Carestream Health 5950 User Manual

Preliminary User Manual

SHORT TERM CONFIDENTIAL

Publication No. AA2204_en

2012-07-27

All rights reserved. No part of this manual may be reproduced or copied in

SHORT TERM CONFIDENTIAL

any form by any mean graphic, electronic, or mechanical, including

photocopying, typing, or information retrieval systems without written

permission.

Contents

SHORT TERM CONFIDENTIAL

1 Overview

How the Imager Works ................................................................................................................. 1-4

Print Sequence .........................................................................................................................1-4

Film Sizes ........................................................................................................................................1-5

Mammography Imaging ............................................................................................................... 1-5

Automatic Image Quality and Processing ....................................................................................1-6

Configure and Monitor the System (Using the Web Portal) .......................................................1-6

Enhanced Serviceability with Remote Monitoring ......................................................................1-6

Agency Compliance .......................................................................................................................1-6

User Guide Conventions ................................................................................................................ 1-7

2 Basic Operating Tasks

The Display Screen ......................................................................................................................... 2-2

Imager Power .................................................................................................................................2-5

Power Switch Location ............................................................................................................ 2-5

Start the Imager ....................................................................................................................... 2-5

Emergency Shutdown or Power Loss .....................................................................................2-6

Restart the Imager ................................................................................................................... 2-6

View the Film Cartridge Information ...........................................................................................2-7

Replace an Empty Film Cartridge ................................................................................................. 2-9

Load a Different Film Size to Match a Print Request ................................................................2-10

Delete All Pending Jobs .............................................................................................................. 2-11

Calibrate the Imager for the Loaded Film .................................................................................2-12

Automatic vs. Manual Calibration ........................................................................................2-12

Make a Test Print .........................................................................................................................2-13

SMPTE Image Prints ............................................................................................................... 2-13

Mammography Test Prints ....................................................................................................2-14

Open or Remove a Cover ............................................................................................................2-15

Access More Functionality with the Web Portal ........................................................................2-16

Access the Web Portal ........................................................................................................... 2-16

3 Maintenance and Troubleshooting

Overview: Status and Error Messages and Codes ........................................................................3-2

Preventive Maintenance ............................................................................................................... 3-3

About the Charcoal Filter ........................................................................................................3-3

Replace the Filter ..................................................................................................................... 3-4

550 Code and Maintenance Symbol .......................................................................................3-5

AA2204_en | 2012-07-27 i

Error Indicators on the Display Screen .........................................................................................3-6

SHORT TERM CONFIDENTIAL

Recognize and Handle a Calibration Error ............................................................................ 3-6

Handle a Required Restart ......................................................................................................3-7

Recognize and Handle a Film Jam .......................................................................................... 3-8

Using the Web Portal to Gain More Information on Errors ....................................................... 3-9

Subsystem Error Codes and Messages ........................................................................................3-10

DICOM (Digital Imaging and Communications in Medicine) ..............................................3-10

Printer ..................................................................................................................................... 3-10

Film Cartridge ........................................................................................................................3-11

Job Manager .......................................................................................................................... 3-13

Condition Codes .......................................................................................................................... 3-14

Film Jam Indication and Areas .................................................................................................... 3-20

Clear Film Jam Code 116 / Jam in Area 1 .............................................................................3-23

Clear Film Jam Code 323 / Jam in Area 2 .............................................................................3-23

Clear Film Jam Code 324 or 325 / Jam in Area 2 ..................................................................3-24

Clear Film Jam Code 326 / Jam in Area 2 or 3 ...................................................................... 3-25

Clear Film Jam Code 543 / Jam in Area 3 .............................................................................3-26

Clear Film Jam code 544 / Jam in Area 3 ..............................................................................3-26

Display Screen is Not Functional .................................................................................................3-27

Call for Support ........................................................................................................................... 3-27

4 Film Technical Information

Spectral Sensitivity of the Film ...................................................................................................... 4-1

Film Image Quality ........................................................................................................................4-2

Environmental Impact ................................................................................................................... 4-2

Undeveloped Film Handling and Storage ....................................................................................4-3

Developed Film Handling and Archival ........................................................................................4-3

Exposing Film to Moisture ............................................................................................................ 4-4

Odor Dissipation ............................................................................................................................4-4

Heat Dissipation ............................................................................................................................. 4-4

Film Recycling ................................................................................................................................ 4-4

5 Specifications

Equipment Specifications ..............................................................................................................5-1

Operating Space Requirements .................................................................................................... 5-1

Environmental Requirements ....................................................................................................... 5-2

Environmental Effects ............................................................................................................. 5-2

Power Requirements ...............................................................................................................5-2

Network Requirements ...........................................................................................................5-2

6 Publication History

ii AA2204_en | 2012-07-27

1

1

2

4

6

5

3

SHORT TERM CONFIDENTIAL

Overview

The Laser Imaging System is a continuous-tone laser imager with an internal

photothermographic film processor. Heat, rather than photo chemicals, is used to

develop the film. This easy-to-use and reliable imager provides high-quality prints. Use

the prints from this system for:

• Diagnostic purposes to determine patient treatments, including imaging for full field

digital mammography

• Referral, sharing, or educational purposes

The system receives and prints from qualified image sources such as medical electrical

equipment (modalities) and workstations over the network. You can send print jobs

simultaneously from multiple image sources. The open design lets you connect to

modalities of all types and vendors.

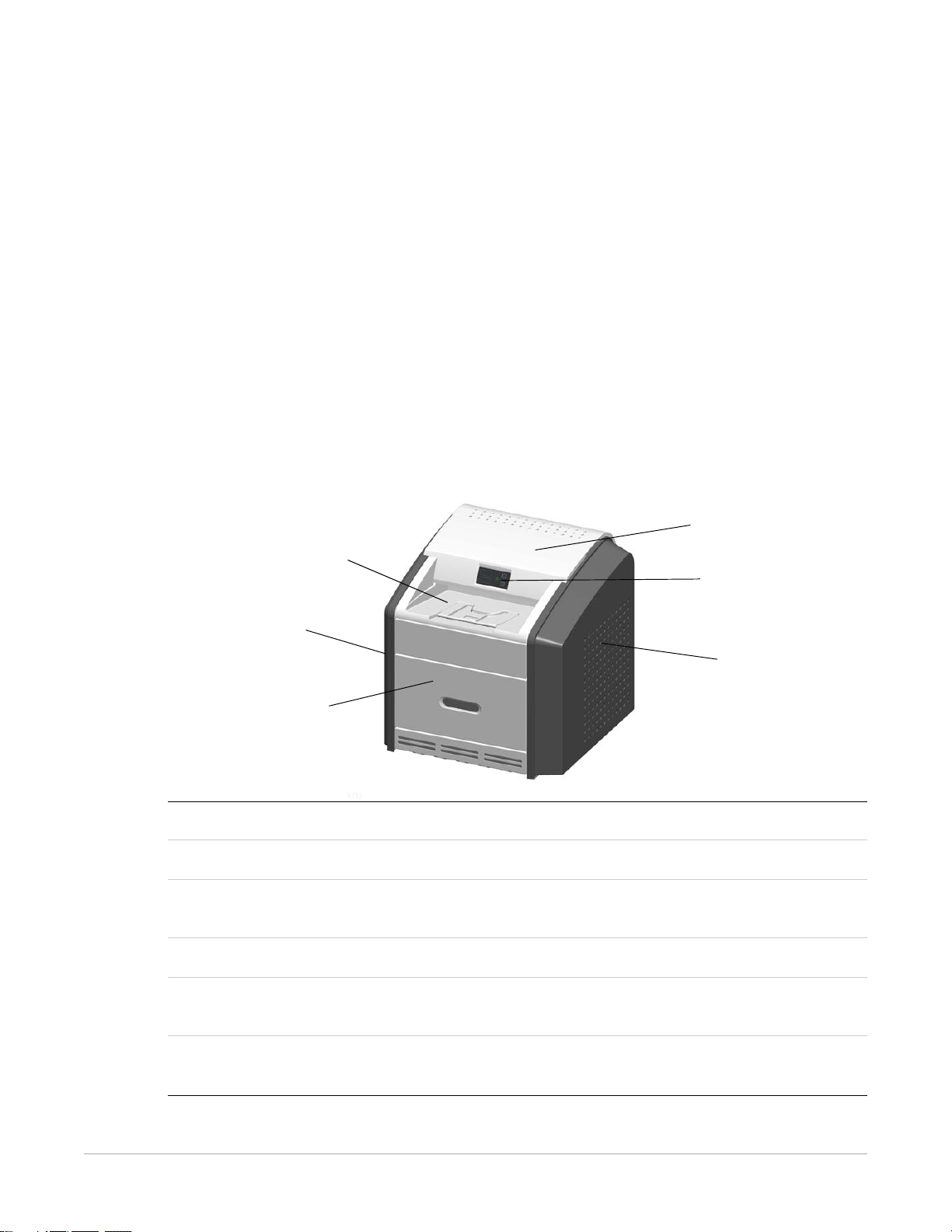

1 Top cover. Covers the processor rollers. The top cover is interlocked.

2 Display screen. Provides an interface to the imager, with status and error information.

3 Right cover. Protects sensitive electronic equipment. The right cover is interlocked and

is only accessed by service personnel.

4 Film supply cover. Covers the upper and lower film supplies. Supports five film sizes.

5 Left cover. Covers the left side of the imager. You might remove the left cover to clear

an occasional film jam. The left cover is interlocked.

AA2204_en | 2012-07-27 1–1

6 Exit tray. Holds up to 50 processed sheets of film. Extend the exit tray to hold large film

(35 x 43 cm, or 14 x 17 in.) as it finishes printing.

Overview

H241_0003DC

H241_0003DCA

1

2

3

4

5

6

7

8

9

10

11

SHORT TERM CONFIDENTIAL

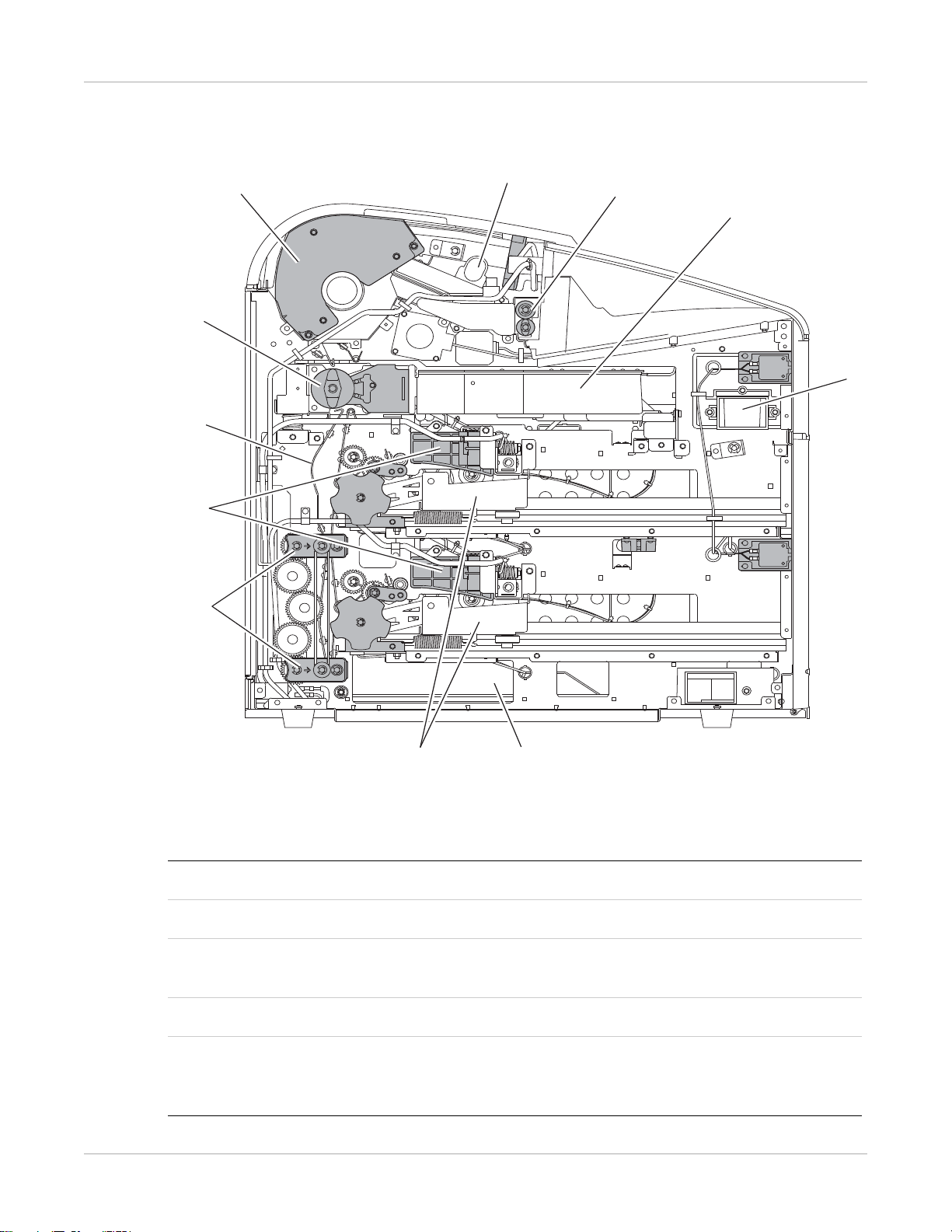

Major Internal Assemblies

1 Airflow manifolds. Remove heat and processing odors from the processor assembly.

2 Exit rollers. Move the film from the processor area to the exit tray.

3 Optics module. Writes the image onto the film while the film is moved through the

exposure transport.

4 Charcoal filter. Absorbs the odors caused by heat processing.

5 Accumulator. Receives the film as it is imaged. When imaging is complete, the film is

sent from the accumulator up to the processor assembly where the heat is applied to

process the image.

1–2 AA2204_en | 2012-07-27

Overview

SHORT TERM CONFIDENTIAL

6 Rollback assemblies (upper and lower). Roll the film cartridge cover back so the

pickup assembly can lift the film. When the imager is not printing, the cover is closed

over the film cartridge to protect the film from light.

7 Feed rollers. Move the film through the imager.

8 Pickup assemblies (upper and lower). Lift a single sheet of film from the supply

cartridge and feed it into the rollers.

9 Transport guides. Orient and center the film while moving the film from the supply to

the imaging portion of the imager.

10 Exposure transport. Moves the film past the scanning laser beam.

11 Processor drum. Provides the heat that processes the image on the film.

AA2204_en | 2012-07-27 1–3

Overview

SHORT TERM CONFIDENTIAL

How the Imager Works

The imager receives, processes, manages, and prints the images on film. The imager has

limited storage to hold a small number of digital images. As images are received for

printing, they are stored in memory, placed in a sequential print queue, and printed in

order. The imager can continue to accept incoming print jobs even if temporarily unable

to print (if the film supply is empty, etc.).

During normal operation, the imager requires very little attention. It prints automatically

in response to print requests from the configured image sources. Information sent with

the images by the image source, such as film type and size and image quality settings, is

applied unless you set the imager to override information that comes from the image

source.

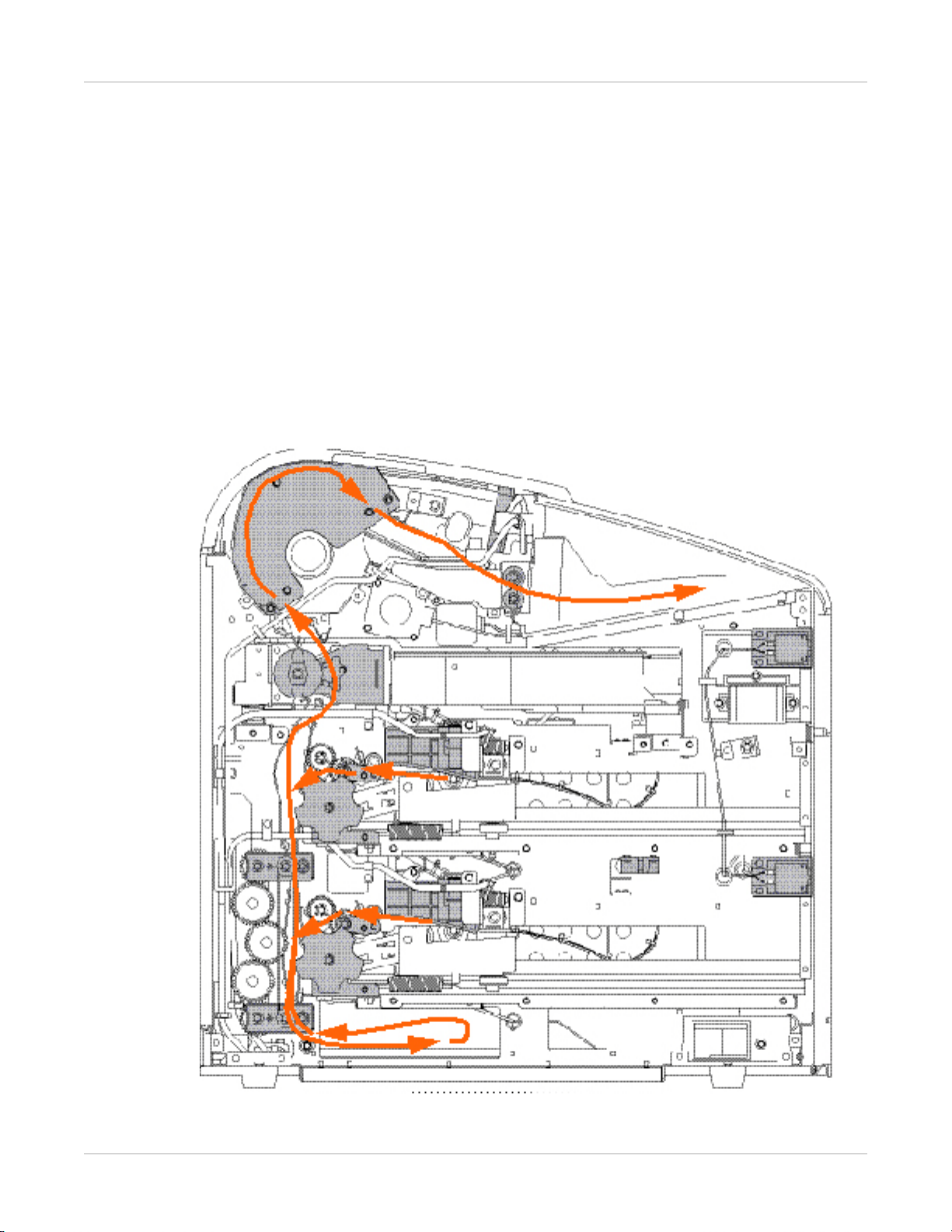

Print Sequence

1–4 AA2204_en | 2012-07-27

Each time the imager receives a print request, the following print sequence occurs. The

Note

SHORT TERM CONFIDENTIAL

arrows show the film path.

1. Suction cups in the pickup area lift a single sheet of film out of one of the supply

cartridges and feed the film into the transport rollers.

2. The transport rollers move the film down into the exposure transport area.

3. The film moves down during imaging (as the optics module writes the image onto

film), reverses direction at the conclusion of imaging, and then the film moves up into

the processor.

4. As the film passes over the processor drum, the heat generated by the drum develops

the film.

5. The exit rollers move the developed film to the exit tray.

Film Sizes

The imager supports five sizes:

• 35 x 43 cm (14 x 17 in.)

• 35 x 35 cm (14 x 14 in.)

Overview

• 28 x 35 cm (11 x 14 in.)

• 25 x 30 cm (10 x 12 in.)

• 20 x 25 cm (8 x 10 in.)

Clear, blue, and mammography film types are supported.

Mammography Imaging

To manage and support mammography imaging, the imager provides these features:

• You can load mammography film in one or both film supplies.

• The imager only prints mammography images on mammography film. If a

mammography image request is received, and:

– a cartridge with mammography film is not loaded,

and/or

– the requested mammography film size is not loaded,

then the imager will request the appropriate film size and type. You must load the

requested size and type to print the mammography job.

• Several mammography-specific test prints are provided, including a default test print

for the routine calibration of mammography film (for example, a density wedge

print). The default mammography test print is configured during installation and can

be changed from the Web Portal.

For help with the quality control process for mammography, see the Quality Control Manual.

Requirements for mammography quality control vary by region.

AA2204_en | 2012-07-27 1–5

Overview

SHORT TERM CONFIDENTIAL

Automatic Image Quality and Processing

An internal densitometer enables the imager to automatically adjust image processing

parameters using Automatic Image Quality Control (AIQC) to produce an optimal image.

The imager adjusts these parameters each time it prints a calibration film.

A calibration film is printed when:

• A film cartridge is inserted in the imager with film of a new lot number.

• You request a calibration film at the display screen or the Web Portal.

• A film cartridge is inserted into the imager for which a current calibration is not

stored.

Related topics

Calibrate the Imager for the Loaded Film

Configure and Monitor the System (Using the Web Portal)

The Web Portal is your interface to additional features. In addition to the installation and

setup of your system, you can view and manage the imager's connections over the

network, configure features, view error messages, and access general status information

at the Web Portal. You can also check film count, film size, and film type.

Related topics

Access the Web Portal

Enhanced Serviceability with Remote Monitoring

Remote Management Services is set up through the Web Portal, and is designed to

enhance efficient system serviceability and simplify analytical and service processes

through the monitoring of your equipment. Additionally, this simplifies the service

process by providing qualified service personnel with faster, easier, and more complete

access to the operational history of each system.

Remote Management Services provides the following for the imager:

• Ability to monitor and diagnose error conditions without introducing “downtime”

• Firewall-safe, Internet transmission of machine data, while complying with patient

confidentiality regulations

• Minimal effort to set up communication

• Flexibility to facilitate specific configurations at each site

Agency Compliance

See the Safety Manual.

1–6 AA2204_en | 2012-07-27

User Manual Conventions

Note

Important

Caution

DANGER

Laser Warning

SHORT TERM CONFIDENTIAL

The following special messages emphasize information or indicate potential risks to

personnel or equipment.

Notes provide additional information, such as expanded explanations, hints, or reminders.

Important notes highlight critical policy information that affects how you use this guide and this

product.

Cautions point out procedures that you must follow precisely to avoid damage to the system or

any of its components, loss of data, or corruption of files in software applications.

Overview

Danger identifies procedures that you must follow precisely to avoid injury to yourself or others.

Laser warnings warn personnel that access to laser radiation is possible and all personnel must

avoid direct exposure to the beam.

AA2204_en | 2012-07-27 1–7

SHORT TERM CONFIDENTIAL

2

SHORT TERM CONFIDENTIAL

Basic Operating Tasks

During normal operation, the imager receives and automatically prints images sent by

modalities over a network. Very little interaction is required. You can do the following:

• Turn the power on (|) and off (0).

• Load the film cartridges.

• Monitor the display screen for status and operating conditions.

Sometimes it will be necessary to perform preventive maintenance, filter replacement,

and other corrective actions such as a restart.

You also may access the Web Portal to perform additional configuration, optimize image

quality, or do troubleshooting tasks.

Related topics

Maintenance and Troubleshooting

Access More Functionality with the Web Portal

AA2204_en | 2012-07-27 2–1

Basic Operating Tasks

SHORT TERM CONFIDENTIAL

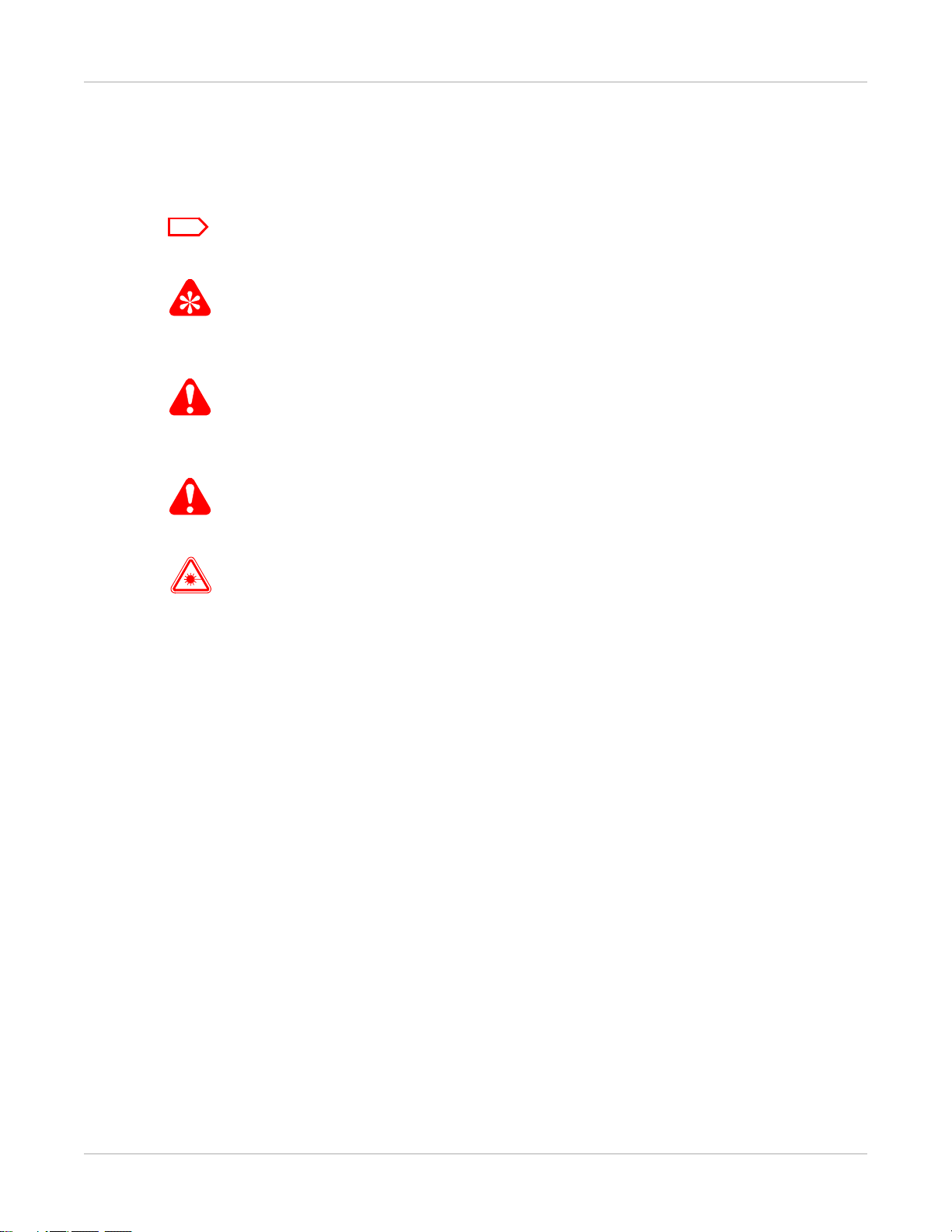

The Display Screen

The display screen communicates the status of the imager.

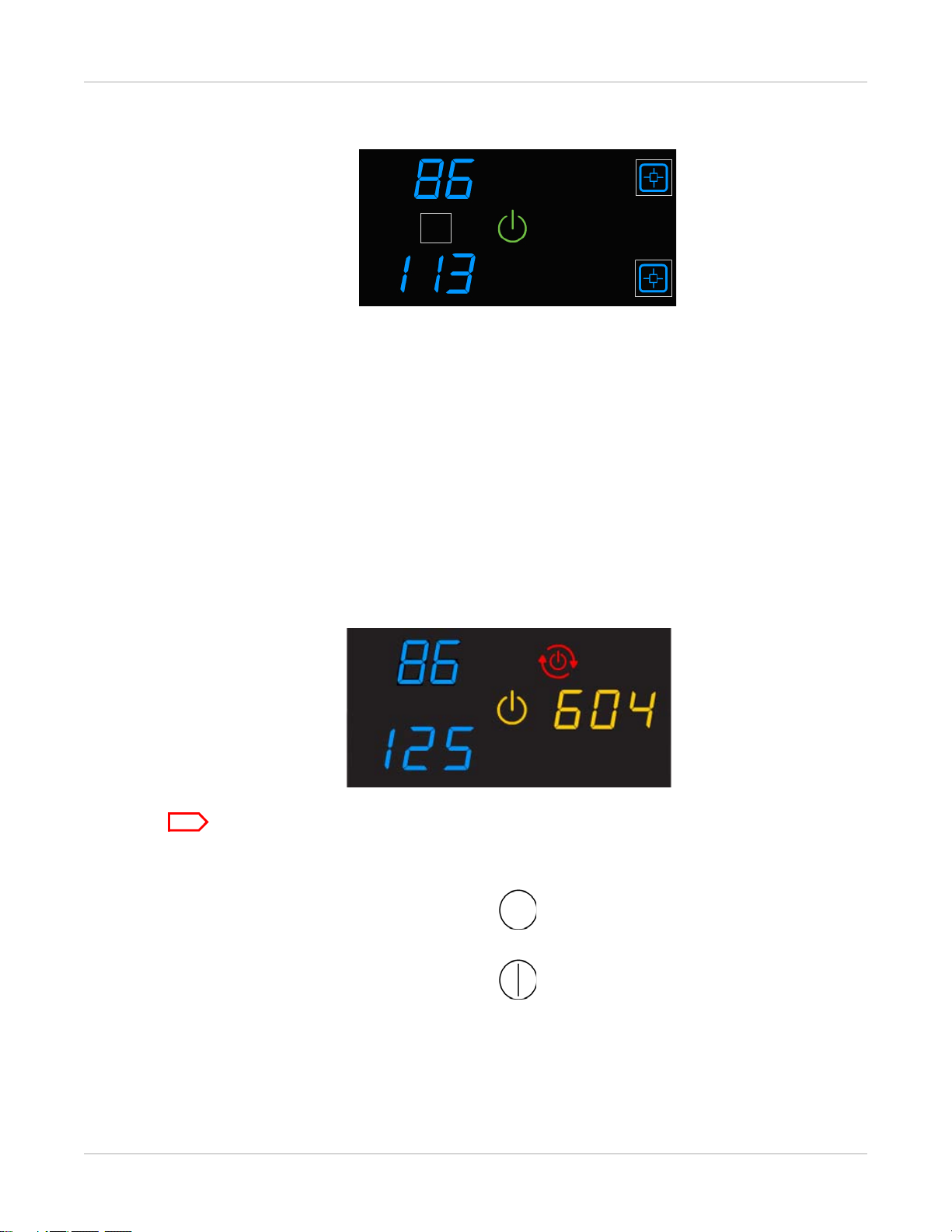

Figure 1: Display screen: normal state, processing a print job from the upper supply. In this

example, there are 86 sheets of film in the upper cartridge and 113 sheets in the lower cartridge.

Symbol or code Description

Upper and lower

left side:

Center right: Error or status code. The 3-digit code displays when the error or status

Film counts. Displays the number of films that are remaining in the upper

and lower film cartridges.

If a blue number does not display while the imager is powered on, the

associated film cartridge is not inserted (or not fully inserted) into the

imager.

condition is present. If the imager is on and a 3-digit code does not

display, the imager is operating normally.

• If a different film size or type has been requested than either of the

loaded sizes, the requested film size displays. For mammography film,

an M displays in front of the film size; B indicates the blue base film,

and C indicates the clear base film.

• When the imager is starting, a countdown displays the number of

minutes until the imager will be ready to print (for example, -4 means

4 minutes until the imager will be ready to print).

2–2 AA2204_en | 2012-07-27

Basic Operating Tasks

Important

SHORT TERM CONFIDENTIAL

Symbol or code Description

Indicator light The light indicates the active cartridge. For example, when printing from

the upper supply, the indicator light appears next to the upper film count.

• When green, operation is normal.

• When amber, the light indicates that there is an issue with the film

supply, such as a jammed film.

Power When the symbol is green, the power is on and the imager is ready to

print.

• The symbol flashes while the imager is processing, calibrating, or

making a test print.

• When the symbol is amber, the imager is not ready to print. Examples

are when the imager has just been started, when a film cartridge is

empty or jammed, and when a cover is removed.

Calibrate Press to initiate film calibration for the film cartridge (upper or lower).

• The symbol flashes while the calibration is in process, when making a

test print (upper or lower), and when the filter must be reset.

• When amber, there is an error such as a failed calibration. The

indicator light associates the error code to the film cartridge.

Pause

To avoid exposing the film to light, do not open the film supply until the

Pause symbol is off. Wait until the symbol is off to replace a cartridge.

• During most normal operation, including when the imager is idle, the

symbol is off.

• The symbol is on while the imager is processing images, test prints,

and during calibration.

• The symbol flashes when a film cartridge cover is being removed and

when the cartridge is open.

If the Pause symbol is on, you can press the symbol to temporarily pause

printing. Any jobs in progress finish printing, then the film cartridge cover

closes.

Film Size When this symbol appears, the requested print job requires a different

film size. The required film size flashes in the location of the error or

status code.

You can also press the symbol to delete the pending jobs that require a

different film size.

Restart Restart the imager. An error code also displays to indicate the reason for

the restart.

AA2204_en | 2012-07-27 2–3

Basic Operating Tasks

SHORT TERM CONFIDENTIAL

Symbol or code Description

Film Jam Film is jammed from the upper or lower cartridge. The error code

Maintenance Preventive maintenance is required. An error code also displays to

Related topics

Maintenance and Troubleshooting

Load a Different Film Size to Match a Print Request

Calibrate the Imager for the Loaded Film

Delete All Pending Jobs

Make a Test Print

confirms the film jam and gives direction on where to find the film inside

the imager. The indicator light associates the error code with the film

cartridge.

indicate the action to take.

Restart the Imager

Preventive Maintenance

2–4 AA2204_en | 2012-07-27

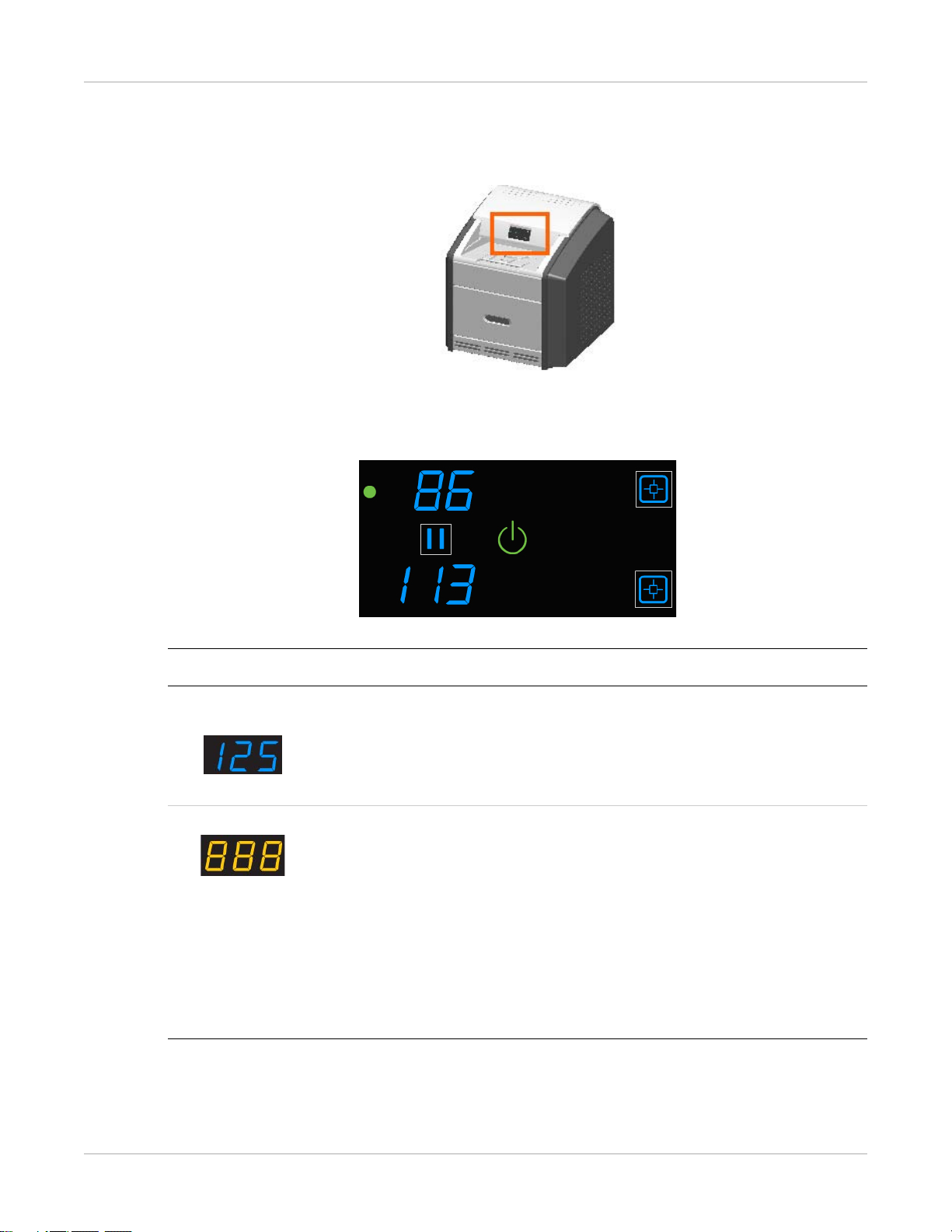

Imager Power

SHORT TERM CONFIDENTIAL

Power Switch Location

The power switch is on the lower back panel.

Basic Operating Tasks

Start the Imager

1. Press the power switch on the back of the imager on.

2. Wait as the imager warms up.

The warm-up period might last up to 30 minutes. The display screen shows the

progress as the imager becomes ready to print.

Figure 2: The imager counts up to zero (0) to indicate how soon the imager will be ready to

print. In this example, the imager will be ready to print in 7 minutes. The amber power symbol

also indicates that the imager is not ready to print.

The warm-up period varies depending on the amount of time the imager has been

off and the ambient temperature. During the warm-up period, the imager can

receive and store images but cannot print films.

When the imager reaches operating temperature, the display screen changes to show

that the system is ready to print, and the imager prints any images that were received

during the warm-up period.

AA2204_en | 2012-07-27 2–5

Basic Operating Tasks

Note

SHORT TERM CONFIDENTIAL

Figure 3: The green power symbol indicates that the imager is ready to process job requests.

Emergency Shutdown or Power Loss

In the event of a power loss, or if an emergency requires an immediate shutdown of the

imager, films in process will not be completed. However, when power is restored, the

imager will restart. After warming up, the imager automatically reprints any films that

were in process when the power was interrupted.

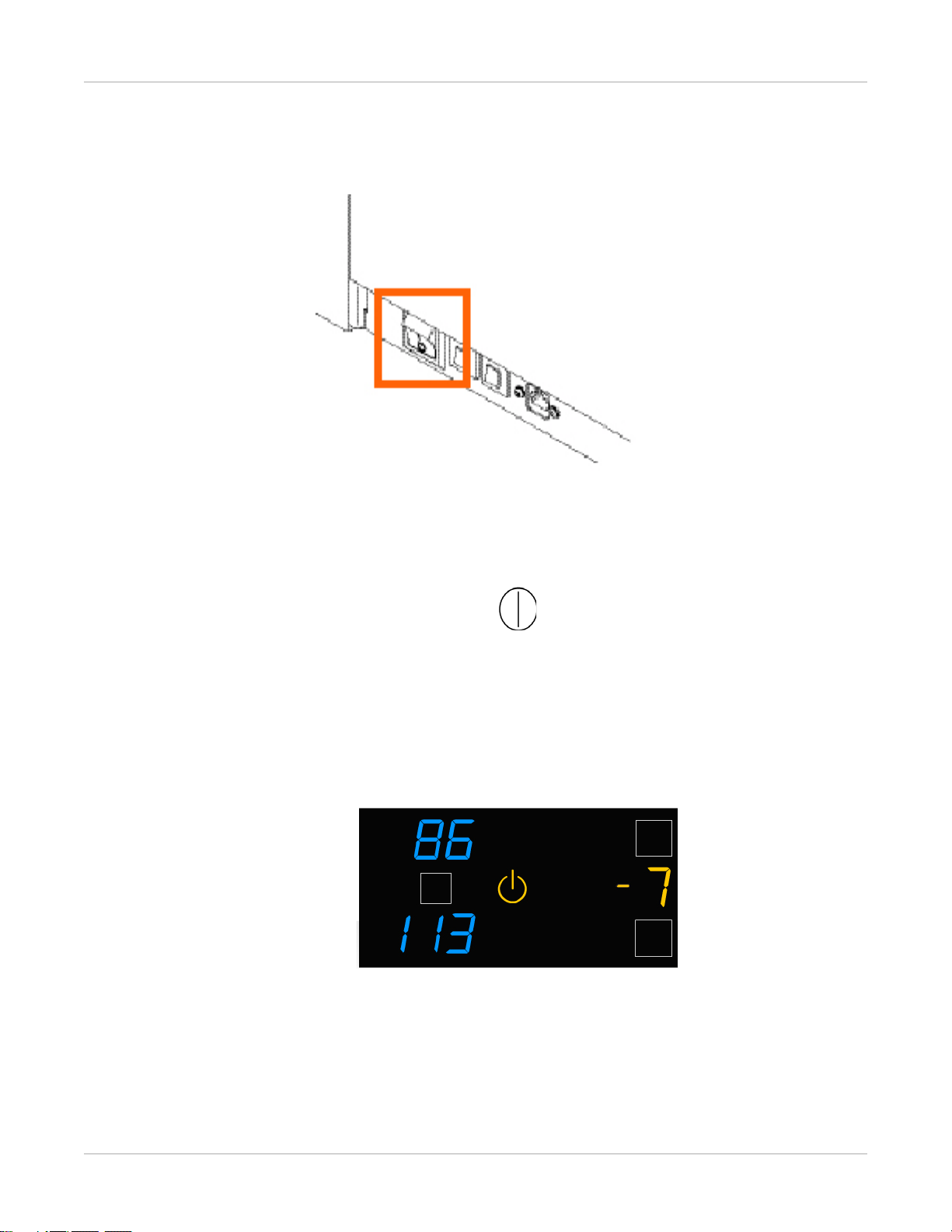

Restart the Imager

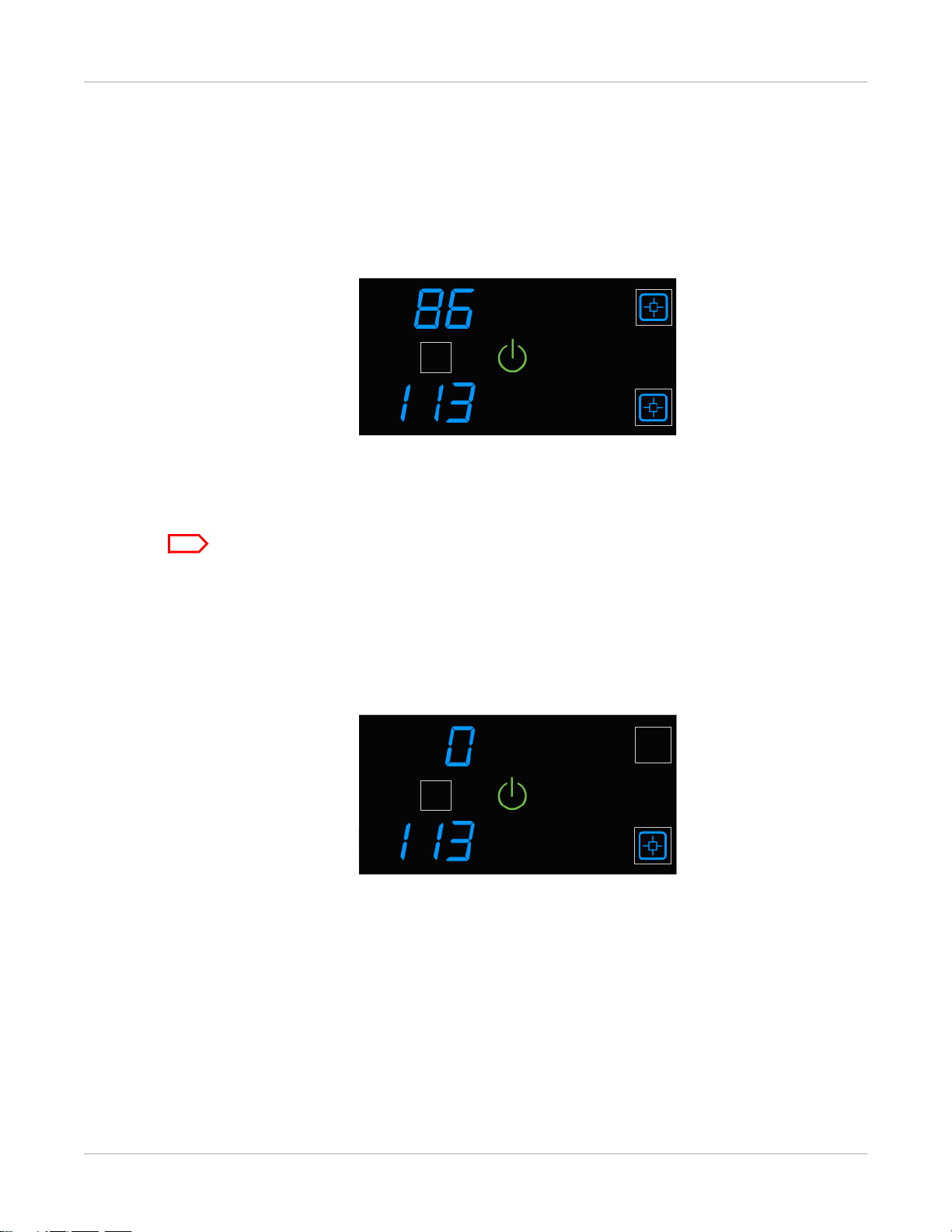

If the imager encounters an error that is usually corrected with a restart, the display

screen shows the Restart symbol.

Figure 4: A restart is required, and the error code indicates the error condition.

Check the Troubleshooting chapter or the Quick Reference Card to identify the error code.

1. Press the power switch on the back of the imager off.

2. Press the power switch on.

If the error does not clear after the restart, it might be necessary to contact a qualified

service provider.

2–6 AA2204_en | 2012-07-27

View the Film Cartridge Information

Note

SHORT TERM CONFIDENTIAL

Film Count

The upper and lower film counts appear on the display screen.

Figure 5: In this example, the upper cartridge has 86 sheets of film, and the lower has 113.

Size/Type of the Loaded Film

To check the size of the loaded film, open the film supply and view the loaded cartridges.

Basic Operating Tasks

Make sure the Pause symbol is off before you open the film supply.

Film Count Flashes “0”

When either cartridge is empty, the film count flashes “0.” Replace the cartridge.

Figure 6: In this example, the upper film cartridge is empty. Replace the upper cartridge.

AA2204_en | 2012-07-27 2–7

Basic Operating Tasks

SHORT TERM CONFIDENTIAL

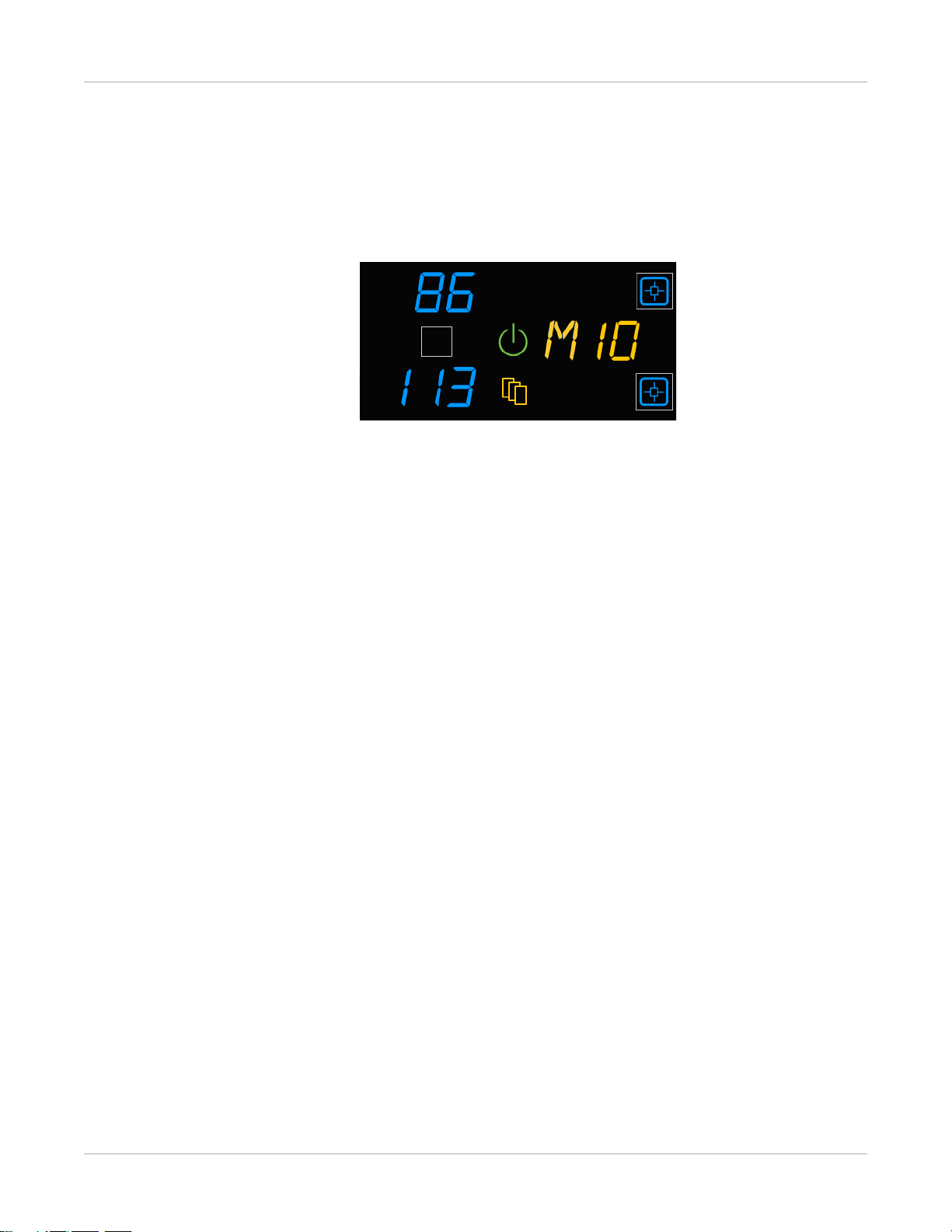

Film Size/Type Flashes

When a film size/type is requested that is not loaded, the Film Size symbol appears, and

the requested film flashes. Change the loaded film to match the print request.

Figure 7: View and load the requested film size/type in the error code location (amber text). In

this example, “M” represents a request for mammography film.

Related topics

Replace an Empty Film Cartridge

Load a Different Film Size to Match a Print Request

2–8 AA2204_en | 2012-07-27

Loading...

Loading...