Reverse osmosis system with pump

WTS

compact

User manual

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

ENG

IMPORTANT

WARNINGS

CAREL Industries reverse osmosis systems (WTS) are advanced products,

whose operation is specifi ed in the technical documentation supplied

with the product or can be downloaded, even prior to purchase, from

the website www.carel.com. Each CAREL Industries product, in relation

to its advanced level of technology, requires setup/confi guration/

programming/commissioning to be able to operate in the best possible

way for the specifi c application. Failure to complete such operations,

which are required/specifi ed in the user manual, may cause the fi nal

product to malfunction; CAREL Industries accepts no liability in such

cases. The customer (manufacturer, developer or installer of the fi nal

equipment) accepts all liability and risk relating to the confi guration

of the product in order to reach the expected results in relation to the

specifi c fi nal installation and/or equipment. CAREL Industries may,

based on specifi c agreements, act as a consultant for the installation/

commissioning/use of the unit, however in no case does it accept liability

for the correct operation of the system and the fi nal installation if the

warnings or suggestions provided in this manual or in other product

technical documents are not heeded. In addition to observing the above

warnings and suggestions, the following warnings must be heeded for

the correct use of the product:

• DANGER OF ELECTRIC SHOCK: Lthe system contains live electrical

components. Disconnect the mains power supply before accessing

inside parts or during maintenance and installation.

• DANGER OF WATER LEAKS: the automatically and constantly fi lls/

drains certain quantities of water. Malfunctions in the connections or

in the system may cause leaks.

IMPORTANT

• Environmental conditions and supply voltage must comply with the

values specifi ed in the product "dataplate".

• Installation, use and maintenance must be performed by qualifi ed staff ,

aware of the required precautions and able to make the operations

involved in the proper way.

• The supply is designed exclusively to humidify rooms in direct mode or

using distribution systems (ducts).

• All the operations performed on the product must be made following

the instructions of this manual. Any uses or modifi cations that are

not authorised by the manufacturer are considered improper. CAREL

Industries declines all liability for any such unauthorised use.

• Do not attempt to open the system in ways other than those specifi ed

in the manual.

• Observe the standards in force in the place where the system is

installed.

• Keep the system out of the reach of children and animals.

• Do not install and use the product near objects that may be damaged

when in contact with water (or condensate). CAREL Industries declines

all liability for direct or indirect damage following water leaks from the

system.

• Do not use corrosive chemicals, solvents or aggressive detergents to

clean the inside and outside parts of the system, unless specifi cally

indicated in the user manual.

• Do not drop, hit or shake the system, as the inside parts and the linings

may be irreparably damaged.

CAREL Industries adopts a policy of continual development. Consequently,

CAREL Industries reserves the right to make changes and improvements

to any product described in this document without prior warning.

The technical specifi cations shown in the manual may be changed

without prior warning. The liability of CAREL Industries in relation to its

products is specifi ed in the CAREL Industries general contract conditions,

available on the website www.carel.com and/or by specifi c agreements

with customers; specifi cally, to the extent where allowed by applicable

legislation, in no case will CAREL Industries, its employees or subsidiaries

be liable for any lost earnings or sales, losses of data and information,

costs of replacement goods or services, damage to things or people,

downtime or any direct, indirect, incidental, actual, punitive, exemplary,

special or consequential damage of any kind whatsoever, whether

contractual, extra-contractual or due to negligence, or any other liabilities

deriving from the installation, use or impossibility to use the product,

even if CAREL Industries or its subsidiaries are warned of the possibility

of such damage.

DISPOSAL:

The system is made up of metal parts and plastic parts. In reference to

European Union directive 2002/96/EC issued on 27 January 2003 and

related national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and such waste

must be collected and disposed of separately;

2. the public or private waste collection systems defi ned by local

legislation must be used. In addition, the equipment can be returned

to the distributor at the end of its working life when buying new

equipment;

3. the equipment may contain hazardous substances: the improper use

or incorrect disposal of such may have negative eff ects on human

health and on the environment;

4. the symbol (crossed-out wheeled bin) shown on the product or

on the packaging and on the instruction sheet indicates that the

equipment has been introduced onto the market after 13 August

2005 and that it must be disposed of separately;

5. in the event of illegal disposal of electrical and electronic waste, the

penalties are specifi ed by local waste disposal legislation.

Warranty on materials: 2 years (from production date, excluding

consumables).

Approval: the quality and safety of CAREL products are guaranteed by

the ISO 9001 certifi ed design and production system.

3

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

4

Content

1. GENERAL FEATURES AND MODELS 7

1.1 Description of the unit .............................................................................................7

1.2 General principle of reverse osmosis ..............................................................7

1.3 ROC operating principle .........................................................................................7

1.4 End of production of desalinated water .......................................................7

1.5 Part description ............................................................................................................8

1.6 Technical specifi cations

(for ROC025500N - ROC040500N - ROC0605000) ..................................9

1.7 Electrical system conformity ................................................................................9

2. INSTALLATION 10

2.1 Installation of cartridges ......................................................................................10

2.2 Diaphragm assembly .............................................................................................10

2.3 Water connections ..................................................................................................10

3. STARTING THE SYSTEM 12

3.1 Checks to be performed whenever starting the system.................12

3.2 Switching on and password entering .........................................................12

3.3 Language selection ................................................................................................12

3.4 First start.........................................................................................................................12

3.5 Checks and adjustment after start ................................................................12

3.6 System stopping .......................................................................................................13

3.7 Summary of the start and adjustment step ............................................13

3.8 List of available menus .........................................................................................14

ENG

4. TROUBLESHOOTING 15

5. MAINTENANCE 17

5.1 Routine maintenance ............................................................................................17

5.2 Overtime maintenance ........................................................................................17

5.3 Disposal ..........................................................................................................................17

5.4 Instructions for emergency situations ........................................................17

6. REGULAR MAINTENANCE RECORDING FORM 18

7. SPARE PARTS 19

7.1 ROC025-ROC040 spare parts ............................................................................19

7.2 ROC060 spare parts ................................................................................................20

8. WATER CIRCUIT 21

8.1 ROC025/040 water circuit ...................................................................................21

8.2 ROC060 water circuit .............................................................................................22

5

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

6

1. GENERAL FEATURES AND MODELS

ENG

1.1 Description of the unit

The reverse osmosis systems described in this manual are purposebuilt for treating water used in technological processes. These units can

resolve the problem of excessive mineral salts in the feed water. Reverse

osmosis systems are made up of the following main components:

•

micron fi lter;

•

high pressure pump;

•

desalination module

•

electrical control panel;

•

expansion vessel.

Carel code Description

ROC025500N

ROC040500N

ROC0605000

(osmotic membranes)

Reverse osmosis system, 25 l/h, with pump and 15 l

expansion vessel

Reverse osmosis system, 40 l/h, with pump and 15 l

expansion vessel

Reverse osmosis system, 60 l/h, with pump and 15 l

expansion vessel

;

Tab. 1.a

1.2 General principle of reverse osmosis

Osmosis is a natural process whereby diluted or lighter solutions

spontaneously pass through semipermeable membranes into more

concentrated solutions.

When a solution passes through a semipermeable membrane, the

pressure on the side with the lower concentration decreases and at the

same time the pressure of the more concentrated solution increases,

until reaching a point of equilibrium, at which point the solution stops

fl owing. The pressure diff erence between the two solutions, in conditions

of equilibrium, is called the “osmotic pressure”.

Reverse osmosis, on the other hand, is a scientifi c process that reverses

this natural process. It involves applying a pressure exceeding osmotic

pressure to the more concentrated solution, so as to reverse the fl ow

through the semipermeable membrane and separate the salts dissolved

in the water.

This principle can be applied to water desalination, for both drinking and

technological uses.

Reverse osmosis has several advantages:

•

water desalination regardless of salt content;

•

no chemicals that need to be drained after use, so no pollution

problems;

•

relatively low running costs compared to ion-exchange resin systems,

above all with high salinity of the water being treated;

•

easy operation.

1.3 ROC operating principle

The feed water enters the cartridge fi lter that guarantees dechlorination

and fi nal fi ltering at 5 m. In this way, the required degree of limpidity for

the water entering the permeators is guaranteed. The supply pressure,

during standard operation, must be at least 1.5 bar, to guarantee the

correct pressure quantity at the pump inlet.

When the pressure exiting the cartridge fi lter is below 0.8 bar, the pressure

switch PS1 sends a dedicated signal to the board, stopping the machine.

Water is then returned from pump P1 so that the membranes can have

the pressure required for the demineralization process. Pressure switch

PS2 is adjusted so that it sends a signal should the permeator pressure

exceed 10 bar.

Treated water fl ows out the system through the permeate pipe supplied

as standard; the system starting and switching off are operated with the

aid of pressure switches PS2 and PS3.

Example: on a 25 l/h machine (ROC025500N) of standard production,

the following approximate values should be found: osmotised water

production 25 l/h, discharge 60 l/h, pressure at the permeators 7-8 bar

(PI1). These values are theoretical ones, because they can change when

the feed water temperature varies and depending on its chemicalphysical specifi cations. These values were taken into account for a

recovery of 30% (TDS 250 ppm and feed water temperature 16°C); for

calculating it, the following operation is required:

RECOVERY (%) =

To adjust the supply pressure to the permeators, you can act on the

by-pass screw on the pump. The feed water temperature remarkably

infl uences both productivity and quality of the permeate. As temperature

increases, even only a few degrees, a higher productivity will be achieved

(with an improved recovery) with a worse conductivity value.

PERMEATE

(PERMEATE+DISCHARGE)

x 100

1.4 End of production of desalinated water

The end of production of desalinated water is automatically managed

by the electronic control through the pressure switches installed on the

permeate piping. The max. pressure switch stops its operation when the

pressure on the downstream circuit exceeds a given value (default 4.0

bar).

The pressure on the downstream circuit is kept through the expansion

vessel (included in the ROC% code).

The min. pressure switch restarts the system when the pressure on the

downstream circuit drops below 2.0 bar (close to an emptying of the

expansion vessel).

Note: WTS Compact systems cannot operate if not coupled with the

expansion vessel.

7

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

1.5 Part description

5

Ø 6

Ø 10 Ø 6

Rif. Description Re. circuit, chapter 9

1 Inlet fi lter

2 Inlet water pressure gauge

3 Fill solenoid valve

4 Min. pressure switch for feed water

5 Control electronic board

6 Lane rotary pump, 150 l/h

7 Motor

8 Pump outlet water pressure gauge

9 Osmotic membrane

10 Start pressure switch

11 Stop pressure switch

12 Flow restrictor drain pipe for ROC025

13 Drain pipeline (dia. 8 mm)

14 Permeate pipeline (dia. 6 mm)

15 TEE for expansion vessel

14

4

12

11

10

9

Ø 8

1415171816

Rif. Description Re. circuit, chapter 9

16 Expansion vessel 15 l

17 Permeate user line (dia. 10 mm)

18 Check valve for user line (ball valve, dia. 10)

In the ROC060 models present:

Rif. Description Re. circuit, chapter 9

19 Pump max. pressure switch

20 Flushing solenoid valve

21 Conductivity meter on the permeate line

2

3

6

1

7

8

13

1.6 Overall dimensions and weight (LxHxW))

Model ROC025500N ROC040500N ROC0605000

With package (mm) 600x450x450 600x450x450 650x700x510

Without package (mm) 420x580x200 420x580x200 600x650x270

Total weight (with package) 21 kg 22 kg 23 kg

580 mm

420 mm

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

Fig. 1.a

650 mm

Tab. 1.b

700 mm

8

1.7 Speci cations of the feed water

Water to be treated must be clear and drinking type; it must comply

with the parameters recommended by the 98/83/EC standard. The max.

allowed concentration is the following:

Appearance 1000 µS

Turbidity < 1 NTU

Iron < 0,15 ppm

SDI (Silt Density Index) < 3

Water temperature 5 ÷ 30 °C

Free chlorine < 0,2 ppm

TDS (Total Dissolved Solids) < 750 ppm

Water hardness < 30 °Fr

SO4 < 75 ppm

SiO2 < 15 ppm

TOC (Total Organic Carbon) < 3 mg/l

COD (Chemical Oxygen Demand) < 10 mg/l

Tab. 1.c

Again depending on the characteristics of the water being treated, the

membrane separates around 93 % of all dissolved salts and can also trap

bacteria. Nonetheless, it is also worth checking the quality of the feed

water, so the membrane will not be damaged over time by the action of

microorganisms.

1.8 Technical speci cations

(for ROC025500N - ROC040500N ROC0605000)

Feed water pressure 1,5...4 bar

Operating pressure 5 - 10 bar

Water temperature 5...30 °C

Room temperature 5...40 °C

Power supply 230V – 50/60Hz monofase

Storage and delivery conditions -5...40 °C and sheltered from

sunlight and excessive humidity

Function conditions 5...40 °C and sheltered from

sunlight and excessive humidity

Tab.1.c

ENG

Minimum feed water fl ow-rate (l/h) 150 (referred to the pump) 150 (referred to the pump) 300 (referred to the pump)

ROC025500* ROC040500* ROC060500*

Production (± 10%) - (l/h) 25 40 80

Drain (for 30 % recovery) - (l/h) 60 90 190

Number of membranes 1 2 2

Membrane model 2" x 15" 2" x 15" 2.8” x 15”

Installed power (W ) 245 245 245

Feed water connection Ø ½" F ½" F ½" F

Permeate connection Ø Dia. 10 mm pipe Dia. 10 mm pipe Dia. 10 mm pipe

Drain connection Ø Dia. 8 mm pipe Dia. 8 mm pipe Dia. 8 mm pipe

Note: the above data refer to clear water, without iron and free

chlorine, at a temperature of 16°C, and TDS of 250 ppm.

1.9 Electrical system conformity

The reverse osmosis desalting kits comply with the following directives:

• Machinery Directive 2006/42/EC;

• Low voltage directive 2014/35/EC

• Electromagnetic compatibility directive (EMC) 2014/30/EC

Tab. 1.d

9

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

2. INSTALLATION

The installation must be performed complying the regulations in

force, according to the manufacturer's instructions and by skilled staff .

The manufacturer cannot be held responsible for a wrong installation.

Electrical safety is obtained only when the equipment is connected to

a plug having an effi cient earthing system, equipped with magnetothermal diff erential protection, as prescribed by the safety standards in

force.

THE MANUFACTURER CANNOT BE HELD RESPONSIBLE FOR POSSIBLE

DAMAGE CAUSED BY THE ABSENCE OF THE EARTHING SYSTEM OR

NON-COMPLIANCE WITH THE STANDARDS IN FORCE.

Secure the system to a wall that can support the total weight with water

(min. 25 kg). Use the supplied screws fi tting them in the holes on the

sides.

Caution: leave enough space at the front so that the operator can

have space enough for adjustment and/or maintenance operations.

2.1 Installation of cartridges

Before fi tting the cartridge in the vessel make sure that water supply is

closed and there is no pressure, then disassembly the fi lter covers using

the supplied wrench. Position the new cartridge as shown in the picture

and reposition the cover in the proper way, tightening it by the wrench.

2.3 Water connections

The reverse osmosis system can operate properly when the water supply

pressure ranges between min. 1.5 bar and max. 4 bar.

If pressure is below 1.5 bar, a pressurizing kit must be installed upstream of

the equipment. On the other hand, if pressure exceeds 4 bar, a dedicated

pressure reducer must be installed upstream of the equipment.

2.3.1 Connection of the system supply

Connect the system supply with a pipe having at least the same diameter

as the one of the equipment (1/2" female GAS coupling). Provide for a

cut-off valve upstream of the system.

Provide for a possible by-pass if water is to be supplied to the users even

when the WTS Compact system is stopped.

by-pass

utenza

users

Fig. 2.a

Model ROC060 has two inlet fi lters: fi rst position the green charcoal one

(CBEC) and then the white micrometric one (CPP)

Fig. 2.b

2.3.2 Connection of the osmotised water line

Connect the pipe of generated water (dia. 6-mm white pipe) to the

couplings of the pressure switches (dia. 6-mm quick coupling).

Fig. 2.c

2.3.3 Connection of the concentrate drain line

Connect the concentrate pipe (dia. 6-mm black pipe) coming from the

fl ow reducer to a free drain (using the dia. 8 black pipe); the connector

between the two pipes D.6 and D.8 is included in the standard supply

(Fig. 2.d, 2.e).

The free drain must be earthed or lower than the same connection. The

supplied connector (3/8" male thread) can be used with the coupling

for a drain pipe, ø 40, from under the sink.

2.2 Membrane assembly

Before fi tting the membrane in the vessel make sure that water supply

is closed and that there is no pressure. Then move away the pipe from

the connector and, if required, disconnect it from the quick couplings to

create space enough for performing the operation. Undo the vessel cap

and fi t the membrane, paying attention to the fi tting direction (black lip

seal facing downwards). Then, make sure that the membrane is properly

positioned and close the vessel cap.

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

Fig. 2.d

10

ENG

2.3.4 Expansion vessel connection

Connect the permeate pipe (white, 6-mm dia. pipe) to the T-shaped

connector (both included in the standard supply). Then, connect them to

booster BV1 valve of the expansion vessel (Fig. 2.g, 2.h).

Coupling for pipe

permeate Ø 6 mm

Precharge valve

Expansion vessel

Fig. 2.e

Caution: it is advisable to install the expansion vessel close to the

WTS Compact, within a range of 3-5 metres. The distance of the user

depends on the diametre of the pipe used for the permeate and on the

pressure required to the feed water. With a permeate pipe having 10 mm

diameter and with a feed pressure request ≈ 1 bar, the recommended

distance should not exceed 20 metres.

2.3.5 Precharge of the expansion vessel

Precharge the expansion vessel using compressed air until reaching a

pressure lower or equal to the min. pressure of the permeate pressure

switch (~1.5 ÷ 1.8 bar). Charge the vessel through the valve located at the

bottom (see arrow, fi g. 2.e).

2.3.6 Storage tank connection

WTS Compact can also be installed with a storage tank equipped with

pump. In this case, the authorisation to operation does not depend on

pressure anymore (as it happened with the expansion vessel), rather it is

determined by the high/low level signal sent by the fl oat inside the tank.

In case of installation of WTS compact with storage tank, comply with the

following instructions:

• open the case of the electronic controller.

• disconnect the cables of the pressure switches from terminals 22-23

and 33-34 (factory fi t wiring).

• connect the high level signal to terminals 22-23 and the low level

signal to terminals 33-34 (Fig. 2.g).

• enable the high level signal from menu "5 HIGH LEVEL - LIVELLO ALTO"

(see paragraph 3.6).

• enable the low level signal from menu "4 LOW LEVEL - LIVELLO BASSO"

(see paragraph 3.6).

• In these menus you can set the logic of the contact (N.C. or N.O.) and

the delay of the signal (DEFAULT 00 sec.)

2.1 Electrical connections

Connect the system to the single phase line 230 V (50 / 60 Hz) single phase

through the supplied socket. The user should not install any other wiring,

unless for connecting an alarm output (to be connected to terminals 19

[N.O.]-20 [C]-21 [N.C.]) or an external remote consent (to be connected

to terminals 37 [common] - 38 [input]). For completeness purposes, the

diagram of all internal connections and available terminals follows:

Caution:

precharge the

expansion vessel at 1.5...1.8 bar

Fig. 2.g

Fig. 2.f

Terminal Description ROC025 - ROC040 ROC060

1[L] - 2[ground] - 3[N] Supply input (230 V) 50/60 Hz x x

4[L] - 5[ground] - 6[N] 230 Vac output for pump supply x x

7[L] - 8[ground] - 9[N] 230 Vac output for metering pump -- -10[L] - 11[ground] - 12[N] 230 Vac for charge solenoid valve x x

13[L] - 14[ground] - 15[N] 230 Vac for drain solenoid valve -- -16[L] - 17[ground] - 18[N] 230 Vac for fl ushing solenoid valve -- x

19[NO] - 20[C] - 21[NC] Alarm output optional optional

22[C] - 23[IN] Max. pressure switch for permeate line / high level x x

24[C] - 25[IN] Input to high pressure switch for pump delivery -- x

26[C] - 27[IN] Pump cut-out switch input -- -28[C] - 29[IN] Metering pump alarm input -- -30[shield] - 31 - 32 Probe for output permeate conductivity -- -33[C] - 34[IN] Min. pressure switch for permeate line / low level x x

35[C] - 36[IN] Low pressure switch input x x

37[C] - 38[IN] Remote on/off input optional optional

39[C] - 40[IN] Filter inlet from softener -- -41[shield] - 42 - 43 Input water conductivity probe -- --

Tab. 2.a

11

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

3. STARTING THE SYSTEM

3.1 Checks to be performed whenever

starting the system

Each unit is pre-calibrated and tested in the factory according to a

suitable testing procedure. At the fi rst starting of the equipment, the user

should check as follows:

• tightness of the various connections;

• operation of the feed water circuit;

• electrical connections;

Now water can be supplied to the system by opening the ball valve

suitably installed upstream. Wait until the complete fi lling and the

wetting of the input fi lter. Check on the pressure gauge if the supply

pressure is enough (1.5 bar).

3.2 Switching on and password entering

After electrical and hydraulic connections, switch the equipment on:

• press the button at least for two seconds. The display will show

"WAIT ON" for a few seconds (the time used by the equipment to

preset), then the current status is displayed.

• pressing the arrows and you can display (in read-only mode)

information about the equipment operation (hour counter,

conductivity, ...).

• press to access the confi guration templates of the system.

• enter the PASSWORD. The default value is "0077". To enter the password,

use the

value. Press

• In this way you enter the list of items that can be modifi ed.

commissioning, thus they do not need any change. Check that the

parameter confi guration complies with the default settings (as per

paragraph 3.8). Comply with the information of the manual and change

only the items listed here below.

and arrows to move the cursor, and to change the

to confi rm.

Caution: the parameters that can be modifi ed were already set at

The procedure is the following:

1. Disconnect the permeate line and temporarily convey it to a free

drain. Slightly open (one third) the feed water tap (suitably installed

upstream of the system), so that the water fl ow coming from the

network decreases to minimum.

2. Switch the system on keeping pressed the button at least for two

seconds. The display shows WAIT ON for a few seconds, then it shows

the main screen. Press

the system.

3. enter the password "0077" to enter the menu 01. Now the equipment

functioning is stopped.

4. Using and arrows, scroll to the menu 14 "SYSTEM TEST". Press

to enter.

5. In this menu, all components are deactivated. You can decide to

activate/deactivate the individual components manually, using the

following buttons of the controller:

inlet solenoid valve

drain solenoid valve (NOT PRESENT)

fl ushing solenoid valve (ONLY ON ROC060)

pump

metering pump (NOT PRESENT)

6. Press to activate the fi ll solenoid valve: in this way, the N.C. valve is

powered and opens the circuit, letting water in.

FOR ROC060 ONLY: press the arrow to operate the fl ushing valve: in

this way, the N.C. valve is powered and opens additional drain, getting

an increased water fl ow and reducing the pressure diff erence between

upstream and downstream of the membranes.

Note: please note that it is always advisable to let the membranes

work at the lowest possible pressure (5...6 bar), above all during start, but

also during the system standard operation. This ensures a longer life of

the same membranes.

to access the confi guration templates of

Fig. 3.a

3.3 Language selection

• With equipment on, press to access the confi guration templates of

the system.

• enter the password "0077" to enter the menu 01

• Using and arrows, scroll to the menu 16 "LINGUA". Press to

enter.

• Scroll the available languages moving and and select among

the available ones (ITALIAN, ENGLISH, FRENCH, GERMAN, SPANISH).

to confi rm.

Press

3.4 First start

During the fi rst start, the purpose is wetting the membranes gradually,

without submitting them to the work pressure (5-6 bar) before they are

completely wet. Water must fl ow according to the main pressure for a

few minutes through fi lters and membranes, before the pump can be

operated.

Water produced during this stage cannot be used. It is advisable to

disconnect the permeate line and free drain all the water produced

during the fi rst start.

7. Leave the system in these conditions for at least 10 minutes.

8. Open again a little bit (two thirds) the water tap upstream of the

system, so that the water fl ow reaching the membranes increases.

Leave the system in these conditions for at least 10 minutes.

9. Fully open the water tap upstream of the system, leave the system in

these conditions for 10 more minutes.

10. Check that the charge valve (and the fl ushing one if present) are

still open. Now, activate the pump pressing the

inside the menu 14).

11. Immediately check the working pressure of the membranes, on the

pressure gauge on the pump delivery side. Turn the adjustment

screw opening the by-pass valve of the pump (anticlockwise

direction), to reduce the pressure to about 2-3 bar. Leave the system

in these conditions for 10 minutes.

12. Close the fl ushing valve if installed (pressing the again). Adjust

again the Bypass (clock wise direction). Make the working pressure

correspond to 5-6 bar, that is the standard operating pressure for a

WTS Compact with new membranes.

13. Quit the menu 14 pressing and go back to the main template of

WTS Compact. Now the equipment is ready to work properly.

button (still from

3.5 Checks and adjustment after start

After start, some checks for the correct operation of the WTS Compact

system must be made.

1. Before connecting the permeate pipe to the expansion vessel, check

that the permeate fl ow rate is correct and the conductivity ranges

between the required values.

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

12

ENG

If the permeate fl ow rate is not enough it is advisable to close slightly

the by-pass valve of the pump, to increase pressure to the permeators

and get a higher fl ow rate of demineralised water (obviously with higher

conductivity).

Should the permeate conductivity become too high and not satisfactory

enough, it is advisable to open slightly the pump by-pass valve, to

reduce pressure to the permeators and get water with a lower salt

content (with a reduction of permeate fl ow rate produced). Please note

that the percentage of salt rejection depends on inlet water quality and

temperature and in no way can it be measured only on the conductivity

value at the outlet. To adjust the pump by-pass, remember the following

basic rules:

• clockwise tightening: close the by-pass, then increase the pressure to

the membranes.

• anticlockwise loosening: open the by-pass, then decrease the pressure

to the membranes.

2. Connect the permeate pipe to the expansion vessel, that now has

no water. Please note that the vessel must have been precharged

with compressed air, till getting a pressure of 1.5-1.8 bar. Let the WTS

Compact operate until the vessel is full and thus until the pump stops

automatically (according to the value on the max. pressure switch).

Check that the stop pressure corresponds to about 4 bar.

3. Manually drain the expansion vessel opening one of the downstream

water taps. Wait until the pump switches on again automatically,

activated by the minimum pressure switch. Make sure that the WTS

Compact starts again when the pressure on the permeate line is

about 2 bar.

3.6 System and intervals of operation

The correct operation of the reverse osmosis system depends on the

continuous production of demineralised water. For a stop shorter

than 10 days, just leave the equipment powered both electrically and

hydraulically, as it occasionally fl ushes the membranes (the default value

is 30 seconds every 24 hours of inactivity). This parameter can be selected

in menu 11H - WASH CYCLE.

For stops longer than 10 days, up to max. 1-2 months, it is advisable to

change the set of periodic fl ushing operations (menu 11H) to 15 minutes

every 48 hours. To change the set of fl ushing operations proceed as

follows:

• enter the list of items that can be modifi ed;

• use the and arrows to select the item "11 CLEANING";

• press

• scroll through all the templates 11A, 11B, 11C pressing , until

template 11H is displayed. Pay attention in order not to change the

default values of the scrolled templates.

• Template 11H is used to set the fl ushing of membranes cyclically

for an x time every n hours. Set the max. duration of the fl ushing,

expressed in minutes and seconds (max. value 99 minutes

and 59 seconds) and the recurrence in hours (max. value 99

hours). Use the

selected digit; use the

Caution: setting "00 h" means that the periodic fl ushing is disabled.

• pressing you return to the main menu confi rming the modifi cations

made.

• pressing you scroll backwards the various templates, until reaching

the main menu without confi rming the modifi cations made.

For inactivity periods longer than 1-2 months, or when you decide to

disconnect the osmosis system from the hydraulic/electric supply, the

system maintenance procedure must be applied. This procedure implies

draining the system completely and then fi lling it using a dedicated

maintenance liquid. This activity must be exclusively performed by

authorised technical staff , as agreed with Carel.

Caution: please note that during equipment the expansion and

accumulation vessel (if present) must be drained. At the following start,

perform a fl ushing procedure of the line and of the vessel, using

demineralised water. It is recommended to drain and fl ush periodically

the expansion vessel also after long periods of standard operation (about

every two months).

and arrows to move the cursor to the

and arrows to enter the value.

3.7 Summary of the start and adjustment step

Close the water tap upstream of the system

CLOSED

Disconnect the permeate line

and temporarily convey it to a drain

Slightly open the water tap (one third)

by 33%

Switch on the system and access menu 14

Start the charge solenoid valve using the UP arrow

Start the fl ushing solenoid valve using the LEFT arrow

Wait 10 minutes

Open the upstream water tap (two thirds)

by 66%

Wait 10 minutes

Completely open the upstream water tap

OPEN

Wait 10 minutes

Activate the pump using the RIGHT arrow

Adjust the pump by-pass so that

pressure reaches 2-3 bar

Wait 10 minutes

Close the fl ushing valve (if present)

Adjust the pump by-pass

so that pressure reaches 5-6 bar

Quit the manual procedure

and restore the standard operation

Check the fl ow rate values of the permeate and its conductivity

Connect the permeate pipe to the expansion vessel

Wait until the vessel is full.

Check that the max. pressure is = 4 bar

Drain the vessel. Check that the min. pressure is = 2 bar

13

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

3.8 List of available menus

1 PROBE CAL. IN Conductivity probe on feed water 1a Zero setting of the conductivity probe not used (due to the ab-

2 PROBE CAL. OUT Conductivity probe on permeate

3 OUT SET POINT Check the conductivity value at the

4 IN SET POINT Check on the conductivity value at

5 LOW LEVEL Min. pressure switch on permeate

6 HIGH LEVEL Max. pressure switch on permeate

7 MINIMUM

PRESSURE

8 MAXIMUM

PRESSURE

9 PUMP TEMP. Protection of the pump motor from

10 FILTER Forced system stop when the

11 CLEANING Flushing at the start or after switch-

WASH CYCLE Flushing of the membranes in a

12 ALARM Output of the alarm signal with

13 RESET Reset of the counter for the work

14 SYSTEM TEST Manual procedure to be activated

15 ALARM TEST Check if the alarm output is

16 LANGUAGE Select the display language Italian / English / French / German / Spanish Italian Italian

17 SET PASSWORD Entering a new password Key in the new password twice to confi rm the choice 0077 0077

18 MAINTENANCE Maintenance warning interval 18a Maintenance warning: enabled / disabled enabled enabled

19 DOSING PUMP Locking alarm signal from metering

20 STAND-BY

INPUT

21 PUMP DELAY Pump delay, recommended when

water

outlet. If conductivity exceeds the

set threshold (3B) for a certain time

(3D), it locks in DRIVER ALARM FOR

SYSTEM STOPPING

the inlet.

line

line

Contact of the min. pressure switch

for feed water

Check of the value of max. pressure

downstream of the pump (from

pressure switch calibrated at 12 bar)

high temperature

upstream softener makes salt

regeneration

ing off the system, before or after

each production cycle

cyclical way, every "n" hours and for

a variable "x" duration

connection to an external device

hours accumulated by the system

individually for each single component: to be used during the FIRST

START of the system

operating

pump

Input for stand-by (remote on-off ) 20a Remote input: enabled / disabled disabled disabled

a return pump is installed upstream

of the system

1b Setting of the reading scale of the conductivity probe

2a Zero setting of the conductivity probe not used (due to the ab2b Setting of the reading scale of the conductivity probe

3a Enabled / disabled not used (due to the ab3b Conductivity set point at the outlet (from 0.0 to 99.9

µS)

3c Reading at fl ushing end alarm(locking): enabled /

disabled

3d Delay time for alarm signal (from 0 min 0 sec to 9 min

59 sec)

4a Enabled / disabled disabled (due to the ab-

5a Enabled / disabled enabled enabled

5b State of the high level contact (high pressure): N.C. /

N.O.

5c Signal acquisition delay (from 0 to 59 sec) 0 sec 0 sec

6a Enabled / disabled enabled enabled

6b State of the high level contact (high pressure): N.C. /

N.O.

6c Signal acquisition delay (from 0 to 59 sec) 0 sec 0 sec

7a Enabled / disabled Enabled Enabled

7b State of the contact with right pressure: N.C. / N.O. N.C. N.C.

7c Signal acquisition delay (from 0 to 59 sec) 05 sec 05 sec

7d Number of attempts before the alarm 4 4

7e Alarm during fl ushing as well: YES/NO YES YES

8a Enabled / disabled disabled (due to the

8b State of the contact with right pressure: N.O. / N.C. - - - N.C.

8c Signal acquisition delay (from 0 to 59 sec) 00 sec 00 sec

9a Enabled / disabled disabled (due to the

9b State of the contact with right temperature: N.C. / N.O.

9c Signal acquisition delay (from 0 to 59 sec)

10a Enabled / disabled disabled (due to the

10b State of the contact with active softener: N.C. / N.O.

10c Signal acquisition delay (from 0 to 59 sec)

11a Enabled / disabled disabled enabled

11b Flushing with pump: YES / NO no yes

11c Flushing with charge solenoid valve open: YES / NO yes yes

11d Flushing at the beginning of production cycle:

enabled / disabled

11e Duration of the fl ushing from production start

(from 0 to 99 min 59 sec)

11f Flushing at the end of production cycle:

enabled / disabled

11g Duration of the fl ushing from production end

(from 0 to 99 min 59 sec)

11h PERIODIC FLUSHING OF MembraneS: duration of the

fl ushing (from 00 min 00 sec to 99 min 59 sec) and

frequency of the fl ushing (from 00 h to 99 h)

12a Enabled / disabled disabled disabled

12b State of the contact with no alarm: N.C. / N.O. - - - - - -

13a Reset of the hour counter: YES / NO

13b Reset of the time interval before next maintenance:

YES / NO

UP Inlet solenoid valve: enabled / disabled

DOWN Discharge solenoid valve: enabled / disabled absent absent

RIGHT Flushing solenoid valve: enabled / disabled absent

LEFT Pump: enabled / disabled

ENT Metering pump: enabled / disabled absent absent

UP Press the arrow up to manually activate the alarm

18b Interval before maintenance warning (from 0 to 19999 h) 240 h 240 h

19a Input for metering pump alarm: enabled / disabled not used (there is no

19b State of the contact with no alarm: N.C. / N.O.

19c Signal acquisition delay (from 0 to 59 sec)

20b State of the contact with no external signal: N.C. / N.O. - - - - - 20c Signal acquisition delay (from 0 to 59 sec) - - - - - 21a Start delay of the pump for the reverse osmosis system

after opening the charge solenoid valve (from 0 to

999 sec)

ROC025 - ROC040 ROC060

sence of the conductivity

meter at the inlet)

sence of the conductivity

meter at the outlet)

sence of the conductivity

meter at the outlet)

sence of the conductivity

meter at the inlet)

N.C. N.C.

N.C. N.C.

absence of the max.

pressure switch)

absence of temperature

sensor on pump motor)

absence of the upstream

softener)

disabled enabled

00 min 00 sec 00 min 20 sec

disabled enabled

00 min 00 sec 00 min 15 sec

00 min 30 sec every 24 h 01 min 00 sec every

metering pump)

000 sec 000 sec

absence of the conductivity meter at the inlet)

already calibrated in the

absence of the conductivity meter at the inlet)

absence of temperature

sensor on pump motor)

disabled (due to the ab-

sence of the upstream

not used (due to the

factory

enabled

80 µS

disabled

5 min 00 sec

disabled (due to the

enabled

disabled (due to the

softener)

08 h

not used (there is no

metering pump)

Tab. 3.a

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

14

4. TROUBLESHOOTING

Alarm Cause Remedy

STOPPED SYSTEM HIGH PRESSURE

STOPPED SYSTEM LOW PRESSURE

CHECK HI-LEVEL

LOW-LEVEL CONTACTS

STOPPED SYSTEM CONDUCTIVITY ALARM

MAINTAIN THE SYSTEM The time set for the scheduled maintenance has

The maximum pressure switch downstream of the

pump measures a pressure higher than the set

value (12 bar) (ONLY FOR ROC060)

The inlet minimum pressure switch measures a

feed water pressure lower than the set value (0.8

bar) for a certain number of consecutive attempts

The contact opening/closing sequence for operation authorisation (in the case of vessel fi lling/

draining) is incorrect

During the production phase, the conductivity

exceeds the set threshold for a certain period of

time (ONLY FOR ROC060)

expired.

- check that the pressure switch is calibrated correctly and that the alarm actually

occurs when the set pressure is exceeded (12 bar, readable from the manometer

downstream of the pump)

- act on the pump by-pass to reduce the pressure downstream of the pump (suggested value between 5 and 10 bar)

- use the menu 8C to set a specifi c delay in reading the maximum pressure switch

(5 seconds)

- If the problem persists, check that the permeate pipe is not obstructed and that the

produced fl ow is close to the nominal value.

- check that the water supply pipe upstream of the system has a suitable diameter

(at least 1/2")

- while reading the inlet pressure on the manometer, check that the supply water

pressure is guaranteed (both static pressure with WTS off and dynamic pressure with

WTS pump on).

- if there is a pressurisation pump upstream of the WTS, check that it operates correctly. If necessary, delay the WTS pump switching-on (menu 21A) of a few seconds

to allow the upstream pressurisation pump to activate.

- check the conditions of the inlet fi lters and the pressure loss caused by them (by

means of a pressure gauge upstream and one downstream of the fi lters). If necessary, replace the fi lter cartridges and clean the inside of the vessels.

- check that the pressure switch is calibrated correctly and that the alarm actually occurs below the set pressure (0.8 bar) Check whether the NC/NO logic of the contact

is implemented correctly (menu 7B, with reference to terminals 35-36). If necessary,

carry out a new calibration of the pressure switch.

- the authorisation to START is given by a minimum pressure switch (when the

pressure drops below 2 bar) or by a fl oat (which indicates the low level). The signal is

controlled by terminals 33-34 of the electronic board. Check that the authorisation to

START activates the signal (check that the signal is enabled in menu 5A; use a tester

to measure the terminal continuity at its ends) and that the signal logic (NC/NO)

complies with the one set in the display (menu 5B)

- STOP is given by a maximum pressure switch (when the pressure reaches 4 bar) or

by a fl oat (which indicates the high level). The signal is controlled by terminals 22-23

of the electronic board. Check that the authorisation to STOP activates the signal

(check that the signal is enabled in menu 6A; use a tester to measure the terminal

continuity at its ends) and that the signal logic (NC/NO) complies with the one set in

the display (menu 6B)

- Carry out an independent measurement of the produced water conductivity (for

example by means of an external conductivity meter)

- check that the conductivity meter on the machine operates correctly; if necessary,

clean the head and/or recalibrate the measuring instrument

- check the conditions of the membranes and monitor their performance deterioration over time

- check the supply water quality: the output conductivity always depends on the

quality of the supply water.

- correct the threshold value set in menu 3B if it is too low

- basically, the fi rst water produced after a period of inactivity will always have a

higher conductivity. It is advisable to increase the alarm delay by a time that can be

set in menu 3D

- if you want to ignore the alarm and you do not want to stop the normal operation

of the WTS, disable the Output Set Point in menu 3A

- reset the scheduled maintenance timer in screen 13B to the value set in menu 18B

- enable or disable the scheduled maintenance warning in screen 18A; use screen

18B to set the time before maintenance request

ENG

Tab. 4.a

15

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

The following problems can be found and solved with the following

procedures:

Problem Solution

The fl ow rate of the permeate is not

the rated one. The demineralised

water quantity from the permeate

line is not enough.

The conductivity of permeate is too

high.

The conductivity meter of the

WTS Compact is not calibrated (on

ROC060 only).

The WTS Compact system never

starts or never stops.

Password 0077 does not work. - Try to enter "0000".

- check that the feed fl ow rate is guaranteed and that there are not obstructions on the charge line. Check the conditions of

the inlet fi lters.

- check that the pressure generated downstream of the pump and reaching the membranes corresponds at least to 5-7 bar.

If necessary, close the by-pass tightening the screw (clockwise). Check that there are no leaks from junctions or pipelines.

- Check the drain line: the installed fl ow restrictor must generate a proper charge loss for generating pressure to the membranes and thus for producing permeate. Check that the relationship between drain water and permeate is about unit (0.8

÷ 1.2). Replace the fl ow restrictor (if necessary).

- check that the membranes are not clogged and refer to the periodic maintenance sheets to check their conditions. In

standard conditions, the membranes have a gradual performance loss over time. If necessary, replace the membranes.

- fi rst of all, measure the conductivity of the feed water, because conductivity value at the outlet can always be compared

with the inlet one (90%-95% of salty rejection with new membranes).

- conductivity is the most signifi cant value but there are others to be taken into account: the reduction of TDS is extremely

important for evaluating the good conditions of the membranes and the good operation of the system.

- when the operating pressure of the membranes is higher, a higher fl ow rate of permeate is generated, with a higher conductivity value. - check that the pressure generated downstream of the pump and reaching the membranes corresponds

approx. to 5-7 bar. If necessary, open the by-pass loosening the screw (anticlockwise).

- check that the membranes are not clogged and refer to the periodic maintenance sheets to check their conditions. In

standard conditions, the membranes have a gradual performance loss over time. If necessary, replace the membranes.

- remove the conductivity meter from its housing and clean the heads. Perform the measurement again.

- check the non-calibration of the conductivity meter on the equipment: to do so, you need to measure the conductivity

of the permeate with a second independent device. Make sure that the calibration of the second conductivity meter is

certifi ed.

- the conductivity meter on the equipment is calibrated following the standard factory procedure and this operation is not

easy to repeat. For a new calibration, proceed as follows: - arrange a buff er solution with known salinity (ranging between 0

and 100 µS), measured through an external device - remove the conductivity meter from its housing and keep it hanging,

still connected to the power line - enter the menu 2A ZERO CALIB - press ENTER to confi rm the value displayed in the

"lettura" box: in this way, the zero is calibrated - If the "lettura" box displays an irregular value, the display shows "ZERO cal

errata"; press ESC to quit without saving, then clean again the heads of the conductivity meter, or replace it. - enter the

menu 2B SLOPE CALIB - dip the conductivity meter in the buff er solution with known conductivity - wait until the "lettura"

value stabilises - press ENTER to save the measurement or press ESC to go back to the previous menu and quit. - if the

conductivity meter measures a conductivity value of the buff er solution extremely diff erent from the actual one (known),

replace the conductivity meter.

- the logic of the permeate pressure switches might have been entered in a wrong way: check on the display that status

N.C. corresponds to menus 5b and 6b.

- the pressure switch could be not calibrated. Check the calibration pressure by monitoring the behaviour of the WTS and

of the pressure switches during the vessel charging (check which is the pressure value that closes the contact) and during

the manual draining of the vessel (check at what pressure value the pressure switch opens the contact).

- check the operation of the pressure switches, possibly disconnecting the cables at the ends of the pressure switch, and

try to enable/disable the WTS opening the contact. If either pressure switch features an irregular operation, replace the

pressure switches.

Please note that the max. pressure switch for the permeate is calibrated at 4 bar and is placed in the high position. The min.

pressure switch for the permeate is calibrated at 2 bar and is placed in the low position.

- If this password as well does not work, make a "RESET PASSWORD" procedure, restoring the default value "0000". Proceed

as follows: - disconnect power supply from the equipment - simultaneously press the buttons "UP" and "ESC" and reconnect power supply.

- For a few seconds the display shows "RESET PASSWORD" before going back to standard operation. The stored password

now is "0000".

- To confi gure a new password, access the menu 17 of the electronic controller.

Tab. 4.b

Please note that the logics of pressure switches on the equipment is the

following:

Pressure

Logic Calibration Operating example

switch

Pump min.

fl ow rate

Permeate

min. fl ow rate

Permeate

max. fl ow rate

N.O. 1 bar >1 bar = closes equipment ON

<1 bar = opens equipment OFF

N.C. 2 bar >2 bar = opens equipment OFF

<2 bar = closes equipment ON

N.C. 4 bar >4 bar = opens equipment OFF

<4 bar = closes equipment ON

Tab. 4.c

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

16

5. MAINTENANCE

ENG

For a good operation of the reverse osmosis system, the working

conditions must be constantly monitored, in particular:

• check that the concentrate of chlorine concentration in the feed water

is not too high (max. 0.2 ppm);

• check that hardness and conductivity of the feed water range between

the limit values (indicated in par. 1.6);

• check the inlet pressure and the charge loss due to the fi lter;

• check the working pressure of the membranes: it should range

between the limit values (max. 10 bar);

• check the conditions of pipes and connections, making sure that there

are no water leaks.

• check the permeate water fl ow and the drain water fl ow; monitor the

recovery value;

• check the conductivity of the feed water and that of the produced

water;

• check the regular operation of the system overtime. It's important that

WTS works regularly. Too long stops aff ect durability and performances;

• avoid any prolonged stagnation of water in the expansion vessel, drain,

rinse it and then refi ll it at regular intervals;

• keep the equipment and the surrounding area properly clean

For all these operation, a monthly frequency is recommended.

It is recommended to note down the operations performed on a copy of

the model shown in chapter 7.

5.1 Routine maintenance

The routine maintenance is extremely important: otherwise, the WTS

operation might be impaired. In particular, a regular use and a regular

production of demineralized water should be ensured, with a suitable

frequency of fl ushing steps.

5.1.1 Replacement of the inlet lters

The inlet fi lter unit is formed by a single CBC charcoal fi lter in the

ROC025500N and ROC040500N units.

On the other hand, the ROC0605000 model is formed by two fi lters with

serial connection; the fi rst one is the CBC charcoal fi lter, while the second

one is a CPP micrometric fi lter.

These fi lters need a continuous monitoring and replacement, when

required.

Replacement of the CBC charcoal lt

abate the content of chlorine in the feed water. The presence of chlorine

in water might damage the membranes beyond repair. The charcoal

fi lter has a chemical operation, combining and absorbing all chlorine

molecules. Performance decay over time is normal. The CBC cartridge

should be replaced:

• every four months if the content of chlorine in feed water is lower that

0.1 ppm.

• every two months if the content of chlorine in feed water ranges

between 0.1 and 0.2 ppm.

Replacement of the 5 μm CPP micrometric lter: the CPP micrometric

fi lter retains the foreign particles over 5 m. The fi lter has a mechanical

operation, making feed water pass through a fi ltering mesh. It is normal

for the fi lter to get clogged over time, making less water pass and

decreasing its pressure.

The replacement of the CPP cartridge is necessary when the system

supply pressure (after passing through the inlet cartridge fi lters) is lower

than 1 bar during standard operation (pressure shown in the pressure

gauge PI01).

5.1.2 Reset of the hour counter for the maintenance

interval

To display the production hours of the system, from the home screen

showing the system status, press ARROW DOWN, sequentially scrolling

through the templates, until reading the working hours of the system

(where one working hour corresponds to one decimal) and the countdown of the hours before the next scheduled maintenance operation,

displayed by default every 240 operating hours (maintenance interval

that can be set through the menu "18B MAINTENANCE").

er: the CBC charcoal fi lter is used to

The reset of the system hour counter (menu "13A HOUR COUNTER

RESET) is not recommended, unless exceptional circumstances occur

(e.g. replacement of the membranes).

The reset of the hour counter for maintenance (menu "13B MAINTENANCE

RESET") must be performed after the equipment has signalled the

maintenance alarm, meaning that an intervention on the system is

required.

The reset of the hour counter can be managed through the user interface,

in menu "13 RESET":

• The display shows the fi rst template "13A HOUR COUNTER RESET".

• The cursor default setting is NO (press OK to confi rm).

• Press ARROW UP or DOWN, to change the setting to YES-NO.

• Press "OK" to confi rm the selection.

• Pressing again, the second template "13B MAINTENANCE RESET" is

displayed

• The cursor default setting is NO (press OK to confi rm).

• Press ARROW UP or DOWN, to change the setting to YES-NO.

• Press "OK" to confi rm the selection.

5.2 Overtime maintenance

Overtime maintenance concerns repair or replacement of one or more

components: usually this type of intervention is not required, unless

exceptional circumstances occur.

5.2.1 Replacement of membranes

Membranes have a natural decay over time, in particular:

• yearly decrease of produced permeate: 7%

• yearly increase of conductivity of the produced permeate: 10%

Membranes, after a longer or shorter period, depending on the features

and the volume of treated water, get clogged, thus reducing their

effi ciency.

The decay of membrane performance can depend on the following main

factors:

• clogging due to precipitation of iron or sulphate and calcium carbonate

• biological clogging

• long interval between CBC charcoal fi lter replacement (resulting in

corrosion due to the presence of chlorine in the feed water)

The replacement is required when the following main parameters in the

system change (recorded at the same temperature of the feed water):

• decrease of the produced water fl ow rate until reaching an insuffi cient

value for the application connected downstream of the osmosis

system;

• too high increase of the conductivity of produced water until reaching

a too high value for the application connected downstream of the

system.

5.3 Disposal

Should you decide not to use the WTS system anymore, it must be

dismantled. This operation must be carried out according to the

regulations in force and with separate collection of the diff erent materials

inside (rubber, plastic, polyethylene, fi breglass, PVC, electronic circuits,

etc.).

5.4 Instructions for emergency situations

In case of fi re, use powder fi re extinguishers in compliance with the

regulations in force. Never use liquid fi re extinguishers.

Pay attention to combustion gases, as they can be extremely toxic.

17

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

6. REGULAR MAINTENANCE RECORDING FORM

Model: WTS Compact Serial number Date of rst start-up

Regular maintenance recording form (to be fi lled in with a monthly interval)

Values to be measured on the spot

Conductivity at the inlet Conductivity at the outlet

Decay quantity Drain quantity

Expansion vessel

Stop pressure (default 4 bar) Air precharge pressure (default 1.8 bar)

Start pressure (default 2 bar)

Spare parts

Micrometric lter

Feed water

pressure

Water pressure

downstream of the

lter

If pressure drop > 1 bar

IMMEDIATELY REPLACE THE FILTER or REPLACE EVERY YEAR

Date of last fi lter replacement:

Pump working pressure

(default from 5 to 10 bar)

Recovery value

permeate / (permeate+drain) = about 40-60%

To measure the precharge pressure, it is

advisable to drain the vessel and use a pressure

gauge to measure the air residual pressure

in the same vessel. It is advisable to perform

this operation every month, to guarantee the

hygiene of the stored water.

Micrometric lter

Quantity of free chlorine in the feed water

If < 0.1 replace 3 months

0.1< If < 0.2 replace 2 months

Date of last fi lter replacement:

Osmotic membrane

Replacement recommended when the conductivity value

of the permeate or the permeate ow rate value is not

satisfactory any more

Regular replacement recommended once every two years.

Date of last membrane replacement:

Various remarks

N. Date Person in charge Signature

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

18

UV light (optional)

The UV light should be replaced every 10000 hours of operation (about once a year).

Date of last UV light replacement:

The removal and cleaning of quartz is recommended approximately every 6 months

Date of last UV/quartz light cleaning:

7. SPARE PARTS

7.1 ROC025-ROC040 spare parts

Where necessary, the parts of the WTS must only be replaced by qualifi ed

personnel, when the appliance is off and depressurised. In all cases,

contact the supplier or the manufacturer directly.

14 16

13

ENG

5

20

2

4

9b

1b

Rif. n° Code Description

1a ROKC00HOU1 Single BLUE container for water inlet fi lter, 10" - 1/2" connection

1b ROKC00FLT2 Cartridge CBEC 10'' – 5 micron

2 - - - Pressure gauge 0-6 bar – radial connection 1/8''

3 ROKL00IV12 Water inlet solenoid valve with coil 230 V – 1/2"

4 ROKC00PSLP N.O. min. pressure switch, made of brass, calibrated at 1 bar - 1/4''

5 ROKC00EP01 Preset electronic control board

6 ROKC00PUMP Pump 150 l/h

7 ROKC00MOT5 Single phase, 230 V, 50/60 Hz, 245 W motor

8 ROKC00MAK1 Kit of pressure gauges for permeate, dia. 25, installed on T-shaped quick coupling (for dia. 6 pipe)

9a ROKC00VESS Vessel for membrane 2" (there are two on ROC040 models)

9b ROKC00MEMB Osmotic membrane (there are two on ROC040 models)

10 ROKL00PSLL Permeate N.C. min. pressure switch, calibrated at 2 bar

11 ROKL00PSHL Permeate N.C. max. pressure switch, calibrated at 4 bar

10-11 ROKC00PSK0 Kit of min./max. pressure switches installed on PVC mount

12 ROKC00FR25 Drain adjuster 800 for ROC025

ROKC00FR40 Drain adjuster 2 x 600 for ROC040 (required quantity: 2)

13 ROKC00BR08 Black pipe, dia. 8 mm for water drain with bracket connector under the sink (L = 3 m)

14 ROKC00P064 PE white pipe, dia. 6 - whole coil L = 100 m

15 ROKC00TEE1 T-shaped connector with quick couplings for dia. 10 pipe

ROKC00RD10 Reduction connection, dia. 10-6 with quick coupling

16 ROKC00KTVE Kit of additional expansion vessel, capacity 15 l + pipe and connectors

ROKC00VE15 Expansion vessel (spare part without pipes and connectors)

17 ROKC00P107 PE white pipe, dia. 10, for permeate line - whole coil L = 150 m

18 ROKC00VALS Quick coupling ball valve for dia. 10 pipe

19 - - - Reduction connection, dia. 10-8 with quick coupling for drain pipe

20 ROKC00WREN Spanner for 10" fi lter tightening

12

11

10

9a

1519

1817

Fig. 7.a

3

6

1a

7

8

Tab. 7.a

19

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

7.2 ROC060% spare parts

14

1c

1b

13

9b

11

10

9a

114

5

3

12

20

8

19

1a

6

7

15

18

17

Fig. 7.b

Rif. n° Code Description

1a ROKL00HOU1 Double WHITE container for water inlet fi lter, 10" - 1/2" connection

1b ROKC00FLT1 Spare fi lter cartridge CBEC 10'' – 10 micron

1c ROKC00FLT3 Spare fi lter cartridge CPP 10'' – 5 micron

3 ROKL00IV12 Water inlet solenoid valve with coil 230 V – 1/2"

4 ROKC00PSLP N.O. min. pressure switch, made of brass, calibrated at 1 bar - 1/4''

5 ROKC00EP01 Preset electronic control board

6 ROKC00PU00 Pump 300 l/h

7 ROKC00MOT5 Single phase, 220 V, 50/60 Hz, 245 W motor

8 ROKL00MA16 Stainless steel, dia. 63 pressure gauge, 0-16 bar, with brass connector - 1/4" rear connection

9a ROKC00VS28 Vessel for membrane 2.8"

9b ROKL00MEMB Membrane 2.8"

10 ROKL00PSLL Permeate N.C. min. pressure switch, calibrated at 2 bar

11 ROKL00PSHL Permeate N.C. max. pressure switch, calibrated at 4 bar

10-11 ROKC00PSK0 Kit of min./max. pressure switches installed on PVC mount

12 - - - Drain adjuster with check valve

13 ROKC00BR08 Black pipe, dia. 8 mm for water drain with bracket connector under the sink (L = 3 m)

14 ROKC00P064 PE white pipe, dia. 6 - whole coil L = 100 m

15 ROKC00TEE1 T-shaped connector with quick couplings for dia. 10 pipe

16 ROKC00KTVE Kit of additional expansion vessel, capacity 15 l + pipe and connectors

ROKC00VE15 Expansion vessel (spare part without pipes and connectors)

17 ROKC00P107 PE white pipe, dia. 10, for permeate line - whole coil L = 150 m

18 ROKC00VALS Quick coupling ball valve for dia. 10 pipe

19 ROKL00PSHP Pump max. pressure switch, in brass, calibrated at 12 bar - 1/4" - N.C.

20 ROKL00IV14 Flushing solenoid valve, 230 V - 1/4"

21 ROKL00EC01 Conductivity meter for permeate conductivity measurement

22 ROKC00WREN Spanner for 10" fi lter tightening

1620

Tab. 7.b

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

20

8.1 ROC025/040 water circuit

ENG

8. WATER CIRCUIT

PRODUCT

DRAIN

INLET WATER

EV

Fig. 8.a

21

Key

PI pressure gauge

PS pressure switch

P electric rotary pump

CV check valve

C.P. control panel

FR fl ow restrictor

BV ball valve

SV solenoid valve

EV expansion vassel

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

ENG

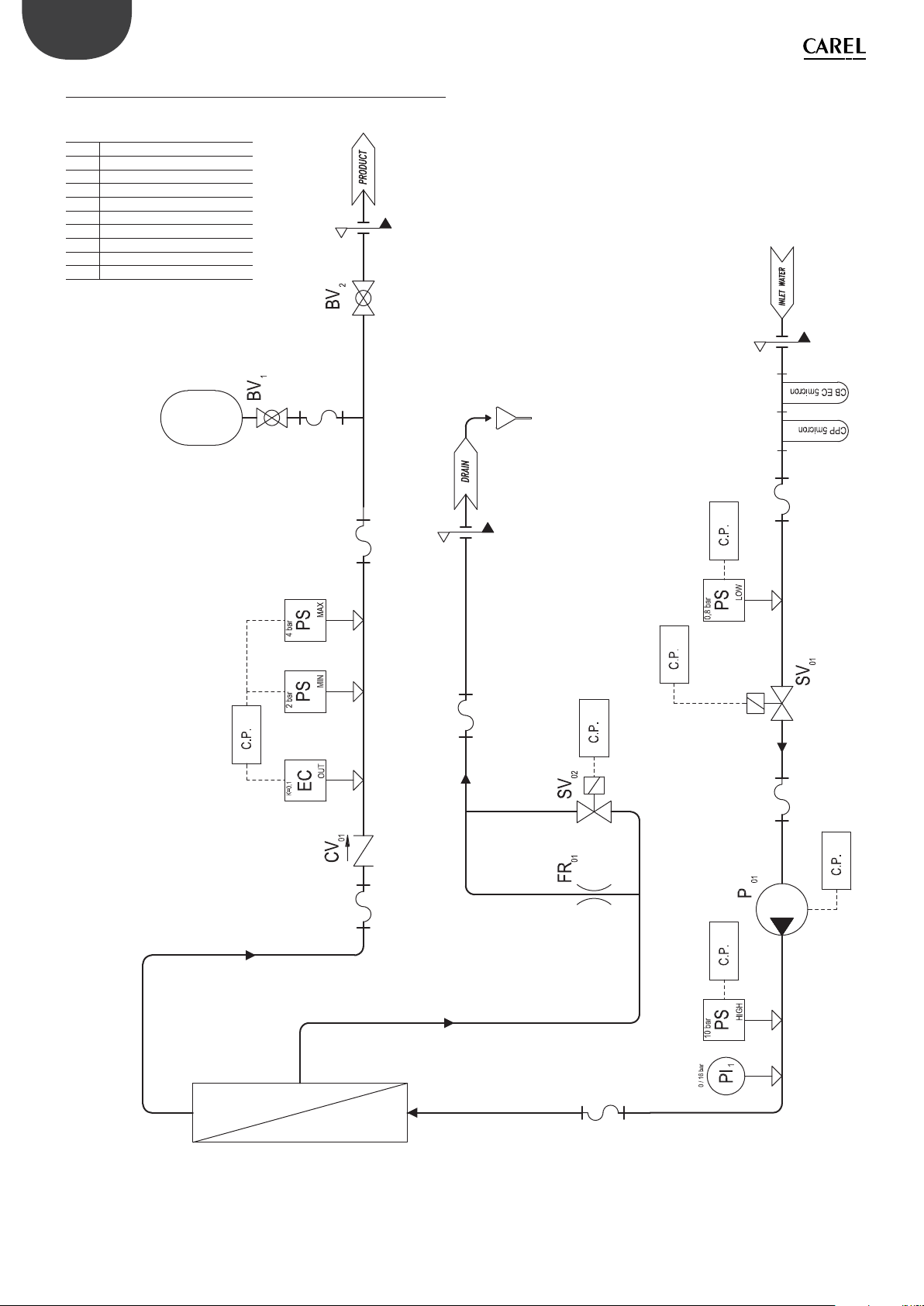

8.2 ROC060 water circuit

Key

PI pressure gauge

PS pressure switch

P electric rotary pump

EC conductivity probe

CV check valve

C.P. control panel

FR fl ow restrictor

BV ball valve

SV solenoid valve

EV expansion vassel

EV

"osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

Fig. 8.b

22

CAREL INDUSTRIES - Headquarters

Via dell’Industria, 11 - 35020 Brugine - Padova (Italy)

Tel. (+39) 049.9716611 - Fax (+39) 049.9716600

e-mail: carel@carel.com - www.carel.com

Agency:

Klimatbyrån AB

Travbanegatan 6, 213 77, Malmö

040-671 27 50

www.klimatbyran.se

"Osmosi inversa" +0300017IE rel. 1.3 - 12.10.2016

Loading...

Loading...