kVent

Controller for ventilation units

Manual

H i g h E f f i c i e n c y S o l u t i o n s

kVent – rel 3.1 – 22/06/2018

1

kVent – rel 3.1 – 22/06/2018

2

WARNING

KEY TO THE ICONS

IMPORTANT

CAREL bases the development of its products on decades of

experience in HVAC/R, on the continuous investments in

technological innovations to products, procedures and strict

quality processes with in-circuit and functional testing on 100% of

its products, and on the most innovative production technology

available on the market. CAREL and its subsidiaries nonetheless

cannot guarantee that all the aspects of the product and the

software included with the product respond to the requirements of

the final application, despite the product being developed

according to start-of-the-art techniques. The customer

(manufacturer, developer or installer of the final equipment)

accepts all liability and risk relating to the configuration of the

product in order to reach the expected results in relation to the

specific final installation and/or equipment.

CAREL may, based on specific agreements, acts as a consultant

for the positive commissioning of the final unit/application,

however in no case does it accept liability for the correct

operation of the final equipment/system.

The CAREL product is a state-of-the-art product, whose operation

is specified in the technical documentation supplied with the

product or can be downloaded, even prior to purchase, from the

website www.CAREL.com.

Each CAREL product, in relation to its advanced level of

technology, requires

setup/configuration/programming/commissioning to be able to

operate in the best possible way for the specific application. The

failure to complete such operations, which are required/indicated

in the user manual, may cause the final product to malfunction;

CAREL accepts no liability in such cases.

Only qualified personnel may install or carry out technical service

on the product.

The customer must only use the product in the manner described

in the documentation relating to the product.

In addition to observing any further warnings described in this

manual, the following warnings must be heeded for all CAREL

products:

• Prevent the electronic circuits from getting wet. Rain, humidity

and all types of liquids or condensate contain corrosive

minerals that may damage the electronic circuits. In any case,

the product should be used or stored in environments that

comply with the temperature and humidity limits specified in the

manual.

• Do not install the device in particularly hot environments. Too

high temperatures may reduce the life of electronic devices,

damage them and deform or melt the plastic parts. In any case,

the product should be used or stored in environments that

comply with the temperature and humidity limits specified in the

manual.

• Do not attempt to open the device in any way other than

described in the manual.

• Do not drop, hit or shake the device, as the internal circuits and

mechanisms may be irreparably damaged.

• Do not use corrosive chemicals, solvents or aggressive

detergents to clean the device.

• Do not use the product for applications other than those

specified in the technical manual.

All of the above suggestions likewise apply to the controllers,

serial boards, programming keys or any other accessory in the

CAREL product portfolio.

CAREL adopts a policy of continual development. Consequently,

CAREL reserves the right to make changes and improvements to

any product described in this document without prior warning.

The technical specifications shown in the manual may be

changed without prior warning.

The liability of CAREL in relation to its products is specified in the

CAREL general contract conditions, available on the website

www.CAREL.com and/or by specific agreements with customers;

specifically, to the extent where allowed by applicable legislation,

in no case will CAREL, its employees or subsidiaries be liable for

any lost earnings or sales, losses of data and information, costs

of replacement goods or services, damage to things or people,

downtime or any direct, indirect, incidental, actual, punitive,

exemplary, special or consequential damage of any kind

whatsoever, whether contractual, extra-contractual or due to

negligence, or any other liabilities deriving from the installation,

use or impossibility to use the product, even if CAREL or its

subsidiaries are warned of the possibility of such damage.

DISPOSAL

INFORMATION FOR USERS ON THE CORRECT HANDLING

OF WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT

(WEEE)

In reference to European Union directive 2002/96/EC issued on

27 January 2003 and the related national legislation, please note

that:

• WEEE cannot be disposed of as municipal waste and such

waste must be collected and disposed of separately;

• the public or private waste collection systems defined by local

legislation must be used. In addition, the equipment can be

returned to the distributor at the end of its working life when

buying new equipment;

• the equipment may contain hazardous substances: the

improper use or incorrect disposal of such may have negative

effects on human health and on the environment;

• the symbol (crossed-out wheeled bin) shown on the product or

on the packaging and on the instruction sheet indicates that

the equipment has been introduced onto the market after 13

August 2005 and that it must be disposed of separately;

• in the event of illegal disposal of electrical and electronic

waste, the penalties are specified by local waste disposal

legislation.

Warranty of the materials: 2 years (from the date of production,

excluding consumables).

Approval: the quality and safety of CAREL INDUSTRIES Hqs

products are guaranteed by the ISO 9001 certified design and

production system.

: separate as much as possible

the probe and digital input signal cables

from the cables carrying inductive loads and

power cables to avoid possible

electromagnetic disturbance. Never run

power cables (including the electrical panel

wiring) and signal cables in the same

conduits.

The product must be installed with the earthconnected,

using the special yellow-green terminal on the terminal

block. Do not use the neutral for the earth connection.

NOTE: to bring attention to a very important subject;

in particular, regarding the practical use of the

various functions of the product.

IMPORTANT: to bring critical issues regarding the

use of the kVent to the attention of the user.

TUTORIAL: some simple examples to accompany

the user in configuring the most common settings.

Application TITLE – rel 1.0 – xx/xx/201x

kVent – rel 3.1 – 22/06/2018

4

CONTENTS

1. INTRODUCTION ............................................................................................................................................................................ 6

1.1 Main features ............................................................................................................................................................................. 6

1.2 Accessories available ................................................................................................................................................................ 6

2. HARDWARE INSTALLATION ......................................................................................................................................................... 7

2.1 Mounting and dimensions .......................................................................................................................................................... 7

2.2 Installation ................................................................................................................................................................................. 7

2.3 Field connection ........................................................................................................................................................................ 8

2.4 Input/Output ............................................................................................................................................................................... 9

3. SOFTWARE CONFIGURATION ................................................................................................................................................... 11

3.2 Unit schema............................................................................................................................................................................. 15

3.3 Board to point .......................................................................................................................................................................... 16

3.4 Software upgrade .................................................................................................................................................................... 16

4. USER INTERFACE ....................................................................................................................................................................... 18

4.1 Display PGDE .......................................................................................................................................................................... 18

4.2 Menu description ..................................................................................................................................................................... 18

4.3 Display th-Tune ....................................................................................................................................................................... 19

4.4 User setpoint ........................................................................................................................................................................... 20

5. FUNCTIONS ................................................................................................................................................................................. 21

5.1 Input functions ......................................................................................................................................................................... 21

5.2 On request ............................................................................................................................................................................... 21

5.3 Cooling/Heating changeover .................................................................................................................................................... 21

5.4 Temperature regulation strategy .............................................................................................................................................. 21

5.5 Fresh air regulation .................................................................................................................................................................. 22

5.6 Humidity regulation .................................................................................................................................................................. 22

5.7 Devices activation .................................................................................................................................................................... 22

5.8 Freeze and frost protections .................................................................................................................................................... 24

5.9 Fans control ............................................................................................................................................................................. 24

5.10 Mixing chamber control ............................................................................................................................................................ 25

5.11 CO2 Regulation ........................................................................................................................................................................ 25

5.12 Boost function .......................................................................................................................................................................... 25

5.13 Minor functions ........................................................................................................................................................................ 25

5.14 Import/Export parameters ........................................................................................................................................................ 25

6. PARAMETERS TABLE ................................................................................................................................................................. 26

6.1 INFO menu in main mask ........................................................................................................................................................ 26

6.2 SET menu in main mask .......................................................................................................................................................... 29

6.3 MODE menu in main mask ...................................................................................................................................................... 31

6.4 HEATING menu in main menu ................................................................................................................................................. 31

6.5 COOLING menu in main menu ................................................................................................................................................ 32

6.6 COOL/HEAT menu in main menu ............................................................................................................................................ 33

6.7 FANS menu in main menu ....................................................................................................................................................... 34

6.8 RECOVERY menu in main menu ............................................................................................................................................. 34

6.9 HUMIDITY menu in main menu ............................................................................................................................................... 35

6.10 IN/OUT SETTINGS menu ........................................................................................................................................................ 36

6.11 SETTINGS menu in main menu ............................................................................................................................................... 43

6.12 UNIT CFG. menu in main menu ............................................................................................................................................... 44

7. ALARMS ....................................................................................................................................................................................... 45

7.1 Alarms interface ....................................................................................................................................................................... 45

7.2 Table of alarms ........................................................................................................................................................................ 46

8. NEW FUNCTIONALITIES FROM VER. 2.1.0 ................................................................................................................................ 48

8.1 Modulating Fresh air damper ................................................................................................................................................... 48

8.2 Additional device signals to send a feedback to external devices ............................................................................................. 48

8.3 Advanced PID settings for the working modes ......................................................................................................................... 48

8.4 HEPA filters management ........................................................................................................................................................ 48

8.5 Regulation CAV and VAV in supply only units .......................................................................................................................... 48

8.6 FieldBus frame configuration ................................................................................................................................................... 48

9. NOTE .................................................................................................................................................................................................. 49

9.1 kVent release notes ...................................................................................................................................................................... 49

kVent – rel 3.1 – 22/06/2018

5

Regulation

Scheduler

R

ecovery

Coils

Fans

Protection

I

nterface

Languages

Unit of

Alarms

Fieldbus1

Ethernet port

1. INTRODUCTION

1.1 Main features

Usability and display – kVent, developed in line with the new

CAREL usability standards, assists the manufacturer in the

configuration of the installation. The menu-based system allows

the application to be configured as a tool for instant diagnostics. All

this is possible by the immediately accessible overview screens

and the commissioning tool.

Quick menus - information on the status of the kVent is accessible

directly from the main menu, without needing to access the

submenus. Configuration, active function and operating

temperature information are arranged in loops of screens, scrolled

by pressing the DOWN button from the main screen.

Main features

measure

Temperature PID regulation based on supply

Humidity PID regulation based on supply or

room humidity

Automatic cooling/heating changeover

Setpoint compensation

VOC and CO2 regulation

4 time bands for each day

3 special periods

6 special days

Rotary heat recovery

Glycol heat recovery

Plate cross-flow recovery

Hydronic systems

Electric heating

Direct expansion

Steam coil

Reverse coil

ON/OFF fan

3 speeds setup

Air pressure control

Air flow control

Filters

Fire/Smoke alarm

Frost protection

Door switch

Browser interface based on WebKit

pGDE for advanced function and service

thTune for end user

3 different parameters access levels

EN, PL, RU, CZ

International

USA

CAN

UK

Automatic and manual management

Log from application

Modbus Master Line

Modbus slave built-in

Bacnet built-in

tEra ready

WebServer / c.field for commissioning

1.2 Accessories available

Below is a list of devices suitable for use with this product. CAREL

features passive, active and serial temperature, humidity and

differential pressure probes, for room or duct installation,

specifically for the air handling unit appliance.

Duct temperature and humidity sensor

(Technical leaflet +050001245)

Outdoor sensors

(Technical leaflet +050001790)

NTC temperature sensors

(Manual +030220655)

PT1000 temperature sensors

(Manual +030220655)

Room air quality sensors

(Technical leaflet +050001300)

Differential air pressure sensors

(Technical leaflet +050000651)

Differential air pressure switches/flow

switches

(Technical leaflets +050000645 +050000647)

Smoke and fi re sensors

(Technical leaflet +050000520)

pGDE terminal

(Technical leaflet +050001050)

pLDPRO terminal

(Technical leaflet +050001840)

thTune terminal

(Technical leaflet +0500017IE)

Fans VFD inverter

(Technical leaflet +050001230)

kVent – rel 3.1 – 22/06/2018

6

2. HARDWARE INSTALLATION

2.1 Mounting and dimensions

The controller is designed to be mounted on a DIN rail. The figure

below shows the dimensions.

2.2 Installation

Environmental conditions

2.2.1

Avoid installing the controller and the terminal in places with:

• exposure to direct sunlight and to the elements in general;

• temperature and humidity outside the product’s range of

operation (see “Technical Specifications”);

• large, rapid fluctuations in room temperature;

• strong magnetic and/or radio frequency interference (avoid

installing near transmitting antennas);

• strong vibrations or knocks;

• presence of explosives or flammable gas mixtures;

• exposure to aggressive and polluting atmospheres (e.g.

sulphur and ammonia vapours, salt mist, fumes) that can

cause corrosion and/or oxidation;

• exposure to dust (formation of a corrosive patina with

possible

• oxidation and reduced insulation);

• exposure to water.

Positioning the controller inside the panel

2.2.2

Install the controller inside an electrical panel in a position where it

cannot be reached and is protected from knocks or impacts. The

controller should be placed inside the panel in a position where it is

physically separated from power components (solenoids,

contactors, actuators, inverters, etc.) and their respective cables.

The ideal solution is to house these two circuits in two separate

cabinets. Proximity to such devices/cables may cause random

malfunctions that are not immediately evident. The panel’s casing

must allow an adequate flow of cooling air.

Attention:

• For safety reasons the controller should be installed inside an

electrical panel so that the only accessible parts are the

display and the built-in terminal’s keypad.

• Install the controller so that the disconnection devices can be

used safely and without hindrance.

• When laying out the wiring, separate as much as possible the

probe cables, digital input cables and serial line cables from

the power cables (connected to contactors, thermomagnetic

devices, etc.) avoid electromagnetic interference.

• Never run power cables and probe signal cables in the same

conduits (including the ones in the electrical panels).

• For control signals, use shielded cables with twisted wires. If

the control cables have to cross over power cables, the

intersections should be as close as possible to 90 degrees;

under no circumstances should the control cables be laid

parallel to the power cables.

• Keep the paths of the probe cables as short as possible and

avoid making spiral paths that enclose power devices.

• In case of malfunctions do not attempt to repair the device,

but contact a CAREL service centre.

Electrical installation

2.2.3

Attention: Before servicing the equipment in any way

disconnect the controller from the power mains by putting the

system’s main switch on OFF.

Make sure the system is provided with a power disconnector

conforming to regulations. Use cable lugs that are suitable for the

terminals used.

Loosen each screw and insert the cable lugs, then tighten the

screws.

There is no limit to the number of wires that can be connected to

each individual terminal. When tightening the terminal screws

apply a tightening torque no greater than 0.6 Nm. For information

on the maximum allowable length of the connections to the

analogue/digital inputs and to the analogue outputs please refer to

the “Technical Specifications” table. In environments subject to

strong disturbance use shielded cables with the braiding bonded to

the earthing conductor in the electrical panel. The terminals can

accept wires with a maximum cross-section of 2.5 mm2 (12 AWG).

After making the connection, gently tug on the cables to make sure

they are sufficiently tight.

Note:

• secure the cables connected to the controller with clamps

placed at 3cm from the connectors;

• if the power transformer's secondary winding is earthed,

make sure the earth conductor is bonded to the conductor

that goes to the controller and is connected to terminal G0.

This applies to all the devices connected to the controller

through a serial network.

Attention:

• Using a supply voltage other than specified can seriously

damage the system.

• Installing, servicing and inspecting the controller should be

done only be qualified personnel and in compliance with

national and local regulations.

• All the very low voltage connections (24 Vac/Vdc or 28 to 36

Vdc

• analogue and digital inputs, analogue outputs, serial bus

connections, power supplies) must have reinforced or double

insulation from the power mains.

• Avoid touching or nearly touching the electronic components

mounted on the boards to avoid electrostatic discharges from

the

• operator to the components, which can be very damaging.

• Do not press the screwdriver on the connectors with

excessive force, to avoid damaging the controller.

• Using the device in any way other than specifi ed by the

Manufacturer can compromise its protection system.

• Use only optional boards and connectors supplied by CAREL.

kVent – rel 3.1 – 22/06/2018

7

on port

DISP

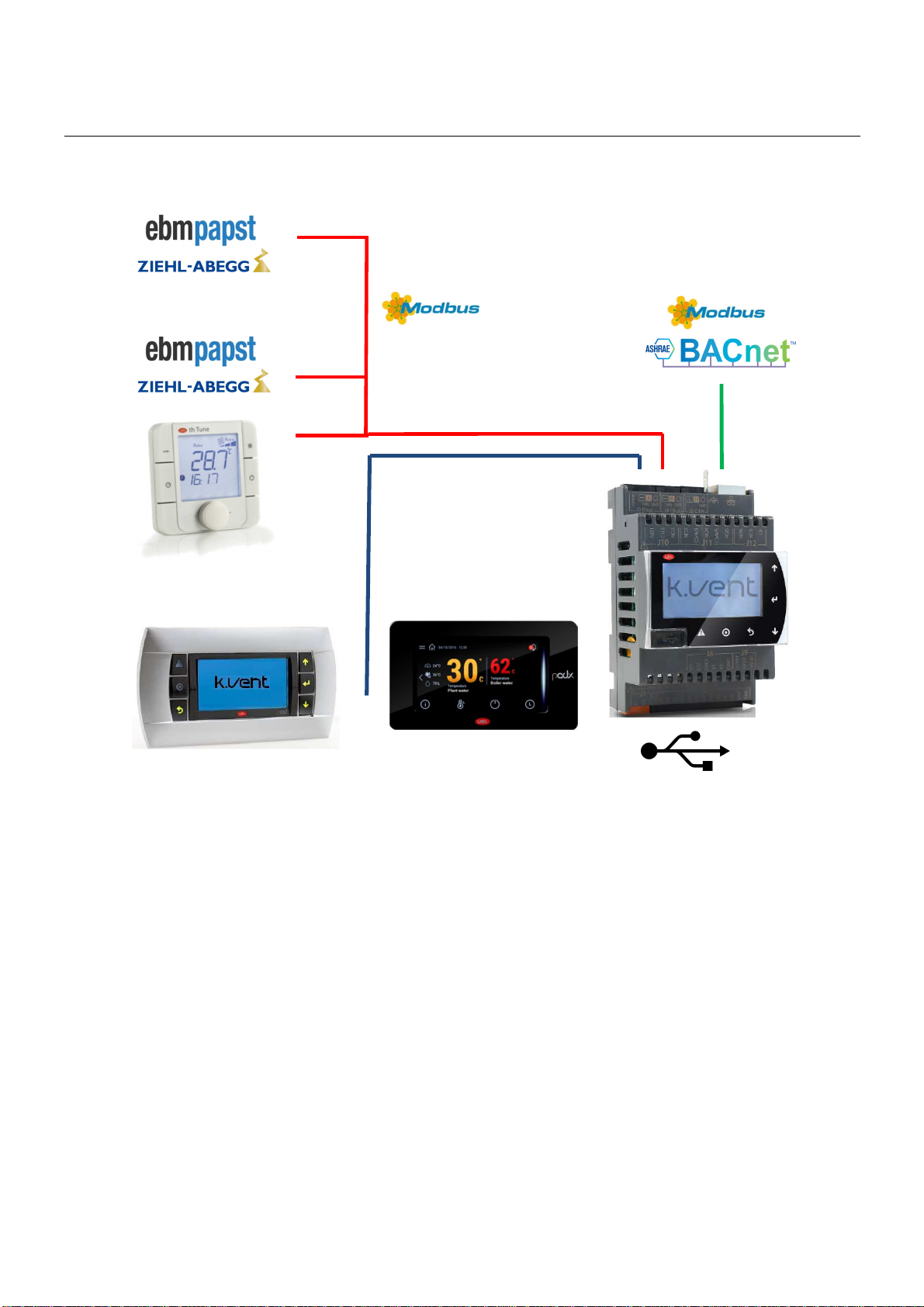

2.3 Field connection

Return fan

Addr. 11

Supply fan

Addr. 12

ModBus® master

protocol on port FB

thTune

Addr. 1

Display protocol

Default frame FieldBus port for ModbusMaster 19200 8N2.

With the following parameters is possible to define a different Frame:

Ha91: Stop bits

Ha92: Parity

kVent – rel 3.1 – 22/06/2018

8

Ref. Description

Acronym

Description

Value

Default

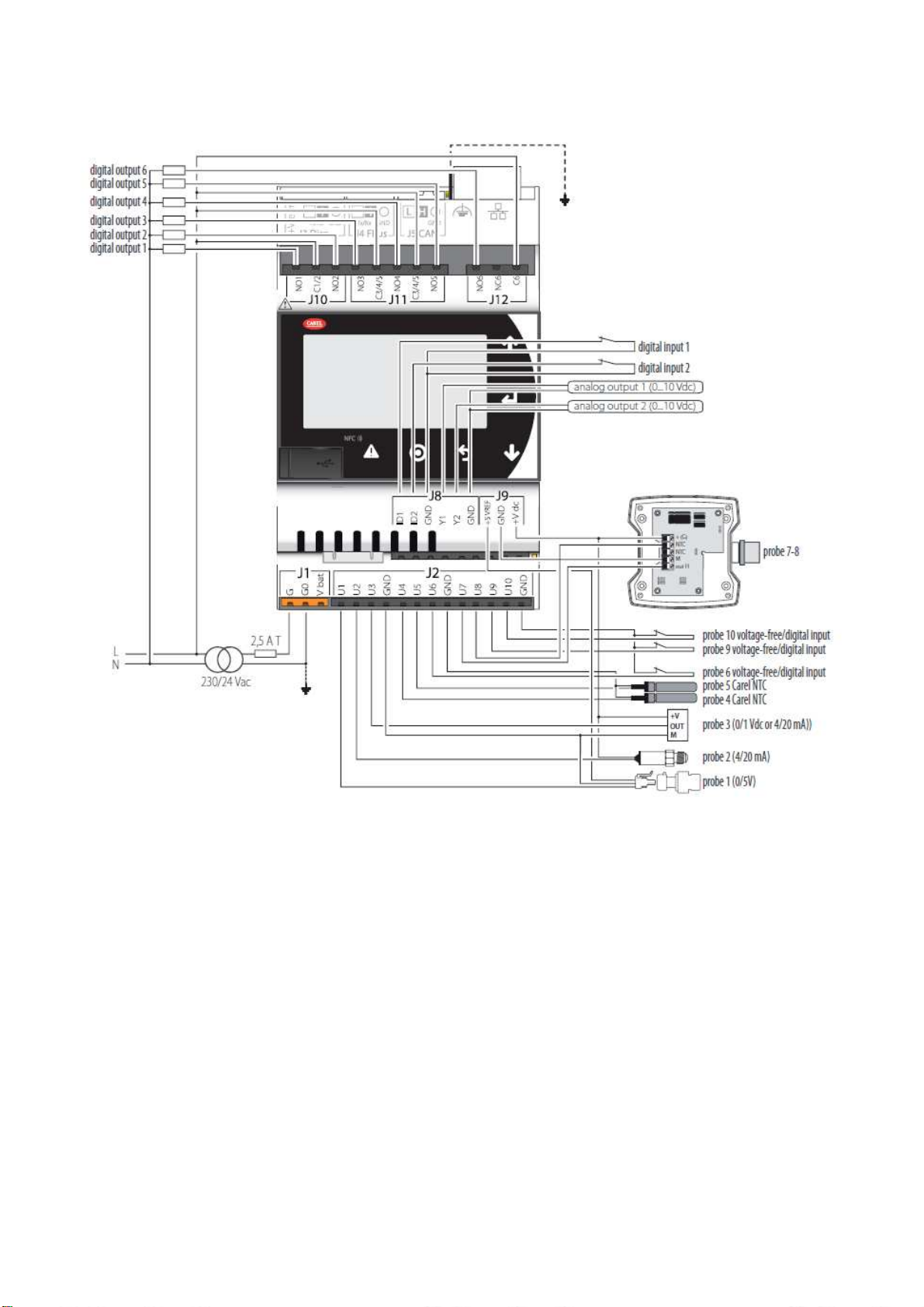

2.4 Input/Output

Connections terminals

2.4.1

Universal I/O In U NTC input 10

In U PT1000 input 10

In U PTC input 10

In U PT500 input 10

In U PT100 input 5

In U

In U

In U

In U

In U

In U

In U Fast digital inputs 2

TOTAL UNIVERSAL 10

Digital inputs In DI Voltage-free contacts 2

TOTAL DIGITAL INPUTS 2

Analog

outputs

Analog

outputs

Analog

outputs

TOTAL ANALOG OUTPUTS 2

Digital outputs Out NO/NC relay output 1

Out NO relay output 5

TOTAL DIGITAL OUTPUTS 6

In/Out

Out U

Out U

Out Y

Out Y

Out Y

Label

Type

0 to 1 Vdc/0 to 10 Vdc input

(powered by controller)

0 to 1 Vdc/0 to 10 Vdc input

(external power supply)

0 to 20 / 4 to 20mA input

(powered by controller)

0 to 20 / 4 to 20mA input

(powered externally)

0 to 5 V input for ratiometric

probe (+5Vref)

Digital input w/ voltage-free

contact

0 to 10 Vdc output, not

opticallyisolated

PWM output, not opticallyisolated

0 to 10 Vdc output, not

opticallyisolated

PWM output, not opticallyisolated

Output for single-pole

stepper motor

0

10

2

4

2

10

5

10

2

2

1

kVent

1 Power connector G(+), G0(-)

2 Vbat: terminal for external Ultracap module (accessory)

3 Universal inputs/outputs

4 +Vterm: terminal power supply

5 Terminal connector

6 Relay digital outputs

8 +5VREF: power supply for ratiometric probes

+VDC: power supply for active probes

9 FieldBus connector

10 BMS connector

11 Analogue outputs

12 Digital inputs

13 CANbus connector

14 Ethernet port

thTune addressing

2.4.2

thTune communicates with the controller throu ModBus network,

so the slave devices must have different ModBus address.

To configure ModBus address of thTune, press buttons

FAN+ON/OFF for 3s, then enter password 22. Parameters are:

kVent – rel 3.1 – 22/06/2018

Addr ModBus address 1 1

bAud Baudrate 2 2

9

Connections example

2.4.3

kVent – rel 3.1 – 22/06/2018

10

Unit setup

Control type

Mandatory I/O

Not available I/O

Recovery

Main-Heater

Recovery

Main

-

Heater

Main

-

Cooler

Reversible

Preheater

R

eheater

Economizer

Humidifier

Hardware

Fa

n type

Recovery control

Heating devices

Cooling devices

Reversible devices

Preheater devices

Reheater devices

Economizer device

Supply regulation

Return regulation

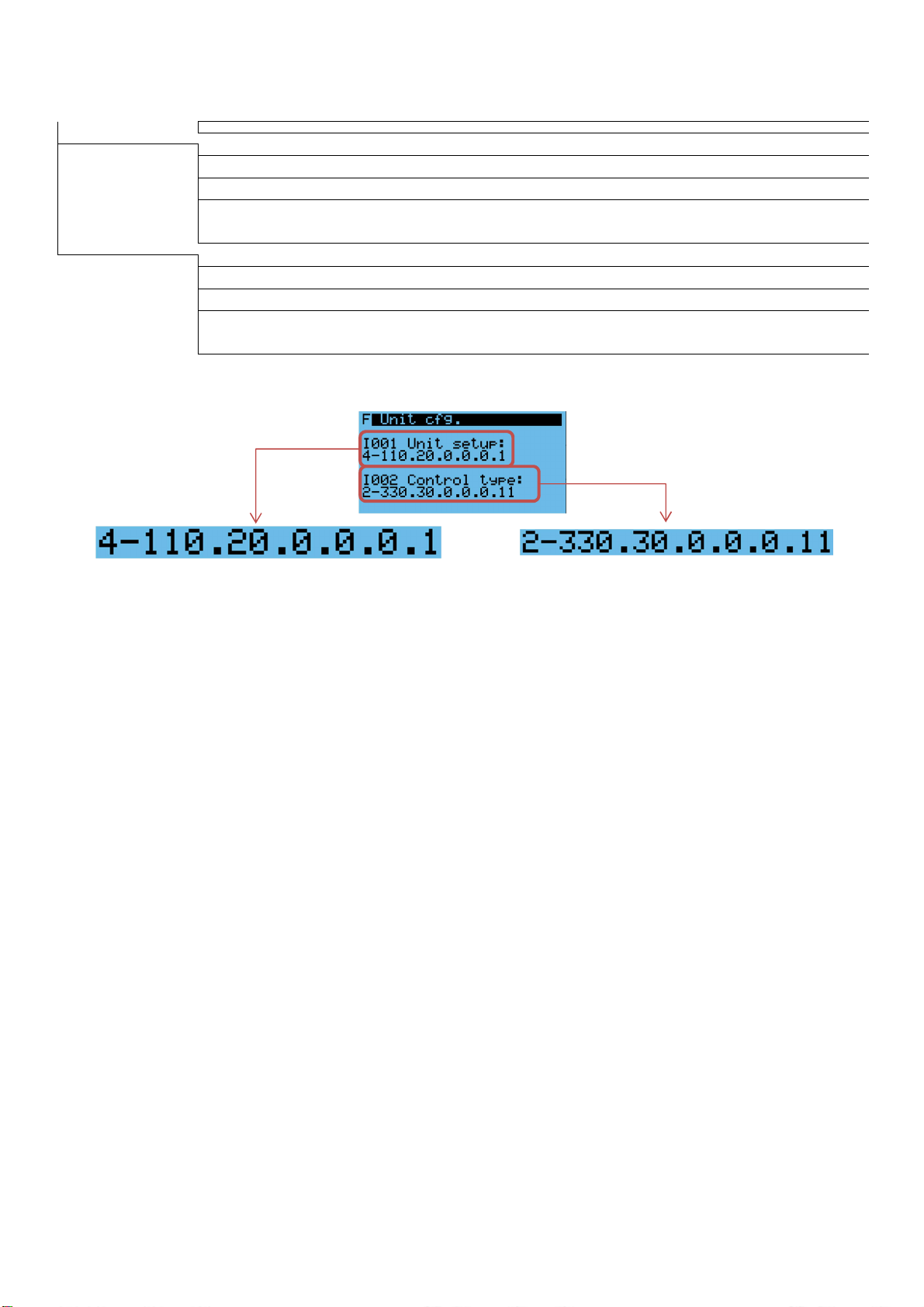

3. SOFTWARE CONFIGURATION

Attention: Structure of the software in class A: the thermal protection safeties for overload and high pressure must act directly on the

actuators and are thus wired in series with the command for coil of the actuators contactors.

The software configuration procedure includes these steps:

1. Configure unit setup unique code in Unit config. menu (I001)

2. Configure control type unique code in Unit config. menu (I002)

3. Assign inputs/outputs with board to point function (menu G)

4. Set regulation and optional parameters

5. Set unit in RUN mode (I003)

Unit setup

3.1.1

To configure the unit is enough to setup an unique application code that determines the devices present on the unit. Here an example of

application code and its meaning and the possible combination on the table.

0 Supply only Supply temperature (AI1)

1 Supply + Exhaust Supply temperature (AI1)

2 Rotary wheel

1 0-10V valve control

2 3 point valve control

3 2 steps control

4 ON/OFF control

3 Glycol

4 Plate cross

1 0-10V valve control

2 3 point valve control

3 2 steps control

4 ON/OFF control

0 None

1 Hot water

1 0-10V valve control

2 3 point valve control

3 0-10V valve in common with cool

kVent – rel 3.1 – 22/06/2018

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Modulating recovery (AO6)

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Recovery 3point valve (DO23, DO24)

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Recovery 2 steps (DO36, DO37)

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Recovery ON/OFF (DO10)

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Recovery ON/OFF (DO10)

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Modulating recovery (AO6)

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Recovery 3point valve (DO23, DO24)

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Recovery 2 steps (DO36, DO37)

Supply temperature (AI1), Exhaust

temperature (AI4), Fresh temperature (AI3),

Recovery ON/OFF (DO10)

Back water temperature (AI6), Fresh

temperature (AI3), Freeze alarm (DI8), Heat

1 (DO4), Modulating heat (AO3)

Back water temperature (AI6), Fresh

temperature (AI3), Freeze alarm (DI8), Heat

1 (DO4), Heat 3 point valve (DO17, DO18)

Back water temperature (AI6), Fresh

temperature (AI3), Freeze alarm (DI8), Heat

1 (DO4), Cool/Heat common (AO12)

11

Exhaust temperature (AI4), Exhaust air pressure (AI14), Exhaust air

filter (DI15), Exhaust air damper (DO9), Recovery (DO10, DO36,

DO37, DO23, DO24, AO6), Exhaust fan (DO15)

Exhaust temperature (AI4), Recovery (DO10, DO36, DO37, DO23,

DO24, AO6)

Recovery 3point valve (DO23, DO24),

Recovery 2 steps (DO36, DO37)

Recovery 2 steps (DO36, DO37), Modulating recovery (AO6)

Recovery 3point valve (DO23, DO24), Modulating recovery (AO6)

Recovery 3point valve (DO23, DO24), Modulating recovery (AO6),

Recovery 2 steps (DO36, DO37)

Modulating recovery (AO6, DO36, DO37, DO23, DO24)

Recovery 3point valve (DO23, DO24),

Recovery 2 steps (DO36, DO37)

Recovery 2 steps (DO36, DO37), Modulating recovery (AO6)

Recovery 3point valve (DO23, DO24), Modulating recovery (AO6)

Recovery 3point valve (DO23, DO24), Modulating recovery (AO6),

Recovery 2 steps (DO36, DO37)

Back water temperature (AI6), Freeze alarm (DI8), Heat alarm

(DI9), Heat 1 (DO4), Heat 2 (DO6), Modulating heat (DO17, DO18,

AO3, AO12)

Heat 2 (DO6), Heat 3 point valve (DO17, DO18), Cool/Heat

common (AO12)

Heat 2 (DO6), Modulating heat (AO3), Cool/Heat common (AO12)

Heat 2 (DO6), Modulating heat (AO3), Heat 3 point valve (DO17,

DO18)

Unit setup

Control type

Mandatory I/O

Not available I/O

Main-Co

oler

Reversible

2 Direct expansion

4 1 digital output Heat 1 (DO4)

5 1 modulating Modulating heat (AO3)

6 2 digital outputs Heat 1 (DO4), Heat 2 (DO6)

7 1 digital output + 1 modulating Heat 1 (DO4), Modulating heat (AO3)

8 2 digital outputs + 1 modulating

9

A

B

3 Electric heater

4 1 digital output Heat 1 (DO4)

5 1 modulating Modulating heat (AO3)

6 2 digital outputs Heat 1 (DO4), Heat 2 (DO6)

7 1 digital output + 1 modulating Heat 1 (DO4), Modulating heat (AO3)

8 2 digital outputs + 1 modulating

9

A

B

4 Steam

1 0-10V valve control

3 0-10V valve in common with cool

0 None

1 Chilled water

1 0-10V valve control

2 3 point valve control

3 0-10V valve in common with heat Fresh temperature (AI3), Cool 1 (DO2),

2 Direct expansion

4 1 digital output Fresh temperature (AI3), Cool 1 (DO2),

5 1 modulating

6 2 digital outputs

7 1 digital output + 1 modulating

8 2 digital outputs + 1 modulating

9

A

B

0 None

1 Hydronic

1 0-10V valve control

2 3 point valve control

2 Direct expansion

3 1 digital output

4 1 modulating Fresh temperature (AI3), Cool/Heat (DO1), Circuit 1 (AI5, AI7, AI8, AI9, DI7, DI18, DO1), Circuit 2 (AI16, AI17,

1 modulating in common with

cool

1 digital output + 1 modulating in

common with cool

2 digital outputs + 1 modulating

in common with cool

1 modulating in common with

cool

1 digital output + 1 modulating in

common with cool

2 digital outputs + 1 modulating

in common with cool

1 modulating in common with

heat

1 digital output + 1 modulating in

common with heat

2 digital outputs + 1 modulating

in common with heat

Heat 1 (DO4), Heat 2 (DO6), Modulating

heat (AO3)

Modulating cool/heat (AO12)

Heat 1 (DO4), Modulating cool/heat (AO12)

Heat 1 (DO4), Heat 2 (DO6), Modulating

cool/heat (AO12)

Heat 1 (DO4), Heat 2 (DO6), Modulating

heat (AO3)

Modulating cool/heat (AO12)

Heat 1 (DO4), Modulating cool/heat (AO12)

Heat 1 (DO4), Heat 2 (DO6), Modulating

cool/heat (AO12)

Back water temperature (AI6), Fresh

temperature (AI3), Heat 1 (DO4),

Modulating heat (AO3)

Back water temperature (AI6), Fresh

temperature (AI3), Heat 1 (DO4), Cool/Heat

common (AO12)

Fresh temperature (AI3), Cool 1 (DO2),

Modulating cool (AO5)

Fresh temperature (AI3), Cool 1 (DO2),

Cool 3 point valve (DO19, DO20)

Fresh temperature (AI3), Modulating cool

(AO5)

Fresh temperature (AI3), Cool 1 (DO2),

Cool 2 (DO3)

Fresh temperature (AI3), Cool 1 (DO2),

Modulating cool (AO5)

Fresh temperature (AI3), Cool 1 (DO2),

Cool 2 (DO3), Modulating cool (AO5)

Fresh temperature (AI3),

Fresh temperature (AI3), Cool 1 (DO2),

Fresh temperature (AI3), Cool 1 (DO2),

Cool 2 (DO3)

Fresh temperature (AI3), Reverse 1 (DO5),

Cool/Heat (DO1), Modulating reverse (AO4)

Fresh temperature (AI3), Reverse 1 (DO5),

Cool/Heat (DO1), Reverse 3 point valve

(DO21, DO22)

Fresh temperature (AI3), Cool/Heat (DO1),

Reverse 1 (DO5),

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 2 (DO6), Modulating heat (AO3),

Modulating cool/heat (AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 1 (DO4), Heat 2 (DO6), Modulating

cool/heat (AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Modulating heat (AO3), Modulating cool/heat

(AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 2 (DO6), Modulating cool/heat (AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Modulating cool/heat (AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 1 (DO4), Heat 2 (DO6), Modulating heat

(AO3)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 2 (DO6), Modulating heat (AO3)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Modulating heat (AO3)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 2 (DO6), Modulating heat (AO3),

Modulating cool/heat (AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 1 (DO4), Heat 2 (DO6), Modulating

cool/heat (AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Modulating heat (AO3), Modulating cool/heat

(AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 2 (DO6), Modulating cool/heat (AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Modulating cool/heat (AO12)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 1 (DO4), Heat 2 (DO6), Modulating heat

(AO3)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Heat 2 (DO6), Modulating heat (AO3)

Back water temperature (AI6), Freeze alarm (DI8), Heat 3 point

valve (DO17, DO18), Modulating heat (AO3)

Heat 2 (DO6), Heat 3 point valve (DO17, DO18), Cool/Heat

common (AO12)

Heat 2 (DO6), Heat 3 point valve (DO17, DO18), Modulating heat

(AO3)

Cooling alarm (DI6), Cool 1 (DO2), Cool 2 (DO3), Cool 3 point valve

(DO19, DO20), Modulating cool (AO5)

Cool 2 (DO3), Cool 3 point valve (DO19, DO20)

Cool 2 (DO3), Modulating cool (AO5)

Cool 2 (DO3), Cool 3 point valve (DO19, DO20), Modulating cool

(AO5)

Cool 3 point valve (DO19, DO20), Cool 2 (DO3), Modulating cool

(AO5)

Cool 3 point valve (DO19, DO20), Cool 1 (DO2), Cool 2 (DO3)

Cool 3 point valve (DO19, DO20), Modulating cool (AO5)

Cool 3 point valve (DO19, DO20), Cool 2 (DO3)

Cool 3 point valve (DO19, DO20),

Cool 3 point valve (DO19, DO20), Cool 1 (DO2), Cool 2 (DO3),

Modulating cool (AO5)

Cool 3 point valve (DO19, DO20), Cool 2 (DO3), Modulating cool

(AO5)

Cool 3 point valve (DO19, DO20), Modulating cool (AO5)

Circuit 1 (AI5, AI7, AI8, AI9, DI7, DI18, DO1), Circuit 2 (AI16, AI17,

AI18, AI19, DI16, DI19, DO31), Circuit 3 (AI20, AI21, AI22, AI23,

DI17, DI20, DO32), Rofftop circuit 1,2,3 (DO16, DO33, DO34),

Reverse 1 (DO5), Reverse 2 (DO7), Reverse 3 point valve (DO21,

DO22), Modulating reverse (AO4), Cool/Heat (DO1)

Circuit 1 (AI5, AI7, AI8, AI9, DI7, DI18, DO1), Circuit 2 (AI16, AI17,

AI18, AI19, DI16, DI19, DO31), Circuit 3 (AI20, AI21, AI22, AI23,

DI17, DI20, DO32), Rofftop circuit 1,2,3 (DO16, DO33, DO34),

Reverse 3 point valve (DO21, DO22)

Circuit 1 (AI5, AI7, AI8, AI9, DI7, DI18, DO1), Circuit 2 (AI16, AI17,

AI18, AI19, DI16, DI19, DO31), Circuit 3 (AI20, AI21, AI22, AI23,

DI17, DI20, DO32), Rofftop circuit 1,2,3 (DO16, DO33, DO34),

Modulating reverse (AO4)

Circuit 1 (AI5, AI7, AI8, AI9, DI7, DI18, DO1), Circuit 2 (AI16, AI17,

AI18, AI19, DI16, DI19, DO31), Circuit 3 (AI20, AI21, AI22, AI23,

DI17, DI20, DO32), Rofftop circuit 1,2,3 (DO16, DO33, DO34),

Reverse 2 (DO7), Modulating reverse (AO4)

kVent – rel 3.1 – 22/06/2018

12

Unit setup

Control type

Mandatory I/O

Not available I/O

Preheater

Reheater

Economizer

Humidifier

Hardware

Fan type

Modulating reverse (AO4) AI18, AI19, DI16, DI19, DO31), Circuit 3 (AI20, AI21, AI22, AI23,

5 2 digital outputs

6 1 digital output + 1 modulating

7 2 digital outputs + 1 modulating

0 None

1 Hot water

1 0-10V valve control

2 3 point valve control

2 Direct expansion

3 1 digital output

4 1 modulating

5 1 digital output + 1 modulating

3 Electric heater

3 1 digital output

4 1 modulating

5 1 digital output + 1 modulating

0 None

1 Hot water

1 0-10V valve control

2 3 point valve control

2 Direct expansion

3 1 digital output Reheater out (DO8) Reheater 3 point valve (DO29, DO30), Modulating reheater (AO10)

4 1 modulating Modulating reheater (AO10) Reheater 3 point valve (DO29, DO30), Reheater out (DO8)

5 1 digital output + 1 modulating

3 Electric heater

3 1 digital output Reheater out (DO8) Reheater 3 point valve (DO29, DO30), Modulating reheater (AO10)

4 1 modulating Modulating reheater (AO10) Reheater 3 point valve (DO29, DO30), Reheater out (DO8)

5 1 digital output + 1 modulating

0 None Eco 3 point valve (DO25, DO26), Modulating eco (AO8)

1 Yes

1 0-10V valve control Modulating eco (AO8) Eco 3 point valve (DO25, DO26)

2 3 point valve control Eco 3 point valve (DO25, DO26) Modulating eco (AO8)

0 None

1 Evaporative

2 Steam

3 IEC+Evaporative

0 Board only

0 ON/OFF Supply fan (DO14) Modulating supply fan (AO1), Modulating exhaust fan (AO2)

1 0-10V signal

0 No regulation

1 VAV

2 CAV

3

Follow supply (only for return)

3

Hepa filter compensation (only

Fresh temperature (AI3), Cool/Heat (DO1),

Reverse 1 (DO5), Reverse 2 (DO7),

Fresh temperature (AI3), Cool/Heat (DO1),

Reverse 1 (DO5), Modulating reverse

(AO4)

Fresh temperature (AI3), Cool/Heat (DO1),

Reverse 1 (DO5), Reverse 2 (DO7),

Modulating reverse (AO4)

Preheater back water temperature (AI10),

After preheater temperature (AI11),

Preheater out (DO11), Modulating

preheater (AO7)

Preheater back water temperature (AI10),

After preheater temperature (AI11),

Preheater out (DO11), Preheater 3 point

valve (DO27, DO28)

After preheater temperature (AI11),

Preheater out (DO11)

After preheater temperature (AI11),

Modulating preheater (AO7)

After preheater temperature (AI11),

Preheater out (DO11), Modulating

preheater (AO7)

After preheater temperature (AI11),

Preheater out (DO11)

After preheater temperature (AI11),

Modulating preheater (AO7)

After preheater temperature (AI11),

Preheater out (DO11), Modulating

preheater (AO7)

Reheater out (DO8), Modulating reheater

(AO10)

Reheater out (DO8), Reheater 3 point valve

(DO29, DO30)

Reheater out (DO8), Modulating reheater

(AO10)

Reheater out (DO8), Modulating reheater

(AO10)

Supply humidity (AI15), Humidifier out

(DO12), Modulating humidifier (AO9)

Supply humidity (AI15), Humidifier out

(DO12), Modulating humidifier (AO9)

Supply humidity (AI15), Humidifier out

(DO12), Modulating humidifier (AO9)

Modulating supply fan (AO1), Modulating

exhaust fan (AO2)

Supply air pressure (AI13), Exhaust air

pressure (AI14), Modulating supply fan

(AO1), Modulating exhaust fan (AO2)

Supply air pressure (AI13) , Exhaust air

pressure (AI14), Modulating supply fan

(AO1), Modulating exhaust fan (AO2)

Modulating supply fan (AO1), Modulating

exhaust fan (AO2)

DI17, DI20, DO32), Rofftop circuit 1,2,3 (DO16, DO33, DO34),

Reverse 1 (DO5), Reverse 2 (DO7),

Circuit 1 (AI5, AI7, AI8, AI9, DI7, DI18, DO1), Circuit 2 (AI16, AI17,

AI18, AI19, DI16, DI19, DO31), Circuit 3 (AI20, AI21, AI22, AI23,

DI17, DI20, DO32), Rofftop circuit 1,2,3 (DO16, DO33, DO34),

Modulating reverse (AO4)

Circuit 1 (AI5, AI7, AI8, AI9, DI7, DI18, DO1), Circuit 2 (AI16, AI17,

AI18, AI19, DI16, DI19, DO31), Circuit 3 (AI20, AI21, AI22, AI23,

DI17, DI20, DO32), Rofftop circuit 1,2,3 (DO16, DO33, DO34),

Reverse 2 (DO7),

Circuit 1 (AI5, AI7, AI8, AI9, DI7, DI18, DO1), Circuit 2 (AI16, AI17,

AI18, AI19, DI16, DI19, DO31), Circuit 3 (AI20, AI21, AI22, AI23,

DI17, DI20, DO32), Rofftop circuit 1,2,3 (DO16, DO33, DO34)

Preheater back water temperature (AI10), After preheater

temperature (AI11), Preheater out (DO11), Modulating preheater

(AO7), Preheater 3 point valve (DO27, DO28)

Preheater 3 point valve (DO27, DO28)

Modulating preheater (AO7)

Preheater back water temperature (AI10), Preheater 3 point valve

(DO27, DO28), Modulating preheater (AO7)

Preheater back water temperature (AI10), Preheater 3 point valve

(DO27, DO28), Preheater out (DO11)

Preheater back water temperature (AI10), Preheater 3 point valve

(DO27, DO28)

Preheater back water temperature (AI10), Preheater 3 point valve

(DO27, DO28), Modulating preheater (AO7)

Preheater back water temperature (AI10), Preheater 3 point valve

(DO27, DO28), Preheater out (DO11)

Preheater back water temperature (AI10), Preheater 3 point valve

(DO27, DO28)

Reheater out (DO8), Modulating reheater (AO10), Reheater 3 point

valve (DO29, DO30)

Reheater 3 point valve (DO29, DO30)

Modulating reheater (AO10)

Reheater 3 point valve (DO29, DO30)

Reheater 3 point valve (DO29, DO30)

Humidifier alarm (DI3), Humidifier out (DO12), Modulating

humidifier (AO9), IEC out (DO35), Modulating IEC (AO11)

IEC out (DO35), Modulating IEC (AO11)

IEC out (DO35), Modulating IEC (AO11)

kVent – rel 3.1 – 22/06/2018

13

Unit setup

Control type

Mandatory I/O

Not available I/O

Plate cross recovery

Water heating

Chiller water

No reversible devices

DX p

reh

eater

No r

eheater

devices

No economizer

No humidifier

Board only

Modulating fan

3 point valve

Signal common with cool

1 digital out

VAV regulation VAV regulation

Signal common with cool

2 EBM fan

0 No regulation Modulating supply fan (AO1), Modulating exhaust fan (AO2)

1 VAV

2 CAV

3 Ziehl Abegg fan

0 No regulation Modulating supply fan (AO1), Modulating exhaust fan (AO2)

1 VAV

2 CAV

for supply)

Follow supply (only for return)

3

Hepa filter compensation (only

3

for supply)

Follow supply (only for return)

3

Hepa filter compensation (only

3

for supply)

Supply air pressure (AI13), Exhaust air

pressure (AI14)

Supply air pressure (AI13), Exhaust air

pressure (AI14)

Modulating supply fan (AO1), Modulating exhaust fan (AO2)

Supply air pressure (AI13), Exhaust air

pressure (AI14)

Supply air pressure (AI13), Exhaust air

pressure (AI14)

Modulating supply fan (AO1), Modulating exhaust fan (AO2)

Modulating supply fan (AO1), Modulating exhaust fan (AO2)

Modulating supply fan (AO1), Modulating exhaust fan (AO2)

Modulating supply fan (AO1), Modulating exhaust fan (AO2)

Modulating supply fan (AO1), Modulating exhaust fan (AO2)

All other I/O not described in the table above, are optional.

According to the table is possible to understand the unit setup in the following example.

kVent – rel 3.1 – 22/06/2018

14

AI Code Analog input

DI Code Digital input

DO Code Digital output

AO Code Analog output

MB ModBus®

E

AI6

AI10

AI11

AI12

AI13

AI14

AI15

AI24

AI25

DI8

DI9

DI12

AI27

DI15

MB2

AO4

AO5

AO3

AO6

AO7

AO9

AO11

DI21

DI22

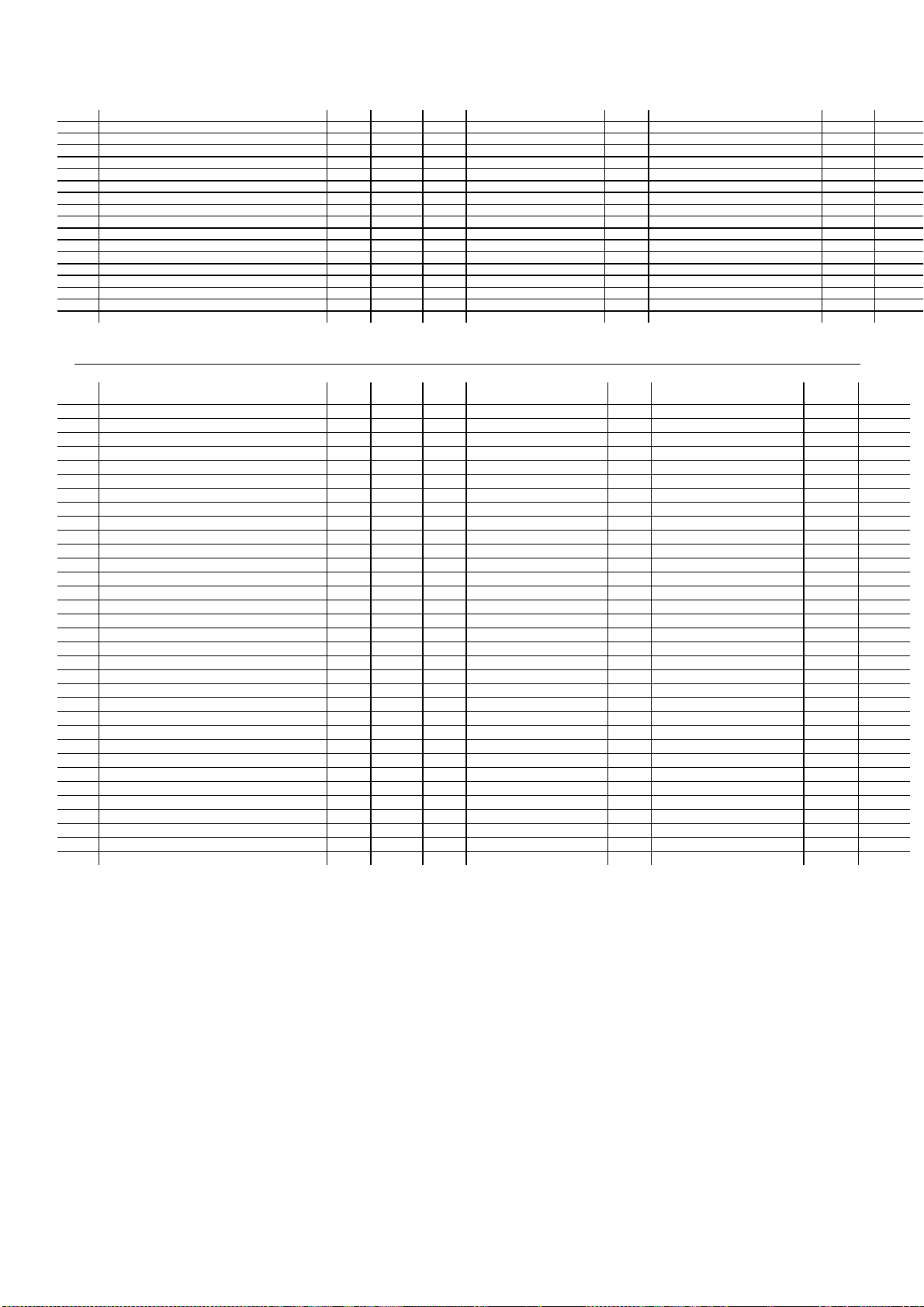

3.2 Unit schema

DO9

AI3

A013

DI13

DI14

AI26

XHAUST

FRESH

DO15

AO2

MB1

DO11

DO1

0

DO35

AO8

DI10

DI11

MB4

DI4

DI1

DO13

DI5

DI6

DO2

DO4

DO1

DO5

DO12

DI3

DO8

AO10

DO14

AO1

DI2

1 Ga01 Supply temperature 1 Gb01 Fire alarm 1 Gc01 Cool/Heat 1 Gd01 Supply fan 1 Exhaust fan

2 Ga06 Return temperature 2 Gb03 Fan overload 2 Gc03 Cooling 1 2 Gd02 Exhaust fan 2 Supply fan

3 Ga11 External temperature 3 Gb05 Humidifier alarm 3 Gc05 Cooling 2 3 Gd03 Heating 4 th-Tune

4 Ga16 Exhaust temperature 4 Gb07 Remote On 4 Gc07 Heating 1 4 Gd04 Reverse

6 Ga26 Back water temperature 5 Gb09 Summer/Winter 5 Gc09 Reverse 1 5 Gd05 Cooling

9 Ga41 Discharge temperature 6 Gb11 Cooling alarm 6 Gc11 Heating 2 6 Gd06 Heat recovery

10 Ga 46 Preheater back water temp. 8 Gb15 Freeze alarm 7 Gc13 Reverse 2 7 Gd07 Preheater

11 Ga51 After preheater temp. 9 Gb17 Heating alarm 8 Gc15 Reheat 8 Gd08 Mix

12 Ga56 CO2 sensor 10 Gb19 Eco 9 Gc17 Exhaust air damper 9 Gd09 Humidifier

13 Ga61 Supply air pressure 11 Gb21 Precomfort 10 Gc19 Recovery 10 Gd10 Reheater

14 Ga66 Exhaust air pressure 12 Gb23 Comfort 11 Gc21 Preheater 11 Gd11 IEC

15 Ga 71 Supply humidity 13 Gb25 Supply filter alarm 12 Gc23 Humidifier 12 Gd12 Cool/Heat signal

24 GaB6 VOC sensor 14 Gb27 Supply filter alarm 2 13 Gc25 Alarm 13 Gd13 Fresh Damper

25 GaC1 Fresh air humidity 15 Gb29 Return filter alarm 14 Gc27 Supply fan 15 Gd15 Main cool req. Optional

26 GaC6 Hepa filter 1 21 Gb41 Supply air flow switch 15 Gc29 Exhaust fan 17 Gd17 Main Heat req. Optional

27 GaD1 Hepa filter 2 22 Gb43 Return air flow switch 17-18 Gc33-35 Heat Op/Cl 19 Gd19 ReHeat req. Optional

23 Gb45 Recovery clogged 19-20 Gc37-39 Cool Op/Cl 20 Gd20 PreHeat req. Optional

24 Gb47 Door Switch 21-22 Gc41-43 Cool/Heat Op/Cl

26 Gb51 External generic alarm 23-24 Gc45-47 Heat rec Op/Cl

25-26 Gc49-51 Mix Op/Cl

27-28 Gc53-55 Preheat Op/Cl

29-30 Gc57-59 Reheat Op/Cl

35 Gc69 IEC humidifer

36 Gc71 Recovery step 1

37 Gc73 Recovery step 2

kVent – rel 3.1 – 22/06/2018

15

Err. pGD description

Error description

3.3 Board to point

kVent allows the manufacturer to setup the Inputs/Outputs (I/O)

according to the application code and its needs: this function is

named board to point. After Unit and control type setup, kVent

recognize the mandatory, suggested and optional I/O. Not

available I/O are not shown in masks.

USB connector from

computer

Suggested I/O are the most common I/O, but not mandatory for

regulation, while optional I/O are up to manufacturer.

When manufacturer setup the I/O according to its needs

(channels, type, logic and limits), there could be an error code in

configuration mask. Here below the error code meaning and the

possible solutions:

1 Reverse not allowed Application code error: cooling device or heating

2 Missing mandatory AI I/O error: a mandatory analog input is not enabled.

3 Missing mandatory DI I/O error: a mandatory digital input is not enabled.

4 Missing mandatory DO I/O error: a mandatory digital output is not enabled.

5 Missing mandatory AO I/O error: a mandatory analog output is not enabled.

6 Wrong AI config. I/O error: analog input configured in not available

7 Wrong DI config. I/O error: digital input configured in not available

8 Wrong DO config. I/O error: digital output configured in not available

9 Wrong AO config. I/O error: analog output configured in not available

10 Missing c.pCOe I/O error: c.pCOe configured in I/O, but not in unit

11 Sensors mismatch I/O error: analog input configured as not available

12 Double DO config. I/O error: same digital output is used for more

13 Double AO config. I/O error: same analog output is used for more

device cannot be enabled with reversible device.

position.

position.

position.

position.

setup.

type in that channel.

functions.

functions.

3.4 Software upgrade

It is possible to load/update the application software of the

controllers family with the following methods:

1. Update from computer by USB cable

2. Update via USB flash drive

3. Update with file transfer via FTP

Attention: only application delivered and approved by

CAREL can be loaded into kVent controller.

Update from computer by USB cable

3.4.1

Connect the computer to the controller via USB cable using device

USB port.

Controller will be shown as a flash memory and it’s possible to load

the binaries into the folder UPGRADE. When the file transfert it’s

done and the cable has been removed, the OS loads the

application into the controller, when the cable has been

disconnected, the OS install the new version.

Update via USB flash drive

3.4.2

Connect the USB flash memory to the USB host port.

USBKey

On system screen it’s possible to select UPGRADE function then

the application program to load into the controller, pressing

ENTER button.

Attention: before updating the kVent controller via USB

connection, check in the system menu that the Device USB port is

enabled (Settings USB Settings PC connection)

Update with file transfer via FTP

3.4.3

The kVent s family controllers fitted with Ehternet port include an

FTP srver that provided acces to the public partition of the file

system. Files and directories in this partion can be read, modified,

created and deleted. FTP can also be used to transfer and .ap1

file, for example to update the image of the operating system or the

application program. This is done using an FTP client, for example

“FileZilla”. The default username to access the file system is

“anonymous”. To protect the contents of the public the file system

against unauthorised access, different user can be created,

assigning each a different access profile, dedicated to each service

and adapted to the individual directory. To update via FTP:

1. Open an FTP client. Enter the IP address of the kVent

controller and the access credentials (default user

“anonymous”, no password)

kVent – rel 3.1 – 22/06/2018

16

2. Drag&drop the software update file from the directory on the

computer to the “UPGRADE” directory on the kVent controller

3. Access the system menu on the kVent and select

“UPGRADE”

Note: when having loaded the update file to the “UPGRADE”

directory via FTP, the update procedure can also be started using

the virtual terminal.

kVent – rel 3.1 – 22/06/2018

17

4. USER INTERFACE

4.1 Display PGDE

The kVent service interface is the pGDE.

The terminal, which is shown in the figure above, has 6 buttons

whose meanings are described below:

Display the list of active alarms

- Alarm

- Prg

- Esc

- Up

- Down

- Enter

The following screen displays an example of the main screen with

an active unit, highlighting the fields and icons used:

Manually reset alarms

Change work mode

Return to the previous screen

Navigate between the display screens or

increase/decrease the value.

Switch from parameter display to edit

Confirm value and return to the parameter list

5. Main temperature regulation

6. Setpoint

7. Indicates access to the user menu using the UP, DOWN and

ENTER keys to confirm

User Menu

4.1.1

On the main screen, the UP and DOWN buttons can be used to

scroll through the functions and ENTER used to select them. No

password is needed to access and edit these parameters.

Info

Set

Mode

Info

The general synoptics for the unit can be shown from the user

menu. The physical status of the inputs, device outputs and probes

are available in a menu connected to the synoptics.

The individual screens of the synoptics are shown below.

Set

In this menu is possible to see the current setpoint and the working

mode, defined by the scheduler. It’s possible to set the setpoint of

the unit and the scheduler. Setpoint is represented by one variable

for each mode.

1. Date and Time

2. Fans speed

3. Operating mode

- STOP

- ECONOMY

- PRECOMFORT

- COMFORT

- AUTO (scheduler)

4. Current unit status:

Opening / Closing dampers

Fans work

Heating

Cooling

Freecooling Freeheating

Humidification

Dehumidification

Active recovery

Normal stop

Emergency stop

Active scheduler

Recovery defrost

Boost function active

Mode

Change operating mode of the unit (stop, economy, precomfort,

comfort, auto, in mask X00a).

Scheduler

4.1.2

On the th-Tune it is possible to set the number of enabled bands

(maximum 6), for each one the starting time and the setpoint of the

room temperature.

On the kVent there are 4 time bands (Z00d) and for each one it will

be possible to set the starting time and the unit status (Off,

Economy, Pre-comfort, Comfort). For each status there will be a

set of values applied: main regulation setpoint, humidity setpoint (if

any humidity probe is present), CO2 level or air flow setpoint (if

differential pressure probe is present).

Besides the daily time band, it will be possible to set up to 3

special periods and 6 special days, for each one it will be possible

to set the unit status (Off, Economy, Pre-comfort, Comfort).

The time bands of the kVent and the set of the th-Tune have the

same priority. The last set that comes it will wins.

The options (I007) of the scheduler are:

1. No scheduler

2. Scheduler by Board

3. Scheduler by thtune

4.2 Menu description

Regardless of the displayed screen, pressing the programming key

accesses the password entry screen which allows access to the

main menu shown below.

The code of the mask is determined by the menu tree.

kVent – rel 3.1 – 22/06/2018

18

Menu description

Param

eters code

A 0..999

B 0..999

C 0..999

D 0..999

E 0..999

F 0..999

Ga 0..99

Gb 0..99

Gc 0..99

Gd 0..99

H 0..999

I 0..999

J 0..999

Heating

Cooling

Reversible

Fans

Recovery

Humidity

In/Out settings

Analog in set

Digital in set

Digital out set

Analog output set

Settings

Unit Cfg.

Logout

Password Management

4.2.1

The program has 3 different password levels:

1. Advanced user (maintenance): read only access to all

parameters. Default password: 0000.

2. Service: read access to all parameters with the ability to edit

some of them (for more information on the parameters that

can be changed, see the parameters table). Default

password: 0001.

3. Manufacturer: read/write access to all parameters. Default

password: 0002.

In the parameters screen, the access needed to edit the

parameters is shown, always with the same codes. An example

follows.

1. ECO

2. PRECOMFORT

3. COMFORT

4. STOP

On-Off

Clock+Mode for

3s

Encoder 1 press Check setpoint

Encoder change Change setpoint

Encoder 2 press External temperature

Encoder 3 press Humidity

In case of humidity or temperature setpoint change from th-Tune,

the setpoint will change until the next change, by scheduler, PGDE

or th-Tune.

In case of StandBy mode by thtune, the unit will be switched OFF.

After a settable time from PGDE, the unit will switch ON and it will

check the conditions. When the set conditions are reached again,

the unit will go to standby condition and it will wait until the next

check.

Note: OnOff of thTune will turn OnOff the display, there will

not be any action in the unit.

Icons meaning

4.3.1

Switch ON-OFF th-Tune display

Exit from settings

Run boost function

Once the password is entered it will be maintained for 5 minutes

from the last time a key was pressed and then the password will

need to be re-entered in order to access the parameters of the

advanced functions. In the Log-Out menu, the password can be

force entered without waiting 5 minutes.

4.3 Display th-Tune

The kVent user interface is the th-Tune, enabled in configuration

mask (I005).

The terminal, which is shown in the figure above, has 4 buttons

whose meanings are described below:

Mode

Clock Enable scheduler

Clock 2s thTune scheduler settings

Fan Change working setpoint:

StandBy mode/Auto mode and stop the

boost function when active

4.3.2

thTune allows to configure the scheduler after pushing CLOCK

button for 2s. The data are stored in the thTune, so when passing

from a time band (hh:mm) to another one the display is proposing

as starting time the hour and minute following the previous one

(hh:mm+1). The th-Tune is checking the consistency of the time

bands.

After the push of “ENCODER” terminal displays “Sel days”.

Rotating “ENCODER” is possible to select a group of days or a

single day:

It’s possible to select up to 6 time bands for each day.

Alarm active. Alarm code appear on the second

thTune row

Fans active

Heating working

Cooling working

Defrosting heat pump

Function locked

Scheduler management

• “7 days” (mon, tue, wed, thu, fri, sat, sun)

• “5 days” (mon, tue, wed, thu, fri)

• “2 days” (sat, sun)

• “Day by day”

kVent – rel 3.1 – 22/06/2018

19

Parameters of a single time band selected are temperature

setpoint and start time.

Setpoint

Time

It’s possible to disable a timeband rotating the encoder and setting

“--:--“ in the display, as the following picture.

To configure an OFF band from thtune, it’s possible to rotate to the

minimum value of setpoint to OFF, as the following picture.

4.4 User setpoint

The comfort zone of the unit can be changed by:

• Fan button of thTune

• Mode settings of pGDE (X00a)

• Digital input, if configured (Gb07)

• Any browser connected to Ethernet port of kVent

• Any master device connected to BMS port

Available comfort zones are ECO, PRECOMFORT and

COMFORT.

This working mode can change the following sets if the functions

are activated:

1. Supply temperature

a. Economy (Z001)

b. Precomfort (Z002)

c. Comfort (Z003)

2. Room/Return temperature

a. Economy (Z004)

b. Precomfort (Z005)

c. Comfort (Z006)

3. Humidity

a. Economy (Z007)

b. Precomfort (Z008)

c. Comfort (Z009)

4. Air quality (CO2)

a. Economy (Z010)

b. Precomfort (Z011)

c. Comfort (Z012)

5. Air quality (VOC)

a. Economy (Z013)

b. Precomfort (Z014)

c. Comfort (Z015)

6. Supply fan speed (in percentage)

a. Economy (Z016)

b. Precomfort (Z017)

c. Comfort (Z018)

7. Return fan speed (in percentage)

a. Economy (Z019)

b. Precomfort (Z020)

c. Comfort (Z021)

thTune can override temperature setpoint determined by comfort

zone, but setpoint will be override again by controller in case of

comfort zone changing.

kVent – rel 3.1 – 22/06/2018

20

AI Code Analog input

Function

DI Code Digital input

Function

Supply

set

5. FUNCTIONS

5.1 Input functions

Here below the list of analog inputs functions:

1 Ga01 Supply temperature Main temperature regulation

2 Ga06 Return temperature

3 Ga11 External temperature

4 Ga16 Exhaust temperature

6 Ga26 Back water temperature Antifreeze control

10 Ga 46

11 Ga51

12 Ga56 CO2 sensor Fresh air regulation

13 Ga61 Supply air pressure VAV and CAV regulation

14 Ga66 Exhaust air pressure VAV and CAV regulation

15 Ga 71 Supply humidity Main humidity regulation

24 GaB6 VOC sensor Fresh air regulation

25 GaC1 Fresh air humidity Freecoling/freeheating enabling

Preheater back water

temperature

After preheater

temperature

Here below the list of digital inputs functions:

1 Gb01 Fire alarm Fire alarm activation

2 Gb03 Fan overload Stop unit

3 Gb05 Humidifier alarm Stop humidifier

4 Gb07 Remote On Start/Stop the unit with timings

5 Gb09 Summer/Winter Define working mode

6 Gb11 Cooling alarm Stop cooling

Gb15 Freeze alarm Stop ventilation

8

9 Gb17 Heating alarm Stop unit and force ventilation ON

10 Gb19 Eco Force unit in Economy mode

11 Gb21 Precomfort Force unit in Precomfort mode

12 Gb23 Comfort Force unit in Comfort mode

13 Gb25 Supply filter alarm Warning dirty filter

14 Gb27 Supply filter alarm 2 Warning dirty filter

15 Gb29 Return filter alarm Warning dirty filter

21 Gb41 Supply air flow switch Check air flow and stop unit

22 Gb43 Return air flow switch Check air flow and stop unit

Gb45

23

24 Gb47 Door Switch Door open

Recovery clogged Recovery in defrost mode

5.2 On request

The On status requires the AND logic of:

• Unit configured by Service (I003)

• No serious alarm

• On by digital input

• On by the OR of the following conditions:

o On by pGD (X00a)

o On by BMS

o On by thTune, if present

o On by scheduler, if enabled

Variable mode is shared with all the control sources.

If any condition go to OFF, the unit will turn OFF.

5.3 Cooling/Heating changeover

The external and room/return temperatures are considered: if

the external temperature is lower than a minimum threshold or

greater than a upper threshold the heating or cooling mode

can be forced:

Heating

Supply setpoint compensation

Fire alarm activation

Recovery control and defrost

FreeCooling/freeheating

Cool/Heat mode changeover

Antifreeze and antifrost control

Fast heating function

Fire alarm in case of return probe

broken

Antifreeze control

Main preheating regulation

Recovery defrost

Force heating valve at 100%

probe isn’t available the heating or cooling mode will be

decided considering the room temperature or the return

temperature (if the probes are available), here below it is

represented the behaviour in case of room temperature:

Cooling

Delay

Heating

Supply setpoint

Delay

2.0°C 2.0°C

Supply temp.

If the room temperature is greater than the setpoint, the unit

starts in cooling mode and remains in cooling mode until the

room temperature becomes lower than the setpoint for a

settable delay (H013), then the heating mode is activated. In

the same way, if the starting temperature is lower than the

setpoint the unit starts in heating mode and remains in heating

mode until the room temperature becomes greater than the

setpoint for the same delay.

5.4 Temperature regulation strategy

Compensation

5.4.1

The regulation of the unit could be done according the return,

supply or room set.

In case of return or room regulation, kVent provides the

compensation control strategy, based on return or room and

external temperature. Compensation modulate the supply

setpoint between the minimum and maximum supply setpoint.

External temperature compensation

100

0

-100

H008

Min heat

H007

Min cool

H009

Return temperature compensation

Return set

Max cool

H010

PID regulation

H005

H006

Max heat

100

0

-100

Final supply setpoint is calculated as following:

-100% is equal to maximum supply setpoint and 100% is equal

to minimum supply setpoint, as in the following graph:

Cooling

Based on room temp.

H012

H011

External temp.

In the middle, between the heating and cooling external

temperature thresholds, or when the external temperature

kVent – rel 3.1 – 22/06/2018

Max set

H001

Min set

H002

-100% 100%

21

Note: To disable external temperature compensation is

possible to setup minimum compensation equal to maximum

compensation.

Supply regulation

5.4.2

The temperature regulation is based on supply temperature

and its setpoint. If the setpoint set is the room set or return set,

according to configuration parameter (I008), this will be

converted to supply set.

To calculate the power of devices, a PID sequence is used.

The following graph show the PID sequence in case of cooling:

100%

0%

Mixing

E024

E025

Recovery

E011

E012

Cooling device

B008

B009

Supply temp.

Set

The following graph show the PID sequence in case of

heating:

Reheat

A035

A036

Supply temp.

Heating device

A016

A017 100%

Recovery

E006

E007

Mixing

E022

E023

0%

Set

With a unique setpoint and different sets of PID parameters,

the first request is calculated with a standard PID. The second

request starts when the first one has reached 100%. The

setpoint for the second device regulation is the same, while the

PID set of parameters are different. According to the PID

behaviour of the second device, the percentage of activation of

the second device at the start up should be equal to ‘’offset’’,

but thanks to the incremental PID it is possible to consider only

the last calculated delta so that there aren’t any bumps, then

the second device will start from the minimum output, then it

will regulate according to PID parameters and supply

temperature.

In case we have more devices and one is not available when

required from the sequential PID regulation - for activation

conditions not verified (i.e. recovery conditions) or active

alarms - the request passes to the other one. If the first device

becomes available again the device will be turned on at 100%.

5.5 Fresh air regulation

In case of unit without the mixing damper, the supply air is

always coming from the outside: if the external temperature is

better than the room or return temperature and the activation

of freecooling/freeheating is verified (external temperature

lower than the regulation temperature of a settable delta), the

bypass damper opens and the heat exchanger is bypassed.

In the following picture we represent the ‘’freecooling’’

enabling, that in case of unit without the mixing damper is the

by-pass damper activation condition, considering as example

the room temperature as regulation variable.

The freecooling is enabled if the external temperature is higher

than the lower supply temperature threshold, while the

freeheating is enabled if the external temperature is lower than

the upper supply temperature threshold.

Delta

2.0°C

Room – Ext Temp.

Set

The bypass damper can be modulated to reach the desired

temperature for the supply air temperature, because the

freecooling can be considered as the first step of sequential

PID regulation.

In case of unit with the mixing damper, the

freecooling/freeheating conditions are the same, but mixing

damper and external one modulate accordingly, and the logic

acts on the bypass damper as in the previous case.

Night kick

5.5.1

If the unit is in standby mode, it starts at a certain hour (H016)

in the night to check the conditions and if there is requests, the

unit switch ON. When conditions are reached, the unit goes

back to standby.

5.6 Humidity regulation

The regulation of the unit could be done according to return,

supply or room set, according to configuration parameter

(I009). The regulation of humidity in kVent is done by absolute

humidity.

Absolute humidity setpoint is the conversion between the

actual temperature setpoint (room, return or supply) and the

relavtive humidity set that the user can change.

Absolute humidity is the conversion between the actual

temperature and the room relative humidity.

Based on these conversions, it’s possible to determine if the

unit should go in humidifying or dehumidifying mode. When the

humidity goes to change mode, a delay is provided to avoid

fast change of humidity control.

Humidification

Delay

F013

Band

F014

Dehumidification

Delay

F013

Set

In case of regulation on return or room temperature, the

application check the supply humidity limits to avoid water of

the ducts. Closer the supply humidity is to the limits, lower the

humidity PID can act.

In case of regulation on supply, the humidity request goes

directly to the devices.

During dehumidification:

- The signal to control the cooling devices is calculate from

the maximum between output temperature PID and the

output humidity PID.

- The main heating devices are disabled and the reheaters

works to compensate the cooling effect.

- Mixing damper is closed.

During humidification:

- Mixing damper is open 100%.

5.7 Devices activation

ON/OFF Recovery

5.7.1

In case of ON/OFF recovery, kVent calculate modulating

recovery request anyway. The digital output is activated by

time, calculated by the request, with a fixed period of 10

minutes.

For example if the request is 60%, the digital output is ON for

360s and OFF for 240s, so the following graph show the

working logic.

kVent – rel 3.1 – 22/06/2018

22

Stages activation

A031 A032 A033 A034

B015 B016 B017 B018

C053 C054 C055 C056

Timings settings

A028 A029 A0030

A040 A041 A042

A051 A052 A053

B011 B012 B013

C050 C051 C052

Recovery

Request

10min

0min

ON time

OFF time

Period fixed to 10minutes

100%

ON time

OFF time

Hydronic circuits in heating

5.7.2

The PID sequence calculates a request 0-100% that is directly

executed by the valves, but in case of water antifreeze

prevent, the water valve opening increase, according to

antifreeze setpoint. For antifreeze details check the related

chapter.