High Efficiency Solutions

humiFog multizone

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

pumping unit

User manual

3

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

WARNINGS

CAREL INDUSTRIES Hq humidifiers are advanced products, whose operation is

specified in the technical documentation supplied with the product or can be

downloaded, even prior to purchase, from the website www.carel.com. Each

CAREL INDUSTRIES Hq product, in relation to its advanced level of technology,

requires setup/configuration/programming/commissioning to be able to

operate in the best possible way for the specific application. The failure to

complete such operations, which are required/indicated in the user manual,

may cause the final product to malfunction; CAREL INDUSTRIES Hq accepts

no liability in such cases.

The customer (manufacturer, developer or installer of the final equipment)

accepts all liability and risk relating to the configuration of the product in order

to reach the expected results in relation to the specific final installation and/or

equipment. CAREL INDUSTRIES Hq may, based on specific agreements, act as

a consultant for the installation/commissioning/use of the unit, however in no

case does it accept liability for the correct operation of the humidifier and the

final installation if the warnings or suggestions provided in this manual or in

other product technical documents are not heeded. In addition to observing

the above warnings and suggestions, the following warnings must be heeded

for the correct use of the product:

• DANGER OF ELECTRIC SHOCK

• The humidifier contains live electrical components. Disconnect the mains

power supply before accessing inside parts or during maintenance and

installation;

• DANGER OF WATER LEAKS

• The humidifier automatically and constantly fills/drains certain quantities of

water. Malfunctions in the connections or in the humidifier may cause leaks;

• For isothermal humidiers: DANGER OF BURNS

• The humidifier contains high temperature components (100°C/212°F);

• For gas-red isothermal humidiers: DANGER OF GAS LEAKS

• The humidifier is connected to the gas mains. Malfunctions in the

connections or inside the humidifier may cause gas leaks.

• The installation of the product must include an earth connection, using the

special yellow-green terminal available in the humidifier.

• The environmental and power supply conditions must conform to the

values specified on the product rating labels.

• The product is designed exclusively to humidify rooms either directly or

through distribution systems (ducts). In addition, for adiabatic-water spraypressure humidifiers, humidification also occurs through the atomisation

rack.

• Only qualified personnel who are aware of the necessary precautions and

able to perform the required operations correctly may install, operate or

carry out technical service on the product.

• Only water with the characteristics indicated in this manual must be used

for steam or water vapour production.

• Warning, demineralised drinking water must be used for adiabatic-water

spray-pressure humidifiers (as specified in the manual). In addition, the

particles of water not absorbed by the air must be removed into the

droplet collection tank (in the humidification section) and by the droplet

separator (at the end of the humidification section).

• All operations on the product must be carried out according to the

instructions provided in this manual and on the labels applied to the

product. Any uses or modifications that are not authorised by the

manufacturer are considered improper. CAREL INDUSTRIES Hq declines all

liability for any such unauthorised use.

• Do not attempt to open the humidifier in ways other than those specified

in the manual.

• Observe the standards in force in the place where the humidifier is installed.

• Keep the humidifier out of the reach of children and animals.

• Do not install and use the product near objects that may be damaged when in

contact with water (or condensate). CAREL INDUSTRIES Hq declines all liability

for direct or indirect damage following water leaks from the humidifier.

• Do not use corrosive chemicals, solvents or aggressive detergents to clean

the inside and outside parts of the humidifier, unless specifically indicated

in the user manual.

• Do not drop, hit or shake the humidifier, as the inside parts and the linings

may be irreparably damaged.

• For adiabatic-water spray-pressure humidifiers: the atomised water must

be distributed using a special atomising ‘rack’ or through distribution

systems specified by CAREL INDUSTRIES Hq

• For isothermal appliances: these are designed to produce steam at

atmospheric pressure, and not pressurised steam. CAREL INDUSTRIES Hq

does not recommend and waives all liability for the use of distribution

devices other than those specified.

CAREL INDUSTRIES Hq adopts a policy of continual development.

Consequently, CAREL reserves the right to make changes and improvements

to any product described in this document without prior warning. The

technical specifications shown in the manual may be changed without prior

warning.

The liability of CAREL INDUSTRIES Hq in relation to its products is specified

in the CAREL INDUSTRIES Hq general contract conditions, available on the

website www.carel.com and/or by specific agreements with customers;

specifically, to the extent where allowed by applicable legislation, in no case

will CAREL INDUSTRIES Hq, its employees or subsidiaries be liable for any lost

earnings or sales, losses of data and information, costs of replacement goods

or services, damage to things or people, downtime or any direct, indirect,

incidental, actual, punitive, exemplary, special or consequential damage of any

kind whatsoever, whether contractual, extra-contractual or due to negligence,

or any other liabilities deriving from the installation, use or impossibility to use

the product, even if CAREL INDUSTRIES Hq or its subsidiaries are warned of the

possibility of such damage.

DISPOSAL

The humidifier is made up of metal parts and plastic parts. In reference to

European Union directive 2002/96/EC issued on 27 January 2003 and the

related national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and such waste must be

collected and disposed of separately;

2. the public or private waste collection systems defined by local legislation must

be used. In addition, the equipment can be returned to the distributor at

the end of its working life when buying new equipment;

3. the equipment may contain hazardous substances: the improper use or

incorrect disposal of such may have negative effects on human health

and on the environment;

4. the symbol (crossed-out wheeled bin) shown on the product or on the

packaging and on the instruction sheet indicates that the equipment has

been introduced onto the market after 13 August 2005 and that it must

be disposed of separately;

5. in the event of illegal disposal of electrical and electronic waste, the penalties

are specified by local waste disposal legislation.

Warranty on the materials: 2 years (from the date of production, excluding

consumables).

Approval: the quality and safety of CAREL INDUSTRIES Hq products are

guaranteed by the ISO 9001 certified design and production system, as well

as by the following marks.

WARNING: separate as much as possible the probe and digital input signal

cables from the cables carrying inductive loads and power cables to avoid

possible electromagnetic disturbance.

Never run power cables (including the electrical panel wiring) and signal

cables in the same conduits.

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

5

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

Content

1. INTRODUCTION AND ASSEMBLY 7

1.1 Description of humiFog ..........................................................................................7

1.2 Components in the system ..................................................................................7

1.3 humiFog system configurations ........................................................................7

1.4 Supply water characteristics.................................................................................7

1.5 Periodic checks for consumables ......................................................................8

1.6 Dimensions and weights ........................................................................................8

1.7 Components (master/slave) .................................................................................9

1.8 Electrical specifications.........................................................................................10

1.9 Opening the packaging .......................................................................................10

1.10 Positioning the cabinet ......................................................................................11

1.11 Opening the cabinet door ................................................................................12

1.12 Components and accessories .........................................................................12

2. WATER CIRCUIT CONNECTIONS 13

2.1 Water circuit installation: instructions .........................................................13

2.2 Water circuit installation: checklist ................................................................13

3. ELEC TRICAL CONNECTIONS 14

3.1 Power supply .............................................................................................................15

3.2 Remote ON/OFF .......................................................................................................15

3.3 Control signals from external voltage-free contact (humidistat) .....15

3.4 Modulating control signal (J2) .........................................................................16

3.5 Heat recovery signal ...............................................................................................17

3.6 Solenoid valve connection for distribution system ............................17

3.7 Water treatment unit contact ...........................................................................18

3.8 Cumulative alarm relay (J15) .............................................................................18

3.9 Pump state contact ...............................................................................................18

3.10 Pump life signal .........................................................................................................18

3.11 Alarm inputs from external devices ...........................................................19

3.12 Backup/rotation (redundancy) ........................................................................19

3.13 Expansion mode/remote actuator ................................................................19

3.14 Master-slave connection .....................................................................................20

3.15 Supervisor network .................................................................................................20

4. PUMPING UNITS 21

4.1 Pumping unit with flow control configuration .....................................21

4.2 Pumping unit with constant pressure control .......................................21

5. DISTRIBUTION SYSTEM 22

5.1 Air handling unit: distribution, atomisation system and

droplet separator ......................................................................................................22

5.2 Direct humidification into the room: distribution and

atomisation system .................................................................................................22

6. APPLICATIONS 23

6.1 Main advantages of humiFog multizone ..................................................23

7. CONTROL 24

7.2 Evaporative Cooling ...............................................................................................25

8. SINGLE ZONE AND MULTIZONE CONFIGURATION 27

8.1 Single zone ...................................................................................................................27

8.2 Multizone application in AHU or room ......................................................28

8.3 Indirect adiabatic cooling applications ......................................................30

8.4 System operation .....................................................................................................30

8.5 Constant pressure systems: notes on capacity control ....................31

9. START UP 32

9.1 Starting ...........................................................................................................................32

9.2 Stopping ........................................................................................................................32

9.3 First start-up .................................................................................................................32

10. USER INTERFACE 33

11. TABLE OF ALARMS 49

12. WIRING DIAGR AMS 52

12.1 Wiring diagram humiFog multizone - Master - CE -

MONOFASE ...................................................................................................................52

12.2 Wiring diagram humiFog multizone - Master - CE -

TRIFASE

(solo per UA10K***) .......................................54

12.3 Wiring diagram humiFog multizone - Master - UL -

MONOFASE ...................................................................................................................56

12.4 Wiring diagram humiFog multizone - Master - UL - TRIFASE .......58

12.5 Wiring diagram humiFog multizone - Slave - CE ................................60

12.6 Wiring diagram humiFog multizone - Slave - UL ................................62

7

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

1. INTRODUCTION AND ASSEMBLY

1.1 Description of humiFog

humiFog is a humidifier and adiabatic cooler that atomises demineralised

water into very fine droplets that evaporate spontaneously in the air,

which is humidified and cooled.

humiFog uses a volumetric pump to pressurise the water, which is

atomised by special stainless steel nozzles.

The sophisticated control system combines the action of an inverter,

which controls the speed and consequently the flow-rate of the pump,

with a series of solenoid valves that activate only the nozzles that are

necessary, allowing the system to always operate at the ideal pressure

to atomise the water, across a wide range of flow-rates (a 5-100 % flow

range working with a constant pressure of 14-100% for operating while

controlling the flow).

The effect of cooling the air is due to the spontaneous evaporation of

the droplets of water: the change in state from liquid to steam occurs by

subtracting energy from the air that, as a consequence, is cooled. Each

kilogram of water evaporated absorbs 0.69 kWh of heat from the air.

humiFog is a complete humidification and/or adiabatic cooling system

that can be used both in AHUs (air handling units) and to humidify or cool

industrial environments by spraying water directly into the environments.

The term zone refers to both AHUs and industrial environments.

1.2 Components in the system

humiFog is made up of:

• a pumping unit that delivers the water at high pressure (25-70 bars).

It also contains the electronic controller that completely manages the

pumping unit, controlling the temperature/humidity in a zone (either

AHU or environment) and managing any other zones connected to

the pumping unit;

• The pumping unit can be set to operate:

- with flow control (maximum precision, minimum energy and water

consumption, only single zone applications);

- at constant pressure (suitable for multizone applications where one

pumping unit supplies the humidification and/or cooling system in

different zones);

• distribution and atomisation system: system of pipes carrying the

pressurised water that house the atomisation nozzles and, in general,

the capacity-control solenoid valves and drain solenoid valves;

• droplet separator (only when installed in an AHU);

• temperature and/or humidity probes (if necessary);

• water treatment system: typically this is a reverse osmosis demineraliser

that supplies water with a low mineral salt content to the humiFog.

1.3 humiFog system configurations

The humiFog system can be used in the following configurations:

• single zone: for humidification and/or cooling applications in a AHU or

an industrial environment;

• multizone: for applications where one pumping unit (master) is

used to supply multiple zones with pressurised water. The master

will control one zone, in the sense that in relation to the zone probe

readings or the external controller, it will activate and control the

distribution and atomisation system so as to maintain the humidity or

temperature level. All other zones will have a controller (slave electrical

panel) that communicates with the master, and in relation to the zone

probe readings or the external controller will activate and control the

distribution atomisation system so as to maintain the humidity or

temperature level.

One important configuration is for indirect adiabatic cooling applications:

a pumping unit can be used to humidify the air in winter and to cool

the discharged air in summer before it enters a heat recovery unit. This

configuration is explained in detail in the chapters below.

humiFog humidifiers are available for:

• maximum flow-rates respectively of 100 l/h,(UA100..) 200 l/h (UA200..),

320 l/h (UA320..), 460 l/h (UA460..), 600 l/h (UA600..);

• type of cabinet: H=single zone master; Z=multizone master; S=slave

cabinet;

• power supply voltage: D= 230 V 50 Hz; U= 208 V 60 Hz;

• shows the version of the launched product (1 - 4)

• damper: 0=without damper; 1=with damper (only versions with 100

and 200 l/h flow-rate)

• features of the pump and circuits: 0= brass; 1=stainless steel; 2=

stainless steel, silicon free

1.4 Supply water characteristics

Why does humiFog require demineralised water?

Humifog only works with demineralised water, to ensure:

• minimum maintenance;

• no blockage of the nozzles;

• no dust (the droplets that evaporate do not leave mineral salts in the

AHU/environment);

• more hygiene.

The use of demineralised water is also required by standards such as

UNI8883 , VDI6022, VDI3803

humiFog must only be supplied with treated water, based on the limit

values listed below. In normal circumstances, this means that the water

must be treated using a reverse osmosis system.

recommended supply water characteristics unit of

measure

limits

min. max.

bH (**)(pH)

6,5 8,5

Specific conductivity at 20°C (**) (σR, 20°C) for steel

pump

µS/cm 0 30

Specific conductivity at 20°C (**) (σR, 20°C) for brass

pump

µS/cm 30 50

Total hardness (**) (TH) mg/l CaCO3 0 25

Temporary hardness mg/l CaCO3 0 15

Total quantity of dissolved solids (cR) mg/l

(*) (*)

Dry residue at 180° (R180°C) mg/l

(*) (*)

Iron + Manganese mg/l Fe+Mn 0 0

Chlorides ppm Cl 0 10

Silicon dioxide mg/l SiO2 0 1

Chlorine ions mg/l Cl- 0 0

Calcium sulphate mg/l CaSO4 0 5

Tab. 1.a

(*) values depend on the specific conductivity; in general:

CR 0,65 * σ

R, 20 °C

; R

180

0,93 * σ

R, 20 °C

(**) main values to keep in consideration for every type installation.

Important: If the specific conductivity is less than 30 µS/cm, the

stainless steel pump should be used.

Important:

(**)

for conductivity values around “0”, contact CAREL

INDUSTRIES for operating suggestions.

Caution: for conductivity higher than 1000 S/cm, it is required to

pre-treat the water before subjecting it to reverse osmosis.

Caution: the pump is able to operate at a maximum temperature of

40°C.

8

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

1.5 Periodic checks for consumables

Summary table of checks and maintenance:

Pump

Check/Replace monthly every 1000 h

Water filters X

Oil level X

Replace oil X

Check/replacement gasket and valves X

Attention: after the first 50 h of exercise you need to replace the oil

pump.

Attention: if the “1000h” check does not identify any leaks or

malfunctions, then the possibility to postpone the replacement

shall be assessed. Typically, in optimum operating conditions, this process

is necessary around 3000 h of operation.

Rack/distribution system

visually check every 1000 h

obstructed nozzles X

solenoid valves X

accessories X

drain and water X

droplet separator X

Tab. 1.b

Installations in AHUs or ducts must also comply with national maintenance

standards (ASHRAE 12-2000, VDI 6022, UNI 8884, VDI 3803, etc.)

Please note that:

• maintenance personnel must reset the hour counter after having

performed the preventive maintenance operations listed in the

columns “after 50 hours” and “every 1000 hours”. If the hour counter

is not reset, the maintenance warnings will no longer be signalled

(to reset the hour counter, see the information under Section 9.8

Maintenance menu/submenu f/screen 02);

• maintenance personnel are responsible for any malfunctions due to a

lack of preventive maintenance. The controller will display maintenance

warning code “C5” after the first 50 hours and, subsequently, routine

maintenance warning code “CL” every 2000 hours, as a reminder for

the operations listed;

• failure to change the oil after the first 50 hours of operation may cause

oil leaks and serious damage to the pumps, reducing operating life;

• maintenance signals do not stop the operation of humiFog.

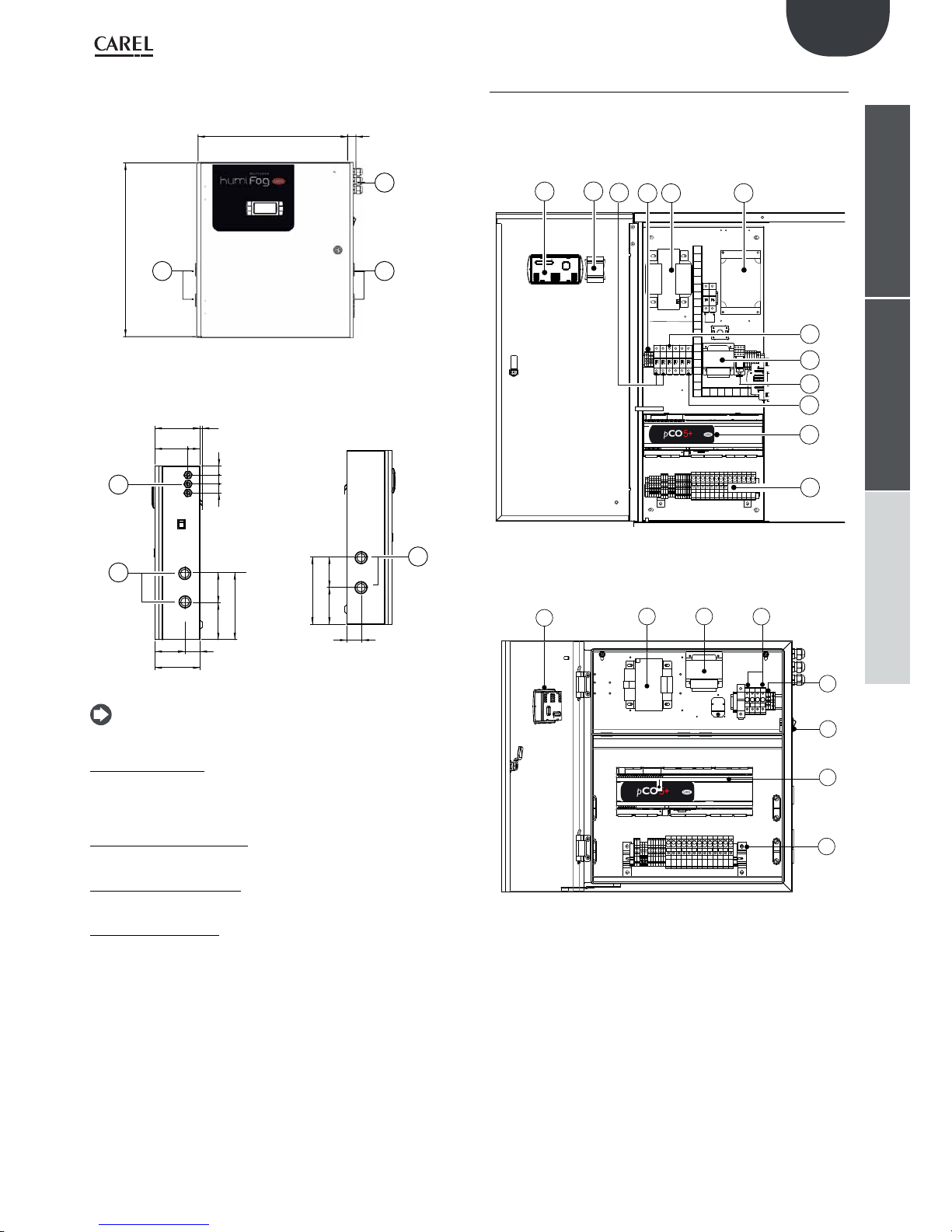

1.6 Dimensions and weights

Humifog master

front view

1030

20

135

550

70

360

860

1

2

3

4

5

6

Fig. 1.a

detail of cabinet, water inlet/outlet

side view

electrical connection side view

90

554

135

2055

105

2558

3

4

5

6

70

360

430

75

75

4040 40 4040

2

1

Fig. 1.b

Key:

1. power supply inlet;

2. terminal block inlet;

3. water inlet;

4. water outlet;

5. drain

6. drain bypass..

N.B.: inlets for electrical connections ready to be cut out, opening

and cable gland installation to be performed by the installer

Packaging dimensions:

• height (H): 1020 mm (40.16 inch);

• width (W) 1100 mm (43.30 inch);

• depth (D) 455 mm (17.50 inch).

Weight of packaged humidifier:

• UA(100,200)(H,Z)4** models: 100 kg (220 lb);

• UA(320,460)(H,Z)4** models: 110 kg (240 lb);

• UA600(H,Z)4** models: 120 kg (265 lb);

• UA1K0(H,Z)4** models: 125 kg (276 lb);

Weight of installed humidifier:

• UA(100,200)(H,Z)4** models: 85 kg (190 lb);

• UA(320,460)(H,Z)4** models: 95 kg (210 lb);

• UA600(H,Z)4** models: 100 kg (220 lb);

• UA1K0(H,Z)4** models: 105 kg (230 lb);

Mechanical specifications:

• Installation: floor standing;

• IP20; (enclosure type 1).

• cabinet operating conditions: 1 to 40 °C (34 to 104 °F) <80 % RH non-

condensing;

• storage conditions: 1 to 50 °C (34 to 122 °F) <80 % RH non-condensing

9

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

Humifog slave

front view

500 28

580

1

22

Fig. 1.c

detail of cabinet, air & water inlet side

view

detail of cabinet, outlet side view (to

nozzles)

150 8

303030

40110

101

50100

150

123

224

1

2

123 101

50

224

2

Fig. 1.d

N.B.: inlets for electrical connections ready to be cut out, opening

and cable gland installation to be performed by the installer

Packaging dimensions:

• height (H): 770 mm (30.14 inch);

• width (W) 605 mm (23.82 inch);

• depth (D) 255 mm (10.00 inch).

Weight of packaged humidifier:

• UA000S(D,U)400 models: 21 kg (46.3 lb);

Weight of installed humidifier:

• UA000S(D,U)400 models: 19.5 kg (43 lb);

Mechanical specifications:

• Installation: wall mounted;

• IP20; (enclosure type 1)

• cabinet operating conditions: 1 to 40 °C (34 to 104 °F) <80 % RH non-

condensing;

• storage conditions: 1 to 50 °C (34 to 122 °F) <80 % RH non-condensing

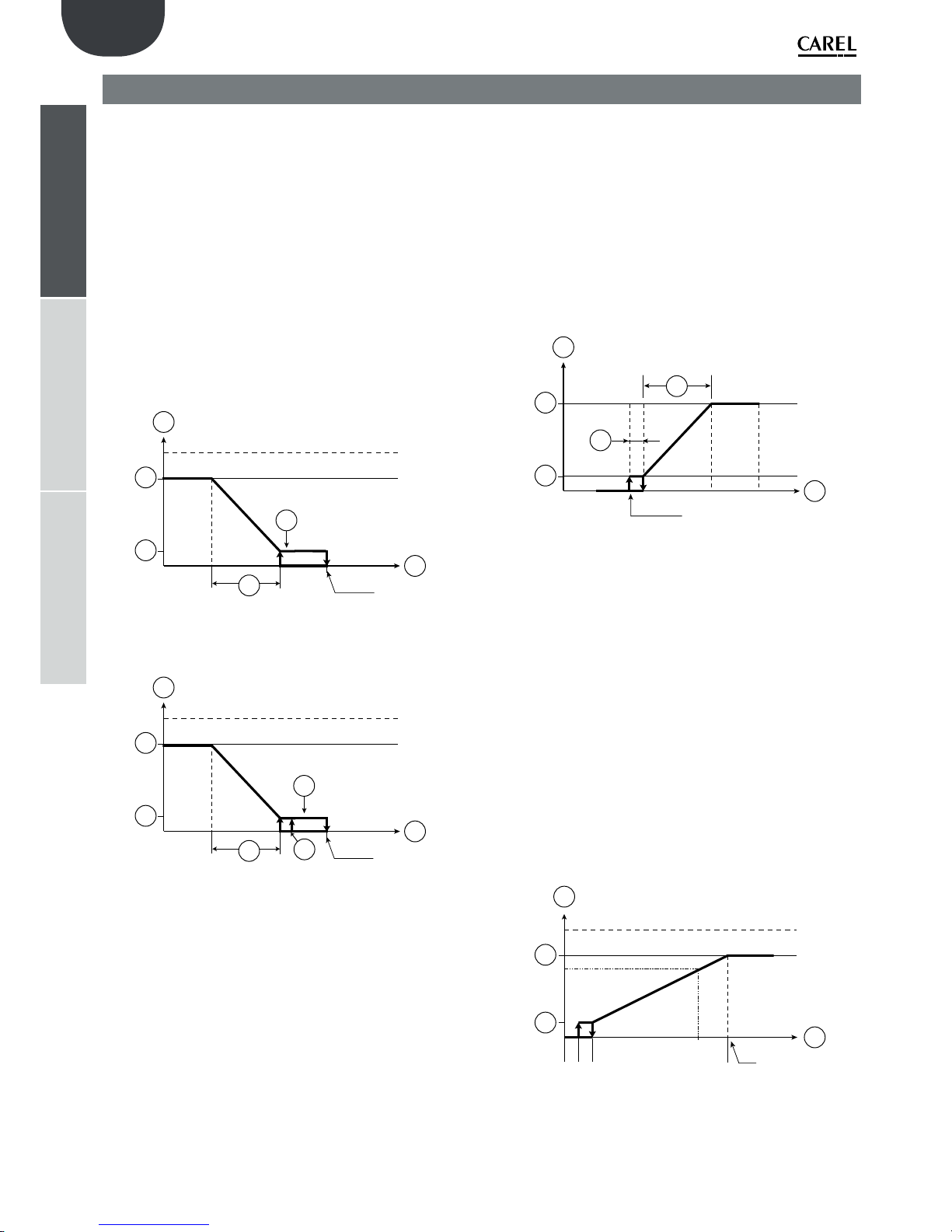

1.7 Components (master/slave)

Electrical components

Master cabinet

F1 F2 F6

F8

F7

F9

1

3

6

4

2

5

9

7

10

8

11

12

Fig. 1.e

Slave cabinet

1

2

8

6

4

3

11

12

Fig. 1.f

Key:

1. terminal rear view.

2. transformer B.

3. main switch G.

4. power supply terminal block.

5. VFD inverter.

6. transformer primary fuse carrier (TRA: F1,F2; TRB:F3,F4).

7. inverter fuse carrier (F6, F7).

8. transformer B secondary fuse carrier (F8).

9. transformer A.

10. start relay K.

11. electronic controller;

12. control terminal block plus fuses

10

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

Water circuit components

12

7

5

6

8

9

11

10

13

23 4

1

Fig. 1.g

16

15

14

17

Fig. 1.h

Key:

1. inlet water pressure reducer with filter;

2. 1st pressure gauge, inlet;

3. water filter;

4. minimum pressure switch (1 bar);

5. 2nd pressure gauge, downstream of the water filter;

6. conductivity sensor;

7. water supply solenoid valve;

8. motor;

9. pulsation damper;

10. outlet pressure gauge, high pressure side;

11. piston pump;

12. maximum pressure switch (95 bars);

13. high pressure control valve;

14. thermostat (70 °);

15. bypass solenoid valve;

16. temperature probe;

17. pressure transducer

18. drain bypass.

1.8 Electrical specifications

MASTER 50 HZ

model UA100*D4** UA200*D4** UA320*D4** UA460*D4** UA600*D4** UA1K0*HL4*

VAC 230 V 230 V 230 V 230 V 230 V 400 V

phases 1 1 1 1 1 3

Hz 50 -60 Hz 50 -60 Hz 50 -60 Hz 50 -60 Hz 50 -60 Hz 50-60 Hz

power 0,955 kW 0,955 kW 1,150 kW 1,150 kW 1,95 kW 4 kW

current 7,0 A 7,0 A 9,2 A 9,2 A 12,0 A 4,6 A

Product in compliance with EN55014, EN61000, EN60204.

Insulation grade III

MASTER 60 HZ

model UA100*U4** UA200*U4** UA320*U4** UA460*U4** UA600*U4** UA1K0*HM4*

VAC 230 V 230 V 230 V 230 V 230 V 460 V

phases 1 1 1 1 1 3

Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

power 0,955 kW 0,955 kW 1,150 kW 1,150 kW 1,95 kW 2.75 kW

current 8,00 A 8,00 A 10,20 A 10,20 A 13 A 4.8 A

FLA 1HP/8 A 1HP/8 A 2HP/12 A 2HP/12 A 3HP/17 A 3HP/6.1 A

SCCR 5KA 5KA 5K A 5K A 5KA 5K A

Product in compliance with UL998

SLAVE

model UA000SD400 UA000SU400

VAC 230 V 208 V

phases 1 1

Hz 50 Hz 60 Hz

power 0,280 kW 0,280 kW

current 2,20 A 2,50 A

FLA - 3/4HP

SCCR - 5KA

Product in compliance with UL998

Tab. 1.c

1.9 Opening the packaging

make sure the humidifier is intact upon delivery and immediately

notify the transporter, in writing, of any damage that may be due to

careless or improper transport;

move the humidifier to the site of installation before removing from

the packaging, grasping the neck from underneath;

for the master cabinet:

position the cabinet near the site of installation (still packaged on the

pallet);

remove the packaging;

unscrew the bolts and remove the pallet (the cabinet is secured to the

bottom of the pallet using 4 bolts);

for the slave cabinet:

open the cardboard box, remove the protective material and remove

the humidifier, keeping it vertical at all times.

Keep the packaging in a cool and dry environment (cardboard box, pallet,

4 bolts used to secure the cabinet to the pallet) for reuse.

11

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

1.10 Positioning the cabinet

Both cabinets: master and slave, should be positioned so as to guarantee

the following:

• read the values on the display;

• access the keypad on the display;

• open the front panels;

• access to the inside parts for checks and maintenance;

• connection of the water supply lines;

• connection to the water distribution lines;

• power and control connections;

• prepare a base of at least 200 mm.

in particular, for the Master cabinet:

It can be positioned wherever the following conditions are ensured:

• clearance for routine maintenance as described in Fig. 1.f

• humidity 20-80% rH non-condensing

• temperature 1-40 °C;

• cabinet compliant with seismic testing standards IEC 60068-2-6, IEC

60068-2-57, IEC 60068-2-64, ISO2041. To ensure compliance with the

above-mentioned standards, the cabinet must be anchored to the

floor using the threaded holes provided (M6 female thread), as shown

in Fig. 1.i.

65

900

65

20 20

310

INSERTI FILETTATI M6

FEMMINA

65

900

65

M6 F

20

310

20

M6 F

Fig. 1.i

Important: the maximum distance between the cabinet and rack/

distribution system is 50 metres, for higher distances contact CAREL

INDUSTRIES.

Positioning procedure:

• after opening the packaging:

• position the cabinet in the final position;

• level the cabinet horizontally.

TV

3751000

100

1075

55

45

100 100

P

Fig. 1.j

Slave cabinet

Fasten it to a solid support surface using the screws and bracket supplied.

Make sure there is enough space for the electrical power supply and

control connections.

rear of the cabinet

390

200

440

drilling template

440

200

390

= =

= =

Fig. 1.k

12

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

1.11 Opening the cabinet door

Master cabinet

Opening Fig. 1.h:

1. Release the water circuit panel:

use a flat-head screwdriver (max. 8 mm);

turn anticlockwise until releasing the panel.

2. Remove the panel:

tilt the panel and lift it.

Closing Fig. 1.h:

3. Reposition the water circuit panel:

Important: insert the bottom pins of the panel in the corresponding

holes (F).

4. Lock the panel:

use a flat-head screwdriver (max. 8 mm);

turn clockwise until the panel is secured

Fig. 1.l

Slave cabinet

1. press and turn anticlockwise with a flat-head screwdriver (max 8 mm)

until releasing the panel;

2. open the cabinet door by turning it to the left.

1

2

Fig. 1.m

1.12 Components and accessories

Once having opened the packaging and removed the front cover of the

humidifier, make sure the following are included:

for master units:

• tool for opening the water inlet filter casing;

• PG13 and PG21 cable glands for the electrical connections (CE versions

only).

• yellow/black pump motor oil cap, to replace the red cap on the pump.

for slave units

• kit of screws with plugs for wall-mounting;

• PG13 and PG21 cable glands for the electrical connections (CE versions

only).

13

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

2. WATER CIRCUIT CONNECTIONS

2.1 Water circuit installation: instructions

The water connections are

•

water inlet;

• high pressure water outlet to the rack (see ”connecting the cabinet to

the rack” in the distribution manual);

• water drain.

Water circuit installation: instructions

To simplify installation and maintenance, install a manual valve

immediately before connecting the water inlet to the cabinet (this valve

is not supplied by CAREL).

humiFog only operates on demineralised water, preferably from a

reverse osmosis system. The specifications and the limits of the water are

described in detail in chap. 1.4 “supply water characteristics”.

1. open the water circuit (vedi par. 1.10 “Opening the cabinet door”):

2. connect the water supply hose:

• the supply hose connection fitting is G1/2”F (NPT1/2”F - UL 60 Hz

version).

• the inside diameter of the supply hose must not be less than

13 mm.

• run the water supply hose through hole “3” Fig. 1.a.

Water drain connection

1. connect the drain “5” Fig. 1.a to the drain system:

• use a hose with inside diameter 10 mm, resistant to demineralised

water.

• connect the hose to the drain connection underneath the cabinet

using a hose clamp.

N.B.: the hose and the clamp are not supplied by CAREL, to

tighten clamp, lift the cabinet.

2. connect the drain bypass “6” Fig. 1.a to the drain system.

Replacing the top oil cap on the pump

1. replace the top oil cap on the pump:

• replace the TOP oil cap ( (Fig. 2.a, A), used for transport only, with

the CAP WITH THE VENT HOLE (Fig. 2.a, B) used in normal operation;

• keep closed cap for future transport.

2. reposition the front panel on the water circuit and close it.

Fig. 2.a

CE versions

model UA100*D4** UA200*D4** UA320*D4** UA460*D4** UA600*D4** UA1K0*HL4*

max flow

rate (l/h;

lb/h;Gd)

100 200 320 460 600 950

220 441 705 1014 1323 2095

634 1268 2028 2916 3805 6023

inlet

pressure

(Mpa,Bar,

PSI)

0,3…0,8 Mpa

3…8 Bar

40…100 PSI

temperat. 1T40 ºC / 34T104 ºF

input G1/2”F G1/2”F

adapter

outlet

(pump)

M16,5m DIN 2353 (G3/8”F) M22,5m

DIN 2353

(G1/2”F)

main

drain

G1/2”F

drain

tray

External stainless steal pipe φ 10 mm/ 0.4 inch

Tab. 2.a

UL versions

model UD100*U4** UD200*U4** UD320*U4** UD460*U4** UD600*U4** UA1K0*HM4*

max flow

rate (l/h;

lb/h;Gd)

100 200 320 460 600 950

220 441 705 1014 1323 2095

634 1268 2028 2916 3805 6023

inlet

pressure

(Mpa,Bar,

PSI)

0,3…0,8 Mpa

3…8 Bar

40…100 PSI

temperat. 1T40 ºC / 34T104 ºF

input NPT 1/2”F (with adapter G1/2” M - NPT 1/2” F)

adapter

outlet

(pump)

NPT3/8F NPT1/2F

main

drain

NPT 1/2”F (with adapter G1/2” M - NPT 1/2” F)

drain

tray

External stainless steal pipe φ 10 mm/ 0.4 inch

Tab. 2.b

2.2 Water circuit installation: checklist

humiFog system name: _____________________________________

Description / notes

Cabinet level

Distance between cabinet-rack/water distribution system: ≤50 m.

Water supply connection

Water inlet pressure ≥3 bars (0.3 MPa, 40 PSI)

Filters filled with water

Drain connected to the water drain system

drain bypass: TFN8x10 NYLON WHITE hose connected to the water

drain

Pump: oil cap replaced with the cap featuring the vent

Supply water within the limit values See the section on “Supply water

characteristics””

Date: _______________

Signature: _______________________________________

14

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

3. ELECTRICAL CONNECTIONS

Master version

F1 F2 F6

F8

F7

F9

1

J15

4

5

J20

J19

J6

J2

3

2

J3

Fig. 3.a

Slave version

J15

4

1

5

J6

3

2

J3

J2

Fig. 3.b

Legenda:

1 L/N/GR Power supply

Important

• make sure that the cable glands

are fitted

• do not run the control and signal

cables through this cable gland.

J2 U1 Main humidity/temperature probe

U2 Limit humidity/temperature probe

U3 AUX probe (temperature display

only)

J3 U5 Segnale recuperatore di calore per

EC, uscita configurabile sia analogi-

ca che digitale

J6 U8 rack temperature probe

J15 NO8 Cumulative alarm relay

J19 NO24 Pumping unit signal

J20 NO27 Pumping unit enable signal

2 PEN/G0A Pumping unit remote enabling

signal

ROAL/G0A Water treatment system control

BKUP/G0A Back up cabinet signal

ROEN/COM comand for water treatment system

ON-OFF/G0A Control signals from external con-

tact type humidistat ON/OFF

RKEN/G0A RACK production enable

FLUX/G0A Air flow

3 NC1÷NC6/GOB Slicing solenoid valves step

NO1÷NO6/GOB Drain solenoid valve step

NOL Drain solenoid valve line

NOV Fan solenoid valve (rack)

4 Field card Field card input for Master Slave

connection

5 Serial Card Serial card input for BMS (Building

Management Systems)

N.B.: feature adequate protection on all activation

outputs to external devices.

15

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

3.1 Power supply

Depending on the model:

• UA****D4** voltage 230 V 1~ 50Hz

• UA****U4** voltage 230 V 1~ 60Hz

• UA1k0*HL4* voltage 400 V 3~ 50Hz

• UA1k0*HM4* voltage 460 V 3~ 60Hz

Important: The cables must conform to local standards.

Install a power switch outside the humidifier to completely isolate

the mains power supply, with earth fault protection (30 mA).

GR

L

N/W

GR

N/W

L

L

N/W

GR

L

N/W

GR

MASTER

SLAVE

GR

L2

L1

GR

L1

L2L3L3

400V Trifase

230V Monofase

Fig. 3.c

CONNECTIONS

Cabinet master - slave 230V Monophase Powersupply cable

L L/F (fase) AWG13 (2,5 mm)

N N/W (neutro) AWG13 (2,5 mm)

GR GR/PE (terra) AWG13 (2,5 mm)

Cabinet master 400/460V Threephase Powersupply cable

L1 L1 (fase 1) AWG13 (2,5 mm)

L2 L2 (fase 2) AWG13 (2,5 mm)

L3 L3 (fase 3) AWG13 (2,5 mm)

GR GR/PE (terra) AWG13 (2,5 mm)

3.2 Remote ON/OFF

Cables • up to 30 m: two-wire cable AWG20/22

electrical specifications of the

contact:

voltage-free contact

GR

PEN

GR

PEN

ROAL

ROAL

BKUP

BKUP

ROEN

ROEN

COM

COM

ONOF

ONOF

RKEN

RKEN

FLUX

FLUX

G0B

G0B

G0A

G0A

G0A

G0A

G0A

G0A

G0B G0B G0B G0B G0B

G0B G0B G0B G0B G0B

21

Fig. 3.d

Key:

1. Pump remote ON/OFF

2. Zone remote ON/OFF

CONNECTIONS

humiFog Master cabinet Remote ON/OFF

PEN (enable pump) NC/NO

RKEN (enable master rack) NC/NO

G0A COM

humiFog Slave cabinet Remote ON/OFF

RKEN (enable slave rack) NC/NO

G0A COM

N.B.: the Master unit is supplied with contacts PEN-G0A and RKENG0A jumpered, the Slave unit is supplied with contact RKEN-G0A

jumpered

3.3 Control signals from external voltagefree contact (humidistat)

a) ON/OFF (C control)

Cables • up to 30 m: two-wire cables cross-section 0.5 mm2

(AWG20)

• greater than 30 m: shielded cables cross-section 1.5

mm

2

(AWG15)

electrical specifications of

the contact

voltage-free contact

GR

PEN

GR

PEN

ROAL

ROAL

BKUP

BKUP

ROEN

ROEN

COM

COM

ONOF

ONOF

RKEN

RKEN

FLUX

FLUX

G0B

G0B

G0A

G0A

G0A

G0A

G0A

G0A

G0B

G0B

1

Fig. 3.e

Contact open: humiFog deactivated

Contact closed: humiFog activated

humiFog Master cabinet ON/OFF humidistat thermostat

ON/OFF NC/NO

GOA COM

b) ON/OFF and limit probe (CH/CT control)

J9

J24

J2

J3

GR

PEN

GR

PEN

ROAL

ROAL

BKUP

BKUP

U

U

U

U

U

U

U

ROEN

ROEN

COM

COM

ONOF

ONOF

RKEN

RKEN

FLUX

FLUX

G0B

G0B

G0A

G0A

G0A

G0A

G0A

G0A

G0B

G0B

1

2

Fig. 3.f

Key:

1. ON/OFF humidistat thermostat

2. limit humidity/temperature probe

16

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

3.4 Modulating control signal (J2)

The control signal input connections depend on the control algorithm

activated.

Cables • up to 30 m: two-wire cables cross-section 0.5 mm2

(AWG20)

the signal may

come from

• modulating control with external controller

• modulating control with ambient humidity probe

• external controller and limit humidity probe

• ambient humidity probe and limit humidity probe

• modulating control with temperature control

• modulating control with temperature control and limit

probe

To set the type of operation, control and signal: “installer menu > type of

control (see chap. 9.11 Installer menù).”

N.B.: shielded cables should be used. The cables must not run near

the 230 V/208 V power cables nor near the contactor cables: this avoids

measurement errors due to electromagnetic disturbance.

a. Modulating control with external controller (P control)

0 to 1 V; 0 to 10 V; 2 to 10 V; 0 to 20 mA; 4 to 20 mA.

SERIAL CARD

J9

J24

J2

J3

J4

J5

FIELD CARD

p

1

U

U

U

U

U

U

U

Fig. 3.g

Key:

1. external controller

Connections:

humiFog cabinet External controller

J2 B1 OUT

GND Reference, shield

b. Modulating control with ambient humidity probe (H control)

0 to 1 V; 0 to 10 V; 2 to 10 V; 0 to 20 mA; 4 to 20 mA

SERIAL CARD

J9

J24

J2

J3

J4

FIELD CARD

1

U

U

U

U

U

U

U

Fig. 3.h

Key:

1. humidity sensor

Connections:

humiFog cabinet Ambient humidity probe

J2 B1 OUT H

+Vdc +(G)

GND M

c. Modulating control with controller and limit probe

(PH/PT control)

0 to 1 V; 0 to 10 V; 2 to 10 V; 0 to 20 mA; 4 to 20 mA

SERIAL CARD

J9

J24

J2

J3

J4

J

FIELD CARD

p

1

2

/T

U

U

U

U

U

U

U

Fig. 3.i

Key:

1. limit humidity/temperature probe;

2. external controller.

Connections:

humiFog cabinet External controller Limit humidity

probe

J2 B1 OUT

B2 OUT H/T

+Vdc +(G)

GND Reference M

d. Modulating control with ambient humidity probe and limit humidity

and temperature probe (HH/HT control)

0 to 1 V; 0 to 10 V; 2 to 10 V; 0 to 20 mA; 4 to 20 mA

SERIAL CARD

J9

J24

J2

J3

J4

J5

FIELD CARD

p

1

2

/T

U

U

U

U

U

U

U

Fig. 3.j

Key:

1. limit humidity/temperature probe;

2. ambient humidity probe.

Connections:

humiFog cabinet External controller limit humidity probe

J2 B1 OUT H

B2 OUT H/T

+Vdc +(G) +(G)

GND M M

e. Modulating control with temperature control (T control)

0 to 1 V; 0 to 10 V; 2 to 10 V; 0 to 20 mA; 4 to 20 mA

SERIAL CARD

J9

J24

J2

J3

J4

J5

U

U

U

U

U

U

U

FIELD CARD

p

1

Fig. 3.k

Key:

1. ambient temperature probe;

17

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

Connections:

humiFog cabinet Ambient temperature probe

J2 B1 OUT T

+Vdc +(G)

GND M

f. Modulating control with temperature control using NTC probe (T

control)

SERIAL CARD

J9

J24

J2

J3

J4

FIELD CARD

U

U

U

U

U

U

U

Fig. 3.l

Connections:

humiFog cabinet NTC probe

J2 B1 NTC

GND NTC

g. Modulating control with temperature control and limit humidity

probe (TH control)

0 to 1 V; 0 to 10 V; 2 to 10 V; 0 to 20 mA; 4 to 20 mA

SERIAL CARD

J9

J24

J2

J3

J4

J

FIELD CARD

p

1

U

U

U

U

U

U

U

Fig. 3.m

Key:

1. ambient temperature probe and limit humidity probe;

Connections:

humiFog cabinet Ambient temperature probe + limit humi-

dity probe

J2 B1 OUT T (main)

B2 OUT H (limit)

+Vdc +(G)

GND M

h. Modulating control with temperature control and limit humidity

and temperature probe (TT/TH control)

0 to 1 V; 0 to 10 V; 2 to 10 V; 0 to 20 mA; 4 to 20 mA

SERIAL CARD

J9

J24

J2

J3

J4

J5

FIELD CARD

p

1

2

H/T

U

U

U

U

U

U

U

Fig. 3.n

Key:

1. limit humidity/temperature probe;

2. ambient temperature probe.

Connections:

humiFog cabinet Ambient temperature

probe

limit probe

J2 B1 OUT T

B2 OUT T/H

+Vdc +(G) +(G)

GND M M

3.5 Heat recovery signal

J3 inlet U5 terminal, analogue or digital configurable signal associated

with the position of the recovery damper

Fig. 3.o

3.6 Solenoid valve connection for

distribution system

For the management of the distribution system, the cabinet controls four

types of solenoid valves:

• normally closed “NC” for capacity-control of the manifolds.

• normally open “NO” for draining the manifolds.

• normally open vent valves.

• normally open line drain valves.

Recommended connection cables: two-wire plus earth AWG 13 (1.5mm²),

maximum length 100 m.

the following table contains the bipolar cable sections suggested in

relation to the number of solenoid valves per step for the NC and NO valves

1 EV per step fino a 4 EV per step Fino a 7 EV per step

Sez.cavo AWG 18 AWG14 AWG10

N.B. in cases up to 4 solenoid valves and up to 7 solenoid valves for a

single step it is necessary to provide the accessories box, code UAKDER6000.

N.B. For electrical distances greater than 30 m contact Carel.

ONOF

ONOF

RKEN

RKEN

FLUX

FLUX

G0B

G0B

G0B G0B G0B G0B G0B G0B

G0B G0B G0B G0B G0B G0B

NC1

NC1

FUSE

NC2

NC3

NC4

NC5

NC6

NO1

NO2

NO3

NO4

NO5

NO6

NOL

NOV

NC2

NC3

NC4

NC5

NC6

NO1

NO2

NO3

NO4

NO5

NO6

NOL

NOV

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

1 2 3 4 5 6 7 8 91011 12 1413

Fig. 3.p

18

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

Rif. Cabinet

terminal

block

Solenoid

valve

connector

Description

Max. no.

of

solenoid

valves per

step.

Master

up to 460

Max. no. of

solenoid

valves

per step.

600/1k0

Max. no. of

solenoid

valves per

step.

Slave

1 NC1 – G0B 1 -2

Capacity-control

sol.valves 1st step

674

2 NC2 – G0B 1 -2

Capacity-control

sol. valves 2nd

step

444

3 NC3 – G0B 1 -2

Capacity-control

sol. valves 3rd

step

444

4 NC4 – G0B 1 -2

Capacity-control

sol. valves 4th

step

442

5 NC5 – G0B 1 -2

Capacity-control

sol. valves 5th

step

222

6 NC6 – G0B 1 -2

Capacity-control

sol. valves 6th

step

222

7 NO1 – G0B 1 -2

Drain solenoid

valves 1st step

674

8 NO2 – G0B 1 -2

Drain solenoid

valves 2nd step

444

9 NO3 – G0B 1 -2

Drain solenoid

valves 3rd step

444

10 NO4 – G0B 1 -2

Drain solenoid

valves 4th step

442

11 NO5 – G0B 1 -2

Drain solenoid

valves 5th step

222

12 NO6 – G0B 1 -2

Drain solenoid

valves 6th step

222

13 NOL – G0B 1 -2 Line drain sole-

noid valves

222

14 NOV – G0B 1 -2 Vent drain sole-

noid valves

11

Tab. 3.c

N.B.: using the solenoid valves supplied by Carel SpA, each individual

cabinet can power up to 22 solenoid valves, divided as follows:

• 10 NC capacity-control solenoid valves

• 10 NO manifold drain solenoid valves.

• 1 line drain solenoid valve.

• 1 vent drain solenoid valve.

Cabinet master 600 l/h and 1000 l/h

• 15 slicing solenoid valves NC

• 15 collector drain solenoid valves NO.

• 1 line drain solenoid valve.

• 1 ventilation solenoid valve

3.7 Water treatment unit contact

Cables • up to 30 m: two-wire cable

cross-section 0.5 mm

2

(AWG15)

Electrical characteristics

allowed by the contact:

• power 50 VA;

• voltage 24 V;

• current 0.5A resistive/inductive

Status of the contact according to master statusr

Master OFF or in standby closed contact

Master ON open contact

Tab. 3.d

GR

PEN

GR

PEN

ROAL

ROAL

BKUP

BKUP

ROEN

ROEN

COM

COM

ONOF

ONOF

RKEN

RKEN

FLUX

FLUX

G0B

G0B

G0A

G0A

G0A

G0A

G0A

G0A

G0B G0B G0B G0B G0B G0B

G0B G0B G0B G0B G0B G0B

NC1

NC1

FUSE

1

Fig. 3.q

Legenda:

1. Pump state contact (can be used for allowing a water treatment plant)

3.8 Cumulative alarm relay (J15)

Activated when one or more alarms is detected via a contact/output that

can be transferred to a supervisory system.

Cable two-wire AWG 15/20

Electrical specifications of

the relay

power 500 VA;

voltage 250 V;

current 2 A resistive/

inductive

Status and operation of

the relay:

contact open no alarm active

contact closed active alarm/alarms

Tab. 3.e

J15

J16

J17 J18

Fig. 3.r

Connections

humiFog cabinet terminal

J15 NO8 normally open

C8 COM

3.9 Pump state contact

J19 inlet NO24 terminal, configurable digital and logical outlet that shows

the pump status: closed contact “open”, free contact “closed”.

Fig. 3.s

3.10 Pump life signal

The J20 inlet NO27 terminal identifies the life signal of the pumping

station. Signal used by humiFog for back-up or pump rotation.

Fig. 3.t

19

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

3.11 Alarm inputs from external devices

Cable two-wire AWG 15/20

Electrical specifications of

the relay

voltage-free contact

Status and operation of

the relay:

contact open no alarm active

contact closed active alarm/alarms

GR

PEN

GR

PEN

ROAL

ROAL

BKUP

BKUP

ROEN

ROEN

COM

COM

ONOF

ONOF

RKEN

RKEN

FLUX

FLUX

G0B

G0B

G0A

G0A

G0A

G0A

G0A

G0A

G0B G0B G0B G0B G0B G

0

G0B G0B G0B G0B G0B G

0

1 2

Fig. 3.u

Key:

1. alarm input from water treatment system;

2. alarm input from AHU pressure sensor (flow switch).

N.B.: the unit is supplied with contacts ROAL-G0A and FLUX-G0A

jumpered.

3.12 Backup/rotation (redundancy)

The backup/rotation function on two master cabinets allows two

pumping units to be used with one single zone and consequently one

rack distribution system.

The backup function guarantees continuous production when the

cabinet that is currently operating shuts down due to an alarm.

The rotation function distributes the number of operating hours equally

between the two cabinets.

Electrical connections:

Connect the two pumping units according to the following diagram.

To complete the electrical connections in backup & rotation mode, a

special junction box with relays (P/N UAKDERBK00) must be installed in

the system.

J20

J19

ID15H

ID15

IDC15

ID16

ID16H

C25

NO25

C25

NO26

NO27

NO28

NO29

U6U7U8

GND

ID9

ID10

ID11

ID12

IDC9

ID13H

ID13

IDC13

ID14

ID14H

J7

J8

J6

PEN PEN

ROAL ROAL

BKUP BKUP

ONOF ONOF

RKEN RKEN

FLUX FLUX

ROEN ROEN

COM COM

GR

G0A G0A G0A

G0A G0A G0A

G0B G0B G0B

G0B G0B G0B

GR

J20

J19

ID15H

ID15

IDC15

ID16

ID16H

C25

NO25

C25

NO26

NO27

NO28

NO29

U6U7U8

GND

ID9

ID10

ID11

ID12

IDC9

ID13H

ID13

IDC13

ID14

ID14H

J7

J8

J6

PEN PEN

ROAL ROAL

BKUP BKUP

ONOF ONOF

RKEN RKEN

FLUX FLUX

ROEN ROEN

COM COM

GR

G0A G0A G0A

G0A G0A G0A

G0B G0B G0B

G0B G0B G0B

GR

G0A

BKUP

Primary Secondary

Backup box

UAKDERBK00

Fig. 3.v

Software configuration: access B. Installer menu > b. Zone settings >

c. Special functions.

1. On screen Bbc08, enable the backup function by selecting the

priority to attribute to the cabinet when starting. One cabinet must

be set as the “Primary cabinet”, while the other must be set as the

“Secondary cabinet”. This configuration is needed to define the

priority of the cabinet that will attempt to start first when both units

are powered on together. Aside from this, there is no functional

difference between the two units.

2. If deciding to enable rotation between the cabinets, set the “Rotation”

parameter on screen Bbc08 to “YES”, and select the number of pump

operating hours before activating the rotation request (default 8 h). .

A system configured in this way will therefore comprise one cabinet that

is operating and one in standby. The cabinet in standby will display “Off

from backup” on the main screen if rotation is not enabled, or “Off from

rotation” if awaiting the time set for rotation.

Important:

• The input signals (external control signal, probes, etc.) must be

connected to both cabinets.

• The operating parameters for the two master units (rack parameters,

number of steps, branch flow-rates, etc.) must be configured in the

same way.

• A “T” connector must be installed in the water circuit to connect the

two pump outlets to the one rack supplied by both units. A nonreturn valve also needs to be installed on the outlet of each pump

(P/N UAKCHV****) upstream of the “T” and the main line drain valve

(UAKCD0000*).

• If rotation is not enabled, the cabinet that requested changeover due

to an alarm with shutdown can only be reactivated following to an

alarm with shutdown on the cabinet that replaced it, even if the alarm

condition that caused the unit changeover has been resolved.

• When rotation is enabled, in the event of unit changeover due to an

alarm, the rotation hour counters are reset and the next request is

ignored.

• The two pumping units must belong to the same zone and use the

same rack. In multizone configurations, the backup of the master

cabinet (pumping unit that supplies the water line for all the zones)

can be implemented, but it will not be possible to have a backup on

the slave cabinets.

For further information and details regarding water circuit and electrical

installation of humiFog in Backup & Rotation mode, see the official

document +050004015 +LEAF INSTAL. BACKUP & ROTATION HUMIFOG

(UAKDERBK00) REL. 1.0 ITA/ENG A3 F/R. A copy of this document will

always be included with part number UAKDERBK00 (backup junction

box).

3.13 Expansion mode/remote actuator

Expansion

The Slave (UA***S****) cabinets can be configured on the Bbc01 screen

as Expansion/Remote actuators.

This mode transforms the cabinet in an I/O expansion for another

Humifog generic cabinet (pumping station or slave) in order to:

• Provide a tool to simplify the wiring if the rack is too far from the

pumping station (Remote Actuator)

• Allow the slave cabinet to use a rack with 6 NC valves on step 1 and 4

NC valves on step 4.

20

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

Remote rack actuator

This mode allows you to control the solenoid valves of the rack in the

area associated with the pumping station via one or two “remote area”

cabinets controlled in serial sequence via the J23 port of pCO5+.

This configuration is particularly useful if the rack is located away from

the pumping station, since it allows to bring the control signal via the

only serial cable in the rack area, reducing the number and length of

the cables of the solenoid valves between the rack and the device that

physically controls it (the remote area cabinet).

To enable the function, proceed as follows:

Electrical connections:

• Connect the expansion (or two expansions) serially in port J23 of the

pCO5+ as follows:

FBJ/J23

BMS2

BMS2

pCOe

Fig. 3.w

• Connect the control signals used for the cabinet configured as “Remote

expansion/Actuator 1”

• Connect the solenoid valves to the remote area cabinet that controls

them. If two cabinets are used, distribute them evenly. For example,

in the case of the first step with 6 collectors, connect three solenoid

valves to the first expansion cabinet and three solenoid valves to the

second cabinet.

Software configuration:

• On the pumping station, enable the use of the remote actuator on

the Bbc09 screen: the software automatically establishes the number

of required actuators (1 and 2) based on the number of collectors

present, and alerts the user via a dedicated pop-up window

Configure the first slave as “Expansion/Remote actuator 1” and the second

one (only at request) as “Expansion/Remote actuator 2”

Note: if you are using this mode, the probe readings of the main

control (U1), limit (U2), auxiliary (U3), heat recovery signal (U5), rack

temperature (U8) and the ventilation solenoid valve are transferred to the

remote area cabinet configured as “Expansion/Remote actuator 1”.

Remote area expansion

The software installed on the remote area cabinet, based on the number

of set collectors, automatically determines whether it is necessary to add

a second cabinet, used as an expansion for the proper management of

the solenoid valves. The system is pre-configured based on the number

of set collectors. The following are necessary to enable the feature:

Electrical connections:

• Connect the J23 port of the remote area cabinet that requires

expansion to the BMS2 port of the cabinet configured as expansion,

as follows:

• Connect the adjustment probes and the ventilation valve (if present)

to the remote area cabinet and distribute the solenoid valves between

the two cabinets. For example, in case of a step with 6 solenoid valves,

connect three to the first cabinet and three to the second cabinet.

Software configuration:

• The remote area cabinet, based on the number of set collectors,

establishes if it is required to expand and alerts the user via a dedicated

pop-up window

• Configure the slave used for the expansion as “Expansion/Remote

actuator 1”

3.14 Master-slave connection

The multi-zone master-slave configuration is serial and done through

optically-isolated integrated Field-bus 485 present in the humiFog unit.

Cable section

Use twisted and shielded two wire cables, AWG20/22

with clamp sections of 2 mm min 0.2 – max 2.5

Connections:

Fieldbus card humiFog master BMS2 humiFog slave

++

-GND GND

+

-

GND

+

-

GND

FieldBus RS485

Fig. 3.x

Note: if the optional card is in the last position on the supervisor

serial line and the line is longer than 100 m, connect the 120 Ω - 1/4 W

line terminal resistors to the pins, as shown in the following figure.

3.15 Supervisor network

J5

J4

J3J2J1

serial card

field card

service card

ID1

ID2

ID3

ID4

ID5

ID7

ID8

IDC1

VG

VG0Y1Y2Y3Y4

B4

BC4B5BC5

B1B2B3

J24

+V term

GND

+5V

ref

GND

+VDC

G

G0

NO8

C7

C4

C1

C8

NO7

NO4

NO1

NC8

C7

NO5

NO2

NO3

C4

C1

Rx-/Tx-

Rx+/Tx+

GND

J9 J10

J11

J12 J13 J14 J15

input: 24 V / V ; 50 to 60 Hz

max. power: 40 VA / 15 W

J3J

2

J1

field card

service car

d

D8D

C

1

4

4

5

1

J24

+

V

t

er

m

N

D

+

5

Vr

ef

N

D

+VD

C

7

7

472

x-

/

Tx-

Rx+

/

Tx

+

N

D

J9

J10J11J12

J13J14J15

input: 24 V / V ; 50 to 60 Hz

max. power: 40 VA / 15

W

DDDDD

D

Fig. 3.y

Optional CAREL cards

network/card protocol supported

PCOS004850 RS485 (standard) CAREL, Modbus®

PCO100MDM0 RS232 (external modem) CAREL for remote connections

PCO1000WB0 Ethernet™

TCP/IP

SNMP v1 &v2c

BACnet™ Ethernet™ ISO8802-2/8802-3

BACnet/IP

PCO1000BA0 Ethernet™ (Modbus®) BACnet™ MS/TP

Important: Follow the instructions shown on the optional cards

for the technical specifications, connections and expansion boards.

Default: CAREL supervisor protocol.

21

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

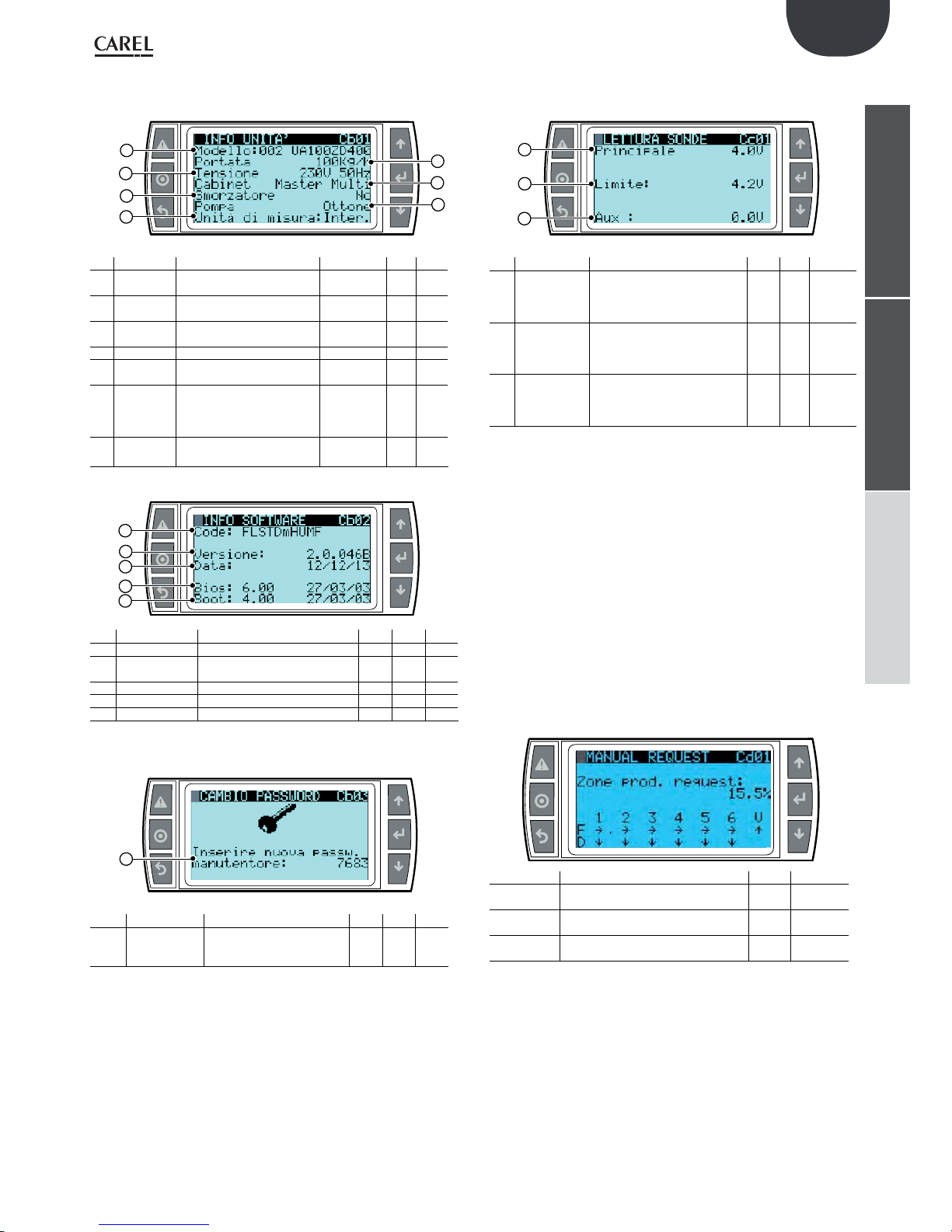

4.2 Pumping unit with constant pressure

control

The humiFog controller manages the water pressure generated to ensure

it remains at a constant level, typically 70 bars.

This configuration is used in the following applications:

• humidification and/or adiabatic cooling (direct) in an AHU (the flow

control configuration is recommended);

• humidification and indirect adiabatic cooling in an AHU fitted with

heat recovery unit (the two distribution systems can atomise water at

the same time);

• humidification and/or adiabatic cooling (direct) in an industrial

environment;

• humidification and/or adiabatic cooling (direct) in multiple zones,

whether AHUs, AHUs fitted with heat recovery units, industrial

environments, or any combination of these.

Note that in the case of humidification and/or cooling adiabatic directly

into rooms, constant pressure control is preferred over flow control: as

the droplets are atomised directly into the environment, to minimise the

space required for evaporation, the smallest possible diameter should

be achieved and therefore the water must be atomised at maximum

pressure. This is represented by constant pressure control, which

maintains the pressure at 70 bars.

humiFog is fitted with an inverter to control the speed of the pump and

maintain the pressure at the rated value set by parameter, typically 70

bars.

The humiFog system will be made up of a pumping unit (master) that

also controls its own zone, as well as a series of zone electrical panels

(slaves) corresponding to the number of remaining zones.

Note that for humidification and indirect adiabatic cooling in an AHU

fitted with heat recovery unit (the two distribution systems may atomise

the water at the same time) a zone panel (slave) will be required.

The water distribution system/systems have nozzles organised into

groups, called steps, which in general each have different capacities.

Based on the flow-rate of water to be atomised in one or more zones, the

humiFog system will activate the required steps until the nozzles atomise

the required quantity of water. Each zone can have up to 6 modulation

steps.

The groups of nozzles are normally configured when selecting the

humiFog system, and the procedure is clearly described in the documents

supplied with the water distribution system (rack or room distribution

and atomisation system)

Constant pressure control rationalises operation of the humiFog pumping

unit as, despite the lower precision, it can treat a number of zones at the

same time without installing a pumping unit for each AHU or industrial

environment.

4. PUMPING UNITS

4.1 Pumping unit with flow control

configuration

humiFog controls the humidification and/or cooling capacity by

continuously controlling the atomised water flow-rate across a wide

range of modulation.

This configuration is used in the following applications:

• humidification and/or adiabatic cooling (direct) in an AHU;

• humidification and indirect adiabatic cooling in an AHU with heat

recovery unit (one atomisation system at a time atomises the water). In

this case, a zone electrical panel will be required, see the next chapters

for further information.

humiFog is fitted with an inverter to continuously and precisely control

the speed of the pump and, consequently, the flow-rate.

The outlet pressure is kept within the optimum water atomisation limits

by the range of modulation of the pump speed and control of the

number of nozzles that atomise the water.

In detail, the nozzles must be supplied at a pressure in the range from

25 to 70 bars, to ensure that the droplets generated have an average

equivalent diameter of 10-15 µm.

Based on the flow-rate of water to be atomised, humiFog will activate the

number of nozzles that ensures the pressure is within the range indicated

above.

It is clear that if the required flow-rate is low, just a few nozzles will be

needed to atomise the water; if the request increases, the increase in

flow-rate will cause an increase in pressure that, if it exceeds 70 bars, will

activate other atomising nozzles, consequently decreasing the pressure

and returning it within the range of optimum values. Similarly, if the

humidification request decreases, the flow-rate and thus the pressure will

decrease and, if the latter falls below 25 bars, some nozzles will be closed

so that the pressure returns within the optimum atomisation range.

This is possible because the nozzles are assembled into groups of up to

four, with different capacities; when suitably activated, these guarantee

continuous modulation of the flow-rate across a wide range, nominally

from 14 to 100% of the maximum flow-rate, with a pressure from 25 to

70 bars.

The groups of nozzles are normally configured when selecting the

humiFog system, and the procedure is clearly described in the documents

supplied with the water distribution system (rack).

The pumping unit in the flow control configuration can only be used for

single-zone applications: one pumping unit supplies just one zone at a

time. Multizone configurations are not possible.

The flow control configuration guarantees maximum humidification and

adiabatic cooling precision as capacity is controlled continuously and

across a wide range.

22

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

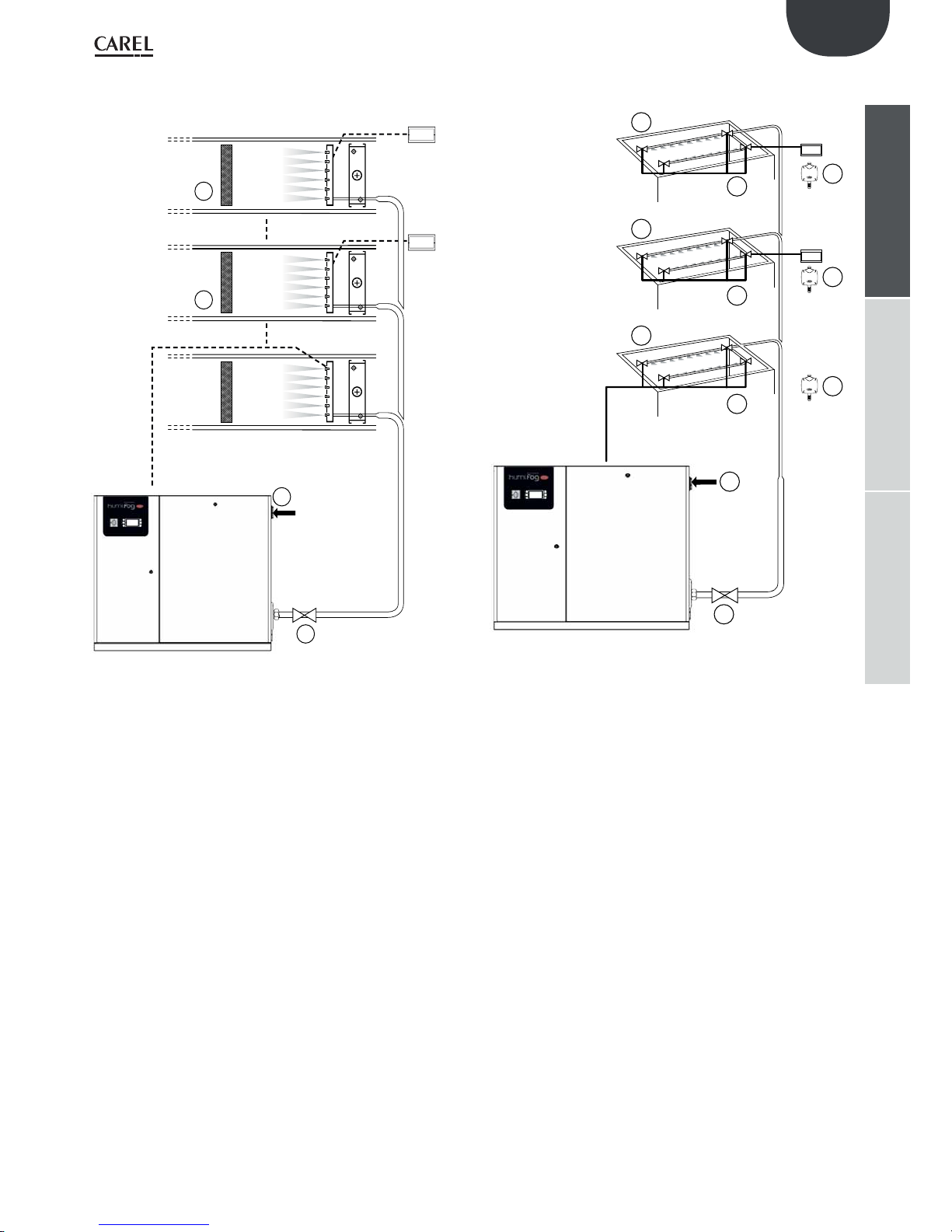

5. DISTRIBUTION SYSTEM

This paragraph briefly describes the distribution and atomisation systems

for AHUs (rack and droplet separator) and for rooms. These are described

in detail in the “humiFog – distribution systems” manual.

5.1 Air handling unit: distribution,

atomisation system and droplet

separator

The rack is supplied made-to-measure based on the AHU/duct and is

made up of various vertical manifolds with atomisation nozzles, each

with activation and drain solenoid valves. Each rack is also fitted with a

main drain solenoid valve installed at the lowest point of the piping that

connects the rack to the pumping unit. In addition, it is fitted with a vent

solenoid valve on the horizontal manifold so as to completely empty

the pipelines. The manifolds house the required number of atomising

stainless steel nozzles located in specific positions, calculated during the

system configuration phase and described in the documents supplied

with the rack.

The droplet separator has the purpose of trapping the droplets of water

that are not completely evaporated, so as to prevent objects located

downstream from getting wet. The droplet separator is supplied in

standard modules that can be assembled on a support structure to cover

the cross-section of the AHU. The structure is always in stainless steel,

and guarantees fast and effective draining of the water trapped by the

droplet separator. The modules are available with glass wool or stainless

steel filters, the latter required for hygiene-certified installations, such as

VDI6022, UNI8884, etc.

The width and height of the rack and the droplet separator vary with

approximately 152 mm within the following limits:

• width: 508…2,788 mm;

• height: 516…279 mm.

If the droplet separator does not exactly cover the cross-section of the

AHU, the free spaces must be sealed to prevent air from bypassing the

droplet separator.

Flexible or stainless steel hoses are supplied for connecting the pumping

unit to the rack.

Note that a droplet collector tank with drain connection must also be

fitted, containing the rack, droplet evaporation chamber and droplet

separator. This tank is not supplied by CAREL.

5.2 Direct humidification into the room:

distribution and atomisation system

This system consists of

• hoses and/or stainless steel pipes for the distribution of pressurised

water;

• capacity-control solenoid valves to shut off the branches of the system

that don’t need to atomise water (on/off operation, N.C.);

• drain solenoid valves to empty the installation and prevent stagnation

of water (on/off operation, N.O., opening pressure 13 bars);

• main drain solenoid valve installed on the lowest point of the piping

that connects the rack to the pumping unit, so as to completely empty

the system and avoid stagnation of water. The solenoid drain valves

are also used to quickly discharge water pressure when the line stops

atomising, avoiding dripping. In addition, the solenoid drain valves

are used for the automatic periodical washing function managed by

humiFog;

• stainless steel manifolds (pipes with holes) with atomising nozzles;

• blower units: compact units featuring manifolds with atomising

nozzles, on-off solenoid and drain valve, plus a fan that creates a stream

of air that carries the droplets and ensures they evaporate completely

before falling in the environment.

The distribution and atomisation system can have up to 6 capacity

modulation steps, where, obviously, each step can have a series of

branches with pipes, manifolds and/or blower units.

Special attention must be paid to the position of the nozzles and the

blower units inside the environment: observe the installation limits

(minimum installation height and minimum horizontal distance from

objects/machinery/people that must not be wetted), as shown in the

“humiFog multizone: distribution system” manual.

23

ENG

“humiFog multizone - pumping unit” +0300066EN - rel. 1.2 - 10.12.2015

installeruserservice

6. APPLICATIONS

humiFog for AHU/ducts is suitable for all applications in which the air

can be humidified and/or cooled adiabatically, atomising demineralised

water. Below are some possible applications of humiFog:

• office buildings

• hotels and call centers

• printing and paper industries

• cleanrooms

• libraries and museums

• textiles industry

• food industry

• direct/indirect adiabatic cooling

• timber industry

• other industrial applications.

The possibility of using an atomising rack for indirect adiabatic cooling

is especially interesting: the air to be discharged is cooled adiabatically

(bringing it to saturation) and is then used to cool the fresh outside air

using an air-air heat exchanger, as shown in the following figure.

1

HE

7

2

3

4

5

6

Fig. 6.a

Key:

1. recirculated air;

2. exhaust air;

3. saturated and cooled air;

4. outside air inlet;

5. heated exhaust air;

6. cooled outside air;

7. fresh air.

6.1 Main advantages of humiFog multizone

The main characteristic of humiFog for AHUs is compliance with the

European standards on air hygiene, as certified by the Institut für

Lufthygiene in Berlin, which has declared it as compliant with the

following standards:

Standard climatisation Hospitals

VDI 6022, page 1 (7/2011) 9 DIN 1946, part 4 (12/2008) 9

VDI 3803 (02/2010) 9 ONORM H 6020 (09/2003) 9*

ONORM H 6021 (09/2003) 9 SWKI 99-3 (05/2003) 9

SWKI VA104-01 (04/2006) 9

DIN EN 13779 (09/2007) 9

Tab. 6.a