Carimali Multi Smart LM Technical Instructions

LB.05080.00 Pag.1 16/04/2014

TECHNICAL

INSTRUCTIONS

MULTI

SMART

www.carimali.com

LB-05080.00 EN

EDITION February 2014

EN ENGLISH

LB.05080.00 Pag.2 16/04/2014

TABLE OF CONTENTS

GENERAL CHARACTHERISTICS .................................................................................................................................................................................. 5

TEST REPORT ON ENERGY CONSUMPTION ............................................................................................................................................................. 7

MACHINE KEYPAD ........................................................................................................................................................................................................... 7

ELECTRIC - HYDRAULIC CONNECTION .................................................................................................................................................................... 8

STARTING UP ..................................................................................................................................................................................................................... 9

ACCESS THE MAIN SETTING MENUS WITH PASSWORD .................................................................................................................................... 13

PROGRAMMABLE PARAMETERS IN ACCORDING WITH PASSWORD ............................................................................................................ 14

INFO-RESET ...................................................................................................................................................................................................................... 16

DOSES PROGRAMMING ................................................................................................................................................................................................ 20

SYSTEM MANAGER ........................................................................................................................................................................................................ 25

MACHINE CONFIGURATION ....................................................................................................................................................................................... 42

PRESET PARAMETERS .................................................................................................................................................................................................. 44

CLEANING PROCESS ABORT ....................................................................................................................................................................................... 45

TROUBLE SHOOTING .................................................................................................................................................................................................... 46

SPECIAL FUNCTIONS FOR MACHINE CALIBRATION .......................................................................................................................................... 51

RECOMMENDATIONS FOR A CORRECT PREVENTIVE MAINTENANCE ........................................................................................................ 52

CONTROL UNIT LEGEND .............................................................................................................................................................................................. 53

LB.05080.00 Pag.3 16/04/2014

INTRODUCTION AND GENERAL NOTES

Thoroughly read the instructions contained in this booklet because it gives important information regarding safety for installation, use and

maintenance.

Keep this booklet in a safe and accessible place for further consultation.

This machine must be used only for the purpose it was designed:

dispensing coffee, cappuccino, pouring hot water.

Any other use is to be considered inappropriate and therefore dangerous.

The manufacturer declines all responsibility for damage caused by any improper, incorrect and unreasonable use of the machine.

The use of any electric appliance implies the observance of some fundamental rules.

More specifically:

The appliance should be placed on a stable flat surface with the bodywork at a minimum distance of 20mm from the back wall,

furthermore, it must be installed taking into account that the highest shelf must sit at a height that is at least 1.5 mt.

During installation, fit a device that guarantees disconnection from the mains, duly sized according to the power of the equipment (see

rating plate), as well as protection against leakage current with a value equal to 30mA.This cut-off device must be assembled on the

power supply line in compliance with installation rules.

do not touch the appliance with your hands or feet wet or damp

do not use the appliance with bare feet

do not pull the power cord to disconnect the plug from the power socket

dot not leave the appliance exposed to the weather (rain, sun, frost)

do not let children or untrained persons use the appliance.

Before carrying out any cleaning and maintenance, disconnect the appliance from the power supply, pulling the plug from the power socket

and turning off the main switch.

In case of failure or malfunction turn the machine off and do not attempt to carry out any repairs or direct operations on the machine.

All repairs must be carried out in an authorized service centre, using original spare parts only.

Failure to comply with the above recommendations will compromise the safety of the machine and the warranty conditions.

If this machine is no longer used we recommend that it is made inoperative by disconnecting the cable from the power supply, and all

potentially dangerous parts are made harmless, especially to protect children who might use the machine for their games.

INSTALLATION NOTES

Installation must be carried out according to the manufacturer’s instructions.

An incorrect installation can cause damage to persons, animals or things; the manufacturer declines all responsibility for such situation.

Place the machine on a table having minimum height of 0,95mt. Furthermore the surface has to be flat, having a maximum inclination of 5°,

in order to secure a perfect stability. Check also that the table can bear the weight of the machine.

This is a commercial machine and is not designed for home use and must be operated by duly qualified persons.

The machine must not be used by children or people with reduced mobility, sensory, mental or lack of experience or education, unless there

is a supervisor.

After unpacking check that the machine is not damaged.

If in doubt, do not use the machine and contact an Carimali S.p.A. Authorized Service Centre.

All packing materials (plastic wrapping, polystyrene, nails, etc.) are potentially dangerous and must be kept out of children’s reach and

disposed of in a safe manner for the environment.

Before connecting the machine to the power supply make sure that the rating information of the machine correspond to that of the power

supply, and that the power supply is adequate to additional power absorption of the machine.

The machine is supplied with power cord and without plug, connect the machine to the main switch with knife switch and protection fuses. In

case of maintenance, open the knife switch.

The machine with single phase voltage, having a rated current more than 16A, must be connected to power supply with a dedicated

impedance.

The electrical safety of this machine can be guaranteed only if correctly connected to an efficient earth circuit as indicated by current

electrical safety regulations.

It is necessary to check this fundamental safety prerequisite, and in case of doubt, ask a professionally qualified technician to check the

circuit.

The manufacturer declines all responsibility for any damage caused by failure to earth the equipment.

In order to avoid any dangerous overheating, we recommend that the power cord be fully unwound.

In case of damage to the cord, contact exclusively an authorized service centre to have it replaced.

The power cord of this machine must not be replaced by the customer.

Do not leave the machine connected unnecessarily.

Turn off the main switch of the machine when not in use.

Do not cover the ventilation openings of the machine.

Place the machine at an adequate distance from walls, objects, etc.

The machine must be connected to a system with a water pressure which is not greater than 0.6 MPa. Do not use pipes and coupling

gaskets already used for previous installations.

If the pressure is greater, a pressure reducer must be installed.

The machine must be connected to a softener.

ENVIRONMENTAL CONDITIONS TO USE THE MACHINE

Environmental temperature: 5 – 30 °C (empty the hydraulic system in case of freezing)

Maximum humidity: 80% relative humidity

Water hardness: 5° eh, 7° dH, 13° Fh

LB.05080.00 Pag.4 16/04/2014

1. Essential operational requirements

1.1 The machine shall be supplied with water for human consumption, in compliance with the laws in force where the installation is

performed. The installer shall check with the owner or manager of the machine if the water complies with the requirements above.

1.2 The components and materials to be used during the installation are those supplied with the machine. In case other components are

needed, the installer shall check if they are suitable to be used in contact with water for human consumption.

1.3 The installer shall set up hydraulic connections in compliance with the rules about hygiene, water safety and environment in force where

the installation is performed.

1.4 At the end of the installation the machine is activated, brought to nominal operating conditions and left in the “ready for operation” mode.

Then it is turned off and the whole water circuit is drained from the initial water to eliminate any impurities.

Then the machine is once again loaded and brought to nominal operating conditions.

When the machine is in the “ready for operation” mode, the following deliveries are performed:

- 2 liters from the hot water outlet (in case there are more outlets, the 2 liters shall be equally divided)

- 1 liter of water from each coffee outlet

- each steam outlet is kept open for 1 minute

At the end of the installation, it is recommended to write a report of the operations that were performed.

USE AND MAINTENANCE NOTES

For a correct functioning of the machine it is fundamental to comply with the manufacturer’s instructions, having qualified personnel to carry

out special maintenance and to check all safety devices.

Do not use the machine without water.

Avoid to expose hands or other parts of the body to the coffee dispensing spouts or to the steam or hot water nozzles.

The water and steam from the nozzles is very hot and can cause severe burns.

The water and steam nozzles and the filter holders are very hot and therefore must be handled with care, holding them in the appropriate

points.

Do not leave the machine in rooms where the temperature is below 0°C or 32°F without having first drained the boiler and the hydraulic

circuit.

Cups and coffee cups must be placed on the cup-warmer tray (if fitted) only after having been fully drained.

Only the crockery related to the machine should be placed on the cup-warmer tray.

Placing any other object on the tray is to be considered incorrect.

The machine is not waterproof and therefore should not be cleaned with water jet.

1. Use of the machine

1.1 At the beginning of operations, and in any case at least once a day, all the water inside the machine shall be changed, following the

instructions:

- for fully automatic machines, carry out a group washing and a power cleaner washing.

- for traditional machines, see the paragraph about draining the boiler.

1.2 Before the steam wand is used, it shall always be purged from the condensation water for at least 2 seconds or according to the

instructions by the manufacturer.

2. Maintenance and repair

2.1 The components used during the maintenance or repair shall be guaranteed to meet the same hygiene and safety requirements as the

machine. Genuire spare parts offer this guarantee.

2.2 After components related to parts that come into contact with water or food are repaired or changed, a washing procedure shall be

carried out as indicated in the paragraph about the rules for the installation.

HACCP SCHEDULE

We hereby declare that our HORECA machines have been designed and constructed to comply the European Community Sanitary law and

that their sales are authorized by the Health Authorities.

A HACCP schedule (Hazard Analysis Critical Control Points) for risk identification and assessment is required. You should carry out a risk

analysis on your premises.

With correct installation, care, maintenance and cleaning with approved detergent, Carimali meet the requirement above mentioned.

Carry out cleaning instruction, provided with machine, every day or at 8 hours shift intervals, to ensure that your system contains a minimum

bacteria.

LB.05080.00 Pag.5 16/04/2014

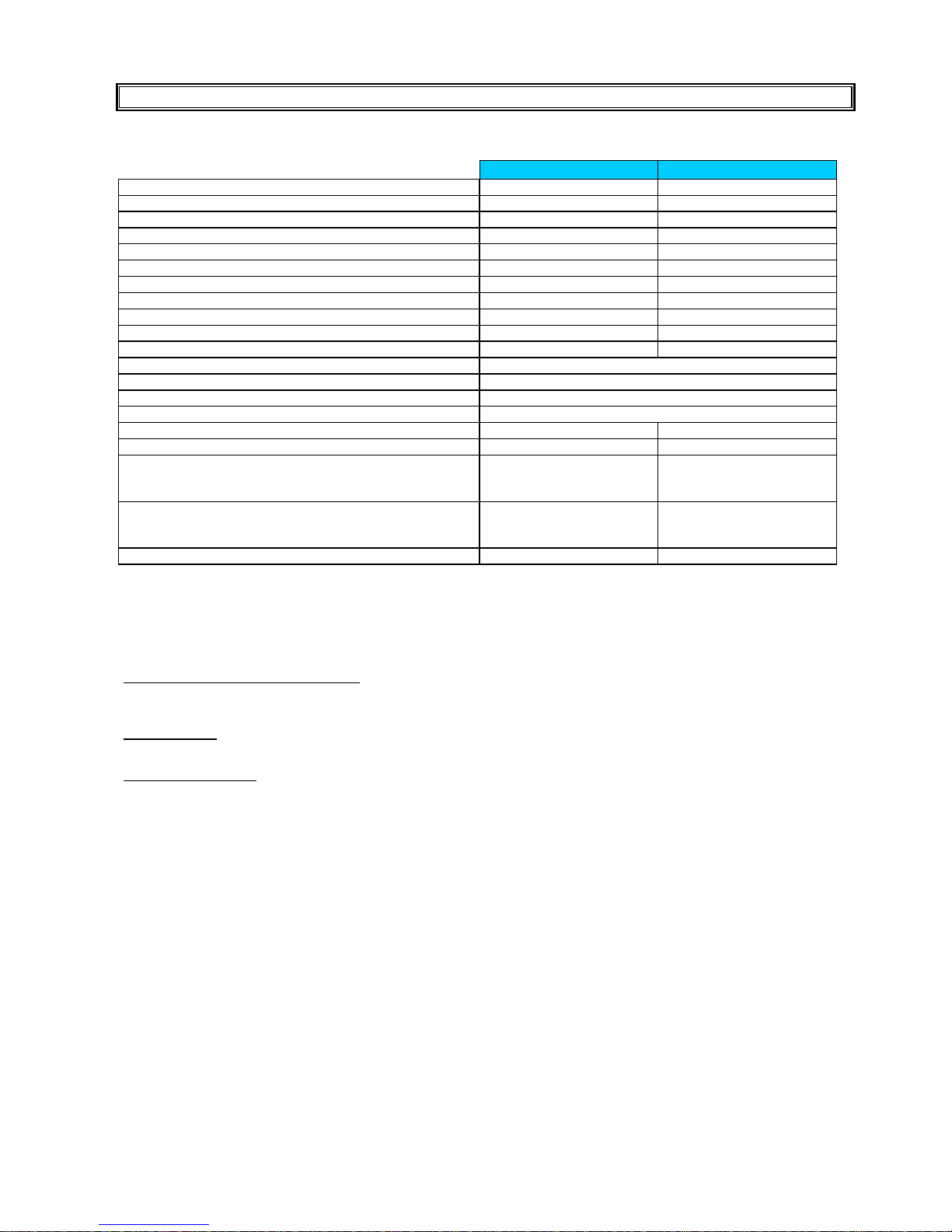

GENERAL CHARACTHERISTICS

MULTI SMART COF MULTI SMART LM

Automatic coffee brewing unit 1 1

Grinder 1 1

Decaffeinated door 1 1

Steam nozzle 1 1

Automatic cappuccino - 1

Hot water dispenser 1 1

Mix Group Optional Optional

Mix cold water Optional Optional

By - Pass Optional Optional

Maximum quantity of coffee dispensed per hour 180 180

Maximum quantity of cappuccino dispensed per hour - 120

Machine Width (mm) 289

Machine height (mm) 592

Machine height with hopper (mm) 814

Machine Depth (mm) 564

Net weight (Kg) 35 35

Boiler capacity (lt) 4 4

Boiler resistor (W) Standard version

Optional version

Optional version

2700+900 (230V~)

2050+710 (200V~)

1200+880 (120V~)

2700+900 (230V~)

2050+710 (200V~)

1200+880 (120V~)

Voltage (V) 230V~ single phase

200V~ single phase

120V~ single phase

230V~ single phase

200V~ single phase

120V~ single phase

Brewer group resistor PTC (W) 70 70

Please note: Multi Smart SELF-version is supplied with hopper with lock and without decaffeinated door and steam

arm.

MACHINES IN SELF CONFIGURATION (see exploded view manual for code number)

Functions are absent or disabled by software:

• extra milk function by pushing the cappuccino/latte dose key: disabled by sw

• function to stop the dose delivery by pushing a dose key: disabled by sw

• function to switch off the machine by pushing Shift and then Info keys: disabled by sw

Included features:

• Kit to block the drip tray

• Kit to block the decaf door

Recommended optionals:

• Lock for beans hoppers

• Direct coffee grounds.

MATERIALS USED:

- Copper for boiler

- Copper and Teflon for hydraulic tubes

- Nickel-plated brass for connections

- Reinforced silicone for the flexible feed tube

- Aluminium with stainless steel lining for the brewing group

- Aluminium for the grinder

- Other accessories in food plastic which are in contact with the ground coffee or drink

- Painted steel bodywork

- ABS plastic for controls area

- Stainless steel and ABS plastic for working area and cups tray.

LB.05080.00 Pag.6 16/04/2014

LB.05080.00 Pag.7 16/04/2014

TEST REPORT ON ENERGY CONSUMPTION

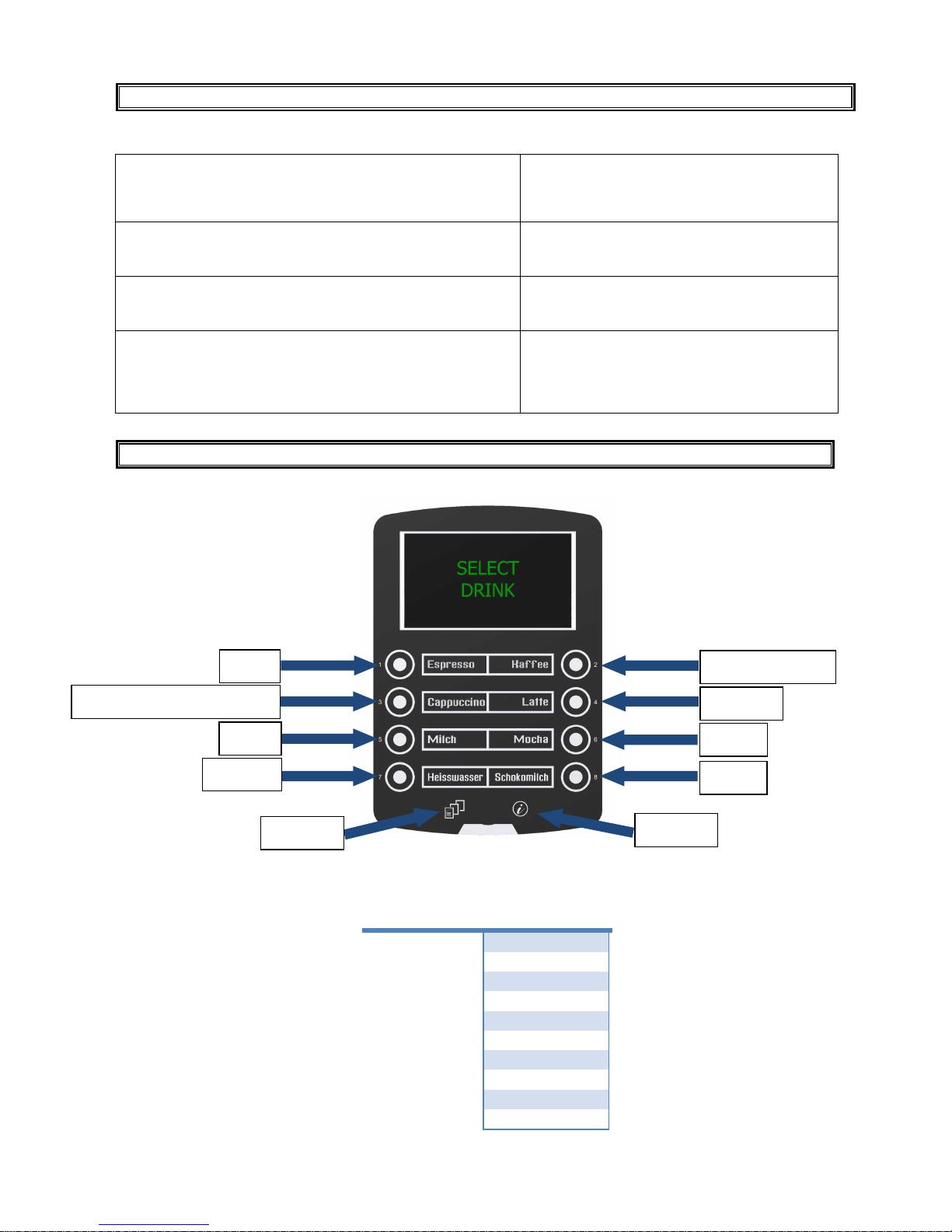

MACHINE KEYPAD

DOSE KEY

FUNCTION

1

Edit

2

Insert blank

3

Delete character

4

Scroll

5

-

6

+

7

Enter

8

Esc

SHIFT

Shift

INFO

Info

Machine type: MULTI SMART

Coffee / Steam boiler heating element 2.7 KW, boiler 4 lt

Machine load 0.940 KW

Environment temperature: 21°C

MEASUREMENT

1. HEAT UP PHASE

To reach operational steam/coffee boiler temperature, 124°C, in 8’.20” (min, sec)

Consumption 0.3 KW/h

HU = 300W/h

2. IDLE PHASE

Stand by at steam/coffee boiler at 124°C during 24 hours

Consumption 3.2 KW/24h

IM = 3200 W/h

3. VENDING PHASE

Delivery of No. 30 cups of coffee of 100ml, one cup every 2 minutes

L = 0.090 Litre

DV = 2700 ml

VM = 450 W/h (vending phase)

DT = 84,4° C (average drink temperature)

ECPL = 166,6 Wh/l (energy consumption per litre)

EDIT

DELETE

CHARACTER

-

ENTER

INSERT BLANK

SCROLL

+

ESC

SHIFT

INFO

LB.05080.00 Pag.8 16/04/2014

ELECTRIC - HYDRAULIC CONNECTION

H2O IN

(1-6 Bar)

H2O OUT

WATER

SOFTNER

WATER

LB.05080.00 Pag.9 16/04/2014

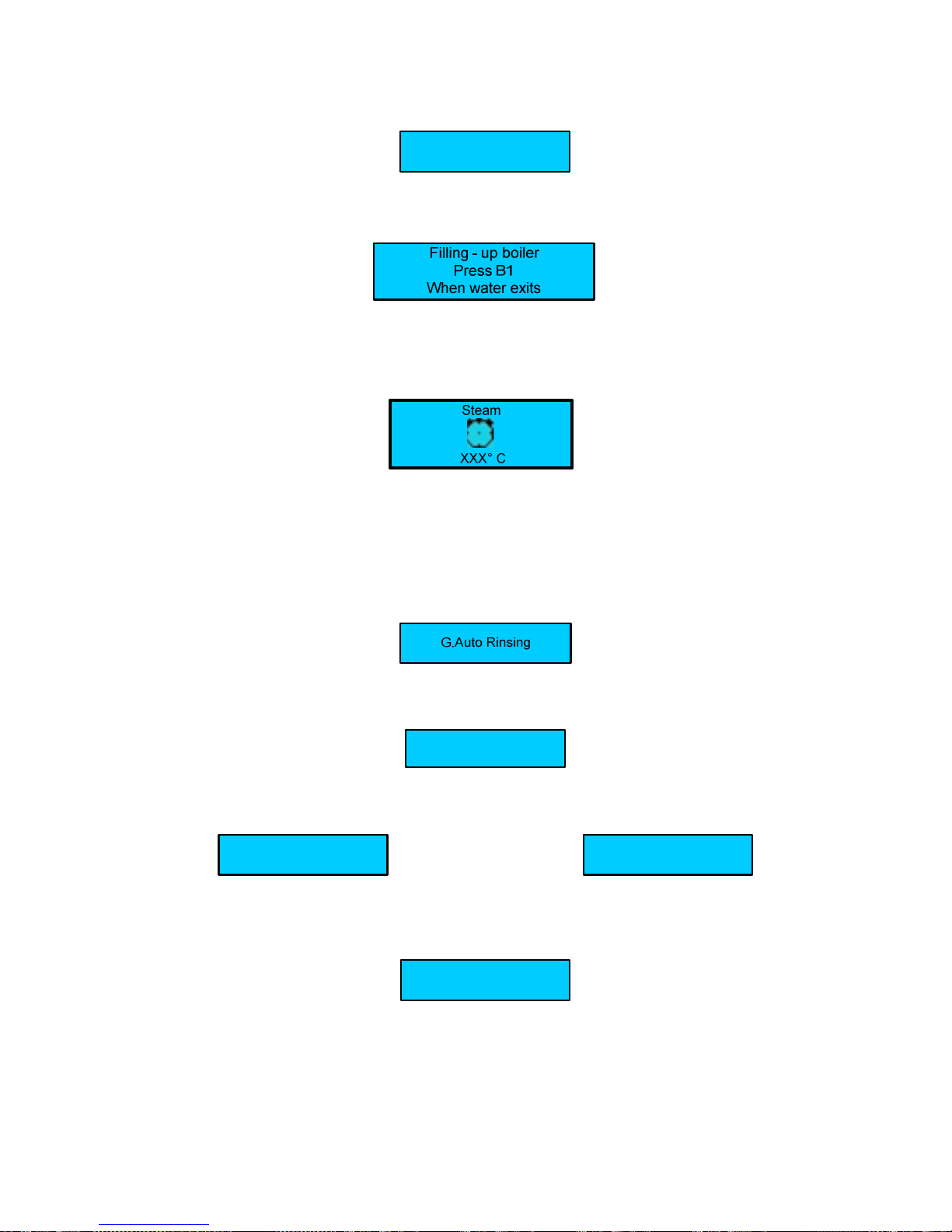

STARTING UP

After having connected the machine to the water and electric networks, turn the switch on (see diagram).

The display shows:

LB.05080.00 Pag.10 16/04/2014

keep key n°9 (shift) pressed and then press key n° 10 ( info), and the machine will set itself to on state.

Filling - up steam boiler

During this stage the steam boiler is being filled up.

WARNING

: The solenoid valve of the milker steam automatically opens to release the air inside the boiler.

When the steam boiler has been filled up, the display shows:

During this stage the exchanger is being filled up

WARNING

:

The upper piston of the coffee group positions itself inside the brewing chamber, and the exchanger starts filling up. When

the coffee spout starts dispensing water, press the key dose N° 1 to confirm that the filling up procedure has been carried

out. When the exchanger has been filled up, the display shows:

Where:

- XXX ° C indicates the temperature of the Steam boiler

WARNING

:

A) DURING THIS STAGE THE MILK FROTHER SOLENOID VALVE WILL STAY OPEN UNTIL 95°C. THIS WILL RELEASE THE AIR

FROM THE BOILER.

B)

WHEN THE BOILER TEMPERATURE OF 50°C ITS REACHED THE MACHINE CARRY-OUT A RINSING GROUP, THIS IS

USEFULL TO RELEASE AIR FROM THE WATER COFFEE CIRCUIT; THE DISPLAY WILL SHOW :

When the set-up temperature is reached , the display shows:

For machine configurations: Standard.

Select drink

For machine configurations: Self.

The display shows:

Select drink

Alternated with the message:

Position the cup

For machine configuration: Self with coin box.

The display shows:

Select Drink

WARNING:

a) For Self with coin box configuration the selections doses are enabled only when the set-up temperature has

been reached.

b) To switch ON the machine on every type of Self – configuration, keep key n°9 (shift) pressed and then press key n° 10

( info), the display shows:

LB.05080.00 Pag.11 16/04/2014

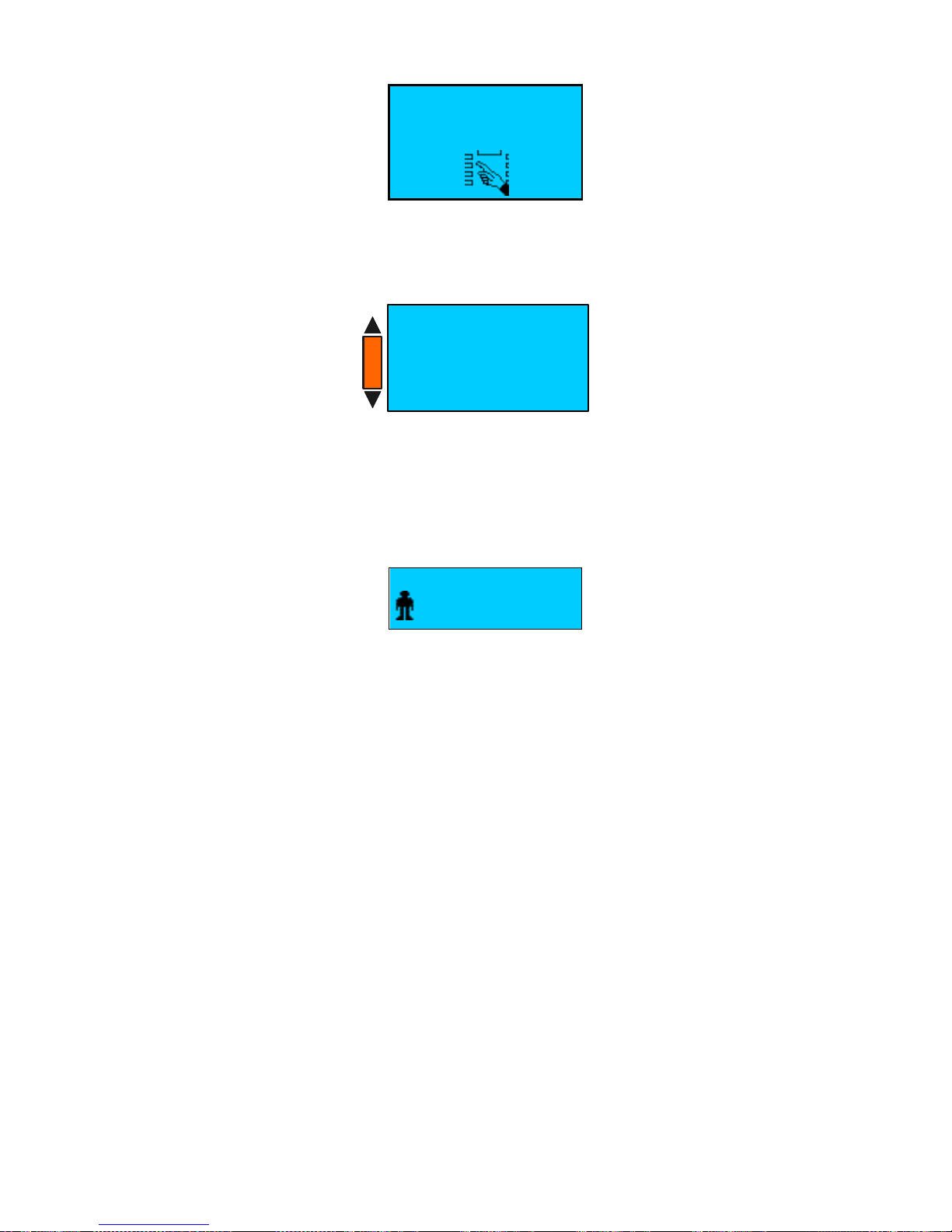

After insert the password ( 61111 ) the machine goes to on.

To switch OFF the machine, open the front door or place the smart card and keep key n°9 (shift) pressed and then press

key n° 10 ( info) ; or keep key n° 9 (shift) pressed for 5 seconds, and after insert the password, the display shows:

Press the key n°6 ( + ) to select OFF and then press the key n°7 ( Enter ) to confirm.

c) In case of temporary voltage drop, the machine will be automatically turned back to the stage previous to the voltage

drop.

If the display shows:

SELECT DRINK

Steam not ready

The displayed message indicates that the set up heating temperature in the steam boiler has not been reached yet, and

therefore milk based dispensing are not enabled.

In that case wait until the boiler has reached the set up heating temperature.

INSERT PASSWORD

TO TURN ON

- - - - -

Select

- Clean

- OFF

- Read dose data

B5 - + B6

B7 Enter Esc B8

+

-

LB.05080.00 Pag.12 16/04/2014

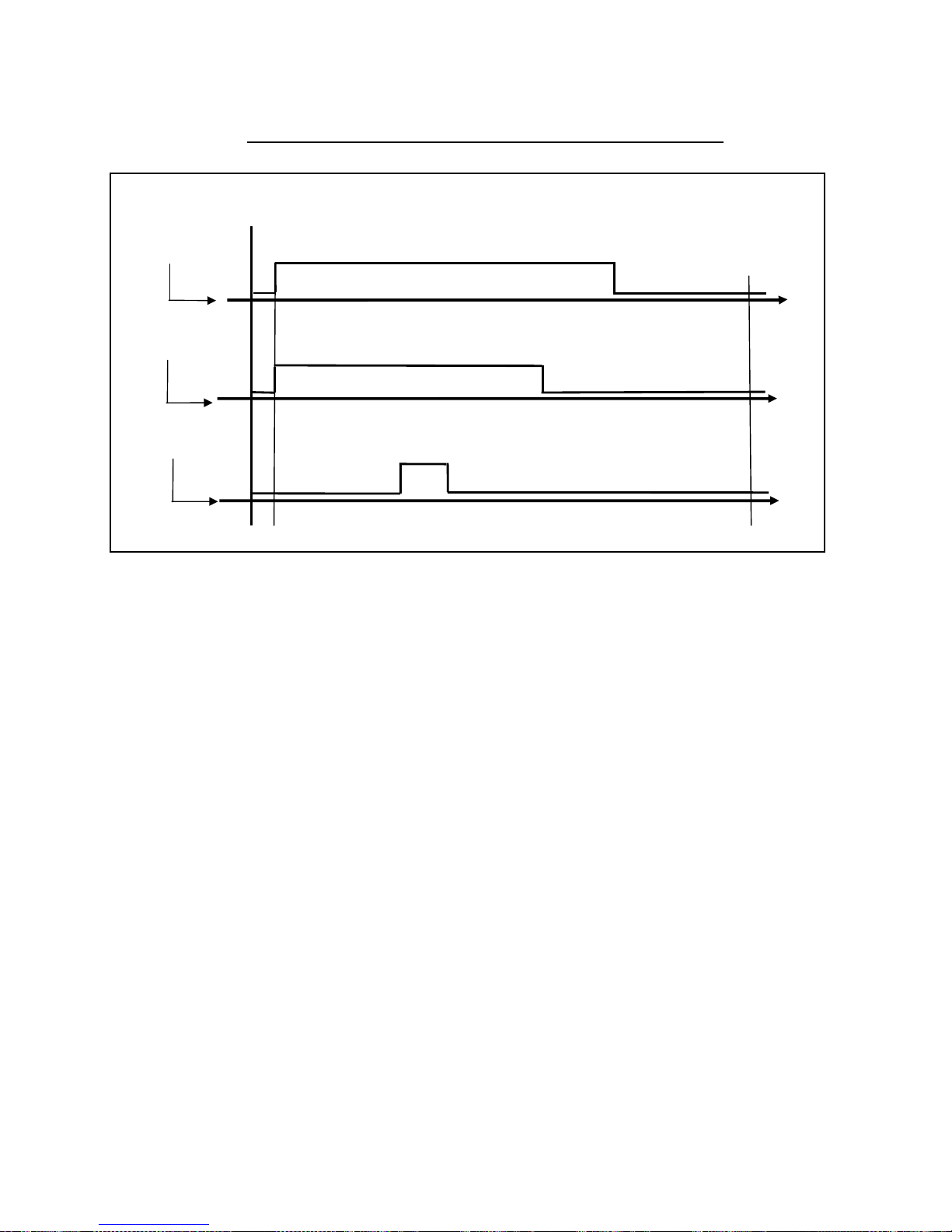

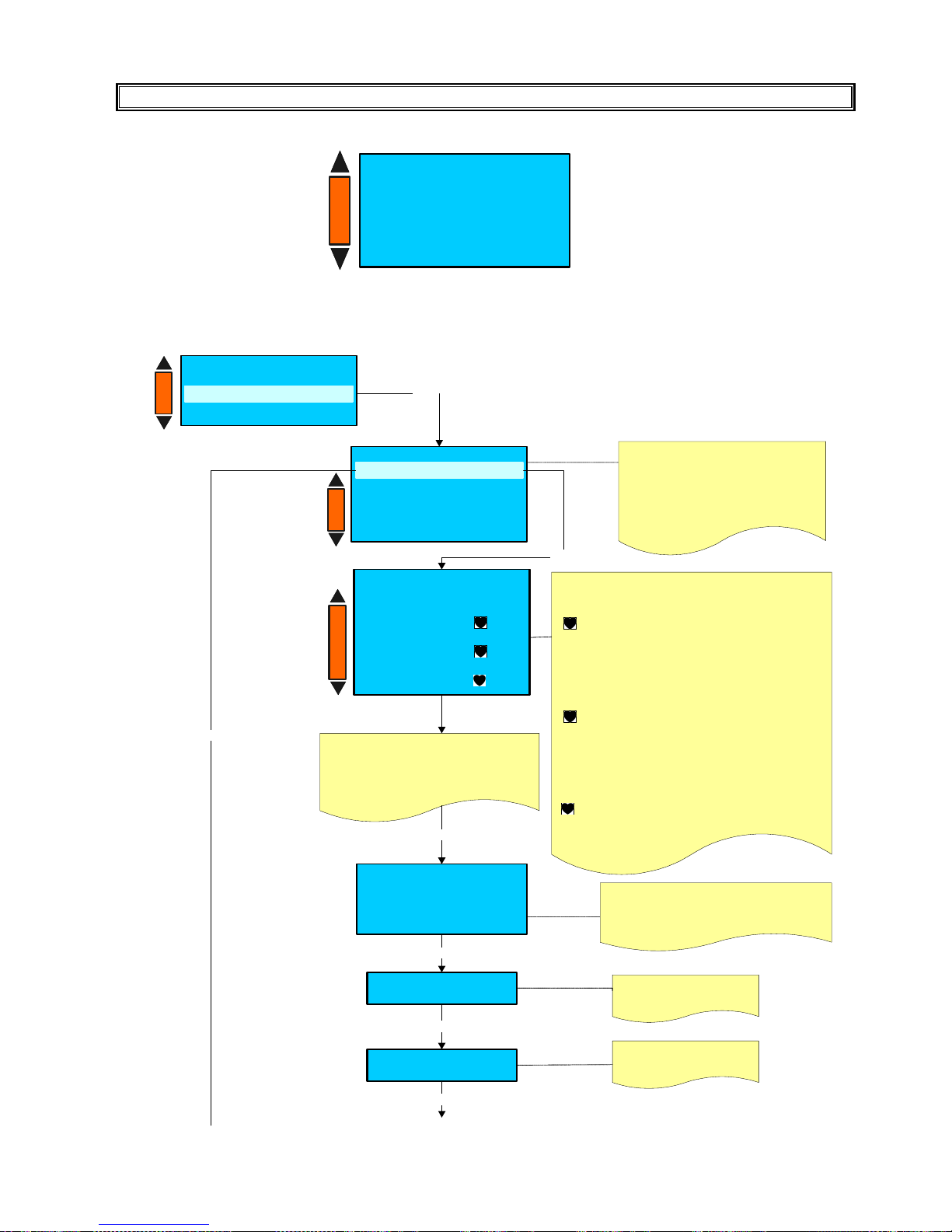

SCHEMATIC SUMMARY OF STEAM AND COFFEE BOILER HEATING PHASE

Heating element On

Temperature sensor

(

Please Wait )

Steam boiler Heating element Off

ON

Set-up ( Select Drink )

OFF

0 °C

°C

Milk frother

solenoid valve

Solenoid valve open

ON

OFF

Solenoid valve close

0 °C

95°C °C

Coffee group

solenoid valve

Rinsing phase

ON

OFF 50°C

°C

LB.05080.00 Pag.13 16/04/2014

ACCESS THE MAIN SETTING MENUS WITH PASSWORD

A) ACCESS THE MAIN SETTING MENUS WITH PASSWORD

To enter the programming environments, a password is required which define the access rights to the different

environments.

The password must be composed with 5 numbers.

To insert the passwords proceed as follows:

- Turn the machine OFF

- Keep N°9 “SHIFT” key pressed for 5 seconds. The display shows:

Enter one of the following passwords:

- Waiter 6 1 1 1 1

- Roaster 1 1 1 1 1

- Owner 2 2 2 2 2

- Service 3 3 3 3 3

- Technician ( for Technician password contact the Carimali S.p.A. Technical Service ).

After insert the password the display shows the main menu programming environments:

KEY REFERENCE FOR PASSWORD

INSERT PASSWORD

- - - - -

Select

- Info reset

- Dose programming

- System manager

+

-

LED

1

3

5

7

2

4

6

8

LB.05080.00 Pag.14 16/04/2014

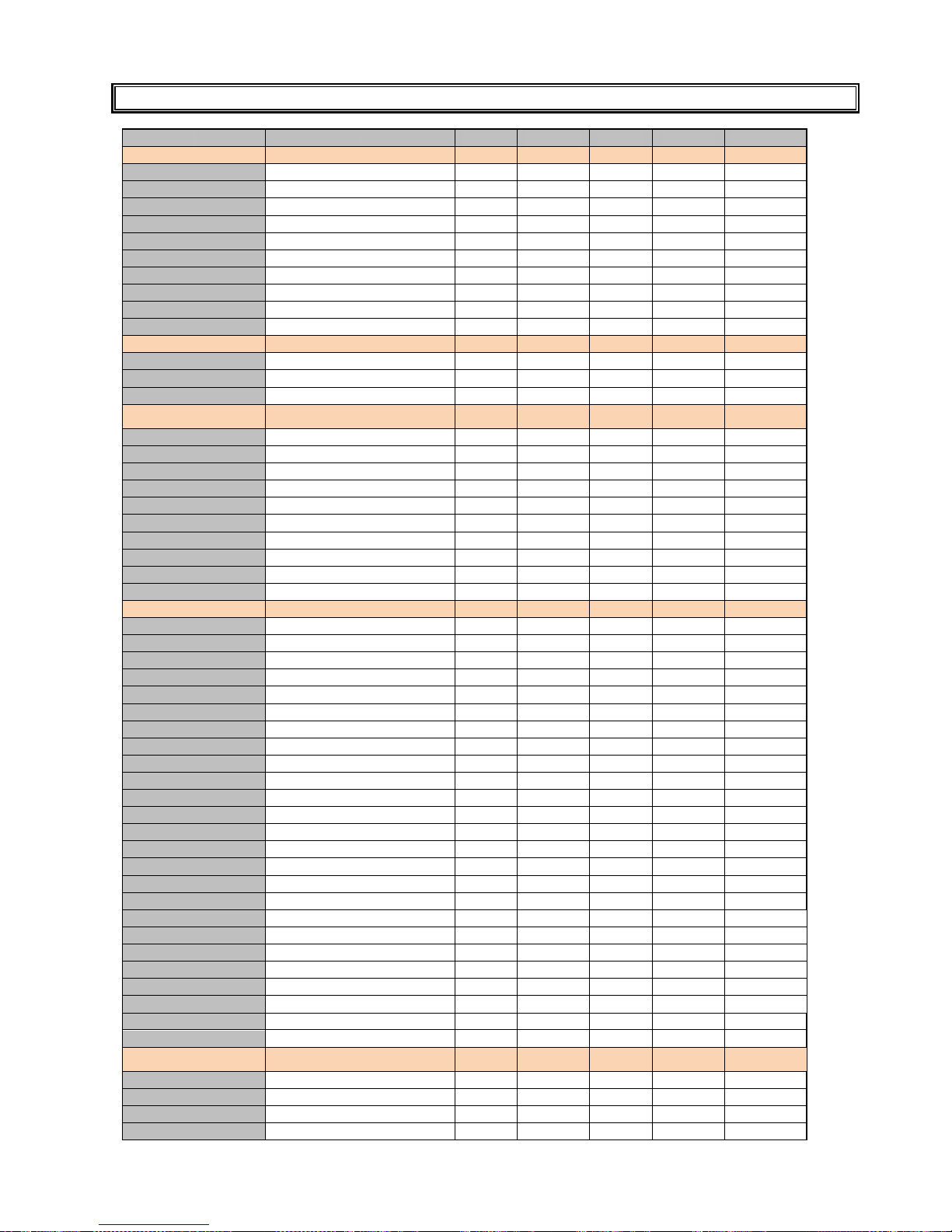

PROGRAMMABLE PARAMETERS IN ACCORDING WITH PASSWORD

WAITER ROASTER OWNER SERVICE TECHNICIAN

INFO - RESET

Reard dose data Douse counter A

X X X X X

Douse counter B

X X X X X

System data Group cleaning

X X

Milker cleaning

X X

Power cleaner

Grinder cycles

X X

Water filter

X X

Group cycles

X X

Total group cycles

X X

Total machine cycles

X X

DOSE PROGRAMMING

Set doses

X X

Price set-up

X X X

Grinder-milker calib.

X X

MACHINE

CONFIGURATION

Main power 200-400v/ 100-120v

X X

Water tank

X

Mix cold water Desabled/Enabled

X

Steam nozze Desabled/Enabled

X

Milker Desabled/Enabled

X

Milk pump Desabled/Enabled

X

Power cleaner Desabled/Enabled

X

Fridge Disable/ Enable

X

Machine type

X

Remote controller

X

MACHINE PARAMETER

Language

X X

Serial Disable/Enable

X X X

Ground N°

X X X X X

Waiting time coffee dose A-B

X

Additional coffee water

X

Rinse after milk dose

X

Waiting time milk dose A-B

X

Additional milk

X

Decimal price

X

Scale factor price

X

Multi vending

X

Token

X

Max credit on card

X

Alarm detail

X

Temp. Misure unit

X

Steam temperature

X° X° X° X X

Keyboard sound

X X

Manual clearing sound

X

Gsm: Sim card pin

X X

Gsm: Service phone number

X X

Modem set-up parameters

X X

Remote password

X X

User message

X X X X X

Serial N°

X X

Installation date

X X

SYSTEM CLOCK

PROGRAMMING

YY-MM-DD Day HH:MM

X° X° X° X X

Clock display Enable/Disable

X X X

Auto start –up Disable/ Enable

X X X

On - Off

X X X

LB.05080.00 Pag.15 16/04/2014

Day Off

X X X

DISPLAY REGULATION

Contrast

X X X

Display mode

X X X

Default colour

X X X

Color shift menu 1

X

Color shift menu 2

X

SERVICE

Clean/Rinse Cleaning time

X X X X

Cycle cleaning alarm

X

Group cleaning Programming

X

Group auto rinsing

X X X X

Milker cleaning program.

X

Milker auto rinsing

X

Maintenance set -up

Water filter

X X

Machine service

X X

Grinders

X X

Group cycles

X X

CHANGE PASSWORD

Turn ON password

X

Roaster

X X X X

Owner

X X X

Service

X X

Technician

X

GROUP MANUAL

MOVEMENTS

Group manual movements

X X

TEST ACTUATORS

Test actuators 1-2-3

X X

Milk pump speed

X X

BOILER DRANING

Boiler draining

X X

ALARM HISTORY

Alarm history

X° X° X° X X

PRESET CONF. DATA X X

Preset configuration data

X X

Where X indicate the available program and X° indicate the partial available program.

N.B. :

A) If the “ PRESET CONFIGURATION DATA “ is done with the password will be reseted only the service accessible

parameters.

LB.05080.00 Pag.16 16/04/2014

INFO-RESET

A1) READ DOSES DATA ( Doses counter A/B )

Enter

Info reset

- System data

Read doses data

Read doses data

- D oses counter B

- R eset doses counter A

- R eset doses counter B

Doses counter A

Enter

Doses counter A

BX XXXXXX

YY Y

B X² XXXXXX

ZZ Z

BX ³ XXXXXX

JJ J

Press the + / - keys to select the count A

or B.

Is possible read two counter A or B,

which can be use one for the total

number of the dispensed daily doses and

another for the total number of the

dispensed weekly or monthly doses .

BX Indicates the number of the key.

XXXXX Indicates the nam e of the selected key.

YY Indicates the number of cups dispensed

Y Indicates the number of decaffeinated

dispensed cups.

BX² XXXXX Indicates the name of the selected

key of the second dose keys menu ( SHIFT

pressed once )

ZZ Indicates the number of the cups dispensed.

Z Indicates the number of decaffeinated

dispensed cups.

BX ³ XXXXX Indicates the name of the selected

key of the third dose keys menu (SHIFT pressed

twice)

JJ Indicates the num ber of the cups

J Indicates the number of decaffeinated

dispensed cups.

Press + / - to select the keys between

B1 to B8 first dose keys menù

B1² to B8² second dose keys menù

B1³ to B8³ third dose keys menù

Group cleaning

X

X : Indicates the n° of Extra

milk carried out

Extra milk

X

Enter

X : Indicates the n° of Group

cleaning carried out

Enter

Total Dose Y

X

Last reset

YYYY - M M - DD - HH:MM

Y: Indicates the couter A o B

X : Indicates the total dose delivered

YYYY - MM - DD - HH:MM

: Indicates the

date and time of the last reset doses counter.

Enter

Enter

Enter

+

-

+

-

+

-

Info reset

- Read doses data

- System data

+

-

LB.05080.00 Pag.17 16/04/2014

A2) READ DOSES DATA ( Reset doses counter A/B )

En ter

In fo res et

- S yste m d a ta

R ea d d os es d ata

R ead d ose s d ata

- D os es c o un ter A

- D os es c o un ter B

- R es et d ose s c ou nte r B

R e se t D o ses c o un te r A

W IT H T H IS O P ER A T IO N W E

R ES ET O N LY TH E D O SE S

C OU N T – E XT RA M IL K A N D

TO T AL C A SH IN G

+ / -

N o

Y e s

En ter

R ese t D ose s C ou nter

P le ase co nfirm

R ese t D ose s C ou nter

Pre s s the + / - ke y s to se le c t

th e co u nt A o r B .

E n ter

E n ter

+

-

+

-

Loading...

Loading...