This take-off technique is not only best for

the SUKHOI, but is the proper way to take off any aircraft, particularly a tail-dragger.

Once in the air, the SUKHOI should have a fairly balanced feel. Rolls will be relatively quick, but very pre-

dictable, and pitch is very positive, but not too sensitive.

Inverted flight takes a small amount of down elevator to

sustain. The rudder is large and powerful, which makes

"stall turns" a breeze and "knife edge flight" a pleasure.

On our prototypes, we did not require any mixing to

compensate roll. The nose did pitch up ever so slightly, but we did not feel it necessary to "dial" it out with the

radio. Snap rolls are very quick and stop instantly. A

note on snaps: you don't need high rate rudder and

elevator to get the SUKHOI to snap properly. If you do

that, the aircraft simply goes deeper in the stall and

decelerates rapidly. Normally, this is not a problem, but

if you try to snap roll on a vertical up-line, it can almost

stop the aircraft. If you snap with low rate, the SUKHOI

will continue to climb cleanly.

Lomcevaks are an absolute delight with the SUKHOI. It

seems to do all variations well, including one in particular. From level flight and full power, pull up about 60º,

roll right 90º, then snap inside left and, after about one

full rotation, apply full down and opposite aileron...then

hang on! Almost always, you can execute two full tumbles...and sometimes more.

Landing the SUKHOI offers no real difficulties.

Because of the low wing loading, it can land very slowly, but be aware of the long landing gear and try to get

most of the "fly" out before you touch down. If you happen to touch down with too much airspeed, be prepared

to release some of the up elevator to prevent the aircraft from bouncing back into the air.

REMINDER

As good as this SUKHOI is, all aircraft have limitations and this one is no exception. Using care and

common sense will help ensure the survivability of

your aircraft. And, of course, always think and fly

safely.

38

Page 39

COLOR SCHEME

DECAL PLACEMENT AT BUILDER'S DISCRETION

PAINTED CANOPY FRAME

BLACK

WHITE

BRIGHT RED

BLACK

WHITE

BRIGHT RED

The following colors were used on the "show

model" photographed for the kit box. Lighting and

printing may alter the appearance of these colors

on the box.

Bright Red

White

Black

39

Loading...

Loading...