Integrated Control Solutions & Energy Savings

MCmultizone

atomising humidi ers

User manual

3

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

WARNINGS

CAREL S.p.A. humidifi ers are advanced products, whose operation is specifi ed

in the technical documentation supplied with the product or can be

downloaded, even prior to purchase, from the website www.carel.com. Each

CAREL S.p.A. product, in relation to its advanced level of technology, requires

setup/confi guration/programming/commissioning to be able to operate in

the best possible way for the specifi c application. The failure to complete such

operations, which are required/indicated in the user manual, may cause the

fi nal product to malfunction; CAREL S.p.A. accepts no liability in such cases.

The customer (manufacturer, developer or installer of the fi nal equipment)

accepts all liability and risk relating to the confi guration of the product in

order to reach the expected results in relation to the specifi c fi nal installation

and/or equipment. CAREL S.p.A. may, based on prior agreements, act as a

consultant for the installation/commissioning/use of the unit, however in no

case does it accept liability for the correct operation of the humidifi er and the

fi nal installation if the warnings or suggestions provided in this manual or in

other product technical documents are not heeded. In addition to observing

the above warnings and suggestions, the following warnings must be heeded

for the correct use of the product:

• DANGER OF ELECTRIC SHOCK

The humidifi er contains live electrical components. Disconnect the mains

power supply before accessing inside parts or during maintenance and

installation.

• DANGER OF WATER LEAKS

The humidifi er automatically and constantly fi lls/drains certain quantities of

water. Malfunctions in the connections or in the humidifi er may cause leaks.

Important

Important:

• The installation of the product must include an earth connection, using the

special yellow-green terminal available in the humidifi er.

• The environmental and power supply conditions must conform to the

values specifi ed on the product rating labels.

• The product is designed exclusively to humidify rooms either directly or

through distribution systems (ducts, atomising racks).

• Only qualifi ed personnel who are aware of the necessary precautions and

able to perform the required operations correctly may install, operate or

carry out technical service on the product.

• For the production of atomised water, only use water with the characteristics

specifi ed in this manual. Important, demineralised drinking water must be

used (as specifi ed in the manual). In addition, the particles of water that are

not absorbed by the air must be removed using the droplet collection tank

(in the humidifi cation section) and the droplet separator (at the end of the

humidifi cation section).

• All operations on the product must be carried out according to the

instructions provided in this manual and on the labels applied to the

product. Any uses or modifi cations that are not authorised by the

manufacturer are considered improper. CAREL S.p.A. declines all liability for

any such unauthorised use.

• Do not attempt to open the humidifi er in ways other than those specifi ed

in the manual.

• Observe the standards in force in the place where the humidifi er is

installed.

• Keep the humidifi er out of the reach of children and animals.

• Do not install and use the product near objects that may be damaged when

in contact with water (or condensate). CAREL S.p.A. declines all liability for

direct or indirect damage following water leaks from the humidifi er.

• Do not use corrosive chemicals, solvents or aggressive detergents to clean

the inside and outside parts of the humidifi er, unless specifi cally indicated

in the user manual.

• Do not drop, hit or shake the humidifi er, as the inside parts and the linings

may be irreparably damaged.

CAREL S.p.A. adopts a policy of continual development. Consequently, CAREL

reserves the right to make changes and improvements to any product

described in this document without prior warning. The technical specifi cations

shown in the manual may be changed without prior warning.

The liability of CAREL S.p.A. in relation to its products is specifi ed in the

CAREL S.p.A. general contract conditions, available on the website www.

carel.com and/or by specifi c agreements with customers; specifi cally to the

extent where allowed by applicable legislation, in no case will CAREL S.p.A.,

its employees or subsidiaries be liable for any lost earnings or sales, losses

of data and information, costs of replacement goods or services, damage to

things or people, downtime or any direct, indirect, incidental, actual, punitive,

exemplary, special or consequential damage of any kind whatsoever, whether

contractual, extra-contractual or due to negligence, or any other liabilities

deriving from the installation, use or impossibility to use the product, even if

CAREL S.p.A. or its subsidiaries are warned of the possibility of such damage.

DISPOSAL

The humidifi er is made up of metal parts and plastic parts. In reference to

European Union directive 2002/96/EC issued on 27 January 2003 and the

related national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and such waste must be

collected and disposed of separately;

2. the public or private waste collection systems defi ned by local legislation

must be used. In addition, the equipment can be returned to the distributor

at the end of its working life when buying new equipment;

3. the equipment may contain hazardous substances: the improper use or

incorrect disposal of such may have negative eff ects on human health and

on the environment;

4. the symbol (crossed-out wheeled bin) shown on the product or on the

packaging and on the instruction sheet indicates that the equipment has

been introduced onto the market after 13 August 2005 and that it must

be disposed of separately;

5. in the event of illegal disposal of electrical and electronic waste, the

penalties are specifi ed by local waste disposal legislation.

Warranty on materials: 2 years (from the date of production, excluding

consumables).

Approval: the quality and safety of CAREL S.P.A. products are guaranteed by

the ISO 9001 certifi ed design and production system, as well as by the

mark..

5

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

Content

6.6 Scheduled set points ......................................................................................23

7. INSTALLER MENU 24

7.1 Type of control ....................................................................................................24

7.2 Probe confi guration.........................................................................................24

7.3 Operating options ...........................................................................................24

7.4 Special functions ...............................................................................................24

7.5 Supervisor ..............................................................................................................25

7.6 External alarms ....................................................................................................25

7.7 pLAN confi guration .........................................................................................25

8. MAINTENANCE MENU 26

8.1 Reset confi gurations .......................................................................................26

8.2 System information (read only) ................................................................26

8.3 Manual procedure ............................................................................................26

8.4 Hour counter ........................................................................................................26

8.5 Alarm log ................................................................................................................26

9. TABLE OF ALARMS 27

10. ADVANCED FUNCTIONS 28

10.1 Wiring diagrams ..............................................................................................28

10.2 Operating principle .......................................................................................32

10.3 Control principles ...........................................................................................32

10.4 Pressure control ...............................................................................................34

10.5 Drain/fi ll ...............................................................................................................34

10.6 Periodical washing of the water line .................................................34

10.7 Automatic cleaning of the atomising heads .................................34

10.8 Pressure overboots ........................................................................................34

11. GENERAL CHARACTERISTICS OF THE

DISTRIBUTION SYSTEM 36

11.1 Atomising head ...............................................................................................36

11.2 Assembly kit .......................................................................................................36

12. DESIGNING A SYSTEM 37

12.1 Sizing an MC system .....................................................................................37

12.2 Sizing the compressor .................................................................................37

12.3 Sizing air/water lines between cabinet & distribution

system ..............................................................................................................................37

13. INSTRUCTIONS FOR INSTALLATION IN ROOMS 39

13.1 Tips for correct installation .......................................................................39

13.2 Assembling the atomising head ...........................................................39

13.3 Positioning the humidity probes ..........................................................39

13.4 Important rules to be followed .............................................................39

14. INSTRUCTIONS FOR INSTALLATION IN DUCTS 41

14.1 Positioning the atomisation manifold ...............................................41

14.2 Important rules to be followed .............................................................42

14.3 Positioning the humidity probes ..........................................................42

14.4 Manifolds for installation in ducts ........................................................42

15. MAIN ADJUSTMENTS 43

1. INTRODUCTION AND ASSEMBLY 7

1.1 MCmultizone atomising humidifi er .........................................................7

1.2 Models ........................................................................................................................7

1.3 Dimensions and weights ...............................................................................7

1.4 Components ..........................................................................................................8

1.5 Electrical specifi cations.....................................................................................8

1.6 Opening the packaging ..................................................................................8

1.7 Positioning the cabinet ....................................................................................8

1.8 Wall mounting........................................................................................................8

1.9 Opening the cabinet door .............................................................................9

1.10 Components and accessories ..................................................................9

2. WATER AND AIR CONNECTIONS 10

2.1 Characteristics of the water line ...............................................................11

2.2 Type of supply water ......................................................................................11

2.3 Characteristics of the air line ......................................................................11

2.4 Type of compressed air ..................................................................................11

2.5 Type of water and air lines ...........................................................................11

2.6 Water and air line accessories ....................................................................11

3. ELECTRICAL CONNECTIONS 12

3.1 Power supply .......................................................................................................13

3.2 Remote ON/OFF (ID & COM) ......................................................................13

3.3 Modulating control signal (J24 & J2) .....................................................13

3.4 Control signals from ext. voltage-free contact i.e. ON/OFF

humidistat (ID & COM) ...........................................................................................14

3.5 Control signals from air line pressure transducer (J2) ................15

3.6 Connection of NO drain solenoid valve at end of water line

(group of ID terminals) ...........................................................................................15

3.7 External utility control (J13) ........................................................................15

3.8 Cumulative alarm relay (J14) ......................................................................15

3.9 Alarm inputs from external devices.......................................................16

3.11 Enable wash water line on external signal .....................................16

3.12 Supervisor network .......................................................................................16

3.13 Proportional 0 to 10 Vdc output ...........................................................16

4. MASTER/SLAVE APPLICATIONS 17

4.1 Applications for one large space or AHU (single point) ............17

4.2 Applications for multiple spaces or AHUs (multizone) .............17

4.3 Setting the serial address for units with multiple slaves ...........17

4.4 pLAN network connection (J11) ..............................................................18

5. STARTING AND USER INTERFACE 19

5.1 Starting ....................................................................................................................19

5.2 Stopping .................................................................................................................19

5.3 First start-up (setting the language) ......................................................19

5.4 Keypad ...................................................................................................................19

5.5 “Main” screen......................................................................................................... 19

5.6 “INFO” screens (read-only) ............................................................................20

5.7 “SET” screen ........................................................................................................... 20

5.8 “pLAN” screen .......................................................................................................20

5.9 Main menu ...........................................................................................................21

6. USER MENU 22

6.1 Alarm thresholds ...............................................................................................22

6.2 Clock ........................................................................................................................22

6.3 Enable scheduler ...............................................................................................22

6.4 Set scheduler .......................................................................................................22

6.5 Weekly scheduler ..............................................................................................22

16. MAINTENANCE 44

16.1 Maintenance procedures ..........................................................................44

16.2 Kits & optional accessories for the air/water line (see chap. 2) ........44

16.3 Kits & optional accessories for the atomising heads

(see chap. 11) ...............................................................................................................44

16.4 Spare parts for air/water line (see paragraph 1.4) ......................45

16.5 Pre-programmed pCO

3

controllers .....................................................46

16.6 Electrical panel kit and spare parts (see paragraph 1.4) .........46

17. TROUBLESHOOTING 47

17.1 Troubleshooting table .................................................................................47

7

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

1. INTRODUCTION AND ASSEMBLY

1.1 MCmultizone atomising humidi er

Humidifi cation system designed for medium/large installations, where are

a large humidifi cation capacity is required with low energy consumption

(high water fl ow without excessive energy costs).

Water and air, suitably regulated in terms of fl ow-rate and pressure, are

delivered to the atomising nozzles in two separate lines. Due to the

special shape of the nozzles, the jet of water is nebulised into a mist of

very fi ne droplets (5 to 8 microns).

The atomised water can then easily change state and vaporise. The

energy required for this transformation is supplied by the ambient air.

For each litre/hour of water that vaporises, in fact, the environment

gives up around 590 kcal (149 SkJ) of energy. Consequently, there is a

decrease in temperature in the environment being humidifi ed, and this

process may be useful in many applications (adiabatic cooling). A timed

automatic system ensures the atomising nozzles are cleaned periodically,

preventing debris or scale from causing malfunctions.

Each atomising head is fi tted with a small piston for cleaning any deposits,

whenever the control cabinet stops operating. The system guarantees

optimal atomisation at all times and prevents dripping when the

installation is off . The electronic controller ensures the ambient humidity

is kept at the required value, showing the relative humidity read in the

room on the display.

The MCmultizone system is essentially made up of: control cabinet and

compressed air-water supply, atomising nozzles, nozzle assembly kit.

1.2 Models

The MCmultizone humidifi ers are available by:

• size: with maximum fl ow-rate of 60 l/h (MC060*), or 230 l/h (MC

models230*);

• type of capacity modulation: ON/OFF (MC models***C*), or

proportional (MC models***H*);

• power supply: single-phase 230 Vac 50 Hz (MC models****D*), or 110

Vac 60 Hz (MC models****1*);

• version: Master (MC models*****M*), or Slave (MC models*****S*);

• type of water used: mains, drinking (MC models*********0), or

demineralised/aggressive (MC models*********1).

Models recommended for speci c applications:

• for duct applications (or air handling units), proportional units with

high humidity limit probe are recommended.

• for applications directly in the room, both ON/OFF and proportional

control units are recommended

1.3 Dimensions and weights

Front view

500 28

580

Air Inlet

Water Inlet

Air Outlet

Water Outlet

Water Drain

Electric Intlet

Electric Intlet

Electric Intlet

224

detail of the cabinet, side view,

water and air inlet

detail of the cabinet, side view,

outlet (to nozzles)

150 8

303030

40110

101

4182

50100

150

123

224

123 101

50

224

Packaging dimensions:

• height (H): 770 mm (30.14 inch);

• width (W ) 605 mm (23.82 inch);

• depth (D) 255 mm (10.00 inch).

Packaged humidi er weight:

• models MC**H(D,1)*0*: 21 kg (46.3 lb);

• models MC**C(D,1)*0*: 20.5 kg (45.2 lb).

Installed humidi er weight:

• models MC**H(D,1)*0*: 19.5 kg (43 lb);

• models MC**C(D,1)*0*: 19 kg (42 lb).

Mechanical speci cations:

• Installation: wall mounting;

• IP40;

• cabinet operating conditions: 1 to 40 °C (34 to 104 °F) <80 % rH non-

condensing;

• storage conditions: 1 to 50 °C (34 to 122 °F) <80 % rH non-

condensing.

8

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

1.4 Components

16

1 3

5

42

11 12 13 14 15

10

86

7

9

Key:

1. Electronic controller

2. Terminal (Master version only)

3. Transformer (CAREL code MCKTR00000)

4. Modulating valve regulator (modulating version only, CAREL code

MCKARVA000)

5. Terminal block (fuse kit MCKFUSE000)

6. Air inlet pressure gauge

7. Air pressure regulator/regulator

8. NC air solenoid valve

9. Air line pressure switch (ON/OFF versions only)

10. Air outlet pressure gauge

11. Water inlet pressure gauge

12. Water pressure regulator

13. NC water solenoid valve

14. Water outlet pressure gauge

15. NO water drain solenoid valve

16. Power supply 110/230 Vac 12 Vdc 0.5 A (modulating version only,

CAREL code MCKAL00000)

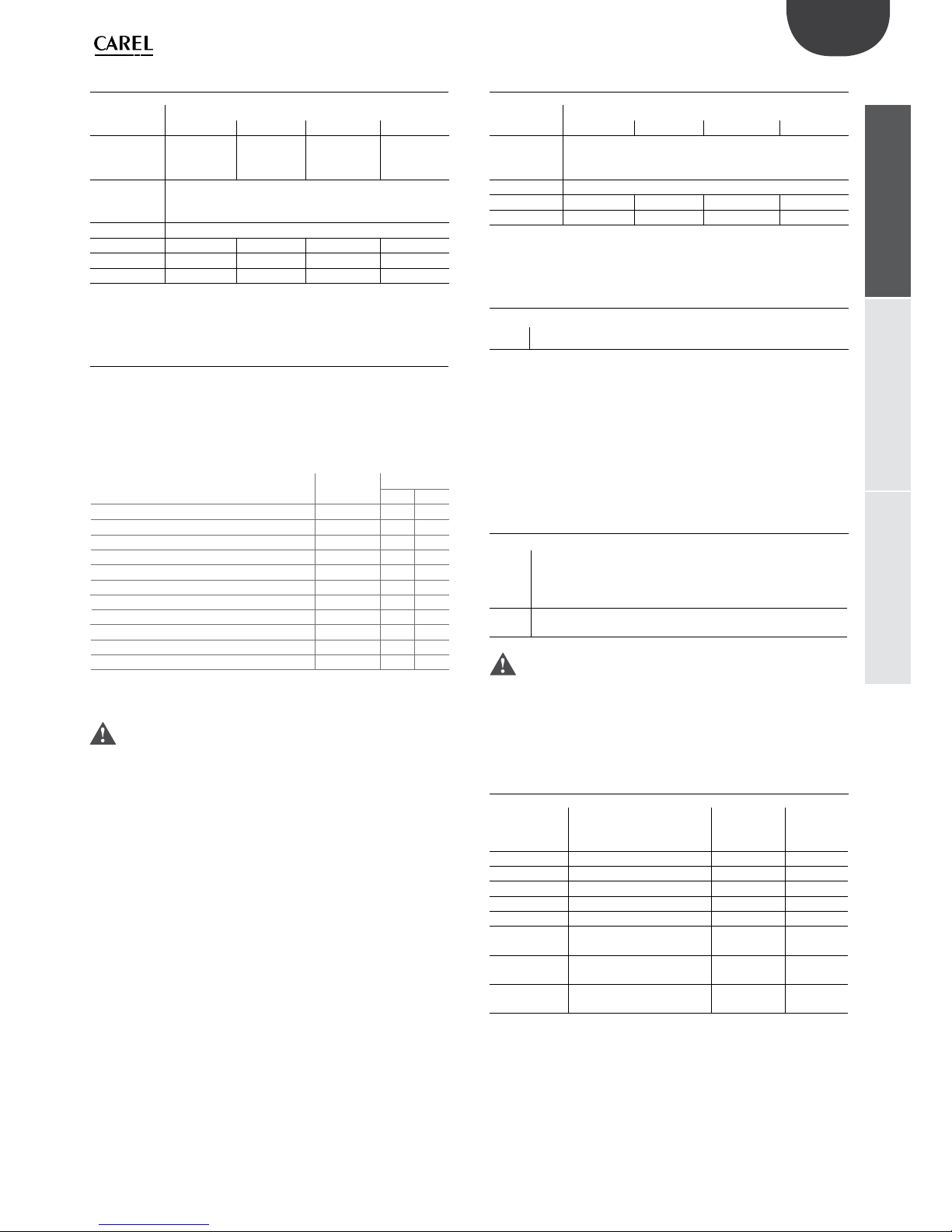

1.5 Electrical speci cations

Models MC****D*** (230 V 50 Hz)

(1)

MC***CD*00 MC***CD*01 MC***HD*00 MC***HD*01

Vac

phases

Hz

230 V

1

50/60 Hz

230 V

1

50 Hz

230 V

1

50/60 Hz

230 V

1

50 Hz

Power 37 W 44 W 41 W 48 W

Current 0.26 A 0.29 A 0.30 A 0.33 A

(1)

Product in compliance with EN55014, EN61000, EN60335

Models MC****1*** (110 V 60 Hz)

(1)

MC***C1*00 MC***C1*01 MC***H1*00 MC***H1*01

Vac

phases

Hz

110 V

1

60 Hz

Power 37 W 44 W 41 W 48 W

Current 0.54 A 0.60 A 0.64 A 0.70 A

(1)

Product approved to UL998 & CSA C22.2 No104

1.6 Opening the packaging

make sure the humidifi er is intact upon delivery and immediately

notify the transporter, in writing, of any damage that may be due to

careless or improper transport;

move the humidifi er to the site of installation before removing from

the packaging, grasping the neck from underneath;

open the cardboard box, remove the protective material and remove

the humidifi er, keeping it vertical at all times.

1.7 Positioning the cabinet

The humidifi er should be positioned so as to guarantee the following:

reading the values on the display;

access to the keypad on the display;

opening the front panel;

access to the inside parts for checks and maintenance;

connection of the air and water supply lines;

connection of the air and water distribution lines;

power and control connections;

Important

Important: the drain hose must be connected directly to a drain

located at least 50 mm below the level of the atomising nozzles

1.8 Wall mounting

Fasten the humidifi er to a solid support surface using the screws and

bracket supplies.

Make sure there is enough space to connect the air and water inlet and

outlet lines.

390

9

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

rear of the cabinet

200

440

drilling template

440

200

390

= =

= =

1.9 Opening the cabinet door

1. press and turn anticlockwise using a fl at-head screwdriver (max 8

mm) until releasing the door;

2. open the door on the cabinet by swinging to the left.

1

2

1.10 Components and accessories

Once having opened the front cover of the humidifi er, make sure the

following are included:

kit of screws with

plugs for wallmounting;

PG13 cable glands for the electrical

connections

10

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

2. WATER AND AIR CONNECTIONS

Important: before proceeding, disconnect the humidifi er from

the power supply.

--RILSAN PA1

1 O 6 8 x 6 DIN 74324 AIM 29 --

--RILSAN PA1

1 O 6 8 x 6 DIN 74324 AIM 29 --

--RILSAN

PA1

1 O 6 8 x 6 DIN 74324 AIM

29 --

11

12

13

13

14

1

2

3

4

1

5

6

6

7

8

9

Air

Water

10

Connections:

1. Install two manual valves upstream of the installation to allow the

air and water lines to be isolated (not supplied by CAREL).

2. Install an oil fi lter (CAREL code MCFILOIL01) to remove particles of

oil from the compressed air

3. Install a 5 micron air fi lter (CAREL code MCFILAIR01) upstream of the

cabinet to solid particles from the compressed air.

4. Install a 5 micron water fi lter (CAREL code MCC05PP005 and the

fi lter casing code MCFILWAT05) to remove solid particles from the

supply water.

5. Optional: install a UV lamp to sanitise the water (CAREL code

MCKSUV00000). The lamp has an external 230 V 50 Hz power supply.

These UV lamps are used to eliminate any bacteria from the supply

water.

6. Install the air and water lines

7. Prepare a hose at least 50 mm below the level of the atomising

nozzles to drain the water remaining in the lines when the installation

is in standby or off .

8. Atomising nozzle assembly kit for rooms and ducts (CAREL code

MCK1AW0000)

9. Atomising nozzles (for the models see par. 11)

10. Optional, install one of the following components:

• pressure gauge at the end of the air line (CAREL kit code

MCKMA04000) to display the pressure at the end of the line;

• a pressure probe at the end of the line (for the codes of the probes

see Chap. 16.2 “Maintenance“) to measure and display the pressure

at the end of the line on the humidifi er display

11. Install the humidity probes (for the codes of the CAREL probes see

Chap. 16.2 “Maintenance“)

12. Install a manual valve at the end of the air line.

13. Install one of the following two valves:

• manual valve at the end of the line (not supplied by CAREL).

• drain solenoid valve (CAREL code MCKDVWL000 or code

MCKDVWL001) to perform the “drain”, “fi ll”, and “washing” functions

(see par. 10.5 “Operating principles”).

14. Optional, install a pressure gauge at the end of the water line

(CAREL code. kit MCKMW02501) to display the pressure at the end of

the water line

Fittings provided for the water connections:

side view, water & air inlet side view, outlet (to nozzles)

1

2

1

2

3

Key:

1. air inlet and outlet

2. water inlet and outlet

3. drain water outlet

11

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

2.1 Characteristics of the water line

Models

MC060*D*0* MC060*1*0* MC230*D*0* MC230*1*0*

max owrate (l/h, lb/h,

G/d)

60 l/h

130 lb/h

380G/d

60 l/h

130 lb/h

130 lb/h

230 l/h

500 lb/h

1450 G/d

230 l/h

500 lb/h

1450 G/d

inlet pressure

(Mpa,Bar,PSI)

0.3 to 0,7 Mpa

3 to 7 Bar

40 to 100 PSI

temperature

1 to 50 ºC / 34 to 122 ºF

inlet

G1/2”F NPT1/4”F G1/2”F NPT1/4”F

outlet

G1/2”F NPT1/2”F G1/2”F NPT1/2”F

drain

TCF 8/10 NPT1/4”F TCF 8/10 NPT1/4”F

2.2 Type of supply water

☺

demineralised water by osmosis;

drinking water ((however more dust in the room

and more frequent maintenance and cleaning the nozzles);

softened water

(the mineral content dissolved in the water is not reduced).

recommended supply water characteristics unit of

measure

limits

min. max.

pH 6.5 8.5

Specifi c conductivity at 20 °C (

σ

R, 20 °C

)

µS/cm 0 50

Total hardness (TH) mg/l CaCO

3

025

Temporary hardness mg/l CaCO3015

Total dissolved solids (cR) mg/l (1)(1)

Dry residue at 180° (R180°C) mg/l (1)(1)

Iron + Manganese mg/l Fe+Mn 0 0

Chlorides ppm Cl 0 10

Silicon dioxide mg/l SiO

2

01

Chlorine ions mg/l Cl

-

00

Calcium sulphate mg/l CaSO

4

05

(

1

)= values depend on the specifi c conductivity; in general:

C

R

≅0,65 * σ

R, 20 °C

; R

180

≅0.93 * σ

R, 20 °C

Important: the supply water must comply with the requirements of

UNI 8884 UNI 8884 standard, “Characteristics and treatment of the water

in cooling and humidifi cation circuits”. According to this standard, the

humidifi er must be supplied with water that, as well as being drinkable

(EC directive 98/83), must remain within the following limits:

• electrical conductivity <100 µS/cm;

• total hardness <5 °fH (50 ppm CaCO3);

• 6.5 < pH < 8.5;

• chloride content <20 mg/l;

• silica content <5 mg/l;

• conductivity less than 30 µS/cm (it is recommended to use the MC

cabinet in the version for aggressive water).

Similar requirements are also specifi ed in the European reference

standards VDI6022, VDI3803.

Upstream of the cabinet, connect the following to the water line:

• a water fi lter with a fi lter size no greater than 5 microns (fi lters available

upon request).

• an expansion vessel (not supplied by Carel SpA) with a capacity of several

litres, to avoid water hammer that may damage the installation.

The water line is tested, and checked at a pressure of 0.35 bars downstream

of the cabinet.

2.3 Characteristics of the air line

Models

MC060*D*0* MC060*1*0* MC230*D*0* MC230*1*0*

inlet

pressure

(Mpa,Bar,PSI)

0.5 to 0.7 Mpa

5 to 7 Bar

80 to 100 PSI

temperature

1 to 50 ºC / 34 to 122 ºF

inlet

G1/2”F NPT1/2”F G1/2”F NPT1/2”F

outlet

G1/2”F NPT1/2”F G1/2”F NPT1/2”F

2.4 Type of compressed air

YES

dry and oil-free air

Upstream of the cabinet connect the following devices (available upon

request):

• a 5 micron fi lter upstream of the cabinet.

• a fi lter to remove oil and particles upstream of the 5 micron air fi lter

The air line is tested, and checked at a pressure of 2.1 bars downstream

of the cabinet.

2.5 Type of water and air lines

YES

copper pipes (mains drinking water only),

plastic hoses,

polypropylene hoses: ensure faster and simpler connections by

welding.

NO

galvanised steel pipe: may lead to the detachment of impurities,

and cause blocking or damage to the nozzles.

Important: Apply sealant to the joints of the pipes and hoses

running to the atomising nozzles (preferably Tefl on or liquid Tefl on).

2.6 Water and air line accessories

code description ttings reference

dwg.

page 10

MCFILOIL01 3/8” oil fi lter for air G3/8”F in /out 2

MCFILAIR01 1/2” air fi lter G1/2”F in /out 3

MCFILWAT05 5” water fi lter container G1/2”F in /out 4

MCKSUV0000 UV sanitising kit G1/4”F in /out 5

MCKPT**000 pressure transducer G1/4”M 10 a

MCKMA04000 air outlet pressure gauge 0

to 4 bars

G1/4”M 10 b

MCKDVWL00* NO solenoid valve at end

of line

G1/4”F in /out 13

MCKMW02501 water outlet pressure gauge

0 to 2.5 bars

G1/4”M 14

12

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

3. ELECTRICAL CONNECTIONS

Wiring

Important:

• make sure that the cable glands are applied;

• to avoid interference, separate the power cables from the probe/external

signal cables.

J2

Control signals from humidity/

temperature probes, external controller

& air line pressure transducer

Power supply

Important: install a power switch outside the humidifi er to completely

isolate the mains power supply.

J13

External utility control

Digital Input

Control signals from external voltage-free contact i.e. ON/OFF humidistat

alarm input from external devices

enable wash water line from external signal

J14

Cumulative alarm relay

J11

Connection for master/slave communication networks (pLAN) External supervisor systems

J24

Power supply for humidity/temperature probes and references for external

controllers

Proportional 0 to 10 Vdc output

pCO3 terminal block

service card

NO8

C7

C4

C1

C8

NO7

NO4

NO1

NC8

C7

NO5

NO2

NO6

NO3

C4

C1

Rx-/Tx-

Rx+/Tx+

GND

J9 J10

J11

J12 J13 J14 J15

J5

J4

J3J2

J1

serial card

field card

ID1

ID2

ID3

ID4

ID5

ID6

ID7

ID8

IDC1

VG

VG0Y1Y2Y3Y4

B4

BC4B5BC5

B1B2B3

J24

+V term

GND

+5V

ref

GND

+VDC

G

G0

max. power: 40 VA / 15 W

1

0

ON

J5

J4

J3J2J1

serial card

field card

service card

J24

J9 J10

J11

J12 J13 J14 J15

J2 J4J24

J10 J13 J14J9 J11

13

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

3.1 Power supply

Depending on the model:

MC****D*** voltage 230V 1~ 50Hz

MC****1*** voltage 110V 1~ 60Hz

Important: The cables must be shielded and conform to local

standards. Install a power switch outside the humidifi er to completely

isolate the mains power supply.

G0

NO4

L

N/W

GR

G0

NO4

ID1

ID1

ID2

ID2

ID3

ID3

ID4

ID4

ID6

ID6

ID7

ID7

COM1

COM1 COM2

COM2

COM3

COM3

F1 1A

F2 1A

L

N/W

GR/PE

Connections:

MC cabinet Power cable

L L/F (phase)

N N/W (neutral)

GR GR/PE (earth)

3.2 Remote ON/OFF (ID & COM)

Use two-wire shielded cable, AWG20/22

G0

NO4

L

N/W

GR

G0

NO4

ID1

ID1

ID2

ID2

ID3

ID3

ID4

ID4

ID6

ID6

ID7

ID7

COM1

COM1 COM2

COM2

COM3

COM3

F1 1A

F2 1A

1

1

Remote ON/OFF

Connections:

MC cabinet Remote ON/OFF

ID1 NC/NO

COM (1 or 2 or 3) CON

GR shield

3.3 Modulating control signal (J24 & J2)

The input control signal connections depend on the control algorithm

activated.

cables

up to 30 m: shielded cables, size 0.5 mm2 (AWG20)

over 30 m: shielded cables, size 1.5 mm

2

(AWG15)

connect the shield (cabinet side) to specifi c earth

terminal GR (see connection diagrams)

the signal can

come from

a. modulating control with external controller

b. modulating control with ambient humidity probe

c. external controller & limit humidity probe

d. ambient humidity probe & limit humidity probe

e. modulating control with temperature control

f. mod. control with temperature control & limit probe

To set the type of operation, control and signal:

installer menu > type of control (see chap. 7).

a. Modulating control with external controller

0 to 1 V 0 to 10 V 2 to 10 V 0 to 20 mA 4 to 20 mA

J4

J3J2

VG

VG0Y1Y2

Y3

B4

BC4B5BC5

B1B2B3

J24

+V

term

GND

+5V

ref

GND

+VDC

1

GR

1

External controller

Connections:

MC cabinet external controller

J24 GND REF

J2 B1 OUT

b. Modulating control with ambient humidity probe

0 to 1 V 0 to 10 V 2 to 10 V 0 to 20 mA 4 to 20 mA

J4

J3J2

VG

VG0Y1Y2

Y3

B4

BC4B5BC5

B1B2B3

J24

+V term

GND

+5V ref

GND

+VDC

1

GR

1

Ambient humidity probe

Connections:

MC cabinet ambient humidity probe

J24

+V term +(G)

GND M

J2 B1 out H

c. Modulating control with external controller and limit

probe

0 to 1 V 0 to 10 V 2 to 10 V 0 to 20 mA 4 to 20 mA

J4

J3J2

VG

VG0Y1Y2

Y3

B4

BC4B5BC5

B1B2B3

J24

+V

term

GND

+5V

ref

GND

+VDC

1

GR

2

GR

1

Limit humidity probe 2 External controller

14

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

Connections:

MC cabinet limit humidity probe external controller

J24

+V term +(G) -

GND M REF

J2

B1 - OUT

B2 out H -

d. Mod. control with ambient probe & limit probe

0 to 1 V 0 to 10 V 2 to 10 V 0 to 20 mA 4 to 20 mA

J4

J3J2

VG

VG0Y1Y2

Y3

B4

BC4B5BC5

B1B2B3

J24

+V

term

GND

+5V

ref

GND

+VDC

1

GR

2

GR

1

Limit humidity probe 2Ambient humidity probe

Connections:

MC cabinet limit humidity probe amb. humidity probe

J24

+V term +(G) +(G)

GND M M

J2

B1 - out H

B2 out H -

e. Modulating control with temperature control

0 to 1 V 0 to 10 V 2 to 10 V 0 to 20 mA 4 to 20 mA NTC

J4

J3J2

VG

VG0Y1Y2

Y3

B4

BC4B5BC5

B1B2B3

J24

+V

term

GND

+5V

ref

GND

+VDC

1

GR

1

Ambient temperature probe

Connections:

MC cabinet Ambient temperature and limit humidity probe

J24

+V term +(G)

GND M

J2 B1 out T

or

J4

J3J2

VG

VG0Y1Y2

Y3

B4

BC4B5BC5

B1B2B3

J24

+V

term

GND

+5V

ref

GND

+VDC

NTC

f. Modulating control with temperature control and

humidity limit probe

0 to 1 V 0 to 10 V 2 to 10 V 0 to 20 mA 4 to 20 mA NTC

J4

J3J2

ID1

VG

VG0Y1Y2Y3Y4

B4

BC4B5BC5

B1B2B3

J24

+V

term

GND

+5V

ref

GND

+VDC

GR

1

1

Ambient temperature and limit humidity probe

Connections:

MC cabinet Ambient temperature and limit humidity probe

J24

+V term +(G)

GND M

J2

B1 out T

B2 out H

Or:

J4

J3J2

ID1

VG

VG0Y1Y2Y3Y4

B4

BC4B5BC5

B1B2B3

J24

+V

term

GND

+5V

ref

GND

+VDC

1

GR

2

GR

1

Limit humidity probe 2 Temperature probe

Connections:

MC cabinet (1) limit hum. probe (2) temperature probe

J24

+V term +(G) +(G)

GND M M

J2

B1 - out T

B2 out H -

3.4 Control signals from ext. voltage-free

contact i.e. ON/OFF humidistat (ID & COM)

Cables:

up to 30 m: shielded cables, size 0.5mm2 (AWG20)

over 30 m: shielded cables, size 1.5 mm

2

(AWG15)

G0

NO4

L

N/W

GR

G0

NO4

ID1

ID1

ID2

ID2

ID3

ID3

ID4

ID4

ID6

ID6

ID7

ID7

COM1

COM1 COM2

COM2

COM3

COM3

F1 1A

F2 1A

1

Contact open: MC unit off

Contact closed: MC unit on

1

ON/OFF humidistat

MC cabinet ON/OFF humidistat

ID2 ON/OFF

COM1 COM

GR shield

15

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

3.5 Control signals from air line pressure

transducer (J2)

Transducer:

CAREL (for the codes of the probes see chap. 16.2

“Maintenance“) -0 to 4 bars/ 4 to 20 mA (-11 to

60 psi). Supplied with cable in diff erent lengths,

depending on the code (10 m, 50 m, 100 m)

J5

J4

J3J2J1

serial card

field card

ID1

ID2

ID3

ID4

ID5

ID7

ID8

IDC1

VG

VG0Y1Y2Y3Y4

B4

BC4B5BC5

B1B2B3

J24

+V term

GND

+5V

ref

GND

+VDC

G

G0

input: 24 V / V ; 50 to 60 Hz

max. power: 40 VA / 15 W

1

GR

1

Pressure probe

Connections:

MC cabinet cable pressure probe

J2

B3 white C

GR shield -

+ VDC black A

3.6 Connection of NO drain solenoid valve at

end of water line (group of ID terminals)

NO solenoid valve

(normally open):

CAREL code MCKDVWL000

or code MCKDVWL001 (20 VA 24 Vac)

Recommended

connection cables

up to 100 m: shielded cables, size 1.5 mm

2

(AWG1.5)

up to 200 m: shielded cables, size 2.5 mm

2

(AWG13)

Electrical speci cations

of the contact

power 500 VA

voltage 250 V

current 2 A resistive/inductive

G0

NO4

L

N/W

GR

G0

NO4

ID1

ID1

ID2

ID2

ID3

ID3

ID4

ID4

ID6

ID6

ID7

ID7

COM1

COM1 COM2

COM2

COM3

COM3

F1 1A

F2 1A

1

NO

1

NO solenoid valve (normally open) water line

Connections:

MC cabinet solenoid valve

G0 1

NO4 2

GR 4

3.7 External utility control (J13)

Cable shielded AWG 15/20

Control to interface MC

with:

compressors

water treatment systems

Electrical specifi cations of

the contact

power 500 VA

voltage 250 V

current 2 A resistive/inductive

Status of the contact in

function of MC status:

MC cabinet OFF or in

standby

contact open

cabinet with

production request

contact closed

1

NO8

C7

C4

NO7

NO4C7NO5

NO6

C4

J13 J14

L

N/W

GR

COM2

COM3

COM3

F1 1A

F2 1A

1

Start compressor / water treatment

Connections:

MC cabinet Output

J13

NO5 ON/OFF

C4 COM

GR shield

3.8 Cumulative alarm relay (J14)

Activated when one or more alarms is detected via a contact/output that

can be transferred to a supervisory system

Cable shielded AWG 15/20

Electrical specifi cations of

the relay

power 500 VA

voltage 250 V

current 2 A resistive/inductive

Status and operation of

the relay:

contact open no active alarms

contact closed active alarm/alarms

1

NO8

C7

C8

NO7

NC8

C7

J14 J15

L

N/W

GR

COM2

COM3

COM3

F1 1A

F2 1A

1

Alarm relay

Connections:

MC cabinet Output

J14

C07 COM

N07 ON/OFF

GR shield

16

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

3.9 Alarm inputs from external devices

Inputs for signalling the

status of external devices

such as:

air fl ow sensor

air compressor alarm

water treatment system alarm

Cable: shielded AWG 15/20

Confi guration of type of

contact:

see installer menu > external alarms

Connections:

water treatment system

contacts: ID3 & COM1

air compressor

contacts: ID4 & COM1

air fl ow switch

contacts: ID6 & COM2

1

2

ID3

COM1

ID4

COM1

3

ID6

COM2

G0

NO4

ID1

ID2

ID3

ID4

ID6

ID7

COM1 COM2 COM3

F1 1A

F2 1A

1

Alarm relay from water treatment

2

Compressor alarm relay

3

Flow switch alarm relay

Connections:

MC cabinet Relay

ID3 ON/OFF

Alarm relay from water treatment

COM1 COM

ID4 ON/OFF

Compressor alarm relay

COM1 COM

ID6 ON/OFF

Air fl ow switch alarm relay

COM2 COM

GR shield

3.11 Enable wash water line on external signal

Manages the washing of the water line based on an external signal.

To do this, set: installer menu > operating options > valve at the end of

the line (YES) > special functions > wash > manual

Cable: shielded AWG 15/20

Status and operation of

the contact:

contact open

wash line not enabled

externally

contact closed

wash line enabled

externally

G0

NO4

L

N/W

GR

G0

NO4

ID1

ID1

ID2

ID2

ID3

ID3

ID4

ID4

ID6

ID6

ID7

ID7

COM1

COM1 COM2

COM2

COM3

COM3

F1 1A

F2 1A

1

1

External contact for activating the wash function

Connections:

MC cabinet Relay for activating wash on ext. signal

ID7 ON/OFF

COM1 COM

3.12 Supervisor network

J5

J4

J3J2J1

serial card

field card

service card

ID1

ID2

ID3

ID4

ID5

ID7

ID8

IDC1

VG

VG0Y1Y2Y3Y4

B4

BC4B5BC5

B1B2B3

J24

+V term

GND

+5V

ref

GND

+VDC

G

G0

NO8

C7

C4

C1

C8

NO7

NO4

NO1

NC8

C7

NO5

NO2

NO3

C4

C1

Rx-/Tx-

Rx+/Tx+

GND

J9 J10

J11

J12 J13 J14 J15

input: 24 V / V ; 50 to 60 Hz

max. power: 40 VA / 15 W

J

3J2

J1

f

ield card

s

ervice car

d

III

ID8ID

C1

B4BC4B5B

C5B1B2B3

J2

4

V

te

rm

ND

V

ND

VD

C

NO

8

4

N

O7NO

4

N

O1

NC

8

N

O5NO2NO3

4

x-

/

Tx-

Rx+

/

Tx

+

ND

J9

J

10

J11

J12J13

J14

J15

input: 24 V / V ; 50 to 60 Hz

max. power: 40 VA / 15 W

DDDDD

D

CAREL optional cards

network/card protocol supported

PCOS004850 RS485 CAREL, Modbus®

PCO100MDM0

RS232 (external

modem)

CAREL for remote connections

PCO1000WB0 Ethernet™

TCP/IP

SNMP v1 &v2c

BACnet™ Ethernet™ ISO8802-2/8802-3

BACnet/IP

PCO10000F0 LON in FTT10 (*) LON-Echelon

PCO1000BA0

Ethernet™

(Modbus®)

BACnet™ MS/TP

(*) When suitably programmed

Important: Follow the instructions provided with the optional

cards as regards the technical specifi cations, connections and

expansions.

3.13 Proportional 0 to 10 Vdc output (J4)

Parallel output to the 0 to 10 Vdc signal sent to the proportional valve.

J5

J4

ID1

ID2

ID3

ID4

ID5

ID7

ID8

IDC1

VG

VG0Y1Y2Y3Y4

BC5

0...10 Vdc

Rif.

MC cabinet Outputs

VG0 REF.

Y1 0 to 10 Vdc

Output speci cations: maximum load 1 kΩ (10 mA)

17

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

4. MASTER/SLAVE APPLICATIONS

• MC master cabinet: unit fi tted with display to manage the operation

of the unit itself and the other units connected

• MC slave cabinet: unit without display that normally works based on

the controls received from the master

• pLAN: serial communication system to connect the master unit to the

slaves across a local network

• each master unit can be connected to up to 5 slave units

• serial address: numeric code that automatically identifi es each unit

cabinet in the installation. Master unit: address 1, Slave unit: address

2. The serial address is already stored in the controller on the unit, and

should only be modifi ed on the Slave unit when there are multiple

units (see paragraph 4.3)

• for the software confi guration of the pLAN net work, see installer menu

> pLAN con guration

4.1 Applications for one large space or AHU

(single point)

• Ideal for large rooms (or air handling units) where the required water

capacity exceeds the output of a single MC cabinet.

• Only the master unit is fi tted with a probe, and the values saved are

applied to all the units connected.

pLAN

Sla

ve

1

Maste

rSl

ave 5

W

ater & Air line

s

up to 5 Slave units

AHU /Room 1

AHU - Air Handling Unit

4.2 Applications for multiple spaces or AHUs

(multizone)

• Ideal for applications in a series of separate rooms (or air handling

units).

• Each MC cabinet is fi tted with a probe, the values saved by each probe

are managed by the cabinet this is connected to.

• To ensure continuity of operation in the event of interruption of the

serial communication see installer menu > type of control > stop slave

offl ine.

pLAN

Sla

ve 1

aster

Slave

5

W

a

ter &Air lin

es

up to 5 Slave units

AHU /Room

2

AHU /Room

1

AHU /Room

1

AHU - Air Handling Unit

4.3 Setting the serial address for units with

multiple slaves

• The serial address is used to automatically identify each MC unit in the

installation.

• The address is already confi gured: for the master unit=1; for the slave

unit=2.

• The slave units do not have terminals.

• In systems with a series of slaves, the serial address must be changed

to avoid having the same address (2) on all the units (causing confl ict

in the event of pLAN communication).

• To set the pLAN address, use the kit PGD0002F0K.

Important: The serial addresses must be changed before

connecting the pLAN network.

Instructions for changing the serial address on the slave units using the

kit PGD0002F0K:

• complete the power supply connections (see paragraph 3.1);

• switch off the MC cabinet (make sure the power supply is

disconnected);

• connect the cable in the terminal kit to output J10 on the cabinet

• switch the cabinet on;

• press the ALARM and UP buttons together until the display shows the

message “self test please wait” (displayed for a few seconds, before the

address setting screen) ;

• set the required address using UP or DOWN (to a value higher than 2)

and press ENTER to confi rm and exit;

• the MC slave unit has now been confi gured with a new serial address,

switch the unit off , disconnect the cable and repeat for the other

units.

Once confi guration has been completed, connect the pLAN serial line

(see the following paragraph)

Important: only change the serial address on the slaves, and not

on the master.

Table of serial addresses (installer’s responsibility, see installer

menu > pLAN confi guration):

unit unit name room or AHU

serial

address

master ................................................ ................................................ 1

slave 1 ................................................ ................................................

.......

slave 2 ................................................ ................................................

.......

slave 3 ................................................ ................................................

.......

slave 4 ................................................ ................................................

.......

slave 5 ................................................ ................................................

.......

18

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

4.4 pLAN network connection (J11)

Use two-wire cables plus earth, AWG 20/22, maximum distance between

two cabinets: 200 m (219 yd).

MASTER

SLAVE

GR

GR

service card

Rx-/Tx-

Rx+/Tx+

GND

J9 J10

J11

service card

Rx-/Tx-

Rx+/Tx+

GND

J9 J10

J11

Connections:

MC Master cabinet J11 MC Slave cabinet

J11

RX+/TX+

J11

RX+/TX+

RX-/TX- RX-/TX-

GND GND

In multizone mode, by disabling the “stop slave off line” function, if the

pLAN is interrupted the slaves operate independently according to the

signals from the probes or/and controllers. In this mode, the values will

not be shown on the master display.

19

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

5. STARTING AND USER INTERFACE

Before starting the humidifi er, check:

water and air connections (chap. 2). In the event of water leaks do not

start the humidifi er before having resolved the problem;

electrical connections (chap. 3)

5.1 Starting

1

0

O

N

5.2 Stopping

1

0

OFF

Note: if the system is stopped for an extended time, open the

valve at the end of the water line to assist drainage. If the system

is fi tted with drain solenoid valves at the end of the line (optional), this is

done automatically.

5.3 First start-up (setting the language)

On power-up, the following screen is displayed:

Select language:

1. English

2. Italiano

3. Deutsch

4. Francais

5. Espaniol

Press ENTER to go the list of languages, then UP to select the desired

language and ENTER to confi rm. This screen remains displayed for 60

seconds.

Subsequently, the following screen will be displayed:

Show language mask at unit start-up Yes/No

• YES: the screen for choosing the language will be displayed when the

humidifi er is started the next time;

• NO: the screen for choosing the language will no longer be displayed

on power-up.

Note: The language can also be changed from the maintenance

menu (maintenance menu > system info > language).

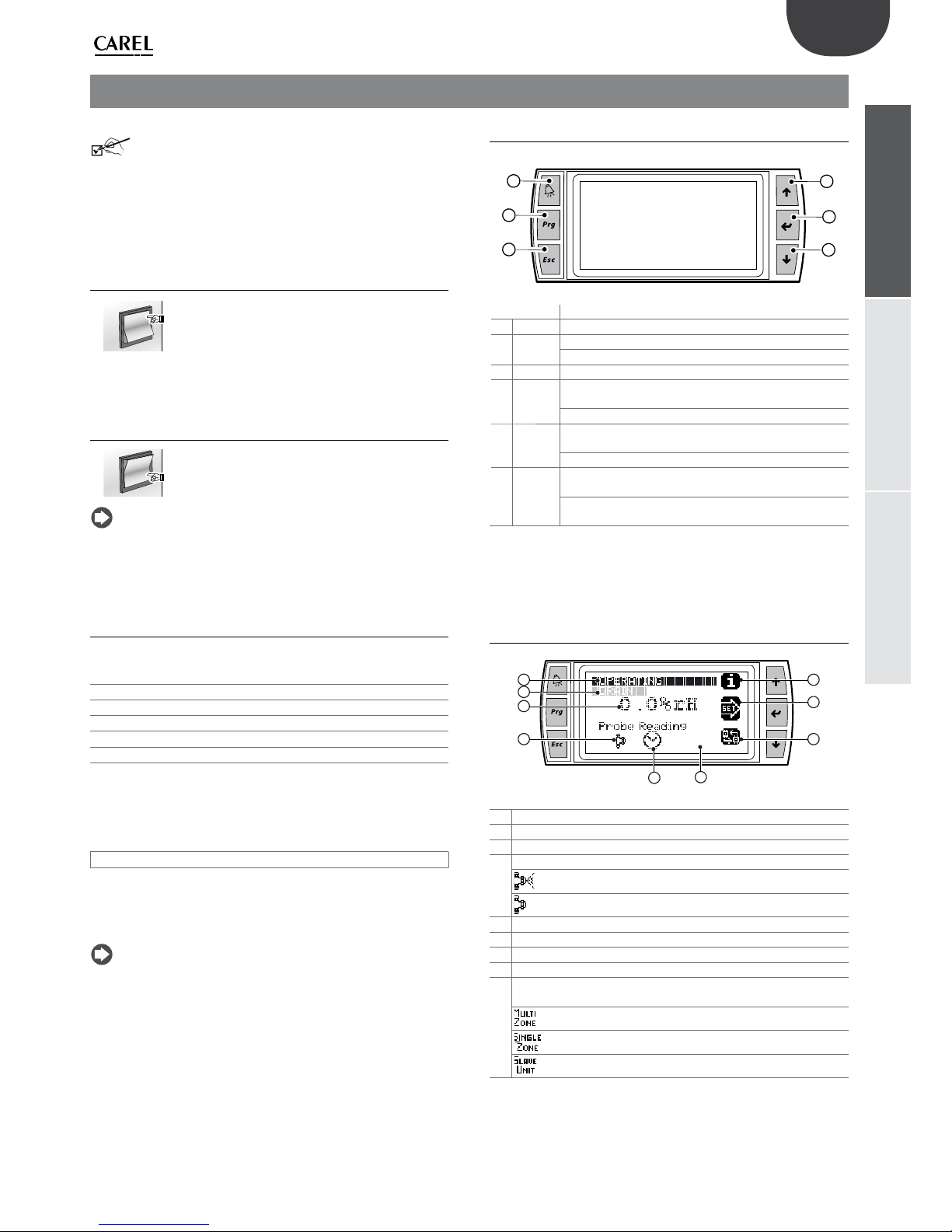

5.4 Keypad

6

4

5

3

2

1

button function

(1)

alarm list active alarms and reset any alarms present

(2)

PRG return to the “main” screen

from the “main” screen access the main menu

(3)

ESC return to the previous screen/display

(4)

UP circular navigation inside the menus, the screens, the

parameters and the values of the parameters

from the “main” screen, access an “INFO menu”

(5)

ENTER select and confi rm (like the “Enter” key on a computer

keyboard)

from the main menu, access the “SET” screen

(6)

DOWN circular navigation inside the menus, the screens, the

parameters and the values of the parameters

from the main screen, access the pLAN screens and connect

to the SLAVE cabinets

5.5 “Main” screen

1

2

3

4

6

5

7

8

9

(1) description of unit status (*)

(2) line 2 description of unit status (**)

(3) value read according to the type of signal connected

(4) status of the atomising nozzles:

atomising nozzles operating

atomising nozzles off

(5) time bands set

(6) access the “INFO” screen (UP button)

(7) access the “SET” screen (ENTER button)

(8) access the “pLAN” screen (DOWN button)

(9) Symbol on display:

no image: master unit not connected to a network (stand alone)

master unit connected to a pLAN network for multiple spaces

master unit connected to a pLAN network for single spaces

slave unit

20

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

(*) Types of descriptions:

• IN OPERATION: atomised water production in progress,

• SHUTDOWN ALARM: production stopped due to an alarm,

• OFF FROM SUPERVISOR: production stopped by supervisor,

• OFF FROM SCHEDULER: production stopped during the set time

band,

• OFF FROM REMOTE: production stopped due to opening of the

“Remote ON/OFF” contact,

• OFF FROM KEYPAD: production stopped from the keypad (see “SET”

screen),

• MANUAL MODE: manual mode activated (see maintenance menu)

• NO REQUEST: unit on without production request.

(**) Types of unit status description, line 2:

• DRAIN: unit draining;

• FILL: unit fi lling the water line;

• CLEANING: unit cleaning the heads on the air line;

• WASHING: unit washing the water line.

5.6 “INFO” screens (read-only)

Series of read-only screens for displaying the main humidifi er status

values. To access, press UP from the “Main” screen. There are two “INFO”

screens; to move from one screen to the next, press UP or DOWN.

Press ESC to return to the “Main” screen.

Info (1/2)

display UOM

Request

50-100 %

Air line

ON/OFF

Water line

ON/Drain

Type of op..

ON/OFF or Modulating

Press. sensor

bar/psi

Date & time

dd/mm/yy 00:00

Info (2/2)

display UOM

Humidifi er model

In production

YES/NO

Hours production

h

Date & time

dd/mm/yy 00:00

5.7 “SET” screen

Used to set the main values for the humidifi er.

From the main screen press:

• ENTER to access the menu;

• ENTER to move from one value to the next;

• UP & DOWN to modify the selected value;

• ENTER confi rm and go to the next value.

Parameter range default UOM

Set point 0 to 100

50 %rH- °C/°F

Humidifi er AUTO / OFF

OFF -

Max. prod. 50 to 100

100 %

Prop. band 2 to 19.9

5 %rH- °C/°F

Limit set (

limit probe set

point)*

0 to 100

80 %rH

Prop. band* 2 to 19.9

5 %rH

* visible only if the limit probe is enabled

5.8 “pLAN” screen

From the main screen press:

• DOWN to access the menu;

• ENTER to select the unit;

• UP & DOWN to move from one unit to the next;

• ENTER to confi rm.

Units connected

1 (master)

2 (slave)

3 (slave)

4 (slave)

5 (slave)

6 (slave)

Current:

Network:

21

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

5.9 Main menu

To access press PRG from the main screen

Buttons:

• UP & DOWN: navigation inside the submenus, screens, and range of

values and settings;

• ENTER: confi rm and save the changes made;

• ESC: to go back (pressed repeatedly returns to the “Main” screen).

1. User

(no password)

1. Alarm thresholds Main probe thresholds

High alarm

Low alarm

Limit probe thresholds

High alarm

Alarm delay

2. Clock Clock

Hour

Day

Month

Year

Format

Day

3. Enable scheduler Enable scheduler

Scheduler On/Off

Variable set point

4. Set scheduler Set scheduler

P1-1

P1-2

P2

P3

P4

5.Weekly scheduler Weekly scheduler

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

6. Scheduled setp. Scheduled set points

Z1

Z2

Z3

Z4

2. Installer

(password 77)

1. Type of control Type of operation

Type of signal or probe

Type of signal or probe

Main

Limit

Unit of measure

Stop slave offl ine

2. Probe confi guration Main probe confi g.

Min value

Max value

Offset

Limit probe confi g.

Min value

Max value

Offset

3. Operating options Operating options (1/2)

Remote p. sensor

Max. air press.

Min air press.

Max air press. offset

Min air press. offset

Operating options (2/2)

Valve at end of line

Alarm relay logic

Prop. s. set point:

4. Special functions Special func. (1/3)

Independent cleaning

Enabled

Period

Duration

Special func. (2/3)

Washing

Start washing

Washing period

Washing duration

Enable fi lling

Filling duration

Special func. (3/3)

Select main screen

display

Language

Show language choice at

start-up?

5. Supervisor Supervisor confi g.

ID number

for BMS network)

Com. speed

Type of protocol

Enable ON/OFF from

supervisor

6. External alarms External alarms

Water treatment

Logic

Compressor

Logic

Flow switch

Logic

7. pLAN confi g. pLAN confi g. (1/2)

pLAN

Mode

Press down arrow

to set unit

pLAN confi g. (2/2)

M1:

S2:

S3:

S4:

S5:

S6:

Alarm delay:

3. Maintenance

(password 77)

1. Reset conf. Confi guration

Save confi g.

Load confi g

Default parameters

Restore default

parameters

code:

Type of humidifi er

2. System info System info

Boot (read only)

Bios (read only)

Code:

Version:

Date:

3. Manual procedure Manual controls (1/2)

Manual procedure

Air valve

Water valve

Drain valve

Valve at end of line

Production status

Manual controls (1/2)

Alarm relay

Prop. output

Prop. valve

4 Hour counter Hour counter

Hours of production

Reset hours

5. Alarm log Alarm log

Alarm (read only)

Log deleted

Time (read only)

Date (read only)

22

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

6. USER MENU

From the main screen press:

• PROG to access the main menu;

• ENTER to select and access the selected menu;

• UP/DOWN to move between the submenus;

• ENTER to enter the submenus

• ENTER to select the parameter and move between the parameters;

• UP/DOWN to modify the parameter;

• ENTER to confi rm selected parameter and go to the next parameter;

• ESC to return to the previous menu.

User menu screens:

1. Alarm thresholds

2. Clock

3. Enable scheduler

4. Set scheduler

5. Weekly scheduler

6. Scheduled set point

6.1 Alarm thresholds

parameter par. name range default UOM

Main probe alarm

thresholds

high alarm 0 to 100.0 100.0 %

low alarm 0 to 100.0 0.0 %

Limit probe alarm

thresholds

high alarm 0 to 100.0 100.0 %

Alarm delay

0 to 999 1 min

6.2 Clock

Used to set the timed activation of the humidifi er

parameter range

hour / min

0 to 23 / 0 to 59

day

1 to 31

month

1 to 12

year

00 to 99

format

dd/mm/yy - mm/dd/yy

weekday

Monday to Sunday

6.3 Enable scheduler

Enable control of the time bands and the set points

parameter enabled

Scheduler On/Off

YES / NO

variable set point

YES / NO

When the time bands are set, the display shows the symbol.

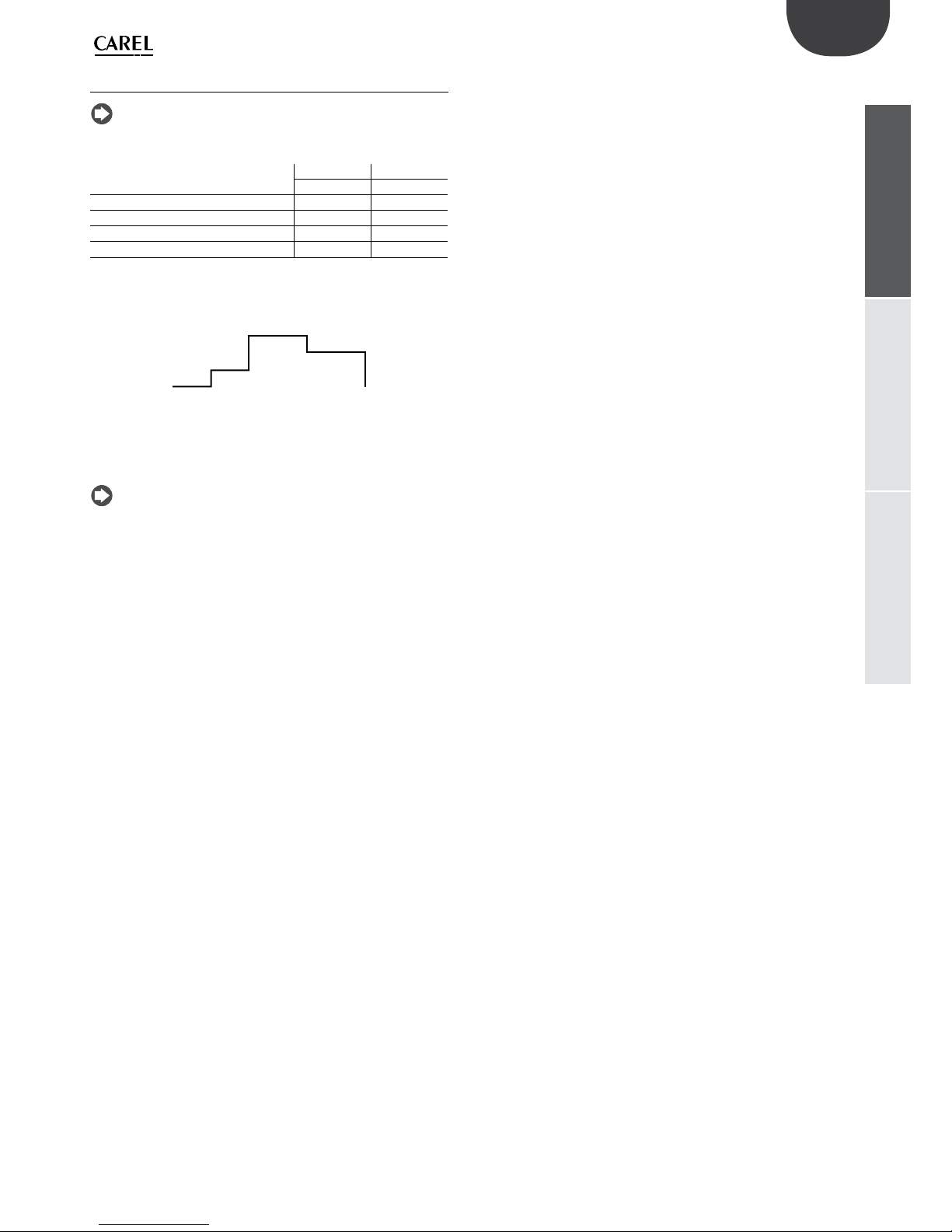

6.4 Set scheduler

Note: this screen is visible if “scheduler ON/OFF” has been enabled

(see the enable scheduler screen).

Setting of the intervals for the operation of the humidifi er over one day

(24h):

time band

ON OFF

P1 P1-1

09:00 13:00

P1-2

14:00 21:00

P2

14:00 21:00

P3

always ON

P4

always OFF

Parameters P1 to P4 can be used set how many times atomised water

production is enabled/disabled over a 24h period:

P1 Two daily ON time bands

0 24h

ON

P1-1 P1-2

OFF OFF OFFON

P2 Individual ON time band

0 24h

P2

OFF OFFON

P3 Always ON

0 24h

ON

P4 Always OFF

0 24h

OFF

6.5 Weekly scheduler

Note: this screen is visible if “scheduler ON/OFF” has been enabled

(see the enable scheduler screen).

Setting of the weekly operation of the humidifi er, using parameters P1 to

P4 (confi gured in the previous screen)

parameter type of time band

Monday

P1 to P4

Tuesday

P1 to P4

Wednesday

P1 to P4

Thursday

P1 to P4

Friday

P1 to P4

Saturday

P1 to P4

Sunday

P1 to P4

23

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

6.6 Scheduled set points

Note: this screen is visible if “variable set point” has been enabled

(see the enable scheduler screen).

Setting of diff erent levels of set points throughout the day (24 h):

parameter

ON SETP.

hours %rH

Z1

00:00 0.0 to

Z2

00:00 0.0 to

Z3

00:00 0.0 to

Z4

00:00 0.0 to

Parameters Z1 to Z4 can be used to confi gure up to four diff erent

temperature set points at diff erent times of a day (parameters Z1, Z2, Z3,

Z4).

Z1 Z2

20% U.R

50% U.R

30% U.R

Z3 Z4

0 24h

By setting the “daily” and “variable set point” time bands, atomised water

production can be programmed according to the needs of the utility.

Note:

• during the “OFF” time band, the humidifi er is NOT actually off , but

rather atomised water production is temporarily disabled, even when

setting manually;

• the “daily” time bands have priority over the “variable set point” bands.

For example, setting P4 each Monday (humidifi er off ), parameters

Z1, Z2, Z3, Z4 (diff erent set point values) will not be observed, as the

humidifi er is not programmed to operate on that day.

24

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

From the main screen press:

• PRG to access the main menu;

• DOWN to move to the installer menu;

• ENTER to move to the password;

• UP/DOWN to enter the password “77“

• ENTER to access the selected menu;

• UP/DOWN to move between the submenus;

• ENTER to select the parameter and move between the parameters;

• UP/DOWN to modify the parameter;

• ENTER to confi rm the selected parameter and go to the next parameter;

• ESC to return to the previous menu.

Installer menu screens:

1. Type of control

2. Probe confi guration

3. Operating options

4. Special functions

5. Supervisor

6. External alarms

7. PLAN confi guration

To navigate inside the screens:

• UP or DOWN to change the value (within the options/range),

• ENTER to confi rm and move the cursor to the next value

• ESC to return to the installer menu.

7.1 Type of control

Settings: type of operation (ON/OFF or modulating), type of signal or

probe, main probe, limit probe, unit of measure & stop slave offl ine.

parameter options/range description

Type of

operation

ON/OFF

modulating

Type of signal

or probe

External contact

External proportional signal

External proportional signal & limit probe

Humidity probe

Humidity probe & limit probe

Temperature probe

Temperature probe & limit probe

Main probe

select between:

NTC; 0-1 V; 2-10 V; 0-10 V (default);

0-20 mA; 4-20 mA; 0-135 ohm; 135-1k ohm

Limit probe

Unit of

measure

°C - bar (default)

°F - psi

Stop slave

offl ine

YES

default

if the pLAN network is offl ine the slave units

stop

NO if the pLAN network is offl ine the slave units

continue

7.2 Probe con guration

Setting of the minimum value, maximum value and off set for the probes

used.

parameter settings range default UOM

Main probe

confi g.

Min value 0 to 100 0 %rH °C/ °F

Max value 0 to 100 100 %rH °C/ °F

Off set -10 to 10 0 %rH °C/ °F

Limit probe

confi g.

Min value 0 to 100 0 %rH °C/ °F

Max value 0 to 100 100 %rH °C/ °F

Off set -10 to 10 0 %rH °C/ °F

7.3 Operating options

Operating options (1/2)

parameter description range default UOM

Remote p. sensor

pressure sensor

at end of line

for balancing

compressed air

system

YES/NO NO

max. air pressure

0 to 4 2.1 bar

min. air pressure

0 to 4 1.2 bar

max air press.

offset

0 to 9.9 0

min air press.

offset

0 to 9.9 0

Operating options (2/2)

parameter description range default UOM

valve at end of

line

to allow automatic

emptying and

periodical washing

of the water line

YES/NO YES

logic alarm relay

alarm relay status

setting

NO/NC NO

proportional signal

set point:

3 to 60 10 %

7.4 Special functions

Special functions: automatic cleaning (1/3)

Nozzle self-clean cycles to reduce the frequency of maintenance.

parameter range default UOM

Enabled

YES/NO YES

Period

0 to

999

30 min

Duration

60 to

999

160 s

Special functions: washing (2/3)

Automatic periodical washing of the water line to increase the hygiene of

the installation.

parameter range default UOM

washing

manual/

automatic

man.

start washing

NO/YES NO

washing period

1 to 99 6 h

washing duration

0 to 15 10 min

enable fi lling

NO/YES NO

fi lling duration

1 to 1000 5 s

Special functions (3/3)

parameter range default UOM

select display on main screen

% signal;

Hours; %rH;

°C/°F

%rH

Language

Italian, English,

French,

German,

Spanish

Show language choice at startup?

YES/NO YES

7. INSTALLER MENU

25

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

7.5 Supervisor

parameter range def. UOM

ID number

for BMS network

0 to 200 1

communication speed

1200; 2400; 4800;

9600; 19200

19200 bps

type of protocol

Carel; Modbus®; Lon;

RS232; Winload

Carel

enable ON/OFF

from supervisor

YES/NO NO

7.6 External alarms

parameter range def. UOM

water treatment

NO/YES NO

logic

NC/NO NC

compressor

NO/YES NO

logic

NC/NO NC

fl ow switch

NO/YES NO

logic

NC/NO NC

7.7 pLAN con guration

pLAN con guration : mode (1/2)

parameter range def. UOM

pLAN master/master+slave

master

Mode multizone/single

point

multizone

pLAN con guration: units present and names (2/2)

parameter range def. UOM

M1(*)

YES/NO YES

S2/S3/S4/S5/S6(*)

YES/NO NO

Alarm delay

0 to 99

30 S

The MASTER and SLAVE units are named by default, however they can be

renamed using the list of the characters shown below.

ABCDEF GHI J KL

MNOP QR S T UV WX

YZ0123456789

+-*:;,()/#%

To modify the character in the space selected, use UP and DOWN, to

confi rm the character and move to the next space press ENTER.

26

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

Important: the operations described in this menu must only be

carried out by qualifi ed personnel.

From the main screen press:

• PRG to access the main menu;

• DOWN to move to the maintenance menu;

• ENTER to move to the password;

• UP/DOWN to enter the password “77“

• ENTER to access the selected menu;

• UP or DOWN to move between the submenus;

• ENTER to select parameter and move between the parameters;

• UP/DOWN to modify the parameter;

• ENTER to confi rm the selected parameter and go to the next

parameter;

• ESC to return to the previous menu.

Maintenance menu screens:

1. Reset conf.

2. System info

3. Manual procedure

4. Hour counter

5. Alarm log

8.1 Reset con gurations

Con guration

Functions:

• save the set confi gurations,

• recall the saved confi guration

parameter range default

save confi gurations

YES/NO NO

load confi guration

YES/NO NO

Default parameters

Functions:

• restore default parameters

• code

parameter range default

restore default parameters

YES/NO NO

code

display only

8.2 System information (read only)

information display

Boot

read only

Bios

read only

Code

read only

Version

read only

Date

read only

8.3 Manual procedure

Important: these operations must only be performed by qualifi ed

personnel, incorrect use may cause serious damage.

These procedures are used to manually test the main functions and

operations of the humidifi er.

Manual procedure (1/2)

parameter range default

manual procedure (*)

YES/NO NO

air valve

ON/OFF OFF

water valve

ON/OFF OFF

drain valve

ON/OFF OFF

valve at end of line

ON/OFF OFF

production status

ON/OFF OFF

Manual procedure (2/2)

parameter range default

alarm relay

YES/NO NO

proportional output

ON/OFF OFF

proportional valve

ON/OFF OFF

(*) To activate the individual manual procedures, fi rst enable the manual

procedure parameter.

8.4 Hour counter

parameter range/display

hours production

display

reset hours

YES/NO

8.5 Alarm log

Recorded trace of the alarms (events) that have been activated. The

humidifi er memory can record up to 200 events (complete with

description and date, press DOWN to scroll the list).

parameter display

Alarm

event description

Log deleted

Time

hh:mm

Date

dd/mm/yy

8. MAINTENANCE MENU

27

ENG

“MCmultizone” +030221981 - rel. 2.3 - 09.12.2014

cabinetdistributionmaintenance

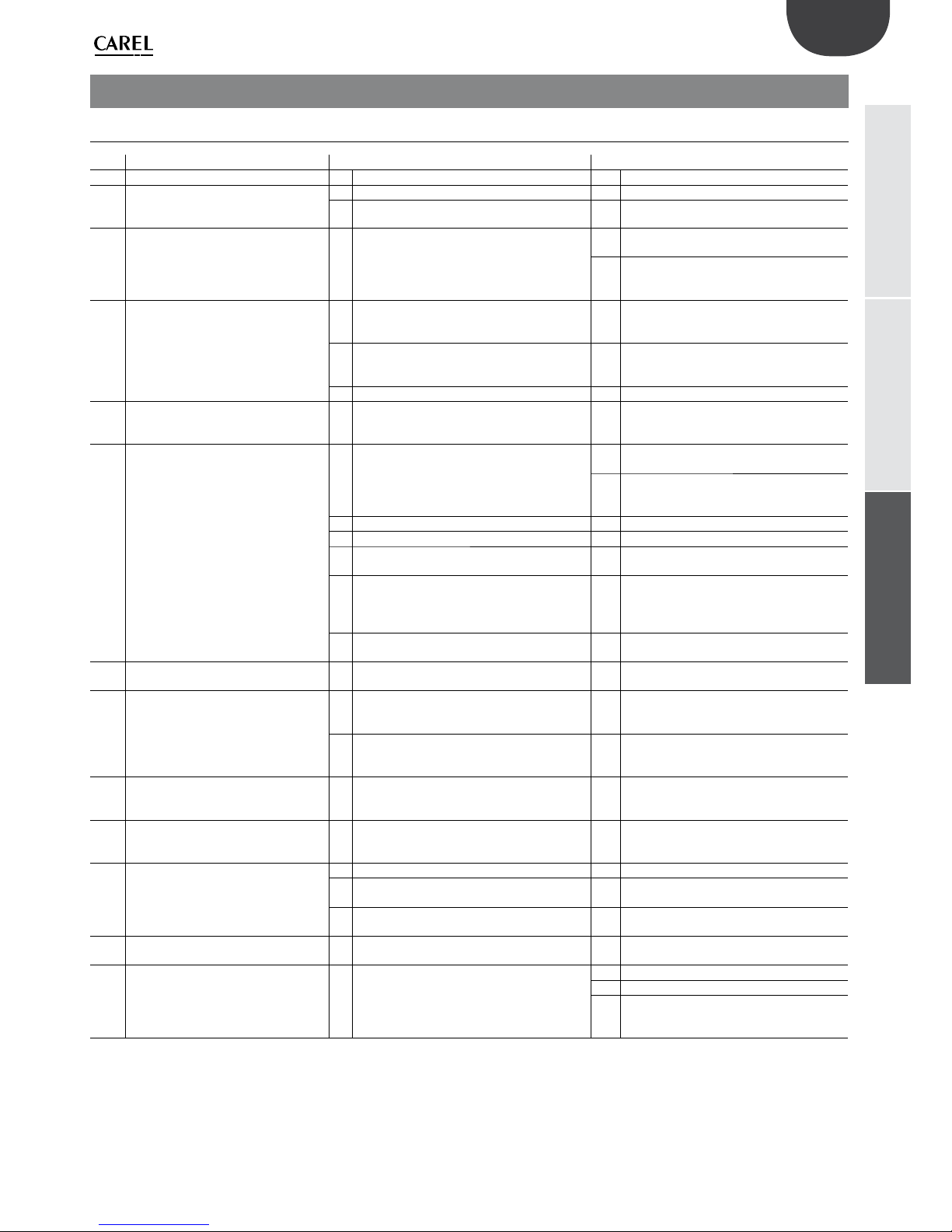

alarms

displayed

meaning cause solution reset alarm

relay

action notes

high humidity humidity

outside of set

limits

value measured

by the probe

greater than the

humidity alarm

threshold

check the set parameter manual inactive signal only on

low humidity humidity

outside of set

limits

value measured

by the probe

less than the

humidity alarm

threshold