Carima IM series, DM250 User Manual

User manual

IM

DLP

3D printer

IM Series

s e R I E S

II

III

IV

V

Soft ware Install and Using

Preparing and Printing

Check Output

Maintenance

01

Carima-Slicer Install

02

Carima-Slicer Using

01

Printing Preparation

02

03

LCD Panel Using Method

Start Printing

01

Output Demount

02

After Output Processing

01

Printer Maintain

02

03

Other Maintain

FAQ

11

13

31

33

40

44

45

50

51

53

I

IM Series Introduction

01

IM Series Information

01

02

03

04

Component Name

Precaution

Whole Process

02

03

07

05

IM Series compatible material

08

C O N T E N T S

DLP Print Method

What is DLP 3D Printing?

DLP: Digital Light Processing Mask Projection Image Hardening Method

• A cross-section photograph of the output is laminated by irradiating the photo-curable liquid

resin with UV light..

• Due to the optical mask, the cross-sectional photograph of the output is totally inspected.

• Because of this surface unit lamination method, the output speed is fast and the surface

roughness high, so it is possible to make use of precision.

I IM Series Introduction

Hello.

This manual provides instructions on how to use the "IM Series".

Understand how to use "IM Series" through the manual and

experience "IM Series" easily and conveniently.

Check List

01 IM Series Information

02

03

04

Component

Precaution

Whole Process

05

IM Series compatible material

I IM Series Introduction

01. IM Series Information

IM Series is an ultra-precise DLP 3D printer, the most suitable printer to

implement a precise model, and is a 3D printer commonly used in the Design,

Jewelry, and Dental industries.

Model Name IM Series

Resolution 1980 X 1080

Light Source UV LED

Printing Size(mm)

96 × 54 × 150 110 × 85 × 200

130 × 74 × 100

Lamination

Thickness(mm)

0.025 / 0.05 / 0.075 / 0.1

Precision 50 μm

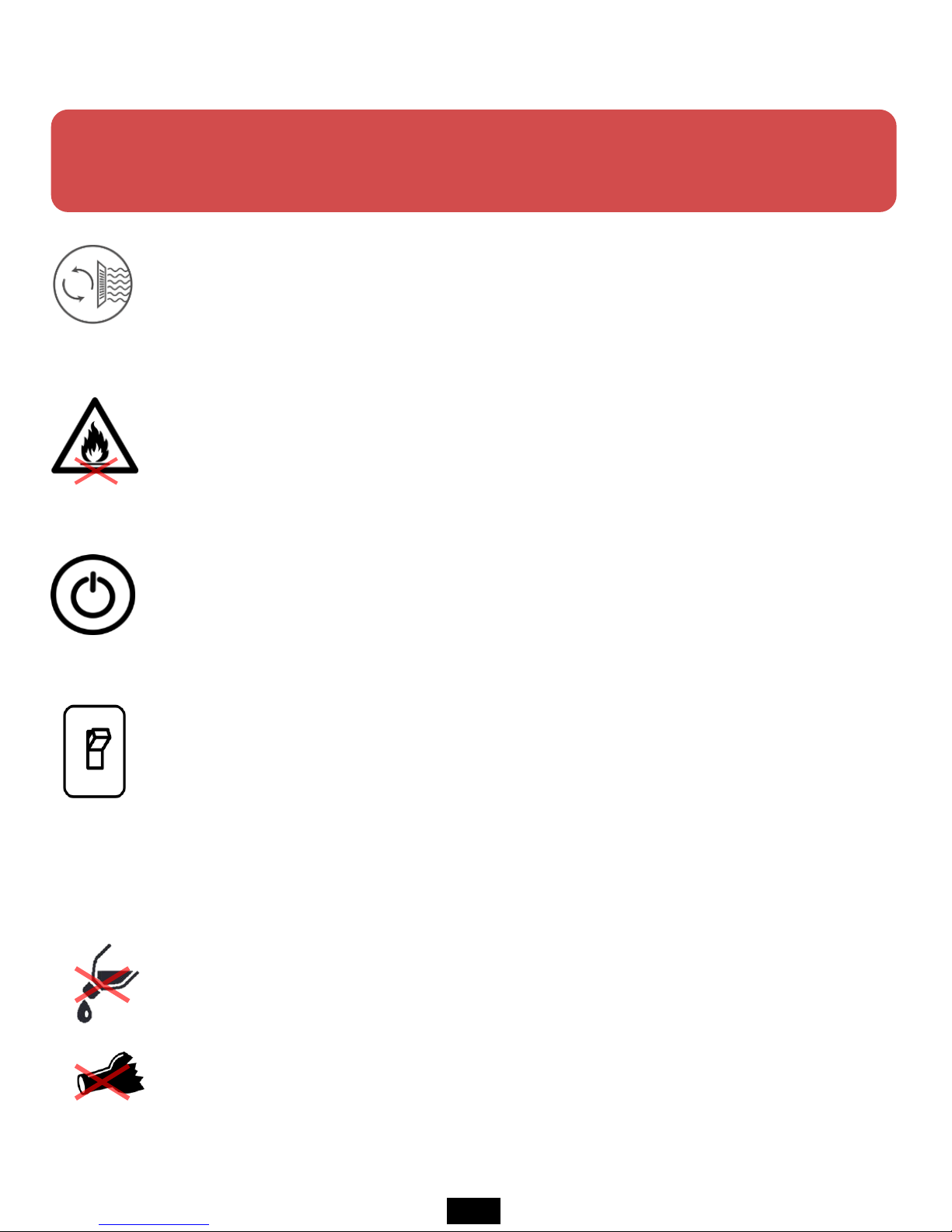

Product Size(mm) 304 x 315 x 622

Weight(kg) 22

Power 100-240V, 50/60Hz, 2.5A, 260W

Material DLP, SLA Resin

Control Type Control method using embedded touch screen

Using

Environment

18-26 (℃) / 20% - 50% (% humidity)

+

If you use the printer in this environment, it will help you to printing better.

1

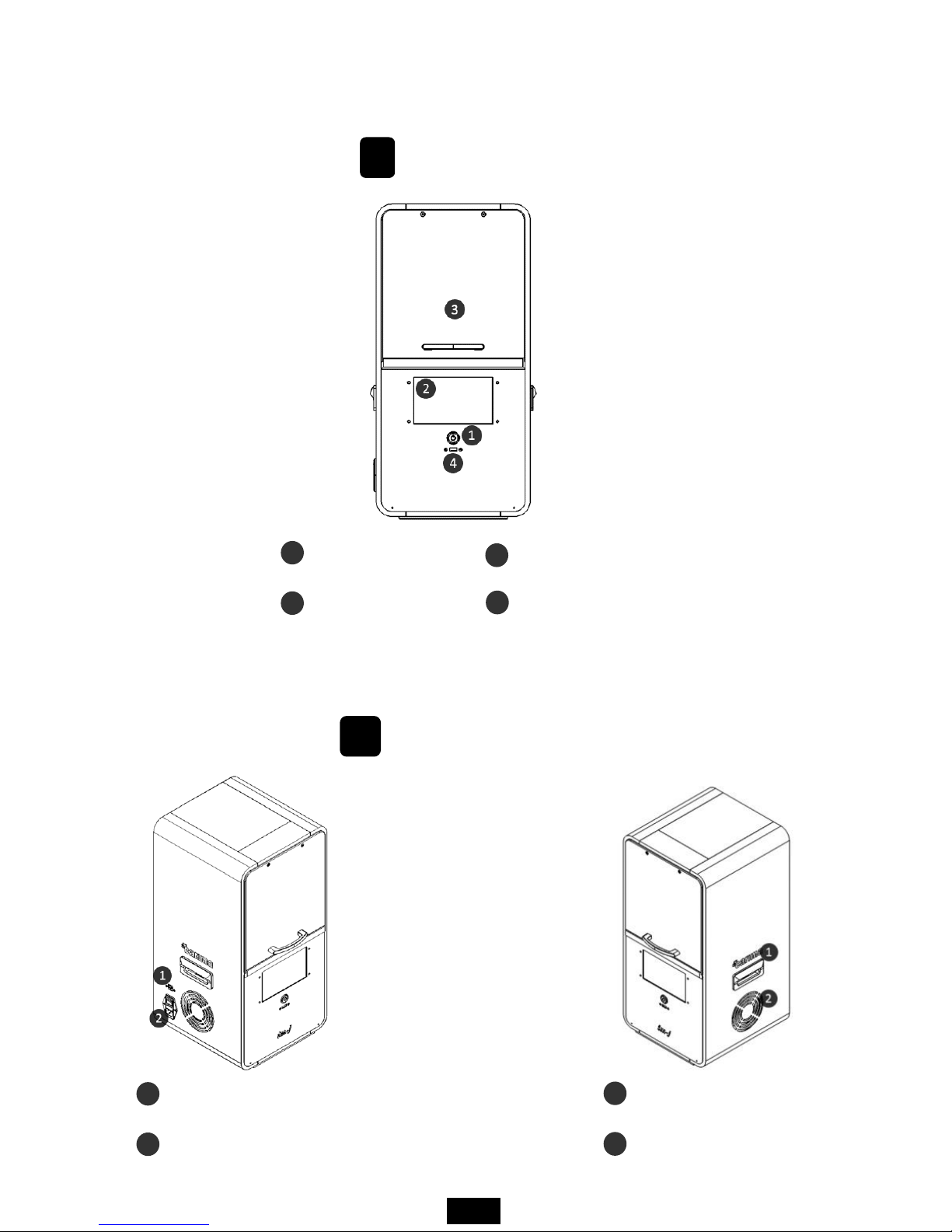

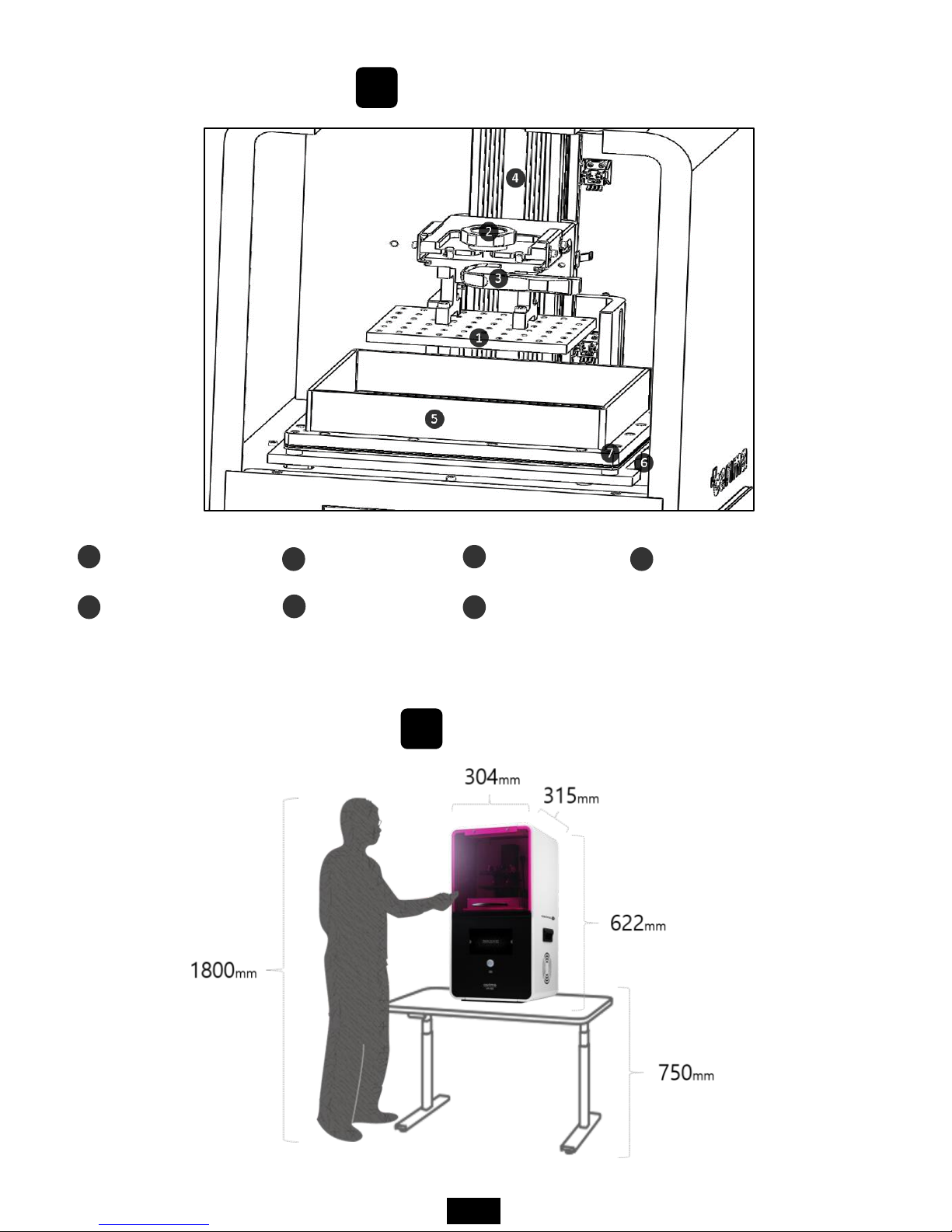

02. Component

A

Front

LED Power Button

LCD Touch Screen

Print Room Cover

USB Port

1

2

3

4

B

Equal Angles

Ethernet port

Power cable ports and switches

1

2

handle

Low Noise Cooling Fan

1

2

2

C

internal structure

Plastic plate

Open sheet tray

Plate fixing pin

Tray tilting axis

1

5

2

6

Plate handle

Tray fixing hex screw

plate vertical movement axis

3

7

4

D

Real Size

3

03. Precaution

This information is intended to protect your safety and property damage.

For your safety, please be aware of the precautions to prevent personal injury or printer damage.

When you print out the printer, it may cause the resin to smell distinctive, so

please install the printer in a well-ventilated place.

When using volatile objects near the printer, do not use it because there is a

risk of fire or explosion.

When moving the printer, be sure to completely shut down the printer, and

then remove the resin or tray to avoid overflowing the resin in the tray.

If the printer is on, do not off the power switch located on the back of the

printer. Forcible termination can shorten the life of the printer engine and

cause mechanical failure. Press the Exit button on the LCD panel to shut down

the printer.

If some objects such as water or other liquids, metal chips, or other conductive

materials are introduced into the printer, it may adversely affect the printer,

such as mechanical malfunction. In addition, do not operate with wet hands

because of the risk of electric shock, please wear the nitrile gloves and using.

4

If you touch the door or touch screen strained with gloves or tools, it may

cause malfunction(Touch screen malfunction, door crack, etc.).

If the tray removed while the plate attached after printing, impurities may fall

inside and cause a failure. First, remove the plastic plate, remove the tray

afterwards.

When removing the tray, be careful that the bearings that were used as the

bearing may be lost (If you lose, you may incur costs).

After the output, take out the resin remaining in the tray with a syringe, filtering

residue with a sieve, and store it separately.

If you put the resin in the tray due to frequent work, keep it closed that is not

exposed to the external environment as much as possible.

If the dyestuff of the resin stored in the tray is separated, it must be mixed with

a rubber spatula before printing.(If the sheet is damaged by storing the resin in

the tray for a long period of time, this is the customer's fault.)

After the output is completed, When you remove the plastic plate with the

printout, be sure to move the tray (tray) that supports the resin that falls down

so that the material does not fall inside the product. If the material falls inside

the product, it may cause deformation or breakdown.

5

If the printer power cable and USB cable are damaged due to being pulled or

stepped on the rough surface, please note that sparking or voltage

malfunction may occur. Also, if there is a lot of current in the power cord or

outlet, there is a risk of fire due to overheating.

The printer has potential risks in terms of chemical composition and voltage.

To prevent injuries to children and pets, install a printer in a safe place to

prevent accidents.

If the printer is installed in a location where there is a lot of humidity or

temperature changes, it may cause deformation or malfunction of the product.

If you disassembling or remodeling the printer artificially, the warranty benefits

will be lost and you will not be held liable for any loss caused by this.

For inquiries regarding A/S inquiries and product warranty, please contact

Carima Co., Ltd. for a friendly consultation.(82-2-3663-8877).

Malfunction or trouble due to non-compliance, tuning, disassembly, etc. are

recognized as customer errors and will be charged during the warranty period.

6

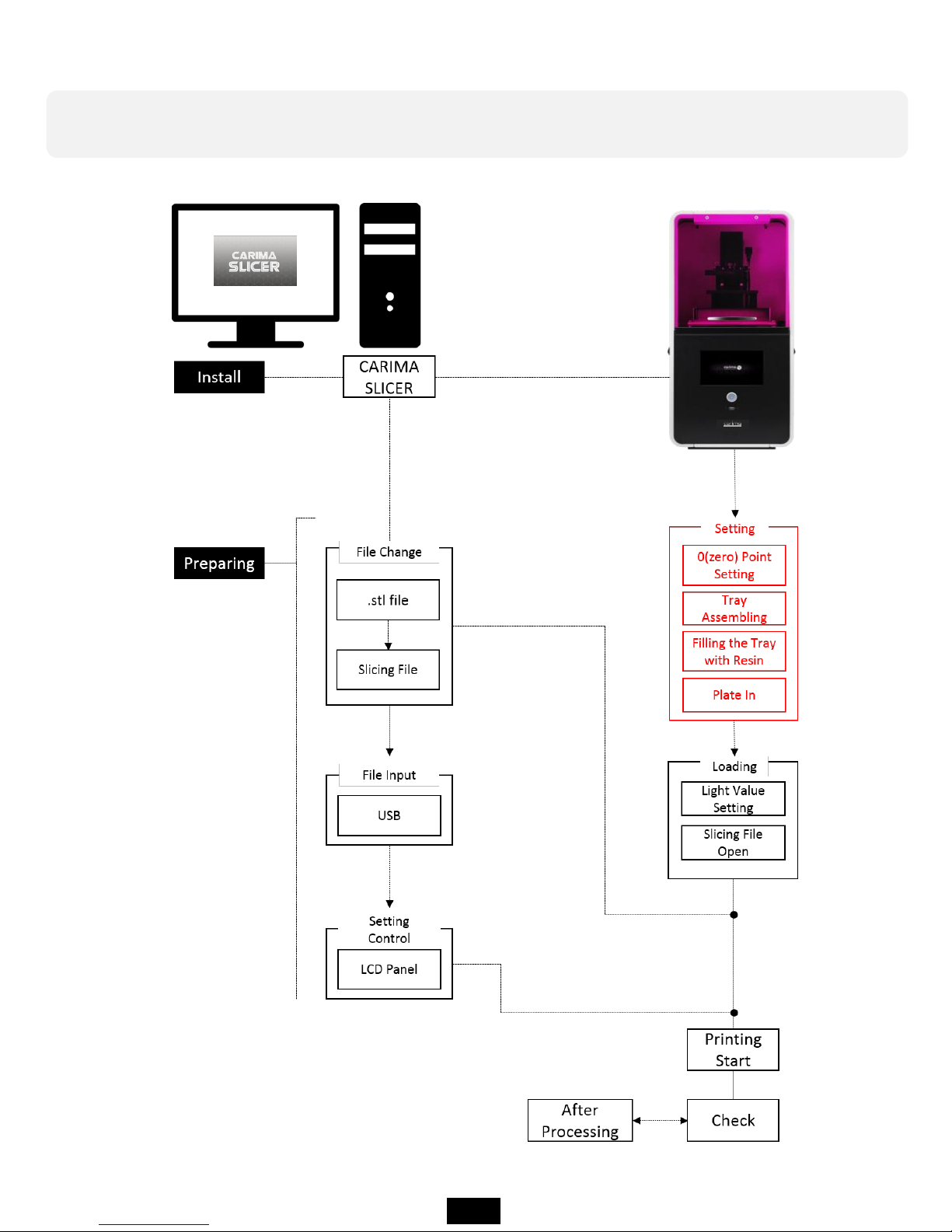

04. Whole Process

In order to output to IM Series, you have to go through the following

procedure.

7

IM Series

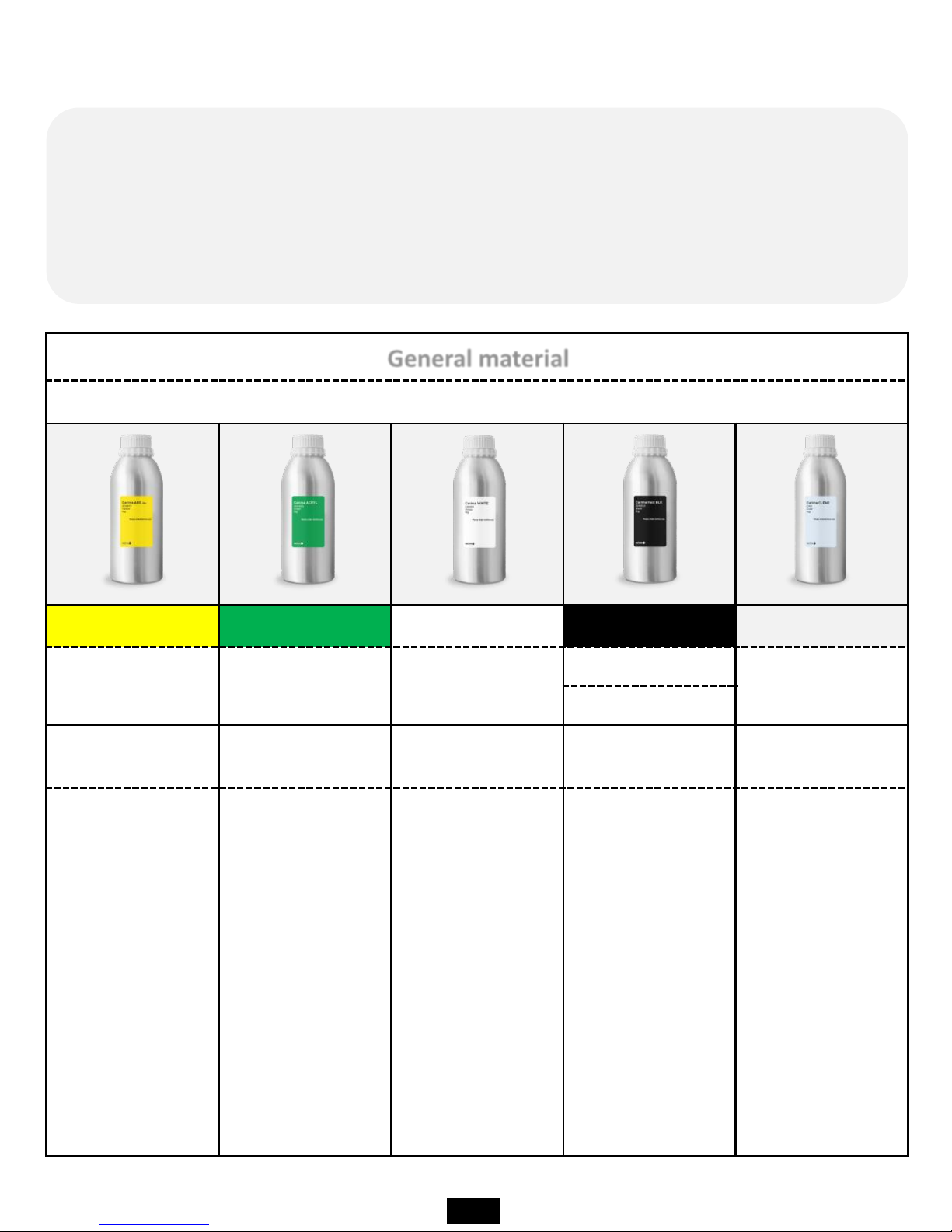

General material

Plastic-based material

Carima ABS-like Carima ACRYL Carima WHITE Carima Fast BLK Carima CLEAR

ABS-3DK83Y ACRYL-3DK83G WHITE-CRM011

Fast BLK-3DKBLK

CLEAR-CRM

CAM008

Prototype

Mock-up

Prototype

Mock-up

Prototype

Mock-up

Prototype

Mock-up

Prototype

Mock-up

Yellow-based

prototypes or

materials that

can be used for

3D modeling in

general.

For green-based

prototypes or for

the production of

full-scale models,

it is generally

possible to use

3D printing with

ABS.

It is a material

that can perform

3D printing work

for white base

prototype or real

size model

production.

It is a black

plastic type

general material

that Carima

developed in-

house, and it is

possible to

realize high

reactivity and

precision.

Transparent

prototypes,

transparent

materials that

can be modeled

on a full scale.

05. IM Series compatible material

The IM Series can be used for 3D printing using materials of various

characteristics. Among Carima's general material range, IM Series can output

all common materials. (However, I am not sure whether it will be possible to

output special materials other than Carima special materials.)

8

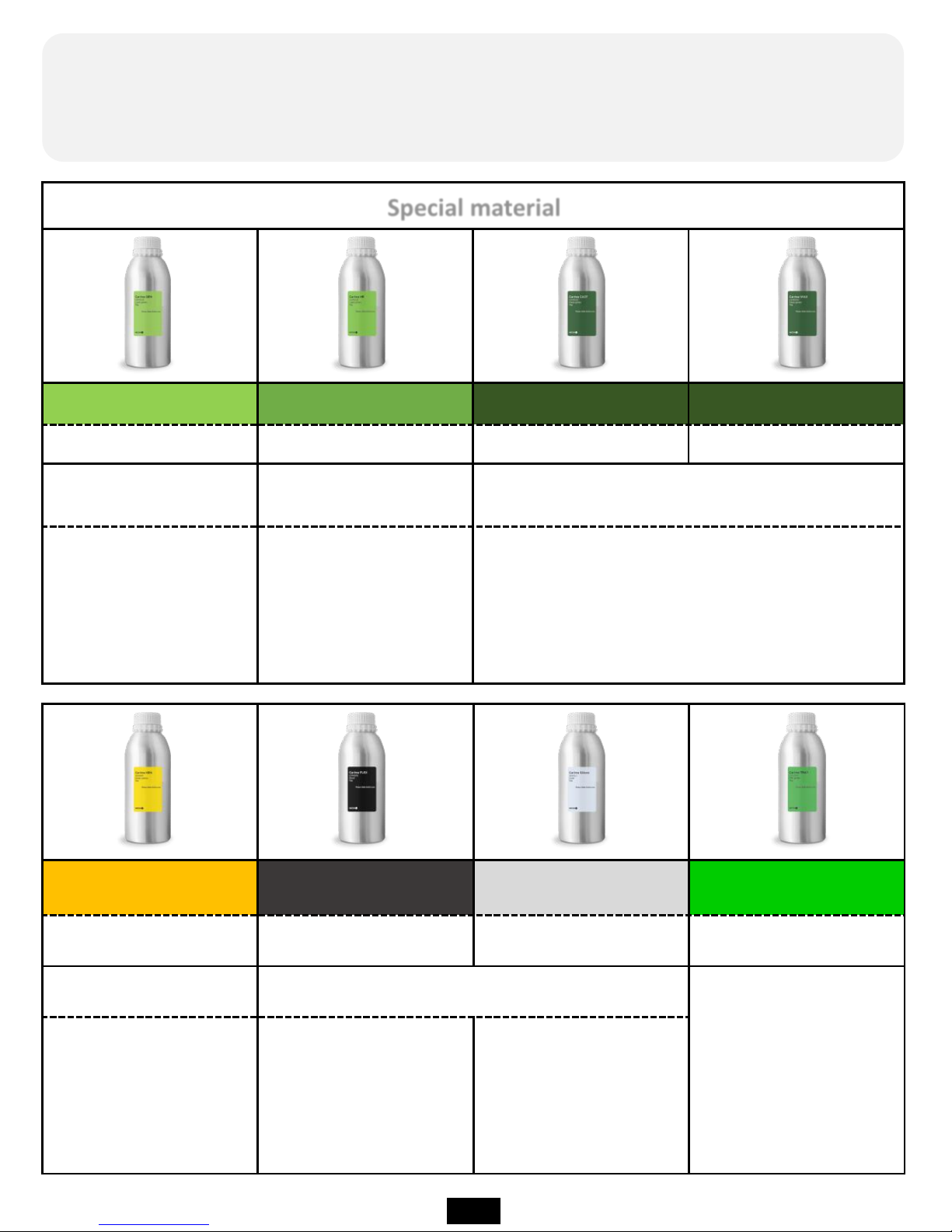

Carima HRN

Carima FLEX Carima Silicon Carima TRAY

HRN-3DKHR1

FLX-CFM005 Silicon-3DKSL1 TRAY-CDV300, CDP011

Heat-resistant material

Flexible material

Dental bracket

dedicated material

Heat-

resistant material

can withstand up to

200 degrees,

yellow base.

Special material with

soft rubber like

features.

Silicon material

Special material

Carima GRN Carima HR Carima CAST Carima WAX

GRN-CRM003 HR-CAM003 CAST-CAM002 WAX-CAM004

Flexible and strength-

based materials

Precision-only material

Precision jewelery output

and casting exclusive material

A material with some

flexibility and strength.

A material capable of

achieving a precision

of about 25 μm to 50

μm.

Rings that require precision, such as necklaces

and accessories The material can be used

professionally from the output of the model.

Among the special materials of Carima, IM Series can output all special

materials(However, I am not sure whether it will be possible to output special

materials other than Carima special materials.)

9

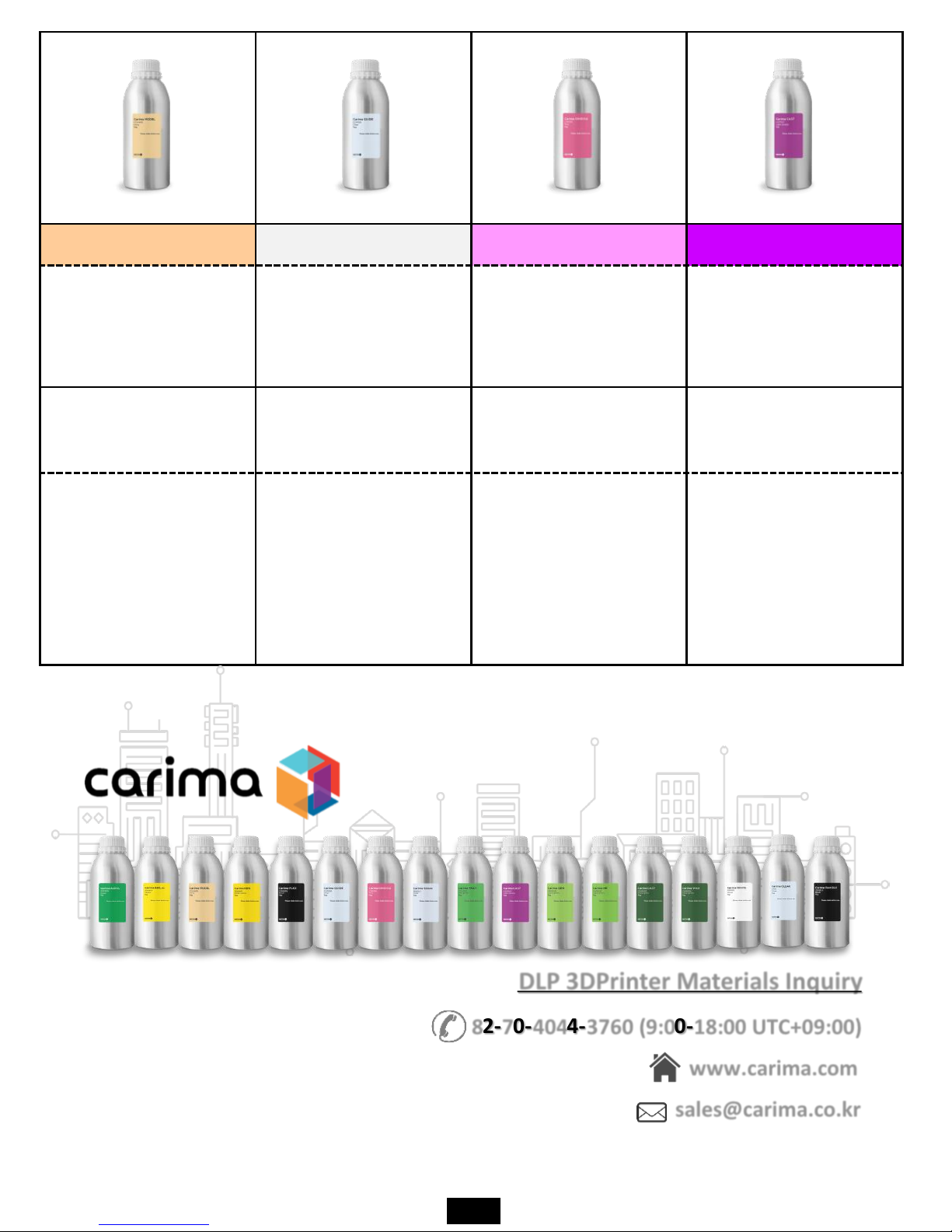

Carima MODEL Carima GUIDE Carima GINGIVA Carima CAST

MODEL-CDV400,

CDP013

GUIDE-CDP010,

CDP001,

CDV600

GINGIVA-CDP015

CAST-CDP012,

CDV100

Dental guide material

Implant guide material Gingiva material

Dental casting only

material

Based on flesh-based

high-precision output

of the dental upper

and lower mandible

Material.

Transparent-based

implant guide only

material.

A material similar to

the gums that can be

used to identify the

shape of the gums that

have subtracted teeth.

A special material that

can open teeth with

gold, silver, etc.

DLP 3DPrinter Materials Inquiry

www.carima.com

sales@carima.co.kr

82-70-4044-3760 (9:00-18:00 UTC+09:00)

10

II Software Install and Using

If you are using the IM Series, you must install

the slicer program provided by Carima.

Realize your imagination and experience

creation with Carima Slicer.

Check List

01

Carima Slicer Install

02

Carima Slicer Using

II Software Install and Using

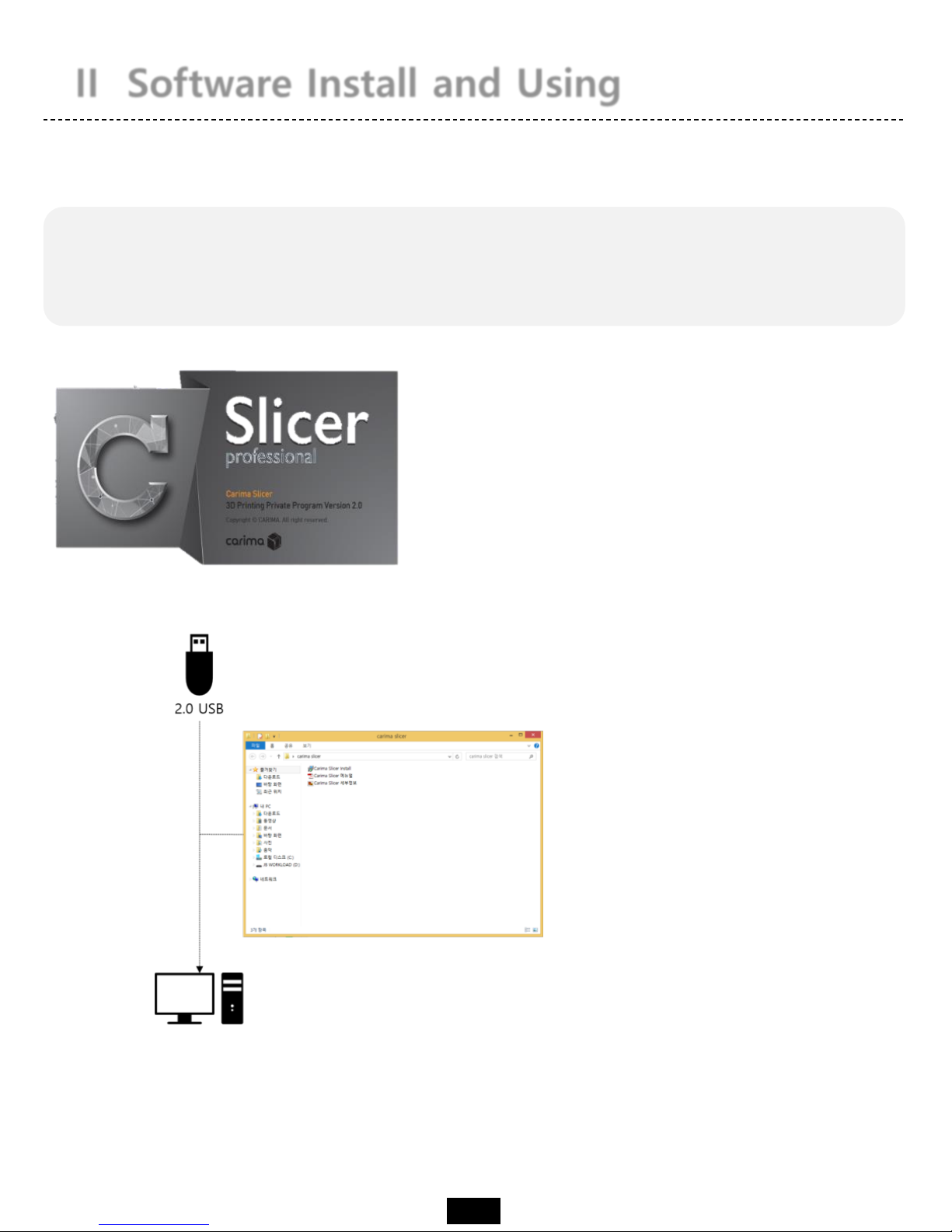

01. Carima Slicer Install

The Carima Slicer is a program that helps you to output from the IM Series.

Carima Slicer is a self-made slicing program

from Carima Co., Ltd. It is a program that

slices each model to output and makes it

into a picture form. It is easy to save it as

file such as stl, jpg, crv.

The Carima Slicer Setup program is attached to the USB

provided by Carima. Install CarimaSLICER with USB.

CarimaSLICER can not be installed on any other PC (or

notebook) other than one PC (or notebook).

★ CarimaSLICER is compatible only with 3D printers manufactured by Carima Co., Ltd.

You can not use CarimaSLICER with other 3D printers.

11

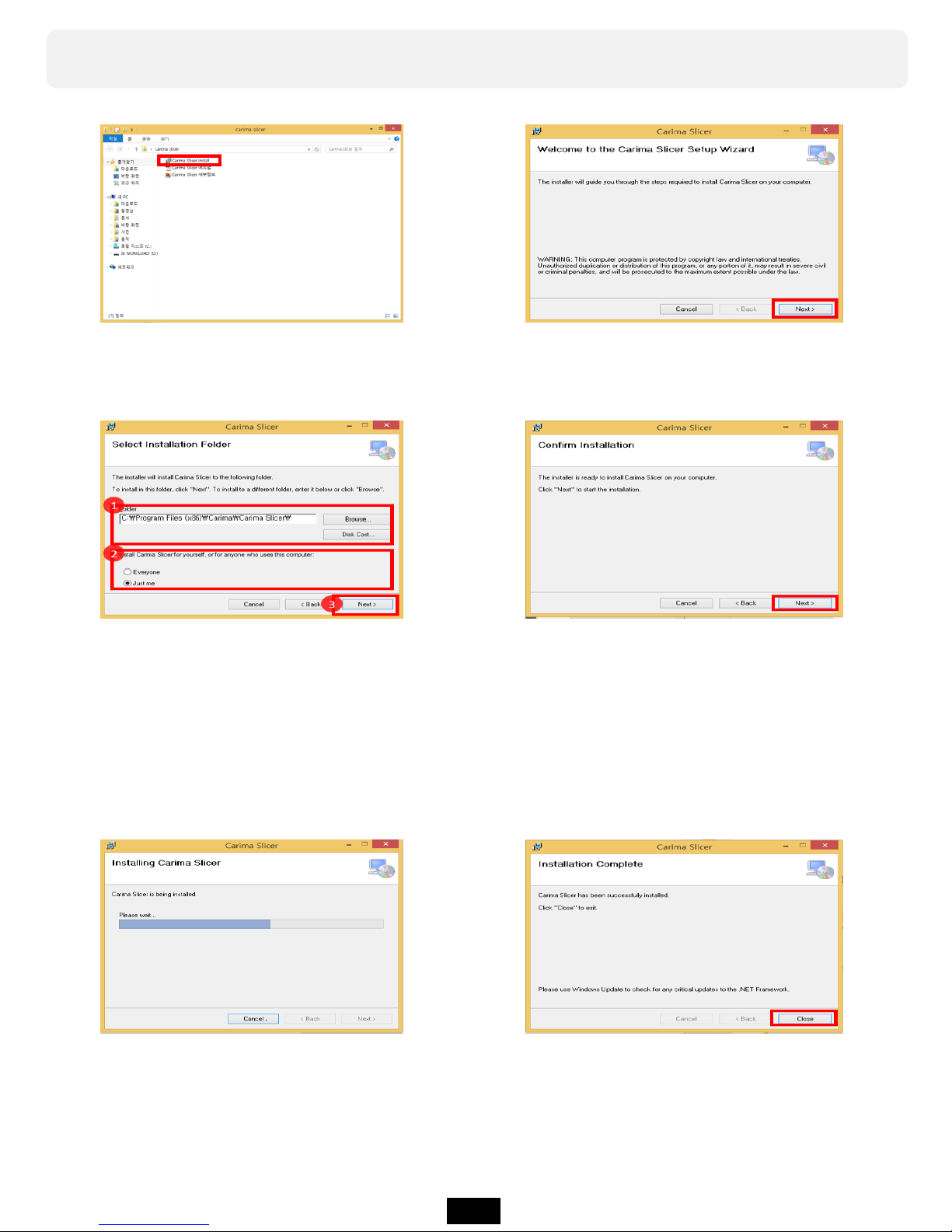

You can install Carima Slicer in the following process.

a. Double-click the Carima-

Slicer Install file.

b. Carima-Slicer Install Setup file

screen. Click Next>.

c. After specifying the path where

Carima-Slicer will be installed,

select one of "Just me" or

"Everyone" of the Windows

account and click Next>.

d. After completing the setup,

please proceed to the final

installation with the message

that installation is completed.

Click Next>.

e. Click Next> to proceed

with the installation.

f. When the installation

is finished, click Close.

12

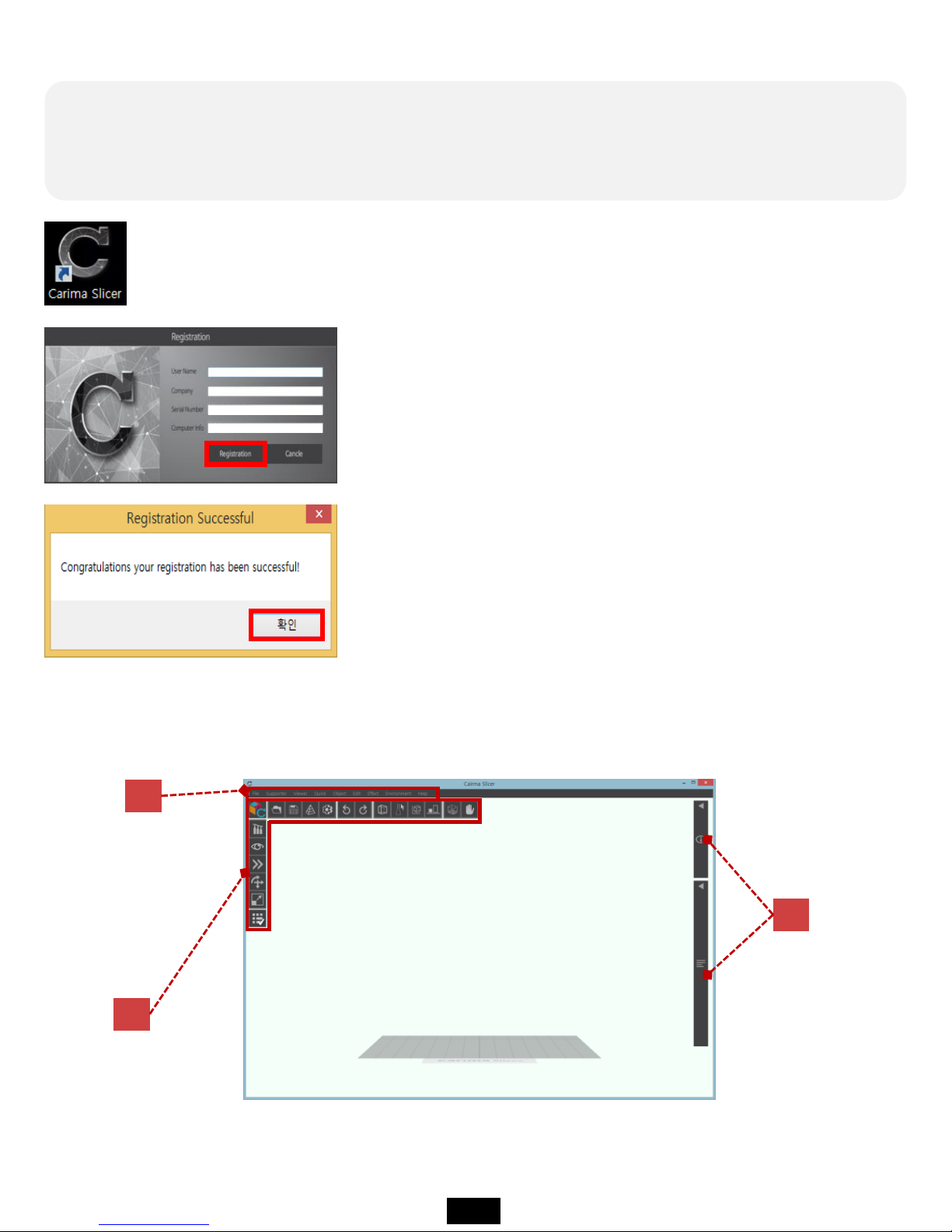

02. Carima Slicer Using

You can apply a variety of settings to ensure easy use of the Carima slicer.

★ If CarimaSLICER is not installed properly, please contact

the following address. Carima 82 - 2 - 3663 - 8877

After registering, if you run Carima Slicer program,

you can see the following interface screen.

C

A

B

Once you have completed the installation, the Carima slicer icon will be created on

your desktop. Double click the icon and start Carima slicer.

When you run Carima Slicer program, you can see the

following registration screen.

On the registration screen, only information about serial

number and computer information is displayed.

Serial Number and Computer Information are automatically

formed, so if you click Registration immediately, you will

get a message that the registration is as follows. Click OK

and meet Carima Slicer!

13

A

Carima-SLICER Basic Manu

1

File

Open

Save

Slicing

Config

Exit

a

b

c

d

e

a

Open

Stored files such as "stl" can be loaded.

b

Save

You can save models that you have worked with a

Carima slicer in slt, crv, and other file formats.

c

Slicing

The imported modeling files can be sliced into single-sided

photo files. The file is in JPGE format.

d

Config

You can change the color of the modeling file, set the user

name, build size, resolution, and image pixels.

e

Exit

Exit the Carima slicer.

1

14

Loading...

Loading...