Carestream Health 4901 Users Guide

DRYVIEW CHROMA Imaging System

SHORT TERM CONFIDENTIAL

H210_0843AC

User’s Guide

For Trade Trial Use Only

Carestream Health, Inc.

SHORT TERM CONFIDENTIAL

150 Verona Street

Rochester, New York 14608

United States

© Carestream Health, Inc., 2012

Printed in China.

CARESTREAM, CHROMA, and DRYVIEW are

trademarks of Carestream Health, Inc.

Pub No. 9G4260_en

Rev. C

Table of Contents

SHORT TERM CONFIDENTIAL

Overview

DRYVIEW CHROMA Imager at your Site............................................................................................................1-1

Intended Use....................................................................................................................................................1-1

Imager Features ...............................................................................................................................................1-2

CHROMA Media .........................................................................................................................................1-2

Network Interfaces.....................................................................................................................................1-2

Power Management Features......................................................................................................................1-3

Configuring and Monitoring the System (using the Web Portal) .................................................................1-3

Enhancing Serviceability with Remote Monitoring ......................................................................................1-3

How the Imaging System Works .......................................................................................................................1-4

System Components .........................................................................................................................................1-4

DICOM Interface ........................................................................................................................................1-4

Imager .......................................................................................................................................................1-5

Back View ..................................................................................................................................................1-7

Control Panel .............................................................................................................................................1-8

Display Screen .........................................................................................................................................1-10

Using the Web Portal to Access Additional Functionality .................................................................................1-12

Accessing the Web Portal .........................................................................................................................1-12

Agency Compliance ........................................................................................................................................1-13

Reference Information ...................................................................................................................................1-13

User Guide Conventions .................................................................................................................................1-13

Working with the Media and Ink

Handling the CHROMA Media (Film or Paper).................................................................................................2-1

Working with the Loaded Media.................................................................................................................2-2

Understanding How Media is Selected for Print Requests ................................................................................. 2-3

Loading the Media Cassette (Cut Sheets) .......................................................................................................... 2-4

Loading the Roll Paper.....................................................................................................................................2-9

Placing the Roll Paper on the Spindle......................................................................................................... 2-9

Loading the Roll Paper into the Imager ......................................................................................................2-9

Readying the Imager to Print to Roll Paper...............................................................................................2-10

Cutting the Roll Paper ..............................................................................................................................2-11

Changing the Media in the Imager..................................................................................................................2-12

Handling a Print Request with a Different Requested Media .....................................................................2-12

Handling a Media Change when the New Print Request is Urgent..............................................................2-13

i

Replacing the Cut Sheet Media .................................................................................................................2-14

SHORT TERM CONFIDENTIAL

Replacing the Roll Paper..........................................................................................................................2-16

Working with Ink........................................................................................................................................... 2-19

Extending the Life of Ink Cartridges During Periods of Inactivity or Low Use............................................2-19

Checking Ink Levels .................................................................................................................................2-20

Replacing Ink Cartridges..........................................................................................................................2-21

Checking Maintenance Tank Levels.......................................................................................................... 2-23

Replacing the Maintenance Tanks............................................................................................................ 2-24

System Settings and Status

Changing the Imager’s Date and Time.............................................................................................................. 3-1

Changing Configuration Items in Maintenance Mode........................................................................................ 3-1

Working in Maintenance Mode ..................................................................................................................3-1

Imager Language ....................................................................................................................................... 3-1

Units of Measurement ................................................................................................................................3-2

Temperature Units .....................................................................................................................................3-2

Auto Cleaning.............................................................................................................................................3-2

Alert Settings.............................................................................................................................................. 3-2

Number of Minutes Before Automatic Sleep Mode .....................................................................................3-3

Return Settings to the Defaults ................................................................................................................... 3-3

Checking Imager Status....................................................................................................................................3-4

Print a Status Sheet .................................................................................................................................... 3-4

View Imager Status.....................................................................................................................................3-4

Setting up Automatic Nozzle Check...................................................................................................................3-5

Setting up Roll Paper Settings...........................................................................................................................3-6

Media Selection ......................................................................................................................................... 3-6

Roll Paper Margins ....................................................................................................................................3-6

Paper Size Check ....................................................................................................................................... 3-6

Paper Skew Check ..................................................................................................................................... 3-6

Set Roll Paper Tension............................................................................................................................... 3-6

Optimizing the Look of the Image ....................................................................................................................3-7

Optimizing Grayscale Images on Film.........................................................................................................3-7

Optimizing Color Images on Paper.............................................................................................................3-8

Optimizing Grayscale Images on Paper ...................................................................................................... 3-8

Maintenance and Troubleshooting

Overview.......................................................................................................................................................... 4-1

Preventing Issues by Keeping the Imager Clean ................................................................................................4-2

Clean the Outside.

Uneven Prints: Clean the Cassette Printing Path .......................................................................................... 4-2

“Dirty” Prints: Clean the Inside ..................................................................................................................4-3

...................................................................................................................................... 4-2

ii

White Powder on the Platen: Clean the Platen............................................................................................ 4-4

SHORT TERM CONFIDENTIAL

Smudged Prints from the Roller................................................................................................................. 4-4

Running a Nozzle Check to Avoid or Correct Print Issues................................................................................. 4-5

Checking and Cleaning the Nozzles............................................................................................................ 4-5

Working with the Print Head...................................................................................................................... 4-6

Correcting Paper Cutting Problems.................................................................................................................. 4-8

Correcting Errors .......................................................................................................................................... 4-12

Introduction ............................................................................................................................................ 4-12

Messages at the Imager Display Screen and Suggested Actions ................................................................ 4-12

Roll Paper Errors .................................................................................................................................... 4-16

Maintenance or Service Call is Required.................................................................................................. 4-17

Troubleshooting ............................................................................................................................................ 4-18

Imager is Not Printing.............................................................................................................................. 4-18

Imager Sounds Like it is Printing, but Nothing Prints............................................................................... 4-18

Prints Do Not Look as Expected............................................................................................................... 4-19

Top Line of the DICOM Interface Screen is Blank .................................................................................... 4-20

Feeding or Ejecting Problems/Media Jams............................................................................................... 4-21

Clearing a Roll Paper Jam........................................................................................................................ 4-24

An Icon on my Print Indicates a Sizing Issue, or some of the Image or Information is Cut Off.................. 4-25

Miscellaneous Issues............................................................................................................................... 4-26

Restarting the Imager .................................................................................................................................... 4-26

The DICOM Interface is Non-Responsive (How to Restart) ............................................................................ 4-27

Restoring the System Software—Ghosting..................................................................................................... 4-27

Calling for Support ........................................................................................................................................ 4-29

Specifications

Dimensions and Clearance .............................................................................................................................. 5-1

Packed Dimensions ......................................................................................................................................... 5-2

Environmental Recommendations ................................................................................................................... 5-2

Temperature.............................................................................................................................................. 5-2

Relative Humidity....................................................................................................................................... 5-2

Surface Levelness....................................................................................................................................... 5-2

Acoustical Noise ........................................................................................................................................ 5-2

Power Requirements ....................................................................................................................................... 5-2

Network Requirements .................................................................................................................................... 5-2

Ink Cartridges.................................................................................................................................................. 5-3

Cartridge Life............................................................................................................................................. 5-3

Temperature

Capacity..................................................................................................................................................... 5-3

Weight....................................................................................................................................................... 5-3

.............................................................................................................................................. 5-3

iii

Media .............................................................................................................................................................. 5-3

SHORT TERM CONFIDENTIAL

Environmental ........................................................................................................................................... 5-3

Storage ...................................................................................................................................................... 5-3

Publication History .......................................................................................................................................... 5-4

iv

Overview

SHORT TERM CONFIDENTIAL

1

Overview

DRYVIEW CHROMA Imager at your Site

The DRYVIEW CHROMA Imaging System produces high-quality color

and grayscale images on film and paper. Use the prints from this versatile

system for diagnostic or referral purposes:

• Print on DRYVIEW CHROMA Medical Film to produce diagnostic

or referral images.

• Print on DRYVIEW CHROMA Matte and Glossy Papers to produce

images for referral, sharing, or educational purposes.

The imager receives and prints from image sources such as medical

electrical equipment (modalities) and workstations over the network.

You can send print jobs simultaneously from multiple image sources.

The open design lets you connect to modalities of all types and vendors.

The imager provides the latest generation of pigment ink technology.

Utilizing 11 ink colors, the imager produces a wide color gamut and

supports up to 43 cm (17 in.) wide media. The supported film and papers

provide consistent quality and resist fading and fingerprints, making the

prints durable and long-lasting.

IMPORTANT: Install the imager in a secure location to protect patient

privacy rights if required by local regulations.

Intended Use

The DRYVIEW CHROMA Imaging System is intended to provide hard

copy images from digital imaging source output signals. The device is

intended for use with DRYVIEW CHROMA film and reflective media

(DRYVIEW CHROMA Medical Film and DRYVIEW CHROMA

Medical Paper). The printer will interface with a variety of digital

modalities, including, but not limited to, CR (Computed Radiology), DR

(Digital Radiology), CT (Computerized Tomography), MRI (Magnetic

Resonance Imaging). The images are to be used for medical diagnosis

and referral to physicians and their patients. The DRYVIEW CHROMA

Imaging System is not intended for use with FFDM or CR

Mammography systems.

Additionally, for the media:

• DRYVIEW CHROMA Medical Papers and DRYVIEW CHROMA

Medical Film are intended to be used in the DRYVIEW CHROMA

Imaging System.

• DRYVIEW CHROMA Medical Film is used to visualize selected

parts of the human body, to determine whether they are normal or

2012-01-27 9G4260_en 1-1

Overview

Media carrier

for cut sheets

CHROMA media

Roll paper

SHORT TERM CONFIDENTIAL

pathologic. It is used by highly trained specialists, such as medical

physicians or radiologic technologists working in diagnostic

imaging. This film is intended for diagnostic or referral purposes.

• DRYVIEW CHROMA Medical Paper, DRYVIEW CHROMA

Medical Paper—Matte/Roll, and DRYVIEW CHROMA Medical

Paper—Glossy/Roll, are intended to be used for referral only. These

media types are not to be used for diagnostic purposes.

Imager Features

CHROMA Media The imager is a wide-format ink jet color printer that supports

DRYVIEW CHROMA Medical Film and DRYVIEW CHROMA

Medical Paper (media). The CHROMA roll paper, media sheets, and

media carriers are specially designed for the CHROMA imager.

You must keep the cut media in the original carrier when you load it into

the imager cassette.

CHROMA media is available in the following sizes and types:

• 20 x 25 cm (8 x 10 in.) blue base film

• 25 x 30 cm (10 x 12 in.) blue base film

• 28 x 35 cm (11 x 14 in.) blue base film

• 35 x 43 cm (14 x 17 in.) blue base film

• 22.0 x 28.0 cm (8.5 x 11.0 in.) matte paper and glossy paper

• A3 (297.00 x 420.00 mm or 11.69 x 16.54 in.) matte and glossy

paper

• A4 (210.00 x 297.00 mm or 8.27 x 11.69 in.) matte and glossy paper

• 297 mm x 100 m matte roll paper

• 11 in. x 100 m matte roll paper

• 297 mm x 75 m glossy roll paper

• 11 in. x 75 m glossy roll paper

For more information about the media, see “Chapter 2 Working with the

Media and Ink”.

Network Interfaces The DICOM interface supports standard Ethernet network interfaces

1000Base-T, 100Base-TX, and 10Base-T.

1-2 9G4260_en 2012-01-27

Overview

SHORT TERM CONFIDENTIAL

Power Management Features

Configuring and Monitoring the System (using the Web Portal)

Enhancing Serviceability with Remote Monitoring

To reduce power consumption, the imager supports sleep mode.

When no print jobs are in progress, the imager enters sleep mode. The

default setting is 15 minutes; the imager enters sleep mode after 15

minutes of no activity. To change the number of minutes, see “Number of

Minutes Before Automatic Sleep Mode” on page 3-3.

The Web Portal is your interface to more features. In addition to the

installation and setup of your system, you can view and manage the

imager's connections over the network, configure features, view error

messages, and access general status information at the Web Portal. You

can also check media count, size, and type.

For more information, see “Accessing the Web Portal” on page 1-12.

CARESTREAM Remote Management Services is set up through the

Web Portal, and is designed to enhance efficient system serviceability

and simplify analytical and service processes through the monitoring of

your equipment. Additionally, this simplifies the service process by

providing qualified service personnel with faster, easier, and more

complete access to the operational history of each system.

Remote Management Services provides the following for the imager:

• Ability to monitor and diagnose error conditions without

introducing “downtime”

• Firewall-safe, Internet transmission of machine data, while

complying with patient confidentiality regulations

• Minimal effort to set up communication

• Flexibility to facilitate specific configurations at each site

2012-01-27 9G4260_en 1-3

Overview

Imager

DICOM interface

SHORT TERM CONFIDENTIAL

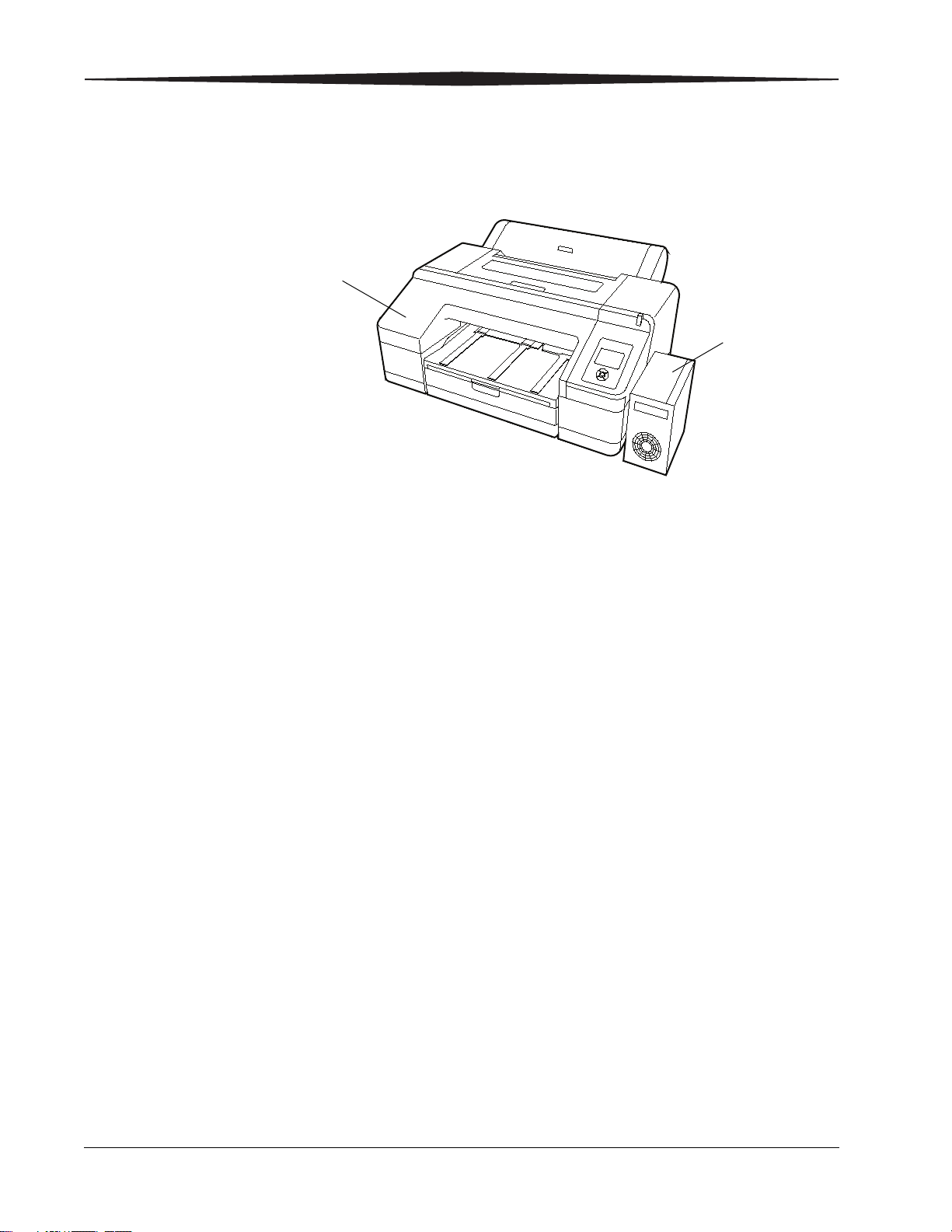

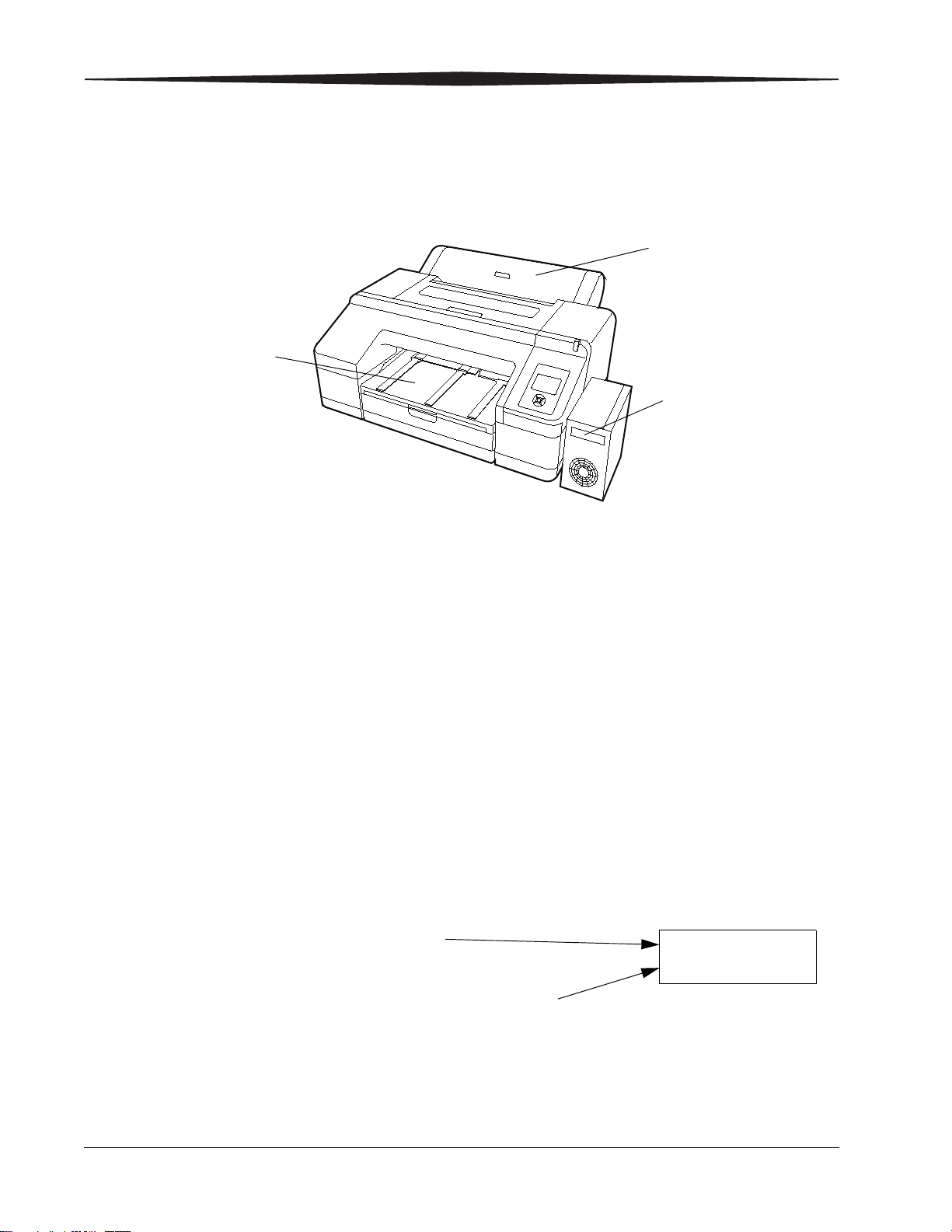

How the Imaging System Works

The imaging system consists of a DICOM interface (a small computer)

and a printer (imager), connected together with a USB cable. The

DICOM interface receives, processes, and manages the images, and the

imager holds the media (film or paper) and ink and prints the images.

The DICOM interface has hard-disk storage to hold a large number of

digital images. As images are received for printing, they are stored,

placed in a sequential print queue, and printed in order. The system can

continue to accept incoming print jobs even if temporarily unable to

print (for example, the media cassette is empty).

During normal operation, the imager requires very little attention. It

prints automatically in response to print requests from the configured

image sources. Information sent with the images by the image source,

such as media type and size and image quality settings, is applied unless

you set the imager to override information that comes from the image

source.

System Components

DICOM Interface The DICOM interface brings the images over the network and formats

them. It applies the processing parameters for optimal image quality and

sends the images to the imager. The small screen at the front of the

DICOM interface displays the installed media size and the requested

media size (if different). It also displays a counter that tracks the

approximate amount of loaded media that remains. For more

information, see “Working with the Loaded Media” on page 2-2.

For instructions to restart the DICOM interface, see “The DICOM

Interface is Non-Responsive (How to Restart)” on page 4-27.

1-4 9G4260_en 2012-01-27

Imager

SHORT TERM CONFIDENTIAL

Overview

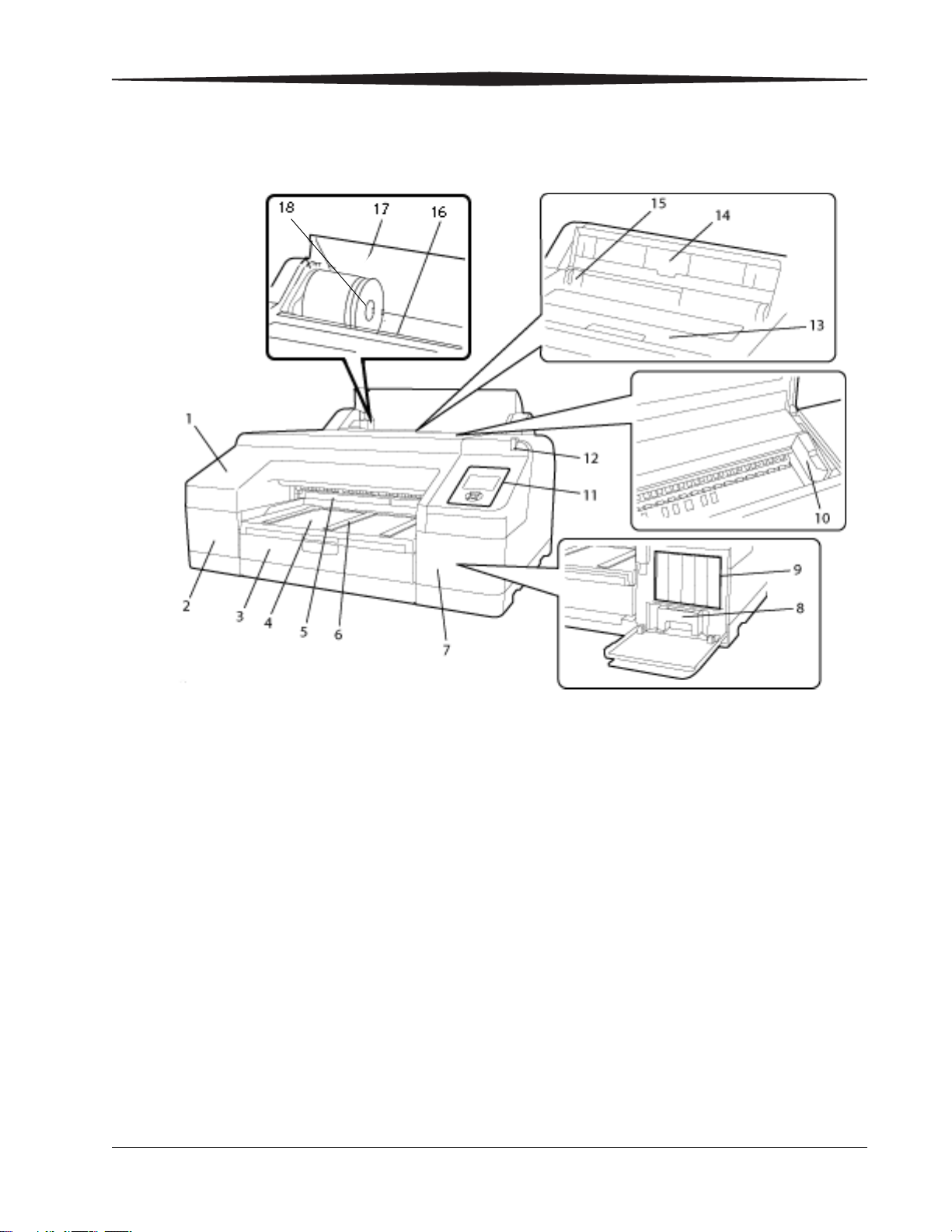

1 Front cover. Closes over the built-in cutter.

2 Cartridge cover (left). Covers ink cartridges #1–6. See “Replacing

the Ink Cartridges” on page 2-21.

3 Media cassette. Houses the cut sheet media in the media carrier. See

“Loading the Media Cassette (Cut Sheets)” on page 2-4.

4 Output tray. Collects the ejected paper and film. Extend the tray

according to the size of the media that is being ejected.

5 Maintenance tank. Collects the waste ink for borderless printing.

(Borderless printing is not supported with this imager release.)

NOTE: In the software, this is referred to as “Maintenance Box 2."

6 Media eject support. Supports the ejected (printed) media.

7 Cartridge cover (right). Covers ink cartridges #7–11 and the ink

maintenance tank. To replace ink or maintenance tank, see “Working

with Ink” on page 2-19.

2012-01-27 9G4260_en 1-5

Overview

SHORT TERM CONFIDENTIAL

8 Ink maintenance tank. Collects the waste ink.

NOTE: In the software, this is referred to as “Maintenance Box 1."

9 Ink cartridges. Install a total of 11 ink cartridges on the left and

right sides. To replace ink, see “Replacing the Ink Cartridges” on

page 2-21.

10 Print head. Fires ink via high-density nozzles while moving left and

right. Do not move the print head by hand.

11 Control panel. See “Control Panel” on page 1-8.

12 Alert lamp. Alerts you with light when an error or warning occurs.

• On—An error occurred. Check the error on the display screen.

• Flashing—Ink or media is low. You can specify if the warning

occurs for the media or the ink. The default is Off (no warning).

• Off—No error.

You can specify when the lamp alerts you. See “Alert Settings” on

page 3-2.

13 Top cover. Covers the inside of the imager.

14 Media support. Supports the media that is fed manually. (Manual

feed is not supported with this imager release.)

15 Manual edge guides. Guides the media that is fed manually.

(Manual feed is not supported with this imager release.)

16 Roller paper feeder. Receives the roll paper in the feeder slot. See

“Loading the Roll Paper into the Imager” on page 2-9.

17 Roll paper cover. Covers the roll paper. Leave the cover closed

except when loading or removing the roll paper. See “Loading the

Roll Paper into the Imager” on page 2-9.

18 Spindle holder. Supports the left side of the roll paper spindle. See

“Loading the Roll Paper” on page 2-9.

1-6 9G4260_en 2012-01-27

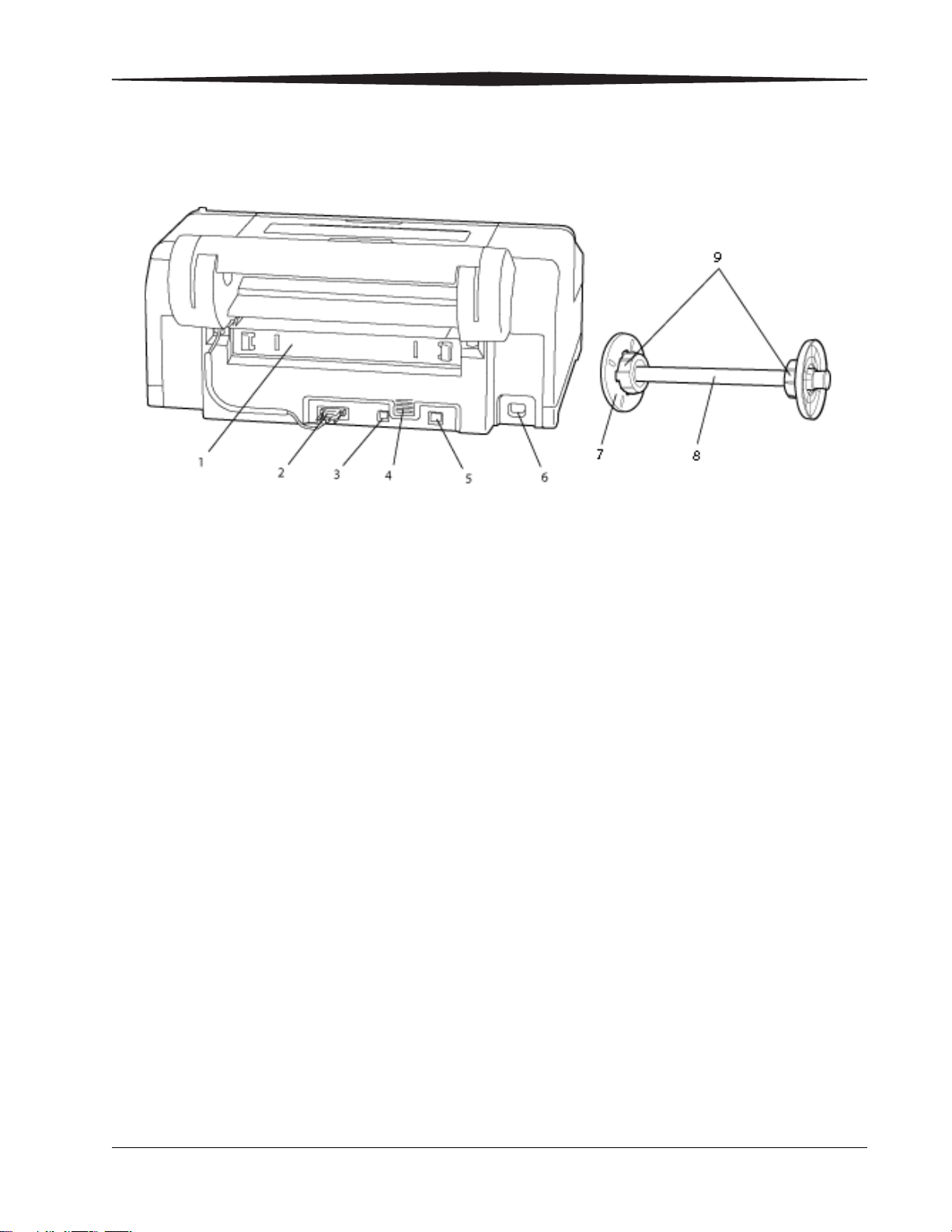

Back View

SHORT TERM CONFIDENTIAL

Overview

1 Rear access panel (covers the rear unit). Allows access to clear

media jams. See “Feeding or Ejecting Problems/Media Jams” on

page 4-21.

2 Roll paper holder unit connector. Always leave the cable

connected.

3 USB connector. Connects the USB cable to the DICOM interface.

4 Airflow vents. Vents the air that cools the inside of the imager.

5 LAN connector. Not supported. The network is connected at the

DICOM interface.

6 AC inlet. Connects the power cable.

7 Movable flange (black). Fixes the roll paper placed on the spindle.

Remove and install when loading or removing the roll paper on the

spindle. See “Placing the Roll Paper on the Spindle” on page 2-9.

8 Spindle. Holds the roll paper. To load roll paper into the

place the roll paper on the spindle. The gray flange on the right side

is fixed on the spindle.

9 Attachment. Leave the attachment installed on the spindle.

imager,

2012-01-27 9G4260_en 1-7

Overview

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SHORT TERM CONFIDENTIAL

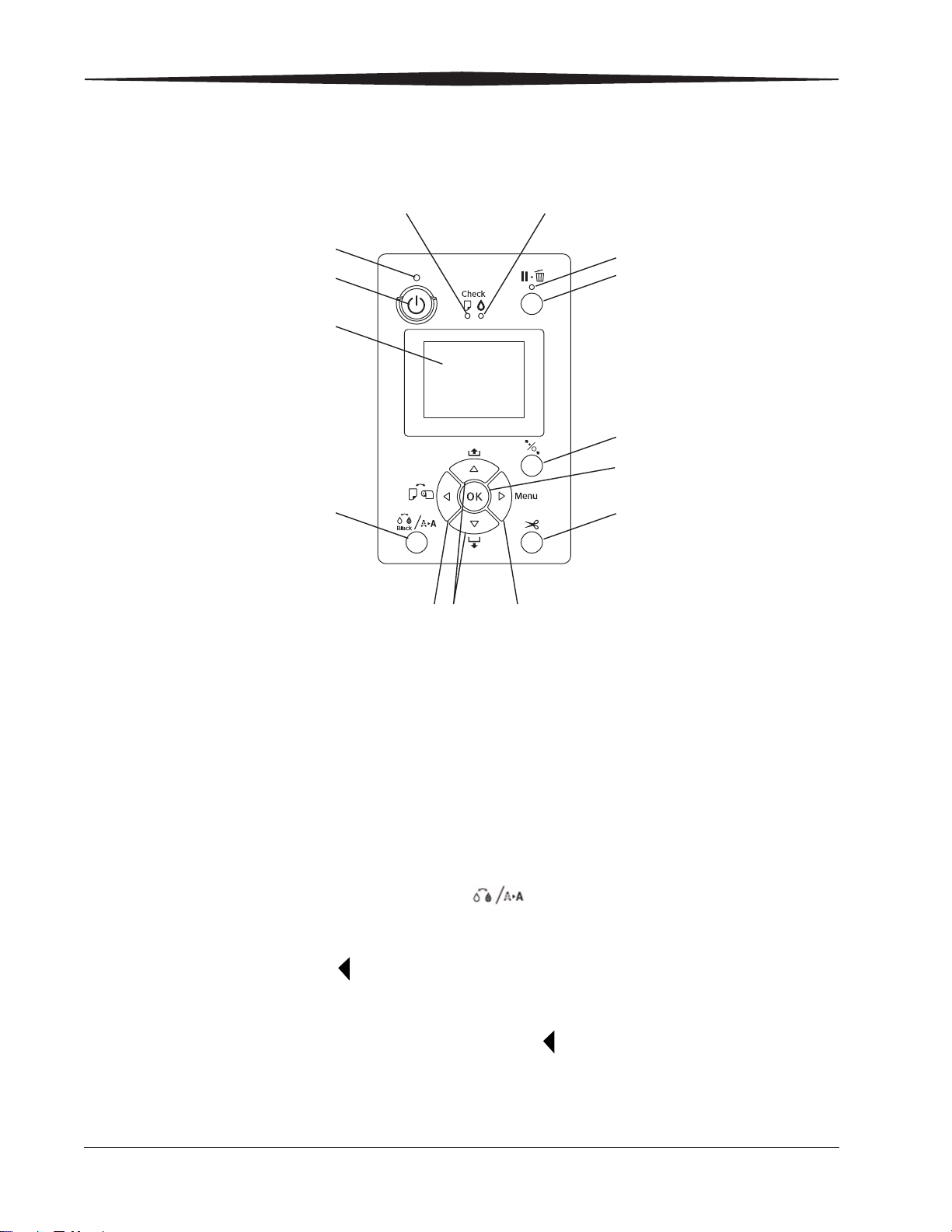

Control Panel

1 Power light. Indicates the operational status.

• On—Power is on.

• Flashing—Receiving data or performing processes such as shutting off the

power, head cleaning, or auto nozzle check.

• Off—Power is off.

2 Power button. Powers the imager on or off. To shut down the imager, press

the Power button. See “Restarting the Imager” on page 4-26.

3 Display screen. Displays the imager status, menus, and error messages. See

“Display Screen” on page 1-10.

4 Ink Menu button.

Provides access to the Ink Menu when the imager is in Ready status. From the

Ink Menu, you can initiate a print head cleaning or a nozzle check.

5 Media Source button. Lets you change between cut sheets and roll paper

at the Paper Type Menu. See “Display Screen” on page 1-10.

Press while the imager is in Ready status to display the Paper Type Menu.

When any menu displays, press to return to the previous screen.

1-8 9G4260_en 2012-01-27

6 Up/down or Media Feed buttons.

SHORT TERM CONFIDENTIAL

• When roll paper is loaded:

– Feed up to 3 m of paper by holding the button.

– Increase the paper feed rate by holding for at least two seconds.

– Press to rewind up to 20 cm of the roll paper.

• If roll paper is not loaded, press to feed media from the cassette and

to eject it from the imager.

• When any menu displays, press an arrow button to navigate through the

menu.

7 Menu button.

• Press in the Ready status (or when no media is loaded) to display the

menu.

• Press when printing to display the Printer Status Menu.

• When a menu displays, press the Menu button to access the next screen.

Overview

8 Paper Cut button. Press to cut the roll paper with the built-in cutter.

NOTE: This feature is not necessary because the CHROMA Imager always cuts

the roll paper automatically at the end of a print.

9 OK button.

• Press when an item is selected from a menu to execute the item.

10 Paper release light and button.

• When pressed after roll paper printing is complete, the paper presser

becomes unlocked, and the roll paper winds up to be removed.

• Press to lock or unlock the paper presser.

11 Pause/Reset button.

• Press to pause a print job. To restart printing, press again, or select Pause

Cancel on the screen and then press OK.

NOTE: To cancel print jobs in process, select Job Cancel on the screen and

then press OK.

• Press while the menu displays to return to Ready status.

12 Pause/Reset light. Indicates if the

• On—Not ready to print. The job is paused or canceled.

• Off—Ready to print.

imager is ready to print.

2012-01-27 9G4260_en 1-9

Overview

1

2

3

5

4

6

SHORT TERM CONFIDENTIAL

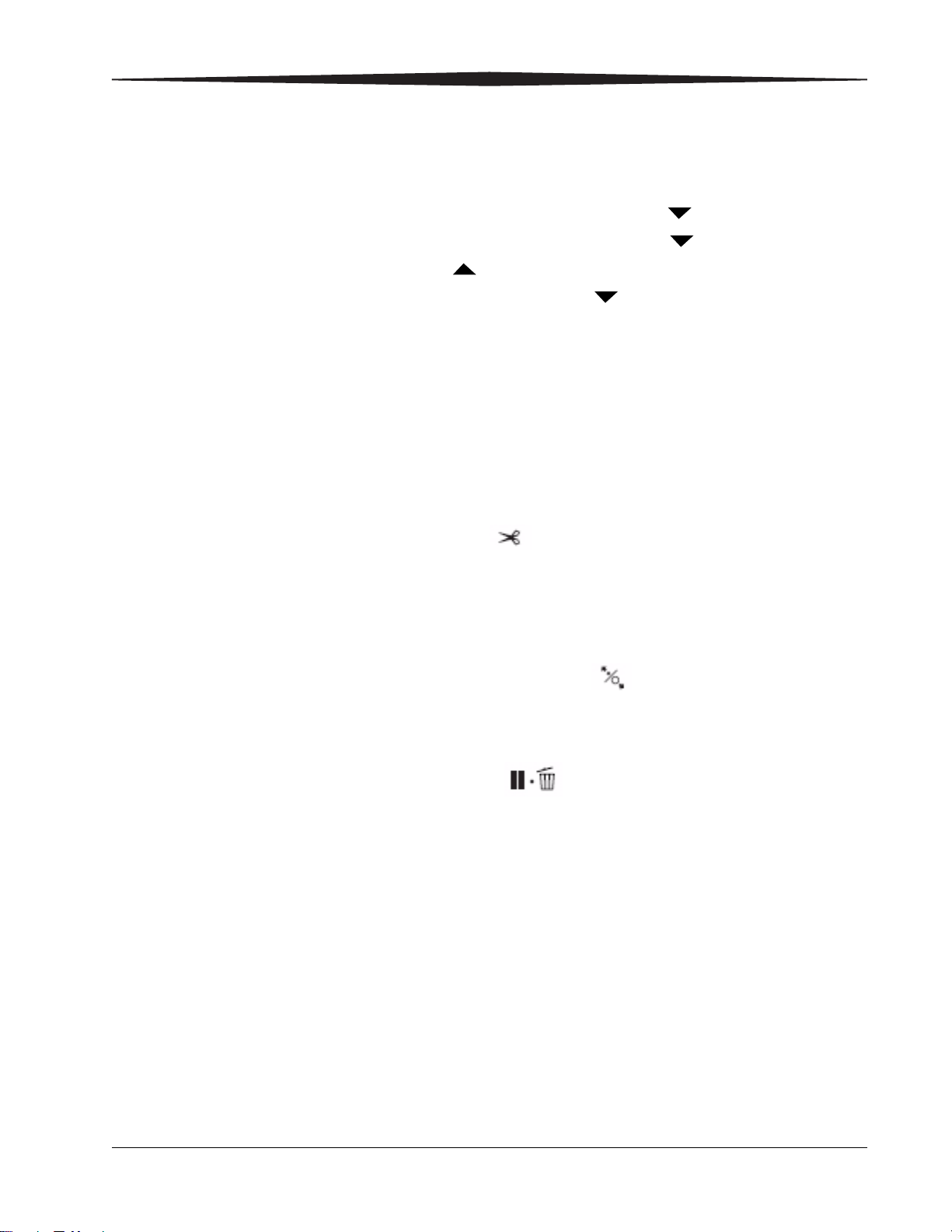

Display Screen

13 Ink alert light. Indicates the ink status.

• On—Indicates errors such as an empty ink cartridge. Check the error on

the display screen. See “Correcting Errors” on page 4-12.

• Flashing—The ink is low. Replace the cartridge to avoid the ink cartridge

becoming empty while printing. See “Working with Ink” on page 2-19.

• Off—No error.

14 Media alert light. Indicates the status of the media.

• On—No media is loaded or the paper setting is not correct. Check the

error on the display screen. See “Correcting Errors” on page 4-12 for help.

• Flashing—Indicates errors such as media jam or skew. Check the error on

the display screen. See “Correcting Errors” on page 4-12 for help.

• Off—No error.

1 Message. Displays status, operational, and error messages.

2 Media source setting. Indicates the media source.

IMPORTANT: If you will use roll paper, it is only necessary to

change the media source initially to Roll

Paper/Cut. After you have enabled the imager to

print to roll paper, you can leave the media source

setting at Roll Paper/Cut.

Prints on roll paper and cuts automatically after printing each

page. This setting supports printing to both roll paper and the

media cassette.

Prints on roll paper but does not automatically cut after

printing.

1-10 9G4260_en 2012-01-27

NOTE: This setting is not used because the CHROMA Imager

always cuts the roll paper automatically.

Overview

SHORT TERM CONFIDENTIAL

Prints from the media cassette only.

3 Ink cartridge status. Displays the approximate level of remaining ink

in the cartridge. The icons change when the ink is low or an error

occurs. See “Checking the Ink Levels” on page 2-20 for more

information.

4 Black ink. Displays the type of black ink that the imager is using. The

imager automatically uses the optimal black ink type for the installed

media.

NOTE: The imager uses either Matte or Photo Black ink to provide

the best quality for the requested print job. Photo Black ink

provides a smooth finish for glossy paper, while Matte Black

ink increases black optical density for matte paper.

5 Maintenance tank status. Displays the status for the maintenance

tanks. See “Checking the Maintenance Tank Levels” on page 2-23 for

more information.

6 Roll paper margin parameter. The margin settings display after the

icon. The margin parameter is set to 3 mm during installation, and

other margin parameters are not supported.

2012-01-27 9G4260_en 1-11

Overview

Left panel to

navigate to

other areas of

the Web Portal

View

status, etc.

SHORT TERM CONFIDENTIAL

Using the Web Portal to Access Additional Functionality

The Web Portal is your interface to additional features. In addition to

the installation and setup of your system, you can view and manage the

imager's connections over the network, configure features, view error

messages, and access general status information at the Web Portal. You

can also check media count, size, and type.

Troubleshooting tools include:

• Optimization of image quality for modalities.

• Retrieval of logs, statistics, and system status.

• Diagnostic utilities, including backup and restore.

The Web Portal provides an online Help system and a user’s guide to

assist you.

Accessing the Web Portal

To access the Web Portal, use a desktop or laptop computer that is

connected to the network.

1. On a desktop or laptop computer, start WINDOWS INTERNET

EXPLORER.

2. In the address field, type: http://<the imager IP address>.

NOTE: The IP address should be written on the back of the Quick

Reference Guide. If you cannot locate the IP address, check with

your network administrator or the person who installed the

imager.

3. Click Go.

The main window for the Web Portal shows the general status, the

number of print jobs queued, the number of jobs waiting for media,

and the media count.

The center panel displays the screens where you view and perform

tasks. The user’s guide for the Web Portal procedures is available by

selecting Documentation from the left panel, and the Help icon

provides context-sensitive Help for fields and pages.

The left panel also provides the links to all other screens.

1-12 9G4260_en 2012-01-27

Agency Compliance

CAUTION:

SHORT TERM CONFIDENTIAL

See the Safety Manual, 9G4259.

Reference Information

The following documentation and information might be useful as you

use and support the CHROMA Imaging System.

• DICOM Conformance Statement—Go to

• CHROMA on the Web—Go to

• CHROMA online registration—Go to

• Web Portal procedures, 9G7572—Access the Web Portal, and then

• Quick Reference Guide, 9G6534—See the most commonly used

• Safety Manual, 9G4259—Access information about safety and

• Media Requirements, 9G8448—Learn how to handle the CHROMA

Overview

http://www.carestream.com/dicom.html

http://www.carestream.com/med-printing.html

http://www.carestream.com/chroma-registration.html

click the Documentation link

CHROMA features at a glance

standards compliance

media

User Guide Conventions

The following special messages emphasize information or indicate

potential risks to personnel or equipment.

NOTE: Notes provide additional information, such as expanded

explanations, hints, or reminders.

IMPORTANT: Important notes highlight critical policy information that

Cautions point out procedures that you must follow precisely to

avoid damage to the system or any of its components, loss of

data, or corruption of files in software applications.

DANGER: DANGER IDENTIFIES PROCEDURES THAT YOU

affects how you use this guide and this product.

MUST FOLLOW PRECISELY TO AVOID INJURY TO

YOURSELF OR OTHERS.

2012-01-27 9G4260_en 1-13

SHORT TERM CONFIDENTIAL

Working with the Media and Ink

SHORT TERM CONFIDENTIAL

2

Working with the Media

and Ink

Handling the CHROMA Media (Film or Paper)

When working with media:

• Avoid touching the printable surface with your bare hands.

Fingerprints might affect print quality. Handle the media by its

edges.

• For optimal performance, allow the media to dry thoroughly. Media

drying time may vary depending on environmental conditions.

• Avoid exposure to moisture and adhesives.

• Do not place sticky notes on the media. Removal of a sticky note

could damage the printed image.

• Before storing printed media, let the media thoroughly dry.

• Remove prints promptly after printing due to limited space in the

output tray.

NOTE: If disposing of used media, manage the disposal appropriately to

protect patient privacy rights, if required by local regulations.

2012-01-27 9G4260_en 2-1

Working with the Media and Ink

Output tray and

media cassette

The DICOM

interface screen

displays information

about the loaded and

requested media

Roll feeder and roll paper

11 x 14 [*** ]

A3

The loaded media size is

11 x 14 in.

The requested media size is A3.

You must unload the 11 x 14 in.

media and then load A3 media

to let the job print.

SHORT TERM CONFIDENTIAL

Working with the Loaded Media

Viewing the Loaded Media Size

Monitoring the Amount of Loaded Media

Checking the DICOM Interface for the Requested Media Size

The DICOM interface screen displays the loaded media size by

dimension, for example, “8.5 x 11” or “A4.” The dimensions are

represented in inches with the exception of “A3” and “A4.”

The DICOM interface screen displays a gauge to help you monitor the

amount of loaded media that remains in the media carrier or on the roll.

A full carrier or roll is represented by the following:

[ * * * * * ]

The asterisks decrease as the carrier or roll is emptied. This example

shows a nearly empty carrier or roll:

[* ]

If a print request has arrived at the imager with a different media size

than the loaded media, the new size appears on the DICOM interface

screen to alert you to install the requested size.

The DICOM interface screen displays the loaded size on the top row and

the requested size on the lower row. For example:

2-2 9G4260_en 2012-01-27

See “Changing the Media in the Imager” on page 2-12 for instructions to

change the loaded media.

Working with the Media and Ink

SHORT TERM CONFIDENTIAL

Understanding How Media is Selected for Print Requests

Your imager can print to both the media cassette and the roll feeder. The

imager automatically selects the media source based on the media type

(film or paper) and size of the job request, for example:

• A job request with film specified at the modality will only go to the

media cassette (because film can only be loaded in the media

cassette).

– If the job request matches the loaded film size, the job prints.

– If the job request matches a supported film size but that size is not

loaded in the cassette, the DICOM interface alerts you that a

different media size is requested. You must load the requested

film size in the media casette so the job can print.

– If the job request does not match a supported film size, then the

imager prints to (or requests) the supported film size that is

closest to and larger than the job request.

• A job request with paper specified at the modality will only print to

paper. If paper is loaded in the media cassette and in the roll feeder,

then the imager uses the image size to determine the media source:

– If the job request matches a size that is already loaded in the

media cassette or can be printed on the roll paper (22.0 x 28.0 cm

/ 8.5 x 11.0 in., A3, or A4), then the job goes to the matching

media.

– If the job request matches a size that is loaded in the media

cassette and can be printed on roll paper (when either A3 or A4

paper is loaded in the media cassette), then the job goes to the roll

paper.

– If the job request does not match a supported paper size, then the

imager prints to (or requests) the supported paper size that is

closest to and larger than the job request. For example, a request

to print on 8.0 x 10.0 in. paper would print on 8.5 x 11.0 in. paper.

2012-01-27 9G4260_en 2-3

Working with the Media and Ink

Media carrier

SHORT TERM CONFIDENTIAL

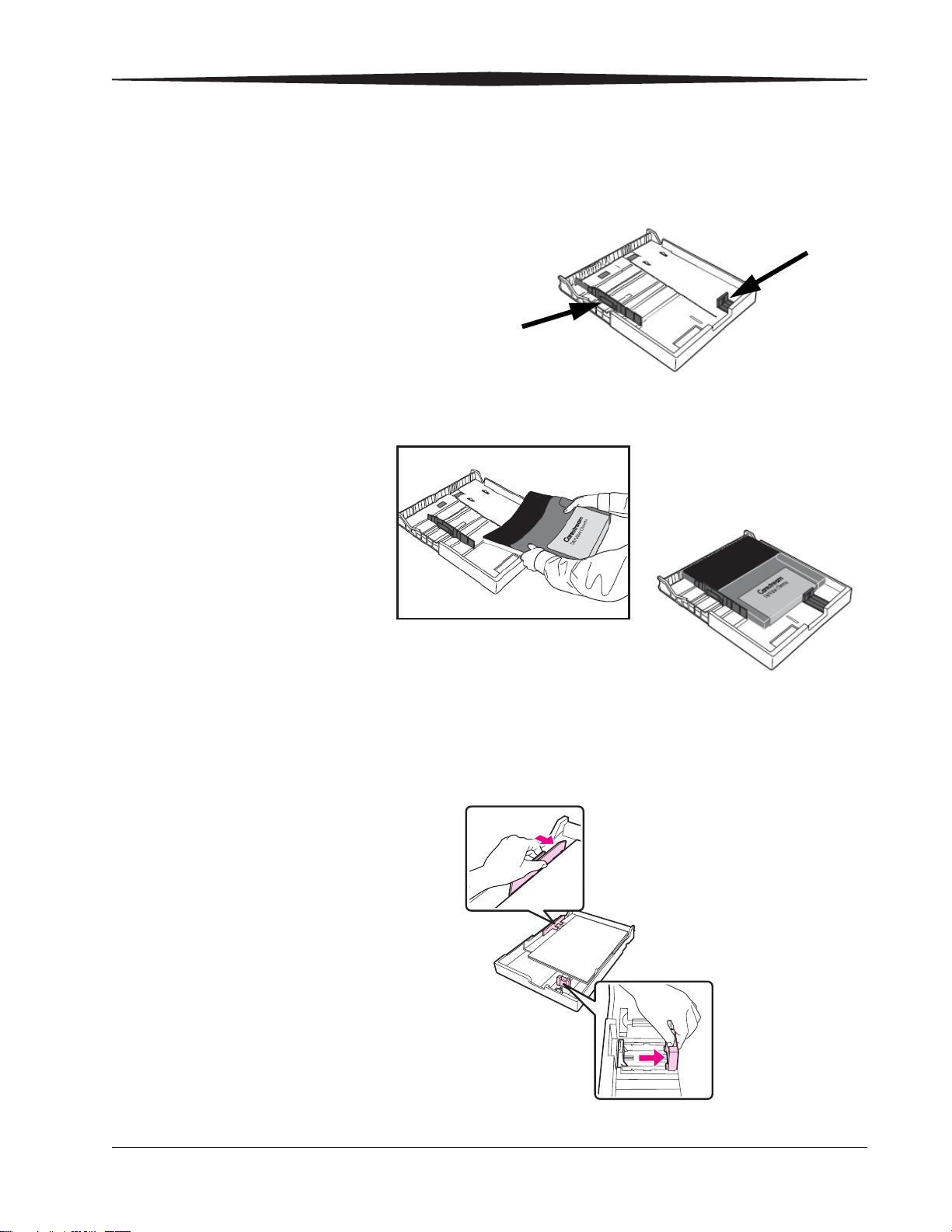

Loading the Media Cassette (Cut Sheets)

IMPORTANT: Do not remove or insert the cassette from the imager while

printing. It may cause the print quality to decline or cause

a jam. If you do remove the cassette while printing, wait

until printing is complete to reinsert it.

IMPORTANT: Always leave the media in the carrier when you load it

into and unload it from the cassette. Store the unused

media in its carrier and in the original carton.

IMPORTANT: Always remove the output tray and the cassette from the

imager to load or remove media. Sliding the media carrier

into the cassette without fully removing the tray from the

imager can cause issues with the media.

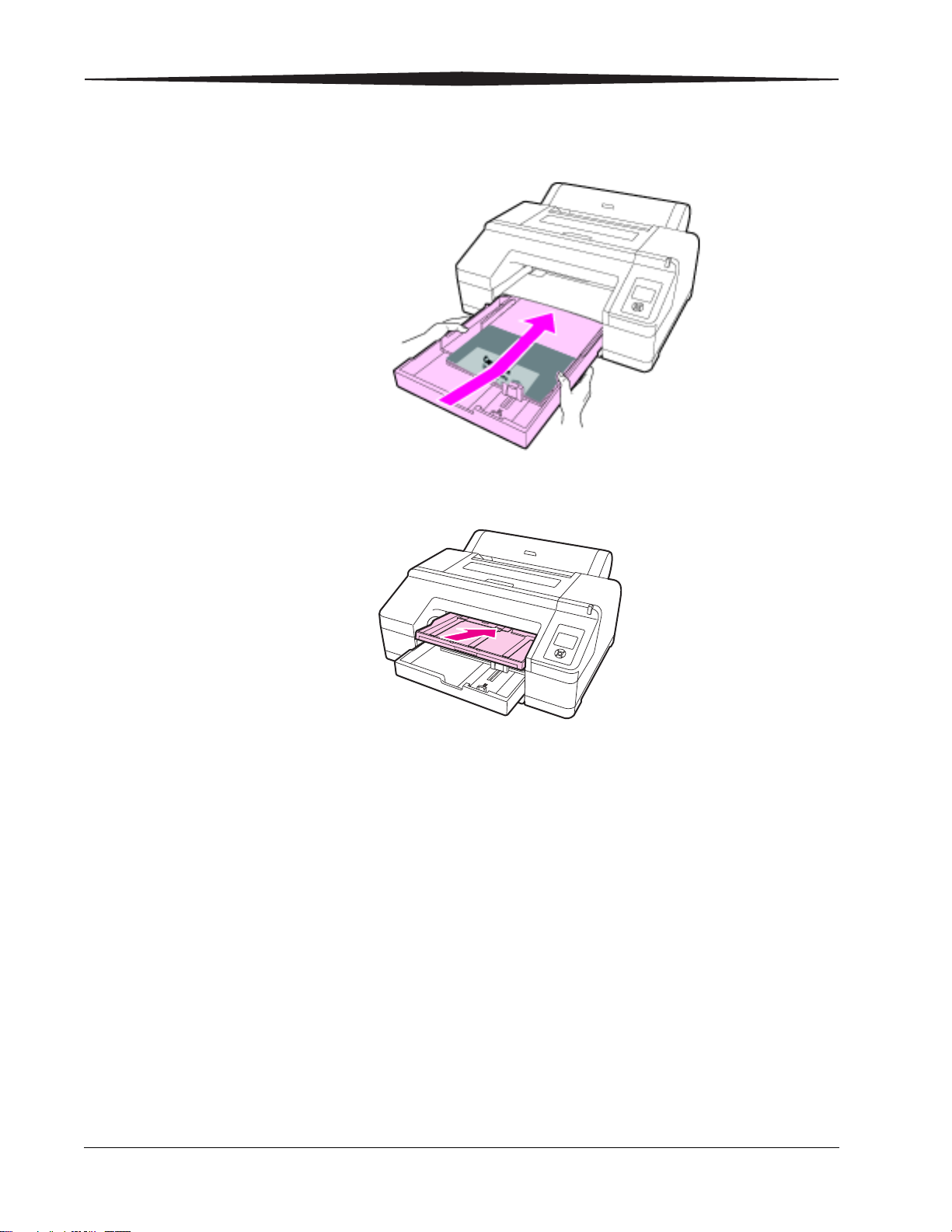

1. Lift the edge of the output tray to remove it.

2. Slide open the media cassette, lift it slightly, and pull it out.

IMPORTANT: Be careful not to drop the media! The media must remain

in the carrier and in the original orientation, with the

same side facing up. Do not remove or lose any sheets

from the media carrier. If any sheets are removed, the

imager cannot accurately track the media count.

3. Open the new media package, and fan the open end. Leave the

media in the carrier when you fan it.

H210_0617AC

2-4 9G4260_en 2012-01-27

Carestream

Working with the Media and Ink

Open the edge

guides to make

space for the media

SHORT TERM CONFIDENTIAL

4. If necessary, expand the edge guides to make space for the media

before you place the media into the cassette.

5. Carefully place the media, with the carrier, into the media cassette.

IMPORTANT: Keep the media carton. If you change the media size in the

imager later, place the media back in the original carton.

6. Adjust the edge guides around the media carrier. Move the guide

without moving the slider.

2012-01-27 9G4260_en 2-5

Working with the Media and Ink

SHORT TERM CONFIDENTIAL

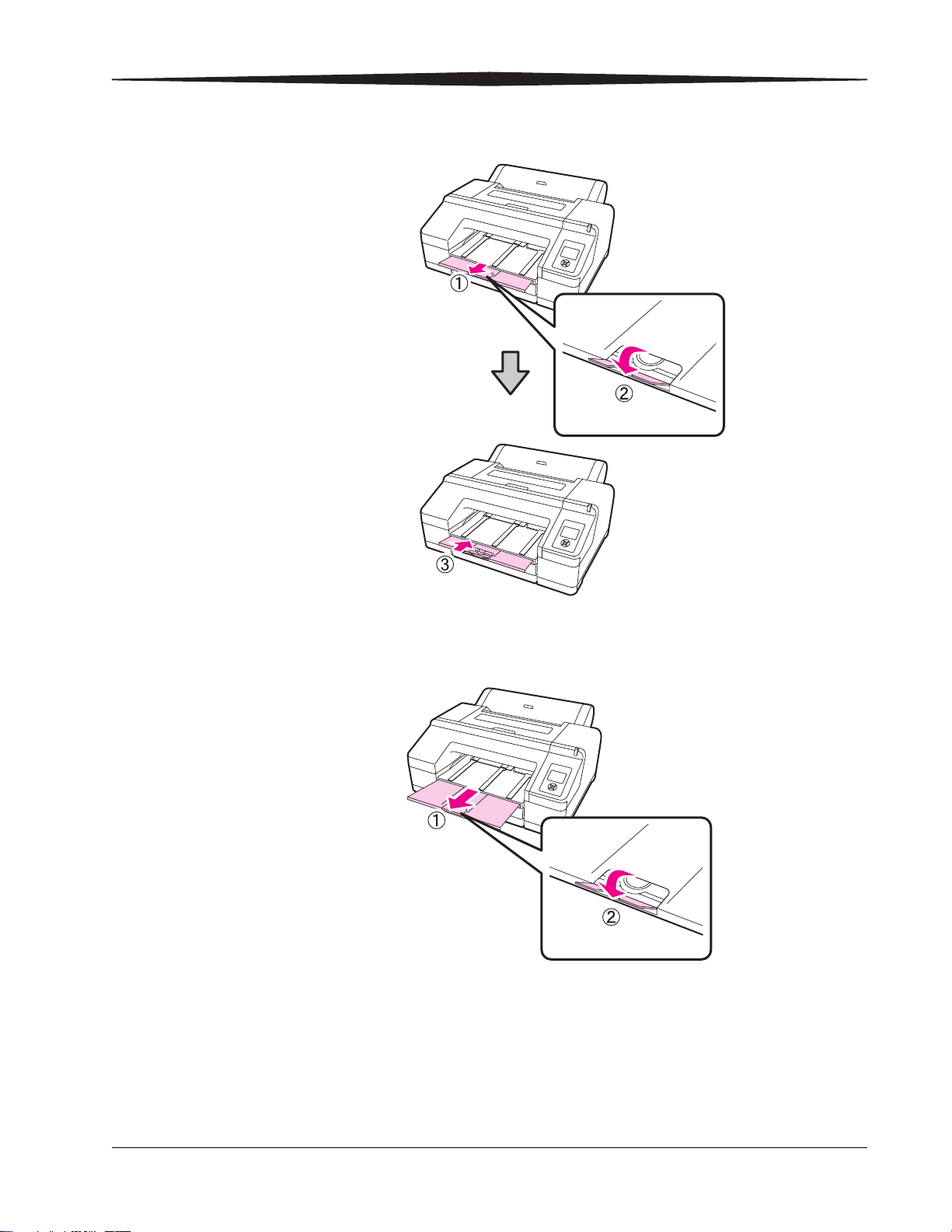

7. Insert the cassette and push it firmly into the imager.

8. Replace the output tray.

9. Extend the output tray for the media size and raise the flap. Adjust

the output tray depending on the size of the media loaded in the

cassette:

• A4: Slide out the third extension of the output tray, raise the flap,

and then push the section back in.

2-6 9G4260_en 2012-01-27

Working with the Media and Ink

SHORT TERM CONFIDENTIAL

• A3: Pull out the third section of the output tray, and then raise the

flap.

2012-01-27 9G4260_en 2-7

Working with the Media and Ink

Roll Paper/Cut

Cut Sheet

SHORT TERM CONFIDENTIAL

10. Check that the imager is on.

11. If you will print:

• Only to the media cassette, check that the Media Source setting is

set to Cut Sheet.

• To both media cassette and roll paper, check that the Media

Source setting is set to Roll Paper/Cut.

NOTE: The Roll Paper/Cut setting supports printing to both roll paper

and to cut sheets in the media cassette.

To change the Media Source setting:

• Press to display the Paper Type Menu.

• Press to select Roll Paper/Cut or Cut Sheet.

•Press OK.

2-8 9G4260_en 2012-01-27

Loading...

Loading...