Carima DP110E Operation Manual

Operation Manual

DLP 3D PRINTER

DP110E

Table of Contents

1. Product Warranty

2. Safety precautions

3. Product Information

Specification, Consumables, Features

4. Names of Parts

5. How to Attach & Detach Tray

6. How to Detach & Attach Build Plate

7. How to Refill Resin

8. Amount of Resin Refill

9. VAT check

10. Maintenance

LED error messages, maintenance

11. DLP engine Lamp Replacement

1

2

4

6

7

8

9

10

11

12

15

Equipment Operation Manual

1

Product Warranty

Thank you for your purchase.

The product is made from precise parts and managed by our quality control.

Carima warrants the product in accordance with following terms If the product

fails during normal use.

Warranty terms

1. If a defect arises with regard to the product during the warranty period,

CARIMA will repair or replace the defective parts of the product with new parts.

2. The warranty period applies for a period of 6 months from the date the Product was

first installed by a consumer.

3. Please contact us at the following numbers.

4. Please keep the original warranty card for future service request.

Exclusions and Limitations

1. If the product or Accessory malfunctions after the Warranty Period expires,

there is no warranty of any kind.

2. It doesn't apply to damage caused by operating the product outside

3. It doesn't apply to damage caused by accident, abuse, miuse, flood,fire,earthquake,

or under abnormal conditions

4. It doesn't apply to the Product damaged in shipping, transit, or on-site handling

during installation.

5. It doesn't apply to a product or part that has been modified to alter functionality

without the written permission of carima

6. If things including item description, installation date, signature are removed, Carima

is not responsible for the loss.

▶ During the warranty period, Carima will either repair or replace

any defective product at no charge.

▶ If a defect arises in the product after warranty period or in the

event of warranty exclusions, we may charge you a fee.

Please contact us for support at +82-2-3663- 8877

Installation date : . . .

Item description :_____________________________________________

2

Safety precautions

- Read this manual carefully for proper handling and operation, before

installing, operating, maintaining and inspecting.

- It is designed to help ensure your own personal safety and to help protect your

equipemnt from potential damage.

- Failure to observe the safety notes may lead to serious injuries and to significant

damages to the system.

! Place the machine in well-ventilated place due to smell of the resin.

! Do not insert tools or parts of body into machine during the printing process.

! Never look directly into light beam in order to protect your eyes.

! Never use gasoline for printing. Please keep it away from the machine.

Also, 3D prints or resin residue shouldn't be swallowed, as It could causedisorientation

and suffocation.

! Stop the printer from processing and take the resin tank out not to overflow resin. and

then turn off the machine and move it.

! Do not turn power switch off when it's on. It reduces life span of engine and could be

one of errors. Get it ended as given in manual

! Putting some of liquid or metal pieces into printer is harmful for fire disease or

electric shock. Also, Do not operate the machine with wet hands protecting from fire or

electric shock.

! Do not ruin main power of printer. Neither change or ruin USB cables or supply power

raised from outside.

! Carefully choose place for installation protecting from pet or child injuries made by

printer

! Standard accessories include sharp tools such as cutter or nipper. Be careful not to cut

yourself on any sharp edges.

! The space inside machine is designed to be taken up by light of engine.

please do not insert anything else inside.

! Protect the machine from dampnes, such as rain and now, and dusty weather.

! Install and operate the machine on a flat level and dry surface. Kepp the machine away

from flammable liquids, gases, and aerosols.

! Do not impose excessive force on the machine.The external housing of your machine

may be damaged Also, Read all instructions before using the machine.

Use of resin

! Be careful about resin from contacting skin or body part.

- If in contact, rinse in running water and make sure to wear gloves during work.

Replacement of resin

Lifetime of optical engine

3

! Remove alien substances and scraps at the bottom of tray.

- Remaining scraps may have adverse effects on the output.

! After replacing resin, stir well before use since precipitates can be formed.

Cleaning of build plate and tray

! Check for alien substances and scraps on build plate and tray every time.

- Remaining scraps may have adverse effects on the output.

- Regular management and cleaning of tray are necessary.

! Coating can be damaged if the tray is cleaned with a sharp object.

- Use a spatula or dry cotton cloth as cleaning tool.

! Poor cleaning can lead to poor quality of output and lifting or cracking of floor.

Lifetime of optical engine lamp is 3,000 ours, and brightness of the lamp can be

reduced by exceeding its lifetime. Replace the lamp after using it for 3,000 hours

to increase quality of output.

Preparation for A/S request

Record error situation, interior of the printer, and LCD display as photograph or

video.

- A/S can be much easier if the user explains the situation clearly.

Product Information

Model Name

DP110E

Resolution of DLP engine

1024 x 768

Build size (mm)

110 x 82 x 190

Layer thickness (mm)

0.025 [0.025/0.05/0.075/0.1 (4 steps)]

X,Y Resolution

100μm

Product size (mm)

380 x 255 x 743

Product weight (kg)

19

Rating

100~240V, 50/60Hz, 2.5A, 260W

Material used

ACRYLIC

System control

Control using touch-type embedded screen included

Environment

18℃ ~ 26℃ (temperature) / 20% ~ 50% (humidity)

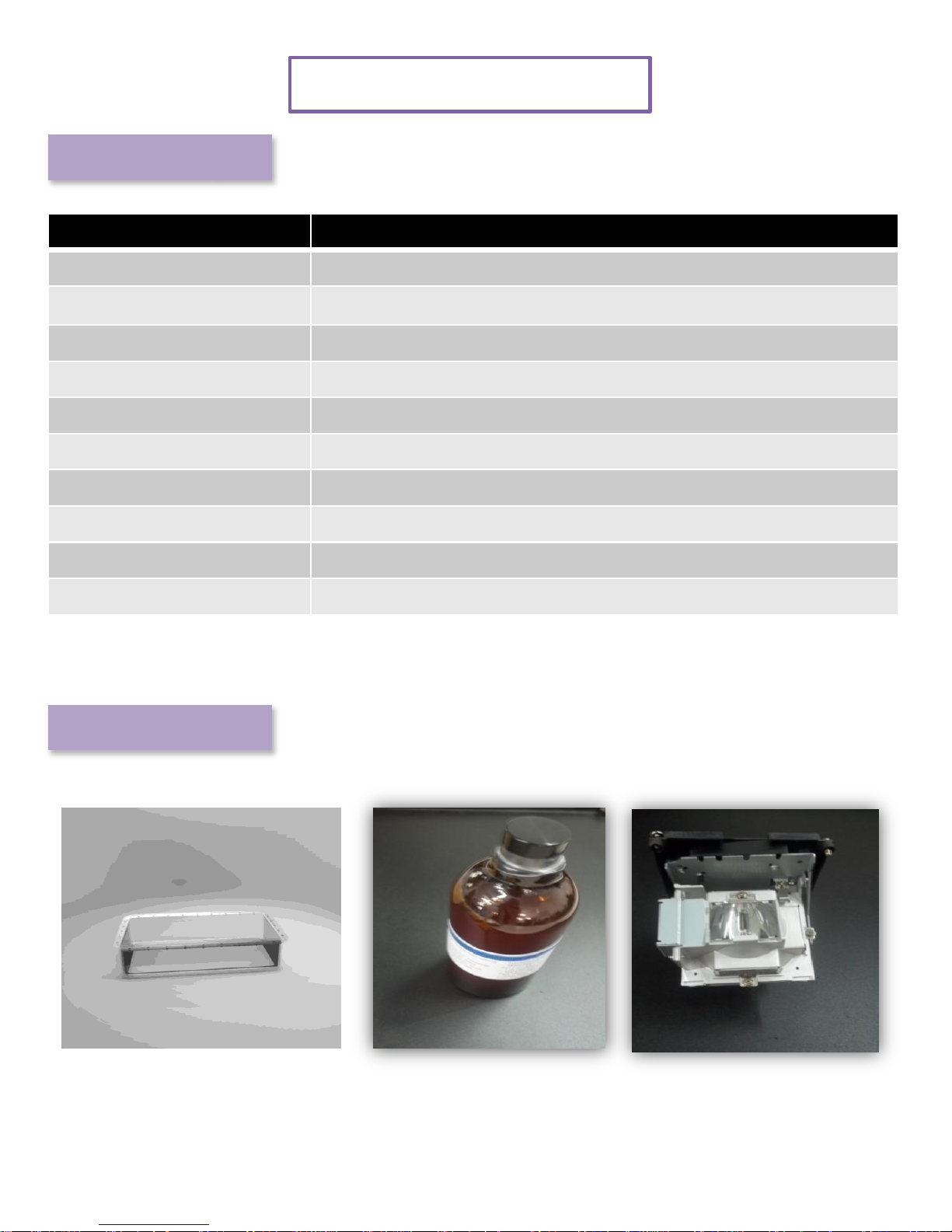

1. Product Spec

2. Consumables

[Special VAT]

[RESIN]

[LAMP]

4

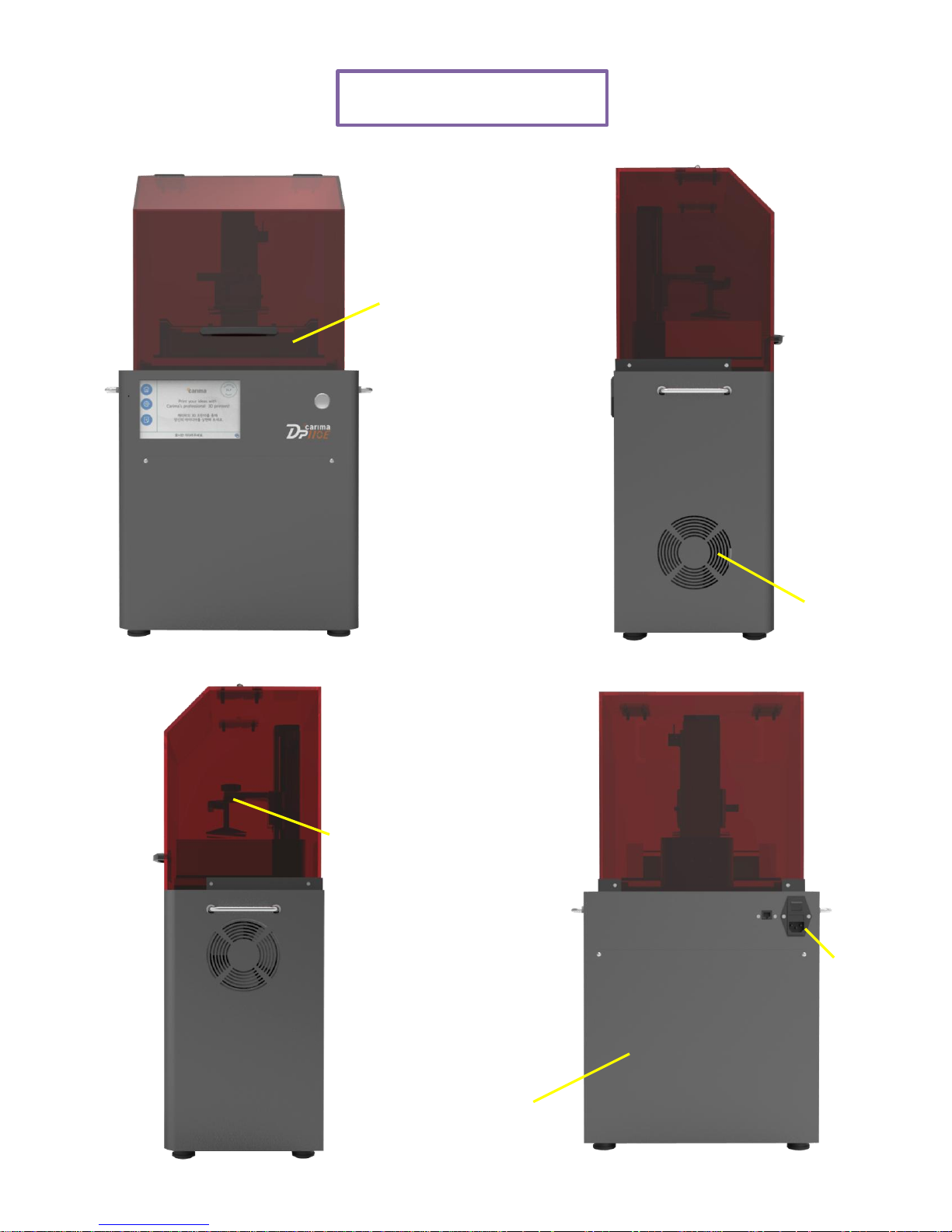

Names of Parts

[Front] [Right side]

[Back]

DLP engine

Tray

Fan

Power

button

Build

plate

[Left side]

5

Equipment Operation Manual

DLP 3D PRINTER DP110E

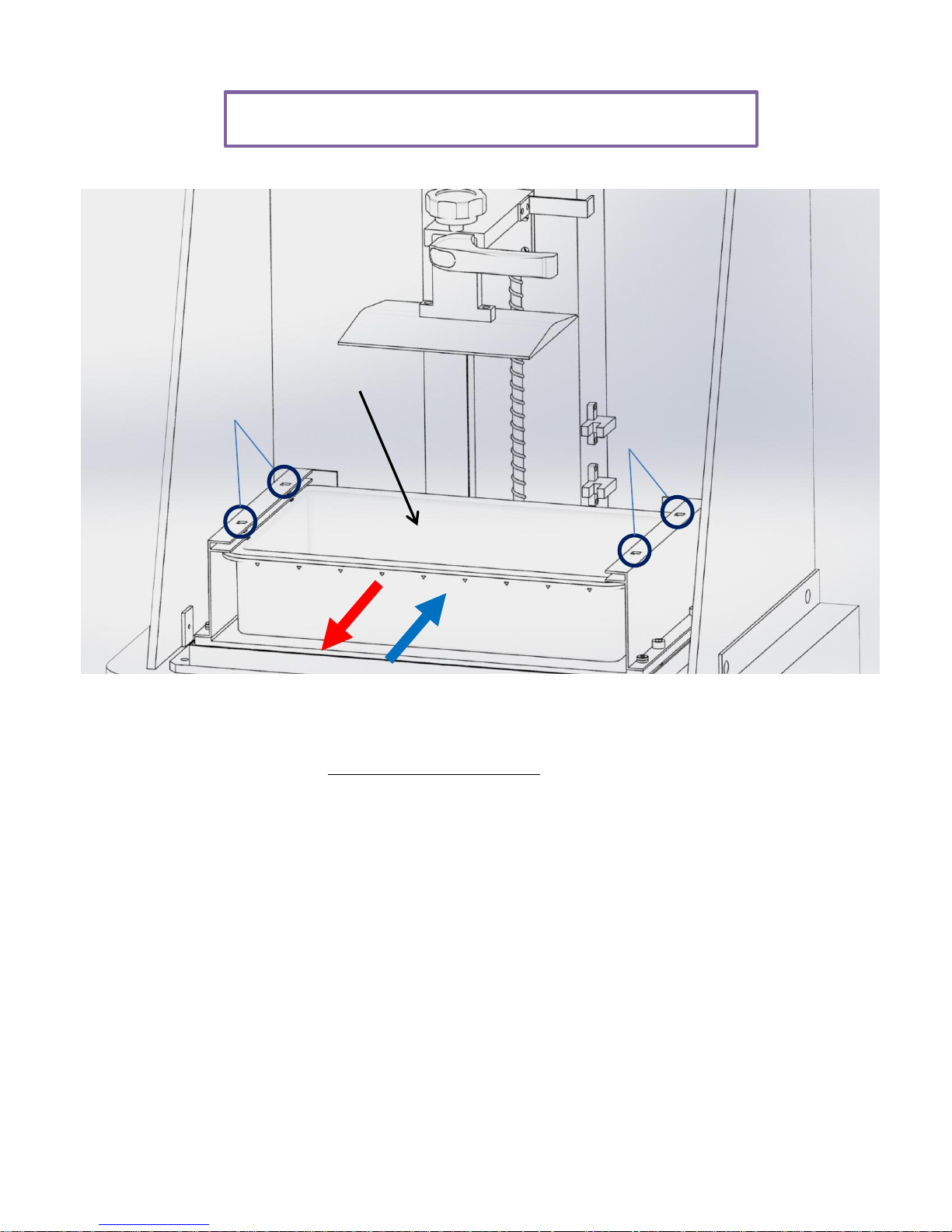

How to Attach & Detach Tray

7

Tray

1. Since the tray is pressed down by spring devices, pull the tray out.

(Be careful when pulling out the tray as resin inside can overflow

and stain the equipment.)

2. Push in the reverse order to attach the tray.

The tray will make “clicking” sound with the spring devices.

(Be careful when pushing in the tray as resin inside can overflow

and stain the equipment.)

Spring devices

Spring devices

How to Detach & Attach Build Plate

8

Build plate lock knob

Build plate

Build plate handle

Loosen

When printing is done, loosen the build plate to detach it by rotating

build plate lock knob counterclockwise. Grab build plate handle and

take out. Reverse the order when attaching the build plate.

Precaution

When detaching the build plate, resin on the build plate may fall off or

spatter over the exterior or equipment to damage or contaminate the

equipment. After removing output, the build plate must be wiped out

cleanly to remove any remaining resin.

Resin left intact for long time can harden and affect output.

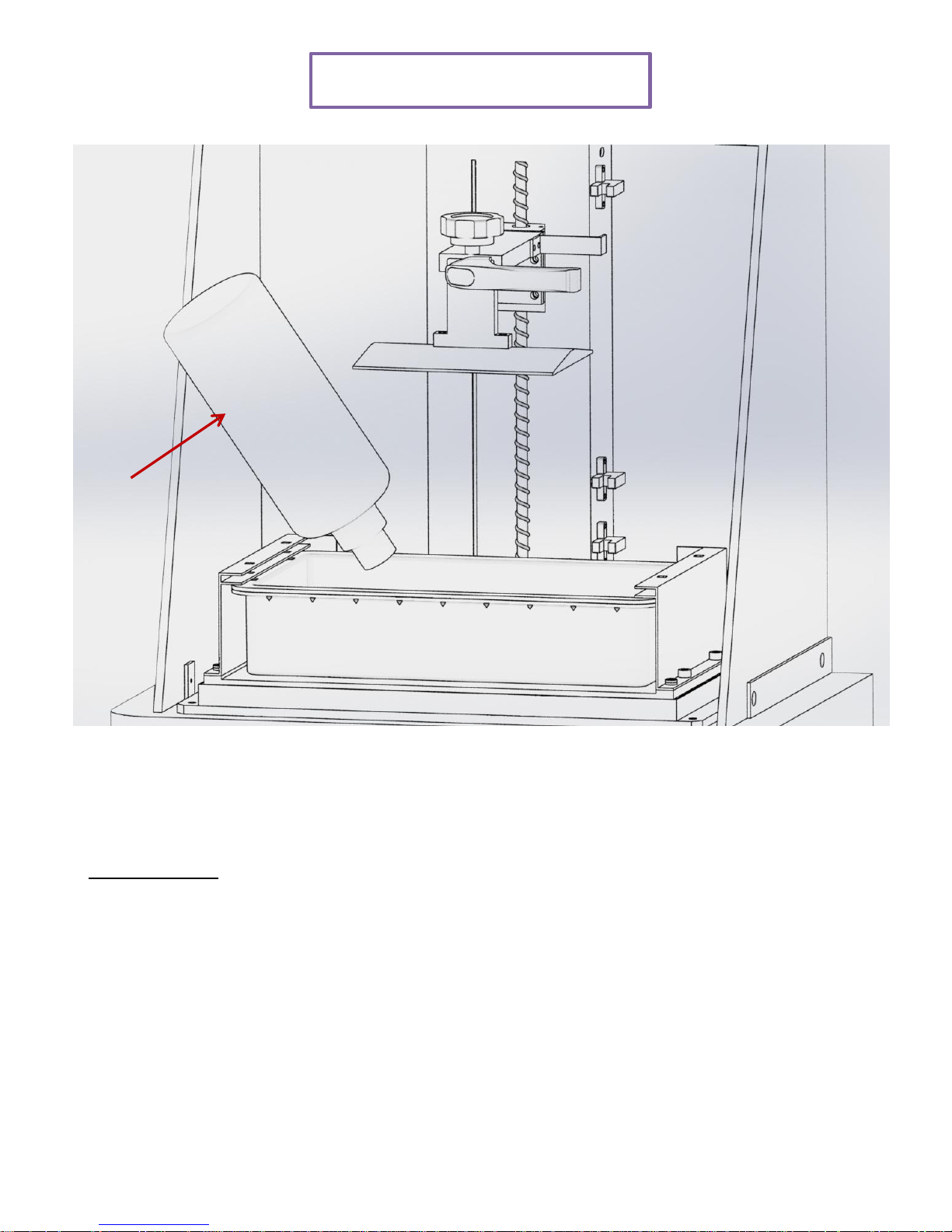

How to Refill Resin

9

Resin

Refill resin as shown in the figure.

Precaution

If possible, refill resin before printing. If it is inevitable to refill resin

while printing, press “pause” button and slowly add resin after the

work comes to a complete stop. Refilling resin while printing can

result in foams that have adverse effects on output.

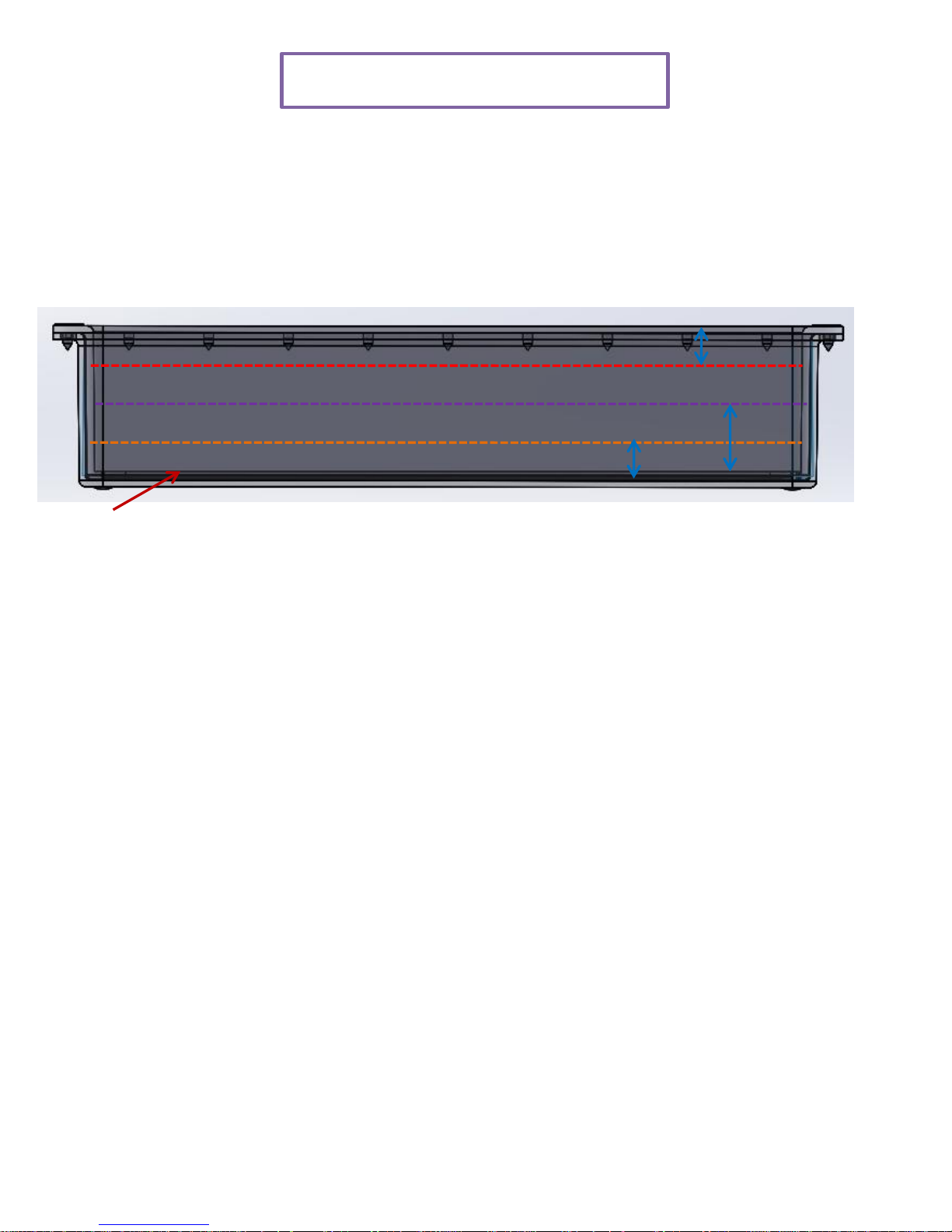

Amount of Resin Refill

10

Sheet surface

Max

5mm

10mm

5mm

Standard

Shell

In general, we recommend filling resin between shell line (250g) and

standard line (500g). Do not exceed max line (800g) when printing

large output.

When filling resin above the max line, resin can flow over the tray with

up-down motion of motor depending on shape of output.

Loading...

Loading...