Integrated Control Solutions & Energy Savings

User manual

For monitoring environmental conditions

• Temperature

• Humidity

• Light

Wireless sensors

3

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

WARNINGS

CAREL bases the development of its products on decades of experience

in HVAC, on the continuous investments in technological innovations

to products, procedures and strict quality processes with in-circuit and

functional testing on 100% of its products, and on the most innovative

production technology available on the market. CAREL and its subsidiaries

nonetheless cannot guarantee that all the aspects of the product and the

software included with the product respond to the requirements of the nal

application, despite the product being developed according to start-of-theart techniques.

The customer (manufacturer, developer or installer of the nal equipment)

accepts all liability and risk relating to the con guration of the product in

order to reach the expected results in relation to the speci c nal installation

and/or equipment.

CAREL may, based on speci c agreements, acts as a consultant for the positive

commissioning of the nal unit/application, however in no case does it accept

liability for the correct operation of the nal equipment/system.

The CAREL product is a state-of-the-art product, whose operation is speci ed

in the technical documentation supplied with the product or can be

downloaded, even prior to purchase, from the website www.carel.com.

Each CAREL product, in relation to its advanced level of technology, requires

setup/con guration/programming/commissioning to be able to operate in

the best possible way for the speci c application. The failure to complete such

operations, which are required/indicated in the user manual, may cause the

nal product to malfunction; CAREL accepts no liability in such cases.

Only quali ed personnel may install or carry out technical service on the

product.

The customer must only use the product in the manner described in the

documentation relating to the product.

In addition to observing any further warnings described in this manual, the

following warnings must be heeded for all CAREL products:

• prevent the electronic circuits from getting wet. Rain, humidity and all

types of liquids or condensate contain corrosive minerals that may damage

the electronic circuits. In any case, the product should be used or stored

in environments that comply with the temperature and humidity limits

speci ed in the manual.

• do not install the device in particularly hot environments. Too high

temperatures may reduce the life of electronic devices, damage them and

deform or melt the plastic parts. In any case, the product should be used

or stored in environments that comply with the temperature and humidity

limits speci ed in the manual.

• do not attempt to open the device in any way other than described in the

manual.

• do not drop, hit or shake the device, as the internal circuits and mechanisms

may be irreparably damaged.

• do not use corrosive chemicals, solvents or aggressive detergents to clean

the device.

• do not use the product for applications other than those speci ed in the

technical manual.

All of the above suggestions likewise apply to the controllers, serial boards,

programming keys or any other accessory in the CAREL product portfolio.

CAREL adopts a policy of continual development. Consequently, CAREL

reserves the right to make changes and improvements to any product

described in this document without prior warning.

The technical speci cations shown in the manual may be changed without

prior warning.

The liability of CAREL in relation to its products is speci ed in the CAREL general

contract conditions, available on the website www.carel.com and/or by

speci c agreements with customers; speci cally, to the extent where allowed

by applicable legislation, in no case will CAREL, its employees or subsidiaries

be liable for any lost earnings or sales, losses of data and information, costs of

replacement goods or services, damage to things or people, downtime or any

direct, indirect, incidental, actual, punitive, exemplary, special or consequential

damage of any kind whatsoever, whether contractual, extra-contractual or

due to negligence, or any other liabilities deriving from the installation, use or

impossibility to use the product, even if CAREL or its subsidiaries are warned

of the possibility of such damage.

DISPOSAL

INFORMATION FOR USERS ON THE CORRECT

HANDLING OF WASTE ELECTRICAL AND ELEC-

TRONIC EQUIPMENT (WEEE)

In reference to European Union directive 2002/96/EC issued on 27 January

2003 and the related national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and such waste must be

collected and disposed of separately;

2. the public or private waste collection systems de ned by local legislation

must be used. In addition, the equipment can be returned to the

distributor at the end of its working life when buying new equipment;

3. the equipment may contain hazardous substances: the improper use or

incorrect disposal of such may have negative e ects on human health and

on the environment;

4. the symbol (crossed-out wheeled bin) shown on the product or on the

packaging and on the instruction sheet indicates that the equipment has

been introduced onto the market after 13 August 2005 and that it must

be disposed of separately;

5. in the event of illegal disposal of electrical and electronic waste, the

penalties are speci ed by local waste disposal legislation.

Warranty on materials: 2 years (from the date of production, excluding

consumables).

Approval: the quality and safety of CAREL S.P.A. products are guaranteed by

the ISO 9001 certi ed design and production system.

Important warning!!!

The rTM SE system devices are

incompatible with the Carel rTM system,

due to an improvement made to the

ZigBee wireless communication

protocol.

4

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

5

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

Content

1. INTRODUCTION 7

1.1 Wireless monitoring devices ........................................................................7

1.2 Codes ................................................................................................................. 8

1.3 Terminology .................................................................................................... 9

1.4 Advantages of the wireless system .............................................................9

1.5 Type of Carel wireless network (MESH) .................................................. 10

1.6 General features of the system .................................................................. 11

1.7 Using the Router ........................................................................................... 11

1.8 General notes ................................................................................................ 11

1.9 Reference standards ..................................................................................... 12

1.10 Battery life ....................................................................................................... 12

1.11 List of sensor system variables (alphabetical order) ............................. 12

2. BP SE SENSOR (BUILT-IN PROBE) 13

2.1 Functions implemented and supervisor variables available ...............13

2.2 Sensor confi guration .................................................................................... 13

2.3 Sensor activation ........................................................................................... 14

2.4 Technical specifi cations ................................................................................ 15

2.5 List of parameters and variables, BP SE Sensor ..................................... 16

2.6 Installation notes ............................................................................................17

2.7 Physical dimensions ......................................................................................17

2.8 Replacing the battery in the BP SE Sensor ...............................................17

2.9 Application examples ....................................................................................17

3. EP SE, SA, SI SENSORS AND CI PULSE COUNTER 18

3.1 Parameters and functions ........................................................................... 18

3.2 Description of the acquisition process ..................................................... 18

3.3 Device confi guration .................................................................................... 18

3.4 Binding procedure ........................................................................................ 19

3.5 Resetting the sensor (unbinding) .............................................................. 19

3.6 General warnings ......................................................................................... 19

4. EP SENSOR (EXTERNAL PROBE) 20

4.1 Functions implemented ...............................................................................20

4.2 Parameters and functions ........................................................................... 20

4.3 Technical specifi cations ................................................................................20

4.4 List of parameters and variables, EP SE Sensor .....................................21

4.5 EP SE Sensor installation notes ..................................................................22

4.6 EP SE physical dimensions .........................................................................22

4.7 EP SE electrical connections .......................................................................22

4.8 Application example .....................................................................................22

5. SA ROOM SENSOR 23

5.1 Functions implemented and supervisor variables available ...............23

5.2 Technical specifi cations ................................................................................24

5.3 List of parameters and variables, SA Sensor ........................................... 24

5.4 Sensor installation notes .............................................................................25

5.5 Physical dimensions ..................................................................................... 25

5.6 Application example .....................................................................................25

6. SI INDUSTRIAL SENSOR 26

6.1 Functions implemented and supervisor variables available ...............26

6.2 Technical specifi cations ................................................................................27

6.3 List of parameters and variables, SI Sensor ............................................ 28

6.4 SI Sensor installation notes ......................................................................... 28

6.5 Physical dimensions ..................................................................................... 29

6.6 Application example .................................................................................... 29

7. CI PULSE COUNTER 30

7.1 Functions implemented ...............................................................................30

7.2 Parameters and functions ........................................................................... 30

7.3 Technical specifi cations ................................................................................ 30

7.4 List of parameters and variables, CI Pulse Counter ..............................31

7.5 CI Pulse Counter installation notes ...........................................................32

7.6 CI Pulse Counter physical dimensions .....................................................32

7.7 CI Pulse Counter electrical connections ................................................... 32

7.8 Connection example ................................................................................... 32

8. AP ACCESS POINT 33

8.1 Main functions ...............................................................................................33

8.2 Parameters and functions ........................................................................... 33

8.3 Confi guration ................................................................................................ 33

8.4 Setting the address .......................................................................................33

8.5 Binding procedure ........................................................................................34

8.6 Resetting the device .....................................................................................34

8.7 Serial communication parameters ............................................................34

8.8 Table of LED status .......................................................................................35

8.9 Technical specifi cations ................................................................................35

8.10 List of Access Point system variables (alphabetical order) ..................36

8.11 List of parameters and variables, Access Point versione ..........................

Modbus RTU

® .....................................................................................................................................

37

8.12 Installation notes ...........................................................................................37

8.13 Electrical connections and physical dimensions ....................................38

9. RO ROUTER 39

9.1 Parameters and functions ......................................................................... 39

9.2 Binding the Router to the Access Point ....................................................39

9.3 Resetting the device .....................................................................................40

9.4 Table of LED status .......................................................................................40

10. ROUTERS WITH OTHER INTEGRATED FUNCTIONS 41

10.1 EP1 Router-Sensor ........................................................................................ 41

10.2 RB Router-Bridge........................................................................................... 41

10.3 RA Router-Actuator ....................................................................................... 42

10.4 Functions implemented ...............................................................................42

10.5 RC Router-Pulse Counter ............................................................................42

10.6 Technical specifi cations ................................................................................43

10.7 List of Router system variables (alphabetical order) .............................43

10.8 List of Router parameters .........................................................................44

10.9 List of RA Router-Actuator parameters ..................................................... 44

10.10 Installation notes ...........................................................................................44

10.11 General warnings ........................................................................................46

11. GENERAL NOTES 47

11.1 Notes for correct installation ...................................................................... 47

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

6

12. RTM SE HANDHELD 48

12.1 General Features ........................................................................................... 48

12.2 Operating modes ..........................................................................................48

12.3 Main menu .....................................................................................................48

12.4 Scan Energy ....................................................................................................48

12.5 Scan Networks ............................................................................................... 49

12.6 Scan Connection ........................................................................................... 49

12.7 Unbinding .......................................................................................................49

12.8 Ping test ...........................................................................................................49

12.9 Network commands .....................................................................................49

12.10 “View Mode” menu ...................................................................................... 50

12.11 “Open Network” menu ...............................................................................50

12.12 “Reset One” menu ......................................................................................50

12.13 Password entry menu ..................................................................................50

12.14 “Set Passw” Menu – Set Access Point password .................................. 51

12.15 Sensors menu ................................................................................................ 51

12.16 List of Sensors ................................................................................................ 51

12.17 Set Sensor address ....................................................................................... 52

12.18 Unbind Sensor ............................................................................................... 53

12.19 Start screen ..................................................................................................... 54

12.20 ZigBee handheld signal meter shutdown ..........................................54

12.21 Notes on operation .....................................................................................54

12.22 ZigBee handheld signal meter electrical specifi cations ...................54

12.23 Physical dimensions .................................................................................... 54

13. ROUTER-SNIFFER 55

13.1 Router-Sniffer .................................................................................................55

13.2 Technical specifi cations: ............................................................................... 55

13.3 Layout ..............................................................................................................55

13.4 LED meanings................................................................................................55

14. Z-CONFIG PROGRAM 56

14.5 Layout examples ..........................................................................................61

15. DIPSWITCH-ID CROSS-REFERENCE TABLE FOR

SENSORS 63

15.1 Dipswitch-ID cross-reference table for sensors ......................................63

7

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

1. INTRODUCTION

1.1 Wireless monitoring devices

For the retro t of food refrigeration and room cooling systems, energy

consumption measurement and I/O management via supervisor, CAREL

proposes the rTM SE wireless system (Remote Temperature Monitoring). This

solution guarantees the maximum in terms of:

• Flexibility;

• Functions;

• Reliability;

• Easy operation

• Reduced installation costs;

• Easy commissioning/service;

• Integration with the most common BMS (Building Management Systems);

This solution ensures considerable savings in terms of installation costs

(eliminating the cost of wiring), o ering exibility in the layout of supermarkets

and allowing faster retro t installation. Ideal for all installations where electrical

wires cannot be laid, i.e. properties that do not have raised oors or false

ceilings.

The retro t of existing systems is required for compliance with HACCP

standards, for monitoring the systems via remote connections, for

recording events and analysing them for scheduled maintenance.

The CAREL rTM SE system can be used in all industrial and trade businesses

that require the prevention of risks relating to the safety and storage of food

for human consumption, in accordance with the HACCP standards; moreover,

it o ers the possibilit y to manage exible spaces very simply, thus reorganising

the layout of showcases in a supermarket without having an impact on the

wired network (communication and power supply);

The system is a network of wireless sensors tted inside the showcases, easy

to con gure and install, connected to a Carel supervisor (PlantVisorPRO or

PlantWatchPRO) for recording the temperature, events and alarm noti cations.

The data measured and the alarms signalled are saved and can be accessed at

any time, in compliance with EN 12830.

The system can be easily installed on all types of refrigeration unit (showcases or

cold rooms), is independent of the controller installed on the unit and requires

no additional wiring because the devices are wireless and battery powered,

meaning signi cant cost savings.

The sensors require no electrical connections as they use a long life battery

(typically 5 to 8 years, depending on the transmission frequency set), a wireless

connection with ZigBee™ technology (mesh) at a transmission frequency of

2.4 GHz authorised for operation in all countries around the world, and are

ready for connection to the most common BMS systems using Modbus®

protocol. The sensors monitor the inputs (temperature, humidity, light and

digital input status) and send the data wirelessly to the Access Point or Router.

Communication between sensors and the Access Point is two way. The

sensors, as well as sending the change in the status of the variables, can also

receive data.

Moreover, a mains powered model has been designed for use in all

applications that require frequent communication (e.g. monitoring oating

suction pressure).

In ambient monitoring applications, the temperature, humidity and light

intensity can all be recorded by simply installing battery powered sensors in

the desired location. The sensors cover a wide range of uses in refrigeration,

air-conditioning and humidi cation applications.

Many applications are also available for remote I/O management from

supervisors

, as the module manages generic I/Os and saves on the cost of

laying cables, without the need for separate power and signal cables.

The wireless devices send the temperature and alarm data wirelessly to the

Router and Access Point, which relay the information to the supervisory system

The CAREL rTM SE system consists of the following components:

• Battery powered devices:

- Temperature sensor from tted inside the showcase, version BP SE (Built-

in Probe);

- Sensor with two external NTC probes and two digital inputs, version EP

SE (External Probe) for showcases and cold rooms;

- Room temperature and humidity sensor for installation in residential

environments,

version SA

- Temperature, humidity and light sensor, SI industrial version;

- Pulse counter to be used with the energy meter module con gured for

pulse counters, version CI;

• Access Point. Wireless receiver that acquires data from the various sensors

in the ZigBee™ network, making such data available to the supervisor via

Modbus® RTU over RS485. Up to 30 sensors can be directly associated with

each Access Point, or a maximum of 60 if one or more Routers are used. The

supervisor (PlantVisorPRO or PlantWatchPRO) can thus see all the variables

in the rTM SE system;

• Router. To be used when the distance between the Sensors and the

Router exceeds 30 m (relays the wireless signals so as to cover greater

distances between the Access Point and sensors), or if there are more

than 30 Sensors in the network. There can be a maximum of 60 Routers in

the wireless network, 48 of which are visible to the supervisor. The Access

Point automatically assigns a serial address in the order in which these are

“bound”, starting from 200 up to 247. Five versions of Router are available,

which also include other functions:

- Router powered at 230 Vac mains voltage, version RO;

- Router Bridge powered at 12-24 Vac, version RB. Integrates the function

to extend the RS485 network;

- Router Sensor powered at 12-24 Vac, version EP1. Integrates the functions

of the battery powered EP SE Sensor);

- Router-Actuator powered at 12-24 Vac, version RA. Integrates the

functions of I/O module or local thermostat;

- Router-Pulse Counter powered at 12-24 Vac, version RC. Integrates the

same functions as the CI battery powered pulse counter;

• Modbus® supervisor system: The rTM SE system is designed to be used

together with Carel PlantVisor PRO or PlantWatch PRO supervisors

Wireless transmission between the various devices uses standard ZigBee™

communication protocol and encryption technology with a Carel private key.

This is an advanced system that has achieved an excellent level of security in

data exchange for wireless communication and is used in many applications.

The CAREL solution uses mesh technology between Access Points and

Routers, ensuring more reliable communication and delivery of the data sent

by the sensor.

Note: ZigBee wireless connection without interoperability.

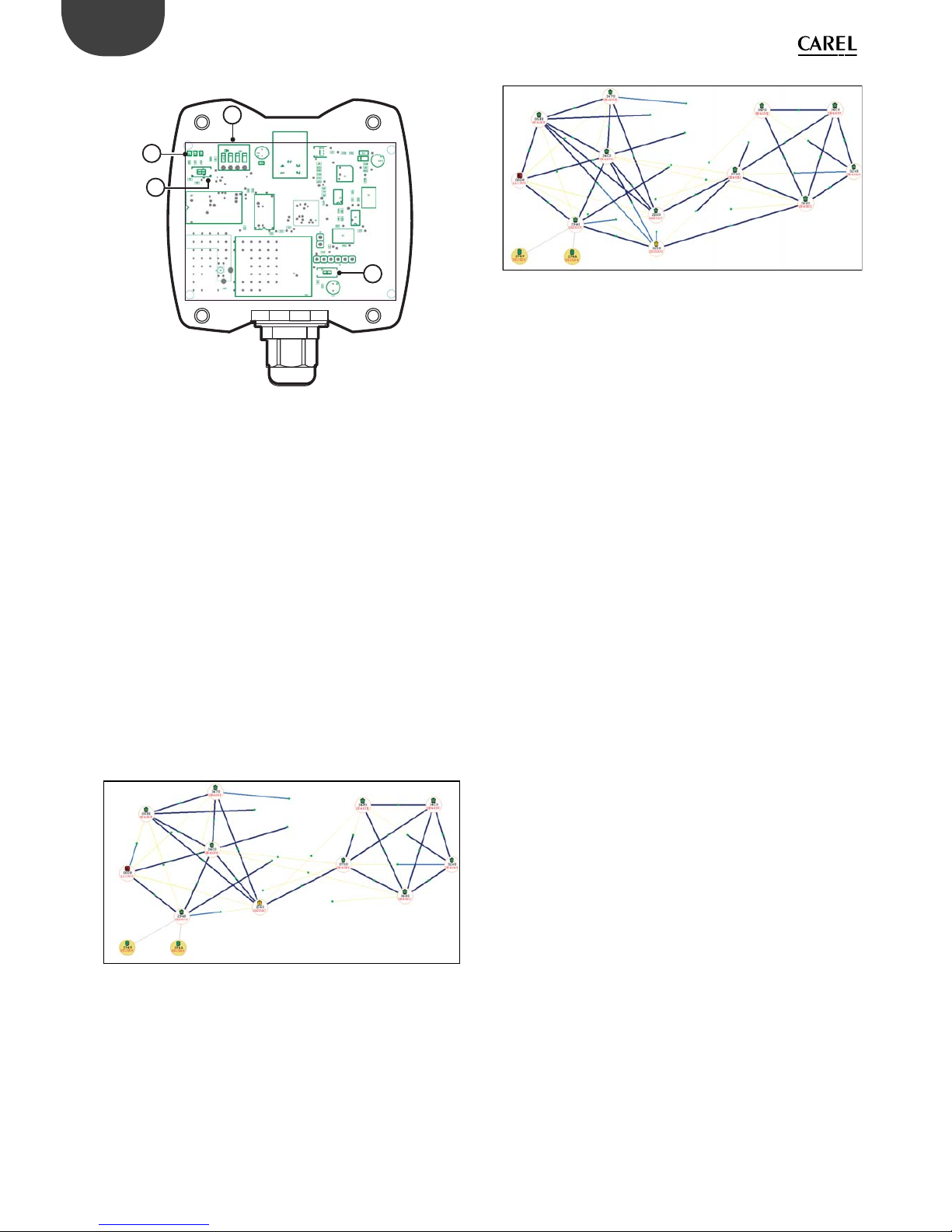

rTM SE handheld: network analyser used to check the ZigBee wireless signal

level and to open/close the wireless network when binding the devices

(sensors and Routers), including the possibility to set the BP Sensor address

and reset the Router and Access Point. Useful during installation;

8

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

1.2 Codes

Code Model Features Power supply

WS01U01M00 BP SE Sensor Temp. for showcases Battery

WS01W02M00 EP SE Sensor Temp for cold rooms or showcases Battery

(*) WS01G01M00 SA Sensor Room temp./humid. Battery

(*) WS01F01M00 SI Sensor Temp./humid./lux for industrial use Battery

(*) WS01E02M00 CI Pulse Counter Pulse counter for energy modules Battery

WS01AB2M20 AP Access Point ZigBee – RS485 Modbus® Access Point 12-24 Vac/dc

WS01RC1M20 RO Router ZigBeewireless repeater 12-24 Vac/dc

WS01VB2M10 EP1 Router-Sensor Repeater with temp. sensor 12-24 Vac/dc

WS01RB2M20 RB Router-Bridge Repeater with RS485 Modbus® bridge 12-24 Vac/dc

(*) WS01HO2M20 RA Router-Actuator Repeater with I/O module - thermostat 12 Vac/dc

(*) WS01NO2M20 RC Router-Pulse Counter Repeater with Pulse counter (energy modules) 12-24 Vac/dc

(*) available soon

Tab. 0.a

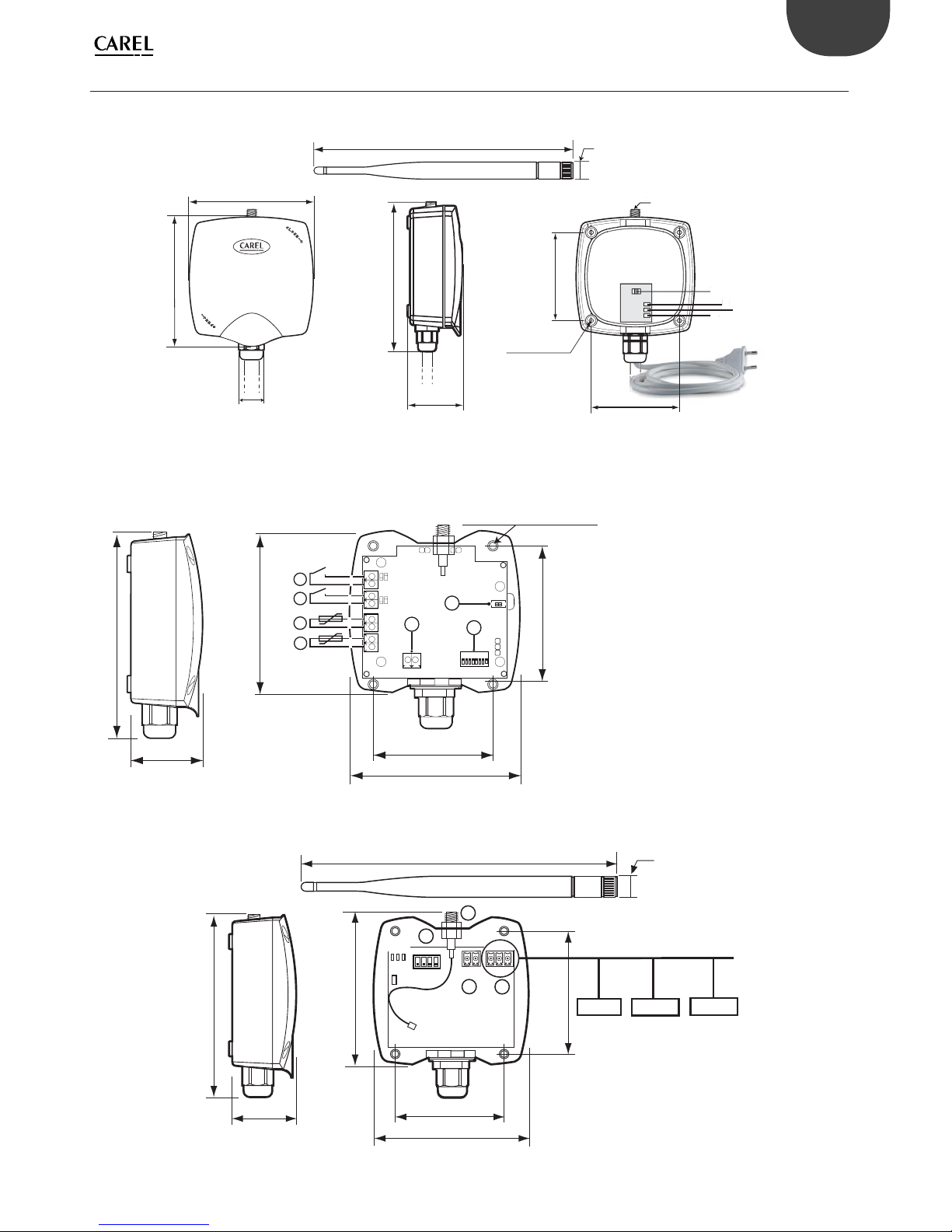

BP SE Sensor EP SE Sensor SA Sensor

SI Sensor Pulse counter CI

Access point RO Router EP1 Router- sensor

RB Router-Bridge RA Router-Actuator RC Router- pulsecounter

Fig. 1.a

9

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

1.3 Terminology

Wireless

Wireless means “without wires”, in contrast to the term wired.

Wireless network

Communications system (series of devices, appliances, methods and

protocols) for the transmission of information via radio, typically radiofrequency technology used instead of wired connections, making the systems

particularly exible.

ZigBee™

Zigbee™ is a set of speci cations based on the IEEE-802.15.4 standard for

the creation of Wireless Personal Area Networks (WPAN). Comparable in

some ways to Bluetooth, it stands out for its very low power consumption

and the reduced cost of implementation, despite having a maximum data

transfer speed of 250 kbit/s. ZigBee™ devices, with compact dimensions and

low costs, are designed to work in dedicated self-organised networks (Mesh

networks) and are used in many elds.

1.4 Advantages of the wireless system

Advantages of a wireless network over a wired network

• Mobility of sensors;

• Easy to install and connect the devices;

• Coverage even where obstacles are present;

• Flexibility in the event of structural modi cations;

• Reduction in wiring costs;

• Robustness.

The advantages of wireless networks can overcome some of the intrinsic limits

in wired systems. Typical network infrastructure features a wired backbone

with wireless access.

Advantages of ZigBee™

• Standard technology;

• Reduced costs;

• Can be used globally;

• Reliable;

• Supports a large number of nodes;

• Easy con guration;

• Long battery life;

• Secure data transmission.

Distance

ConsumptionVelocity

Fig. 1.b

All brands and names shown in the diagram are registered trademarks and

the property of their respective owners.

10

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

Advantages of working at 2.4 GHz

Band of frequencies No. of channels Data parameters Use

Symbol rate Bit rate Mapping

868-868.6 MHz 1 20Kbit/s 20 Kbaud Binary Europe

902-928 MHz 10 40Kbit/s 40 Kbaud Binary North America

2.4-2.4835 GHz 16 250Kbit/s 62.5 Kbaud 16-ary orthogonal Worldwide

The band centred around 2.45 GHz (used in the wireless sensor system for

refrigeration) is the only one that can be used all over the world, without

needing to apply for special licenses. In addition, the ISM band (Industrial,

Scienti c and Medical) exploits the full potential of the standard, that is,

can use 16 transmission channels with a bit rate of 250 kbit/s.

Types of nodes

ZigBee™ Access Point - Co-ordinator and Gateway;

- Must be available and on in every network

- Coordinates the creation of the network;

ZigBee™ Router;

- Participates in the delivery of the messages, and must always be on;

- Available in Router-Bridge version for extending a wired local network

(for a list of approved controllers, see chapter on the features of the

Router), and EP1 Router-Sensor version.

ZigBee™ End-Device (sensors);

- Node with limited wireless functions;

- Low power consumption;

- Low cost;

For data communication with the Access Point, the end device uses a “parent”

for e ective wireless transmission; this may be a Router or the Access Point

itself.

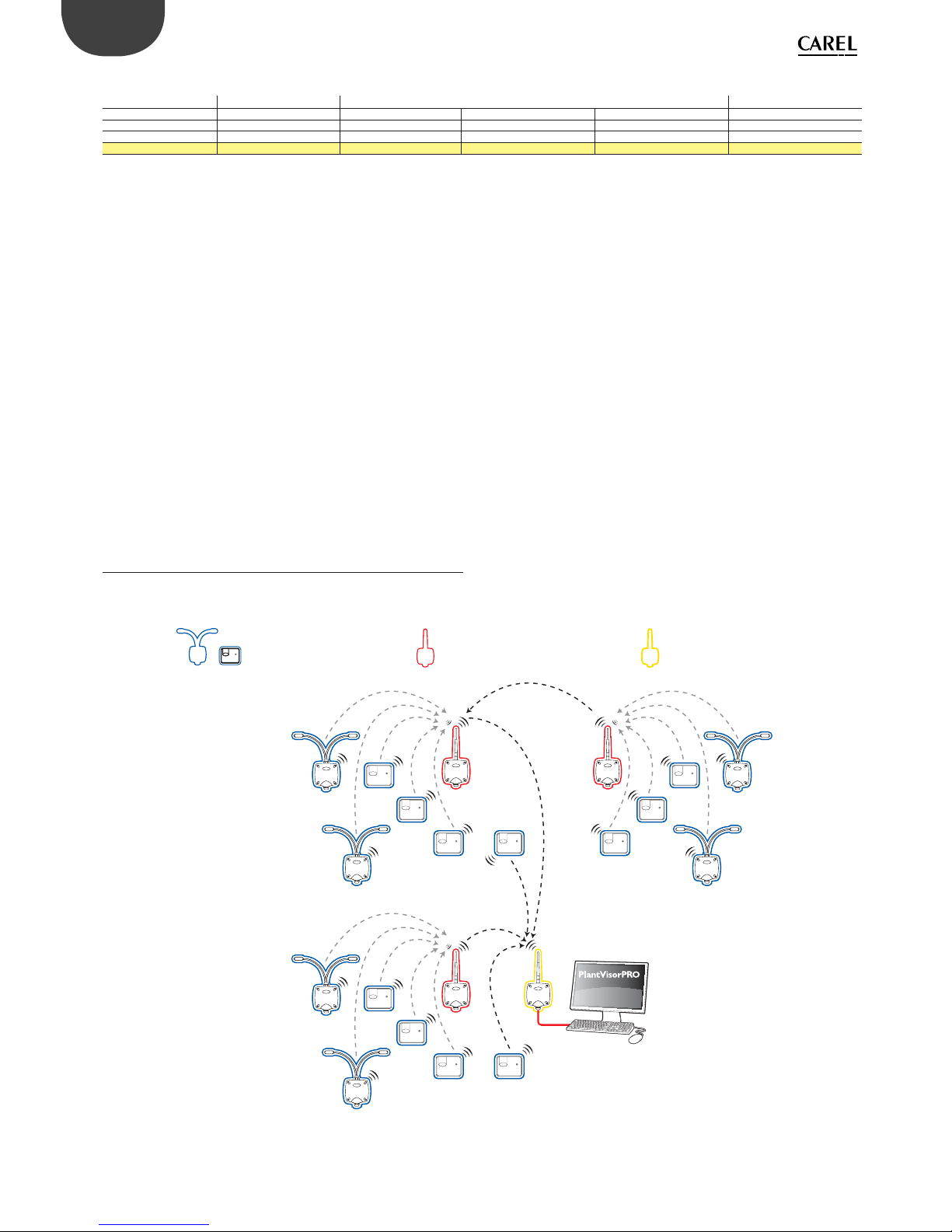

1.5 Type of Carel wireless network (MESH)

Legenda:

ZigBee» End-Device:

Sensors BP and EP (S)

ZigBee Router-Bridge (R)

ZigBee Coordinator -

Access point (AP)

RS 485 ModBus

S

S

S

S

S

S

R

R

S

S

S

S

S

R

S

S

S

S

S

S

AP

Fig. 1.c

Tab. 0.b

11

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

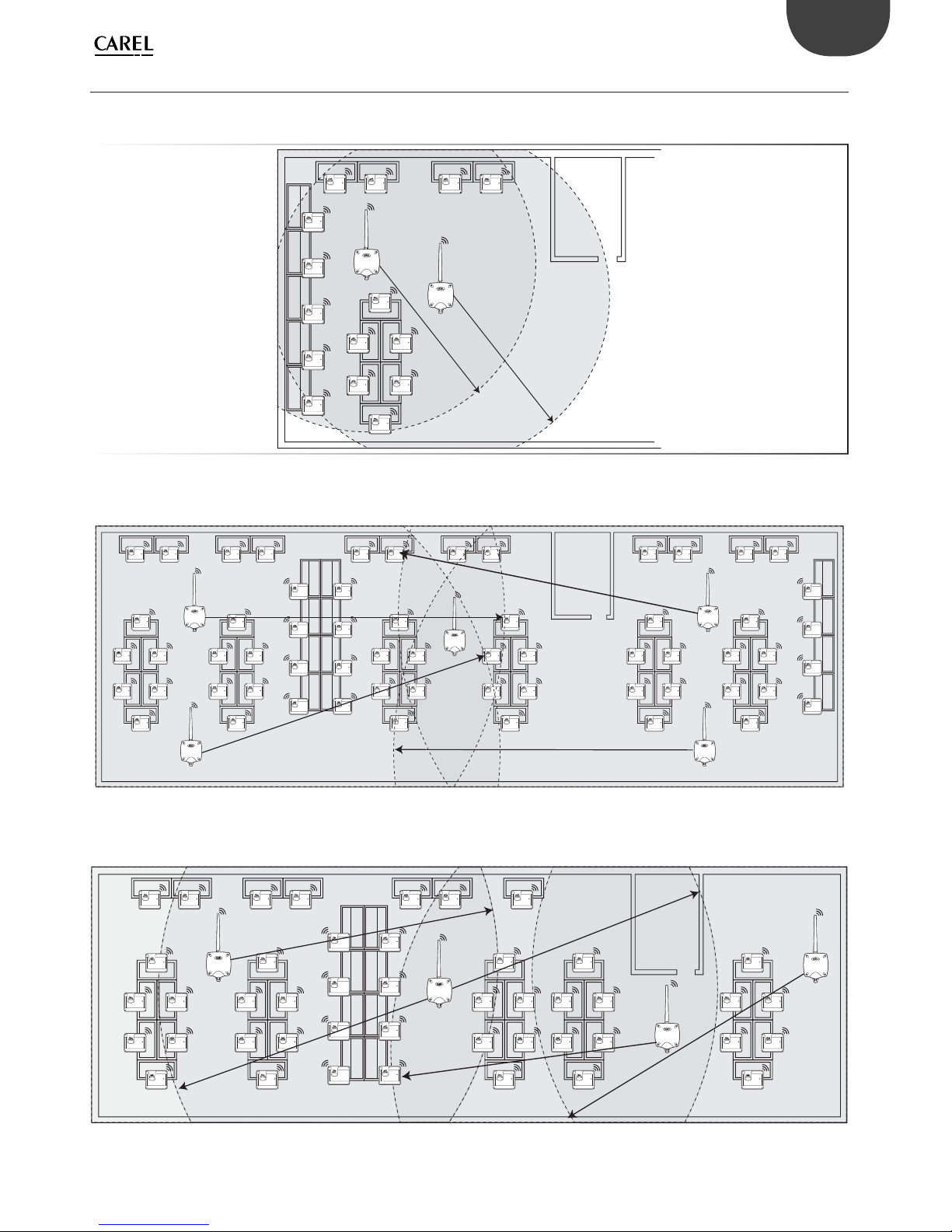

Example of a Mesh network

The MESH layout, used in the wireless sensor system for refrigeration between

coordinator nodes (access points) and router-bridge devices, ensures a high

tolerance to faults, as if one sensor loses wireless communication, the radio

signal still manages to nd an alternative route to reach the destination.

R

AP

RS 485 ModBus

R

R

Fig. 1.d

1.6 General features of the system

Maximum distance between Access Point/Router and Sensors in open eld

(outdoors): 100 m.

Maximum distance between Access Point/Router and Sensors with eld of

sight (indoors): around 30 m (inside rooms and built-up areas).

Transmission frequency: selectable from 2405 to 2480 MHz.

Number of channels available: 16.

Transmission power:

• Access Point 0 dBm

• Router 230Vac +10 dBm

• Router Bridge 0 dBm

• EP1 Router-Sensor +10 dBm

• RA Router-Actuator +3 dBm

• Router-Pulse Counter +10 dBm

• BP SE Sensor +3 dBm

• EP SE Sensor +3 dBm

• SA Room Sensor +3 dBm

• SI Industrial Sensor +3 dBm

• CI Pulse Counter +3 dBm

Wireless protocol: ZigBee™ without interoperability.

Standard: 802.15.4.

Reception sensitivity:

• Access Point -92 dBm

• Router SE 230Vac -97 dBm

• Router Bridge -92 dBm

• Router EP probe1 -97 dBm

• RA Router-Actuator -95 dBm

• Router-Pulse Counter -97 dBm

• BP SE Sensor -95 dBm

• EP SE Sensor -95 dBm

• SA Room Sensor -95 dBm

• SI Industrial Sensor -95 dBm

• CI Pulse Counter -95 dBm

For battery powered devices:

• Maximum current for battery powered devices only: 35 mA, in transmission.

• Current in standby: 1 µA.

Maximum HOP levels: 7 (hops).

Maximum number of wireless network devices:

• 30 for each Access Point (with 1 Router up to 60 units);

• 16 Routers directly connectable to the Access Point up to a maximum of 60

devices on the same network;

• 16 Router directly connectable to each Router up to a maximum of 60

devices on the same network;

Maximum number devices on Modbus® RS485 network:

• 7 Access Point;

• 111 Sensors;

• 60 Routers, max 48 of which monitored by the supervisor;

• On Modbus network in combination with other devices up to max 247

units.

1 234567

R

R

R

R

R

R

R

Access point

Router-Bridge

Max 60 sensors

Fig. 1.e

1.7 Using the Router

When does the Router need to be installed?

The Router is required whenever a direct connection is not possible between

the Access Point and the Sensor; this may occur when:

• The distance between Access Point and Sensor is greater than 30 m MAX

with visibility between the instruments.

• There is no visibility between the Access Point and the Sensor, and/or

there is shielding infrastructure that reduces the wireless communication

distance.

• In addition, the Router is required if the number of Sensors managed

exceeds 30 devices.

In addition, this is used to improve the reliability of the wireless connection,

the Router network can in fact nd an alternative path if one of the direct

connections between the sensors and the access point fails.

Recommended:

Up to 15 sensors 1 Router;

from 16 to 30 sensors 2 Routers;

from 31 to 45 sensors 3 Routers;

from 46 to 60 sensors 4 Routers.

1.8 General notes

The radio range of the devices is around a hundred metres in an open eld,

that is, without any obstacles.

In a closed eld the range varies signi cantly based on the type of environment

and the surrounding objects (shelves, furniture, metal walls etc.).

Thick partition walls or reinforced ceilings and oors may represent impassable

obstacles.

The ideal position of the devices, especially the routers, often cannot be

de ned theoretically but must be found by trial and error in the actual

installation.

Serial address assignment is valid for all devices

Make sure not to assign the same serial address ID to two devices in the same

wireless network.

12

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

1.9 Reference standards

The Carel wireless sensors have been tested in accordance with the following

standards:

INDUSTRIAL ENVIRONMENT

EN61000-6-4, EN61000-3-2, EN61000-3-3, EN61000-6-2

ETSI EN 301 489-17 V1.2.1, ETSI EN 301 489-1 V1.4.1

RES., COMM. AND LIGHT IND. ENVIRONMENT

EN61000-6-3; EN61000-3-2, EN61000-3-3; EN61000-6-1

Compliant with EN 13485 (Instruments for measuring the temperature of

foodstu s)

1.10 Battery life

Transmission time in min. Sensor battery life in years

13

55

10 8

15 8

Tab. 0.cTab. 1.c

The battery life is purely indicative and depends on the cycle transmission

time set and the quality of the wireless connection. If the device does not

communicate correctly with the Access Point (distance or interference

problems) battery life will be reduced due to the continuous attempts to

restore connection to the Access Point/Router.

1.11 List of sensor system variables

(alphabetical order)

Name

Description

ADD_HIGH_T_DELAY If when a high temperature is measured the “door open” or

“defrost in progress” signals are present, the device delays

the alarm by the value set for ADD_HIGH_T_DELAY (HR12).

ALM_BATTERY Provides the at battery signal (1 if < 2800 mV).

ALM_GENERAL Provides a general sensor fault signal.

ALM_LONG_DEFROST Provides the alarm status for the Defrost input (1=Alarm);

ALM_PROBE_1 Temperature measurement alarm on probe 1. This may

be caused by a value outside of the maximum range or

by the probe not connected correctly (open or shortcircuited).

ALM_PROBE_2 Temperature measurement alarm on probe 2. This may

be caused by a value outside of the maximum range or

by the probe not connected correctly (open or shortcircuited).

AP_RX_RADIO_LEV Wireless signal level received from the Access Point for the

sensor (see note 1).

AUTO_DELAY De nes a delay time for the evaluation of the type of

showcase when auto-con guration mode is enabled.

AVERAGE_PARAM Weight for calculating the average, as per the formula with

weight M.

AVG_TEMPERATURE Temperature value calculated as the weighted average (in

tenths of a degree °C).

BATTERY_CHARGE De nes the residual charge, counting power consumption

corresponding to the operations e ectively carried out.

This can be used, together with the BATTERY_LEVEL value,

for a more complete evaluation of battery charge status.

Full charge mAh.

BATTERY_LEVEL Battery voltage value (mV). The rated value is 3600 mV,

below 2800 mV the battery is discharged.

CMD_PASSW_1 Only used by con guration systems.

CNT_REJOIN Wireless network parameter for internal use

DEFROST_ALM_DELAY Delay time (wait) in minutes before Defrost alarm signal

DEFROST_POL Logical state of the defrost input based on the electrical

state of the contact (open or closed).

DOOR_POL Logical state of the door input according to the electrical

state of the contact (open or closed).

EN_AUTO_CONF Enable automatic con guration mode (1= enabled).

EN_CMD_PW Only used by con guration systems.

EN_DI_DEFROST Enable/disable defrost digital input.

EN_DI_DOOR Enable/disable door digital input.

EN_HI_TEMP_ALM Enable the high temperature alarm signal (if=1), otherwise

the alarm is not measured/signalled. Used for both probes

1 and 2.

EN_SCAFFALE Selects the medium temperature shelf display case

(1=shelf)

FW_VERSION FW revision

HI_TEMP_ALM_1 Provides the status of the high temperature alarm for

probe 1

HI_TEMP_ALM_2 Provides the status of the high temperature alarm for

probe 2

HI_TEMP_TRESHOLD High temperature signal thresholds (in tenths of a degree

°C)

HI_TEMP_TRESHOLD_1

High temperature signal threshold for probe 1. Can be set

in tenths of a degree centigrade

HI_TEMP_TRE-

SHOLD_2

High temperature signal threshold for probe 2. Can be set

in tenths of a degree centigrade

HIGH_TEMP_DELAY Delay (waiting) time in minutes before the high tempe-

rature alarm is actually signalled. Used for both probes 1

and 2

ID_SER_ADDR Sensor serial address, set using the rTM SE handheld or by

switch. Used as the sensor identi er

IN_1_STATUS Status of digital input 1

IN_2_STATUS Status of digital input 2

LAST_RX_DELAY Wireless network parameter for internal use

LO_TEMP_ALM Provides the status of the low temperature alarm

LO_TEMP_ALM_1 Provides the status of the low temperature alarm for probe

1

LO_TEMP_ALM_2 Provides the status of the low temperature alarm for probe

2

LO_TEMP_TRESHOLD Low temperature signal threshold (in tenths of a degree

°C). Signal without delays.

LO_TEMP_TRE-

SHOLD_1

Low temperature signal threshold for probe 1. Can be set

in tenths of °C. Signal without delays

LO_TEMP_TRE-

SHOLD_2

Low temperature signal threshold for probe 2. Can be set

in tenths of °C. Signal without delays

MAC_ADDR_0 Unique 32 bit unit identi er, LSB. Used to uniquely identify

each sensor

MAC_ADDR_1 Unique 32 bit unit identi er, MSB. Used to uniquely identi-

fy each sensor

MACHINE_CODE Peripheral identi er for the supervisor

MIN_RSSI_LEVEL Wireless network parameter for internal use

MIRROR_IS Wireless network parameter for internal use

MODE_AUTO_TRESH De nes a threshold in °C below which the procedure

for the automatic recognition of the type of showcase is

activated.

MODE_PARAM De nes the values to be assigned or auto-assigned for the

identi cation of the e ective operating mode. For each

of the four modes, the associated parameters can be set

separately, and are loaded when the mode is activated

NETWORK_ID Wireless network parameter for internal use

OFFS_TEMP Temperature measurement o set, within a maximum of

±9.9 °C.

OFFS_TEMP_1 Calibration o set for probe 1, within a max of ±9.9 C;

OFFS_TEMP_2 Calibration o set for probe 2, within a max of ±9.9 C;

RX_MESSAGE_CNT Wireless network parameter for internal use

RX_MSG_LEVEL Wireless signal level received for the sensor in dBm+100

(see note 1).

TEMPERATURE Instant temperature value (in tenths of a degree °C).

TEMPERATURE_1 Provides the temperature values measured by probe 1. The

temperature reading is in the range from -50°C to +90°C;

TEMPERATURE_2 Provides the temperature values measured by probe 2. The

temperature reading is in the range from -50°C to +90°C;

TIME_STAMP Value expressed in hours:minutes associated with the last

wireless data transmissions received. This can be used to

synchronise the measurements from di erent units with

the same clock. Variable added by the Access Point for

each sensor.

TRANSM_CYCLE De nes the wireless data transmission time to the Access

Point. The value is set in seconds, but must correspond

(rounded o ) to a multiple of 60, thus in minutes (see

note 2).

TX_MESSAGE_CNT Wireless network parameter for internal use

TX_POWER Wireless network parameter for internal use

Tab. 0.dTab. 1.d

Note:

• The two values provide an indication of the wireless signal levels seen from

the sensor and the Access Point. The minimum value must be greater than

8, for medium reception from 15 to 30, and excellent for values greater than

30.

• To maximise battery life, the number of transmissions should be limited to

the minimum possible.

13

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

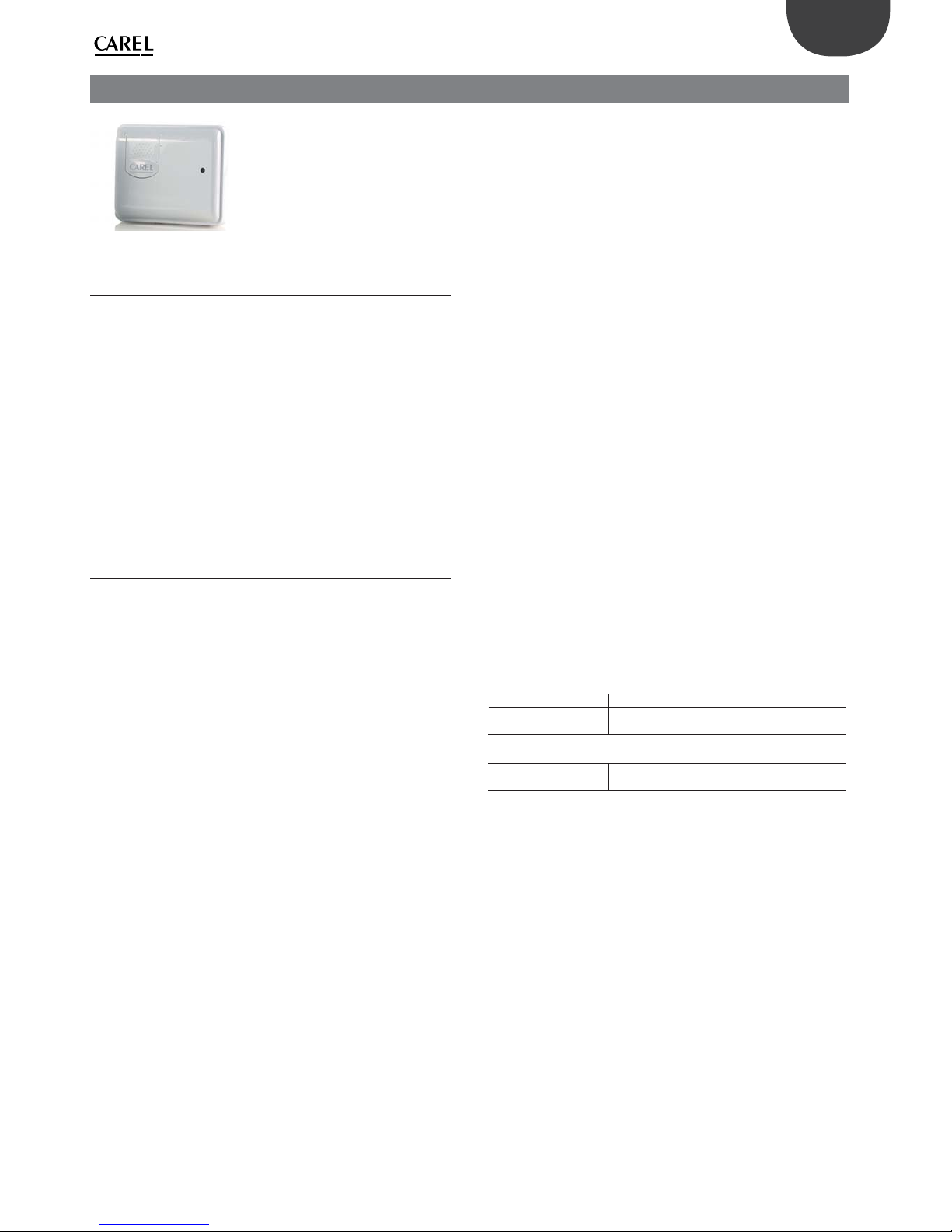

2. BP SE SENSOR BUILTIN PROBE

The BP SE Sensor is designed to be positioned directly inside the showcases, tted using its own fastening bracket. The rear features

metal shielding that, combined with the thermal insulation inside the shell, prevents the formation of frost at the rear of the sensor,

and consequently better thermal insulation from the wall.

Fig. 2.a

2.1 Functions implemented and supervisor

variables available

• Instant temperature measurement performed every minute.

• Measurement ltering with weighted average based on parameter setting

for product temperature simulation.

• Data transmission at settable intervals, in minutes (the parameter a ects

battery life).

• Monitoring of temperature thresholds for high temperature (HACCP) or low

temperature (product freezing) alarm signals.

• Automatic mode with preset parameters according to the showcase/

display case (normal, low temperature or open shelf).

• Local mode for Clean showcase status signal. Activating the Clean button

disables the high temperature alarms.

• TimeStamp for recording the instant measurement, expressed in hh:mm.

• Battery level in mV and residual charge in mAh.

• Wireless signal level in dBm +100 (less than 8=low, 15-30=medium, higher

than 30=excellent);

• Temperature alarm status related to the high and low thresholds.

2.2 Sensor con guration

The sensor is supplied with the address ID set to 127 and cannot be used with

the default ID; the range of available addresses is from 16 to 126. To assign the

ID use the rTM SE handheld accessory. For details on the address assignment

procedure see the instructions in the chapter on the rTM SE handheld further

on.

In emergency situations a new ID can be assigned (limited to the range from

16 to 99) using a magnet (e.g. magnetic screwdriver Carel code 0000000722),

as follows:

1. Position the magnet on SW1, holding it in position when the green LED

comes on;

2. The following will be shown in sequence:

- Green LED ON for 2 to 3s then OFF for 3 to 4s;

- Orange LED ON for 3 to 4s;

- Remove the magnet when the LED switches o ;

- After a few moments the LED comes on yellow for 1s. This indicates

that programming procedure is active (if no actions are performed,

programming mode ends after 4/5 s, indicated by a double yellow ash,

leaving all the settings unchanged);

3. Move the Clean switch SW2 up and down a number of times equal to the

tens of the serial address being set (e.g. 10, once – 50, ve times). Each

time switch SW2 is moved up the red LED comes on for 1 s, (con rming

stimulation);

4. Subsequently use the magnet to stimulate switch SW1 a number of times

equal to the units (e.g. 1, once – 5, ve times). Each time the magnet moves

over the switch the green LED comes on for 1 s (con rming stimulation).

The order is not important (tens or units rst);

5. After 4/5 s the sensor exits the procedure, with the yellow LED ashing

twice (indicating the end of serial address setting mode);

6. Subsequently the sensor shows the serial address using a sequence of

ashes repeated cyclically three times. To read the codes, see the chapter

“Display sensor serial ID” further on.

7. Moving switch SW2 up interrupts the cycle;

The sensor address has been set and it’s ready to be bound to an Access Point.

The procedure can be performed before or after binding to the Access Point.

Make sure not to assign duplicate serial addresses, also considering other

devices in the network. For further information and explanations on the

procedure, see the rTM SE system installation guide.

Binding procedure

Binding is a special procedure used to associate the sensors with the Access

Point. Once completed, the sensors will send the temperature data measure

wirelessly only to the Access Point de ned as its parent. Following this, the

Access Point will forward the data to the Modbus® RTU RS485 serial network.

The binding procedure requires the activation of the Access Point wireless

network and activation of the con guration switch SW1 using a magnet (see

the gure), done by passing the special magnet over magnetic switch SW1

for a few seconds. The LEDs will come on in sequence: green (1s), yellow (4 to

5s), green (6 to 10s). If at the end of the sequence the red LED ashes brie y (1

to 2s), binding with the Access Point has failed. If the operation is successful,

successively activating switch SW1 will start manual data transmission,

signalled by the green LED ashing quickly twice.

If the automatic or manual data transmission fails, the red LED will ash brie y

after the green LED comes on.

After this operation the sensor will start sending data on the temperature

measured, in the time interval set by parameter. Check that the LED comes on

for a few seconds at regular intervals, based on the transmission time set for

parameter (HR_01 TRANS_CYCLE). When the operation has ended close the

wireless network on the Access Point. The wireless network can be opened

and closed using the rTM SE handheld accessory.

Display sensor serial ID

To check the sensor serial address, proceed as follows:

• Move switch SW2 (CLEAN) up, stimulate SW1;

• The LED starts ashing in sequence. Count the number of the ashes to

calculate the hundreds (Yellow), tens (Green) and units (Red). Removing

the magnet or lowering the button exits the display probe serial address

procedure.

• Move switch SW2 back down.

Yellow Red Green

X 100 X 10 X 1

Hundreds Tens Units

Tab. 2.a

Example

0 yellow ashes 5 red ashes 7 green ashes

057

Sensor address ID=57

Tab. 2.b

Resetting the sensor (maintaining the serial address)

The reset procedure is required when the sensor needs to be moved and

associated with another wireless network (di erent Access Point). This

operation may be required to recon gure the sensor in a di erent wireless

network. The value of the serial address remains the same, and after a new

binding operation the sensor is reactivated in the wireless network. To reset

the sensor, proceed as follows:

1. Place the magnet near magnetic switch SW1 (the green LED will come on);

2. Hold the magnet in place until the green LED goes o and the yellow LED

comes on (after approx. 6 to 10 sec.);

3. When the yellow LED comes on, move the magnet immediately away

from the sensor and check that the LED ashes quickly before going o

(RESET COMPLETE).

To check that the sensor has been reset, proceed as follows:

1. Make sure the Access Point wireless network is closed (L1 ashing slowly

1s);

2. Stimulate switch SW1 on the sensor with the magnet;

3. Check that LEDs come on in the following sequence:

- green LED (1 s);

- yellow LED (4 to 5 s);

- green LED (15 s);

- red LED (1 s);

Make sure that there are no sensors with the same serial address in the new

network. If this is the case, assign a new serial address.

14

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

RESET sensor and assign default serial address (=127)

To restore the sensor serial address to the default value, proceed as follows:

1. Place the magnet near magnetic switch SW1, the green LED will come on.

2. Hold the magnet in position until the green LED goes o and the yellow

LED comes on (after approx. 6 to 10 s);

3. Immediately remove the magnet from the sensor and at the same time

move the CLEAN switch (SW2) up, making sure the yellow LED ashes a

few times.

4. Move the CLEAN switch to the OFF position and make sure the yellow LED

completes a rapid sequence of ashes (RESET COMPLETE);

Otherwise repeat the procedure.

To check that the sensor has e ectively been reset, proceed as follows:

1. Make sure the Access Point wireless network is closed (L1 ashing slowly

1 s);

2. Stimulate the switch SW1 with the magnet;

3. Check that LEDs come on in the following sequence:

- green LED (1 sec.);

- yellow LED (4 to 5 sec.);

- green LED (15 sec.);

- red LED (1 sec.);

Completing the reset procedure and assigning the default serial address

returns the sensors to the same status as a new device.

To assign a new address, repeat the serial address assignment procedure.

Note:

1. The sensor can only be reset if it has already been bound to an Access

Point.

2. Note that, after resetting the sensor, the number of devices set for the Access

Point remains unchanged. Realignment will occur after a maximum of around

2 hours.

Meaning of the switches and LED signals

CLEAN

SW2

SW1

Led

NTC

Fig. 2.b

Key:

SW1 Internal magnetic con guration switch (above the LED, labelled).

Can be activated by external magnet

SW2 Magnetic CLEAN switch (open = CLEAN MODE)

LED Two-colour red/green (yellow if both are on)

NTC Located inside the case in thermal contact directly with the front wall

The following table describes how the LEDs ash whenever SW1 or SW2 are

stimulated or when data is transmitted.

Action LED sequence (times in s.) Meaning of the signal

Stimulating SW1 /

data transmission

Green ashing (approx. 1s) Communication with

Access Point occurred

correctly

Stimulating SW1 /

data transmission

Green ashing (approx. 1s) red

ON (approx. 0.5s)

Communication with

Access Point NOT

successful

Stimulating SW1 /

data transmission

Green ashing (approx. 1s) OFF

(approx. 1s) red ON (approx.

0.5s)

Communication with

Access Point NOT

successful

Stimulating SW1

Green ON (approx. 1s)yellow

ON (4..5s) green ON (approx.

15s) red ON (approx. 1s)

BP SE Sensor in Reset

status

Binding with Access

Point failed

Stimulating SW1

Green ON (approx. 1s)yellow

ON (4..5s) green ON (6..10s)

OFF

Binding with Access

Point successful

Open CLEAN cover

(SW2)

Red ON (approx. 1s)green ON

(approx. 0.5s)

CLEAN mode activated

Reset procedure

Green ON (approx. 2..3s) OFF

(approx. 6..7s)yellow ON

(approx. 2..3s)OFF (approx.

1s)yellow ashing (approx. 1s)

Sensor being reset

Reset procedure

and assign default

serial address

Green ON (approx. 2..3s)OFF

(approx. 6..7s)yellow (approx.

2..3s) yellow ashing (depends

on when the CLEAN door

is closed)OFF (approx.1s)

yellow ashing (approx. 1s)

Reset sensor plus return

serial address to default

value

Tab. 2.c

Note: the LED is two-colour, red and green, which becomes yellow when both

LEDs are on at the same time. There may be di erent shades of yellow due to

di erent tolerance in the brightness of the red and green LEDs.

2.3 Sensor activation

When the sensor is put in SLEEP mode using the rTM SE handheld during

the procedure to assign the serial address (no transmission-minimum power

consumption), the sensor is e ectively in standby; nothing is transmitted

until movement of the CLEAN switch is activated (sleep status). Activation is

not reversible, and the sensor will send the temperature measured every 16

min (default value) if the Access Point that the sensor has been bound to is

switched on.

To exit sleep mode, proceed as follows:

• Power up the Access Point;

• Move the CLEAN switch to the ON position (SW2);

• Make sure the red LED comes on for a few seconds.;

• When the red LED comes on immediately the CLEAN switch to the OFF

position;

• The LED on the sensor remains on until it has connected to the Access Point.

If the operation fails, the sensor returns to sleep mode, if however it’s successful

normal operation will resume, with data being sent every 16 min.

Check operation by stimulating the sensor.

Resetting the sensor in sleep mode

If the sensor needs to be reset when in sleep mode (Access Point network

parameters forgotten), proceed as follows:

• Move the CLEAN switch to the ON position (SW2);

• Wait for the red LED to come on;

• Stimulate SW1 continuously while the red LED remains on.

• Keep SW1 stimulated until the LED ashes (yellow) ;

• Remove the magnet from SW1 and move switch SW2 back down.

• Reset completed.

Led

Posizione switch OFF

Switch OFF position

Posizione switch ON

Switch ON position

Fig. 2.c

Parameters and functions

The BP wireless sensor reads the temperature and manages the associated

alarms at one minute intervals.

The data is then transmitted at the intervals set by parameter, according to the

application and the expected battery life. The sensors work most of the time in

low power mode, so as to save battery power. They are activated to make the

measurements and send the data at the preset time.

Activate switch SW1 to send the sensor data manually, or check the connection.

The CLEAN button is used to set cleaning status or deactivate the showcase,

thus disabling the high temperature alarms.

When returning from CLEAN mode, the high temperature alarms are disabled

for a time equivalent to the auto-con guration cycle (AUTO_DELAY).

15

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

The sensor takes individual instant temperature measurements, however can

also provide a weighted average, used to better approximate the product

temperature. The logic for the alarms and all the other functions depends on

the instant temperature measurement.

Wireless communication is activated automatically in the following situations:

• moving the CLEAN mode switch (SW2);

• stimulating the magnetic switch (SW1).

In all other cases, data transmission is de ned by the set transmission cycle.

Note:

• The temperature measurement, with the update of the instant and average

values, is performed at 1 minute intervals.

Important: the value is displayed on the supervisor after the set sensor

transmission time .

The average temperature value is calculated using the following formula:

Temp_AVG = (Temp_AVG-1 * (M - 1) + Temp_Ist) / M

Where:

• Temp_AVG-1 Previous average temperature value

• Temp_Ist Instant temperature measurement

• M Average weight (= AVERAGE_PARAM)

The average function also introduces an average measurement delay with a

time constant equal to the average weight value (in minutes).

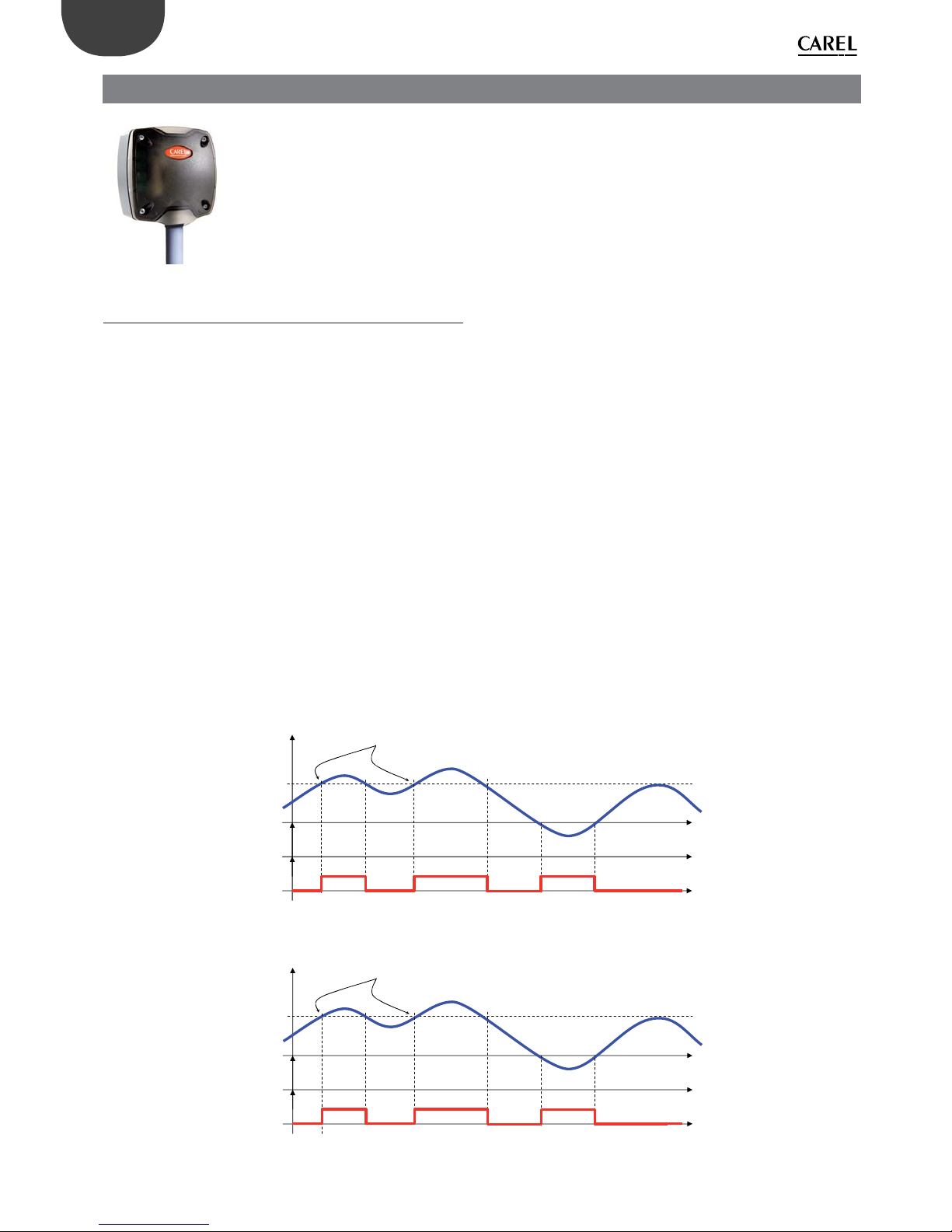

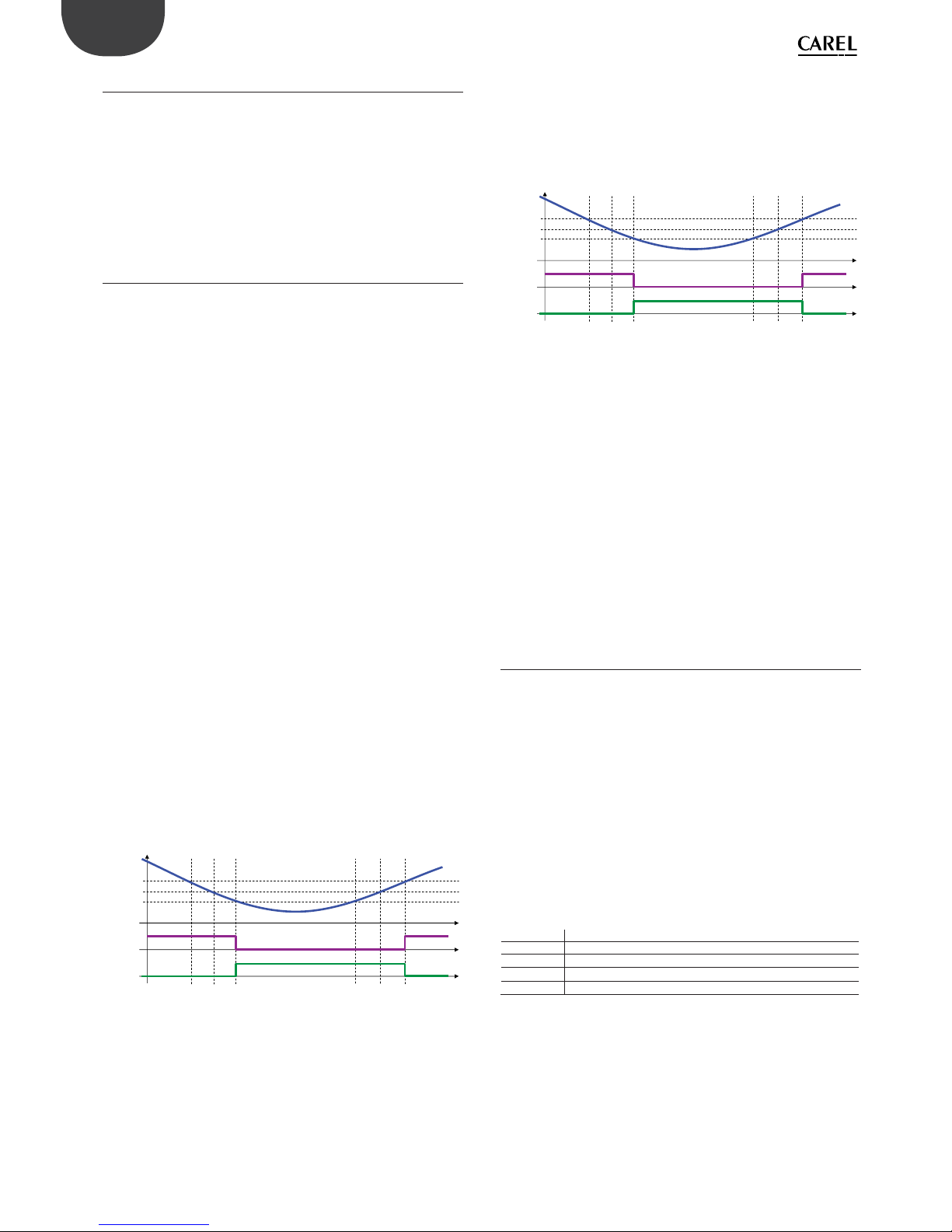

High temperature alarm function:

Alarm delay

HIGH_TEMP_DELAY

Alarm delay

HIGH_TEMP_DELAY

EN_HI_TEMP_ALM

LO_TEMP_ALM_1

HI_TEMP_ALM_1

Reset counter alarm

Start counter alarm delay

HI_TEMP_TRESHOLD

LO_TEMP_TRESHOLD

Temp. °C

Time

Alarm ON

Fig. 2.d

• When the threshold is exceeded, the alarm is signalled only if this persists

for a time greater than the delay set;

• If the temperature returns within the threshold before the delay time, the

accumulated count is reset;

• The alarm is reset instantly when the temperature returns within the

threshold.

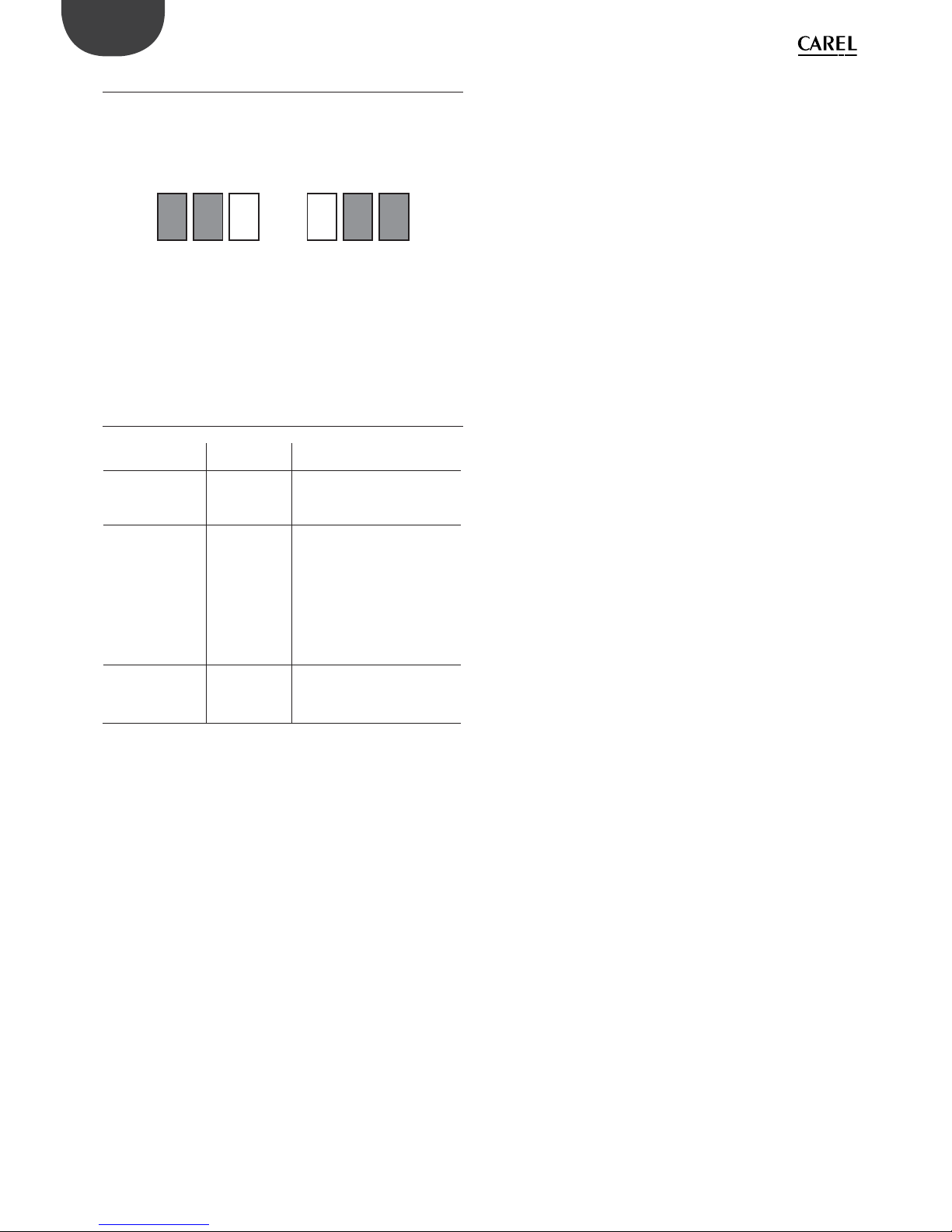

Default values for the modes settable for the MODE_PARAM

parameter

MODE 0

Generic use

MODE

1LOW

showcases

MODE

2MED

showcases

MODE 3MED

shelf cases

High temp. threshold

-15 °C -15 °C +10 °C +8 °C

Low temp. threshold

-40 °C -40 °C -2 °C -2 °C

HACCP delay 180 min. 120 min. 120 min. 120 min.

Average weight 1 (Instant) 16 (16 min.) 8 (8 min.) 12 (12 min.)

Tab. 2.d

Automatic con guration procedure

The automatic recognition procedure is used to recognise the type of

showcase and consequently con gure the parameters for the showcase

that the sensor is installed on. The automatic recognition cycle is activated (if

enabled by EN_AUTO_CONF):

• When the temperature falls below the threshold MODE_AUTO_TRESH;

• When returning from CLEAN mode, closing the switch;

• When a previous cycle is completed.

When the AUTO_DELAY time has elapsed, if the following conditions are true:

• Final temperature rise less than 1°C/h;

• Final temperature within a xed band of temperatures for the various types

of showcase:

- medium temp. showcases = from -2°C to + 6°C

- low temp. showcases = less than -10°C.

The MODE_PARAM parameter is given the new value corresponding to the

type of showcase and the associated values for the alarm thresholds, alarm

delay and average weight are loaded;

Note:

• In the event of increases in temperature for low temperature showcases,

the recognition procedure is disabled for 3 times the value of AUTO_DELAY,

to avoid false recognitions.

• The temperature alarms are always enabled, if MODE_PARAM and

consequently the associated parameters are changed, the alarm logic

depends on the new parameters.

• The parameters associated with each mode (0-3) are saved separately and

permanently, and are loaded automatically when the mode is changed.

• The values of the parameters associated with the mode must be set (by the

supervisor) making sure that MODE_PARAM does not change, otherwise

the values transferred may be ignored.

2.4 Technical speci cations

Power supply 3.6V 2500 mAh lithium battery, “AA” size

Maximum power input 100 mW

Battery life in normal operating

conditions

From 3 to 8 years, depending on the transmission time set.

(CAREL is not responsible for the speci ed

battery life)

Radio frequency speci cations Frequency: selectable from 2405 to 2480 MHz

Power transmitted: 0dBm

Wireless protocol: ZigBee

Operating conditions -40T50°C

Storage conditions -20T60°C

humidity range: <80% RH non-condensing

Precision of temperature measurement

± 1 °C -10T30°C;

± 2 °C -30T40°C

Response time to temperature

variations

> 20 minutes

Compliant with EN 13485

Index of protection against atmospheric agents

IP65

Classi cation according to protection against electric shock

Can be integrated into class I or class II

appliances

Environmental pollution Normal

PTI of insulating materials 250 V

Period of stress across the insulating parts

Long

Category of resistance to heat

and re

category D (box and cover)

Immunity against voltage surges category 1

Software class and structure Class A

Disposal observe local legislation for the disposal of

electrical material

Product code WS01U01M0 - Wireless sensor ver. BP SE IP65

-40 to 50°C

Accessories WS00BAT000 Battery

WS00B01000 Plastic case only

0000000722 Magnet for activating SW1

Tab. 2.e

16

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

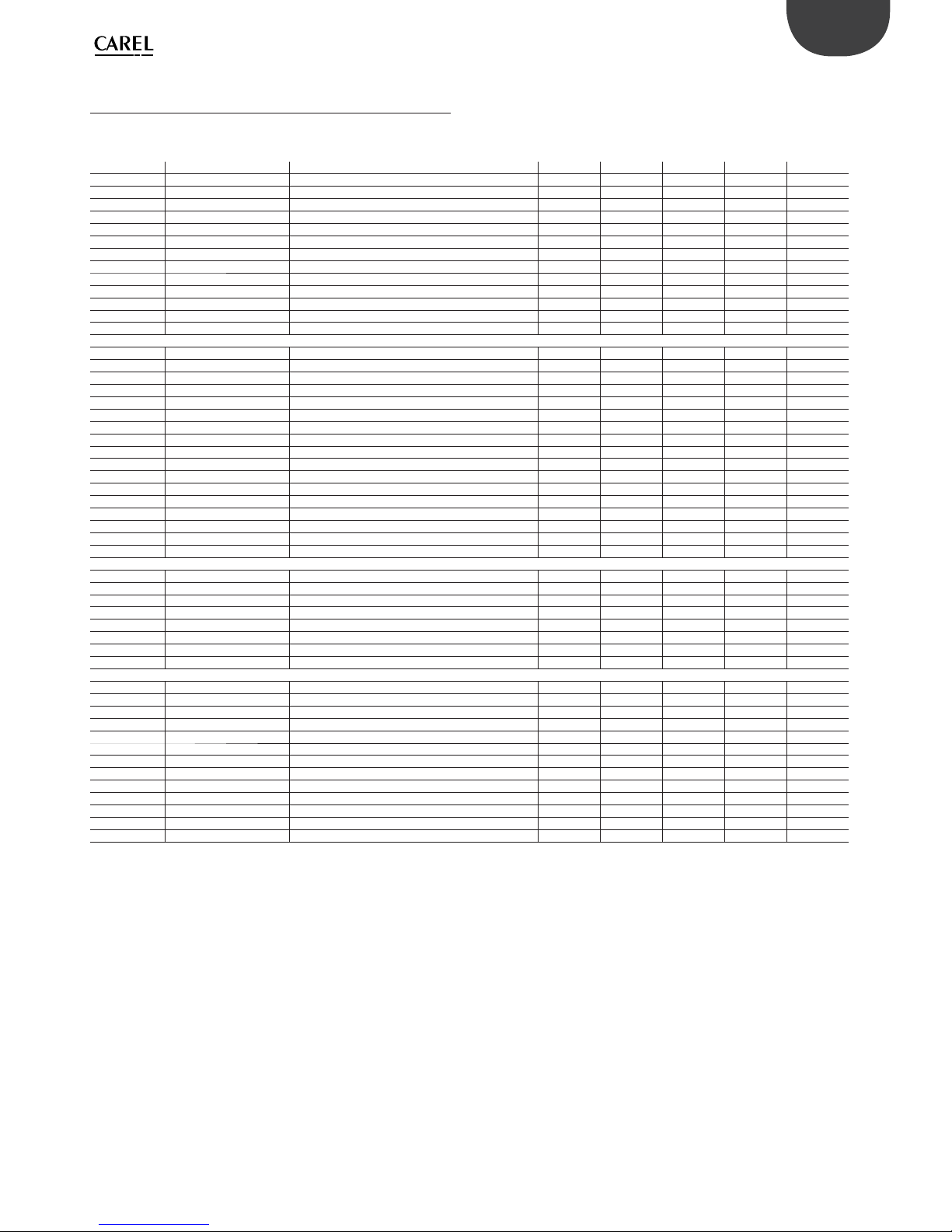

2.5 List of parameters and variables, BP SE

Sensor

Below is the table of supervisor parameters for the BP SE Sensor.

Variable Index Name Description Def. Min Max UoM “ Type R/W”

HR0 ‘CMD_PASSW_1’ ‘Command Password (1)’ 0 0 65535 - R/W

HR1 ‘TRANSM_CYCLE’ ‘TX data cycle time’ 960 60 3600 sec R/W

HR2 ‘HI_TEMP_TRESHOLD’ ‘Threshold high Temp.’ -150 -400 500 0,1°C R/W

HR3 ‘LO_TEMP_TRESHOLD’ ‘Threshold low Temp.’ -400 -400 500 0,1°C R/W

HR4 ‘HIGH_TEMP_DELAY’ ‘Delay High Temp. Alarm’ 120 0 254 min R/W

HR5 ‘MODE_AUTO_TRESH’ ‘ Threshold Auto Temp.’ 120 0 500 min R/W

HR6 ‘AVERAGE_PARAM’ ‘Parameter Avg-readings’ 16 1 60 - R/W

HR7 ‘AUTO_DELAY’ ‘Delay for AUTO-Con g’ 120 2 254 min R/W

HR8 ‘MODE_PARAM’ ‘Par. MODE for cabinets’ 1 0 3 - R/W

HR9 ‘OFFS_TEMP’ ‘O set Temperature Measure’ 0 -99 99 0,1°C R/W

HR10 ‘MIN_RSSI_LEVEL’ ‘Minimum rssi level counted (internal use)’ 0 0 99 - R/W

HR11 ‘CNT_REJOIN’ ‘Max counter value before rejoin (internal use)’ 30 1 255 - R/W

IR0 ‘MACHINE_CODE’ ‘Unit type - machine code’ 63 - - - R

IR1 ‘FW_VERSION’ ‘Firmware version (Major/Minor)’ 2051 - - - R

IR2 ‘TX_MESSAGE_CNT’ ‘Total Number of TX radio messages’ 0 0 65535 - R

IR3 ‘RX_MSG_LEVEL’ ‘Radio signal Level’ 0 0 100 dBm+100 R

IR4 ‘ID_SER_ADDR’ ‘Carel_ID Serial_Address DIP-SW value’ - 16 127 - R

IR5 ‘BATTERY_LEVEL’ ‘Battery Level’ - 0 3600 mV R

IR6 ‘AVG_TEMPERATURE’ ‘Temperature average Value’ - -500 1000 0,1°C R

IR7 ‘ TEMPERATURE ‘ ‘ Temperature Value’ - -500 1000 0,1°C R

IR8 ‘BATTERY_CHARGE’ ‘Counter battery remaining charge’ - 0 65535 - R

IR9 ‘MAC_ADDR_0’ ‘Unit unique identi er Mac-Address LSB’ - 0 65535 - R

IR10 ‘MAC_ADDR_1’ ‘Unit unique identi er Mac-Address MSB’ - 0 65535 - R

IR11 ‘LAST_RX_DELAY’ ‘Time from last AP Rx message’ - 0 65535 - R

IR12 ‘RX_MESSAGE_CNT’ ‘Counter - AP Rx messages’ - 0 65535 - R

IR13 ‘TIME_STAMP’ ‘Time stamp for Temp. readings (100*hour+minute) ‘ - 0 2359 R

IR14 ‘AP_RX_RADIO_LEV’ ‘Radio Lev. for AP Rx messages’ - 0 100 dBm+100 R

IR15 ‘NETWORK_ID’ ‘Net work address ‘ - 0 65535 - R

IR16 ‘MIRROR_IS’ ‘Mirror Input Status (internal use)’ - 0 65535 - R

CS0 ‘EN_CMD_PW’ ‘Trig. PWD (internal use)’ 0 0 1 - R/W

CS1 ‘EN_HI_TEMP_ALM’ ‘Enable High Temp. Alarm’ 1 0 1 - R/W

CS2 ‘EN_AUTO_CONF’ ‘Enable auto con guration MODE’ 0 0 1 - R/W

CS3 ‘EN_SCAFFALE’ ‘Type of cabinet ( 1= sca ale)’ 0 0 1 - R/W

IS0 ‘ALM_BATTERY’ ‘Battery Alarm’ - 0 1 - R

IS1 ‘ALM_GENERAL’ ‘Unit General Alarm’ - 0 1 - R

IS2 ‘ALM_PROBE_1’ ‘Temperature sensor Alarm’ - 0 1 - R

IS3 ‘HI_TEMP_ALM_1’ ‘High Temperature Alarm’ - 0 1 - R

IS4 ‘LO_TEMP_ALM_1’ ‘Low Temperature Alarm’ - 0 1 - R

Tab. 2.f

Key:

HR = Holding register

IR = Input register

CS = Coil Status

IS = Input Status

17

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

2.6 Installation notes

The sensor is installed on the bracket supplied as follows:

1. Fasten the bracket to the wall with two screws, supplied together with the

sensor, considering that the unit being installed is a radio device, and thus

taking the necessary precautions;

2. Couple the sensor to the bracket, making sure it clicks and locks into place.

N.B. To remove the sensor from the bracket, lift the release spring using a

suitable screwdriver and lift the sensor.

click

Fig. 2.e

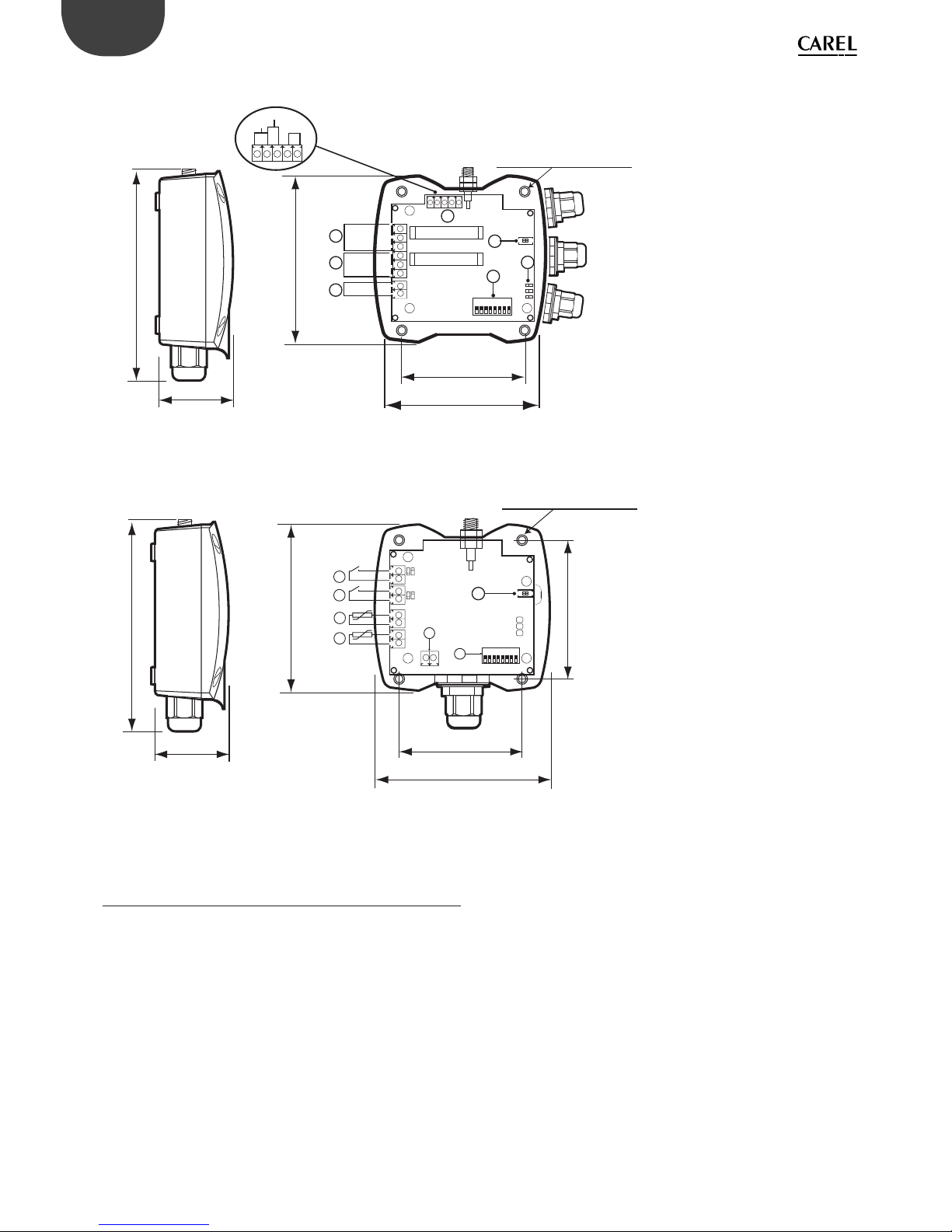

2.7 Physical dimensions

7.527 83.9

71.634

SW1

SW2

NTC

LED

44

50

Fig. 2.f

2.8 Replacing the battery in the BP SE

Sensor

The case of the BP SE wireless sensor has been designed to provide high

protection. When opening the two plastic shells to replace the battery, the

locking catches may be damaged or break. Consequently, the spare battery

is supplied together with a new case. Take maximum care when removing

the electronic board from the old shell and placing it in the new one, so as to

not damage the electronic components. Make sure battery polarity is correct.

Remove the product label from the old case and place it on the new one.

Rules for disposing of the battery

Do not dispose of the product as municipal waste; it must be disposed of

through specialist waste disposal centres.

The product contains a battery that must be removed and separated from the

rest of the product.

Improper use or incorrect disposal of the product may negative e ects on

human health and on the environment.

The public or private waste collection systems de ned by local legislation

must be used for disposal.

In the event of illegal disposal of electrical and electronic waste, the penalties

are speci ed by local waste disposal legislation.

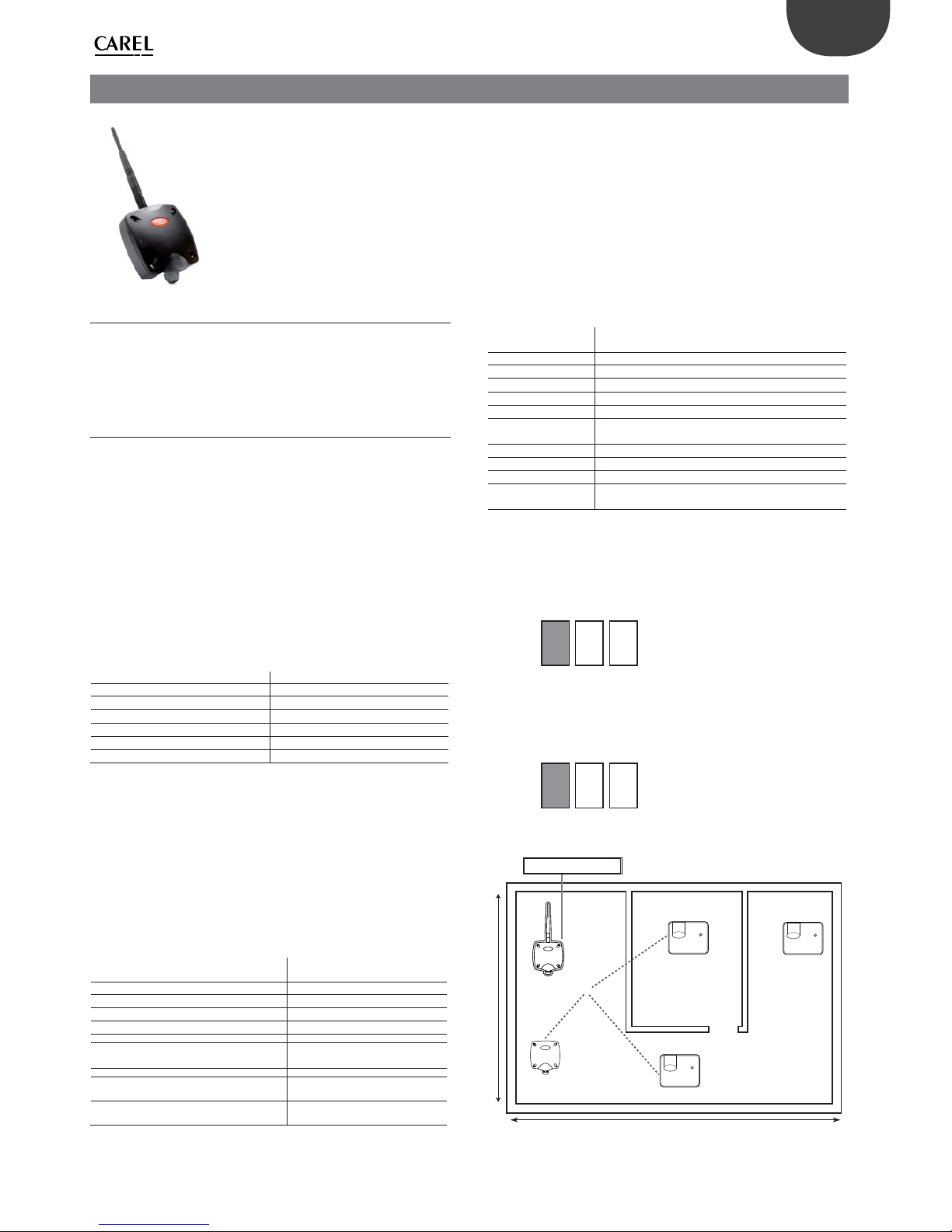

2.9 Application examples

Supermarket showcases

Fig. 2.g

Fig. 2.h

Example of supermarket layout and installation connections

RS 485 ModBus

Router/Bridge

Fig. 2.i

18

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

3. EP SE, SA, SI SENSORS AND CI PULSE COUNTER

3.1 Parameters and functions

The wireless devices read the temperature and manage the associated

alarms at intervals set by the transmission time parameter, according to

the application and the expected battery life. The sensors work most of the

time in low power mode, so as to save battery power. Press the button or

stimulate the magnetic switch to send the sensor data manually, or check the

connection.

3.2 Description of the acquisition process

The devices acquire all the values before sending their status to the Access Point.

Consequently, the device sampling interval is equal to the transmission time.

3.3 Device con guration

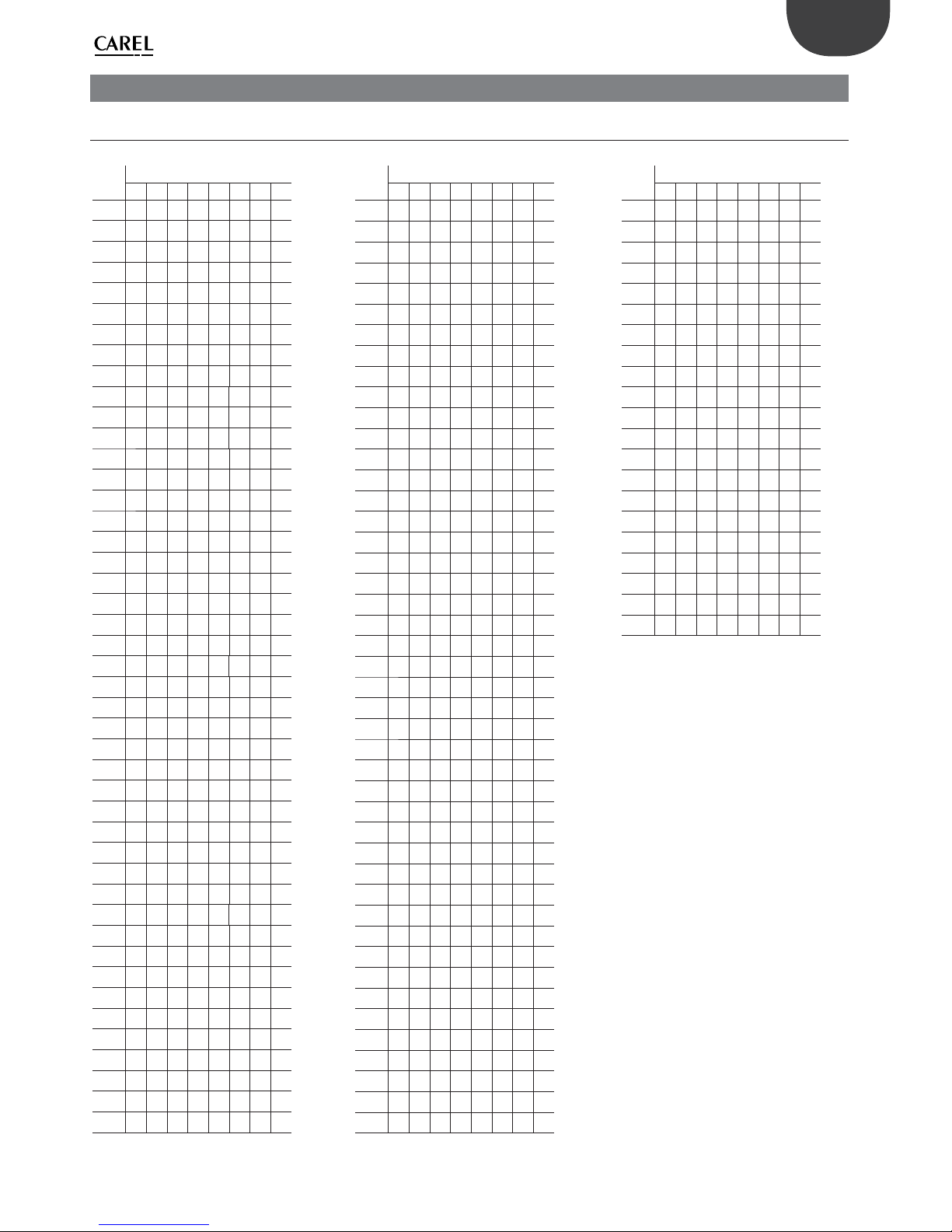

Select the desired network address using the 8 dipswitches (0=OFF; 1=ON) as

shown in the table. The possible sensor addresses are from 16 to 126.

Address

Dipswitch Notes

12345678

0..15 x x x x x x x x address not allowed (*)

16 0 0 0 0 1 0 0 0

17 1 0 0 0 1 0 0 0

18 0 1 0 0 1 0 0 0

19 1 1 0 0 1 0 0 0

20 0 0 1 0 1 0 0 0

...127 0 1 1 1 1 1 1 1 Reserved. Do not use

128,...199 1 1 1 0 0 0 1 1 address not allowed (*)

200...256 x x x x x x x x address not allowed (*)

Tab. 3.a

For the complete list see the table at the end of the manual.

(*) The address may be set however the device cannot connect to the Access

Point/Router. Pressing the button the LED ashes quickly in sequence to

indicate an invalid address.

EXAMPLE required sensor address setting 117:

Decimal value: 117

Conversion to binary notation:(MSB) 0111 0101 (LSB)

Reverse the value of the string (10101110) and assign dipswitches from (LSB)

1 to 8. (MSB).

Dipswitch

1 2 3 456 7 8

x x x xxx x x

0 0 0 010 0 0

1 0 0 010 0 0

0 1 0 010 0 0

1 1 0 010 0 0

0 0 1 010 0 0

0 1 1 111 1 1

1 1 1 000 1 1

x x x xxx x x

Tab. 3.b

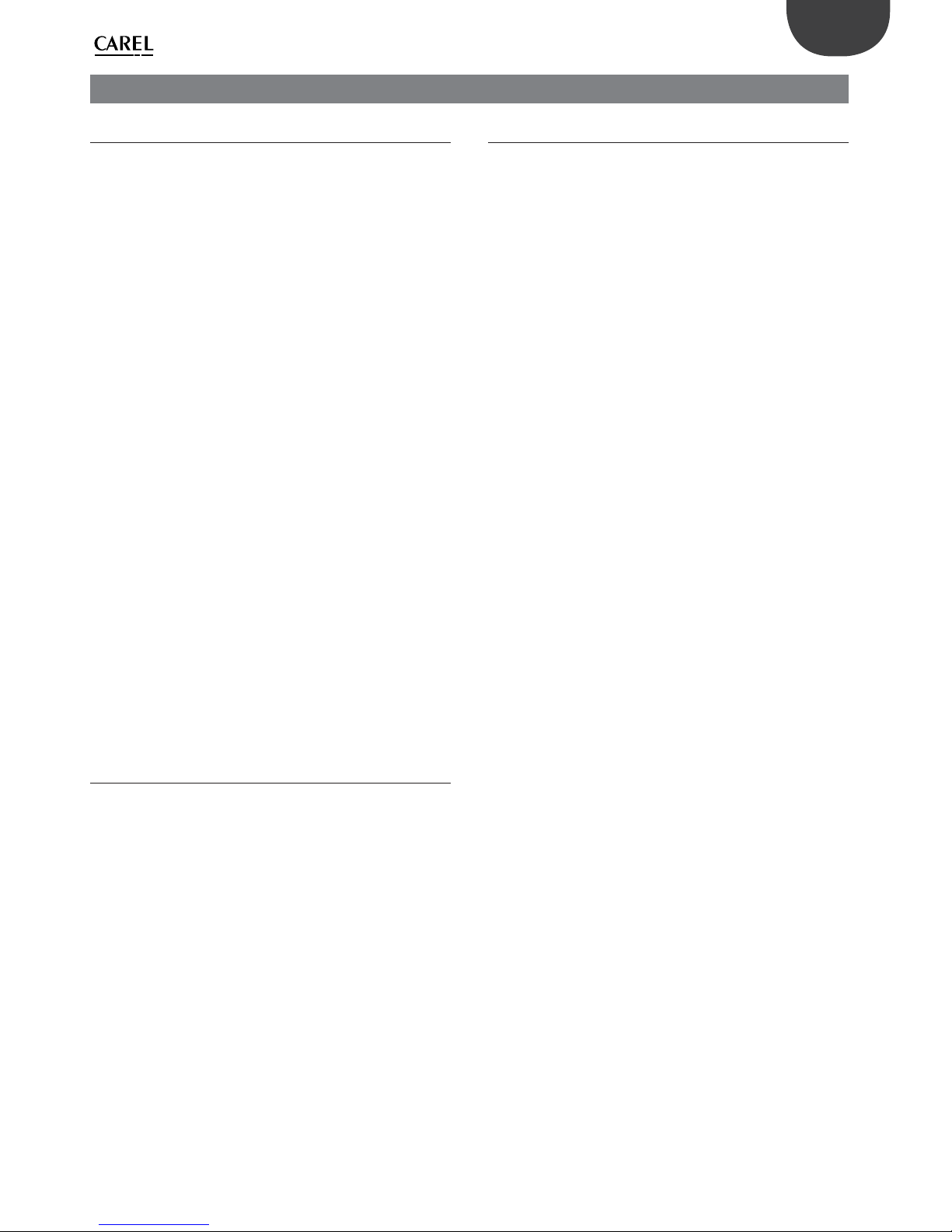

This section provides all the information common to the devices whose serial ID is con gured by dipswitch. Refer to the speci c instructions for each device.

EP SE SA Sensor SI Sensor CI Pulse Counter

Fig. 3.a

19

ENG

“Wireless probes” +0300030EN - rel. 1.0 - 16.07.2010

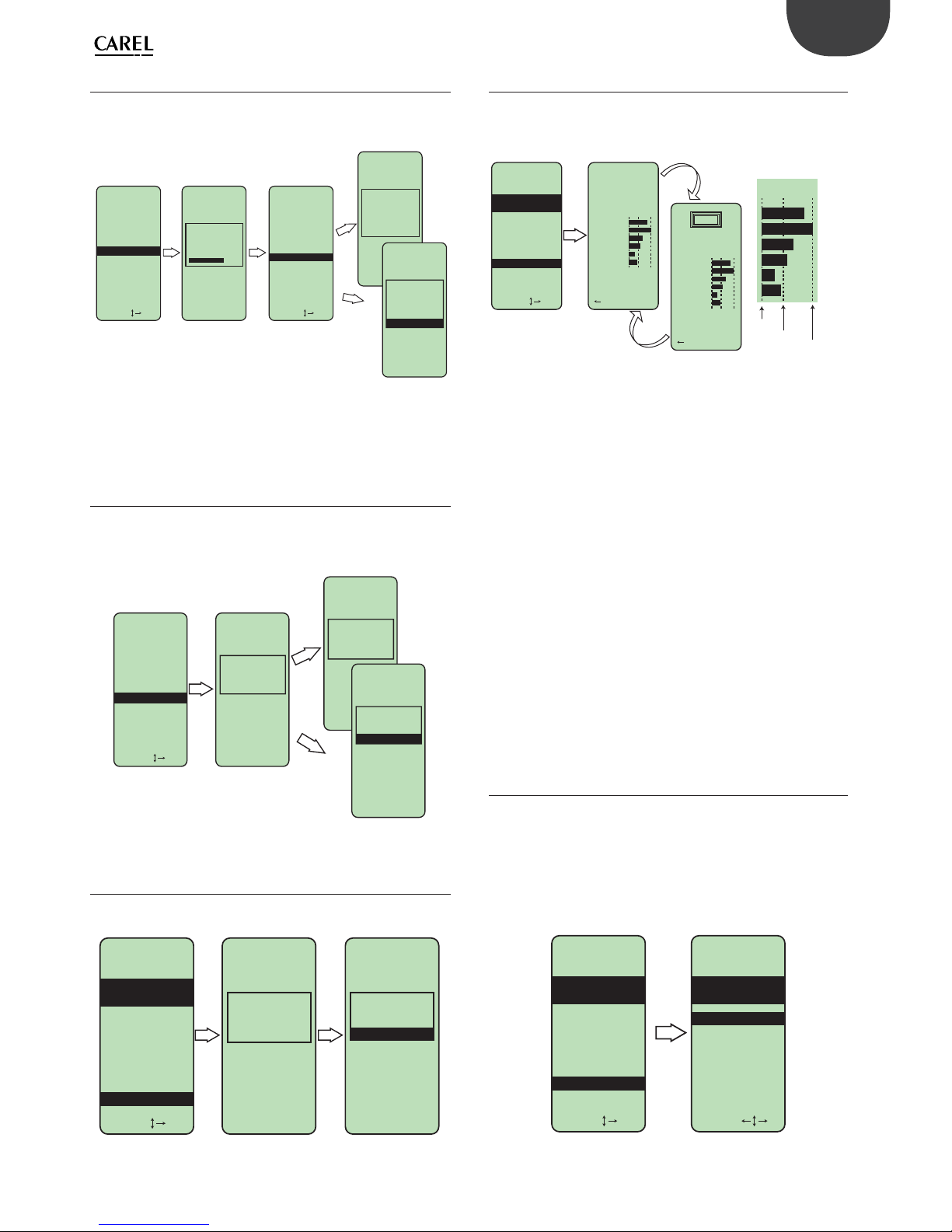

3.4 Binding procedure

Binding is a special procedure used to associate the sensors with the Access

Point. Once completed, the sensors will send the temperature data measure

wirelessly only to the Access Point de ned as its parent. Following this, the

Access Point will forward the data to the Modbus® RTU RS485 serial network.

Before performing this operation, make sure that the sensor serial address has

been set.

After having opened the domain on the Access Point (see the instructions in

the chapter on the Access Point), proceed as follows on the sensor:

Remove the protection from the contact on the battery to power up the

device;

Check that the LED comes on for a few seconds with brief ashes.

Press the button once or activate the magnetic switch. Pressing it again

activates a procedure to check the quality of the wireless signal (see the

chapter “Analysing wireless signal quality”);

LED L1 on the sensor remains on until connection to the Access Point is

complete, ashing for around 10s, then L1, L2 and L3 ash together for a few

seconds (wireless network connection).

The procedure for analysing wireless signal quality then starts for around 1

minute. The following come on in sequence:

1. L1 Indicates wireless transmission has occurred;

2. L1-L2 Indicates the signal has been received by the Access Point;

3. L3 ashes from 1 to 3 times, based on the quality of the wireless signal;

- 1 ash, wireless connection with minimum signal strength;

- 2 ashes, wireless connection with medium signal strength;

- 3 ashes, wireless connection with excellent signal strength;

Button T1 is connected in parallel with the magnetic switch. The case does not

need to be opened to stimulate the sensor for communication

Note: if LED L1 ashes once instead of remaining on, it means that the sensor

has already been bound to an Access Point. In this case, reset the sensor (see

Resetting the devices)

The Access Point shows that connection has been made by LED L3 coming

on for around 1s., even if another node in the network is sending a message.

Check the con guration: the sensor will be correctly bound if whenever the

button is pressed or the magnetic switch is activated, the LEDs come on for a

1 min sequence.

• L1, on for 1s;

• L1-L2, on for 1s;

• L3, ashes from 1 to 3 times, based on the quality of the wireless signal;

- 1 ash, wireless connection with minimum signal strength;

- 2 ashes, wireless connection with medium signal strength;

- 3 ashes, wireless connection with excellent signal strength;

For the EP SE Sensor, in normal operation LED L1 ashes for 1s every 20s. In

general, for the other devices, the LED comes on whenever data is sent, and

consequently based on the device transmission time.

Important: the sensor binding operation may fail if:

- the distances are high and/or there is infrastructure that does not allow

communication between the devices (see the example of sensor S2 in Figure

4.c);

- the maximum limit of sensors allowed for the Access Point has been reached

(max 30). In this case, an additional Router-Bridge is needed for up to a

maximum of 60 sensors.

3.5 Resetting the sensor (unbinding)

The reset procedure is required when the sensor needs to be moved and

associated with another wireless network (di erent Access Point). This

operation may be required to recon gure the sensor in a di erent wireless

network. The value of the serial address remains the same, unless the

con guration dipswitches are moved. After a new binding operation the

sensor is reactivated in the wireless network. To reset the EP SE Sensor, proceed

as follows:

1. Remove the battery (press the button to discharge any residual energy in

the circuit) and replace the battery in its socket (LEDs L1, L2, L3 come on

at the same time, then ash quickly and switch o ).

2. Immediately after the LED have switched o (within a few seconds) press

button T1 until the pairs of LEDs L1-L3 and L2 ash alternately.

3. Release the button. LEDs L1, L2, L3 will ash brie y and then switch o .

To make sure the sensor has e ectively been reset:

1. Make sure the Access Point wireless network is closed (L1 ashes slowly

1s).

2. Press button T1 on the sensor and make sure LED L1 comes on and

remains on for around 20 sec.

WARNING: The sensor has been unbound (reset) and maintains the same

network address assigned.

To change the address, remove the battery, move dipswitches 1 to 8, and

replace the battery.

Note:

1. The sensor can only be reset if it has already been associated with an

Access Point;

2. Resetting the sensor does not delete the space reserved inside the Access

Point, which will continue to maintain the data saved inside. Note that,

after resetting the sensor, the number of devices set for the Access Point

remains unchanged. Realignment will occur after a maximum of around

2 hours.

Important: pay careful attention to avoid duplicate assignment of network

serial addresses, so as to avoid overlapping temperature values.

The sensor is supplied with the battery already tted, and with the positive

pole insulated by a protective lm; this must be removed after assigning the

network serial address.

3.6 General warnings

When replacing the battery, strictly observe the following instructions.

The battery may explode if replaced with another of an incorrect type. Dispose

of the used batteries according to the standards in force;

Install the sensor with the cable gland facing downwards;

Replacing the battery

Remove the cover, remove the battery, and replace with another of the same

type. Close the cover again.

Rules for disposing of the battery

Do not dispose of the product as municipal waste; it must be disposed of

through specialist waste disposal centres.

The product contains a battery that must be removed and separated from the

rest of the product.

Improper use or incorrect disposal of the product may negative e ects on

human health and on the environment.

The public or private waste collection systems de ned by local legislation

must be used for disposal.

In the event of illegal disposal of electrical and electronic waste, the penalties

are speci ed by local waste disposal legislation.

20

ENG