µRack

Standard compressor racks single/two circuit

User manual

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFUL LY IN THE TEXT!

WARNINGS

CAREL bases the development of its products on decades of experience in HVAC, on the continuous investments in technological innovations to products, procedures and strict quality

processes with in-circuit and functional testing on 100% of its products, and on the most innovative production technology available on the market. CAREL and its subsidiaries nonetheless

cannot guarantee that all the aspects of the product and the software included with the product respond to the requirements of the final application, despite the product being developed

according to start-of-the-art techniques. The customer (manufacturer, developer or installer of the final equipment) accepts all liability and risk relating to the configuration of the product in

order to reach the expected results in relation to the specific final installation and/or equipment. CAREL may, based on specific agreements, acts as a consultant for the positive

commissioning of the final unit/application, however in no case does it accept liability for the correct operation of the final equipment/system.

The CAREL product is a state-of-the-art product, whose operation is specified in the technical documentation supplied with the product or can be downloaded, even prior to purchase, from

the website www.carel.com.

Each CAREL product, in relation to its advanced level of technology, requires setup / configuration / programming / commissioning to be able to operate in the best possible way for the

specific application. The failure to complete such operations, which are required/indicated in the user manual, may cause the final product to malfunction; CAREL accepts no liability in such

cases.

Only qualified personnel may install or carry out technical service on the product.

The customer must only use the product in the manner described in the documentation relating to the product.

In addition to observing any further warnings described in this manual, the following warnings must be heeded for all CAREL products:

• Prevent the electronic circuits from getting wet. Rain, humidity and all types of liquids or condensate contain corrosive minerals that may damage the electronic circuits. In any case,

the product should be used or stored in environments that comply with the temperature and humidity limits specified in the manual.

• Do not install the device in particularly hot environments. Too high temperatures may reduce the life of electronic devices, damage them and deform or melt the plastic parts. In any

case, the product should be used or stored in environments that comply with the temperature and humidity limits specified in the manual.

• Do not attempt to open the device in any way other than described in the manual.

• Do not drop, hit or shake the device, as the internal circuits and mechanisms may be irreparably damaged.

• Do not use corrosive chemicals, solvents or aggressive detergents to clean the device.

• Do not use the product for applications other than those specified in the technical manual.

All of the above suggestions likewise apply to the controllers, serial boards, programming keys or any other accessory in the CAREL product portfolio.

CAREL adopts a policy of continual development. Consequently, CAREL reserves the right to make changes and improvements to any product described in this document without prior

warning.

The technical specifications shown in the manual may be changed without prior warning.

The liability of CAREL in relation to its products is specified in the CAREL general contract conditions, available on the website www.carel.com and/or by specific agreements with customers;

specifically, to the extent where allowed by applicable legislation, in no case will CAREL, its employees or subsidiaries be liable for any lost earnings or sales, losses of data and information,

costs of replacement goods or services, damage to things or people, downtime or any direct, indirect, incidental, actual, punitive, exemplary, special or consequential damage of any kind

whatsoever, whether contractual, extra-contractual or due to negligence, or any other liabilities deriving from the installation, use or impossibility to use the product, even if CAREL or its

subsidiaries are warned of the possibility of such damage.

DISPOSAL

INFORMATION FOR USERS ON THE CORRECT HANDLING OF WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE)

In reference to European Union directive 2002/96/EC issued on 27 January 2003 and the related national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and such waste must be collected and disposed of separately;

2. The public or private waste collection systems defined by local legislation must be used. In addition, the equipment can be returned to the distributor at the end of its working life when

buying new equipment.

3. The equipment may contain hazardous substances: the improper use or incorrect disposal of such may have negative effects on human health and on the environment;

4. The symbol (crossed-out wheeled bin) shown on the product or on the packaging and on the instruction sheet indicates that the equipment has been introduced onto the market after

13 August 2005 and that it must be disposed of separately;

5. In the event of illegal disposal of electrical and electronic waste, the penalties are specified by local waste disposal legislation.

WARNING: separate as much as possible the probe and digital input signal cables from the cables carrying inductive loads and power cables to avoid possible electromagnetic disturbance.

Never run power cables (including the electrical panel wiring) and signal cables in the same conduits

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFUL LY IN THE TEXT!

CONTENTS

1 PRODUCT ...................................................................................................................................................................................................... 7

1.1 General functions ..............................................................................................................................................................................................7

1.2 Main characteristics ..........................................................................................................................................................................................7

2 USER INTERFACE .......................................................................................................................................................................................... 8

2.1 Buttons - LEDs - Icons ......................................................................................................................................................................................8

2.2 LED display and Icons ......................................................................................................................................................................................9

3 STARTING THE UNIT .................................................................................................................................................................................. 10

3.1 Starting for the first time ..................................................................................................................................................................................10

3.2 Unit configuration ............................................................................................................................................................................................10

3.3 Meaning of the inputs / outputs .......................................................................................................................................................................10

4 COMPRESSOR MANAGEMENT .................................................................................................................................................................. 13

4.1 General settings ..............................................................................................................................................................................................13

4.2 Compressor rotation .......................................................................................................................................................................................13

4.3 Compressor control .........................................................................................................................................................................................13

4.4 Number of compressors started with probe 1 fault .........................................................................................................................................14

4.5 Compressors with different capacities ............................................................................................................................................................15

4.6 Manually enable/disable the compressors ......................................................................................................................................................15

4.7 Special MT-LT units ........................................................................................................................................................................................16

4.8 Compressor time settings ...............................................................................................................................................................................16

5 FAN AND INVERTER MANAGEMENT ......................................................................................................................................................... 18

5.1 Fan management ............................................................................................................................................................................................18

5.2 Dead band control ...........................................................................................................................................................................................18

5.3 Inverter management ......................................................................................................................................................................................19

5.4 PWM-PPM management ................................................................................................................................................................................21

5.5 Floating condenser control ..............................................................................................................................................................................21

6 VARIOUS SETTINGS .................................................................................................................................................................................... 22

6.1 Manual device operation .................................................................................................................................................................................22

6.2 Compressor hour counter and maintenance alarm .........................................................................................................................................22

6.3 Set point variation from digital input ................................................................................................................................................................22

6.4 Type of refrigerant ...........................................................................................................................................................................................22

6.5 Auxiliary probe management ..........................................................................................................................................................................22

6.6 Prevent high discharge pressure ....................................................................................................................................................................23

7 ALARM MANAGEMENT .............................................................................................................................................................................. 24

7.1 Alarms with automatic reset ............................................................................................................................................................................24

7.2 Alarms with manual reset ................................................................................................................................................................................24

7.3 Semiautomatic alarms ....................................................................................................................................................................................24

7.4 Alarm relay ......................................................................................................................................................................................................24

7.5 Alarms from analogue inputs: temperature probe and pressure transducer: ..................................................................................................25

8 THE SUPERVISOR NETWORK ..................................................................................................................................................................... 26

8.1 Serial boards ...................................................................................................................................................................................................26

8.2 Communication protocols ...............................................................................................................................................................................26

9 USER INTERFACE ........................................................................................................................................................................................ 26

10 LIST OF PARAMETERS .............................................................................................................................................................................. 27

11 ON/OFF FAN CONTROL BOARD (CODE CONVONOFF0) .................................................................................................................... 32

12 PWM TO 0 TO 10 VDC (OR 4 TO 20 MA) CONVERSION BOARD FOR FANS (CODE CONV0/10A0) ................................................ 33

13 PROGRAMMING KEY (CODE PSOPZKEYA0) .......................................................................................................................................... 33

14 SUPERVISOR MANAGEMENT ................................................................................................................................................................... 33

15 DEFAULT CONFIGURATIONS .................................................................................................................................................................. 36

16 GLOSSARY ................................................................................................................................................................................................. 37

17 TECHNICAL SPECIFICATION .................................................................................................................................................................... 37

18 PRODUCT CODES LIST ............................................................................................................................................................................ 38

19 APPENDIX: COMPRESSOR RACK CONTROLLER, EXAMPLES OF APPLICATION DIAGRAMS ................................................ 39

20 APPENDIX: CHANGES INTRODUCED IN FW RELEASE 2.0 FOR MRK0000XX0 ........................................................................... 41

21 APPENDIX: CHANGES INTRODUCED IN FW RELEASE 2.1 ............................................................................................................. 42

22 APPENDICE: MODIFICHE INTRODOTTE NELLA RELEASE FW 2.2 ................................................................................................ 42

Cod.

C

1

1.1

123456789111111

1

1.2

Main

f

•

•

•

•

•

Devic

e

Comp

r

•

•

Progr

a

•

•

•

•

•

Hard

w

•

AREL +03P22

0

Product

General

f

. Read press

u

. Manageme

n

. Manageme

n

. Setting of th

. Rotation of

t

. Fan speed c

. Compresso

r

. Possibility t

o

parameter v

. Possibility t

o

0. Multifunctio

1. Set point va

r

2. Possibility t

o

3. Enable com

p

4. Proportiona

l

5. Floating con

6. Optional te

m

a-

O

b-

A

c-

C

d-

S

Main ch

a

unctions

Control of co

m

Control of con

Complete ma

n

Complete alar

m

Connection to

s controlled

essors (up to 4

h

Condenser fa

n

PWM speed c

o

mming

Display and c

o

Three levels o

f

Possibility to c

o

Possibility to c

o

Possibility to

m

are

The product c

o

431 rel. 2.2 date

unctions

re transducers, d

i

t of compressors

t of compressor

r

e number of co

m

he compressors

(

ontrol (PWM OU

T

and fan dead ba

enter the comp

alues.

enter the fan se

t

n input: general

H

iation from digit

a

set the compres

s

ressors from th

e

plus integral fun

denser set point

perature probes

utside air

mbient air

ompressor disc

h

uction temperat

u

racteristic

s

pressor suction

p

densing pressure

agement of the

o

management;

serial line for su

p

ermetic compres

s

s (max 4)

ntrol

ntrol of the valu

e

parameter prote

c

nfigure all the u

n

nfigure the mai

n

odify the access

l

mes ready for p

a

d 10/02/12

splay data in BA

R

with the same a

n

acks with two cir

c

pressors – fans o

FIFO and by tim

e

PUT)

nd management

ressor set point i

point in BAR or

d

P alarm, ON/OF

F

l input

or-fan thermal o

v

“Maintenance” s

ction for the fan i

n

, with high temp

e

arge temperatur

e

re

ressure

(compressor dis

c

utputs available;

ervision / telema

i

ors, no part up t

o

s measured, on

L

tion: SEL (USER)

it parameters usi

unit parameters

evel to the para

m

nel installation, 3

°C (depending

o

d different capac

uits, MT and LT

n the unit

). FIFO rotation

o

n BAR and displ

a

egrees centigrad

e

, change SET PO

I

erload/generic a

l

creen

verter.

rature alarm thre

s

harge)

ntenance;

2 hermetic-load

ED display

, PRG (INSTALLE

R

ng a hardware k

e

via serial line.

eters from the k

e

2x74, and DIN ra

i

7

n the type of ref

r

ities

f the fans.

y the value in °

C

e, depending on

t

INT,…

larm as automati

c

s

hold:

capacity-controll

e

), SEL+PRG (MA

N

y.

ypad (only from

l mounting.

igerant gas)

by pressing the

he control probe

/manual

d compressors)

UFACTURER)

MANUFACTURE

R

“UP” and “DO

W

used (pressure

o

level).

N” buttons toge

t

r NTC).

her when displa

y

µRack

ing the

Cod.

C

2

The p

r

As we

l

param

2.1

+

+

AREL +03P22

0

User inter

f

oduct uses a 3 di

l as displaying t

h

eters. The followi

Buttons

-

Button

abc(d

(

abc

d

abc

a

EU-

- U-- bcd

e P P

t

431 rel. 2.2 date

ace

git LED display w

e values measur

e

ng figures show t

h

LEDs - Ic

o

) Press the butto

) Press the butto

) Press the butt

o

control pressure

/

) Press the butto

control pressure

/

) Press the butto

) Press the butto

) Press the butto

n

) Press the butto

) Press the butto

) Press the butto

) Press the butto

n

) Press the butto

xample:

nit “A” single cir

c

standard LP1

the arrows scroll

t

nit “B” two circu

standard LP1

the arrows scroll

t

) Press the butto

) Press the butto

n

) Press the butto

) Press the butto

ress the two but

t

ress the two but

t

1. comp

/

2. high/l

o

o switch the disp

l

d 10/02/12

ith minus sign an

d

d and the oper

a

e µRack for pan

e

ns

n, when switchin

g

n for more than

5

n for more than

temperature)

n for more than

3

temperature)

n for more than

5

n when the list o

f

when the num

e

n when a digital

v

n for more than

5

n when the list o

f

when the num

e

n to display the o

t

uit

o HP-B2 –B3

it

o LP2-HP-B3

n for more than

5

when the list of

n when the num

e

n when a digital

v

ons together for

5

ons together, wh

e

fan set point

w threshold

ay of the same p

a

decimal point t

o

ting conditions o

l installation and

the instrument

o

sec, to set the p

a

3 sec, when th

e

sec when the li

s

sec to select bet

w

parameters is di

s

ric value of a par

a

alue is displayed

sec to set the pa

parameters is di

s

ric value of a par

a

her controlled v

a

sec to select the

parameters is di

s

ric value of a par

alue is displayed

seconds to set t

h

n the numeric v

a

rameter from B

A

8

display the mo

n

f the unit, the u

s

for DIN rail mou

n

Fig. 2.a

D

e

n, until the strin

g

ssword for acce

s

list of paramet

e

t of parameter g

r

een the display

played to move

t

meter is display

e

(YES-NO) to cha

n

ssword for acces

s

played to show t

h

meter is display

e

lues. The “label”

probe displayed

played to move t

o

ameter is display

e

(YES-NO) to cha

n

he PWD for acce

s

lue of one of th

e

R to °C.

itored values, an

d

er terminal (disp

l

ting.

scription

“DEF” is shown

o

sing the INSTALL

E

rs is displayed, t

o

oups is displayed

of the values in “

B

o the next param

d to increase the

ge the setting.

ing the USER par

a

e numeric value

d to accept the n

of the probe will

b

permanently as t

h

the previous pa

d to decrease th

e

ge the setting

sing the MANUF

A

following param

e

ICONS for the s

ay and keypad)

c

n the display, to

R parameters.

accept the mo

d

,

“-/-”, “-C-”, “-r-”,

AR” or “°C”.

ter.

value.

meters.

of the parameter

umeric value and

e displayed, and

e main probe.

ramete

r

value.

CTURER parame

t

ters is displayed:

tatus of the devi

c

an be used to

m

load the default

v

ifications and re

“-A-”, “-M-”, to r

e

.

return to the list

then the numeri

ters and thus con

es and operating

odify the unit o

p

alues.

t

urn to the main

turn to the main

of parameters.

value.

figuring the contr

T

µRack

modes.

erating

display

display

oller.

ab. 2.a

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

9

2.2 LED display and Icons

The display shows the control value, temperature or pressure. depending on the selection made from the keypad.

In the event of alarms, the display shows the monitored and the alarm information in sequence.

ICONS

Description

On when the unit of measure selected is BAR

On when the unit of measure selected is °C

On when there is an ACTIVE ALARM

1) On when the MANUFACTURER parameters are being configured

2) If flashing with the ALARM icon indicates the compressor maintenance hours have been exceeded.

1) On when the value read by the suction probe is displayed

2) If flashing with the ALARM icon indicates the activation of suction probe alarms:

High Temp.

Low Temp.

Probe not connected

1) On when the value read by the discharge probe is displayed

2) If flashing with the ALARM icon indicates the activation of discharge probe alarms:

High Temp.

Probe not connected

1) On when the fan parameters are being configured.

2) On when at least one fan is operating

3) If flashing with the ALARM icon indicates the activation of fan alarms

1) On when the compressor parameters are being configured.

2) On if at least one compressor step is active

3) If flashing with the ALARM icon indicates the activation of the compressor alarms

1

2

3

4

1) Indicates the state of the compressors and capacity control on

2) If flashing indicates the ON/OFF call for a new compressor step, while the device is awaiting the expiry of the delay times.

3) If the controller is used for fan control only (“/01”=0) then the icon shows the status of the fans.

Tab. 2.b

Cod.

C

3

3.1

After

h

W

hen

Unit

w

3.2

The u

n

/

09. T

h

First t

h

Relay

n

•

•

The s

e

If 4 d

e

contr

o

contr

o

3.2.1

Inputs

only).

exists

w

If 4 de

Param

•••••••••••••

3.2.2

The c

o

The u

n

123

4

Shutti

n

•

•

3.3

3.3.1

T

Analo

g

Input

B1

B2

B3

B4

AREL +03P22

0

Starting t

h

Starting

f

aving checked th

e

started for the fir

s

ith 2 compressor

s

Unit con

f

it can be set as s

e maximum nu

m

e compressors +

o. 5 may be:

an alarm

a fan

lection is made a

vices are select

e

lled (e.g.: 2 com

p

l or inverter, can

b

Input confi

g

from 1 to 4 are

a

The user can de

c

hen the contact

vices , or less, ar

e

eter /15 can be u

0: no functi

o

1: unit ON-

O

2: change s

e

3: general h

4: general h

5: general l

o

6: general l

o

7: general l

o

8: general l

o

9: liquid lev

e

10: liquid le

v

11: fan ther

m

12: fan ther

m

Unit ON/O

F

ntroller is norma

l

it can be switche

. Alarm (para

m

. Supervisor

(

. Digital inpu

t

. Parameter (

p

g down the unit,

switches th

e

stops the m

Meaning

Table of an

he tables below

d

ue inputs

Descriptio

Ratiometri

c

Room tem

Outside ai

r

Ratiometri

c

431 rel. 2.2 date

e unit

or the fir

s

connections, p

o

t time, the contr

o

+ 2 fans + alar

m

iguration

ingle or two circu

ber of devices, c

o

capacity contr

o

utomatically acco

d (e.g.: 2 compr

ressors (not ca

p

e set for the fan

s

uration

larm inputs for t

h

ide whether the

is closed) by sett

i

connected to th

e

sed to configure

t

n

FF (ON contact

N

t point (set1- set

2

igh pressure swit

c

igh pressure swit

c

w pressure switc

h

w pressure switc

h

w pressure switc

h

w pressure switc

h

l alarm NC

el alarm NO

al overload/gen

al overload/gen

F

ly configured as

a

d on and off by:

eter A22 can b

e

parameter /38 c

a

(parameter /15

c

arameter /39 ca

as shown on the

controller off;

anagement of th

e

of the inp

u

alogue inputs

escribe the type

n

discharge press

u

perature probe (

d

temperature pr

o

suction pressur

e

d 10/02/12

t time

wer-up the unit.

ller performs a L

A

relay.

it, the number of

mpressors + fan

l and then the fa

rding to the num

b

essors (not cap

a

acity-controlle

d

, managed using

e compressors a

n

alarm inputs are

ng parameter /1

4

controller, input

he multifunction

C)

)

h NC

h 1 NO

circuit 1 NC

circuit 1 NO

circuit 2 NC

circuit 2NA

eric NC

eric NO

lways ON.

used to select

w

n be used to ena

an be used to c

o

n be used to swit

c

display by the m

e

various devices

a

ts / outpu

of the probes th

a

re probe

isplay) / auxiliar

y

be (floating cond

probe / probe i

n

MP TEST and us

compressors for

o

s, is 5 (maximum

ns will be allocat

e

er of devices (fa

n

city-controlled

)

) + 3 fans), outp

the PWM signal.

d fans configure

d

normally closed

(

.

5 automatically

b

input:

hether or not a b

r

le unit shutdow

n

nfigure the multi

f

h the unit on or

ssage “OFF”:

nd the related al

ts

t can be connect

e

probe

enser control) / a

2nd circuit

10

es the default val

ne or two circui

t

number of relay

s

d, in sequence.

s and compress

o

+ 2 fans) rela

y

ut no. 5 is autom

. If 5 devices are

the alarm condit

ecomes a multif

u

roken probe alar

m

from the super

v

unction input as

O

off)

arms.

d to the inputs a

uxiliary probe

es selected by

C

s using paramete

).

rs) selected.

5 can be used

atically used to c

o

controlled by th

e

ion exists when t

h

nction input.

should switch t

h

isor).

N/OFF).

nd their characte

r

Type of pr

o

RATIOMET

R

CAREL NTC

CAREL NTC

RATIOMET

R

A

REL for all the c

o

/01; the numbe

r

as an alarm rela

y

ntrol a fan. In a

d

unit, input no. 5

e contact is ope

n

e unit off).

istics.

bes that can be

IC pressure prob

e

temperature pro

b

temperature pro

b

IC pressure prob

e

nfiguration para

m

r of fans can then

y (default settin

g

dition, the use o

f

is automatically

a

n) or normally o

p

connected

(0 to 5 Volt) or

e (-50T100°C; R

/

e (-50T100°C; R

/

(0 to 5 Volt)

eters:

be set using par

a

), while if 5 dev

speed control, b

y

n alarm input (fa

en (the alarm c

o

NTC if /16

T 10 k at 25°C)

T 10 k at 25°C)

T

µRack

meter

ices are

y

phase

n alarm

ndition

ab. 3.a

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

11

Digital inputs

Input Description Type of device connected

ID1

Compressor 1 / fan alarm Generic compressor/fan alarm. Voltage-free contact.

ID2 Compressor 2 /

capacity-control

/ fan alarm

Generic compressor /

Power contactor for capacity control activation

/fan alarm.

Voltage-free contact.

ID3 Compressor 3 /

capacity-control /

fan alarm

Generic compressor /

Power contactor for capacity control activation

/fan alarm.

Voltage-free contact.

ID4 Compressor 4 /

capacity-control

/ fan alarm

Generic compressor /

Power contactor for capacity control activation

/fan alarm.

Voltage-free contact.

ID5 Fan alarm / Multifunction input Generic alarm:

- compressor/fan.

- from general high/low pressure switch.

- fan thermal overload.

- liquid level.

Unit On-Off. Voltage-free contact.

Tab. 3.b

Digital outputs

Input Description Type of device connected

No1-C1 Compressor 1 / fan Power contactor for starting the compressor / fan

No2-C2 Compressor 2 / fan Power contactor for starting the compressor / fan

No3-C3 Compressor 3 / fan Power contactor for starting the compressor / fan

No4-C4 Compressor 4 / fan Power contactor for starting the compressor / fan

No5-C5 Alarm / fan Power contactor for starting the fan / voltage-free contact for signalling unit alarm

Tab. 3.c

Analogue outputs

Outputs Description

Y1

Fans speed controller (PWM)

Tab. 3.d

3.3.2 Wiring diagrams:

Panel installation:

Fig. 3.a

ext. temp. probe

amb. temp. probe

alarm 4

alarm 2

alarm 1

alarm 3

multifunctio nD.I./ alar m

Line

L

N

P

Line

LN

P

24 V

TRADR1W04

PSOPZKEY*

MCH2004850

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

12

DIN rail installation:

Fig. 3.b

Rack

Line

L

N

Rack

ext. temp. probe

amb. temp. probe

alarm 4

alarm 2

alarm 1

alarm 3

multifunction D.I./alarm

P

Line

LN

P

FCSER00000

FCSER00000

TRADR1W04

24 V

Cod.

C

4

Inputs

• Suc

t

• Dig

• Mu

l

Outpu

• Co

m

4.1

Param

•

n• c

• t

y

The c

o

In the

4.2

Rotati

o

Rotati

o

If the

c

numb

e

In the

Three

LIFO

r

The fi

r

• S

t

• S

t

FIFO

r

The fi

r

• S

t

• S

t

This s

e

Rotati

o

The c

o

numb

e

4.3

In the

Propo

Propo

r

the di

f

Figure

Settin

g

SP + 1

SP +

2

…

SP +

D

ON

OFF

F

i

Dead

This t

y

meas

u

time

e

stopp

e

stop r

e

AREL +03P22

0

Compress

used:

t

ion pressure pro

b

tal inputs dedica

t

tifunction input f

o

ts used:

pressor output

s

General

s

eters used for O

N

umber of compr

e

ompressor times

pe of control

mpressors are m

case of two circui

Compres

n (parameter r0

5

n automatically

e

ompressor is of

f

r of compresso

r

default configura

t

different types of

otation (no rota

st compressor to

art: C1,C2,C3,C4.

op:C4,C3,C2,C1.

otation

st compressor to

art: C1,C2,C3,C4

op: C1,C2,C3,C4.

lection enables t

h

n by time

mpressor that st

a

r of operating h

o

Compres

default configura

t

rtional band

tional band cont

r

ferential band. P

a

4.1 shows the ac

t

the parameters

l

*DF/ (No. of ste

p

*DF/ (No. of ste

p

F for th

1° compr.

co

m

g 4.a

band

pe of control fea

t

red value excee

d

lapsed outside o

d when the mea

s

quests. In this ca

s

431 rel. 2.2 date

or manag

e

be/probes

ed to the compr

e

r generic alarm

(

and capacity c

ettings

/OFF control:

ssors (capacity

-

anaged by the co

ts, the set point a

sor rotatio

) of the compre

s

xcludes any com

p

for alarm or dis

a

s available.

ion, FIFO rotatio

n

rotation can be s

e

tion)

start will be the l

a

start will be the fi

e rotation of the

rts will be the on

urs will stop.

sor contro

l

ion, “dead band

”

ol calculates, bas

e

rameters r01 (se

t

t

ivation points fo

r

isted above, eac

h

s) for the first;

s) for the secon

d

e last.

pr./capac. contr.

DF

ures the definiti

o

s the limit to the

f the dead band.

ured value falls

b

e too, the first d

e

d 10/02/12

ment

ssor safety devic

e

general suction

p

ontrol

controlled and

ntroller based on

nd the differentia

n

sor calls ensures

ressors with alar

bled, is exclude

has been select

e

t: for the capac

i

st to stop, first c

a

rst to stop.

compressors so

a

e with the lowest

control is activat

e

d on various pa

r

point) r02 (diffe

r

a system with 4

s

individual step

w

;

c

o

compr./

capac. c

o

n of a dead ban

d

right (measured

The first device

elow the dead b

a

vice stops imme

d

s

ressure switch 1

a

not)

a pressure set p

o

also need to be

t

hat the number

o

m or that are dis

a

d

from regulatio

n

d.

ty control, only

d

pacity control a

s to even out as

m

number of opera

d (parameter r0

6

ameters (SP, DF

a

ential).

teps.

ill have a differe

n

mpr./

capac.

ntr.

RP

to the side of t

h

value greater tha

will start immedi

nd (measured v

a

iately, while the

o

13

nd 2)

int (parameter r

0

set for the secon

d

f operating hou

r

bled.

and rotation; th

e

devices rotation t

y

ctivated will be

t

much as possible

ting hours. Whe

n

).

nd the number

o

tial as follows:

e set point, withi

n SP + DZN, se

e

ately, while the

o

lue less than the

thers wait the d

e

Key:

SP

DF

RP

1) and differenti

a

circuit (paramet

e

s and the numbe

activation/dea

c

pe available is LI

he last deactiva

t

the number of c

o

stopping the exa

f devices set) th

e

which no devic

Figure 4.3). Th

e

thers will wait t

h

set point), and r

e

lay time betwee

n

Compressor se

t

Compressor dif

f

Pressure read

l (parameter r02

)

rs r03 and r04).

of starts of the

d

tivation threshol

d

O (no dependi

n

ed:

mpressor operat

t opposite is tru

e

points where th

e

is started or sto

number of devi

c

e set time betw

e

mains there for

a

stops (r09).

point (r01)

erential (r02)

, measured by th

ifferent compres

s

s are re-calcula

t

g by r05) para

m

ing hours.

, that is, the com

devices must s

w

pped. The devic

e

es to be activate

d

en starts (r07).

S

period equal to

e suction probe.

ors balance out.

ed based from

a

eter:

pressor with the

h

itch on and off, i

n

s are activated w

varies accordin

g

imilarly, the dev

the time betwee

n

µRack

ctual

ighest

side

hen the

to the

ices are

device

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

14

Also see the paragraph on Time settings.

The program will switch the devices on according to the start-up logic configured and the availability of the devices

DOffZ

DOnZ

NZ

SP

DZN

RP

Fig. 4.b

Compressor dead band with variable times

The user can decide to set a variable time between calls, depending on whether the pressure is moving away from the dead band. In particular, the activation /

deactivation time of the outputs decreases as the distance from the dead band increases. To set this function, the following parameters must be configured:

• Maximum compressor on time/ capacity control (parameter r08)

• Minimum compressor on time/ capacity control (parameter r07)

• Pressure differential within which the time varies. (parameter r11)

• Maximum compressor off time/ capacity control (parameter r10)

• Minimum compressor off time/ capacity control (parameter r09)

Fig. 4.c

Key:

InPress

Suction pressure DTNZ Differential within which the time varies

STPM Control set point TOnMax Maximum compressor on time

RBM Control band TOnMin Minimum compressor on time

NZ Dead band TOffMax Maximum compressor off time

DOnZ Device activation zone TOffMin Minimum compressor off time

DOffZ Device deactivation zone

In the activation phase, the following cases are possible:

1. Pressure equal to point b

same call time as the “maximum compressor on time”

2. Pressure between point b and point b + DTNZ

type of call between “Max on time” and “Min on time”

3. Pressure greater than or equal to point b + DTNZ

same call time as “Min on time”

In the deactivation phase, on the other hand, the following cases are possible:

1. Pressure equal to point STPM

same call time as the “maximum compressor off time”

2. Pressure between point STPM and point STPM - DTNZ

type of call between “Max off time” and “Min off time”

3. Pressure greater than or equal to point STPM - DTNZ

same call time as “Min off time”

N.B. To make the device call time constant in the activation phase, simply set the times TOnMax and TonMin to the same value. The same is true for the deactivation

phase.

4.4 Number of compressors started with probe 1 fault

In the event of a suction probe fault or not connected alarm, parameter /07 indicates the number of outputs (compressors and capacity control, configured with

capacity-controlled compressors), forced on, so as to ensure minimum cooling/operation of the installation.

For two circuits, the parameter relating to the second circuit /08 must also be set. This will be related to the probe in the 2nd circuit.

Key:

DOffZ

Device deactivation zone

DOnZ Device activation zone

NZ Dead band

DZN Dead band differential

RP Suction pressure read

SP Set point

STPM

RBM

NZ DOffZ DOnZ

InPress [ºbar]

TOnMin TOffMin

TOnMax TOffMax

DTNZ

B

DTNZ

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

15

4.5 Compressors with different capacities

Parameter /02 is used to choose the option of compressors with different capacities.

This allows more load steps and therefore finer control.

Once the capacity of the individual compressors has been defined (parameters /03, /04, /05, /06), the software, based on the requirements of the installation and the

compressors available (without alarms or timers), will calculate the most suitable combination to satisfy the requirement. Whenever the requirement changes, the

software recalculates the most suitable combination. The combination will always be greater than or equal to the requirement.

If two compressors have the same capacity, the compressor with the lower index will always be the first to start.

4.5.1 Proportional band control with different capacity compressors

Based on the pressure, the set point and the differential, the software will proportionally calculate the capacity required to bring the pressure back near the set point.

At the set point plus differential the requirement will be at the maximum value, while it will be null for pressure values around or less than the set point.

alDifferenti

pressSetpointCapacityMax

requiredCapacity

)(_

_

−×

=

4.5.2 Dead band control with different capacity compressors

The software will calculate the maximum number of combinations possible with the compressors available.

At certain intervals of time (see the paragraph on Compressor dead band with variable times), the software will call a sequence with a higher capacity.

In the deactivation phase, the opposite will occur, while in the dead band no compressors will be started or stopped.

An increase in the requirement will correspond to a different combination.

Fig 4.d

4.5.3 Example of compressors with different capacities

The following example looks at an installation featuring 3 compressors with different capacities, using proportional band control. As can be seen, there are 8 possible

combinations available.

Set point 1.0 bar

“r01”

Differential 2.0 bar “r02”

Comp1 5 kW “/03”

Comp2 7 kW “/04”

Comp3 15 kW “/05”

Maximum capacity 27 kW “/06”

Pressure Requirement kW Comp1 Comp2 Comp3 Total active capacity kW

1.1

1.35 X

5

1.6 8.1 X X 12

1.8 10.8 X X 12

2 13.5 X 15

2.1 14.85

X 15

2.4 18.9 X

X 20

2.5 20.25

X X 22

3 27 X X X 27

Tab 4.a

4.6 Manually enable/disable the compressors

A compressor can be temporarily disabled from the control sequence. This function is very useful when needing to perform maintenance on an individual compressor.

The corresponding alarms are still managed.

The following parameters are used: M01,M02,M03,M04 to enable the manual operation of the compressors. The real manual function is managed using parameters:

M05,M06,M07,M08.

On unit models with capacity control (/01=9,10,...14) the comp ressors cannot be manually enable d/disabl ed d irectl y. T o exploit para met ers M01,..,M08,

the unit model needs to be changed (/01=1 for configurations 9, 10 and 11; /01=3 for configurations 12 and 13; /01=4 for configuration 14).

DOffZ

DOnZ

NZ

SP

DZN

RP

Key:

DOffZ

Device deactivation zone

DOnZ Device activation zone

NZ Dead band

DZN Dead band differential

RP Suction pressure read

SP Set point: compressors (S2); fans (S1)

Cod.

C

4.7

4.7.1

The h

a

mediu

speed

Below

This t

y12

4.7.2

Low p

r

Low p

r

High

p

Temp

e

Temp

e

4.8

The fo

Time

b

Param

This a

p

Mini

m

Sets t

h

R

C

m

AREL +03P22

0

Special

M

Manageme

n

rdware features

o

m installations, h

a

managed by the

is an example di

a

pe of system can

. the compre

s

. the max nu

m

allocated to

Probes and

Functio

n

essure circuit 1

essure circuit 2

ressure circuit di

s

rature 1

rature 2

Compres

llowing is a list of

etween stop re

q

eter C06 sets a st

plies both in the

um compressor

e minimum time

p

431 rel. 2.2 date

T-LT unit

s

nt of compresso

f the µRack cont

r

ving the advanta

speed controller

o

gram:

be controlled by

sors must have t

h

ber of compres

s

probe LP1, and t

h

values controll

e

charge

sor time s

e

all the time para

m

uests with HP

p

op delay betwee

n

dead band and i

n

ON time

the compressors

Fig 4.f

TMinOn

Fl

o

d 10/02/12

r racks with LT a

oller can be ada

p

ge of being com

p

r external press

u

µRack in the foll

o

e SAME CAPACI

T

ors in the MT un

i

e other compre

s

d

B4 (pressure)

B1 (pressure)

B1 (pressure)

B2 (temperatu

r

B2 (temperatu

r

B3 (temperatu

r

ttings

eters used for c

o

revent active

one compresso

r

the proportiona

stay on, that is,

o

ating condenser SET

Condenser

Liquid r

e

nd MT circuits a

ted for the contr

o

act and offering l

re switches, and

s

wing conditions:

Y

t and LT unit is 4.

sor rack to probe

Input

e)

e)

e)

mpressor mana

g

and the next, if t

h

l band.

nce activated, m

u

T[s]

T[s]

Do

ucom

ceiver

16

nd condenser o

n

l of a special typ

e

ow cost solution

s

eparate manage

m

Fig 4.

e

There can there

f

LP2.

C

LP1

LP2

HP

B2

B3

ement (and not

he high pressure

st remain on for

t

K

e

R

C

mTM

T

ble circuit

pressor unit

µR

a

ly.

of compressor

r

. These are com

p

ent of the com

p

ore be combinati

o

de on display

capacity contr

o

prevention (prev

e

t

he time set by th

y:

Com

p

p Com

p

inOn Mini

m

Time

ack that is becom

ressor racks with

ressors in the M

T

ns of 2+2, 3+1,

Type of u

n

A- Single cir

c

B- Compres

s

A -B

B

A (press –

t

B (only te

m

A

(AUX pr

o

B (not use

d

A

lways pre

s

l).

nt) function is a

c

is parameter (pa

r

ressor call

resso

r

um ON time

ing more widely

only the conden

s

and LT units.

1+1. One compr

e

it:

uit compressor rac

or racks with 2 circ

temp)

p)

be)

)

sent

tive.

ameter C01).

MT display cabinet

group

LT display cabinet

sed in small an

d

ing section, and

w

ssor rack will be

uits M

T

-BT

T

µRack

ith fan

ab 4.b

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

17

Minimum compressor OFF time

Sets the minimum time the compressors stay off. The devices are not started again if the minimum time selected (parameter C02) has not elapsed since the last stop.

Fig. 4.g

Minimum time between starts of different compressors (proportional band)

This represents the minimum time that must elapse between the start of one device and the next. This parameter allows simultaneous starts to be avoided (parameter

C03).

Fig 4.h

With capacity control compressors is established fixed delay = 5 s, between a capacity control and the following.

Minimum time between starts of the same compressor

Sets the minimum time that must elapse between two starts of the same compressor.

This parameter limits the number of starts per hour. If, for example, the maximum allowable number of starts per hour is 10, to guarantee this limit simply set a value of

360 (parameter C05).

Key:

R

Compressor call

Cmp

Compressor

TSameSw

Minimum time between starts of the same compressor

T

Time

Fig 4.i

Key:

R

Compressor call

Cmp Compressor

TMinOff Minimum OFF time

T Time

Key:

R

Compressor calls

Cmp1 Compressor 1

Cmp2 Compressor 2

TDiffSw Minimum time between starts of different compressor

T Time

T[s]

R

T[s]

Cmp

TMinOff

T[s]

R

T[s]

Cmp1

T[s]

Cmp2

TDiffSw

T[s]

R

T[s]

Cmp

TSameSw

Cod.

C

5

Inputs

• Dis

c

• Dig

• Mu

l

Outpu

• Co

n

• Co

n

5.1

The o

p

One t

h

“prop

o

5.1.1

Propo

Propo

r

the di

f

Figure

Settin

g

SP + 1

SP +

2

…

SP +

D

ON

OFF

5.2

This t

y

The d

e

activat

Simila

r

the ti

m

The p

r

Fan r

o

The r

o

Rotati

o

If the

f

fans

a

Two d

AREL +03P22

0

Fan and i

n

used:

harge pressure/t

e

tal inputs for the

tifunction input f

o

ts used:

denser fan outp

u

denser fan spee

d

Fan man

a

eration of the fa

n

ermal overload i

s

rtional band” co

n

Fan control

rtional band

tional band cont

r

ferential band.

5.1 shows the ac

t

the parameters

l

*DF/ (No. of ste

p

*DF/ (No. of ste

p

F for th

Dead ba

n

pe of control feat

vices are activat

e

d varies accordi

n

ly, the devices ar

e between devic

e

ogram will switc

h

tation

tation of the fan

s

n automatically

an is off for alar

m

vailable.

ifferent types of

r

431 rel. 2.2 date

verter ma

mperature prob

e

fan safety device

s

r generic alarm

(

ts

control (PWM o

u

gement

s depends on th

e

featured for eac

h

trol is set (para

m

ol calculates, ba

s

t

ivation points fo

r

isted above, eac

h

s) for the first;

s) for the secon

d

e last.

Fig. 5.

a

d control

ures the definitio

n

d when the mea

s

g to the time ela

p

e stopped when

t

stop requests. I

n

the devices on a

, settable by pa

r

excludes any fa

n

or disabled, is

otation can be s

F

d 10/02/12

nagement

general discharg

e

tput)

value read by t

h

fan step. This h

a

eter r21), and FI

F

ed on various pa

a system with 4

s

individual step

w

;

DF

of a dead band

ured value exce

e

sed outside of t

h

he measured val

u

this case too, th

ccording to the s

t

ameter r20, is a

i

s with active al

a

excluded from r

e

et:

ig. 5.b

pressure switch

)

e discharge pres

s

s a settable imm

O rotation (para

m

rameters (SP, DF

teps.

ill have a differe

n

R

to the side of the

ds the limit to th

e

e dead band. Th

e

e falls below th

e

first device stop

art-up logic confi

g

med at balancin

g

rms.

gulation and rot

a

18

ure (or temperat

ediate reset and

w

eter r20).

and the numbe

r

tial as follows:

P

set point, within

right (measure

d

first device will

s

dead band (me

a

s immediately, w

h

ured and the av

a

the number of

o

tion; the activati

Key:

SP

DF

RP

ure) sensor.

ill only be valid

f

of devices set) t

h

which no device

i

value greater th

a

tart immediately

,

sured value less

t

ile the others w

a

ilability of the de

v

perating hours

a

on/deactivation t

Fan set point

Fan differential

Pressure read

Key:

DOffZ

NZ

DOnZ

DZN

RP

SP

or the specific fa

n

e points where

t

s started or stop

p

n SP + DZN, see

while the others

han the set poin

t

it the delay time

b

ices

nd starts of the

d

resholds are re

-

Device deac

t

Dead band

Device activ

a

Dead band

d

Discharge p

r

Fan set poin

t

. In the default c

o

he devices must

ed.

Figure 5.2). The

will wait the set t

i

), and remains t

h

between stops.

different fans.

-calculated base

ivation zone

tion zone

ifferential

essure read

nfiguration,

switch on and of

f

number of devic

e

me between star

t

ere for a period

e

from actual nu

m

µRack

, inside

s to be

s.

qual to

ber of

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

19

LIFO rotation (no rotation parameter r20=0)

The first fan that to start will be the last to stop.

• Start: Fan1, Fan2, Fan3, Fan4.

• Stop: Fan3, Fan3, Fan2, Fan1.

FIFO rotation (parameter r20=1)

The first fan that to start will be the first to stop.

• Start: Fan1, Fan2, Fan3, Fan4.

• Stop: Fan1, Fan2, Fan3, Fan4.

The rotation of the fans is implemented when called.

Various fan parameters

In the event of a discharge probe fault or not connected alarm, parameter /12 sets the number of fans that are forced on.

5.3 Inverter management

The fan controller is enabled by parameter /10.

A minimum limit value can be set for the inverter (parameter r29), as a percentage.

To assist the start of the inverter, a time can be set, expressed in seconds, during which the inverter is forced on at 100% at startup before proceeding with the normal

regulation. This parameter is called “Speed Up Time” (parameter r27).

Management of the fans slaved to the compressors

Parameter “/13” defines whether the fans can be activated independently or whether at least one compressor must be on. This is used to prevent the condenser fans

operating with high outside temperatures work when no compressor is operating. Typical application: cold rooms cold stores.

Parameter “/13” default = 0 (independent control).

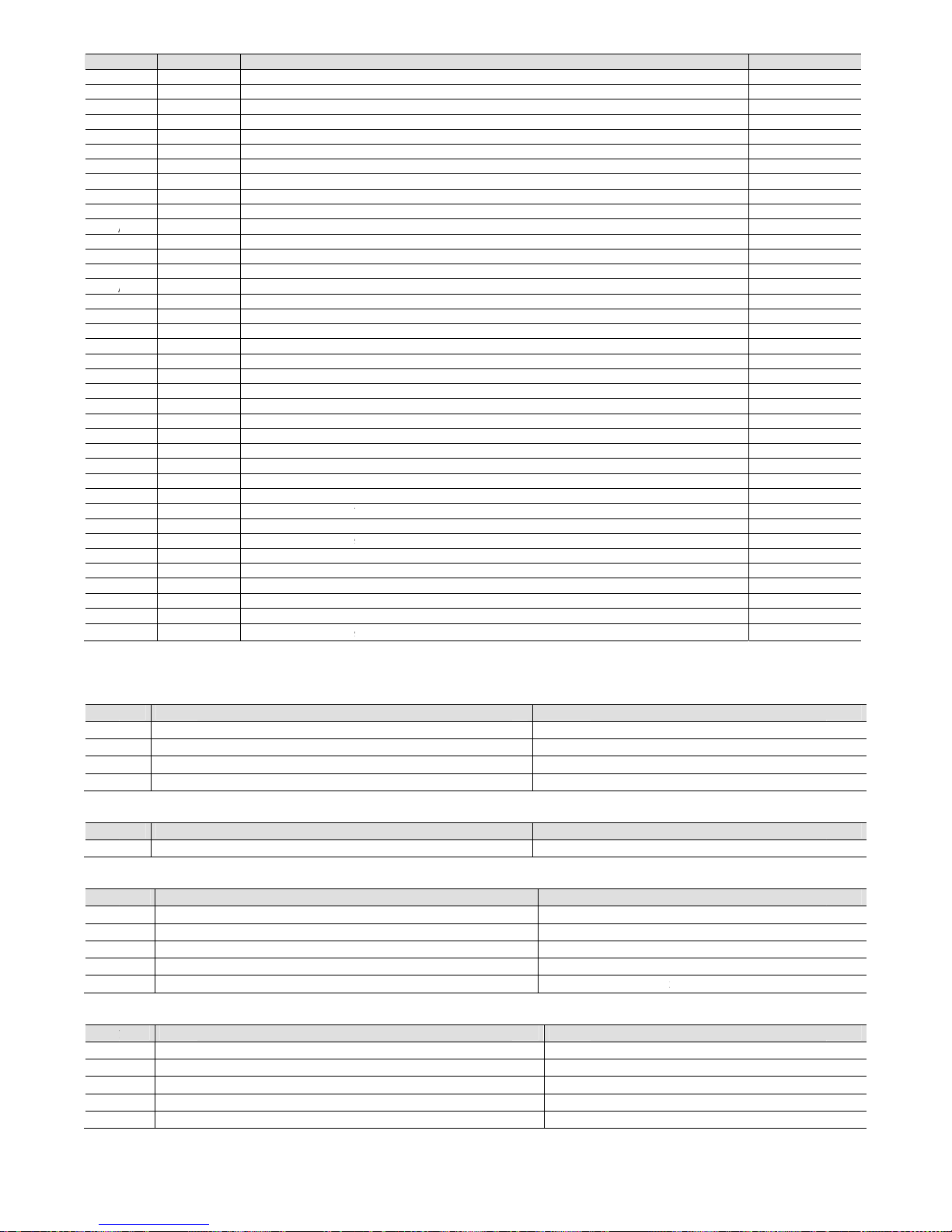

Inverter control

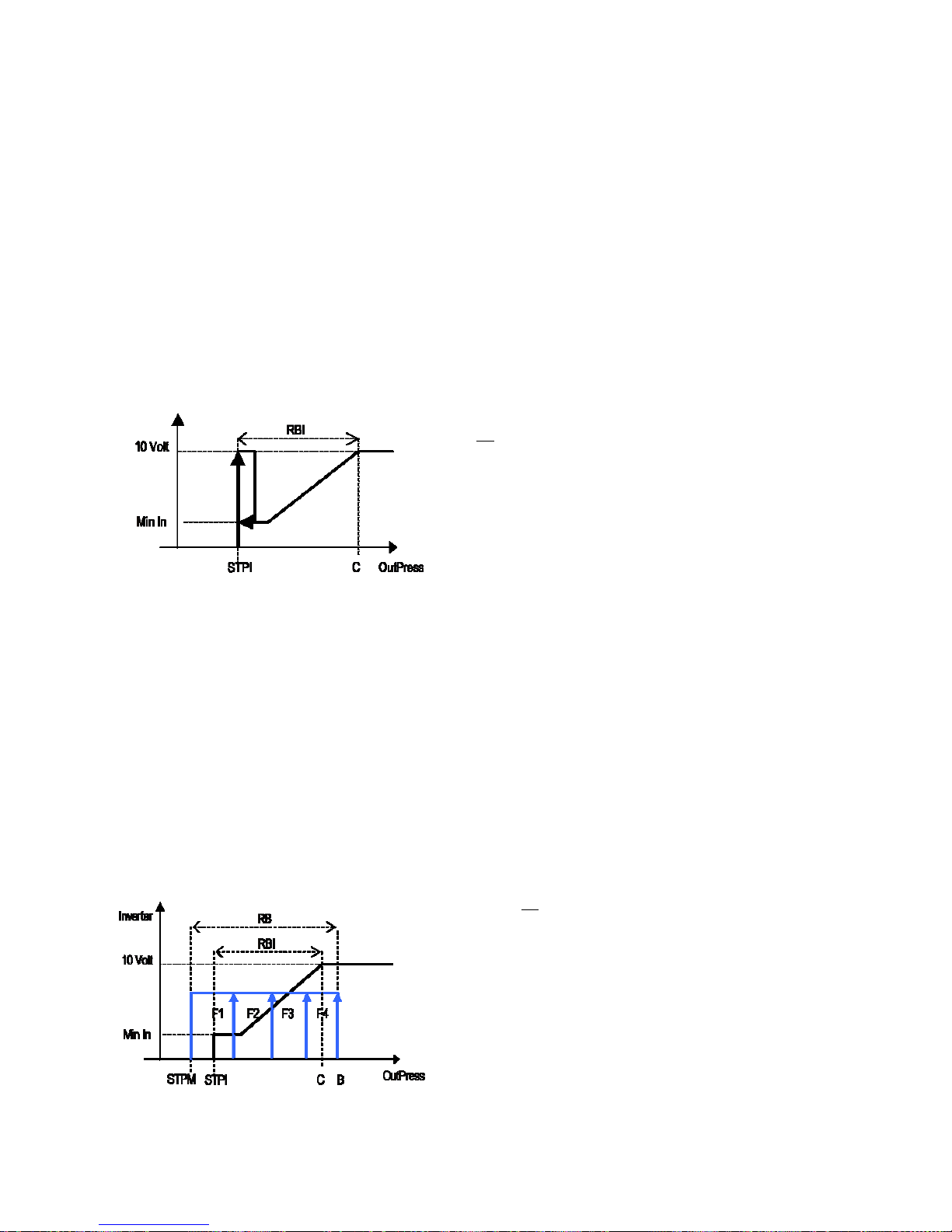

Proportional band

This control requires the inverter set point STPI to be set (parameter r18 ), plus an inverter differential RBI (parameter r19).

If the value measured by the discharge probe is less than or equal to the value of the inverter set point, the inverter output will be 0.

Between the inverter set point STPI and point C (set point + differential), the value of the inverter output will be proportional to the value read by the discharge probe,

and in any case not less than the minimum inverter output MinIn. If the value measured by the discharge probe is greater than or equal to the inverter set point +

differential, the output will be at the maximum value. The control is not associated with any fan and can work without fans being configured.

Proportional control, set by parameter r21, may be proportional only (parameter r21=0) or proportional + integral (parameter r21=1).

Key:

STPI Fan inverter set point

RBI Inverter differential

Min In Minimum inverter opening

C Fan set point + differential

Key:

RB Fan differential

RBI Inverter differential

STPM Discharge set point

STPI Inverter set point

C Inverter set point + inverter differential

B Discharge set point + Fan differential

Min In Minimum value of the inverter control output

Fig.5.d

Fig. 5.c

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

20

Proportional and integral control (PI)

To minimise any deviations in stable operating conditions between the controlled value and the set point, typical of proportional control, a proportional plus integral

strategy (P+I) can be sued.

This strategy helps overcome situations of stalemate in which the working point remains steadily at a value other than the set point.

PI control adds the integral action to proportional control. This action, when a control error persists, has an increasing effect over time on the overall control action.

The parameter that defines the integral action is the integral time (r22).

The default value is 600 s (10 min). The integral time corresponds to the time taken by the integral action, with a constant error, to balance the proportional action.

The lower the integral time, the faster the response of the control.

For further information, refer to classic control theory.

N.B.: Make sure the integral time is not set too low, otherwise control may become unstable.

The following figure highlights the difference between the proportional control and proportional plus integral control (with inverter):

Proportional control Proportional + Integral control

T[s]

SP

RP

T[s]

10 Volt

Min In

T[s]

RP

SP

T[s]

10 Volt

Min In

Fig. 5.e

Key:

RP

Pressure read

SP Set point

T Time

Min In Minimum inverter output value

Dead band control

This control requires the setting of inverter set point, the inverter pressure differential for “dead band” control (parameter r21) and the “inverter ramp up time”

(parameter r28).

Three zones are defined: activation zone DOnZ, dead band NZ and deactivation zone DOffZ, in which the program behaves differently (see the figure).

In the activation zone DonZ, the fans are started as follows:

- The inverter is activated as soon as there is demand, with a value no less than the minimum inverter opening MinIn;

- The inverter output is increased according to the times set by parameter r23.

- If the inverter output reaches 100%, the situation persists

In the dead band NZ, the inverter output does not undergo any variation.

In the deactivation zone DoffZ, the fans are stopped as follows:

- The inverter output is progressively brought to the minimum value, according to the times set by parameter r24.

When reaching the minimum value, the fans are stopped.

Key:

InPress

Discharge pressure

B Set point + differential

StpM HP set point

DOnZ Activation zone

DOffZ Deactivation zone

NZ Dead band

T [s] Time

Inverter Inverter status

NFan Number of fans on

Fig. 5.f

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

21

5.4 PWM-PPM management

On the controller, the “fan control” output generates a PWM signal.

This output is used to drive phase control modules that directly control the fan speed.

The output, depending on how it is configured, can generate a pulse width modulation (PWM) signal.

The example below shows two graphs representing the two modes.

In the graph, it can be seen that the request is 80% of the maximum value.

PWM

V

[5 Volt]

T[s]

80%

Fig. 5.g

The PWM signal controls, for example, the CAREL FCS* series, CONVONOFF, CON0/10A0 modules.

ON/OFF fan control board (code CONVONOFF0)

The CONVONOFF0 modules convert the PWM signal sent from terminal Y to an ON/OFF signal. In practical terms, Y can be used to control a relay. Switching power 10A

at 250 Vac in AC1 (1/3 HP inductive).

PWM to 0 to 10 Vdc (or 4 to 20 mA) conversion board for fans (code CONV0/10A0)

The CONV0/10A0 modules convert the PWM signal sent from terminal Y to a standard 0 to 10 Vdc (or 4 to 20 mA) signal.

Calculation of the minimum and maximum fan speed

This procedure should only be performed if fan speed control boards are used (code MCHRTF*0*0). It must be stressed that if the ON/OFF modules (code

CONVONOFF0) or the PWM / 0 to 10 V converters (code CONV0/10A0) or FCS are used, the “Min. triac” parameter (r29) should be set to zero, and the “Max. triac” r30

parameter to the maximum value is the impulse period (r31)=0.

Given the range of different motors existing on the market, the voltages supplied by the electronic board that correspond to the minimum and maximum speed can be

set. For this purpose (and if the default values are not suitable), proceed as follows:

1. Set the fan inverter to always On. Force inverter parameter, M17.

2. Set “Max triac” and “Min triac” to zero.

3. Increase “Max triac” until the fan operates at a speed considered sufficient (make sure that, after having stopped it, it starts rotating if left free);

4. “Copy” this value to the “Min triac” parameter; this sets the voltage corresponding to the minimum speed;

5. Connect a voltmeter (set for 250 V, AC) between the two “L” terminals (the two external contacts).

6. Increase “Max triac” until the voltage stabilises at around 2 Vac (inductive motors) or 1.6, 1.7 Vac (capacitive motors);

7. Once the optimum value is found, it should be seen that even when increasing “Max triac”, the voltage no longer decreases.

8. Do not increase “Max triac” any further, so as to avoid damaging the motor;

9. Set the force inverter parameter back to AUTO.

The operation is now complete.

5.5 Floating condenser control

If this function is enabled using parameter r32, the following parameters need to be set.

a) DELTA T (r33) (condenser exchanger parameter, typically related to the type of exchanger used)

b) Minimum condensing pressure (r25 in °C)

c) Maximum condensing pressure (r26 in °C)

The condenser set point is the value resulting from “DELTA T + Outside air temperature”, as with high outside temperatures the condensing temperature cannot be too

low (no possibility of energy savings). This is used to optimise the operation of the fans. The maximum and minimum pressure values are the range in which floating

control can operate.

ATTENTION: enabling this controller, the parameters “r16” (ventilation set) and “r18” (inverter ventilation set) are no more visibile since the relevant set point become

function of the external temperature + delta.

The following parameter are displayed in temperature always, not depending by used probe (pressure or temperature):

r17 (

Set the minimum value of suction probe)

r19 (

Fan inverter differential)

r25 (

Set the lower limit of the fan set point)

r26 (l Set the upper limit of the fan set point)

Cod.

C

6

6.1

The in

param

The o

n

The m

W

hen

If swit

c

Impo

r

6.2

Param

This p

a

Param

These

Param

The c

o

6.3

This f

u

An off

s

The o

f

6.4

By sel

e

The fo

6.5

The s

o

The t

w

No.

1

2

If the

a

Exam

p

AREL +03P22

0

V

arious s

e

Manual

d

dividual devices

c

eters Mxx.

ly support provi

d

anual activation

o

even just one m

a

hing the board o

f

tant: Use this fu

n

Compres

eter C07 is used

t

rameter is expre

s

eters C08 C10 C

1

parameters are a

l

eters C09 C11 C

1

mpressor maint

e

Set poin

t

nction is useful

w

et is added to th

e

fset can be defin

e

Type of

r

cting the type of

llowing table lists

Auxiliar

y

ftware can mana

g

o probes can be

Channel

N

B2 -

r

-

a

B3 -

o-a

uxiliary probe se

l

le of HT alarm

m

A

larm O

F

431 rel. 2.2 date

ttings

evice ope

r

an be activated

m

ed in manual op

e

f the speed cont

r

nual procedure i

s

ff and on again, t

h

nction with care

!

sor hour c

o

o set the alarm t

h

sed in the hund

r

12 C14 are used

t

so expressed in t

13 C15 are used

t

nance alarm is s

h

variation

hen needing to i

n

compressor set

d using paramet

e

efrigerant

refrigerant used i

the types of gas

m

probe ma

e two auxiliary t

e

configured with

p

TC probe

oom temperatur

e

uxiliary probe

utside temperat

u

uxiliary probe

ected, a high te

m

anagement

Fig. 6.

a

F

Set Poi

Diff. 2°

C

d 10/02/12

ation

anually, ignorin

g

ration is the alar

m

ollers sets the co

r

enabled, the “M

e function is ter

m

Operating the

d

unter an

d

reshold for the

m

eds of hours, as t

t

o check the nu

m

he tens of hours,

t

o reset each indi

v

own by an alarm

from digit

a

crease or decre

a

point when the

m

r R34.

n the installation

(

anaged:

Refrigera

n

R134a

R290

R600

R600a

R717

R744

R404A,R4

0

nagement

mperature prob

e

arameters /21 a

n

probe, read-onl

y

re probe for Floa

perature thresho

l

nt

A

larm O

N

the times and t

h

management f

u

responding outp

u

A

NUFACTURER”

i

inated.

evices manuall

y

maintena

n

aintenance of th

e resolution of t

h

ber of operating

h

as the resolution

idual hour coun

t

code, as well as

b

l input

se the set point

d

ultifunction inpu

t

parameter /35),

t

t

7C,R410A,R507

C

s, in addition to t

h

d /22:

t

ing condenser c

o

d can be set (par

temperature

22

e rotation, and i

unction.

ts to the maxim

u

con on the displ

a

may cause da

m

ce alarm

e 4 compressors.

he display is only

ours of the com

p

of the display is

o

er.

y the simultane

o

uring night-time

o

t, set for this fun

c

he software will

a

C

oTePrBu2-

AmCa M

Tab. 6.a

he suction and di

ntrol

Tab. 6.b

ameter A16, A17

ndependently fro

m value.

y will FLASH!

age to the insta

3 digits.

ressors installed

.

nly 3 digits.

us activation of t

h

peration.

tion, is closed.

utomatically calc

u

mplete name

trafluoroethane

opane

tane

methyl propane

(

monia (NH3)

rbon dioxide (C

O

ixes of gases

scharge probes.

)

. This alarm has

a

m the temperatu

r

llation!

e Maintenance a

late the conversi

o

isobutane)

2)

utomatic reset,

w

re control functio

nd Alarm icons.

on of the pressur

e

ith a fixed differ

e

ns, by setting the

to temperature.

ntial of 2°C.

µRack

related

µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

23

6.6 Prevent high discharge pressure

This function is enabled by parameter /32.

In order to prevent the activation of the general high pressure switch (total shutdown of the compressors, with manual reset), a “prevention” function can be enabled by

setting a pre-alarm threshold; this function gradually decreases the capacity of the unit.

The high pressure prevention (Prevent HP) function is only enabled during the activation and deactivation of the compressors.

If the discharge pressure exceeds the threshold set (parameter /33), the activation of any compressors is disabled and a prevent alarm is generated. In addition, all the

compressor load steps are deactivated, observing the times set for parameter C06.

If the discharge pressure falls below the Prevent threshold, any other compressor start calls are ignored, for a set time called Prevent time 1 (parameter A13).