Carestream Health 6850 User Manual

DRYVIEW 6850 Laser Imager

User’s Guide

150 Verona Street

Rochester, New York 14608

© Carestream Health, Inc., 2010

CARESTREAM and DRYVIEW are trademarks of

Carestream Health, Inc.

The Kodak trademark and trade dress are used under license

from Kodak.

Pub No. 2G8647

Rev. A

Table of Contents

1 Overview

6850 Laser Imager...........................................................................................................................................1-1

Intended Use....................................................................................................................................................1-1

System Components .........................................................................................................................................1-2

How the Laser Imager Works...........................................................................................................................1-3

Film Throughput..............................................................................................................................................1-4

Agency Compliance..........................................................................................................................................1-4

User Guide Conventions ...................................................................................................................................1-4

2 Using and Maintaining the Imager

Operator Control of the Imager........................................................................................................................2-1

Turning Imager Power ON and OFF..................................................................................................................2-1

Power ON...................................................................................................................................................2-2

Normal Power OFF.....................................................................................................................................2-2

Emergency Power OFF ...............................................................................................................................2-2

Power Failures...........................................................................................................................................2-3

Power Save.................................................................................................................................................2-3

Using the Touch Screen....................................................................................................................................2-3

Touch Screen Functions.............................................................................................................................2-4

Touch Screen Help.....................................................................................................................................2-5

General Help........................................................................................................................................2-6

Specific Screen Help ............................................................................................................................2-6

Installation Road Map......................................................................................................................................2-6

Physical Setup............................................................................................................................................2-6

Configuration.............................................................................................................................................2-6

Imager Passcode..............................................................................................................................................2-7

Loading and Removing the Film Cartridges.......................................................................................................2-8

Drawers and Doors..........................................................................................................................................2-9

Opening Film Drawers and Main Door.......................................................................................................2-9

Opening the Film Registration Door...........................................................................................................2-9

Opening Air Intake Door............................................................................................................................2-9

Film Drawers and Main Door Manual Override Latch...............................................................................2-10

Filter Maintenance .........................................................................................................................................2-11

Cleaning the Electronics Filter..................................................................................................................2-11

i

Changing the PMM...................................................................................................................................2-11

3 Troubleshooting

Overview..........................................................................................................................................................3-1

Error and Alarm Indications............................................................................................................................3-1

Correcting Errors.......................................................................................................................................3-1

Correcting Film Jams With the Imager Powered ON ...................................................................................3-2

Correcting Film Jams With the Imager Powered OFF..................................................................................3-2

Touch Screen is not Functioning................................................................................................................3-2

Calling for Support...........................................................................................................................................3-2

4 Adding a Modality and Configuring Modality Image Quality

Introduction ....................................................................................................................................................4-1

Adding a Modality............................................................................................................................................4-1

Configuring Modalities Automatically...............................................................................................................4-1

Configuring Modalities Manually......................................................................................................................4-3

Configuring Modalities that use PLUTs .......................................................................................................4-3

Configuring Modalities that use TFT Sets and Contrast Tables.....................................................................4-4

Fine Tuning the Image with TFTs Sets and Contrast Tables.........................................................................4-4

Performing a Contrast Test.........................................................................................................................4-6

5 Film Technical Information

General Description.........................................................................................................................................5-1

Spectral Sensitivity .....................................................................................................................................5-1

Image Quality.............................................................................................................................................5-1

Environmental Impact................................................................................................................................5-2

Storing and Handling Undeveloped Film ....................................................................................................5-2

Handling Developed Film...........................................................................................................................5-3

Archiving Developed Film ..........................................................................................................................5-3

Exposing to Moisture.................................................................................................................................5-3

Dissipating Odor........................................................................................................................................5-3

Dissipating Heat.........................................................................................................................................5-4

Recycling Film ...........................................................................................................................................5-4

6 Specifications

Location...........................................................................................................................................................6-1

Equipment Specifications...........................................................................................................................6-1

Operating Space Requirements..................................................................................................................6-1

Other Location Considerations...................................................................................................................6-2

Environmental Requirements...........................................................................................................................6-3

Temperature..............................................................................................................................................6-3

Relative Humidity.......................................................................................................................................6-3

ii

Altitude...................................................................................................................................................... 6-3

Floor Vibration.......................................................................................................................................... 6-3

Floor Levelness.......................................................................................................................................... 6-3

Environmental Effects...................................................................................................................................... 6-4

Power Requirements....................................................................................................................................... 6-4

Network Requirements.................................................................................................................................... 6-4

Film................................................................................................................................................................. 6-5

Film Types................................................................................................................................................. 6-5

Film Sizes.................................................................................................................................................. 6-5

Film Storage and Throughput.................................................................................................................... 6-5

Glossary

iii

1

Overview

6850 Laser Imager

Intended Use

The DRYVIEW 6850 Laser Imaging System is a continuous-tone laser

imager with an internal photothermographic film processor. Heat, rather

than photo chemicals, is used to develop the film. The Laser Imager

prints images on KODAK DRYVIEW Laser Imaging Film, which is

packed in 125-sheet cartridges. Depending on the configuration of your

Imager, you can load up to three cartridges simultaneously.

The DRYVIEW 6850 Laser Imaging System (DRYVIEW 6850 Laser

Imager) is intended to provide high-resolution hard copy images from

digital imaging source output signals. The device is intended for use

with DRYVIEW media including DVM (DRYVIEW Mammography)

films. The imager will interface with a variety of digital modalities,

including, but not limited to, CR (Computed Radiology), DR (Digital

Radiology), CT (Computerized Tomography), MRI (Magnetic

Resonance Imaging) and FFDM (Full Field Digital Mammography).

Image resizing is used to preserve true geometric size images. The

images are to be used for medical diagnosis and referral to physicians

and their patients.

2010-11-04 2G8647 1-1

Overview

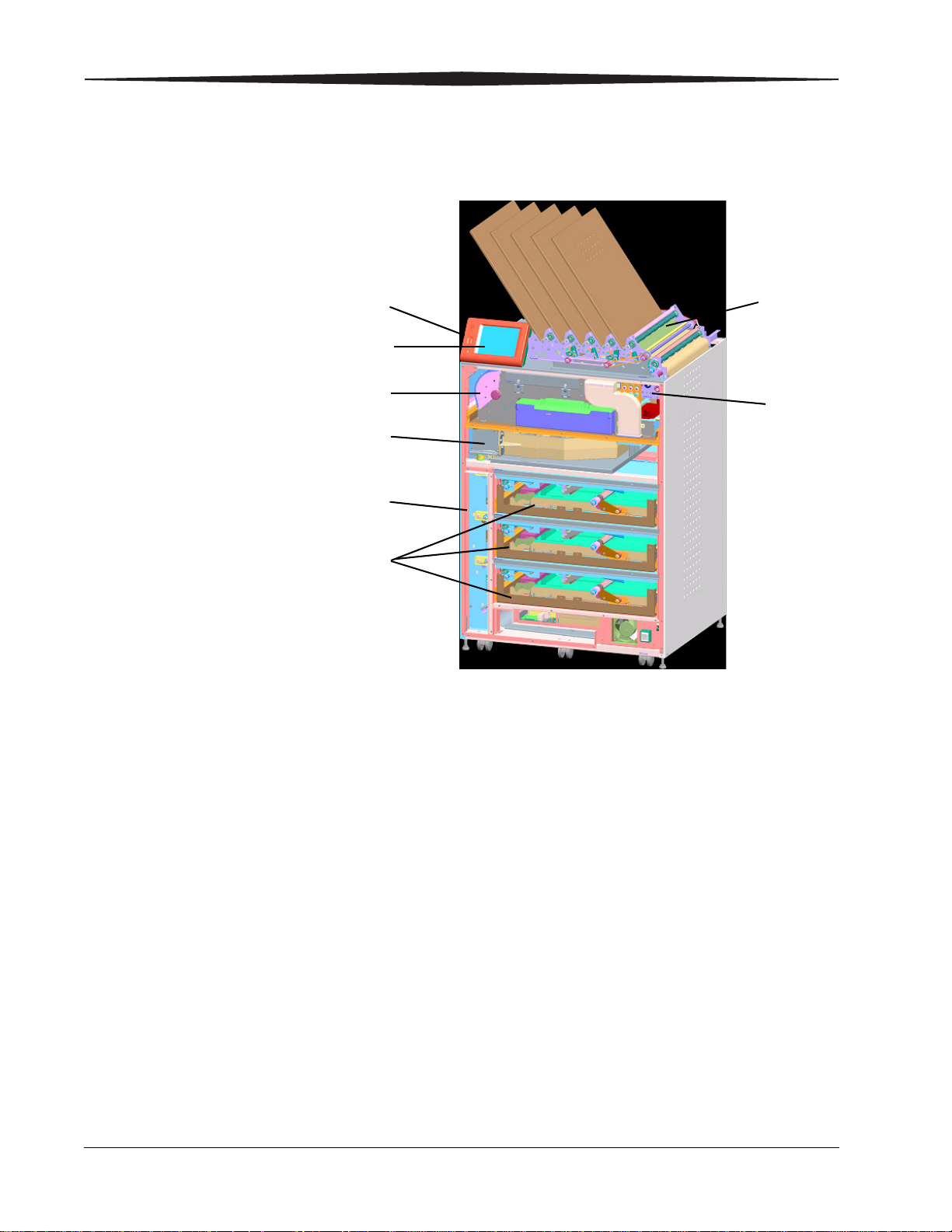

1

2

3

4

5

6

7

8

System Components

1 Film drawers. Your Imager may be configured for one, two, or three

film drawers. Each film drawer can hold any of five different sizes of

DRYVIEW Laser Imaging Film. You can select the film cartridge in any

drawer for printing.

2 Film registration. The film registration orients and centers the film

while moving the film from the film drawers to the imaging portion of

the Imager.

3 Film imaging. The optics module writes the image onto the film

while the film is moved through the exposure transport.

4 Film processor. The film processor uses heat to develop the image

written onto the film by the laser in the optics module.

5 Densitometer. The densitometer receives the film after it passes

through the processor and performs a density check to confirm image

quality when a calibration is run.

6 Film sorter. Your Imager may be configured without a sorter. The

film sorter receives the processed film and transports the film to the

selected film bin on top of the Laser Imager. Each of the five bins

holds 50 sheets of film.

1-2 2G8647 2010-11-04

7 Local panel. The local panel contains the power button used to turn

1

2

3

4

5

6

power ON/OFF for the Imager during normal operations. It also

contains the touch screen.

8 Touch screen. The touch screen is your interface to the Laser

Imager. The screen accepts your commands and gives you status

information about Imager functions.

How the Laser Imager Works

When the Laser Imager receives a print request, it determines the

requested film size and type then selects the appropriate film cartridge.

Each time the Imager receives a print request, the following print

sequence occurs.

Overview

Print Sequence

1. Suction cups in the pickup area lift a single sheet of film out of the supply

cartridge and feed the film into the transport rollers.

2. The transport rollers move the film down into the registration transport

area, where film registration takes place.

2010-11-04 2G8647 1-3

Overview

CAUTION:

LASER WARNING:

Film Throughput

Agency Compliance

3. The film registration transport then moves the film into the exposure

transport.

4. As the film moves through the exposure transport, the optics module

writes the image onto the film, then moves the film into the film

processor.

5. As the film passes over the processor drum, the heat generated by the

drum develops the film.

6. The film transport rollers move the developed film through the

densitometer to the sorter and out to one of the bins.

Prints up to 160 films (35 x 43 cm or 14 x 17 in.) per hour. Smaller film

sizes print more quickly.

See the DRYVIEW 6850 Laser Imager Safety Manual, 2G8646.

User Guide Conventions

The following special messages emphasize information or indicate

potential risks to personnel or equipment.

NOTE: Notes provide additional information, such as expanded

explanations, hints, or reminders.

IMPORTANT: Important notes highlight critical policy information that

Cautions point out procedures that you must follow precisely to

avoid damage to the system or any of its components, loss of

data, or corruption of files in software applications.

DANGER: DANGER IDENTIFIES PROCEDURES THAT YOU

Laser warnings warn personnel that access to laser radiation is

possible and all personnel must avoid direct exposure to the

beam.

affects how you use this guide and this product.

MUST FOLLOW PRECISELY TO AVOID INJURY TO

YOURSELF OR OTHERS.

1-4 2G8647 2010-11-04

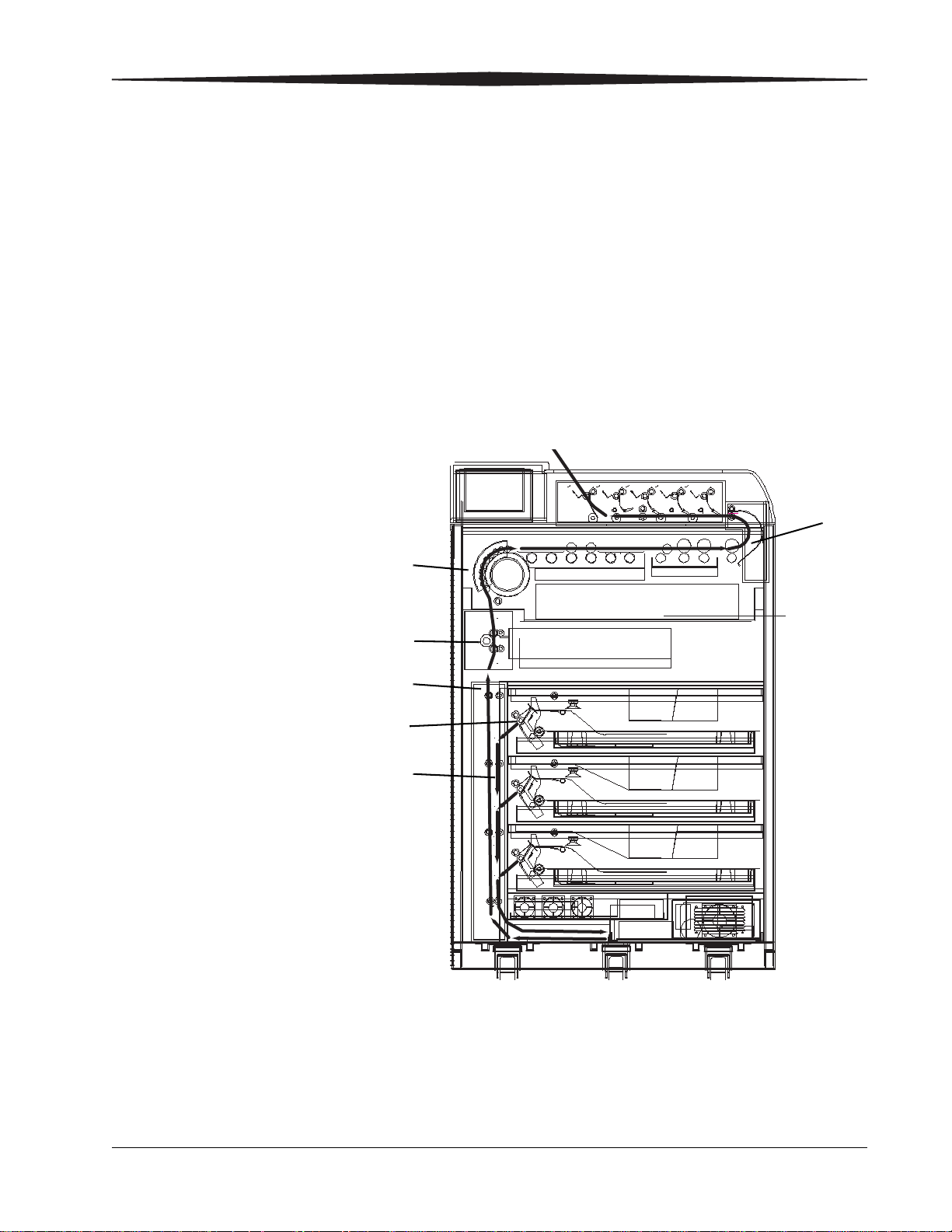

2

Power button

Power switch

Local panel

Using and Maintaining the Imager

Operator Control of the Imager

During normal operation, the 6850 Laser Imager receives and

automatically prints images sent by modalities over a network. Very

little operator control is required. The main responsibilities of the

operator are:

• turning Imager power ON and OFF.

• loading film cartridges.

• taking recommended actions when preventive maintenance (PM) or a

filter maintenance request is indicated on the touch screen.

• monitoring and controlling some Imager functions using the touch

screen.

Turning Imager Power ON and OFF

There is a power switch and a power button on the 6850 Laser Imager.

The power switch should only be used the first time the Imager is

powered ON or when an immediate shutdown is required. For normal

operations, use the power button.

2010-11-04 2G8647 2-1

Using and Maintaining the Imager

Power ON IMPORTANT: After the initial startup of the Imager, the power button on

the local panel should be used to power ON and power

OFF the Imager.

If this is the first time the Imager has been powered ON, set the power

switch to the "|" (ON) position and press the power button on the local

panel. The Imager performs a power-up self test that takes about five

minutes. After the self test, there are some initial boot-up screens before

the local panel Main Screen appears.

After the power-up test, the Imager begins a warm-up period that can last

up to 30 minutes. The warm-up period varies depending on how long the

Imager has been turned OFF, the ambient temperature, and whether the

Imager is in power save mode. During warm-up, the Imager can receive

and store images but cannot print films. When the Imager reaches

operating temperature, it starts printing any images accumulated during

the warm-up period.

During warm-up, you can use the touch screen to check the contents of

the film drawers and to open the film drawers to load new film cartridges

if necessary.

Normal Power OFF IMPORTANT: The local panel should be used to turn OFF power to the

imager, except in an emergency. Using the main power

switch could cause the imager to shut down incorrectly

and possibly cause some corruption of the operating

system.

Turn the Imager OFF if you do not expect to use it for an extended

period of time.

1. On the local panel, press the power button.

2. On the touch screen, touch:

• Power OFF

• OK

All films in process will be completed before the Imager does a

controlled shutdown (similar to a computer shutdown).

Emergency Power OFF If an emergency arises that requires the immediate shutdown of the

Imager, press the power switch "O" (OFF) at the lower right front of the

Imager. The Imager will shut down. Films in process will not be

completed and will remain where they are until removed (see

“Correcting Film Jams With the Imager Powered OFF” on page 3-2).

To restart the Imager, press the power switch "|" (ON). After warming

up, the Imager automatically reprints any films that were in process

when power was interrupted.

2-2 2G8647 2010-11-04

Using and Maintaining the Imager

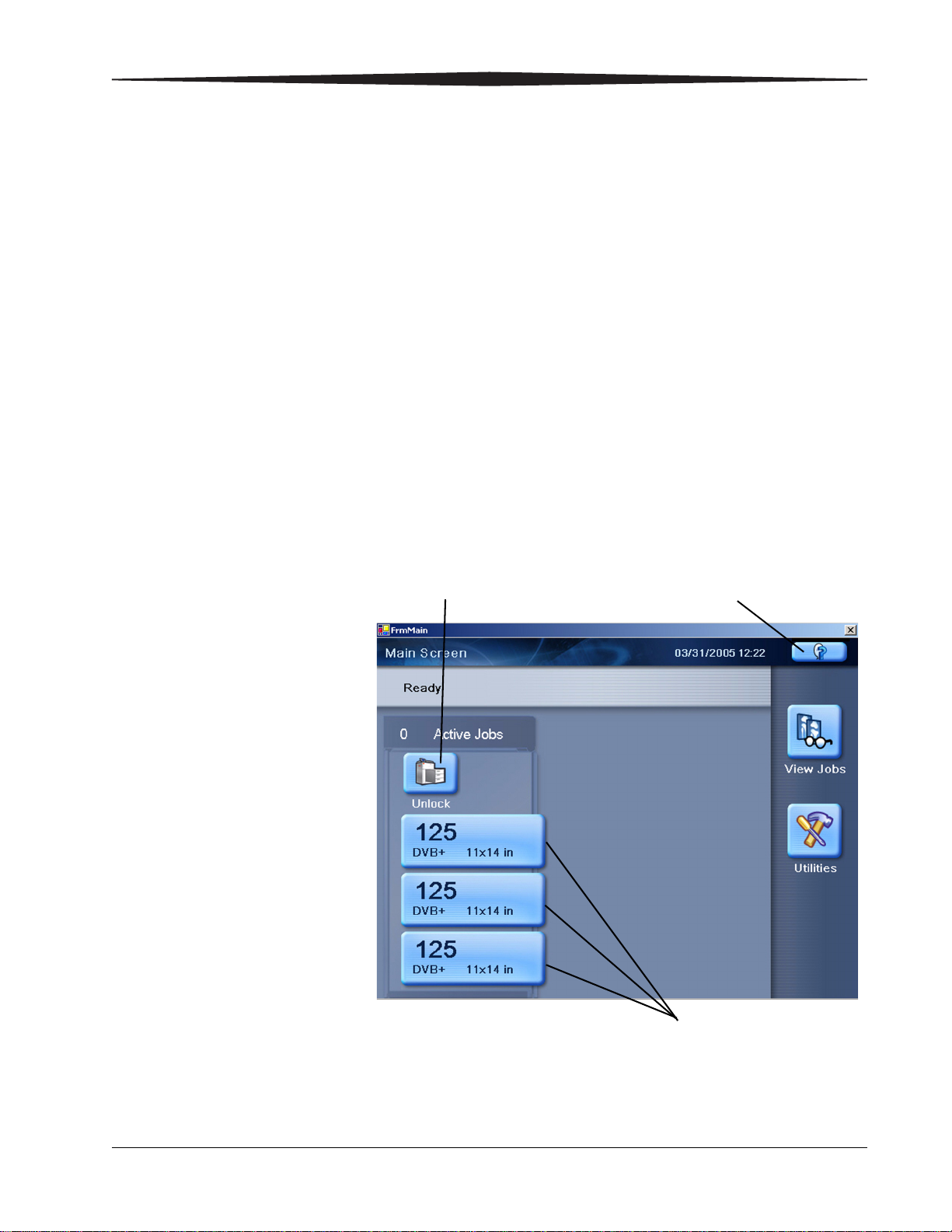

Unlock icon Help icon

Film drawer icons

Power Failures In the event of a power loss, the 6850 Laser Imager shuts down. Films in

process will not be completed and will remain where they are until they

are removed (see “Correcting Film Jams With the Imager Powered OFF”

on page 3-2).

To restart the Imager after power is restored, turn OFF the power switch

on the Imager and then turn it ON. After warming up, the Imager

automatically reprints any films that were in process when power was

interrupted.

NOTE: If the Imager does not restart after pressing the power switch, press

the power button on the local panel (see “Turning Imager Power ON

and OFF” on page 2-1).

Power Save The Imager has a Power Save option, which lets you reduce the power

consumption of the Imager during periods of inactivity. To learn more

about the Power Save option, see the general help information on the

touch screen (see “General Help” on page 2-6).

Using the Touch Screen

Use the touch screen to monitor Imager operations and to control some

Imager functions.

2010-11-04 2G8647 2-3

Using and Maintaining the Imager

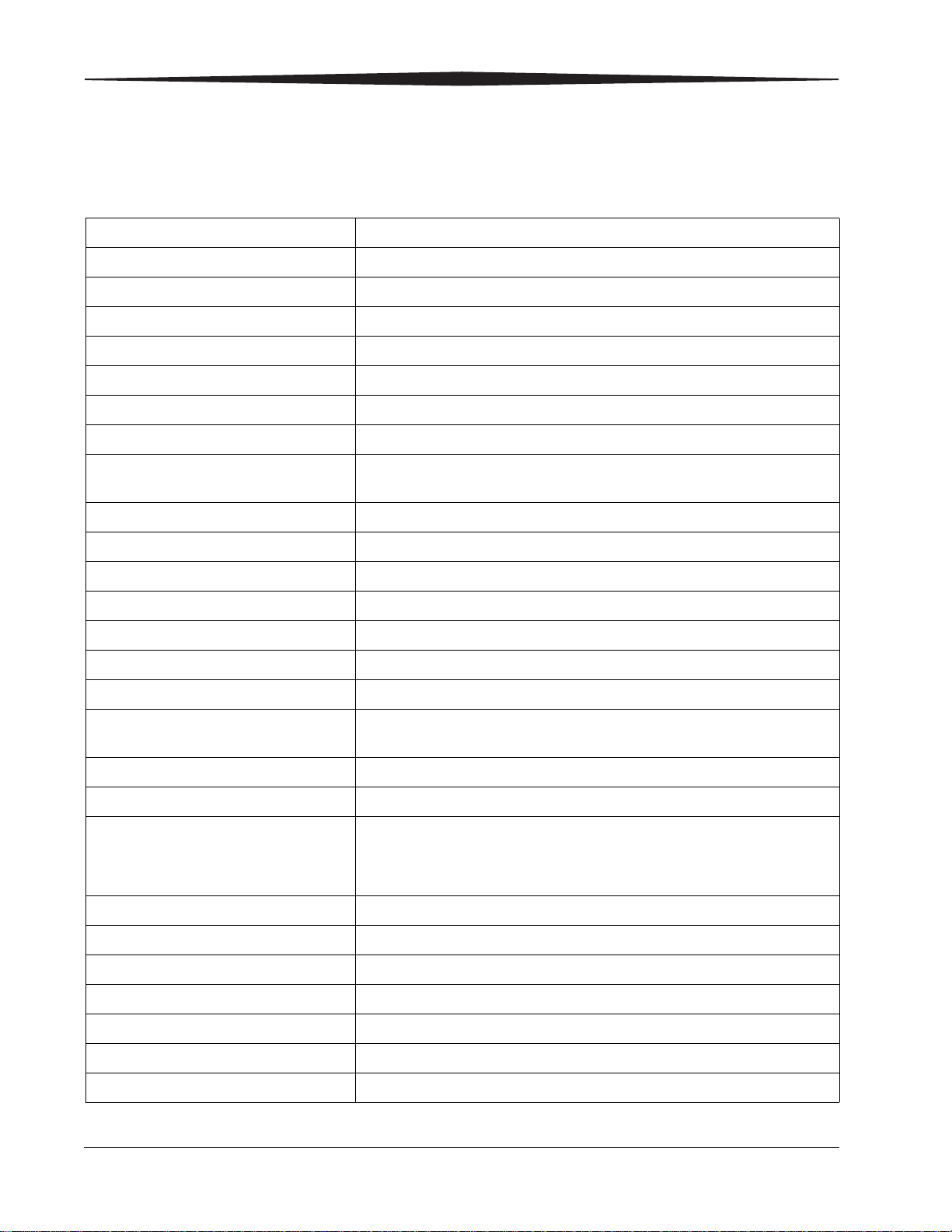

Touch Screen Functions

How To Touch

Add a modality Utilities>Configuration>Installation Assistant>Configure Modality

Adjust volume Utilities>User Operations>Speaker volume

Assign sorter bins Utilities>User Operations>Sorter bin

Backup system Utilities>Configuration>Backup

Calibrate film Film drawer icon>Calibrate Film Supply

Calibrate touch screen Utilities>Configuration>Calibrate touch

Change date/time Utilities>Configuration>Date & Time

Change preventive maintenance

module (PMM)

Change language Utilities>Configuration>Change language

Change passcode Utilities>Service>Change passcode

Change service number Utilities>Service>Service number

Clean electronics filter Utilities>User Operations>Change Filter

Use the following table to navigate the touch screen. All functions begin

at the Main Screen.

Utilities>User Operations>Change Filter

Configure Imager Utilities>Configuration>Installation assistant

Configure modality Utilities>Configuration>Configure modality

Configure network Utilities>Configuration>Network

Configure Remote Management

Services

Disable printing Utilities>Service>Printing enabled

Enable printing Utilities>Service>Printing disabled

Log filter change Utilities>User Operations>Change Filter

Log PM done Utilities>Service>Preventive Maintenance

Ping Utilities>Service>Ping

Reset modality Utilities>Configuration>Reset modality

Restore from backup file Utilities>Configuration>Restore

Run mammo test patterns Film drawer icon>Mammo test patterns

Run test patterns Film drawer icon>Test Patterns

Utilities>Configuration>Remote management

or

Utilities>Service>Preventive Maintenance

Schedule power save Utilities>User Operations>Power save schedules

2-4 2G8647 2010-11-04

Loading...

Loading...