User manual

IM

DLP

3D printer

IM Series

s e R I E S

II

III

IV

V

Soft ware Install and Using

Preparing and Printing

Check Output

Maintenance

01

Carima-Slicer Install

02

Carima-Slicer Using

01

Printing Preparation

02

03

LCD Panel Using Method

Start Printing

01

Output Demount

02

After Output Processing

01

Printer Maintain

02

03

Other Maintain

FAQ

11

13

31

33

40

44

45

50

51

53

I

IM Series Introduction

01

IM Series Information

01

02

03

04

Component Name

Precaution

Whole Process

02

03

07

05

IM Series compatible material

08

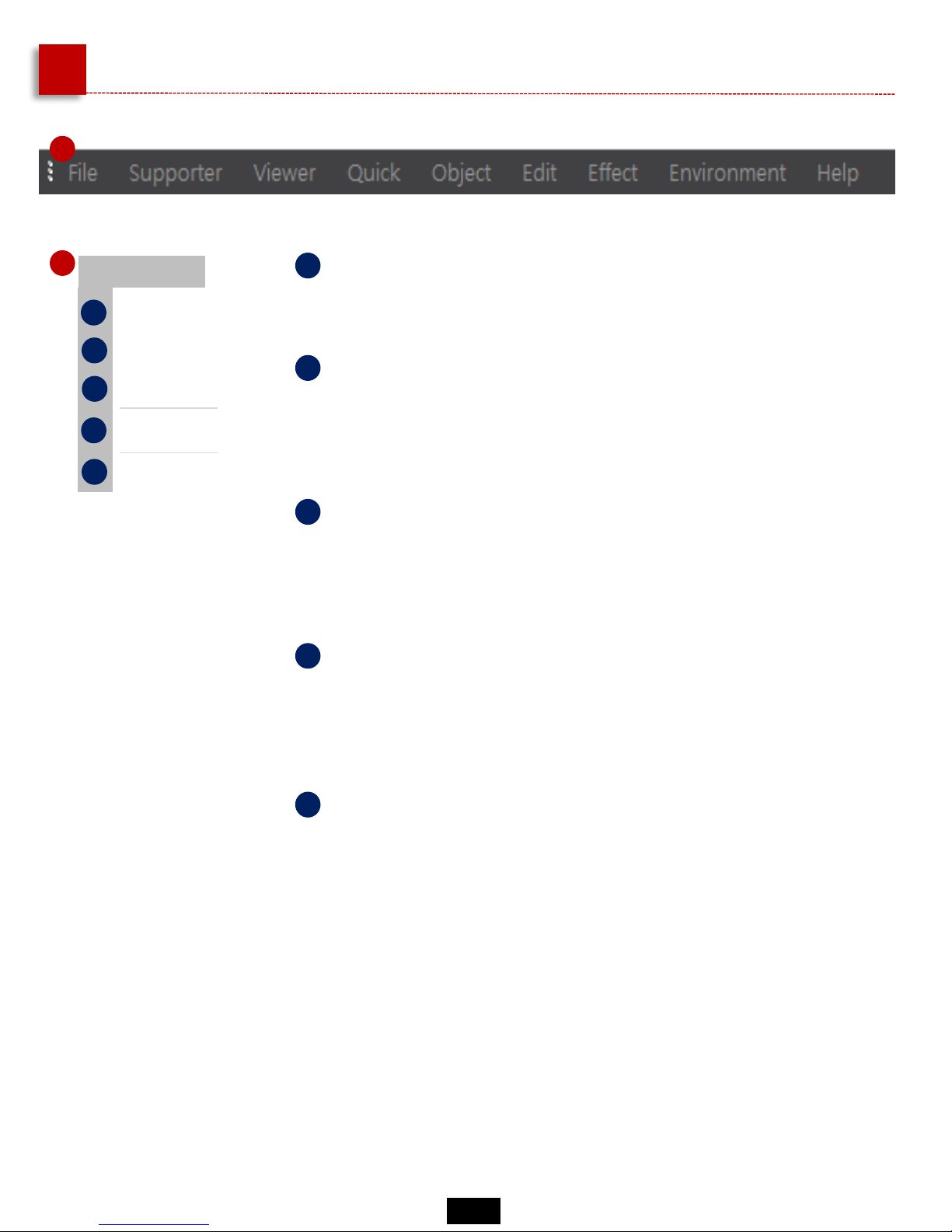

C O N T E N T S

DLP Print Method

What is DLP 3D Printing?

DLP: Digital Light Processing Mask Projection Image Hardening Method

• A cross-section photograph of the output is laminated by irradiating the photo-curable liquid

resin with UV light..

• Due to the optical mask, the cross-sectional photograph of the output is totally inspected.

• Because of this surface unit lamination method, the output speed is fast and the surface

roughness high, so it is possible to make use of precision.

I IM Series Introduction

Hello.

This manual provides instructions on how to use the "IM Series".

Understand how to use "IM Series" through the manual and

experience "IM Series" easily and conveniently.

Check List

01 IM Series Information

02

03

04

Component

Precaution

Whole Process

05

IM Series compatible material

I IM Series Introduction

01. IM Series Information

IM Series is an ultra-precise DLP 3D printer, the most suitable printer to

implement a precise model, and is a 3D printer commonly used in the Design,

Jewelry, and Dental industries.

Model Name IM Series

Resolution 1980 X 1080

Light Source UV LED

Printing Size(mm)

96 × 54 × 150 110 × 85 × 200

130 × 74 × 100

Lamination

Thickness(mm)

0.025 / 0.05 / 0.075 / 0.1

Precision 50 μm

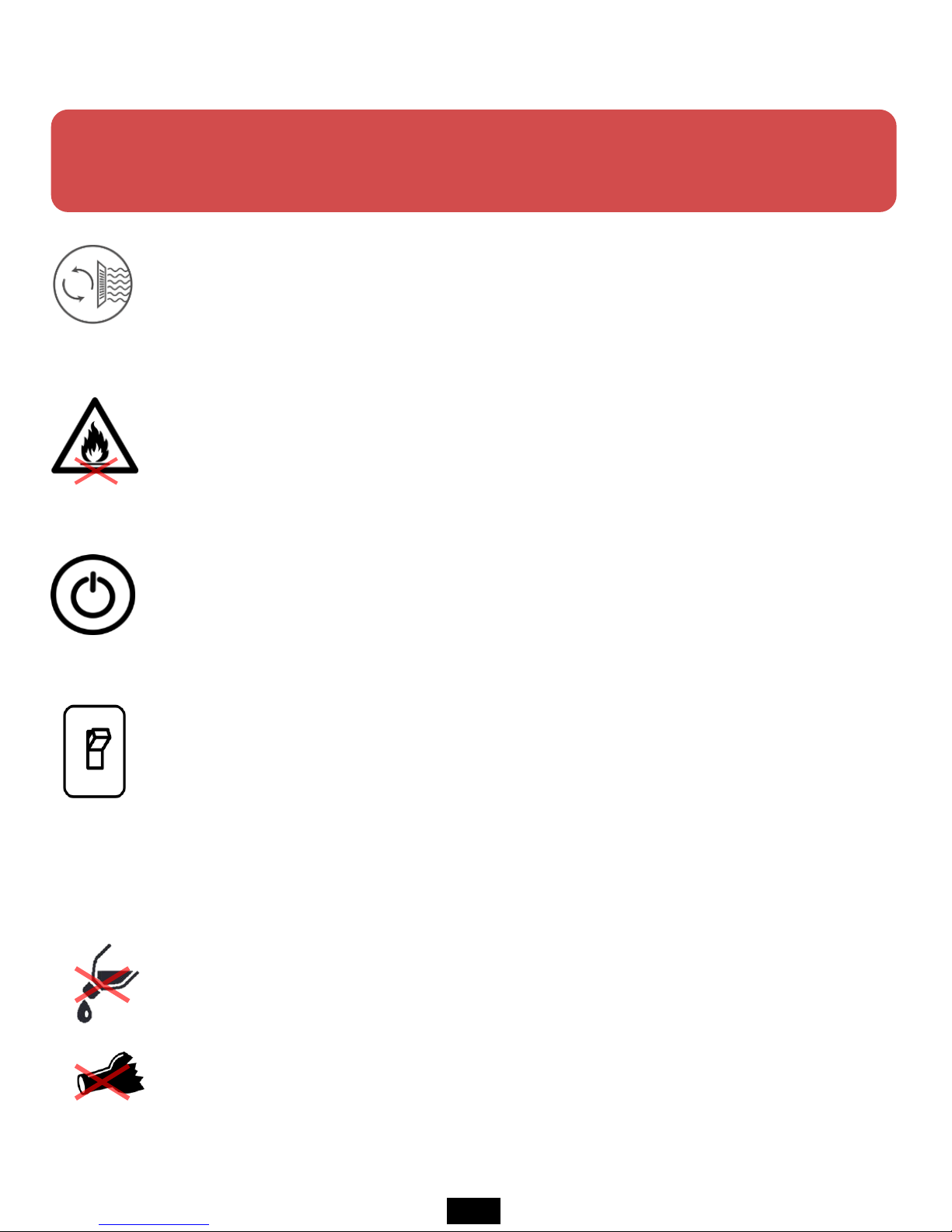

Product Size(mm) 304 x 315 x 622

Weight(kg) 22

Power 100-240V, 50/60Hz, 2.5A, 260W

Material DLP, SLA Resin

Control Type Control method using embedded touch screen

Using

Environment

18-26 (℃) / 20% - 50% (% humidity)

+

If you use the printer in this environment, it will help you to printing better.

1

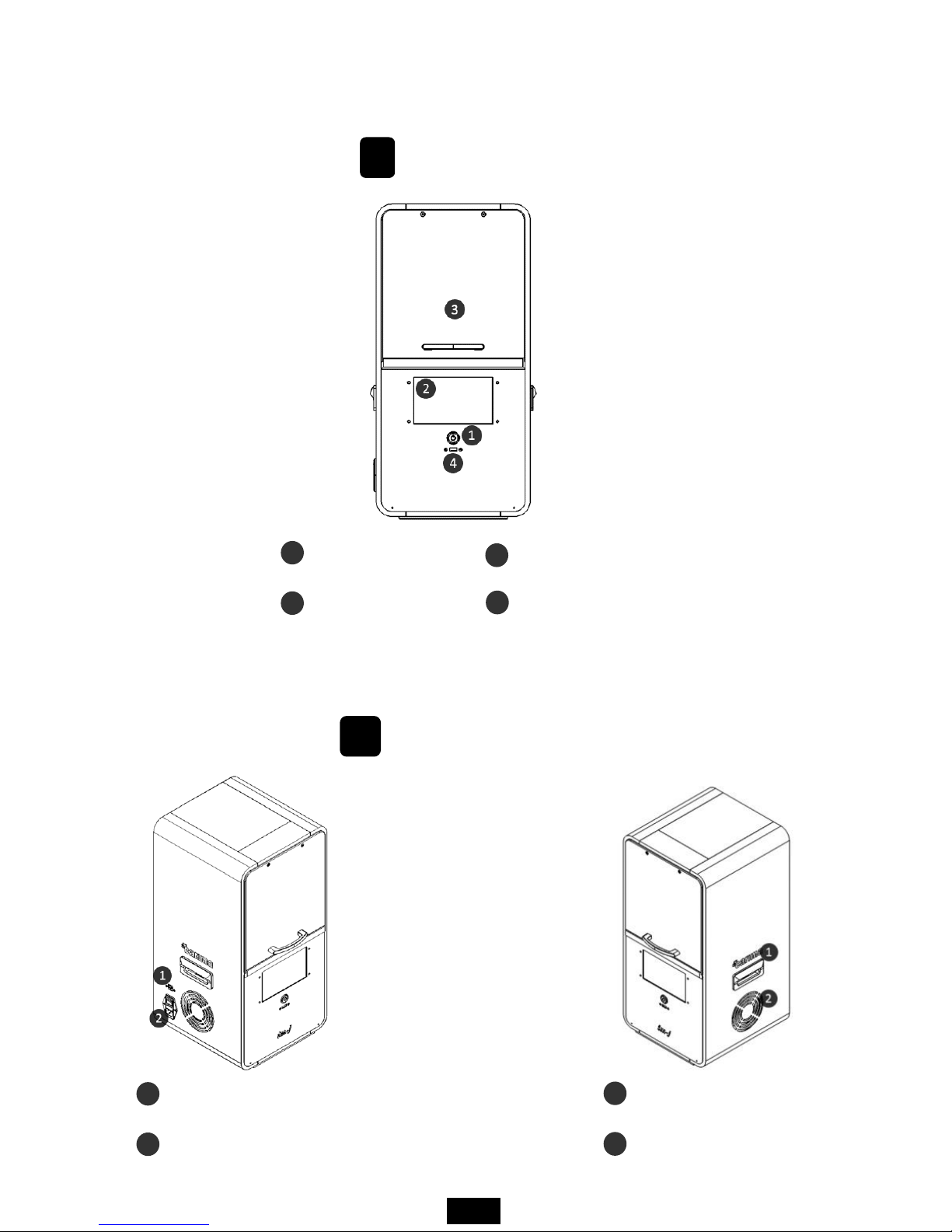

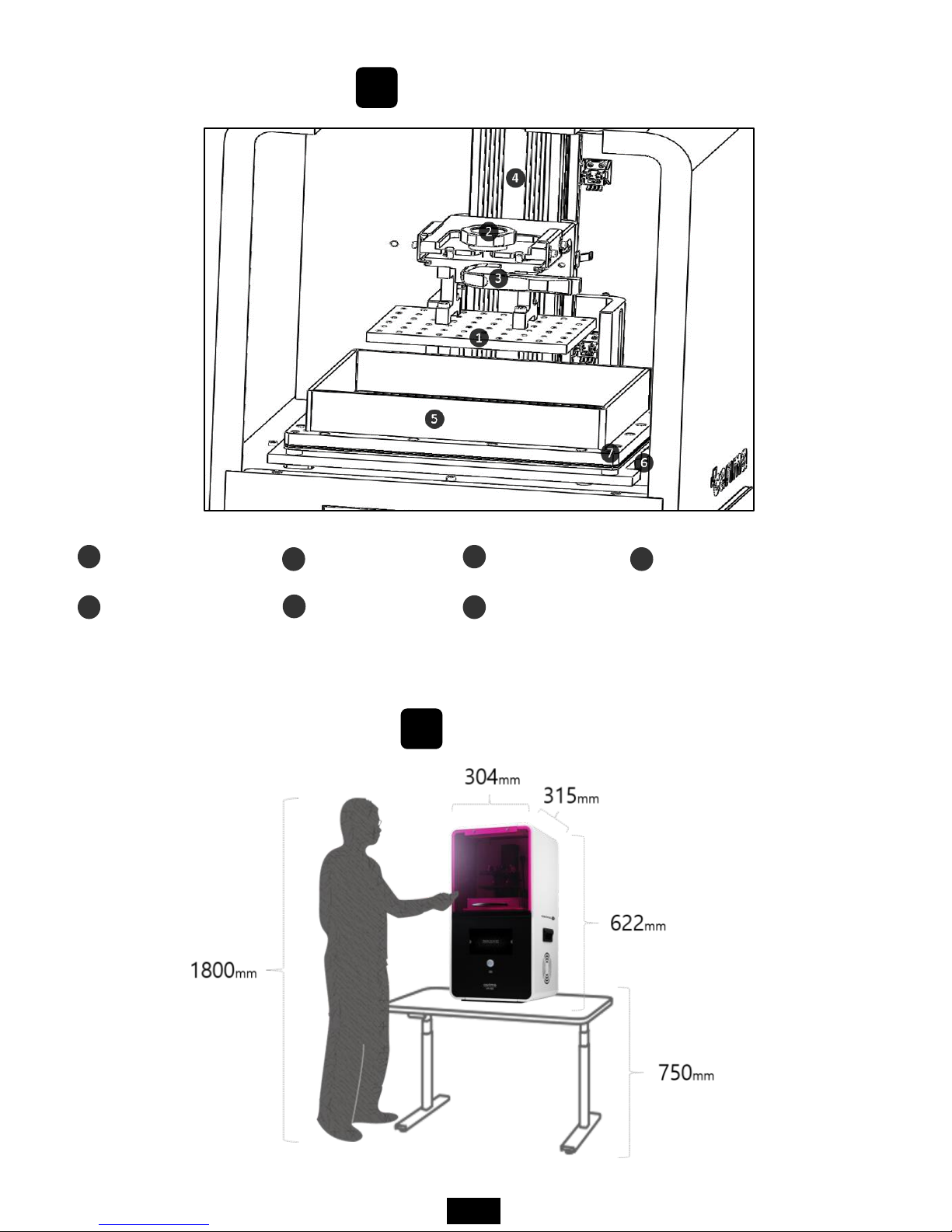

02. Component

A

Front

LED Power Button

LCD Touch Screen

Print Room Cover

USB Port

1

2

3

4

B

Equal Angles

Ethernet port

Power cable ports and switches

1

2

handle

Low Noise Cooling Fan

1

2

2

C

internal structure

Plastic plate

Open sheet tray

Plate fixing pin

Tray tilting axis

1

5

2

6

Plate handle

Tray fixing hex screw

plate vertical movement axis

3

7

4

D

Real Size

3

03. Precaution

This information is intended to protect your safety and property damage.

For your safety, please be aware of the precautions to prevent personal injury or printer damage.

When you print out the printer, it may cause the resin to smell distinctive, so

please install the printer in a well-ventilated place.

When using volatile objects near the printer, do not use it because there is a

risk of fire or explosion.

When moving the printer, be sure to completely shut down the printer, and

then remove the resin or tray to avoid overflowing the resin in the tray.

If the printer is on, do not off the power switch located on the back of the

printer. Forcible termination can shorten the life of the printer engine and

cause mechanical failure. Press the Exit button on the LCD panel to shut down

the printer.

If some objects such as water or other liquids, metal chips, or other conductive

materials are introduced into the printer, it may adversely affect the printer,

such as mechanical malfunction. In addition, do not operate with wet hands

because of the risk of electric shock, please wear the nitrile gloves and using.

4

If you touch the door or touch screen strained with gloves or tools, it may

cause malfunction(Touch screen malfunction, door crack, etc.).

If the tray removed while the plate attached after printing, impurities may fall

inside and cause a failure. First, remove the plastic plate, remove the tray

afterwards.

When removing the tray, be careful that the bearings that were used as the

bearing may be lost (If you lose, you may incur costs).

After the output, take out the resin remaining in the tray with a syringe, filtering

residue with a sieve, and store it separately.

If you put the resin in the tray due to frequent work, keep it closed that is not

exposed to the external environment as much as possible.

If the dyestuff of the resin stored in the tray is separated, it must be mixed with

a rubber spatula before printing.(If the sheet is damaged by storing the resin in

the tray for a long period of time, this is the customer's fault.)

After the output is completed, When you remove the plastic plate with the

printout, be sure to move the tray (tray) that supports the resin that falls down

so that the material does not fall inside the product. If the material falls inside

the product, it may cause deformation or breakdown.

5

If the printer power cable and USB cable are damaged due to being pulled or

stepped on the rough surface, please note that sparking or voltage

malfunction may occur. Also, if there is a lot of current in the power cord or

outlet, there is a risk of fire due to overheating.

The printer has potential risks in terms of chemical composition and voltage.

To prevent injuries to children and pets, install a printer in a safe place to

prevent accidents.

If the printer is installed in a location where there is a lot of humidity or

temperature changes, it may cause deformation or malfunction of the product.

If you disassembling or remodeling the printer artificially, the warranty benefits

will be lost and you will not be held liable for any loss caused by this.

For inquiries regarding A/S inquiries and product warranty, please contact

Carima Co., Ltd. for a friendly consultation.(82-2-3663-8877).

Malfunction or trouble due to non-compliance, tuning, disassembly, etc. are

recognized as customer errors and will be charged during the warranty period.

6

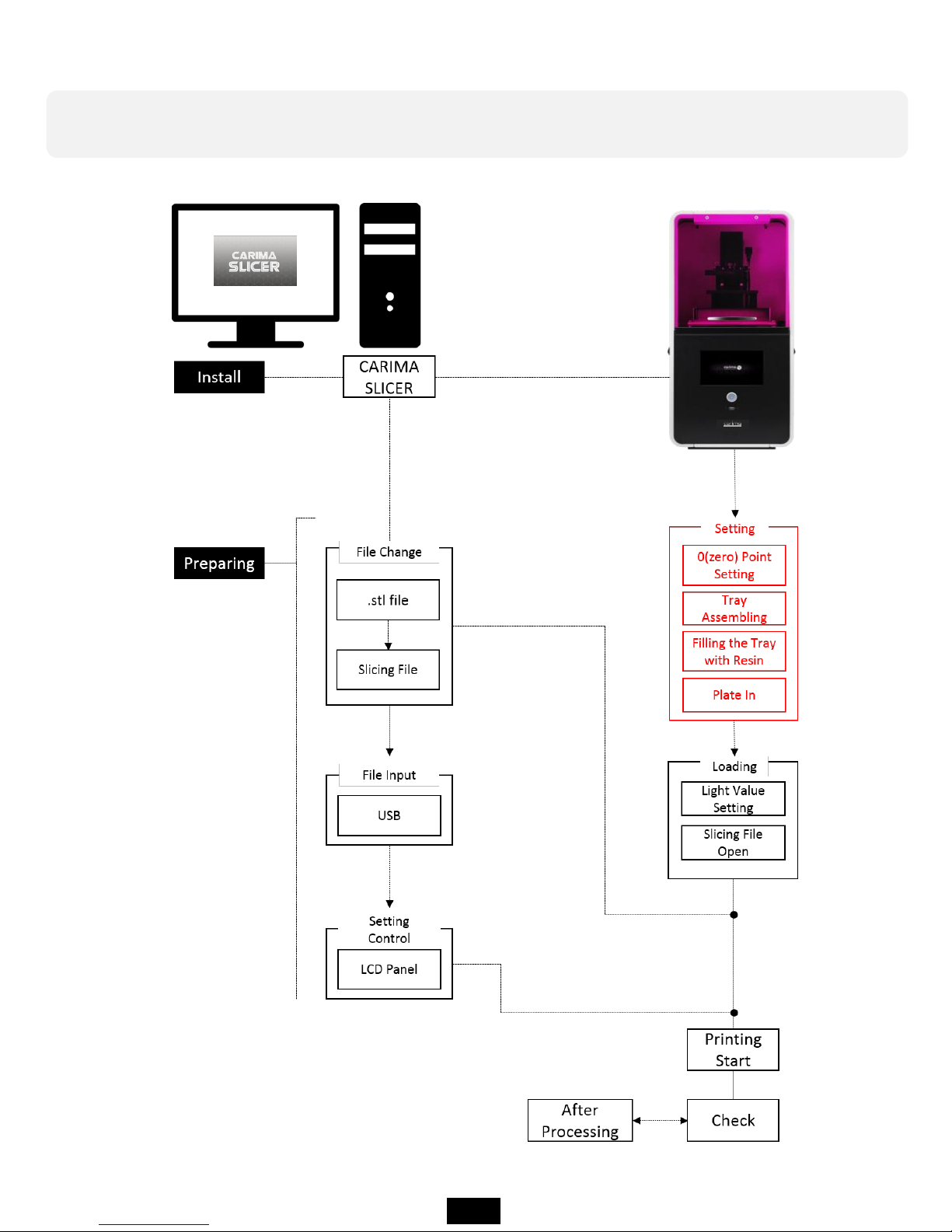

04. Whole Process

In order to output to IM Series, you have to go through the following

procedure.

7

IM Series

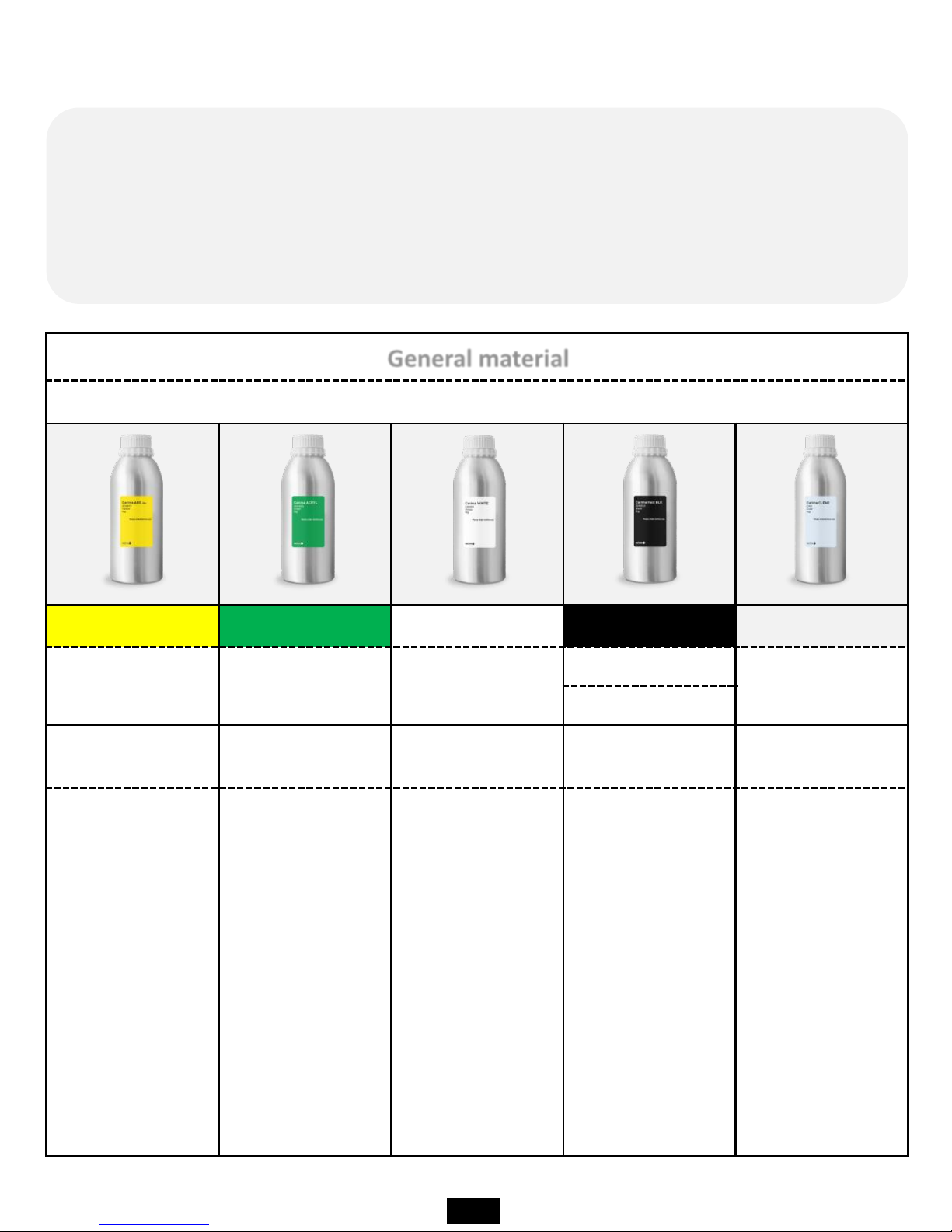

General material

Plastic-based material

Carima ABS-like Carima ACRYL Carima WHITE Carima Fast BLK Carima CLEAR

ABS-3DK83Y ACRYL-3DK83G WHITE-CRM011

Fast BLK-3DKBLK

CLEAR-CRM

CAM008

Prototype

Mock-up

Prototype

Mock-up

Prototype

Mock-up

Prototype

Mock-up

Prototype

Mock-up

Yellow-based

prototypes or

materials that

can be used for

3D modeling in

general.

For green-based

prototypes or for

the production of

full-scale models,

it is generally

possible to use

3D printing with

ABS.

It is a material

that can perform

3D printing work

for white base

prototype or real

size model

production.

It is a black

plastic type

general material

that Carima

developed in-

house, and it is

possible to

realize high

reactivity and

precision.

Transparent

prototypes,

transparent

materials that

can be modeled

on a full scale.

05. IM Series compatible material

The IM Series can be used for 3D printing using materials of various

characteristics. Among Carima's general material range, IM Series can output

all common materials. (However, I am not sure whether it will be possible to

output special materials other than Carima special materials.)

8

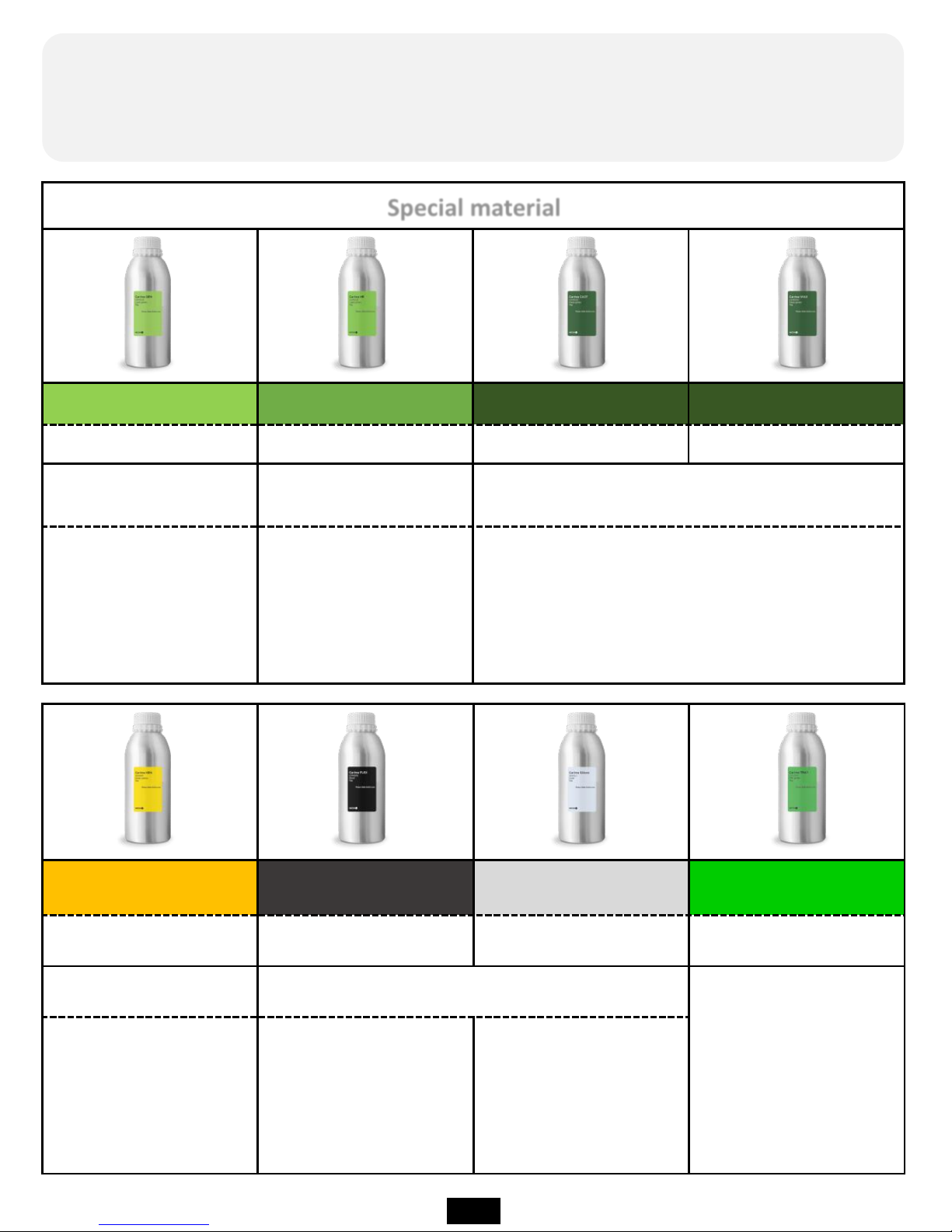

Carima HRN

Carima FLEX Carima Silicon Carima TRAY

HRN-3DKHR1

FLX-CFM005 Silicon-3DKSL1 TRAY-CDV300, CDP011

Heat-resistant material

Flexible material

Dental bracket

dedicated material

Heat-

resistant material

can withstand up to

200 degrees,

yellow base.

Special material with

soft rubber like

features.

Silicon material

Special material

Carima GRN Carima HR Carima CAST Carima WAX

GRN-CRM003 HR-CAM003 CAST-CAM002 WAX-CAM004

Flexible and strength-

based materials

Precision-only material

Precision jewelery output

and casting exclusive material

A material with some

flexibility and strength.

A material capable of

achieving a precision

of about 25 μm to 50

μm.

Rings that require precision, such as necklaces

and accessories The material can be used

professionally from the output of the model.

Among the special materials of Carima, IM Series can output all special

materials(However, I am not sure whether it will be possible to output special

materials other than Carima special materials.)

9

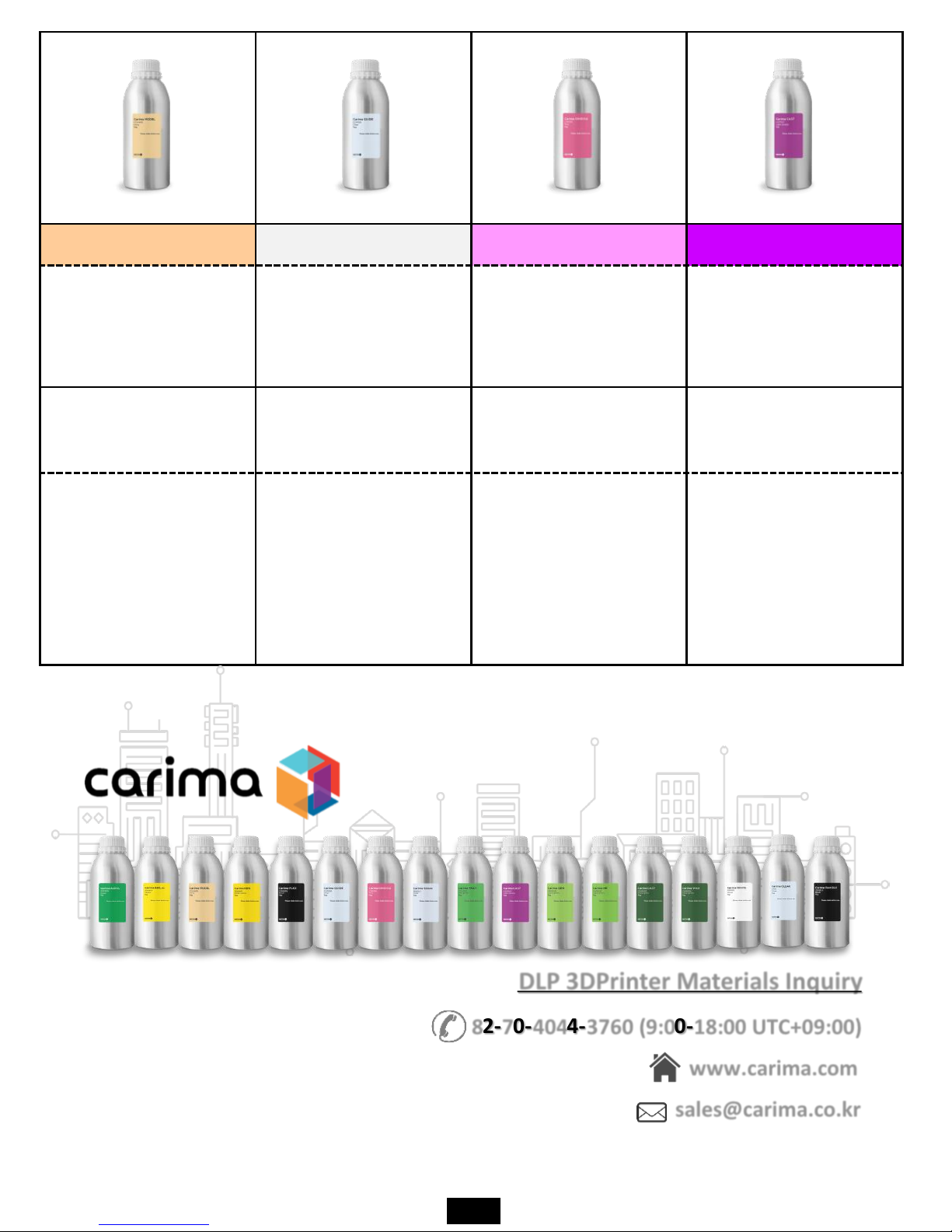

Carima MODEL Carima GUIDE Carima GINGIVA Carima CAST

MODEL-CDV400,

CDP013

GUIDE-CDP010,

CDP001,

CDV600

GINGIVA-CDP015

CAST-CDP012,

CDV100

Dental guide material

Implant guide material Gingiva material

Dental casting only

material

Based on flesh-based

high-precision output

of the dental upper

and lower mandible

Material.

Transparent-based

implant guide only

material.

A material similar to

the gums that can be

used to identify the

shape of the gums that

have subtracted teeth.

A special material that

can open teeth with

gold, silver, etc.

DLP 3DPrinter Materials Inquiry

www.carima.com

sales@carima.co.kr

82-70-4044-3760 (9:00-18:00 UTC+09:00)

10

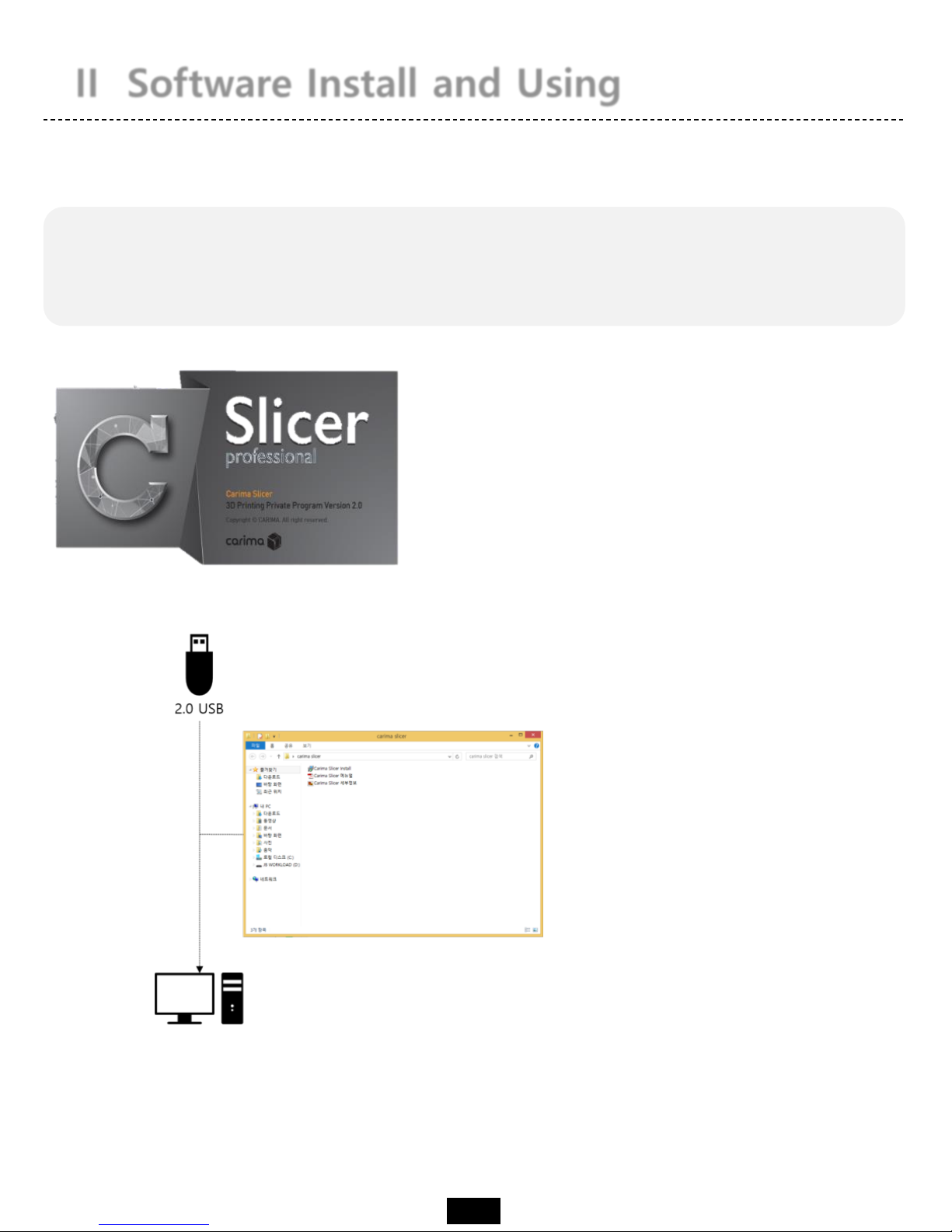

II Software Install and Using

If you are using the IM Series, you must install

the slicer program provided by Carima.

Realize your imagination and experience

creation with Carima Slicer.

Check List

01

Carima Slicer Install

02

Carima Slicer Using

II Software Install and Using

01. Carima Slicer Install

The Carima Slicer is a program that helps you to output from the IM Series.

Carima Slicer is a self-made slicing program

from Carima Co., Ltd. It is a program that

slices each model to output and makes it

into a picture form. It is easy to save it as

file such as stl, jpg, crv.

The Carima Slicer Setup program is attached to the USB

provided by Carima. Install CarimaSLICER with USB.

CarimaSLICER can not be installed on any other PC (or

notebook) other than one PC (or notebook).

★ CarimaSLICER is compatible only with 3D printers manufactured by Carima Co., Ltd.

You can not use CarimaSLICER with other 3D printers.

11

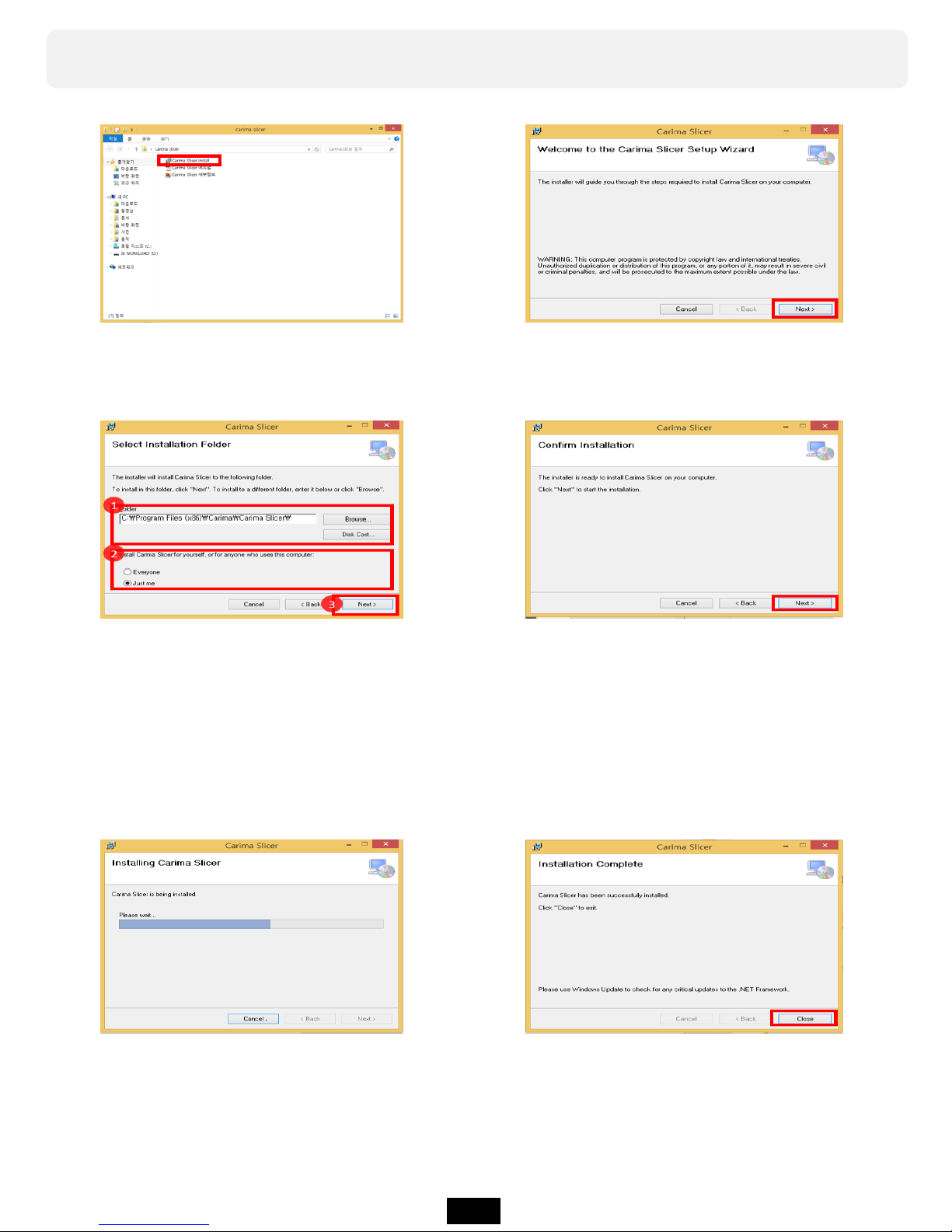

You can install Carima Slicer in the following process.

a. Double-click the Carima-

Slicer Install file.

b. Carima-Slicer Install Setup file

screen. Click Next>.

c. After specifying the path where

Carima-Slicer will be installed,

select one of "Just me" or

"Everyone" of the Windows

account and click Next>.

d. After completing the setup,

please proceed to the final

installation with the message

that installation is completed.

Click Next>.

e. Click Next> to proceed

with the installation.

f. When the installation

is finished, click Close.

12

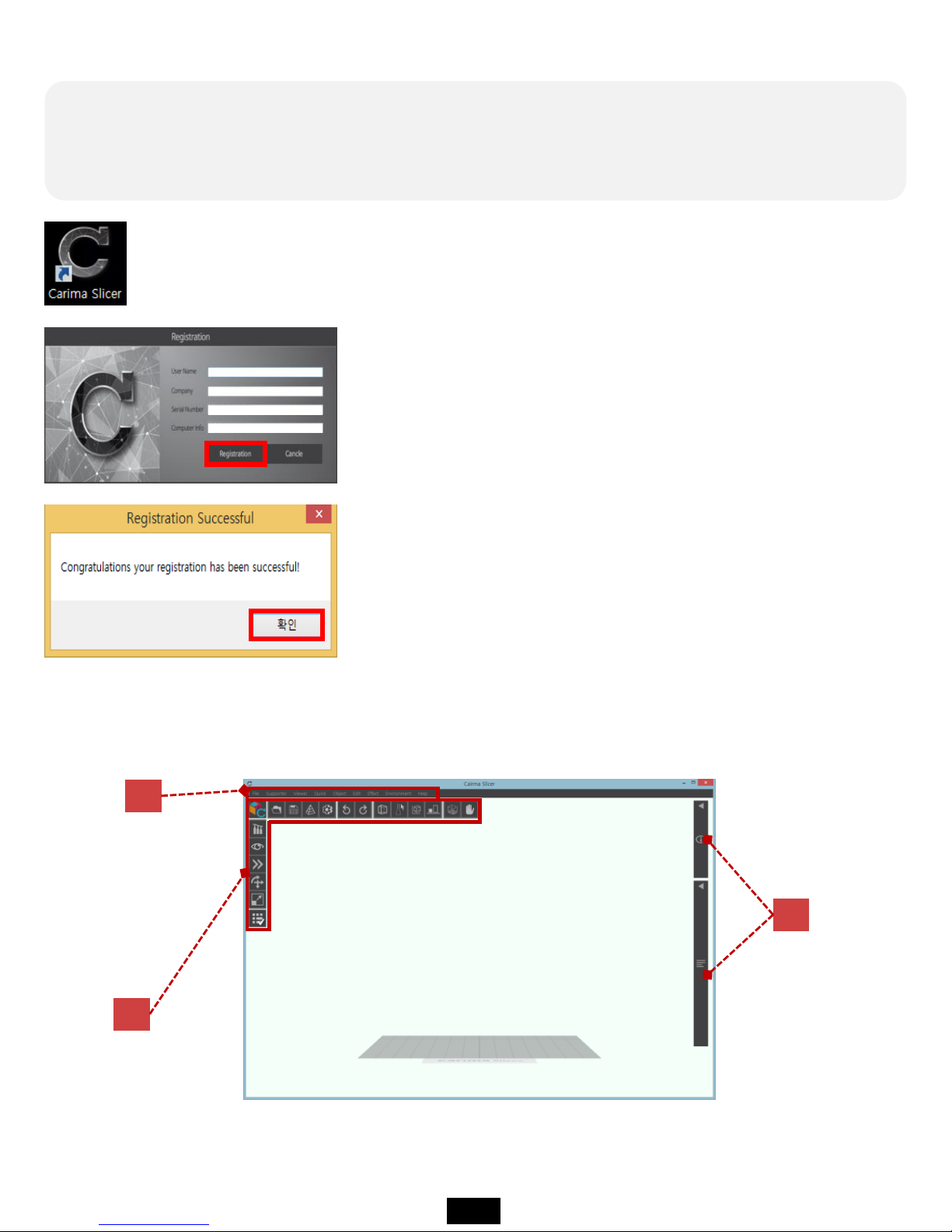

02. Carima Slicer Using

You can apply a variety of settings to ensure easy use of the Carima slicer.

★ If CarimaSLICER is not installed properly, please contact

the following address. Carima 82 - 2 - 3663 - 8877

After registering, if you run Carima Slicer program,

you can see the following interface screen.

C

A

B

Once you have completed the installation, the Carima slicer icon will be created on

your desktop. Double click the icon and start Carima slicer.

When you run Carima Slicer program, you can see the

following registration screen.

On the registration screen, only information about serial

number and computer information is displayed.

Serial Number and Computer Information are automatically

formed, so if you click Registration immediately, you will

get a message that the registration is as follows. Click OK

and meet Carima Slicer!

13

A

Carima-SLICER Basic Manu

1

File

Open

Save

Slicing

Config

Exit

a

b

c

d

e

a

Open

Stored files such as "stl" can be loaded.

b

Save

You can save models that you have worked with a

Carima slicer in slt, crv, and other file formats.

c

Slicing

The imported modeling files can be sliced into single-sided

photo files. The file is in JPGE format.

d

Config

You can change the color of the modeling file, set the user

name, build size, resolution, and image pixels.

e

Exit

Exit the Carima slicer.

1

14

2

a

Manual formation of type 1 supporters

Type 1 supporter manually formed from

printout and bottom

b

Manual formation of type 2 supporters

Type 2 supporter(Blue) that is manually

formed between printout and output

c

Base supporter

Outputs and supporters serve as support from

bottom

c

Type 1 supporter automatic formation

Automatically form type 1 supporter that

serves as a support from the printout and

from the bottom

e

Type 2 supporter automatic formation

Automatically form type 2 supporter that

serves as a support from the printout and from

the bottom

f

Automatic formation of all supporters

All supporters automatically formed

g

Delete all type 1 supporters

Delete all formed Type 1 supporters

h

Delete all type 2 supporters

Delete all formed Type 2 supporters

i

Delete all supporters

Remove all formed supporters

j

Supporter Settings

Change setting value such as supporter size

and length

Type 1. supporter

(Yellow)

Type 2. supporter

(Blue)

15

3

Viewer

Front

Top

Left

Right

Bottom

a

b

c

d

e

3

a

Front view

The loaded model can be seen from the front.

b

The imported model can be seen from above.

Top view

c

Left view

You can see the loaded model on the left.

d

You can see the loaded model on the right.

Right view

e

The imported model can be seen below.

Bottom View

Quick

Reflection in the X axis

d

e

Reflection in the Y axis

Reflection in the Z axis

a

b

c

a

Invert to X axis

Reversing the direction of the

model along the X axis

Move to the Center of X-Y Plane

Move to the Bottom of Z axis

b

Inverse to Y axis

Reverse direction of model in Y axis

c

Invert to Z axis

Reversing the direction of the

model along the Z axis

d

Centered on X-Y axis

Centered on X-Y axis

e

Z axis positioning

Zero position from the current

position to the bottom of the Z-axis

(molded plate)

4

4

16

5

Object

Move Object

d

Rotate Object

Scale Object

a

b

c

Arrange

Copy Object

Delete Object

e

f

Reset Crima Platform

g

a

Move model

You can move the model.

b

Model rotation

You can rotate the model.

c

Model Size

You can change the size of the model.

d

Origin placement

You can place the moved or rotated model

back to the origin.

e

Copy

You can copy the model the same way.

f

Delete

You can delete the model.

g

Initial Screen

The first time the Carima slicer returns to its

initial state.

5

Edit

Undo

Redo

a

b

c

Clear Undo Buffer

a

Back to Previous Work

You can return to the previous operation.

b

Go back to work

You can go back to work later.

c

Initialize workload

You can initialize the imputed computer

memory because of the large amount of

nested workloads.

6

6

17

Effect

Alpha Blending

d

Marking Slope Area

Boxing Selected Object

a

b

c

Outline Selected Object

a

Translucent effect

The model has a translucent effect.

b

The part where supporters will be formed is

displayed.

Show supporter formation part

c

Model Box Formation

A corner angle appears as the size of the

model.

d

Displays the outline of the model.

Model contouring

7

7

8

Environment

Expand Displayed Toolboxes

d

Rearrange Displayed Toolboxes

Show Build Platform

a

b

c

Show Notice Boundaries

8

a

View all action tools

All work tools appear to be visible.

b

Rearrange the wrong work tools.

Rearrange all working tools

c

Build view

Builds can be viewed in clear boxes.

d

You can hide or show the front panel.

Show and hide frontal display

Help

User Manual

About

a

b

a

Download the Manual

You can download the Carima slicer manual in

PDF format.

b

You can check the current slicer program

information.

About the Carima Slicer Program

9

9

18

Slicing Process

The initial start point of Start Slice # is set to 1.

If slicing is in progress, error, or pause, the slicing must be resumed and the starting point

can be set using Start Slice #.

a

Precision setting

Precision can be set in micron (㎛) units. The lower

the number, the greater the number of slices.

b

Anti-aliasing effect

You can reduce the appearance of the staircase type

shown in the sliced picture.

c

File name

You can set the file name to be sliced.

d

Set file storage location

You can set the location of the file to be saved.

The files are stored in crv, jpg format files.

e

Getting started with slicing

Slicing begins.

f

Show slicing progress

You can check the slicing progress.

19

A

B

C

D

A

B

C

D

Identify the entire slicing file

Check the front of the printout

Checking the image of a section slice

of the output

Supporter of printout

With the mouse wheel up and down, you can see all the cross-

sectional layers of the sliced output one after another.

a partial cross section

20

B

Carima-SLICER Toolbox

Open file

You can import modeling files

such as stl.

The imported modeling files can be

sliced into single-sided photo files. The

file is in JPGE format.

Save the file

You can save models that you have

worked with a Carima slicer in slt,

crv, and other file formats.

sliced

Detailed

settings

You can change the color of the

modeling file, set the user name, build

size, resolution, and image pixels.

undo

Redo

Bounding

Show

supporters

Translucent

effect

Rearrangement

Build

platform

Border mark

During modeling, if the model is outside

the build platform scope, a boundary

mark appears.

The build platform is formed in the form

of a box, so you can see clear build rules.

Reverts to the previous operation.

Go back to the next operation.

A corner angle appears as the

size of the model.

The part where the base

is formed is displayed

(red part).

The model has a translucent effect.

You can place the moved or rotated

model back to the origin.

21

Supporter Tool

There are all the options associated with the support that you set

up to secure your output.

Type 1 supporters can be

created (manual).

The model displays the part

where the supporter runs.

A supporter is created in the red area (the

supporter will be created even if it is not

red).

Display

Before

After

display

Type 1 supporters can be

created (automatic).

22

You can create a type 2

supporter (manual).

Type 2 supporters can be

created (automatic).

The Type 2 supporter is a supporter that connects between the two to make the most of the

fine or precise part of the model.

You can remove the type 1

supporter that you created.

You can remove the type 2

supporter you created.

You can remove all generated

supporters.

Type 1 and Type 2 supporters

can be created automatically

(random settings).

You can add a base supporter

to the output (yellow base).

You can set supporter length,

size, thickness and so on.

23

View Manu

You can set the output to be viewed in various ways.

Front view

Top view

Bottom View

Right view

Left view

24

Quick Manu

This menu allows you to change the output direction to various

directions.

Switching up and down

Tilting left and right

Forward and backward

switching

Bottom (Zero) All axis

coordinate alignment

Bottom (Zero) Z-axis (Up and Down) Coordinate alignment

25

Move Manu

• Move to Z-axis

(up and down)

• Move to X axis

(left and right)

Top View

• Move to Y axis

(front and back)

Top View

You can freely move the printout left, right, front and back, up

and down.

26

Rotate Manu

The output can be freely rotated at various angles.

ex) Rotate 90 degrees

Top View

• X-axis rotation

• Y-axis rotation

• Z-axis rotation

27

Scale Manu

Output can be adjusted to various sizes.

• Resize X axis: You can narrow or widen to the left or right.

• Resize Y axis: You can narrow or widen in the forward and backward direction.

• Adjust Z scale: Narrow or widen up or down

• Full size adjustment: can be narrowed or widened in all directions

28

Etc. Tool

Ancillary work tools include border marks, build marks, forward alignment, and

translucent effects.

Ability to view printout

Translucent effect

Ability to display the entire build

Show Build

The boundary of the part that is

displayed in red when the output

size is changed or the build is

exceeded due to movement

Border mark

Function to rearrange forward again

Forward Sort

Open and close all work tools

Open & Close Work Tool

29

You can check the information about the printout, application tools such as

supporters, etc.

C

Object Information

30

III Preparing & Printing

Before printing, you must preparing the IM

Series state that can output.

Now we will explain the procedure from the

first opening to the output of the IM Series.

Check List

01

Printing Preparation

02 LCD Panel Using Method

03

Start Printing

III Preparing & Printing

01. Printing Preparation

To start output to the IM Series, you must first set the material. For material

setting, there are tray preparation, resin swelling, plate.

2

3

Fixing the plate and place with the fixing pin.

Prepare the printing by pouring resin into the tray.

1

Fit the separated formative plate into the formative top.

If you scratch the sheet of ⑤ with a sharp blade or cutter knife, be careful not only to tear it

but also to contaminate the engine room with resin.

31

All you really need to know

Information on the use of resin

When using a resin, please use all means wearing nitrile gloves. When

replenishing resin, please charge it before possible output. Inevitably, when

replenishing the resin during printing, press the "Pause" button and slowly

insert the resin after the operation is completely stopped. Charging the resin

during printing can cause bubbles and adversely affect the printout.

Information about using the tray

As you print, the surface of the sheet is punctured, torn, and

loosened. In this case, since the resin seeps out and can not be

used, replace it with a new tray.

If the user accidentally prints or hardened debris hurt the

surface of the sheet, these symptoms will appear in a short time.

Information on formative plate maintain

Information about using the tray

You can clean the modeling plate by scratching the

molding plate with wax or wiping it with a wet tissue. If

you want to use another resin for output, please wipe the

resin before you clean it.

The life span of the optical engine lamp is 20,000 hours, and the

lamp brightness may be lowered when used over the life span.

If the lamp usage time exceeds 20,000 hours, you can improve

the output quality by replacing the lamp.

32

LCD Panel Tree

02. LCD Panel Using Method

On the LCD panel, you can make most of the settings required for printing.

Initial Screen

main

screen

Right

and

Left

move

Output

data

Right

Preferences

Left

Formation parameter

setting

Set the plate height

Printer settings

Printer information

Output related

settings

Data-related

settings

Screen

Touch

Move between dataHelpPreparing service

Administrator

mode

This menu is used by Carima

technician for visiting A / S.

Access is in Carima

>

>

Basic Menu

Inaccessible menu

Preparing menu

Shut

down

33

LCD Panel Usage

HOME

A. Initial Screen

When the printer is turned on, the loading screen appears.

Make your ideas come true with Carima's 3D printer!

B. Main Home Screen

a b

a

b

Preferences

Output and data-related settings

34

LCD Panel Usage

• Formation parameter setting

Environment Set

1

2

3

4

The shape parameter setting menu allows you to fine-tune

the light of the engine being examined for output.

1

2

3

4

a

The basic exposure time means the time to shoot the output image from the optical engine at the time of molding

The initial exposure time means the exposure time for attaching the output to the molding plate during molding

The initial exposure layer means the number of layers to which the initial exposure time is to be applied

The divided exposure time means the time for dividing the exposure time

35

LCD Panel Usage

Environment Set

a

• Set the plate height

1

2

3

1

2

3

The height of the plate can be set to the amount of

movement of the plate after printing,

after printing, or during normal operation.

During molding, the movement amount of the plastic plate can be set during the printing.

After molding, the amount of movement of the molding plate can be set after the output.

The movement amount of the plate can be set when the tray separation, the cleaning of

the molding surface, and generally the movement of the plastic plate are required.

36

LCD Panel Usage

Environment Set

a

• Printer settings

1

2

3

The printer settings are for use with LCD Embedded.

You can set the language settings, embedded update settings,

cleaning the plastic surface(sheet) of the tray, and so on.

1

2

3

Language setting: You can set the language such as Korean, English, Japanese.

(See p.36 Additional Information)

Update: There is a way to update via Embedded update via USB and to update (online

update) by accessing Carima's update server.

Currently "Online Update" is in preparation for service (see p.36 Additional Information)

Cleaning the mold surface: When the mold surface is cleaned by the menu that is

used when there is residue or residue on the sheet due to the output failure, OFF

turns on and UV light is irradiated for 2 ~ 3 seconds.

After the light is illuminated, the menu changes to OFF again.

(See p.36 Additional Information)

37

LCD Panel Usage

Environment Set

a

• Printer information

1

2

3

The printer information includes the model name, build size,

resolution, storage space, IP address, and software version for

the printer you are using.

1

2

3

You can check information such as product name, build size, resolution, storage

space, IP address, and software version.

Tip: You can find information that will help you with your output.

We are currently in the process of preparing the service.

Administrator mode: Administrator mode is used by Carima technician during business

trip A / S. Customers can not use it, but if you have any questions, please contact

Carima Customer Service (82-2-3283-8877).

38

LCD Panel Usage

Environment Set

a

• Printer shutdown

Press the Exit button to exit the printer.

Additional Information

• This message will appear when cleaning

the molding surface.

• 프린터 설정에서 USB업데이트를 진행하면

이와 같은 메세지가 나타납니다.

• Pressing the save button at the bottom

right of the molding surface height setting

will display a message like this.

• If you do not have an update file when you

perform USB update from the printer settings,

this message will appear.

• LCD임베디드 언어를 설정하면 이와 같은

메세지가 나타납니다.

• The above picture shows the administrator

mode screen.

• This menu is not available to customers.

39

Start Printing

Output and data-related settings

b

• Data List

When you press the directional key located in the middle right of the main menu,

the data list of this output appears.

If the data is not modeled when you click on

the data, this message appears.

If you press the data again in the right data list,

the data saving icon and data delete icon will appear.

1 2

1 2

1

2

Data storage message

Data delete message

03. Start Printing

On the LCD panel, you can make all the settings required to output to the

DM250.

40

Start Printing

Output and data-related settings

b

• Printing

If you click the data you want to print on the right data list,

brief information of the printout appears on the left.

When you press the circle here, the output starts.

The data to be output is read.

Just before the printout, a message will be

displayed to remind you that the sculpture

is attached to the molding plate.

Printing starts.

41

Start Printing

Output and data-related settings

b

• During printing, setting

If you press the circle "Print" during printing, the setting menu will appear as shown on the right.

1

2

3

4

1

Pause

2

Preview

3

Auto shutdown

4

Stop and terminate printing

• Pause the print job in progress.

• Press again to start printing.

• You can stop the print job and preview

the progressed output.

• The print job is completed and the

printer is automatically shut down.

• Stop the print job in progress and

terminate the output.

42

Start Printing

Output and data-related settings

b

After canceling the output, Main Screen: From this screen,

Data can be loaded and output.

• In the Output Shortcut Menu, you will be taken directly to the screen of the corresponding

output so that you can print out the previous output.

• If you want to print another output, press the blank screen (red part) in addition to the circle

menu to move to other data.

43

IV Check Output

When printing is finished, the printout must be

removed from the printer.

Be sure to read the information to remove the

printouts and improve the output quality.

Check List

01

Output Demount

02

After Processing Output

01. Output Demount

When the output is complete, you should remove the printout from the

mastering plate. Wear nitrile gloves and remove the printouts.

When the output is completed, the

formative plate with the output is

automatically raised.

In this state, turn the fixing pin to

remove the formative plate.

Put the formative plate upside down to

remove the printout. Detach the output and

using a cutter such as a knife or scraper.

※ Caution

Please be careful when using cutter

knife or hera.

44

02. After Output Processing

If the printout is removed from the formative plate, manual work such as

cleaning, supporter removal, and curing is required. You should still wear

nitrile gloves.

45

1

Removing supporters

The supporter can be output with the supporter 1 or 2 type according to the method set in

the slicing program before output, and both supporter 1 and 2 type can be set and output.

When the output is complete, remove the supporter by hand from the printout removed

from the plate.

After curing without removing the supporter, you can remove it using the nipper on the

base component when removing the supporter.

If the supporter remains on the cut of the supporter in the printout, you can use a

sandpaper to polish the surface by polishing.

Density Usage

Purchase

recommended

Sandpaper Type

60-120

For removing rough and rough surfaces (Metal, high-strength plastic such as

FRP, cement)

Cloth

180-280 Frequently used sandpaper, abrasive polishing of various materials Cloth

320-600 Uses of ordinary sandpaper, peeling paint slightly Cloth / Paper

800-2000

Less frequently used sandpaper, precious metal, polished, painted surface

Lightly polished

Paper

Sandpaper always starts from a low room, finishes with a high room,

and does not have to go through all the sandpaper types one time.

46

2

Washing

When the output is completed, the resin remains on the printout, and the remaining resin

can be cleaned with alcohol. The higher the alcohol concentration, the better the wash.

Alcohol can clean the remaining resin in the output. It is

easier to clean if you put the alcohol into the sprayer and so

on.

After the alcohol is cleaned, dry it with an air compressor so

that the alcohol is completely dried.

Air Compressor is not

sold in Carima.

Fine parts of the printout can be removed with a thin brush or

toothbrush.

47

3

Curing

What is “Curing”?

Hardness of things or body

Making materials harder by processing or heat-treating materials

m

o

p

monomer : Polymers that attract other molecules to form bonds

oligomer : Polymers in which the units are polymerized to about 2-20

photo-initiator : A substance added to the UV resin to absorb energy

from the ultraviolet lamp to start the polymerization reaction

Immediately after output

: Molecular structure not fixed

Curing

: Chemical reaction

After curing

: Bonding and stiffness

Caution

• When using a UV curing unit, do not look directly at the UV,

but use sunglasses or goggles that can be blocked.

48

CL-50

CL-50 Internal Structure

Product Specification

Model Name CL-50

Lamp UV Curing Lamp(50W 1EA)

System Lamp-side Forced Air Cooling

Power 50/60Hz AC 85~265V

Size(mm) 250(W) – 270(D) – 383.6(H)

Made in Korea (Carima Co., Ltd.)

Caution

• Please note that if the curing is done for a long time, it may affect the output(UV curing

machine: 2-3 minutes curing / UV LED: curing for 30 minutes or more).

• It is possible to reduce the deformation of the printout by performing the work frequently with

less time than hardening time.

49

V Maintenance

It is important to keep the IM Series in good condition for a

long time without problems.

Now you will be informed about printer management, supplies

management, frequently asked questions and A/S.

Check List

01

Printer Maintain

02

03

Other Maintain

FAQ

01. Printer Maintain

It is important to keep the printer well in order to use it for a long time. In

this regard, I will tell you how to clean and manage your printer.

If you do not use the printer for a long period of time, remove

the power cable from the printer and store the printer in a

shady place.

If the resin falls or flows into the printer, wipe it with alcohol

on the towels (tissues, kitchen towels, etc.).

If dust has accumulated on the engine lens, wipe it with a lens

cleaning agent on the microfiber towel. When you wipe the

lens, wipe the lens gently as you circle.

Damage to the engine lens can adversely affect print quality.

When cleaning, please handle it carefully.

50

02. Other Maintain

Consumables related to the printer include trays, resin, and basic components.

1

Tray(Vat) Management

Consumables related to the printer include trays, resin, and basic components. If

you want to remove the resin that you used earlier and use other resin,

completely remove the resin from the existing tray with the syringe included in

the base component.

Then use the trays to clean the remaining resin with alcohol-impregnated towels.

When using various resins, it is recommended to use individual trays for each

resin in CARIMA CO., LTD. Resins are not well wiped by nature, or mixed with

other resins, which can adversely affect print quality.

If there is residue on the tray,

• You can remove debris with your hands with nitrile gloves.

• When removing the residue using the hera, be careful not to

damage the tray sheet surface (it is not recommended to use hera

directly on the sheet).

Resin residue

Sheet surface

51

2

Resin Management

Resins are vulnerable to sunlight or a variety of light. Always keep it in

a shady place where it can not be used for a long time.

When the tray with the resin is pulled out from the printer and stored,

it is possible to store it by using a product (foil, etc.) that can block the

light.

Never mix with other resin.

Resin is a chemical component. Please wear goggles and sunglasses

and a mask when you use it because the resin may splash and enter

your eyes or cause a chemical odor that makes your respiratory

system worse.

3

Resin Discard

Type of Waste

Household chemicals such as used soaps, detergents, etc.

Solid wastes that have been output

Toilet paper and paper with no chemicals

Waste

water

If there is a purification device in the building, it may be disposed of

in a drainage port, but if there is no purification device, it should be

entrusted to the waste disposal company.

Output

waste

If it corresponds to general waste, it is treated as general waste

without being entrusted to the waste disposal company.

harmfulness

waste

(Liquid)

Must be entrusted to waste disposal company.

52

03. FAQ

We would like to inform you about the contents of the most inquiries while

using the 3D printer of Carima Co., Ltd.

Q

The engine does not turn on.

A

Turn off the power, turn down the switch at the back, and then turn it on again.

If the power does not turn on after that, please contact Carima.

Q

How much resin does it fill?

A

Resin should be poured in small increments as needed.

Fill only one third of the tray at the beginning.

Q

The output is blank.

A

Check if the engine light is on and set the exposure time again. If you still can

not print after this, please contact us.

Q

If the output falls during output, how do I?

A

First stop the operation and turn off the engine, take out the tray and filter the

debris. At this time, the resin on the molding plate may fall on the engine.

Q

What is the life span of the resin?

A

After opening the resin, up to 6 months is the period of use.

The resin may become hardened when exposed to light, so please keep it out of

the reach of light.

53

Q

When I do not use the equipment, how do I manage it?

A

Unused equipment should first be emptied of resin in the tray, and the tray

should be lightly rinsed with alcohol. The equipment must be unplugged and

stored away from the environment (rain, wind, sunlight).

Q

How do I clean the tray?

A

If there is any resin in the tray, check whether there is any residue. If there is any,

remove the clean resin separately through the funnel and the sieve net. Wipe the

resin inside the tray lightly with tissue paper and alcohol. Make sure that the

resin and alcohol do not get into the tray gap.

Q

I inserted a slicing file and it says that the resolution is different.

A

If the resolution of the device is not correct, it will not be output. Be sure to

check the resolution and build size of the device in "config" before slicing.

Q

What's the difference between "crv" and "stl" files?

A

The crv file is the default extension file of the carima slicer. Supporter and model

are separately recognized and stored so that they can be modified at any time

when the supporter work is completed and saved.

In the case of the stl file, supporters are bundled into a single chunk like the

model and can not be modified when saved.

54

Seoul Head Office

- Product and Sales-

070-4044-3760

9:00 – 18:00 UTC+09:00(Mon-Fri)

sales@carima.co.kr

- Technology Support -

02-3663-8877

9:00 – 18:00 UTC+09:00(Mon-Fri)

carima@carima.co.kr

167, Gonghangdaero, 59da-gil, Gangseogu, Seoul, Korea 07555

www.carima.com l carima@carima.co.kr

Tel. 82-2-3663-8877 l Fax. 82-2-3283-4466

ⓒ All copyright is reserved by Carima

IM Series Manual(English) v 1.2 l 2017. 05. 08.

Product Warranty Certificate

◎ Distributor

Carima Co., Ltd. guarantees this product in accordance with the consumer damage compensation

regulations. We guarantee free repair within the warranty period for performance and function

problems that occurred under normal use within the warranty period.

◎ Warranty contents

1. If the product manufactured by Carima Co., Ltd. breaks down

due to functional problem, defective problem, environmental

damage during delivery, we will compensate for free repair or

replacement.

2. Even if the product is covered by the warranty period, it can

not be repaired under the following conditions.

• Malfunction due to careless handling.

• The user disassembles the product, not the technician.

• Malfunction caused by user modifying the product.

• In case of repairs using parts and accessories other than the

parts and accessories provided by the head office.

※ Carima Coating Co., Ltd. guarantees the contents of this warranty.

Where to buy Carima Head Office

Service

center

Product

Name

Serial

Number

Date of

purchase

Warranty

Loading...

Loading...