Page 1

Wingspan: 68”

Length: 61”

Weight: 7.5-8.5 lbs.

Engine Size: 2-cycle .60 -.90

4-cycle .90 -1.20

KIT K-55

INSTRUCTIONS

If there’s an aerobatic subject that can challenge the thrill of the Goldberg Ultimate, it’s this Extra 300! The Extra’s generous

moments, light wing loading and strong airframe make it an excellent airplane for the aerobatic pilot, whether he is learning

his first maneuvers or is an unlimited class competition flyer.Yet with all it’s aerobatic potential, this is still a very well-behaved

aircraft, making takeoffs and landings a breeze.And when it comes to engines

, please note: bigger is not better. A good .60

will do an excellent job. A larger than recommended engine may overly stress your model, causing structural failure.

WARNING

A radio-controlled model is not a toy. It is capable of causing serious bodily injury and property damage. It is the buyer’s

responsibility to build this kit correctly and to properly install the motor, radio, and all other equipment.The first test flights

should be made only with the assistance of an experienced R/C flyer. The model must always be operated and flown in

accordance with the safety standards of the Academy of Model Aeronautics.

Per the Federal Communications Commission, you are required to use only those radio frequencies specified “for Model

Aircraft.”

Pt. #2060 - 8/97

The Extra 300

© Copyright 1991

Page 2

2

ITEMS NEEDED TO COMPLETE THIS KIT

1 RADIO GUIDANCE SYSTEM (4 CHANNEL

MINIMUM REQUIRED)

1 ENGINE 2-CYCLE .60-90

4-CYCLE .90-1.20

PROPELLER (TO MATCH ENGINE SIZE)

1 3” DIAMETER SPINNER (LARGE ENOUGH

FOR PROP TO FIT WITHOUT MODIFICATION)

1 FUEL TANK TO MATCH ENGINE (12 OZ.

SHOWN ON PLAN)

1 24” SILICONE FUEL LINE

2 3” DIAMETER WHEELS

1 1-1/4” DIAMETER TAILWHEEL

1 2 OZ. BOTTLE MEDIUM CYANOACRYLATE

GLUE

1 CYANOACRYLATE ACCELERATOR

1 20-MINUTE EPOXY

1 LIGHTWEIGHT BALSA FILLER

1 1/2 x 8 x 12” FOAM PADDING

3 ROLLS OF COVERING

FUEL-PROOF PAINT FOR COWL AND

WHEELPANTS

OPTIONAL ITEMS

SCALE PILOT

PITTS STYLE MUFFLER

SMOKE SYSTEM

COMMERCIAL INCIDENCE GAUGE

NECESSARY TOOLS AND SUPPLIES

MISCELLANEOUS RUBBER BANDS

WAXED PAPER

MODELING KNIFE AND RAZOR BLADES

SANDPAPER (ASSORTED GRITS, INCLUDING

COARSE (80), MEDIUM (150) AND FINE (220-

320)

SANDING BLOCK

“T” PINS (at least 75)

BUILDING BOARD (24”x60”)

ELECTRIC DRILL

1/16” DRILL BIT

3/32” DRILL BIT

5/16” DRILL BIT

3/8” DRILL BIT

ALLEN WRENCH SET

SMALL SCREWDRIVER

MASKING TAPE

LONG NOSE PLIERS

COVERING IRON AND HEAT GUN

RAZOR SAW

SPRAY BOTTLE

SMALL SOLDERING IRON & SOLDER

10” 30°-60°-90° DRAFTING TRIANGLE

Page 3

3

USING THIS INSTRUCTION MANUAL

Before you start gluing and sanding, take some time

becoming familiar with the plans and looking through this entire

Instruction Booklet. It is designed to guide you through the

construction process step by step, so build in the order given in

this book. Balancing, setting up and flying the model are also

covered.

Like a full-size airplane, the Extra 300 is built from basic

structures (stabilizer, fin, wing, etc.), which are then assembled

into the complete airplane.

Special procedures or comments will usually be explained

before a step, so you will be prepared. If a step begins with a

statement like “Note,”‘Warning,”or “Important,” it is a good idea

to read through the step before doing it.

A check-off box appears at the beginning of each step .Check

these boxes as y ou b uild, so you can tell at a glance what steps

you have completed. Some steps are repeated and must be

marked twice, as in the case of the left and right wing panel.

Some of the instructions deal with general procedures.Boxes

are not needed for these sections.

HOW T O READ THE PLAN

There are two plan sheets in this kit, showing the Fuselage

(Body), the Wing, and the Tail Par ts. Everything on the plan is

drawn to full-size and shape and shows how the finished parts

fit together.

The plan is drawn to show the model completely assembled,

but as a result, the areas inside or underneath are covered up,

making it hard to understand how these parts fit together.

Therefore, for clarity, some par ts are drawn with hidden lines,

others with breakaway views, and some are entirely removed

from the structure and shown separately.

For example, on the fuselage, the left side of the completed

model has been removed to show the details inside.Sometimes

a surface is broken away to reveal the detail behind or

underneath.Dashed lines indicate details that are hidden behind

or under another part of the surface.

The model is made from four varieties of wood:balsa, bass,

birch, and various plywoods. Each kind of wood has its own

characteristic

end grain pattern

(as viewed from the end) which

has been drawn on the plan.Y ou can easily use these end grain

patterns to identify what kind of wood is shown for a part, if you

are in doubt.

HOW T O USE THE PLAN

The plan is used in several ways. The wings, stabilizer, and

fin are assembled directly over the plan. Each wood part is

matched over its corresponding location printed on the plan and

pinned in place. To prevent ruining your plan from gluing your

wings, etc. to it, cover the area you are working on with waxed

paper.

The paper the plan. is printed on can expand or contract

slightly with changes in temperature or humidity .Because of this,

a preformed part such as the notched wing trailing edge may not

exactly match the plan.This is no problem, as slight deviations

in the outline or size will not noticeably affect flight perf ormance.

Because the fuselage plugs together and is self-aligning, it is

not built directly over the plan. As you assemble the fuselage,

you will find the plan helpful in identifying parts and how things

fit together.

The plan also shows the installation of a typical radio, battery

and all remaining equipment and hardware needed to complete

the model. By referring to the examples shown, you should be

able to install your own radio, etc., even if it is not the same as

what is shown on the plan.

IDENTIFYING PARTS

Parts for the wing are bundled together;likewise, parts for the

tail assembly are also grouped. Die-cut plywood and balsa

sheets of common sizes are bundled together, so they are less

likely to be damaged during shipping and handling.

The various screws, hinges, and fittings are packaged in

plastic bags.

PREPARING FOR ASSEMBLY

Set a flat, warp-free pinning board on your work bench. Any

material that accepts pins, such as insulation board, soft

plywood, or dry-wall (sheet rock) will work.

Important:

any

warps or bends in the pinning board will result in wings or

tail surfaces that are also warped or bent, making your

model more difficult to fly.

Make sure that the pinning board

is flat by laying a straight edge across it. You may be able to

correct a warped board by shimming its low areas.

Position the area of the plan (such as the stabilizer) on which

you are going to build ov er the pinning board and tape it in place

so the plan lays flat and wrinkle free.

Place a sheet of waxed paper or plastic kitchen wrap ov er the

work area to prevent the C/A glue from sticking to y our plan and

ruining it.

CONSTRUCTION TIPS

In assembling your model, the follo wing tips will prove helpful.

IMPORTANT: ALWAYS READ A FEW STEPS AHEAD.This

will alert you to coming instructions and will help you plan

accordingly.

You may find it convenient to empty all of the small parts from

the hardware bags into a common container, such as a

margarine tub.This will help you find items quickly.

When drilling any 1/16” holes in balsa, you may find it easier

to twist the drill between your thumb and index finger. This

procedure allows more control in positioning the drill on the

center mark.

Punch out only the die-cut (D/C) parts you need as you

proceed. This will help you keep track of parts, especially the

small ones.

After completing each section of the aircraft, you may w ant to

go back and reglue the joints, just in case some area has been

missed. Be careful not to use too little glue, which will leave the

model weak or too much glue, which can make the model hea vy .

Properly glued joints are important to the overall strength of the

model. Medium C/A glue is recommended for most parts of the

assembly, although Jet Epoxy may be used when more time is

needed for careful placement.

INTRODUCTION

Page 4

4

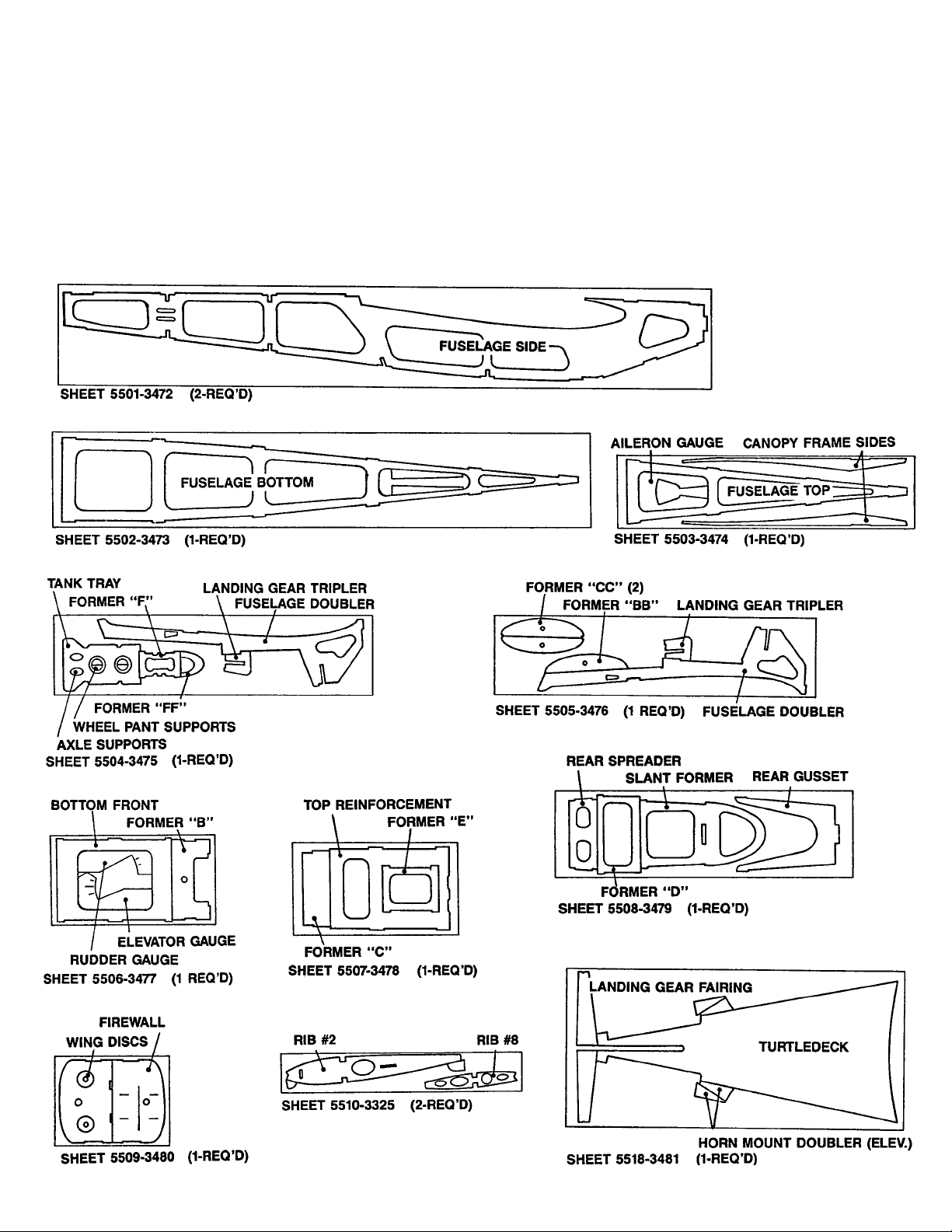

PARTS IDENTIFICATION

WOOD PARTS

Be careful Men removing parts (such as fuselage sides) from the

die-cut sheets.Long parts are fragile until glued into a structural

unit. If necessary, use a razor knife or razor saw to assist in the

removal of parts from the sheet.Sometimes a little trimming and

sanding can improve parts, Mere desired. Save scrap until the

model is completed, in case a part is missing or damaged. Also,

scrap is used in some building steps.

ABOUT THE WOOD IN THE KIT

We strive to supply good quality materials in your kit.Wood parts

are inspected with regard to the function they will serve. If an

imperfection is spotted in a scrap corner of a die-cut sheet and

doesn’t affect actual parts, the sheet is considered acceptable.

Also, internal stresses in wood are reliev ed as it is cut into parts.

These relieved stresses ma y cause some parts to bow. Bows in

wood parts (such as leading edges) readily straighten out as they

are glued into a structural unit

Page 5

5

Page 6

6

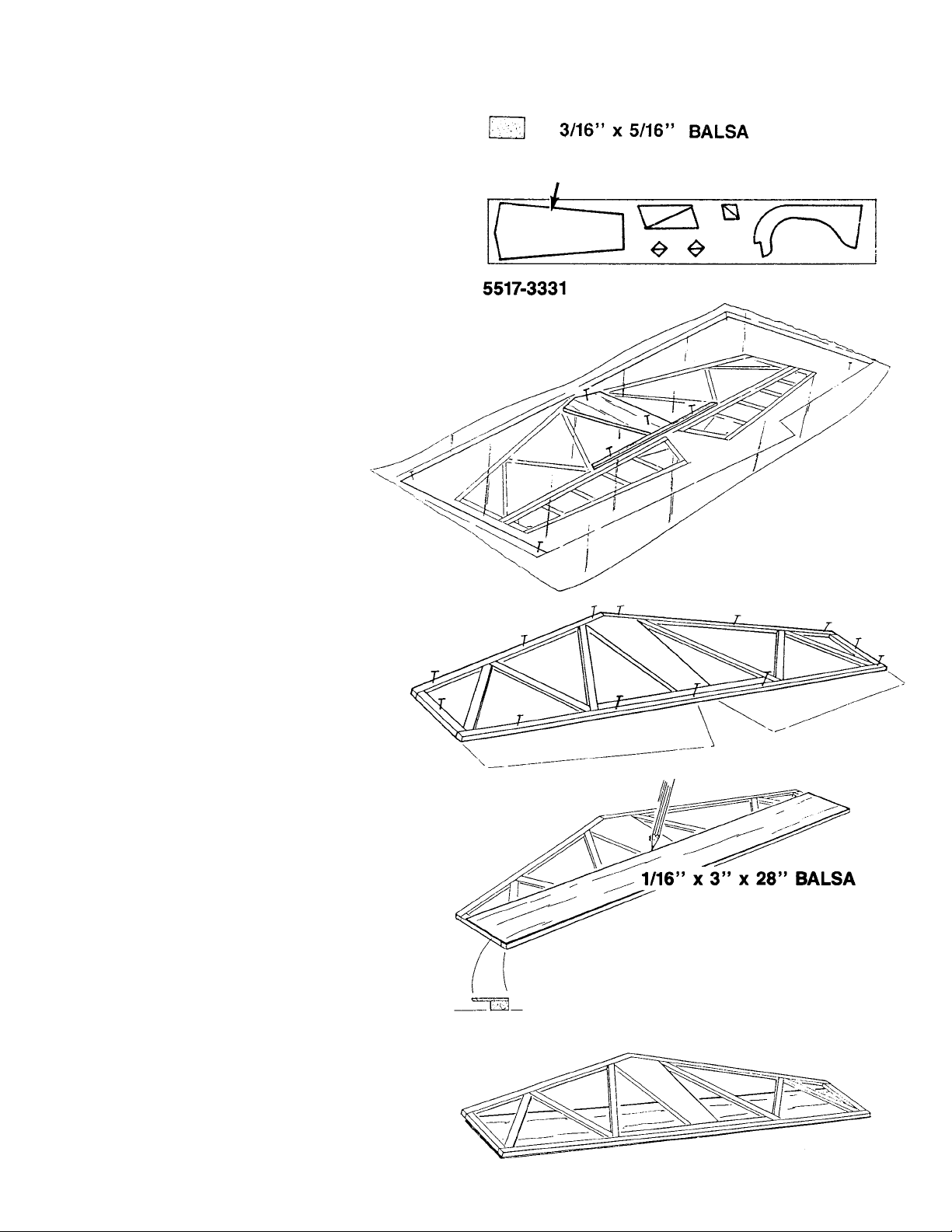

HORIZONTAL STABILIZER CONSTRUCTION (5 Steps)

1. Collect all of the items you will need to construct the

HORIZONTAL STABILIZER. They include:

(1) D/C SHEET 5517 3/16” BALSA PT. # 1331

Includes:

CENTER PLATFORM

(5) 3/16 x 5/16 X 28” BALSA STICKS PT. #4371

(4) 1/16 x 3 x 30” BALSA SHEETING PT.#4539

2. ■■ Lay the horizontal stabilizer portion of the plan over the

building board and place the waxed paper over the

plan.You will also need “T” pins, an X-Acto

®

knife with

a #11 blade, and a razor saw.

■■ Pin the CENTER PLATFORM over the plan.

■■ Cut a 3/16 x 5/16”balsa stic k and glue it to the platform

with medium CA, pinning it over the plan.

3. ■■ Trim the remaining 3/16 x 5/16” balsa sticks to fit the

plan, pinning and gluing as you go. In cutting the

diagonal trusses for the tail, trim them to fit well.If a bit

oversize, don’t force them in place. The pieces should

fit before gluing

4. ■■ Place a 1/16 x 3 x 28” balsa sheet flush to the trailing

edge (T.E.) of the stabilizer and mark the sheet width

onto the stab sticks.

HINT: In selecting the sheeting for the stab , choose the firmer

or heavier wood. whenever sheeting any surface, is

helpful to lightly sand both sides of the sheet before

using medium C/A. Also, whenever joining sheeting,

“truing”the edges to be glued with a long sanding b lock

and prefitting can make a big difference.

■■ Remove the sheet and apply medium C/A to the stab

sticks up to the sheet-width mark

■■ Place the glued stab frame over the 1/16” sheeting,

making sure that the trailing edge is flush with the

sheet.

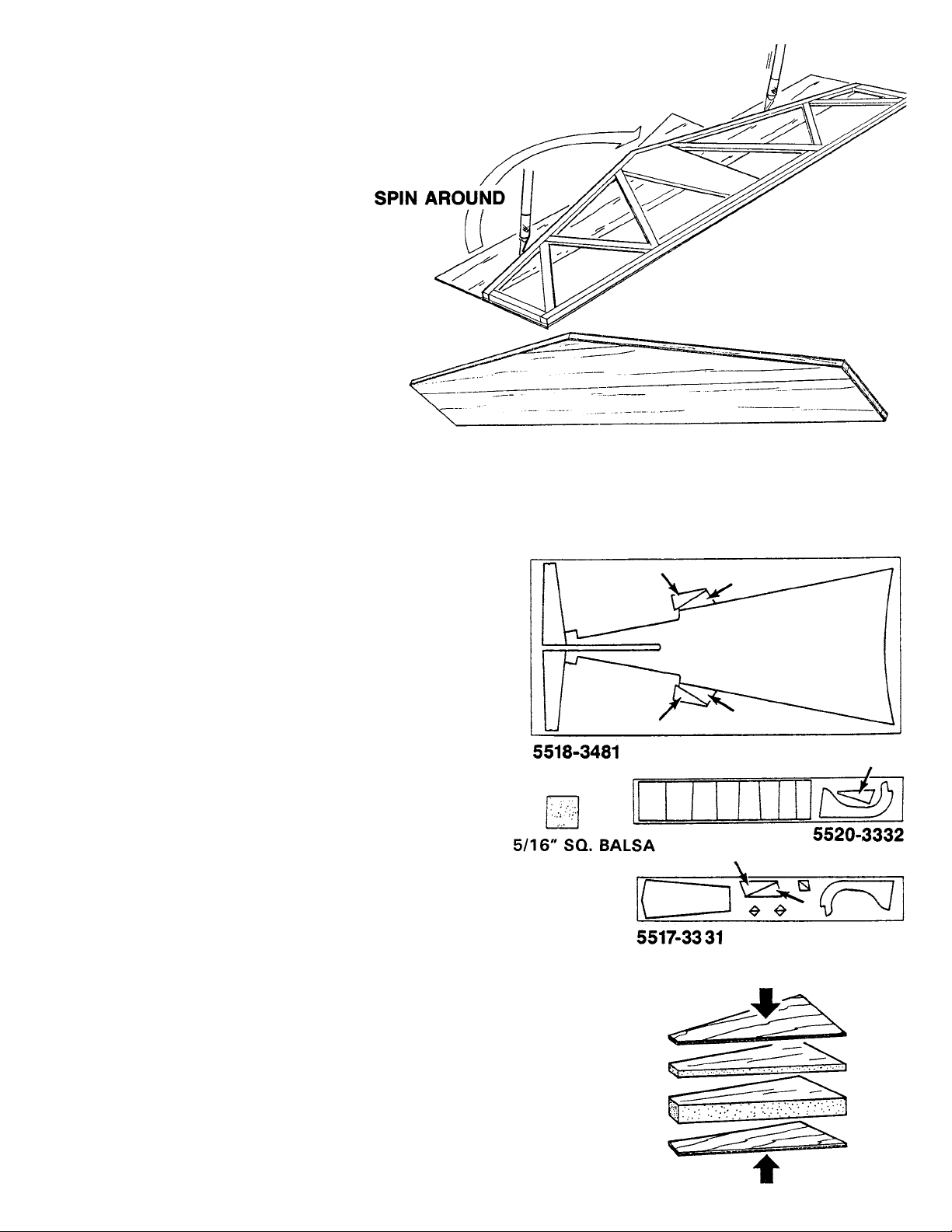

Page 7

7

5. ■■ Glue the remainder of the stab frame and install

another 1/16” balsa sheet. Then, tr im the sheeting to

the profile of the stab.

■■ Spin the cut-off around and glue to the remaining space

on the frame.

■■ Flip the stab over and sheet it as shown above.

ELEVATOR CONSTRUCTION (4 Steps)

1. ■■ Collect all of the parts needed to build the two

ELEVATOR HALVES.They include:

(5) 5/16” sq.x 16”BALSA STICKS PT. #4370

(1) BIRCH PLY D/C SHT. 5518 CONTAINING:

(4) HORN MOUNTS PT. #3481

(1) D/C BALSA SHT. 5520 CONTAINING:

(2) HORN MOUNT CORES PT. #3332

(2) D/C SHT. 5517 (BALSA) CONTAINING:

(1) BALSA CORNER GUSSETS PT. #3331

(1) BALSA HORN MOUNT CORES PT. #3331

2. ■■ Laminate the two 1/32”PL YWOOD HORN MOUNTS to

the 3/16” and 1/16” BALSA CORES.

■■ Make two such assemblies, one for each elevator half.

THIS COMPLETES THE HORIZONTAL STABILIZER. PUT IT

ASIDE FOR NOW;YOU WILL NOT NEED IT UNTIL YOU ARE

READ Y T O INST ALL THE HINGES.

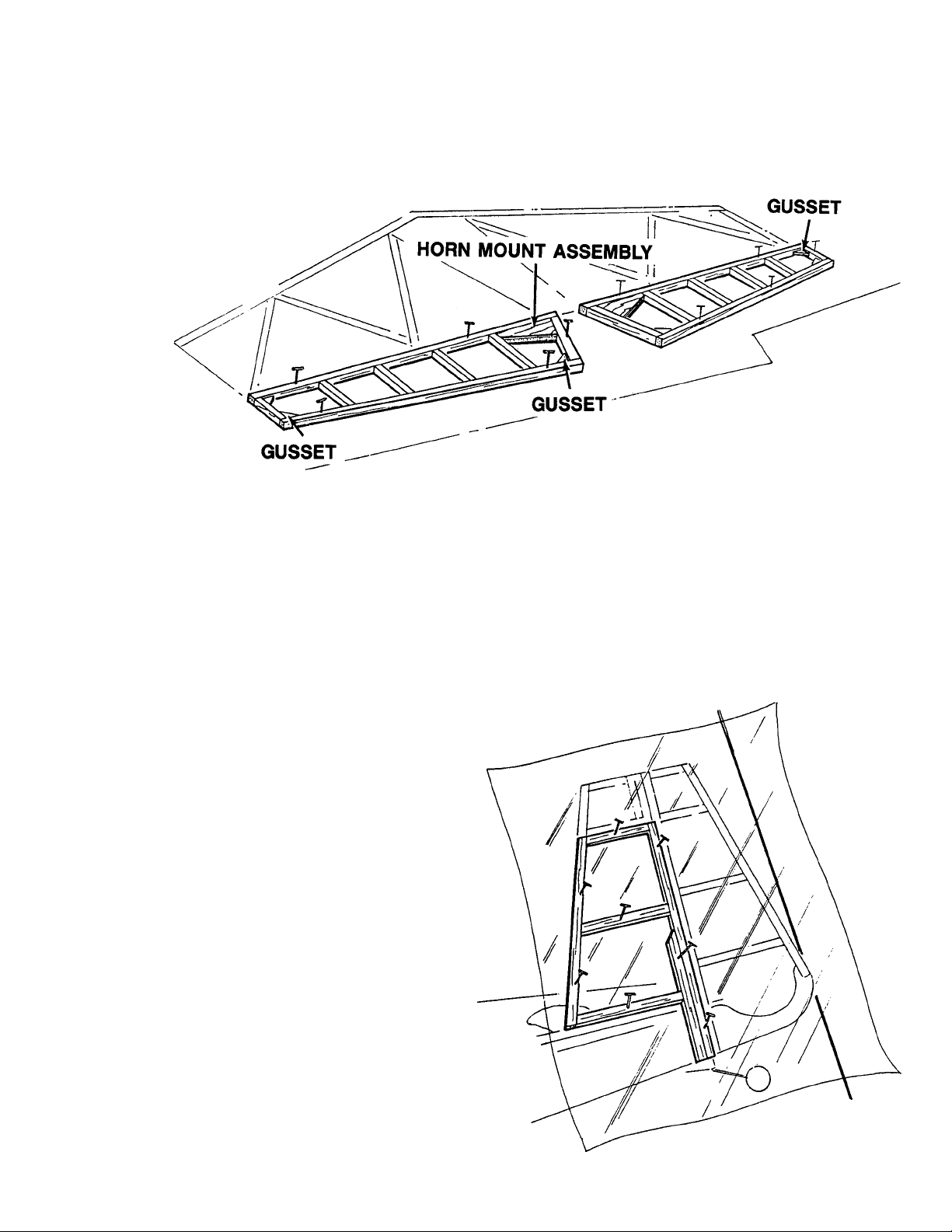

Page 8

8

3. ■■ Place waxed paper over the elevator section of the

plan.

■■ Trim and glue the 5/16” square balsa sticks over the

plan, pinning as you go.

4. ■■ Glue the HORN MOUNT ASSEMBLIES and the

CORNER GUSSETS into the frame.

1. ■■ Collect the items needed to construct the VERTICAL

FIN.They include:

(3) 3/16 x 5/16 x16” BALSA STICKS PT. #4369

(2) 1/16 x 3 x 18” BALSA SHEETS PT. #4538

2. ■■ Cover the fin portion of the plan with waxed paper.

■■ T rim the 3/16 x 5/16”balsa sticks and pin over the plan,

gluing as you go.

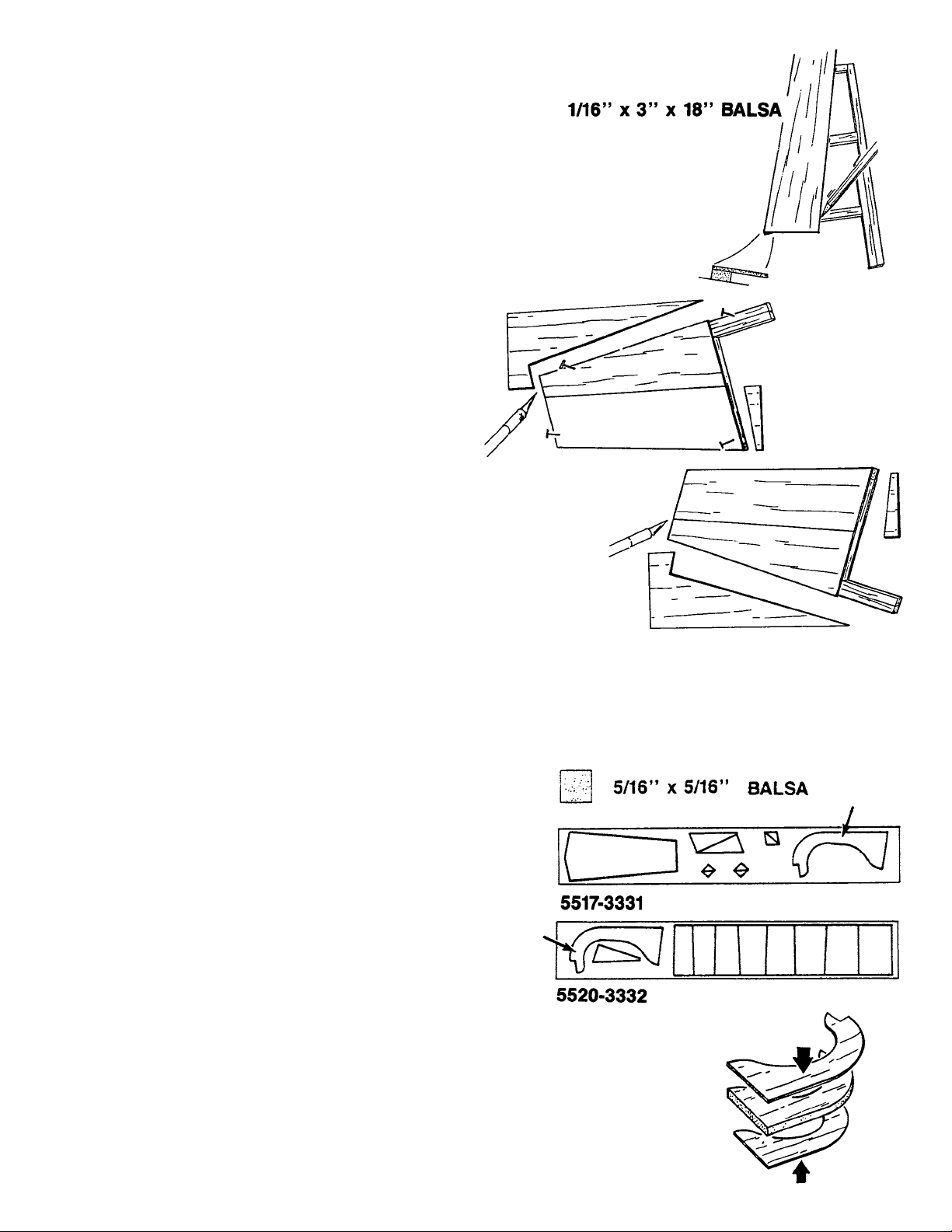

VERTICAL FIN CONSTRUCTION (4 Steps)

Page 9

9

3. ■■ Place the 1/16” balsa sheeting flush with the Leading

Edge (L.E.) and mark the width of the sheet onto the

frame.

■■ Apply Jet to the frame, up to the width marks, and

permanently install the sheeting. Pin down to insure a

flat assembly.

■■ Trim the sheeting and use the drop-off to cover the

remaining area of the fin side, trimming to the profile of

the fin as you go.

4. ■■ Flip the fin over and repeat the sheeting operation, as

illustrated.

THIS COMPLETES THE VERTICAL FIN CONSTRUCTION.

PUT IT ASIDE UNTIL YOU ARE READY TO INSTALL THE

HINGES.

1. ■■ Collect all of the parts you will need to construct the

RUDDER.They include:

(3) 5/16” sq. x 16”BALSA STICKS PT. #4370

(1) D/C BALSA SHT. 5517 PT. #3331

CONTAINING:

(1) 3/16” HORN MOUNT

(2) D/C BALSA SHT. 5520 PT. #3332

CONTAINING:

(1) 1/16” HORN MOUNT

2. ■■ Laminate the three horn mounts as shown, making

sure that the 3/16” horn mount is in the middle.

RUDDER CONSTRUCTION (4 Steps)

Page 10

10

3. ■■ Cover the RUDDER por tion of your plan with waxed

paper and pin the laminated horn mount assembly over

the plan.

4. ■■ Trim, glue, and pin the 5/16” square balsa sticks over

the plan as shown.

NOW GATHER THE HORIZONTAL STABILIZER, THE

ELEVATOR HALVES, THE FIN AND THE RUDDER AND

PROCEED TO THE NEXT SECTION, “ROUNDING AND

HINGING.”

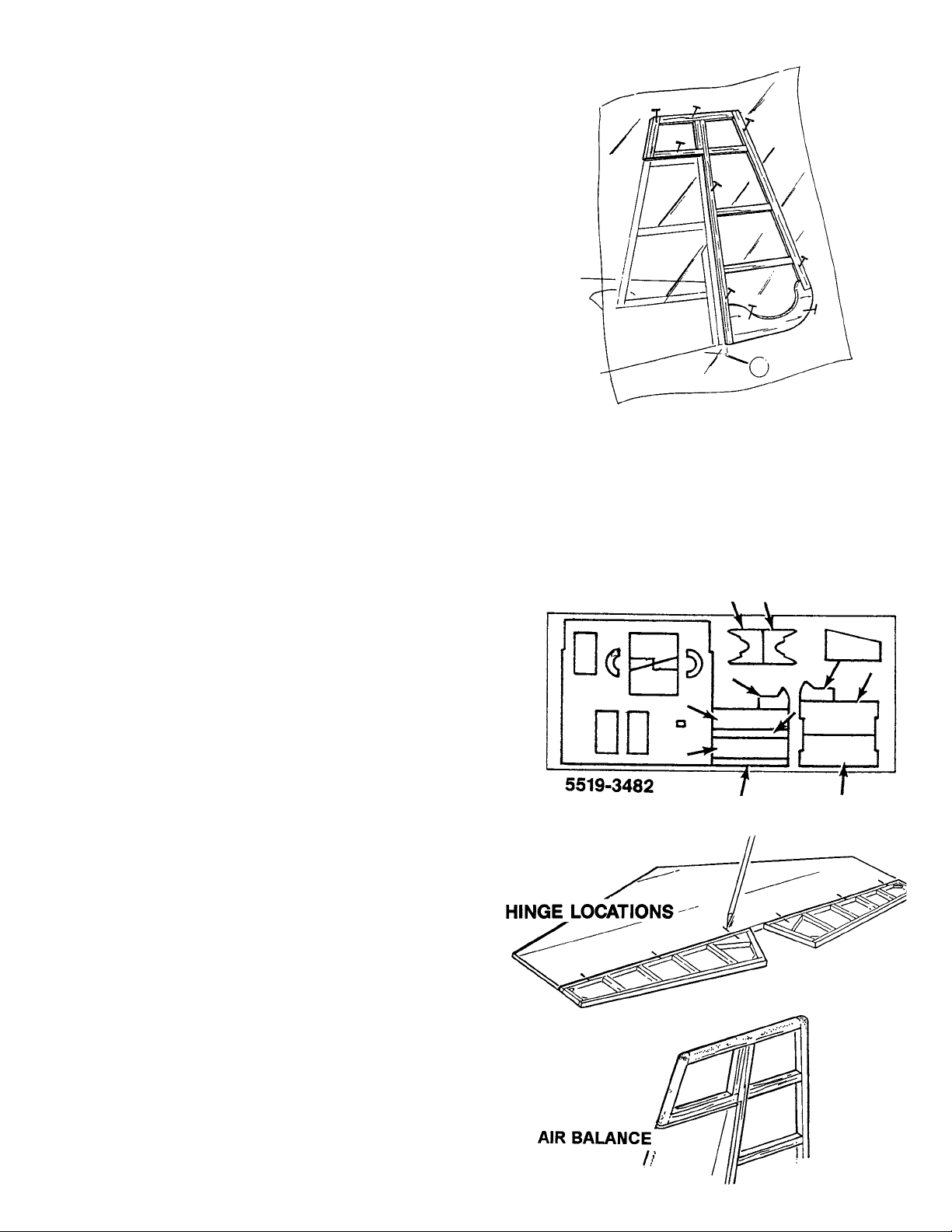

ROUNDING & HINGING (11 Steps)

1. ■■ Collect all of the items needed to complete this section.

In addition to the following kits parts, you wiII need a

small drill, drill bits, a modeling knife, a sharp pencil, a

sanding block, and fine and medium grit sandpaper.

(9) JET HINGES PT. #1667

(1) D/C PLY SHT. #5519 PT. #3482

CONTAINING:

(1) ROUNDING TOOL

(1) “R”BEVEL TOOL

(1) “AE”BEVEL TOOL

(1) CG NYLON CENTERLINE MARKER PT. #1425

2. ■■ From the plan, transfer the hinge locations onto the

rudder and the elevator halves.

■■ Next, transfer the hinge locations from the rudder to the

fin, and from the elevators to the stab.

NOTE: Leave a 1/16” gap between the air balance on both the

rudder and the fin.

Page 11

11

3. ■■ Using the centerline tool, scribe the centerline onto the

rudder post, the fin post, the hinge line of the stabilizer,

and onto both elevators

4. ■■

Carefuly cut a slot approximately 1/2” deep and slightly

wider than the hinge, using your favorite knife blade.

5. ■■

After all slots have been made, mark the center of your

hinge and insert a pin (see illus.) This will hold the

hinge in place while sliding the matching part (aileron,

etc.) onto the JET HINGE.

DO NOT GLUE!

■■

With both surfaces hinged and assembled, check the

alignment. For good control response, the hinge gap

should be as small as possible, but should

allow for full deflection when needed.

Remove the hinges.

6. ■■ Assemble the two bevel tools and install a str ip of

medium grit sandpaper, as shown.

7. ■■ Using the tool marked “R,” bev el the rudder-side of the

hingeline to a point at the centerline.You may want to

bevel near the air balance with a knif e , if you can’t use

the tool in the corner.

■■ Using the tool marked “AE,” bevel the elevators to a

point at the centerline.

8. ■■ T emporarily hinge the rudder/fin and the stab/elev ators

to check the surface alignment and to round the

perimeter of the assemblies.

Page 12

12

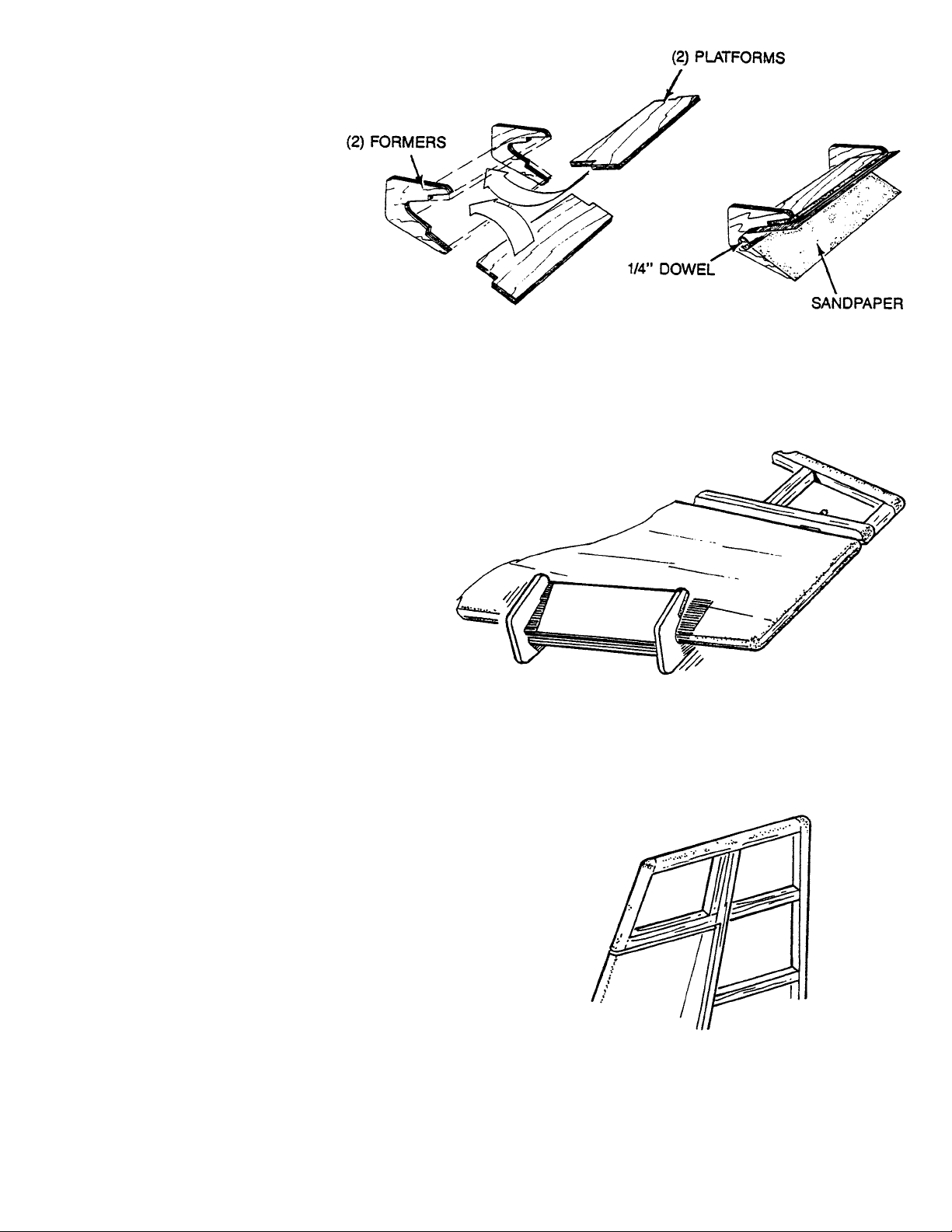

9. ■■ Assemble the Rounding Tool and install a piece of

medium sandpaper.

10. ■■ Using the tool, round the perimeter of the fin/rudder and

the stab/elevators.

■■ When you are satisfied with the shape, use a piece of

fine sandpaper to remove the deep scratches.

11. ■■ Finish sand all of the tail par ts, using a sanding block

and fine sandpaper.

HINT: Sanding will cause gaps at the joints to fill with balsa

dust. Use this to your advantage by putting a drop of

thin C/A glue into the gap. Then sand after the glue

dries.

■■ Separate the fin from the rudder and the elevators from

the stabilizer.

THIS COMPLETES THE CONSTRUCTION OF THE TAIL

SECTION PARTS.PUT THEM ASIDE UNTIL YOU ARE READ Y

TO A TTACH THEM T O THE FUSELAGE.

Page 13

13

THE INSTRUCTIONS WILL LEAD YOU THROUGH THE

ASSEMBLY SEQUENCE, OCCASIONALLY SENDING YOU

BACK TO REPEAT STEPS. CAREFULLY READ EACH STEP

BEFORE YOU PROCEED TO DO THE INSTRUCTION.

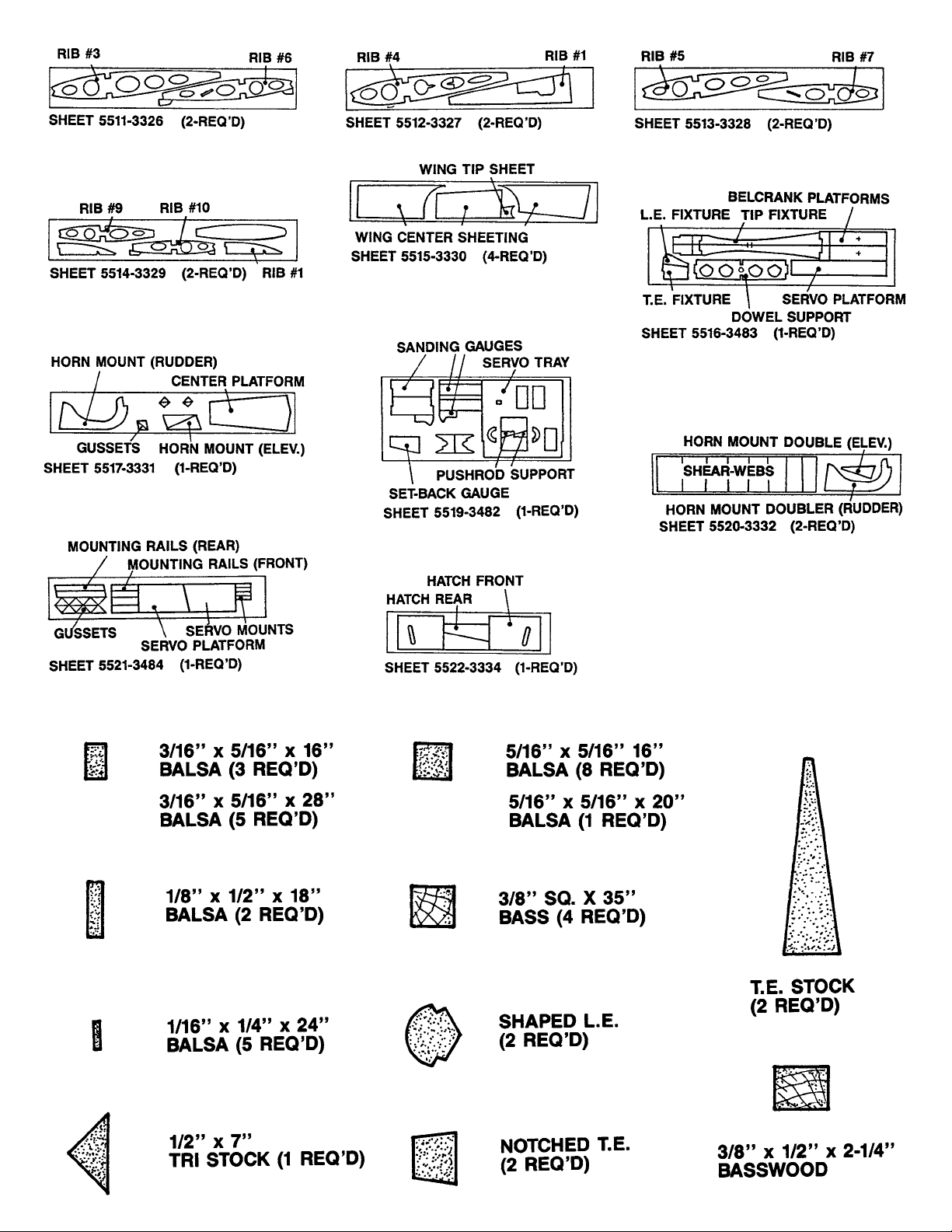

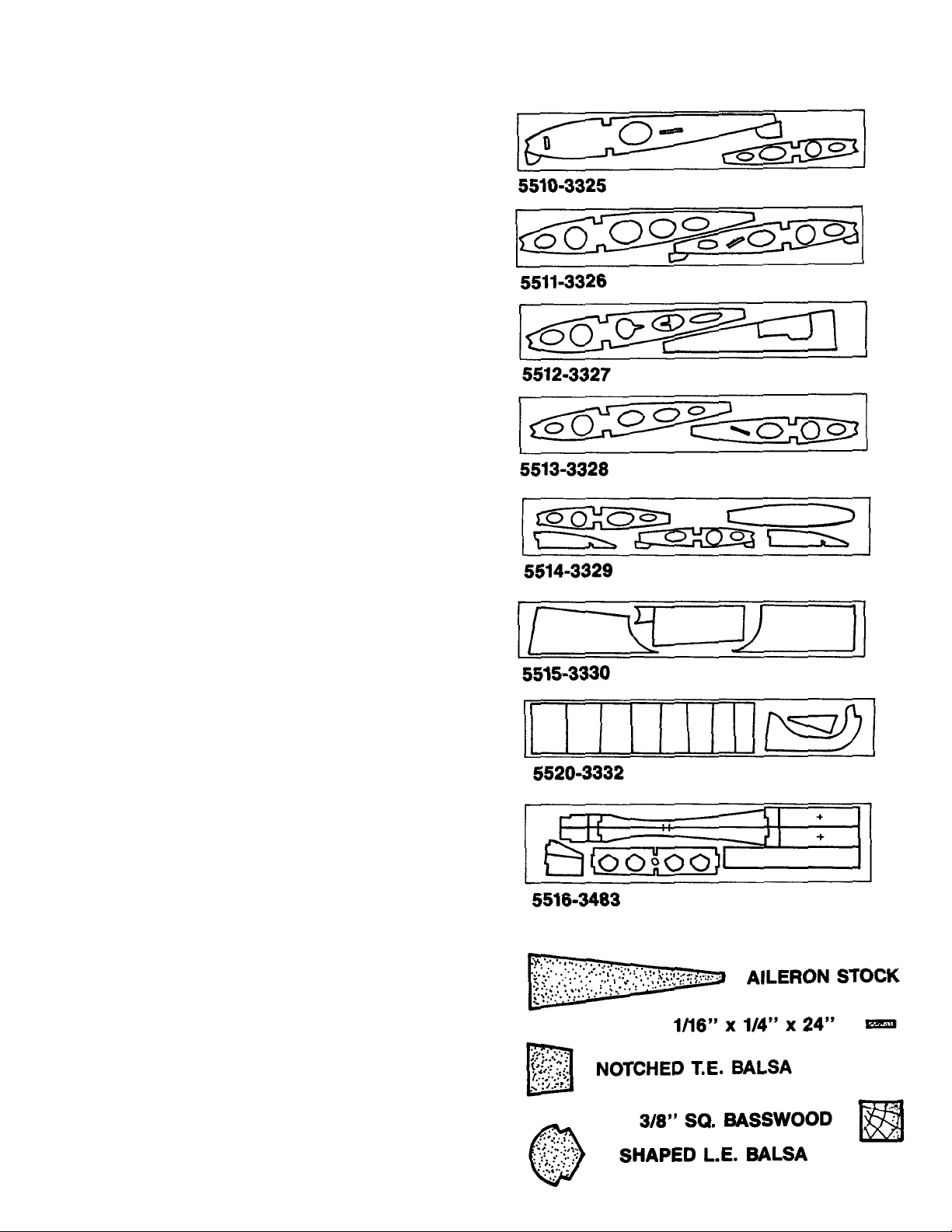

1. Find all the parts that you will need to build the wing.

THEY INCLUDE:

(4) 3/8" SQ. X 35" SPAR BASS (MIL #4528)

(2) SHAPED L.E BALSA (MIL #4524)

(2) NOTCHED T.E BALSA (MIL #4523)

(2) WING RIBS 2 & 8 BALSA (D.C. 5310-3325)

(2) WING RIBS 3 & 6 BALSA (D.C. 5511-3326)

(2) WING RIBS 4 & 1 BALSA (D.C. 5512-3327)

(2) WING RIBS 5 & 7 BALSA (D.C. 5513-3328)

(2) WING RIBS 1, 9 & 10 BALSA (D.C. 5514-3329)

(4) WING CENTER SHEETING BALSA

(D.C. 5515-3330)

(2) SHEAR-WEBS BALSA (D.C.5520-3332)

(2) WING JOINER PLY

(2) BELCRANK PLATFORMS PLY

(D.C. 5516-3483)

(2) DOWEL SUPPORT PLY (D.C. 5516-3483)

(1) WING SUPPORT FRT PLY (D.C. 5516-3483)

(1) WING SUPPORT REAR PLY (D.C. 5516-3483)

(1) WING SUPPORT TIP PLY (D.C. 5516-3483)

(1) SERVO PLATFORM PLY (D.C. 5516-3483)

(1) DOWEL GUIDE PLY (D.C. 5509-3480)

(2) INBOARD T.E. BALSA (MIL #4526)

(5) 1/16" x 1/4" x 24" CAPS BALSA (STK #4525)

(2) AILERONS BALSA (MIL #4527)

(6) 1/16" x 2-3/4" x 35" BALSA (SHT #4888)

(4) 1/16" x 2-1/2" x 35" BALSA (SHT#4887)

(1) 3/4" x 33" NYLON FABRIC (NYL #5210)

(1) 5/16" x 4-3/4" DOWEL BIRCH (MIL #1759)

(2) .063" x 20-3/4" AILERON WIRE (MTL #1230)

(2) .063" x 7" THREADED ROD (MTL #1270)

(2) AILERON BELCRANKS (NYL #1410)

(2) AILERON BUSHINGS (MTL #1182)

(2) 2-56 NUT (MTL #1115)

(2) 2-56 x 1/2" MACHINE SCREW (MTL #1041)

(2) #2 WASHER (NYL#1461)

(4) NYLON SNAP-NUT (NYL #1138)

(3) 1/16" I.D.x 1" BRASS TUBE (BRS #1376)

(1) AILERON COUPLER BLOCK (NYL #1427)

(1) 2-56 x 3/4" MACHINE SCREW (MTL #1042)

(1) 2-56 x 1/8" MACHINE SCREW (MIL #1040)

(1) SNAP LINK (NYL #1405)

(8) FLEX POINT HINGES (NYL #1449)

(1) C.G.CENTERLINE TOOL (NYL #1425)

CONSTRUCTING THE WING (35 Steps)

Page 14

14

NOTE:IF USING AN ENGINE LARGER THAN A.60 2-CYCLE,

YOU WILL WANT TO FOLLOW THE INSTRUCTIONS FOR THE

TWO SERVO OPTION, WHICH ARE FOUND IMMEDIATELY

AFTER THE WING SECTION.

NOTE:Y OU WILL BE BUILDING TWO WING HAL VES.DO NOT

BUILD BOTH HALVES OVER THE SAME SECTION OF THE

PLAN. FOLLOW STEPS CAREFULLY TO AVOID

CONFUSION

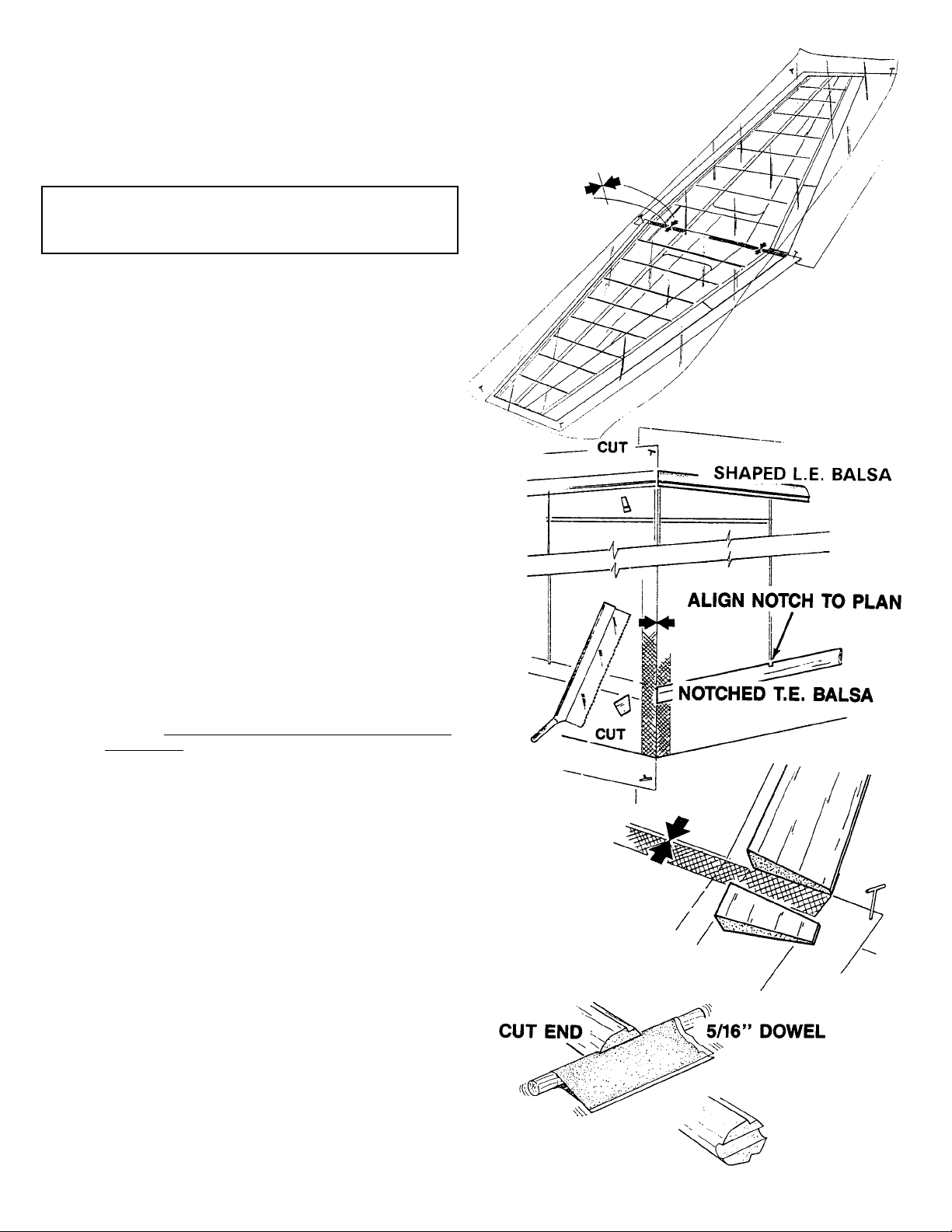

2. ■■ Cut the vying plan along the dotted line.Position the left

wing plan overlapping the right plan, aligning the

arrows as shown. Pin or tape the plan to the building

board and cover with waxed paper,

3. ■■ Lay a shaped LEADING EDGE over the plan and cut

the angle at the centerline. Repeat this step on the

other L.E.

■■ Next, place the notched TRAILING EDGE over the over

the plan, aligning the notches to insure that y

ou cut the

correct end. Cut the angle at the centerline and then

repeat this step on the other notched T.E.

■■ Referring to the plan, cut the inboard T. E. parts to the

correct length and angle.

4. ■■ Wrap a piece of fine sandpaper around the 5/16”

DOWEL and sand the wing pin notch into the angle-cut

end of the shaped L.E.

Page 15

15

5. ■■ Scissors-pin a 3/8” sq. BASSWOOD SPAR over the

plan, as shown. Make sure that the end is on the plan

centerline.

6. ■■ Pin tabbed Rib #2, #6, and #10 over the plan, but DO

NOT GLUE at this time.

7. ■■ Place the notched T.E.on the support tabs, with the cut

end at the centerline. Press the ribs into the notches

and glue.

■■ Remove the other ribs from their sheets.

IMPORTANT: Save the “horseshoe”- shaped punch out in

Rib #4, as you will need it for Step #29.

■■ Place the remaining ribs into the notched T.E.and onto

the spar, but DO NOT GLUE. Make sure that you

correctly install Rib #7, as shown.Match the bellcrank

support slot direction to Rib #6.

Page 16

16

8. ■■ Position the shaped L.E. onto the support tabs. Make

sure that the beveled/notched end is in line with the

wing centerline. Use a drafting triangle to project the

wing centerline to the L.E. end.

■■ Using the set-back gauge for correct positioning, gently

slide the top spar into the rib notches.

■■ Check the wing alignment with the plan underneath.

Then, place a drop of Jet glue at each joint along the

Leading Edge, the Spar, and the Trailing Edge.

9. ■■ Glue the balsa shear webs to the

front side of the spars, centering the

shear webs between the wing ribs.

NOTE: IF YOU ARE USING THE TWO-AILERON SERVO

SYSTEM, OMIT THE FOLLOWiNG.

■■ Drill a 1/16” diameter hole at the center mark on each

of the aileron bellcrank supports and glue the suppor t

between Ribs #6 and #7.

10. ■■ Edge glue two sets of three 1/16 x 3 x 36”balsa sheets.

■■ Measure 3-5/16” from opposite edges, as shown, and

mark.

■■ Cut along the line established by the two marks.Repeat

this process on the other glued sheet. This gives you

the L.E. sheeting for the entire wing.

Page 17

17

11. ■■ Position a full sheet edge against the L.E. shoulder.

Align the corner with the L.E. centerline end and roll

onto spar.

■■ Mark the sheet in line with the top spar end and cut

along the line formed. Use this sheet as a template to

cut the other three L. E.sheets.

12. ■■ Glue the L.E. sheeting to the L.E. shoulder, ribs, and

spar, pinning or taping to secure until dry.

■■ Glue the 1/16 x 2-1/2 x 36” Trailing Edge sheeting to

the notched T.E.and the wing ribs.

13. ■■ To glue the center sheet in place, first install the front

and back pieces.Then, slide the center piece in tightly.

Trimming may be necessary.

■■ Place some glue on the wing tip sheeting and slide in

place.

■■ Cut the 1/16 x 1/4”balsa capstrips to fit and glue to the

wing ribs.

14. ■■ Trim the sheeting along the wing centerline.

Page 18

18

15. ■■ Glue the pretrimmed Trailing Edge par t to the wing.

Align the “angle-cut” side with the notched T.E. Make

sure the top of the T.E.and the wing sheeting are flush

over the entire length.

REMOVE THE WING PANEL AND GO BACK TO STEP #3.

MAKING SURE

TO WORK OVER THE OTHER HALF OF THE

WING PLAN. REPEAT THE CONSTRUCTION SEQUENCE

FOR THE OTHER WING PANEL.

AFTER COMPLETING STEP #15 FOR THE SECOND TIME,

GO ON TO THE NEXT STEP.

16. ■■ Glue the front, rear, and tip wing fixture supports, as

shown.

17. ■■ Locate the wing fixtures and pin to the plan. Align the

marks on the tip fixtures to the spar on the plan.

18. ■■ Laminate the top and bottom portions of Rib #1.

Page 19

19

19. ■■ Pin the right wing panel to the building board, directly

above the wing plan outline.

■■ With the cut-outs pointing down assemble the dowel

support to one of the Rib #1 front sections, BUT DO

NOT GLUE.

■■ With the dowel support assembly inserted into the fixed

right wing panel, slide the left wing half into position.

Sand and trim to fit, as needed.When satisfied with the

fit, pin the left wing to the board, directly above the plan.

20. ■■ Lightly sand joiners and spars for maximum bond.

Then, apply 20 MINUTE EPOXYto the wing joiners and

insert into the wing around the spars.

■■ Clamp to form a gap-free joint. Check to see that the

wing is firmly on the fixtures while the joiners are drying.

21. ■■ Laminate the rear portion of Rib #1.

NOTE: IF YOU ARE PLANNING T O USE THE TWO-AILERON

SERVO SYSTEM, DO NOT PUNCH OUT THE

CENTER-MOUNTED SERVO BLANK, AS SHOWN

HERE. GLUE IT IN PERMANENTLY.

■■ Install the rear portion of Rib #1 directly over the

centerline and glue.Trim to fit, if needed.

NOTE: OMIT THE FOLLOWING STEP, IF BUILDING THE

TWO-SERVO OPTION.

■■ Install and glue the servo mount into the slots in Ribs

#2 and onto Rib #1.

Page 20

20

22. ■■ Drill a 5/16” diameter hole at the center mark of both

discs.Then, slide the dowel through the Leading Edge,

the support, and the dowel guide.

■■ Insert the remaining front por tion of Rib #1 onto the

dowel.Generously EPOXY the entire front rib area, as

well as the dowel support tabs in Rib #2.

23. ■■ Crack off all of the support tabs.

■■ Glue the remaining pretrimmed L.E. sheeting to the

wing. Pin or tape to secure until dry.

■■ Fit and trim the T.E.sheeting and glue to the wing

NOTE: IF YOU ARE USING THE TWO-SERVO

OPTION, GO ON TO STEP 31.

24. ■■ Bend a 5/16” x 900 angle at one end of the .063

diameter x 20-3/4” wire pushrod.

■■ Install an aileron bellcrank onto the bend.(See plan for

correct orientation.) Secure with a snapnut. Place a

drop of JET glue on the snap-nut.

Page 21

21

■■ Slide the pushrod assembly through the openings in

the wing ribs from Rib #6 toward the center.

■■ Install the hardware to mount the bellcrank to the

platform.

25. ■■ Using the plan for reference, cut the aileron pushrod

exit holes in the T.E.sheeting.

26. ■■ Make to pushrods to fit the template shown here.

27. ■■ Install the threaded pushrods onto the bellcranks and

secure with a snap-nut.Place a drop of JET glue onto

the snap nuts.

■■ Referring to the plan, fix the bellcranks in the neutral

position with a “T”pin.

28. ■■ Assemble the aileron coupler.

Page 22

22

29. ■■ Slide one 1/16” ID.x 1”brass tube onto the left aileron

pushrod and one tube onto the right aileron pushrod.

■■ Slide the aileron coupler assembly onto both pushrods.

The coupler block should be centered on the wing

centerline.

■■ Check that the bellcranks are still “fixed”in the neutral

position and solder the coupler tube to each pushrod.

The other brass tubes will be positioned after the servo

is mounted.

30. ■■ Connect the aileron ser vo to the pushrod. Locate the

servo so that the bellcranks are in the neural position.

Tighten the setscrew and mount the servo.

■■ In each wing half, center the brass tubes on the aileron

pushrods at Rib #4.

■■ Glue the “horseshoe”-shaped balsa piece (retained

from Step #7) to Rib. 4, laterally locking the brass

bushing in the wing.

Page 23

23

31. ■■ Cut out the opening for the aileron servo as you install

the center sheeting.

NOTE: IF Y OU ARE USING THE TW O-SER V O OPTION,CUT

A SMALLER OPENING FOR SERV O LEAD ACCESS

ONLY.

■■ Glue the tip sheeting in place and install the capstrips.

■■ Remove the wing assembly from the building board.

32. ■■ Sand flat the end ribs and glue the balsa tip rib to both

tips.

■■ Sand the perimeter to match the airfoil.

33. ■■ Sand the wing, blending all the seams and joints. Use

a tack rag to remove all of the dust when finished.

34. ■■ Star ting at the front of the servo cut-out, completely

wrap the center of the wings with 3/4”nylon tape.Smear

glue through the fabric weave, using a plastic bag to

protect your finger.

■■ Trim the excess at the rear servo cut-out.

Page 24

24

35. ■■ At this time, transfer hinge locations from the plan to

the ailerons.Next, transfer these marks to the wing.Be

sure to leave a 1/16”gap between the aileron and the

T.E. center section.

■■ Use a CGM centerline tool and scribe a hinge

centerline into both ailerons and wing halves.

■■ Hinge the ailerons just like you did the elevator and

rudder

■■ Bevel the ailerons to the center scribe line, using the

bevel tool marked “AE.”

■■ Temporarily hinge the ailerons to the wing to test the

fit.Then, sand the aileron to the tip plane of the wing.

NOTE: Permanent assembly of the ailerons to the wings,

as well as control horn installation, is done after

covering.

IF YOU ARE INSTALLING ONLY ONE SERVO, THE WING

CONSTRUCTION IS NOW COMPLETE.

NOTE: The two-servo option should be used for aircraft

using an engine larger than a .60 2-cycle.

1. ■■ Collect the following parts needed to install an aileron

servo in each wing panel.

(1) D/C SHT. #5521 PLY PT. #3484

CONTAINING SERVO MOUNTING PARTS

(1) D/C SHT. #5522 BALSA PT.#3334

CONTAINING HATCH COVERS

(16) #2 x 5/16” SHT.METAL SCREW PT. #1086

(16) #2 WASHER PT. #1138

TWO-SERVO SYSTEM CONSTRUCTION (6 Steps)

TO BE INSTALLED ON A COMPLETED WING

Page 25

25

2. ■■ Laminate the two ply front platform supports and glue

to the spar, centering between Ribs #6 and #7.

■■ Glue the rear platform support to Ribs #6 and #7 and

to the T.E.sheeting.

3. ■■ Drill a 1/16”diameter hole in each corner of the platform

and mount to the rails, using four of the #2 x 5/16”

screws and washers.

4. ■■ Glue the corner gussets to the servo mounts and fasten

the assemblies to a servo.

5. ■■ Glue a corner gusset to each corner of the ser vo bay,

as shown.

■■ Fabricate the balsa hatch and drill a 1/16”diameter hole

in each corner.

■■ Center the servo arm in the slotted hole of the hatch

cover to locate the servo. Remove the hatch and glue

the servo gussets and mounts to the platform.

6. ■■ After the wing is covered, and with both the servo and

aileron in the neutral position, measure and connect the

pushrod.

THIS COMPLETES THE WING.NOW LET’S MOVE ON TO THE

FUSELAGE.

Page 26

26

1. ■■ Gather all of the parts needed to construct the

FUSELAGE.They include:

(2) D/C SHT. 5501 PLY SIDES PT. #3475

(1) D/C SHT. 5502 PLY FUSE BOTTOM PT. #3473

(1) D/C SHT. 5503 PLY PT. #3474

CONTAINING TOP & BACKUPS

(1) D/C SHT. 5504 PLY PT. #3475

CONTAINING DOUBLER, TRIPLER, FORMERS &

FUEL T ANK TRAY

(1) D/C SHT. 5505 PLY PT. #3476

CONTAINING DOUBLER, TRIPLER & FRMRS

(1) D/C SHT. 5506 PLY FRMRS & GAUGES PT. #3477

(1) D/C SHT. 5507 PLY FORMERS PT. #3478

(1) D/C SHT. 5508 PLY FORMERS PT. #3479

(1) D/C SHT. 5509 PLY FIREWALL PT. #3480

(1) D/C SHT. 5518 PLY TURTLEDECK PT. #3481

(1) 1/32” PLY FRONT/TOP SHEET PT. #4602

(1) BASS WING MOUNTING BLOCK PT. #4372

(1) 1/4” PLY LANDING GEAR BLOCK PT. #4373

(2) BASS MOTOR SPACER PT. #4374

(1) 1/2” x 7” BALSA GUSSET PT. #4217

(2) 1/8 x 1/2 x 18” BALSA STICK PT. #4376

(6) 6-32 BLIND NUT PT. #1124

(6) 6-32 x 1-1/4” SOCKET HD. SCREW PT. #1024

(2) #6x3/4”WASHER PT. #1144

(4) #6 x 3/4” SHT. METAL SCREW PT. #1082

(2) MAIN LANDING GEAR WIRE PT.#1322

(2) MOTOR MOUNT PT.#1466

2. ■■ Carefully remove the parts from the die sheets and

lightly sand the rough edges of each part.

3. ■■ With the scribe lines exposed, glue FIREWALL

FORMER “AF”to the other fire w all half. Make sure the

top and side edges match. Note the bottom offset fit.

Tape together and allow the assembly to dry on a flat

surface.

■■ Drill a 3/8” diameter hole at the center mark.

CONSTRUCTING THE FUSELAGE (36 Steps)

Page 27

27

4. ■■ Position the ‘DRIVE W ASHER,”of y our engine over the

drive washer on the plan.

■■ Place the MOT OR MOUNT against the firewall over the

plan.Y ou may require spacers to accomplish the proper

position.

■■ Tack glue the engine to the mounts.

NOTE: MAKE SURE THAT THIS DIMENSION IS AT LEAST

1/4”.If not, use basswood spacers between the firewall

and the motor mounts.

5. ■■ Place the motor assembly over the “AF” side of the

firewall.

■■ Measure 1/2 of the total distance between the mounts,

from the scribe mark on the firewall to one of the

mounts.

■■ With the holes on the vertical scribe marks on the

firewall, mark all four mounting bracket locations.

■■ Drill a 5/32” hole at each location.

■■ T urn the firewall ov er and insert the four 6-32 blind nuts.

Seat them with a soft hammer blow.

■■ Coat the edges of the nut with JET GLUE. Be careful

to not get glue in the threads. Put the assembly aside

for now.

6. ■■ Locate, glue, and trim the 1/8 X 1/2” balsa doublers to

the four formers, “D,” “E,” “F” and the SLANT former.

Page 28

28

7. ■■ Glue the wing-saddle doublers to the inside of the

fuselage sides.Reference the landing gear block area

and the wing curve for the correct alignment.

8. ■■ Glue the landing gear triplers onto the wing saddle

doublers.Make sure that the landing gear wire slots are

in line.

9. ■■ With the triplers face to face, tape the fuselage sides

together at the rudderpost end. Use a scrap piece of

3116” balsa spacer between the sides.

■■ Install Former “D” (balsa doubler forward) and secure

with a rubber band.

■■ Install Formers “E” and “F,” using rubber bands to

secure at each former.

10. ■■ Slide the fuselage top under the rubber bands and

press into position. Loosen the tape at the rudderpost

end to allow top to fit.

Page 29

29

11. ■■ Slide in the “SLANT” former.

12. ■■ Flip the fuselage over and install the bottom sheet.

■■ Position the fuselage over the TOP VIEW of the plan

and check the alignment.Use small pieces of masking

tape to secure the structure as you go.

■■ Sight-check down the fuselage to insure against twist.

13. ■■ When the fuselage is perfectly aligned, glue all of the

seams created by the sides, top, bottom and formers.

Page 30

30

14. ■■ Glue the landing gear block to the fuselage assembly.

Make sure the groove is facing out.

■■ Glue Former “C” to the landing gear block and the

triplers.

15. ■■ Glue in Former “B.” Check that the former is flush with

the fuse side slot.

16. ■■ Glue the FIREWALL onto the fuselage assembly .Make

sure that the blind nut flanges are on the inside.

17. ■■ Glue the bottom-front piece in place.

Page 31

31

18. ■■ Use the wing to locate the doubler disc. Correctly

position the disc to Former “B”and epoxy in place.

19. ■■ T o the wing mounting bloc k, insert a 6-32 blind nut into

each hole on the surface Mere the holes are centered.

Make sure that the nut spurs are full set into the wood.

Tap with a hammer to insure a good fit.

20. ■■ With the blind nuts on the under side, test fit (and trim,

if necessary,) the b lock assembly into the cutouts in the

doublers.When you have a proper fit, Epoxy in place.

21. ■■ Install the gusset into the slot in the slant former and

down into the notches in the doublers. The gusset

should also rest on the wing mounting block.When you

are satisfied with the fit, glue in place.

22. For the next few steps, you will need the wing.

■■ Place the fuselage on a stable, flat surface. Insert the

wing pin dowel into the hole in Former “B.” Slide the

wing as far forward as it will go.

■■ True the wing to the fuselage by adjusting the distance

from the wing-tip to the tail until both sides are equal.

When you are satisfied, secure the wing to the fuselage

with tape.

Page 32

32

23. ■■ Flip the wing/fuse over and drill a small pilot hole (no

larger than 7/64”) through the wing.

■■ Remove the wing from the fuse and drill a 5/32” hole,

using the pilot hole as a guide.

■■ Test bolt the wing to the fuselage and check to make

sure the tip-to-tail dimensions are still equal.

24. ■■ Trim and glue the 1/2” balsa triangle stock behind the

firewall.

25. ■■ Glue in the top reinforcement.

26. ■■ Glue in the remaining triangle stock, as shown.

Page 33

33

27. ■■ Locate Former “BB” at a 900 angle to the front

reinforcement and glue.

28. ■■ Glue one edge of the 1/32” ply TOP SHEET to the fuse.

Then, using a spray bottle to soak the sheet, slowly roll

to the opposite side, gluing as you go.

NOTE: MARK THE CENTERLINE ON THE TOP SHEET AND

THE FUSE TO INSURE A CORRECT FIT.

■■ Sand the edges in line with the firewall and Former “BB . ”

29. ■■ Install Former “FF directly above Form “F”and at a 900

angle to the fuse top.

30. ■■ Mark the center line onto the horizontal stabilizer and

on the stab platform of the fuselage.

■■ Glue the stabilizer to the platform, locating it on the

centerlines and against Former “FF.” Check the

stabilizer to insure that it is parallel to the base.

Page 34

34

31. ■■ Install the vertical fin. Inser t the rudderpost into the

rudderpost slot. Tilt the fin forward until it rests on the

top surface of the stab.

■■ Check that the assembly is square, using a 900

triangle.

■■ Permanently glue the fin to the stabilizer and fuselage.

32. ■■ Glue the ply “BACKUP”pieces to the stab on each side

of the fin.

33. ■■ Slide the 1/32” ply turtledeck around the fin.

■■ With a water spray bottle, liberally soak the top

centerline of the turtledeck.This will allo w the plywood

to be formed without splitting.

■■ Wrap the ply around the formers and down onto the

fuselage sides.Sand the sides for a smooth fit.

34. ■■ When satisfied with the fit, apply glue to the formers,

fuselage sides, fin and stab.

■■ Quickly wrap the plywood down to the fuselage and

tape in place until dry.

35. ■■ Bevel the plywood edge at the fuselage lap-joint and

sand the edge flush with the slant former.Fill the step

with CGM Model Magic filler.

■■ Apply additional filler to the fin and stabilizer seams and

blend to create a smooth transition.

36. ■■ Go over the fuselage, sanding all seams and joints with

medium sandpaper. Then, sand the entire fuselage

with fine grit sandpaper.The effor t you put into finish

sanding will show, as no covering material will hide a

poor sanding job!

■■ Now go back to all of the built-up parts to inspect the

sturdiness of joints and to finish sand. When satisfied

with the finish, the aircraft is ready for covering.

Page 35

35

1. ■■ Collect the parts needed to construct the LANDING

GEAR FAIRINGS. They include:

(2) LANDING GEAR 3/16”WIRE PT.#1322

(2) LANDING GEAR STRAP PT. #1418

(4) #2 x 3/8” SHT. METAL SCREW PT. #1087

(1) D/C SHT. #5518 1/32” PLY PT. #3481

CONTAINING (2) FAIRINGS

(2) BALSA SHEET 1/16 x 2-7/8 x 10” PT. #4886

2. ■■ Install the LANDING GEAR WIRES and secure them

in place with the nylon straps and screws.

3. ■■ T ack glue the plywood F AIRINGS to the wire gear .Align

the half moon notches with the wire and keep the root

end parallel to the fuse bottom.

4. ■■ Edge-glue the two 1/16 x 2-7/8 x 10” BALSA SHEETS

together and cut:

(6) 1/2” cross-grained strips

(6) 1” cross-grained strips.

5. ■■ Laminate three 1”strips to the ply failing.Wet the balsa,

if necessary, to bend into position.

6. ■■ Repeat the process with the 1/2”strips on the front side

of the fairing.

7. ■■ Sand the completed fairings to shape.Y ou ma y want to

remove the fairing from the wire to shape it. After the

fairings are covered or painted, permanently attach

them with silicon adhesive.

CONSTRUCTING LANDING GEAR FAIRINGS (7 Steps)

Page 36

36

1. ■■ Collect the following parts.

(1) D/C SHT. #5503 (REMAINDER) PLY PT. #3474

CONTAINING (2) RAILS

(1) D/C SHT. #5505 (REMAINDER) PLY PT. #3476

CONTAINING (2) FORMER “CC”

(1) D/C SHT. #5508 (REMAINDER) PLY PT. #3479

CONTAINING (1) SPREADER

(1) DOWEL 1/4 x 1-3/4” BIRCH PT. #1755

(1) CANOPY PT. #9515

(1) COCKPIT INSERT PT. #9518

(2) 4-40 BLIND NUT PT. #1125

(2) 4-40 x 1/2” PAN HEAD SCREW PT.#1048

(2) #2 WASHER PT. #1139

2. ■■ Mount the wing to the fuse.

■■ Position the two rails on top of the wing, as sho wn.T ape

to the wing, if you wish.

■■ Referring to the plan for the distance between the two

Formers “CC”, glue them to the rails.Use the 1/4”dowel

as an alignment pin to the fuselage Former “BB.”

■■ Install the rear spreader into the slots in the rails and

glue.

3. ■■ Drill a 3/32” hole through the rail and the fuselage tab.

■■ Press a blind nut into each tab and, temporarily, bolt

the canopy frame to the fuselage.

CONSTRUCTING THE CANOPY FRAME (6 Steps)

Page 37

37

4. ■■ Pretrim the back flip-up portion of the cockpit insert.

■■ Glue the top of the frame and place the insert in

position.

■■ Trim the insert flush with the outside of the rails.

■■ Add control sticks and pilot (both not included in kit), if

desired. Also, paint the interior at this time.

5. ■■ Trim the canopy along the scribe line.You may want to

trim it a little long and precisely fit it to the wing and

fuselage.

6. ■■ Paint the canopy deck up to the canopy crease.

ASSEMBLING THE WHEEL PANTS (6 Steps)

1. ■■ Clean up the edges of the pant halves by gently sliding

them over sandpaper on a flat surface.

2. ■■ On both the outer and the inner pant half, drill a 3/16”

hole at the axle location.

■■ Glue the two support plates to the inner pant half.

■■ Glue the axle support plate to the outer pant half,

aligning the center mark on the plate concentric with

the hole.

3. ■■ Rough-cut the wheel opening in all four pant halves.

Then glue an outer half to an inner half, forming a lap

joint.Align the outer half edge to the scribe line on the

inner half all around.

Page 38

38

4. ■■ Carefully trim to the wheel well line.Use a small round

file to clean up the edges.

■■ Fill the step of the lap seam with filler and sand smooth.

Repeat if necessary.

■■ Repeat the process for the other wheel pant.When both

are finished to satisfaction, paint.

5. ■■ Slide the wheel pant, collar, wheel, and other collar

onto the landing gear axle.

■■ Snap the landing gear into the pant groove and

permanently install the nylon strap.

■■ With the wheel in the center of the pant, tighten set

screws in the collars, allowing the wheel to spin freely.

6. ■■ Install the tailwheel bracket.Secure using two #2 x 3/8”

screws.

■■ With the horn bracket on the wire, notch the bottom of

the rudder and glue in the bracket.

■■ Install a 1-1/4” diameter wheel.

ASSEMBLING THE ENGINE COWL (9 Steps)

1. ■■ Carefully cut the cowl halves along the scribe lines

around the perimeter. Sand the edges straight along

the top and bottom seam line. Don’t forget the cowl

exhaust area.

Page 39

39

2. ■■ Cut the front piece along the scribe line around the

circumference.

■■ Cut out the two air intake openings on each side of the

spinner ring along with the bottom opening and the

prop shaft opening. Use a small round file to lean up

the edges of each intake.

3. ■■ Glue the front piece onto one of the sides.

4. ■■ Glue the joiner strip to the top and bottom seam.Leave

half of the strip width exposed to allow a gluing surface

for the other cowl half.

5. ■■ Glue the remaining half to the front piece and onto the

joining strip. Fit all seams as tightly as possible. This

will eliminate excessive filling and sanding.

6. ■■ Fill the seams with filler and sand smooth.

7. ■■ Paint the cowl with a good quality, fuel resistant paint.

8. ■■ Permanently install the motor mounts to the firewall

using four 6-32 x 1-1/4” socket head screws with

washers.

NOTE: If you are not using the engine spacers, you must cut

the screws so they do not interfere with the fuel tank.

Don’t forget right thrust.

■■ Screw the engine to the mounts using four #6 x 3/4”

screws with washers.

9. ■■ Slide the cowl on over the engine and install the spinner

backplate on the prop-shaft.

■■ Allow a 1/16” space between the backplate and the

cowl. Locate the cowl off the spinner backplate and

attach to the fuselage using four 4-40 x 3/8”screws and

washers.See plan for locations.

NOTE: If you prefer to install fiberglass,rather than plastic

parts, these may be obtained directly from Carl

Goldberg Products. See ordering information on

the Parts List.

Page 40

40

1. ■■ Rubber band the tank to the platform.

2. ■■ Make a small opening in the firewall. Attach the fuel

lines and feed them through the opening in the firewall.

3. ■■ Slide the tank platform forward and insert the tabs into

the notches in the firewall.

■■ Glue the wide end of the platform to the notches in

Former “B.”

FUEL TANK INSTALLATION (3 Steps)

RUDDER CABLES

ELEVATOR PUSHROD GUIDE

A word here about rudder actuation. The EXTRA uses a

“pull/pull” system. The rudder servo must be located as shown

on the plans to insure the correct cable alignment with the cable

exits.This is not a problem if the die cut servo tray (D/C SHEET

5519, supplied in this kit) is used. Solder the threaded coupler

to the cables, being careful to keep both assemb ly lengths equal.

With the servo in the neutral position, trim tab centered, attach

the cables to the control horn and to the servo arm. Adjust the

snap-links until the rudder is perfectly straight. A ball bear ing

servo is recommended for the rudder control.

Y ou will note that the plans show an ele vator support guide glued

to the top of Former “D .”This two-part support is on D/C SHEET

5519 and is to be installed after the servo is connected to the

elevator horns.

After you finish covering the entire model, permanently install

the hinges.The GENERAL INFORMATION BOOK also covers

this.

Page 41

41

Use the control surface trav el gauges supplied in this kit on D/C

SHEETS 5503 and 5506. The gauges provide two settings:

GENTLE response, and a quicker AEROBATIC mode. Even if

you are a proficient flyer , w e encourage y ou to start out with the

gentle marks and work up to the aerobatic settings.This will give

you an opportunity to experience the different trav el responses .

AILERON GAUGE

Place the gauge at Rib #10 (wing tip) to measure aileron travel.

Equal movement up and down. Note the GENTLE and

AEROBATIC setting marks.

ELEVATOR GAUGE

With the point point ‘UP,” locate the gauge at the tip of the

horizontal stab.The travel movements are not the same up and

down.Note the GENTLE and AEROBATIC setting marks.

RUDDER GAUGE

Locate the gauge at the air balance space.Flip the gauge to the

opposite side to check opposite travel. Note that there is only

one setting for rudder.

CONTROL SURFACE TRAVELS

SETTING UP AND FLYING THE EXTRA 300

SETTING UP

Time spent in setting up pays big dividends during your first

flights. Some flyers prefer VTR on flying surfaces, Mile others

prefer EXPO.If you choose EXPONENTIAL, start with 25% and

adjust from there. Set the throws to the higher setting and use

the EXPO to “soften the neutral.” For VTR, inhibit the dual rate,

but set as follows:AILERON 65%, ELEV ATOR 65%.Note again

that the max throws are in the high position on the travel gauges ,

which is a good starting point. From there, adjust to personal

taste.

Balance is very important, as too far forward will cause the

aircraft to want to nose over on takeoff, par ticularly in grass.

Balance that is too far back will make the aircraft pitch unstable

and difficult to control. Balance CAREFULLY, reference the

plans.Start with the f

orwardlocation and add tail weight carefully.

FL YING TIPS

This EXTRAis v ery easy to fly , if properly set up .On take off the

plane has excellent stability, but it will feel nose heavy. Always

use full up elevator when taxiing to prevent nosing over. Keep

first flights short and check the aircraft often.

Landing is quite straight forward.The plane is “clean” and will

glide well.However , it won’t snap unless rudder is applied.Try to

land in a 3-point configuration and, Men the mains touch, release

some of the “up”used in the flair. This will eliminate the bounce

on landings.

In knife edge, the EXTRA will take some opposite aileron flight

to keep the wings perfectly v ertical.It can be hand flo wn or , with

a computerized radio, automatically mix in the correction. Mix

4% opposite aileron for rudder direction used. No elevator mix

is required.

Page 42

42

FLYING SNAP ROLLS

Pull up and climb at 45 degrees, and go to knife edge.

After 4 or 5 snaps the Extra will be ready to fly out straight and

level.

KNIFE EDGE SPIN

A unique maneuver to observe so here’s what to do:

ENTER A CONVENTIONAL SPIN. . .

The plane will go into a knife edge spin and will lose altitude very

quickly. . .so be advised!

SETTING UP AND FLYING THE EXTRA 300

AFTER 1-1/2 SNAPS...

50% RUDDER THEN...

FULL RUDDER AND FULL AILERON

FULL UP...

FULL DOWN...

FULL LEFT RUDDER AND FULL LEFT AILERON

FULL UP...

FULL DOWN...

AFTER 1 OR 2 TURNS.. .

Page 43

43

Height: 1.25 Inches

Length: 4.75 Inches

Typeface: Sans/Bold

Color: Blue

Quantity: 2 (sides)

COLOR SCHEME & DECAL LOCATIONS

COLORS:

R DEEP RED

W WHITE

B MIDNITE BLUE

BOTTOM / T OP VIEW

SIDE VIEW

Height: 1.75 Inches

Length: 16.25 Inches

Typeface: Sans/Bold

Color: Blue

Quantity: 2 (sides)

Height: 4.50 Inches

Length: 23.00 Inches

Slant: 20 Degrees

Typeface: Univers/Black

Color: White

Quantity: 1 (Bottom)

Height: 1.25 Inches

Length: 8.50 Inches

Slant: 20 Degrees

Typeface: Univers/Black

Color/Qty: Blue/2 (Top)

White/2 (Bottom)

Height: 4.25 Inches

Length: 28.00 Inches

Slant: 20 Degrees

Typeface: Univers/Black

Color/Qty: Blue/2 (lop)

White/1 (Bottom)

Page 44

For your next kit...

Loading...

Loading...