humiFog - UA

Pressure Atomizing Multi-Point

Zone Control Panel

User manual

READ AND SAVE

THESE INSTRUCTIONS

We wish to save you time and money!

We can assure you that the thorough reading of this manual will guarantee correct

installation and safe use of the product described

WARNINGS

BEFORE INSTALLING OR HANDLING THE HUMIDIFIER PLEASE CAREFULLY READ AND FOLLOW THE INSTRUCTIONS AND

SAFETY STANDARDS DESCRIBED IN THIS MANUAL AND ON THE LABELS ATTACHED TO THE humiFog.

CAUTION: ALWAYS DISCONNECT THE MAIN POWER BEFORE OPENING OR SERVICING THE HUMIDIFIER!

This appliance has been designed exclusively to directly humidify in ducts and AHUs through the atomizing rack.

The quality of the water used affects the operation of this unit, so the humiFog must be supplied with treated water (Reverse

Osmosis or Deionized). The installation, use, and maintenance operations must be carried out according to the instructions

contained in this manual and on the labels applied internally and externally.

IMPORTANT: BEFORE beginning installation:

Check for shipping damage to carton. Mark the shipping waybill accordingly.

Open cartons and check for any hidden damage. Mark the shipping waybill accordingly.

Check packing slip to ensure all items have been received. Notify CAREL of any shortages or damaged parts. You must

notify CAREL within 5 working days of any shortages.

The conditions of the environment and the power supply voltage must comply with the specified values listed on the data

label in the humidifier.

All other uses and modifications made to the humidifier that are not authorized by the manufacturer are considered

incorrect, and the manufacturer assumes no liability for the consequences of any such unauthorized use.

Please note that the humidifier contains powered electrical devices and high pressure components.

All service and/or maintenance operations must be performed by qualified personnel who are aware of the necessary

precautions and are capable of performing the operations correctly.

Disconnect the humidifier from the main power supply before accessing any internal parts.

The humidifier must be installed in accordance with all local and national standards.

WARNING: Your humidifier requires water to operate. Do NOT mount it above materials or machinery that could be

damaged if a leak occurs. CAREL assumes no responsibility for consequential or inconsequential damage as a result of any

leaks.

Disposal of the parts of the humidifier: The humidifier is made up of metallic and plastic parts. All parts must be disposed of

according to the local standards on waste disposal.

Warranty on materials: 2 years (from the date of production, excluding the consumable parts).

Page 2 of 38

TABLE OF CONTENTS

1. HOW THE humiFog WORKS ................................................................................................................. 4

2. COMPONENTS ....................................................................................................................................... 5

2.1 Main pumping station ........................................................................................................................................ 5

2.2 Microprocessor control system ....................................................................................................................... 5

2.3 Atomizing nozzles .............................................................................................................................................. 6

2.4 Distribution ......................................................................................................................................................... 6

2.5 Zone Control Panels .......................................................................................................................................... 6

2.6 Zone Control PaneL Dimensions and weights ................................................................................................ 7

2.7 zone control cabinet components .................................................................................................................... 8

3. MODELS ................................................................................................................................................ 8

3.1 Zone Control PANEL CODING GUIDE .............................................................................................................. 8

4. ZONE CONTROL CABINET POSITIONING AND MOUNTING ................................................................ 9

4.1 Zone Control Positioning and Mounting NOTES ............................................................................................. 9

4.2 Zone Control PANEL CLEARANCES ................................................................................................................ 9

4.3 Zone Control drilling template ........................................................................................................................ 10

5. ELECTRICAL WIRING ........................................................................................................................... 10

5.1 Wiring Connection Layouts (UAZN***108) ..................................................................................................... 10

5.2 Wiring Connection Layouts (UAZN***109) ..................................................................................................... 11

5.3 DETAILS OF (2) AND (3) TERMINAL BLOCKS (UAZN***108) ....................................................................... 12

5.4 DETAILS OF (2)(TBS1) AND (3)(TBS3,TBS4) TERMINAL BLOCKS (UAZN***109) ...................................... 12

5.5 Electrical Wiring ............................................................................................................................................... 13

5.6 Control signals from external voltage-free contact (humidistat)(UAZN***108) ................................................. 14

5.7 Modulating control signal(UAZN***108) ......................................................................................................... 15

5.8 control signal Wiring (UAZN***109) ................................................................................................................ 16

5.9 Solenoid Valve connection For Distribution System (UAZN***108) ............................................................. 17

5.10 Solenoid Valve connection For Distribution System (UAZN**109) .............................................................. 18

5.11 Cumulative alarm relay (J15) .............................................................................................................................. 19

5.12 Inputs from external devices .............................................................................................................................. 19

5.13 Supervisor Network ......................................................................................................................................... 19

5.14 Pumping Station to Multi Zones ..................................................................................................................... 20

5.15 Duplex Control Wiring / Multiple zones per Air HandleR .............................................................................. 21

6. START-UP ............................................................................................................................................ 22

6.1 Startup Checklist.............................................................................................................................................. 22

6.2 Re-addressing the Controllers and Displays for Multi-zone or Duplex Systems ....................................... 22

6.3 Re-addressing PCO3 controller ...................................................................................................................... 23

6.4 Re-addressing PGD display ............................................................................................................................ 23

7. THE humiFog CONTROLLER ............................................................................................................... 24

7.1 MULTI-ZONE IN SINGLE ahu SETUP OVERVIEW .......................................................................................... 25

7.2 SYSTEM STATUS ............................................................................................................................................. 25

7.3 Main Menu ........................................................................................................................................................ 26

7.4 Service menu .................................................................................................................................................... 28

7.4.1 Service Settings Submenu ............................................................................................................................................................ 29

7.4.2 Manual Management Submenu ................................................................................................................................................... 30

7.5 Manufacturer Submenu ................................................................................................................................... 30

8. REPLACEMENT PARTS ........................................................................................................................ 32

8.1 See specific material list(s) provided with unit. ............................................................................................ 32

9. WIRING DIAGRAM .............................................................................................................................. 33

10. WARRANTY ......................................................................................................................................... 37

Page 3 of 38

A

A

1. HOW THE humiFog WORKS

The humiFog humidification system is a high pressure atomizing system designed to produce a fine mist that readily

evaporates to raise the relative humidity. The atomizing humidifier is an efficient humidification system that is especially

suitable for larger installations, where high flow-rates of water are required without the necessity of excessive energy

expenditure. When the humidity value in the environment is less then the desired value, as measured by a probe or external

controller, the controller starts the volumetric piston pump, which sends the “treated” water to the nozzles.

The treated water; using a reverse osmosis or deionizer system, is pumped at a pressure of 1000psi (75bar) and sent via the

connection pipes to the atomizing nozzles. The nozzles then reduce the jet of water into a multitude of very fine water

droplets (10-20 microns). Because of the fine droplet size, the water can then easily change its state and vaporize. The energy

required for this transformation is supplied by the ambient air; at a rate of 690 W per liter/hour. Consequently, there is a

decrease in temperature in the environment being humidified, and this process may be useful in many applications (adiabatic

transformation).

The humiFog unit must be supplied with treated water, for the following reasons:

To reduce the introduction into the environment of dust due to the mineral salts found in the untreated water.

To minimize the clogging of the nozzles.

PUMPING STATION

B

TOMIZING MANIFOLDS

A

800-1,000 psi

TOMIZING NOZZLES

Mist Eliminator

A - Duct/AHU Distribution

Page 4 of 38

B - Ambient/Room Distribution

(Direct manifolds)

Fig. 1.a

2. COMPONENTS

A humiFog system is made up of the following components:

Pumping station, containing the electrical panel and the volumetric piston pump.

Microprocessor control system.

Distribution system with the atomizing nozzles; for ducts/AHUs or rooms.

Zone control panels for controlling the distribution staging in each zone or AHU.

2.1 MAIN PUMPING STATION

The main pumping station features an energy efficient combination of an advanced Inverter Duty Motor and a Variable Frequency

Drive. This combination allows for the precise control of the volume of outlet water from the positive displacement pump. The

positive displacement pump is a reliable component that is designed for long life and minimal maintenance. By adjusting the

speed of the pump, the pressure and the flow rate of the nozzles are precisely modulated according to the requirements of the

application. The station also incorporates a user friendly display, allowing the user to visually change set points, and other usermodified fields.

The main pumping station controls the water output using “Constant Pressure” principles. This type of control allows a single

pumping station to supply humidification to multiple ducts/AHUs or rooms. In this setup, the humiFog controller manages the

speed of the pump according to the “Constant Pressure” set point, increasing the speed if the pressure decreases (opening more

zones/branches of the circuit) and decreasing the speed if the pressure increases (closing one or more branches of the circuit).

With this configuration, the humiFog controller can manage the humidity control and distribution directly (one zone/AHU); or the

distribution control is managed by an additional external zone controller (multiple zones/AHUs).

2.2 MICROPROCESSOR CONTROL SYSTEM

The humiFog control system is based on the latest, state of the art, CAREL pCO

programmable controller. This controller operates a Variable Frequency Drive to

modulate water pressure and water flow according to requirements. Control can be

stand-alone using humidity and temperature sensors, or the system can be controlled by

a DDC signal. Modbus, BACnet, Echelon and TCP/IP protocol interface is available. A LAN

(Local Area Network) connection allows up to 32 systems to be connected to share sensor

information, or even operate redundantly.

No. Description

1 Electric motor

2 Piston pump

3 Electrical cabinet

4 Controller-display

5 Low pressure hydraulics

6 Motor/pump drive assembly

7 Low pressure water inlet

8 High pressure water outlet

9 Drain water outlet-thermal valve

10 Drain water outlet-relief valve

11 Water filter

Tab.2.a

Fig. 2.b

Page 5 of 38

2.3 ATOMIZING NOZZLES

The humiFog atomizing nozzles are constructed of stainless steel and are available in three capacities: 3.3, 6.2

& 8.8 lbs/hr (1.5, 2.8 & 4.0 kg/hr). Working on the centrifugal/whirljet principle, they have no targets to drip or

require adjustment. An internal 60 micron filter is used to prevent jamming of the nozzle, and a special

internal valve closes the orifice to avoid dripping and prevent any ambient contamination when the nozzle is

off. The nozzles are mounted uniformly in the distribution manifolds.

2.4 DISTRIBUTION

The following diagrams illustrate the typical applications in ducts (Fig. 2.c) or directly in the rooms (Fig. 2.d).

The ambient humidity is measured by a probe (1), or receives a command signal from an external controller, and is read by the

controller contained in the humiFog pumping station (6). The controller then compares the humidity measured in the room

against the humidity set point, starting, when necessary, the production of the pump. The demineralized water produced by the

water treatment system (7) is brought to high pressure by the humiFog pump (6), sent to the manifolds for distribution into the

duct or directly into the room (5), and then atomized by the nozzles (4). The percentage of water fog evaporated depends on the

temperature and speed of the air, as well as on the relative humidity reached. In duct applications, any non-evaporated droplets

are separated by a mist eliminator filter or cooling coil (2), collected in the bottom tank (3) and immediately discharged. The

control system built into the pumping station controls the banks of nozzles supplied with solenoid “zone” valves.

Duct or AHU

Ambient

Fig. 2.c Fig. 2.d

2.5 ZONE CONTROL PANELS

The humiFog Zone Control Panels utilize the latest state-of-the-art CAREL pCO programmable controller. This controller

operates the distribution system, by interfacing with the selected control system, and then controlling the water solenoid valves

for appropriate modulation. Control can be stand-alone using humidity and temperature sensors, or the system can be controlled

by a DDC signal. Modbus, BACnet, Echelon and TCP/IP protocol interface is available. A LAN (Local Area Network) connection

allows up to 32 Controller devices to be connected to share sensor information, or even operate redundantly. The zone control

cabinets are also used to control each zone, in a multi-point humiFog system. In this type of system, all of the zone control panels

communicate to each other, and to the pumping station panel, by a pLAN network.

Multi zone setup configuration may involve multiple zones within the same air handler. There are two primary methods

of how to distribute water through a multi zone setup, parallel or staged control. With parallel control, each zone connected to

the pumping station will be activated simultaneously and operate at the same output level. Staged control will run one zone to its

maximum capacity before activating the next zone. This choice will affect the zone demand display of the zone control cabinets,

as described in the section 7.1 of this manual.

Page 6 of 38

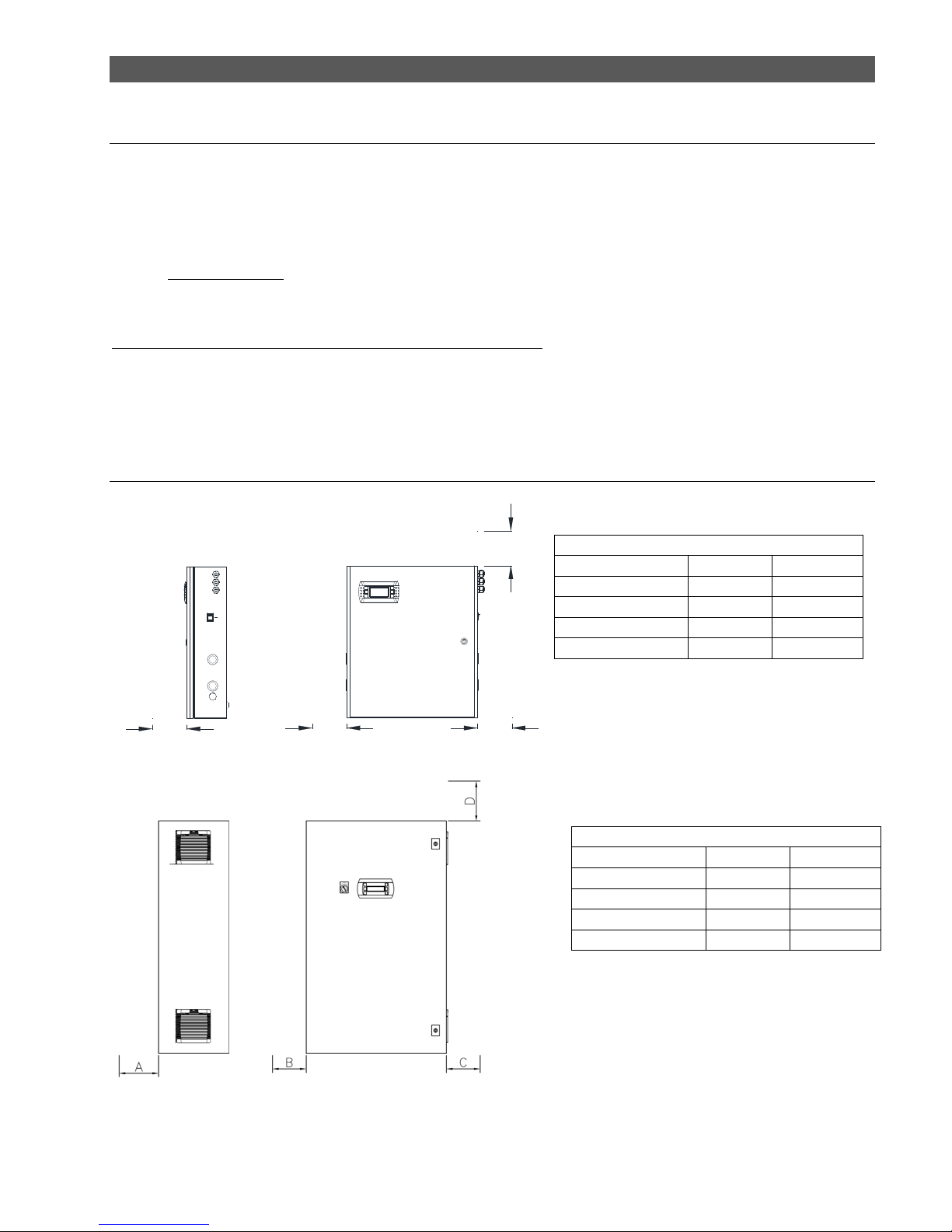

2.6 ZONE CONTROL PANEL DIMENSIONS AND WEIGHTS

19.7" [500.3mm]

22.9" [580.5mm]

5.9" [150.0mm]

8.8" [223.0mm]

2.4" [62.2mm]

1.6" [39.7mm]

PROBE CABLE INLETS

ON / OFF SWITCH

4.8" [122.5mm]

2.1" [52.3mm]

2" [51.0mm]

1.2" [30.0mm]

2.4" [59.7mm]

3.3" [82.6mm]

3.5" [89.6mm]

4.8" [122.5mm]

7.6" [193.4mm]

8.8" [223.0mm]

Weight Table, UAZN***108

weight installed

lbs / kg 53 / 24

weight packaged

lbs / kg 66 / 30

Weight Table, UAZN***109

weight installed

lbs / kg 142 / 64.1

weight packaged

lbs / kg 190 / 86.2

Page 7 of 38

2.7 ZONE CONTROL CABINET COMPONENTS

1

2

8

9

7

6

3. MODELS

5

Key (UAZN***108)

1 terminal rear view

2 transformer B

3

3 main switch G

4 power supply terminal block

4

transformer primary fuse carrier

5

(TRA:F1,F2;TRB:F3,F4)

transformer B secondary fuse carrier

6

(F8)

7 transformer A

8 electroni c controller

9 control terminal block with fuses

Key(UAZN***109)

1 PGD

2 main switch G

3 Transformer A

4 Transformer B

5 Transformer C

6 Transformer A fuse carriers (F1,F2)

7 Transformer B fuse carriers (F4,F5)

8 Transformer C fuse carriers (F9,F10)

Fill and Drain fuse carriers (FU7, FU8,

9

FU11, FU12)

10 Controller Wiring fuse carri er (FU6)

Customer Power, Sensor and Alarm

11

Terminal Blocks (TBS1)

12 Power Supply Terminal Bl ocks (TBS2)

Fill/Drain Solenoid Terminal Blocks

13

(TBS3, TBS4)

Solenoid Valve Relays (RD1-9,RF1-

14

9,RV1)

15 electronic controller

3.1 ZONE CONTROL PANEL CODING GUIDE

UA

humiFog

Page 8 of 38

ZN 0 YYYY U

Zone Control

Cabinet Type of Cabinet Available – Sequencing Number Custom

0 = Standard U= USA

Zone Control Panels

4. ZONE CONTROL CABINET POSITIONING AND MOUNTING

4.1 ZONE CONTROL POSITIONING AND MOUNTING NOTES

The humiFog zone control cabinets are designed to be wall mounted. There are appropriate holes in the back of the

cabinet, for mounting to the wall. Use appropriate fasteners for supporting the weight of the cabinet and its components. Maintain

clearances around the cabinet as noted below. This allows for proper ventilation, maintenance and user operation of the cabinet.

The cabinet should be placed locally centered to the pumping station, and distribution zone points. For ducted systems, the zone

control cabinet should be close to the duct/AHU. For ambient systems, the zone control cabinet should be mounted centrally to

the zone areas.

IMPORTANT NOTE: The maximum distance between the zone control cabinet and the rack/distribution is 50ft

(15meters). It is recommended that the unit be fixed in position so that the electrical connections do not become damaged.

All connecting wiring is done by installer. Certain clearances must be maintained around the unit for safety and

maintenance.

The cabinet can be placed wherever the following conditions are met:

Cabinet protection index: IP20 / Nema Type 1 (unless specified otherwise)

Operating conditions: 20-80% RH non condensing, 34-104ºF (1-40ºC)

Storage conditions: 10-90% RH non condensing, 34-122ºF (1-50ºC)

4.2 ZONE CONTROL PANEL CLEARANCES

C

UNIT CLEARANCES (UAZN***108)

FACE OF UNIT DIM (IN) DIM (MM)

FRONT (D) 24 610

LEFT SIDE (B) 4 102

RIGHT SIDE (A) 4 102

TOP (C) 12 305

D

AB

Tab. 4.b

UNIT CLEARANCES (UAZN***109)

FACE OF UNIT DIM (IN) DIM (MM)

FRONT (A) 24 610

LEFT SIDE (B) 4 102

RIGHT SIDE (C) 4 102

TOP (D) 12 305

Tab. 4.b

Page 9 of 38

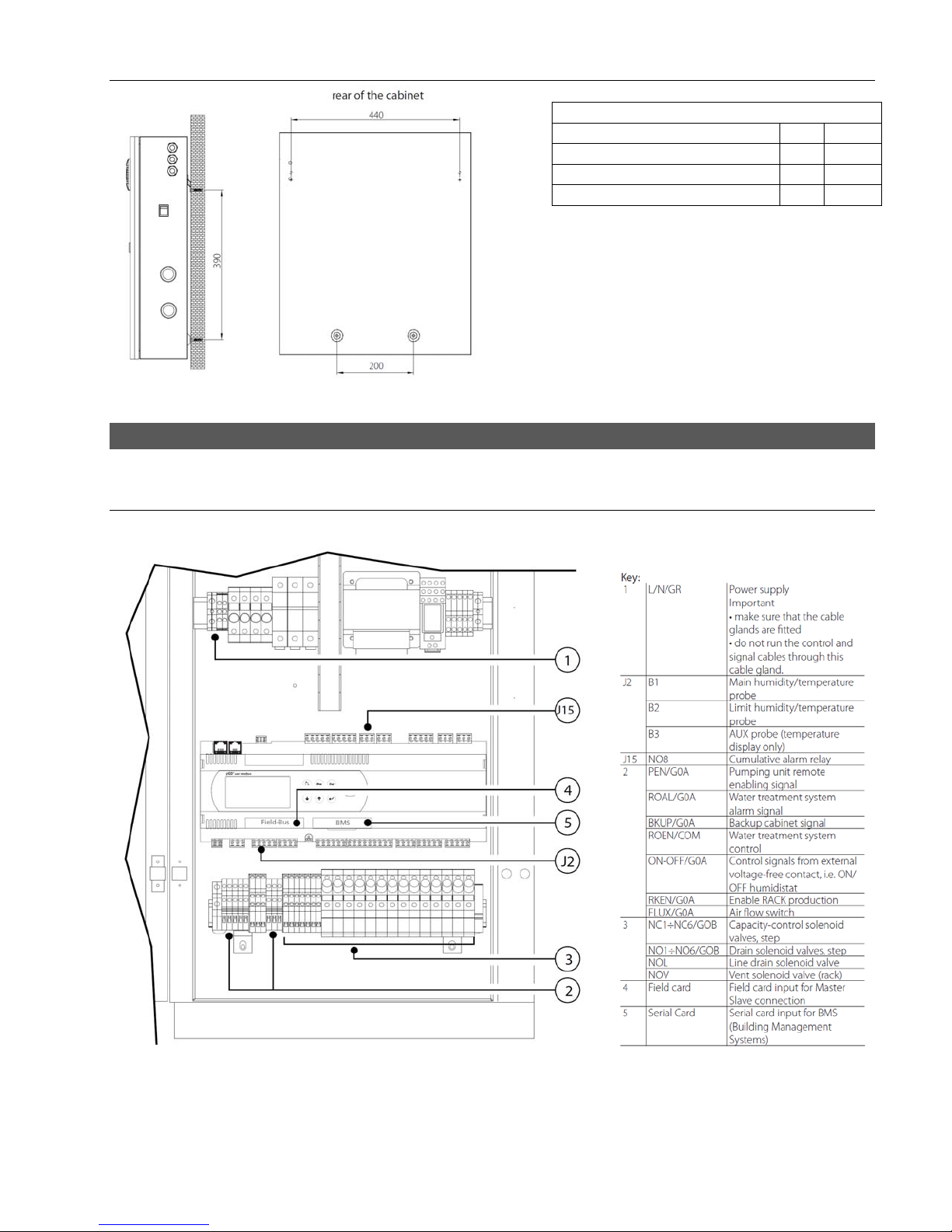

4.3 ZONE CONTROL DRILLING TEMPLATE

5. ELECTRICAL WIRING

5.1 WIRING CONNECTION LAYOUTS (UAZN***108)

Drilling Hole Conversion Table

Dimension mm in

Upper Horizontal 440 17.32

Lower Horizontal 200 7.87

Vertical Space Between Horiz. 390 15.35

Page 10 of 38

5.2 WIRING CONNECTION LAYOUTS (UAZN***109)

Page 11 of 38

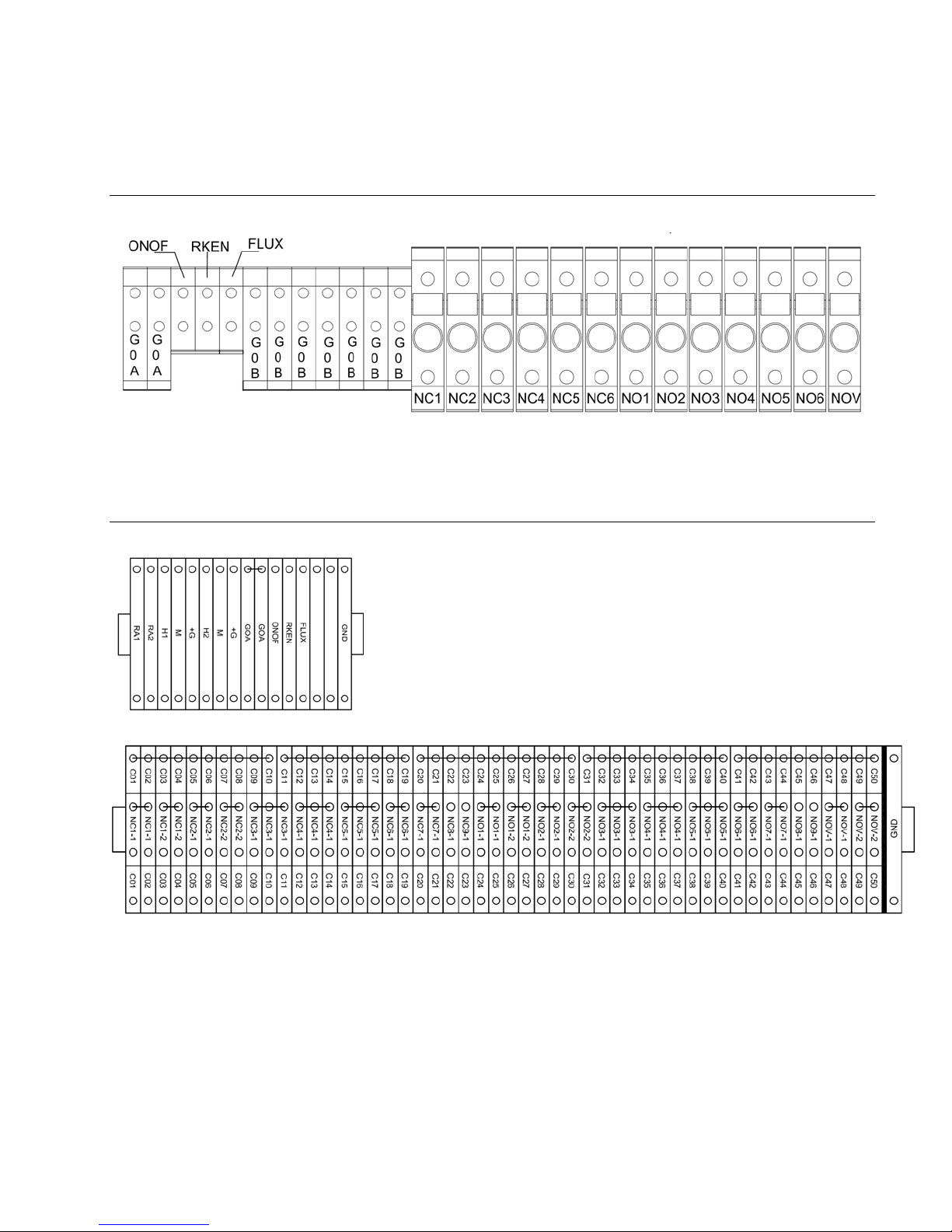

5.3 DETAILS OF (2) AND (3) TERMINAL BLOCKS (UAZN***108)

5.4 DETAILS OF (2)(TBS1) AND (3)(TBS3,TBS4) TERMINAL BLOCKS (UAZN***109)

(3)

(4)

Page 12 of 38

5.5 ELECTRICAL WIRING

Check that the power supply voltage to be connected matches the value indicated on the rating plate inside the electrical

panel.

An external, fused disconnect should be provided according to local and/or national electrical codes.

NOTE: To avoid unwanted interference, the power cables should be kept separate from

any control wiring.

All wiring must be in accordance with local, state and country electric codes.

NOTE: Tolerance allowed on main voltage = -15% to +10%

Power is connected to the main switch inside the control panel at the bottom right.

Connect wires to the top of the switch/terminal labeled L, and N. There is also a

ground bar/lug labeled GR

Power Table, UAZN******

External Disconnect Size,

Model Voltage Current

UAZN00108U 115 V~ 4.1 FLA at least 5 Amps

UAZN00109U 120 V~ 17.3 FLA at least 25 Amps

provided by Installer

Fig. 5.a

Page 13 of 38

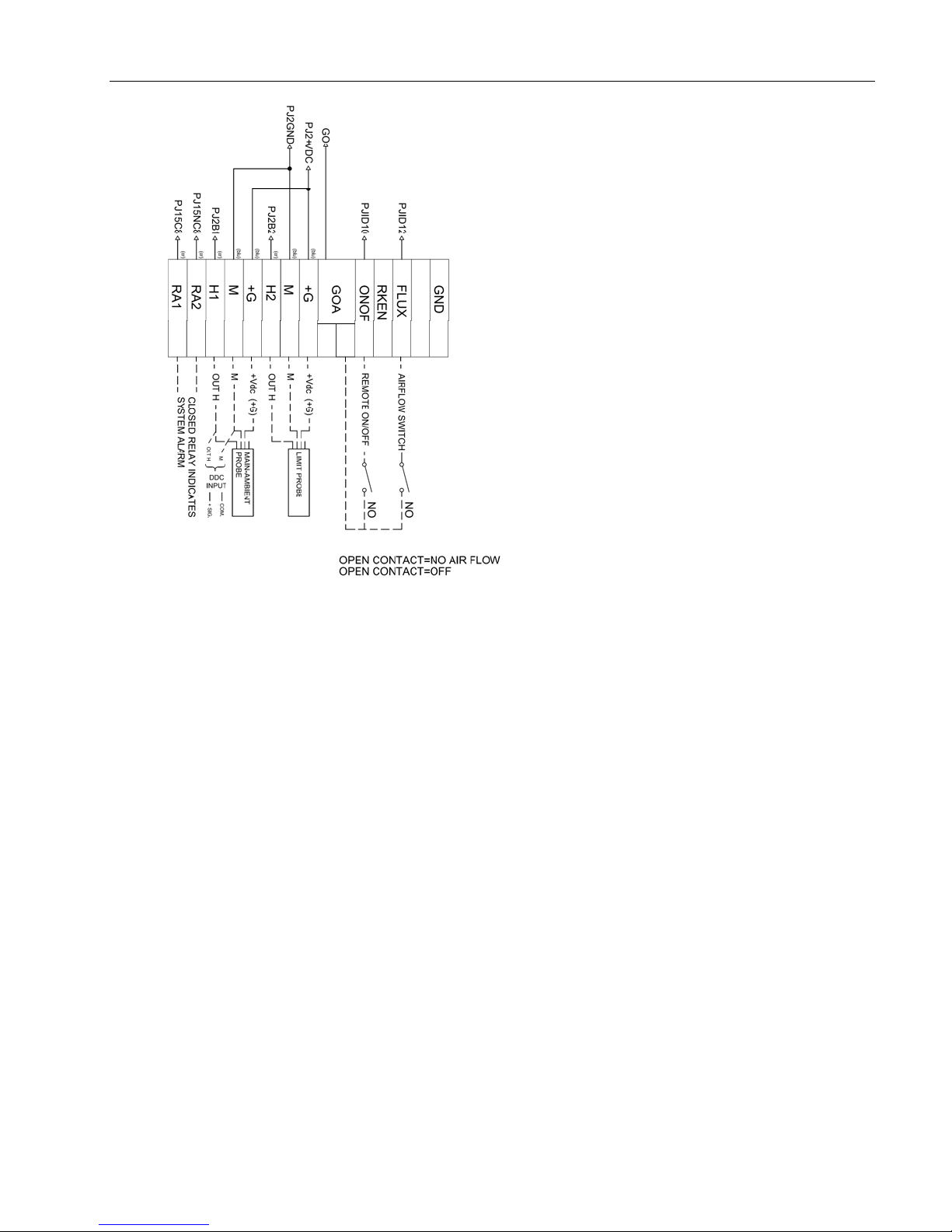

5.6 CONTROL SIGNALS FROM EXTERNAL VOLTAGE-FREE CONTACT

(HUMIDISTAT)(UAZN***108)

IMPORTANT NOTE: When grouping cabinets in a staged (cascaded) or parallel system, control signals, sensors, &

switches ONLY need to be connected to the master zone control cabinet of each group, addressed at location “1”.

Page 14 of 38

5.7 MODULATING CONTROL SIGNAL(UAZN***108)

IMPORTANT NOTE: When grouping cabinets in a staged (cascaded) or parallel system, control signals, sensors, &

switches ONLY need to be connected to the master zone control cabinet of each group, addressed at location “1”.

The control signal input connections depend on the control algorithm activated

Cables Up to 30 m : two-wire cables cross-section 0.5mm2

The signal may

come from:

To set the type of operation, control and signal: ”installer menu > type of control (see chap. 9.11 Installer menu)

-N.B. Shielded cables should be used. The cables must not run

near the 120 V power cables nor near the conductor cables;

this avoids measurement errors due to electromagnetic disturbance.

(AWG20)

-Modulating control with external controller

-Modulating control with ambient humidity probe

-External controller and limit humidity probe

Page 15 of 38

5.8 CONTROL SIGNAL WIRING (UAZN***109)

Page 16 of 38

5.9 SOLENOID VALVE CONNECTION FOR DISTRIBUTION SYSTEM (UAZN***108)

For the management of the distribution system, the cabinet controls four

types of solenoid valves:

• normally closed “NC” for capacity-control of the manifolds.

• normally open “NO” for draining the manifolds.

• normally open vent valves.

2

Recommended connection cables: two-wire plus earth AWG 18-20 (0.5-1.0 mm

maximum length 100 m.

REF.

1 NC1 - GOB 1 - 2

2 NC2 - GOB 1 - 2

3 NC3 - GOB 1 - 2

4 NC4 - GOB 1 - 2

5 NC5 - GOB 1 - 2

6 NC6 - GOB 1 - 2

7 N01 - GOB 1 - 2

8 N02 - GOB 1 - 2

9 N03 - GOB 1 - 2

10 N04 - GOB 1 - 2

11 N05 - GOB 1 - 2

12 NO6 - GOB 1 - 2

14 NOV - GOB 1 - 2

),

CABINET

TERMINAL

BLOCK

SOLENOI

D

VALVE

CONNEC

TOR

DESCRIPTION

Capacity-

control sol.

Valves 1st step

Capacity-

control sol.

Valves 2nd step

Capacity-

control sol.

Valves 3rd step

Capacity-

control sol.

Valves 4th step

Capacity-

control sol.

Valves 5th step

Capacity-

control sol.

Valves 6th step

Drain solenoid

Valves 1st step

Drain solenoid

Valves 2nd step

Drain solenoid

Valves 3rd step

Drain solenoid

Valves 4th step

Drain solenoid

Valves 5th step

Drain solenoid

Valves 6th step

Vent drain

solenoid valves

MAX. NO.

OF

SOLENOID

VALVES

PER STEP

3

3

3

1

1

1

3

3

3

1

1

1

1

Page 17 of 38

5.10 SOLENOID VALVE CONNECTION FOR DISTRIBUTION SYSTEM (UAZN**109)

The above diagram is meant to be a general guide.

See job specific submittal for UAZN***109 For wiring diagrams,

terminal block labeling and connections.

Label DESCRIPTION

CO1 - CO50 Commons For Valves

NC* Fill Valves

NO* Drain Valves

NOV* Vent Valves

Page 18 of 38

5.11 CUMULATIVE ALARM RELAY (J15)

5.12 INPUTS FROM EXTERNAL DEVICES

5.13 SUPERVISOR NETWORK

Supervisor network is through the pumping station unit. Please see the pumping station manual.

Page 19 of 38

5.14 PUMPING STATION TO MULTI ZONES

Pumping stations are wired to the multi-zone control panels by pLAN connections. Please see diagram below, as well as the

CAREL pCO platform manual for specific

instructions.

J11

RXTXRXTX+

Slave Pumping

Station

UA***H****

pLAN CONNECTION

J11

RXTX-

RXTX+

GND

GND

High pressure water line

Zone Control

Cabinet

UAZN*

Solenoid

Valve

Wiring

AHU

Zone Control

Solenoid

Valve

Wiring

J11

RXTX-

RXTX+

GND

Cabinet

UAZN*

AHU

Next zone,

if applicable

WIRING FROM PUMPING STATION, TO ZONE

CONTROL CABINET(S)

NOTES:

1. Use a twisted pair shielded cable to zone

control cabinets.

2. Connect to terminal block J11 of PCO3 in

each zone cabinet.

3. Connect the shield to the GND at pumping

station end only.

Page 20 of 38

5.15 DUPLEX CONTROL WIRING / MULTIPLE ZONES PER AIR HANDLER

WIRING FROM ZONE CONTROL CABINET TO

DUPLEX PUMPING STATIONS

NOTES:

1. Use a twisted pair shielded cable to pumping

stations.

2. Connect to terminal block J11 of PCO3 in each

pumping station.

3. Connect the shield to the GND at zone control

end.

Rx/Tx+ must match on all PCO controllers. Rx/Txmust also match on all PCO controllers.

For a duplex system, both pumping stations are wired to one or

more zone control panels by pLAN connections. Please see

diagram 6.d, as well as the CAREL pCO platform manual for specific

instructions.

For multiple zones in the same air handler, the same wiring rules apply for the pLAN connections. For multiple

zones each with multiple zone control cabinets, the number of cabinets per each zone must be the same. Contact the factory for

additional details regarding this.

Fig. 6.d

Page 21 of 38

6. START-UP

IMPORTANT INSTRUCTIONS/WARNINGS:

Before connecting the water to the pumping station, flush the supply pipe for 10 minutes by piping water directly into the

drain.

Before starting the pumping station, verify that the humidifier is in full operational condition. The hydraulic and electrical

equipment should not be locked out. There should not be any water leaks and the electrical components must be dry.

If a hazard does seem to exist, the system should be locked out immediately and the problems corrected before continuing.

6.1 STARTUP CHECKLIST

Before starting the humidifier, the following should be checked:

Water is connected, the line has been flushed, and external valves are open.

Drain is connected and run to an open drain.

Electricity is connected in accordance with instructions, local codes and data labels in the unit.

The external power fuses/disconnect are installed and intact.

All control wiring is done and tested.

Airflow switch is wired to open on air flow loss.

Hi-limit humidistat is wired to open on humidity rise above set point.

Unit wires have been checked to make sure they and all connectors are tight from shipping.

The high pressure water outlet piping is run correctly to the distribution system.

The proper capacities for each stage of the manifold system are installed in the zone control cabinet.

For a multi-zone system, the addresses of the zone controls cabinets are changed.

For a duplex system, the addresses of the pumping stations are changed.

6.2 RE-ADDRESSING THE CONTROLLERS AND DISPLAYS FOR MULTI-ZONE OR DUPLEX

SYSTEMS

The default addresses for a zone control cabinet are “1” for the PCO3 controller and “30” for the PGD display. The default

addresses for the pumping station cabinet are “16” for the PCO3 controller and “32” for the PGD display. For multi-zone or

duplex systems, the additional cabinets on the pLAN must have their addresses changed before they can operate correctly.

When changing addresses, the pLAN connections between each of the PCO3 controllers must be removed. The connections

are restored once the readdressing is completed.

For multi-zone system,

o the PCO3 controllers in the additional cabinets can be assigned addresses sequentially upward.

o the PGD displays in the additional cabinets can be assigned addresses sequentially downward.

For a duplex system,

o the PCO3 controller in the additional pumping station cabinet must be changed to “17.”

o the PGD display in the additional pumping station cabinet must be changed to “31.”

pLAN ADDRESS TABLE

Pumping

Station

Zone

Control

PCO3 Controller PGD Display

Default Multi-zone Duplex Default Multi-zone Duplex

16 N/C 17 32 N/C 31

1 2, 3, …, 15 N/A 30 29, 28, …, 18 N/A

Tab. 7.a

Page 22 of 38

6.3 RE-ADDRESSING PCO3 CONTROLLER

To change the address of the PCO3 controller, the address of the PGD display must be set to “0” first. (The procedure for

setting the address of the PGD back to the proper address is described in 6.2.2.)

1. Unplug J11 connector from PCO3 controller.

2. Press the up, down, and enter keys (3 keys on the right hand side of remote display) for approximately 3 seconds.

3. The screen should show “Display address setting.”

4. Press the enter key and change value to “0.”

5. Press enter.

6. Shut down power to the PCO3 controller, wait 3 sec, and then turn power back on to the PCO3 controller.

7. As unit is powering on, press and hold the up and alarm buttons (top left and top right buttons on PGD remote

display) until “pLAN address” is displayed.

8. Change to desired address.

9. Press enter.

10. The PCO3 is now address to the value you last entered.

6.4 RE-ADDRESSING PGD DISPLAY

1. Unplug J11 connector from PCO3 controller.

2. Press the up, down, and enter keys (3 keys on the right hand side of remote display) for approximately 3 seconds.

3. The screen should show “Display address setting.”

4. Press the enter key and change this value to 18-32. This address must be different from the address of the PCO3

controller.

5. Press enter.

6. Press the up, down, and enter keys (3 keys on the right hand side of remote display) for approximately 3 seconds.

7. You will be taken to the same screen as before, but this time you will see “I/O Board Address” displayed underneath

“Display address setting.”

8. Press the enter button 2 times so the text box is blinking beside “I/O Board address.”

9. Change this to the same address that you assigned to the PCO3 controller.

10. Then, press enter.

11. The next screen displayed will show “Terminal config” press enter to continue.

12. The following screen will show P:(address of PCO3 controller) in upper left corner.

13. Trm1 None will be blinking. Change “none” to the addressed you entered in step 4 (address of PGD display.)

14. Press enter 1 time and change the next field to Pr.

15. Press enter 5 times and change ok? From no to yes.

16. Press enter.

17. The PGD remote display is now addressed to your PCO3 controller.

Page 23 of 38

7. THE humiFog CONTROLLER

The humiFog controller features a comprehensive information display that shows the operation of the system at a glance:

Alarm

Program

Escape

Up

Enter

Down

+

Up +

Down

Turns off the buzzer and displays the first alarm screen in the alarm-loop.

A red LED located under the Alarm button will be energized when there are alarms present. If the red

LED is blinking, that means an alarm has occurred, but the condition has been corrected and the alarm

can now be reset.

Shortcut to the Technician’s Menu, where all application settings can be reached. If protected, a

password will need to be entered.

Escapes to previous screen-loop. When already in the Technician’s Menu, pressing ESC takes you to the

main status screen.

If ESC’s green LED is blinking, part of the system is under “Manual Control.”

Cycles upward through the screens, when cursor is in top left corner. When cursor is in a field, the value

of the field is increased. The longer the button is held, the faster the value increases.

Cycles through fields in a screen. When in a field, pressing ENTER confirms the current value into the

field and goes to the next field.

Cycles downward through the screens, when cursor is in top left corner. When cursor is in a field, the

value of the field is decreased.

The longer the button is held, the faster the value decreases.

Shortcut to quickly see the Software Application’s Version Number and Date.

It is in this screen from which you can restore the Factory Settings,

+

+

NOTE: The standard humiFog display will have fields that can display values or fields that can accept values. If pressing the

ENTER key places the cursor next to the display field, the UP and DOWN keys can be used to change that value.

Page 24 of 38

Escape +

Program

Escape +

Alarm

by pressing

Shortcut to quickly see the System Type and Number of Humidification Stages.

When in the Alarm History Screen, pressing ESC+PRG will erase the history.

Keyboard shortcut to reset all Manually controlled points to Automatic control.

When in the System Run Hours screens, pressing these keys will reset the currently selected Stage’s Run

Hours.

, then , then , and finally one last time.

7.1 MULTI-ZONE IN SINGLE AHU SETUP OVERVIEW

Depending on the system setup variables, there can be significant differences in the user interface options. Some

options may have more selections to choose from, and some menu selections may be absent altogether.

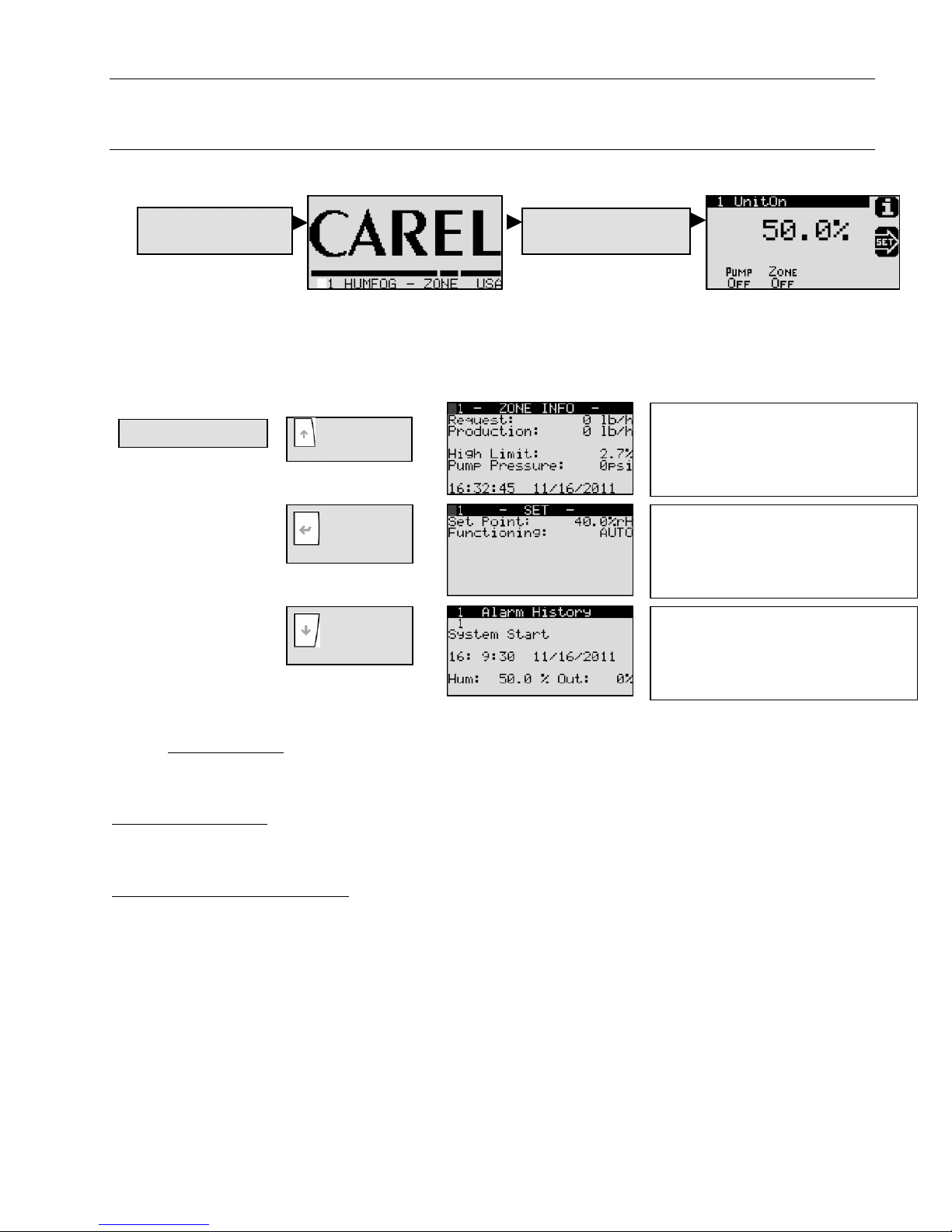

7.2 SYSTEM STATUS

On initial power-up, the controller will go through a series of self-tests and then activate the program, bringing up

the following screens. The visibility of some screens is dependent on the configuration of the system.

1. Power-up Unit

During power-up, the controller performs an alarm test. The alarm key will be red, and must be pushed twice to clear the

alarms. To check the “Alarm History”, use DOWN key from System Status Screen. The 1st alarm is a “System Start Alarm”, and

the 2nd alarm is a “No Air Flow Alarm”. Note: The “No Air Flow Alarm” occurs whether the AF digital input is open (low

voltage) or closed (high voltage) at power-up. Actions that can be performed from the System Status Screen:

System Status Screen

Up

Enter

Down

IMPORTANT NOTE: The System Status Screen can vary depending on the setup options in section 7.4 ,

MANUFACTURER SUBMENU. See section 5.11 for a review of multiple zone setup options. If the setup involves multiple zones

in the same air handler, choosing parallel or staged setup will change the System Status Screen as follows:

Parallel Zone Control: Each zone cabinet will display the same demand percentage because each cabinet is operating

simultaneously at the same level of output. The output level displayed is that of the entire zone & pumping system.

Staged (Cascaded) Zone Control: Zone control cabinets operate in a linear sequence, with zone activation occurring

only after the previous one has reached 100%. Due to the variation in demand among cabinets, the master cabinet (address

1) will display the demand value of entire system capacity. The remaining cabinet(s) will only display its own output relative

to its capacity. For example, the zone at address 1 may read 50%, indicating that the system capacity is 50% while the zone

demand at address 1 is actually 100%. For the subsequent zones, however, the demand displayed is the actual output of that

zone.

System Status Screen

No changes can be made at this

screen. It provides a summary of the

current zone and pump operation, as

well as system demand.

Use the ENTER key and UP/DOWN

key to change humidity SET POINT.

FUNCTIONING can be set to AUTO or

OFF. Use the ENTER key to activate

new value.

Use the UP/DOWN key to view alarms.

ESC key will take you back to previous

screen.

Page 25 of 38

7.3 MAIN MENU

A

Use

A

To access the “MAIN MENU”, press PRG from the “System Status Screen” shown above.

List of Main Menu selections: (Use the UP/DOWN arrows to scroll through this list)

1. User

2. Installer

3. Maintenance

.

r

1. Alarm threshold

2. Clock

B. Installer

1. Service Password

C. Maintenance

1. Service Password

To access the “Main Menu”, press PRG twice from the System Status Screen.

. On/Off Unit

1. On/Off Unit

B. Setpoint

1. Humidity Setpoint

C. Clock / Scheduler

1. Clock

Use the ENTER key and UP/DOWN

key to change the HIGH, LOW, and

ALARM DELAY values. When the

desired value is reached, use the

ENTER key to activate new value.

Use the ENTER key and UP/DOWN

key to change the MONTH, DAY,

YEAR, HOUR, and/or MINUTE. When

the desired values are reached, use

the ENTER key to activate the clock.

Manufacturer SubMenu (see below)

a. Configuration

b. I/O Configuration

c. Factory Settings

e. Initialization

Use the UP/DOWN keys to select

password and ENTER to confirm.

Access is granted to SERVICE MENU,

see 7.3 “SERVICE MENU” below.

Use the ENTER key and UP/DOWN

key to change to SWITCH OFF or

SWITCH ON. The “Actual state” will

change to “OFFbyKEY” or “UnitOn”.

Use the ENTER key to confirm.

Use the ENTER key and UP/DOWN

key to change the SET POINT. When

the desired value is reached, use the

ENTER key to activate new value.

Use the ENTER key and UP/DOWN

key to change the MONTH, DAY,

YEAR, HOUR, and/or MINUTE. When

the desired values are reached, use

the ENTER key to activate the clock.

Page 26 of 38

y

D. Input/Output

1. Analog Input

This screen displays the humidity

sensor reading or DDC value.

2. Digital Input

3. Relay Output

E. Data Logger

F. Board Switch

G. Service

1. Alarm Histor

1. Board Switch

b. Information

d. Working Hours

e. BMS config.

f. Service Settings

g. Manual Management

Displays the remote control state.

The “Off” state results from a “high”

voltage signal to the Remote On/Off

digital input port.

Displays the state of the relays. A

dark box, or “On” state, indicates a

“high” voltage signal to the solenoids

for that stage. (Screen layout varies

with number of stages.)

This screen displays the most recent

alarm. The UP and DOWN keys

allows scrolling through the entire

alarm history.

Displays information from the

controller at the indicated address. If

enabled, other controllers in a multizone installation can be selected. Up

to 32 zones can be connected.

Access is granted to SERVICE

MENU, see 7.3 “SERVICE MENU”

below.

Page 27 of 38

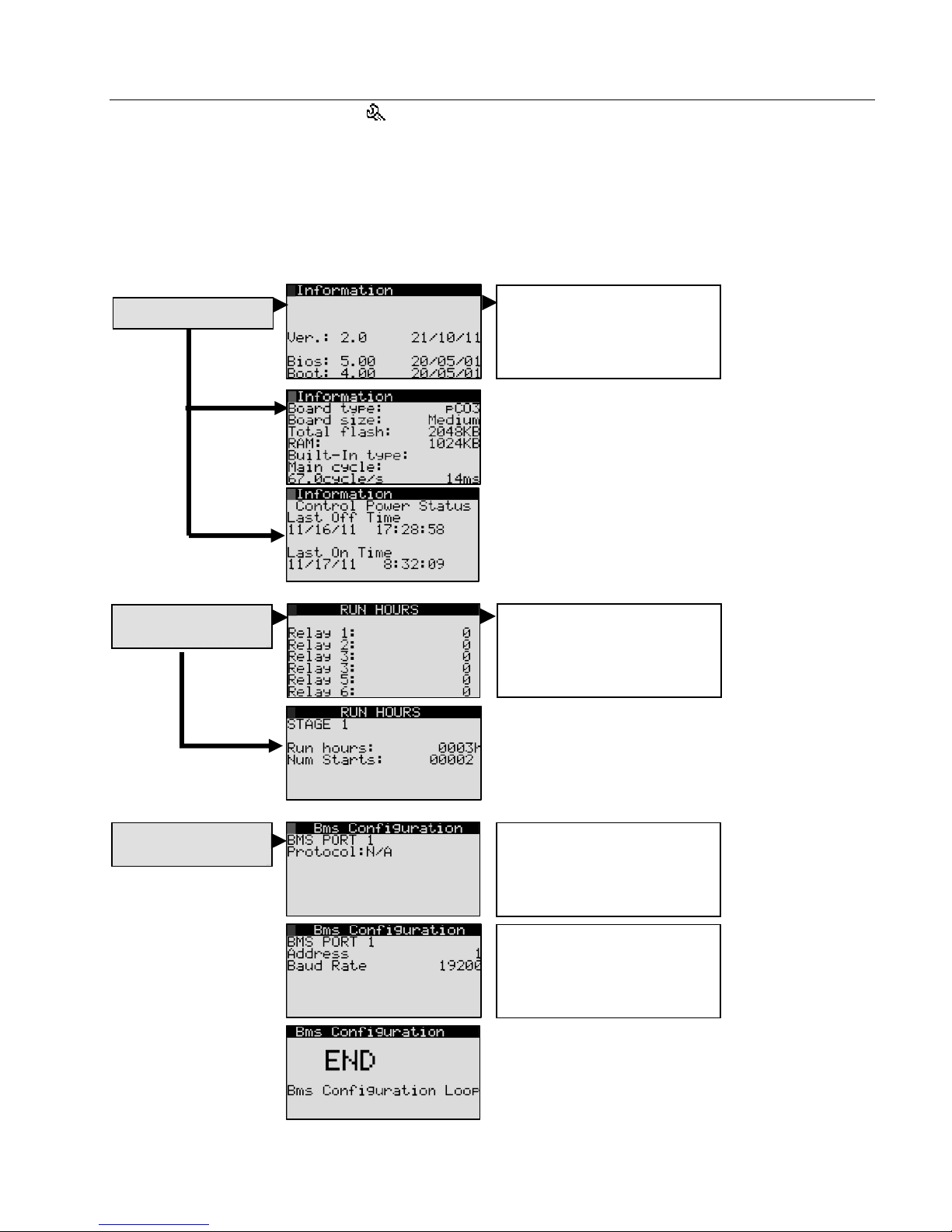

7.4 SERVICE MENU

To access the “Service menu”, scroll to “3. Maintenance” from “Main Menu”, and press ENTER when highlighted. The

factory default password is 22.

List of “Service Submenu” selections: (Use the UP/DOWN arrows to scroll through this list. Selections “a” and “c” are not

available.)

b. Information

d. Working Hours

e. BMS config.

f. Service Settings

g. Manual Management

b. Information

d. Working Hours

e. BMS config.

Page 28 of 38

Displays information on

controller software, hardware,

and power. Use the UP/DOWN

keys to alternate screens.

Displays cumulative run-time for

each stage. (Screen layout

varies with number of stages.)

Use ENTER to select Protocol

and UP/DOWN key to select

Protocol type. ENTER again to

confirm selection.

Use ENTER to select Address

or Baud rate and UP/DOWN

key to change. ENTER again to

confirm selection.

f. Service Settings

g. Manual Management

7.4.1 Service Settings Submenu

To access the “Service Settings Submenu,”

Scroll through the “G. Service” submenu to “F. Service Settings”

Press ENTER when “Service Settings Submenu” is highlighted.

Input the password.

List of Service Settings Submenu selections: (Use the UP/DOWN arrows to scroll through this list.)

a. Working hour set

b. Probe adjustment

c. Regulation

d. User DEV/Change PW1

a. Working hour set

b. Probe adjustment

c. Regulation

d. User DEV/Change

PW1

Use UP/DOWN key and

ENTER key to input password.

Default code is 22. The

password can be changed by

the service technician.

Use UP/DOWN key and

ENTER key to input password.

Default code is 22. The

password can be changed by

the service technician.

Use UP/DOWN key and

ENTER key to reset run hours.

Display will change momentarily

to Yes, and then will change

back to No.

Use UP/DOWN key and

ENTER key to choose Control

Sensor or High Limit Sensor.

Use the UP/DOWN key to

change the offset (0-53.5).

Default setting disables High

Limit Sensor, causing Value=0.

Use I/O configuration on

Manufacturer Submenu to

enable the High Limit Sensor.

Use the ENTER key and

UP/DOWN key to select and

change the Parameter values.

Consult Carel before making

changes.

Use the ENTER key and

UP/DOWN key to change the

Password. When the desired

value is reached, use the

ENTER key to activate.

Go to

Service Settings

Submenu

Go to

Manual Management

Page 29 of 38

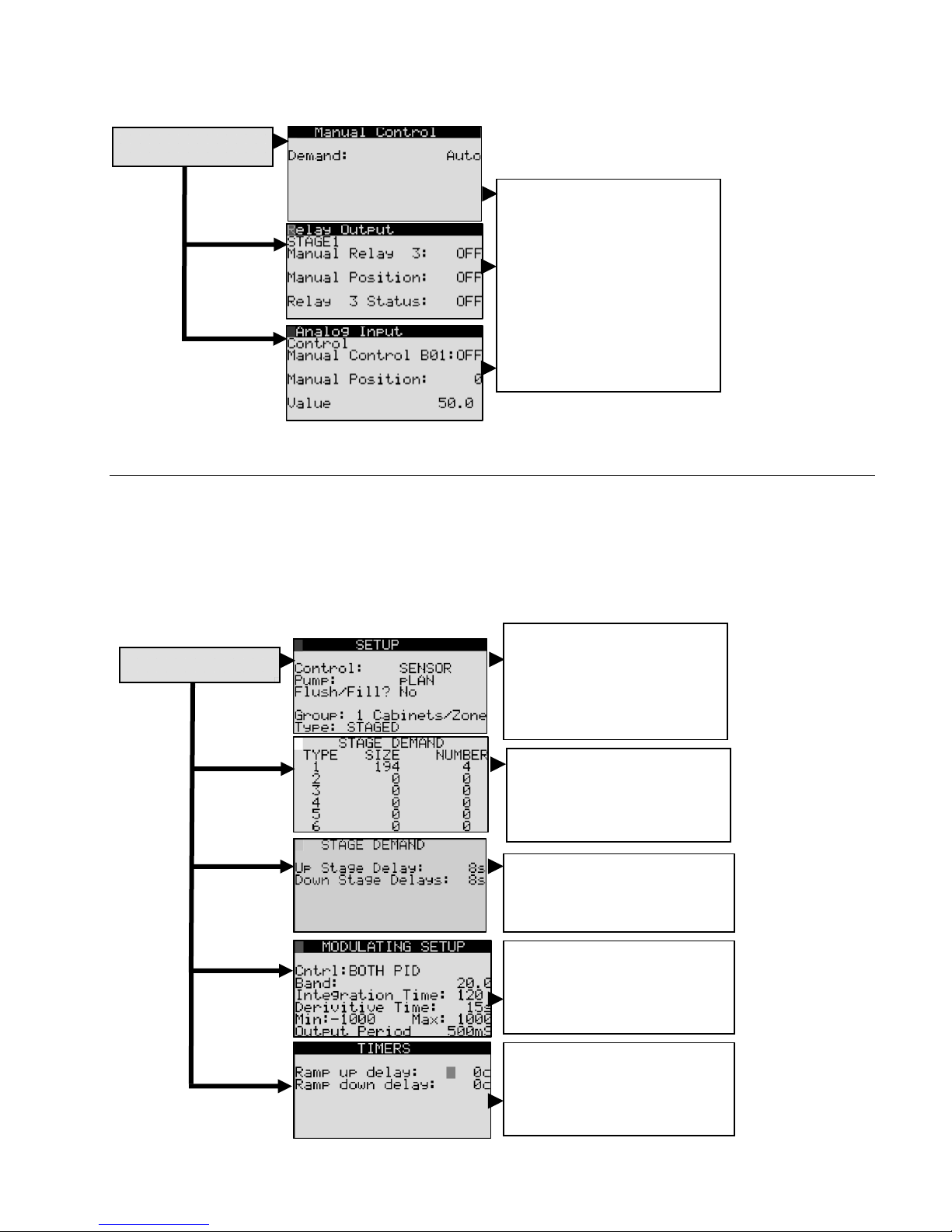

7.4.2 Manual Management Submenu

To access the “Manual Management Submenu,”

Scroll through main menu to “G. Service” and then “g. Manual Management”. Press ENTER and input the password.

g. Manual Management

Use the UP/DOWN keys to

scroll through screens.

DEMAND, STAGES, DRAINS,

RELAY OUTPUTS, DIGITAL

INPUTS, and ANALOG INPUTS

can all be controlled manually.

Use the ENTER key to select

the parameter being changed.

Use the UP/DOWN keys to

change the settings. (Screen

layout varies with number of

stages.)

7.5 MANUFACTURER SUBMENU

To access the “Manufacturer Submenu,” scroll through the “Main Menu” and select “B. Installer”. The settings in the

“Manufacturer Submenu” are password-protected. Unauthorized users should contact their Carel representative before

accessing the “Manufacturer Submenu.”

List of Manufacturer Submenu selections: (Use the UP/DOWN arrows to scroll through this list. Selection “d” is not available.)

a. Configuration

b. I/O Configuration

c. Factory Settings

e. Initialization

a. Configuration

Use the ENTER key and

UP/DOWN keys to change

control type, pump

communication, group/ type

quantity, and type (PARALLEL

or STAGED)

Use the ENTER key and

UP/DOWN keys to change the

water output for each stage to

match the humiFog system

being controlled.

Use the ENTER key and

UP/DOWN keys to change the

delay time for stage activation.

Page 30 of 38

Use the ENTER key and

UP/DOWN key to select and

change the Modulating Control

values. Consult Carel before

making changes.

Use the ENTER key and

UP/DOWN keys to change the

delay time for zone activation.

b. I/O Configuration

c. Factory Settings

e. Initialization

Use the UP/DOWN keys to

scroll through screens. Use the

ENTER and UP/DOWN keys to

Disable/enable inputs

Change RH signal type

o 0-1,5,10 VDC

o 4-20 mA

o NTC, -50T90, 10T 170,

nu10, PT1000, SPKP

o On/Off (Note: other

choices not used for RH)

Change max/min values

Use the UP/DOWN keys to

scroll through screens. Use the

ENTER key and UP/DOWN

keys to

Disable/enable inputs

Change the action (A

closed condition results in a

“high” voltage signal to the

digital input port.

Change time delay (up to

999 s)

Use the ENTER key and

UP/DOWN key to select and

change the Parameter values.

Consult Carel before making

changes.

Use the ENTER key and

UP/DOWN key to select and

change capacity setting.

Consult Carel before making

changes.

Use the ENTER key and

UP/DOWN key to reset all values

to global settings. To complete

initialization, turn unit off and on.

Use the ENTER key and

UP/DOWN key to select SAVE

options. There is an identical

screen for USER SAVE custom

options. ENTER will confirm the

choice.

Use the ENTER key and

UP/DOWN key to YES or NO.

Exercise caution when accessing

this screen since it can erase

everything.

Use the ENTER key and

UP/DOWN key to change access

passwords. ENTER will confirm

the selected digit.

Enabling the Remote

On/Off by a supervisor

requires a change to

the Factory Settings.

Page 31 of 38

8. REPLACEMENT PARTS

8.1 SEE SPECIFIC MATERIAL LIST(S) PROVIDED WITH UNIT.

1

8

Typical Zone Control Cabinet

2

Tab. 8.1

Item Description Part Number

8 CAREL PCO3 MEDIUM CONTROLLER

7 ISOLATION TRANSFORMER

3 MAIN SWITCH G

4 POWER SUPPLY TERMINAL BLOCK

2 MAIN CONTROL TRANSFORMER

TRANSFORMER B SECONDARY FUSE

6

CARRIER

5 TRANSFORMER PRIMARY FUSE CARRIER

1 CAREL PGD DISPLAY PGD1000FW0

9 CONTROL TERMINAL BLOCK PLUS FUSES

7

9

6

5

CONTACT

CAREL

CONTACT

CAREL

CONTACT

CAREL

CONTACT

CAREL

CONTACT

CAREL

CONTACT

CAREL

CONTACT

CAREL

CONTACT

CAREL

3

4

Page 32 of 38

S90

PGD

From Previous

Zone Cabinet

(J11) or Pump

Cabinet (J11)

RXTX-

RXTX+

GND

To Next Zone

Cabinet (J11)

TB-NC1 TB-NC2

B

NO2

NO1

C1

B B

NO3

C1

C4

9. WIRING DIAGRAM

TB-NC5

TB-NC3

B

NO7

NO6

NO5

NO4

C7

C7

C4

TB-NC4

NO8

NC8

NO10

NO9

C8

C9

OPEN RELAY INDICATES

SYSTEM ALARM

NO11

TB-NC6

C9

NO12

NC12

C12

TB-N01 TB-N02

NO13

NC13

C13

C14

TB-N03

TB-N04

BB

NO15

NO16

NO14

C14

C17

NO18

NO19

NO17

NO20

C17

J10

J9

J11

J12

J13

J14

J15

J16

J17

J18

J21

J22

3

Extra-Large

C21

B

TB-N05

TB-N06

NO21

J19

NO23

NO22

TB-N0V

J20

NO25

NO28

NO24

C25

C21

NO29

NO27

NO26

C25

J24

J1

+Vterm

GND

G0

G

J2

+5 Vref

GND

B3

B2

B1

J3

+VDC

BC4

BC5

B5

B4

GA

VG0

VG

TB-GOA

J4

Y3

Y4

Y2

Y1

J5

IDC1

ID8

ID7

ID4

ID3

ID5

ID2

ID1

ID6

B8

GND

ID9

TB-ONOF

M

+(G)

OUT H/T

M

+(G)

OUT H/T

REF

OUT.DDC

J7

ID12

ID10

ID11

TB-FLUX

0-10V AMBIENT

ID13H

IDC9

ID13

0-10V LIMIT

PROBE

PROBE

0-10V EXT.

CONTROL

J8

IDC13

ID14

ID14H

G0A

GA

0

B

G0B

GB

F5

F8

TR-A

0

24

TR-B

00

24

120

120

T1

T2

T3

F1

F2

F3

G

F3

F4

N

L

GR

N

L

120

VAC

GND

DISCONNECT SWITCH AND LISTED

PRIMARY OVER--CURRENT

PROTECTION TO BE PROVIDED BY

INSTALLER

T4

F4

Panel Builder Wiring

Final Assembly or Customer Wiring

Page 33 of 38

NOTES:

1. CABINET AND WIRING MUST BE UL508A ASSEMBLED.

2. CABINET SHALL BE CONTRUCTED WITH FINGERSAFE COMPONENTS.

3. CABINET SHALL BE CONTRUCTED AS TYPE 12.

4. WIRE COLORS SHALL BE AS FOLLOWS:

Black - All ungrounded conductors operating at supply voltage (wire numbers 1-4)

Red - Ungrounded AC control conductors at below supply voltage (all wires unless marked otherwise)

Orange (or) - All ungrounded conductors that remain energized when the main disconnect switch is "off"

Blue (blu) - Ungrounded DC control conductors at below supply voltage

White - All grounded AC current-carrying conductors, regardless of voltage

White w/ orange stripe - All grounded AC current-carrying conductors that remain energized when the

main disconnect switch is "off"

White w/ blue stripe - All grounded DC current-carrying conductors,regardless of voltage

Green( w/ or w/o yellow stripe) - Earth grounding.

NO1

NO2

NO3

NO4

NO5

NO6

NO9

NO7

NO10

NO11

NO12

NO14

NO15

NO16

NO17

NO18

NO19

NO20

NO21

NO23

NO22

TRA-0V

PCO PCO3000AS0

PGD PGD1000FW0

G MAIN DISCONNECT SWITCH

TR-A

TR-B

F1, 2

F3, 4

F5

F8

FNC*

NO*

NOV

NC*

NO*

NOV NO VENT VALVE

S90 PCO-PGD CABLE

ID10

ID12

TRANSFORMER (PCO)

TRANSFORMER (RELAYS)

FUSE: 5X20 1A 250V FAST

FUSE: 5X20 4A 250V SLOW

FUSE: 6.3X32 3.15A 250V SLOW

FUSE: 10.3X38 20A 600V FAST

FUSE: 5X20 6.3A 250V FAST

NC FILL VALVES (STAGE #)

NO DRAIN VALVES (STAGE #)

0

TERMINAL JUMPER

GOA

ONOF

G

0

B

AIR FLOW SWITCH

HUMISTAT-REMOTE ON/OFF SWITCH

0

0

B

B

COM FOR

0

B

ONOF

FLUX

0

B

0

0

B

B

G

G

G

G

G

G

NC1 NC2 NC3 NC4 NC5 NC6 NO1 NO2 NO3 NO4 NO5 NO6 NOV

1

2

3

4

5

6

7

8

9

10

11

12

14

NO

OPEN CONTACT=NO AIR FLOW

NO

OPEN CONTACT=OFF

FLUX

RKEN

GOA

Page 34 of 38

WIRING DIAGRAM FOR UAZN***109

Page 35 of 38

Page 36 of 38

10. WARRANTY

Limited Warranty

All products manufactured by CAREL USA, LLC are warranted to the original purchaser to be free from defects in materials and

workmanship in the course of normal and reasonable use for a period of 2 years and 1 month from the date of shipment (The

OEM controls warranty is 2 years from date of manufacture), humidifier replacement parts warranty is 90 days from date of

Invoice. Warranty replacement parts are warranted for remainder of original unit warranty or 90 days, whichever is longer, so

long as the product has been installed and operated in accordance with all appropriate manuals and wiring diagrams, and

started up by a qualified CAREL USA technician. Any product or part that is found to be defective will, at the option of CAREL

USA, LLC be replaced or repaired. CAREL USA, LLC reserves the right to inspect any part or installation before replacing or

repairing defective parts. After startup of the product, labor for repairs or replacement of parts is not covered by this warranty.

Products not included in this warranty are NTC and PTC probes, transformers (TRA series), and routinely replaceable parts

such as filters, nozzles, pump parts, and gaskets. CAREL USA, LLC assumes no liability for consequential or inconsequential

damage, or damage due to negligence or improper use. Under the terms of this warranty, the original purchaser may have

certain legal rights and other rights, which may vary from state to state. The Warranty will not be considered valid if a product

is damaged due to negligence, mishandling or misapplication, or if the product label is missing. CAREL USA will attempt to

repair or replace the products within two (2) months of the receipt of the returned goods.

NOTES

Page 37 of 38

Page 38 of 38

+03U222081 Rel. 2.0 13/12/2012

Loading...

Loading...