CO

2

High e ciency condensing unit

OEM user manual

READ CAREFULLY IN THE TEXT!

Integrated Control Solutions & Energy Savings

NO POWER

& SIGNAL

CABLES

TOGETHER

ENG

WARNINGS

CAREL bases the development of its products on decades of experience in

HVAC, on continuous investments in technological innovations to products,

procedures and strict quality processes with in-circuit and functional testing

on 100% of its products, and on the most innovative production technology

available on the market. CAREL and its subsidiaries/affi liates nonetheless

cannot guarantee that all the aspects of the product and the software included

with the product respond to the requirements of the fi nal application, despite

the product being developed according to start-of-the-art techniques. The

customer (manufacturer, developer or installer of the fi nal equipment) accepts

all liability and risk relating to the confi guration of the product in order to

reach the expected results in relation to the specifi c fi nal installation and/or

equipment. CAREL may, based on specifi c agreements, acts as a consultant for

the positive commissioning of the fi nal unit/application, however in no case

does it accept liability for the correct operation of the fi nal equipment/system.

The CAREL product is a state-of-the-art product, whose operation is specifi ed

in the technical documentation supplied with the product or can be

downloaded, even prior to purchase, from the website www.carel.com.

Each CAREL product, in relation to its advanced level of technology, requires

setup/confi guration/programming/commissioning to be able to operate in

the best possible way for the specifi c application. Failure to complete such

operations, which are required/indicated in the user manual, may cause the

fi nal product to malfunction; CAREL accepts no liability in such cases. Only

qualifi ed personnel may install or carry out technical service on the product.

The customer must only use the product in the manner described in the

documentation relating to the product.

In addition to observing any further warnings described in this manual, the

following warnings must be heeded for all CAREL products:

• prevent the electronic circuits from getting wet. Rain, humidity and all

types of liquids or condensate contain corrosive minerals that may damage

the electronic circuits. In any case, the product should be used or stored

in environments that comply with the temperature and humidity limits

specifi ed in the manual;

• do not install the device in particularly hot environments. Too high

temperatures may reduce the life of electronic devices, damage them and

deform or melt the plastic parts. In any case, the product should be used

or stored in environments that comply with the temperature and humidity

limits specifi ed in the manual;

• do not attempt to open the device in any way other than described in the

manual.

• do not drop, hit or shake the device, as the internal circuits and mechanisms

may be irreparably damaged;

• do not use corrosive chemicals, solvents or aggressive detergents to clean

the device.

• do not use the product for applications other than those specifi ed in the

technical manual.

All of the above suggestions likewise apply to the controllers, serial cards,

programming keys or any other accessory in the CAREL product portfolio.

CAREL adopts a policy of continual development. Consequently, CAREL

reserves the right to make changes and improvements to any product

described in this document without prior warning.

The technical specifi cations shown in the manual may be changed without

prior warning.

The liability of CAREL in relation to its products is specifi ed in the CAREL

general contract conditions, available on the website www.carel.com and/

or by specifi c agreements with customers; specifi cally, to the extent where

allowed by applicable legislation, in no case will CAREL, its employees or

subsidiaries/affi liates be liable for any lost earnings or sales, losses of data

and information, costs of replacement goods or services, damage to things

or people, downtime or any direct, indirect, incidental, actual, punitive,

exemplary, special or consequential damage of any kind whatsoever, whether

contractual, extra-contractual or due to negligence, or any other liabilities

deriving from the installation, use or impossibility to use the product, even

if CAREL or its subsidiaries/affi liates are warned of the possibility of such

damage.

IMPORTANT

NO POWER

& SIGNAL

CABLES

READ CAREFULLY IN THE TEXT!

Separate as much as possible the probe and digital input cables from cables

to inductive loads and power cables, so as to avoid possible electromagnetic

disturbance.

Never run power cables (including the electrical panel cables) and signal

cables in the same conduits.

TOGETHER

DISPOSAL

INFORMATION FOR USERS ON THE CORRECT HANDLING OF WASTE

ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE)

In reference to European Union directive 2002/96/EC issued on 27 January

2003 and related national legislation, please note that:

• WEEE cannot be disposed of as municipal waste and such waste must be

collected and disposed of separately;

• the public or private waste collection systems defi ned by local legislation

must be used. In addition, the equipment can be returned to the distributor

at the end of its working life when buying new equipment;

• the equipment may contain hazardous substances: the improper use or

incorrect disposal of such may have negative eff ects on human health and

on the environment;

• the symbol (crossed-out wheeled bin) shown on the product or on the

packaging and on the technical leafl et indicates that the equipment has

been introduced onto the market after 13 August 2005 and that it must be

disposed of separately;

• in the event of illegal disposal of electrical and electronic waste, the

penalties are specifi ed by local waste disposal legislation.

Warranty on materials: 2 years (from production date, excluding consumables).

Approval: the quality and safety of CAREL S.P.A. products are guaranteed by

the ISO 9001 certifi ed design and production system.

3

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

4

Content

1. INTRODUCTION 7

1.1 General features .............................................................................................. 7

1.2 Components and accessories ......................................................................7

2. INSTALLATION 8

2.1 Main board: description of the terminals .................................................. 8

2.2 10A single-phase inverter .............................................................................. 9

2.3 12-16 A single-phase, 18-24 A three-phase inverter .............................. 10

2.4 12 A single-phase inverter PSD2 ............................................................... 11

2.5 Unipolar E2V valves for R744 ..................................................................... 14

2.6 Pressure probes (SPKT00**8C0) ..............................................................14

2.7 Temperature probes .....................................................................................14

2.8 General connection diagram ...................................................................... 15

2.9 Functional diagrams ..................................................................................... 16

2.10 Installation ...................................................................................................... 18

3. USER INTERFACE 19

3.1 Graphic terminal ...........................................................................................19

3.2 Description on the display .......................................................................... 19

ENG

4. MENU DESCRIPTION 20

4.1 Main menu ..................................................................................................... 20

5. COMMISSIONING 21

5.1 Guided commissioning procedure ........................................................... 21

6. FUNCTIONS 22

6.1 Unit ON/OFF .................................................................................................. 22

6.2 BLDC compressor .........................................................................................22

6.3 Compressor control ......................................................................................25

6.4 Compressor management on LT units (DSS and independent) .......27

6.5 Fans ..................................................................................................................28

6.6 Oil management ...........................................................................................29

6.7 HPV valve management .............................................................................. 32

6.8 RPRV valve management ............................................................................ 33

6.9 Generic functions ..........................................................................................34

6.10 Default value management ........................................................................ 35

7. FAST COMMISSIONING 36

7.1 MPXPRO confi guration (SW version t 4.0) ............................................ 36

7.2 Ultracell confi guration (SW version t 2.0)..............................................38

7.3 Ultra EVD EVO module commissioning ..................................................43

7.4 Connecting MPXPRO/Ultracella controllers to Hecu ............................44

8. SIGNALS AND ALARMS 47

8.1 Alarm management ......................................................................................47

8.2 Compressor alarms ...................................................................................... 47

8.3 Pressure alarms .............................................................................................48

8.4 Anti liquid return MPX valve alarm .......................................................... 49

8.5 High pressure prevention ...........................................................................49

8.6 MPXPRO/UltraCella alarms .........................................................................49

8.7 Alarm table .....................................................................................................50

9. SOFTWARE UPDATE 58

9.1 Uploading/updating the software .............................................................58

9.2 Software revision history ............................................................................. 61

5

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

1. INTRODUCTION

ENG

1.1 General features

Hecu CO2 is a control system for complete management of R744

condensing units fi tted with BLDC compressors. The serial connection

between the condensing unit and the evaporators controlled by

MPXPRO/UltraCella and CAREL EEV expansion valves represents one of

the main features of this solution, contributing to the energy effi ciency

and reliability of the entire system. The control board is designed for

DIN rail assembly and is fi tted with plug-in screw terminals, as well

as incorporating a driver for managing two electronic expansion

valves. A user terminal (PGDe or pLDpro) is also available for service or

commissioning the system.

Main features:

• Modulation of cooling capacity by BLDC compressor with inverter;

• Management of a fi xed-speed backup compressor;

• Management of two modulating fans;

• Card with built-in driver for CAREL unipolar valves;

• Management of unipolar high-pressure valve (HPV);

• Management of unipolar fl ash gas valve (RPRV );

• Serial communication with evaporators (max 5);

• RS485 serial for BMS;

• Floating suction pressure set point;

• Floating condensing pressure set point;

• Advanced algorithm for calibrated oil injection to the compressor;

• Oil speed boost for oil return to the compressor;

• Oil recovery washing for oil return to the compressor;

• Vast confi guration of defrost functions;

• Suction and discharge superheat control;

• Ample confi guration of alarms.

1.2 Components and accessories

Part number Description

A ECU70TS0C0 Hecu CO2 controller, 230Vac, RTC, 2 unipolar EEV,

A ECU70TS0D0 Hecu CO2 controller, 230Vac, RTC, 2 unipolar EEV,

A ECU80TS0C0 Hecu CO2 controller, 24Vac, RTC, 2 unipolar eev,

A ECU80TS0D0 Hecu CO2 controller, 24Vac, RTC, 2 unipolar EEV,

A PSD101021A Power+ 10 A, 200-240 Vac 1Ph, IP00

A PSD1012200 Power+ 12 A, 200240 Vac 1Ph, IP20/IP44

A PSD1016200 Power+ 16 A, 200240 Vac 1Ph, IP20/IP44

A PSD1018400 Power+ 18 A, 280480 Vac 3Ph, IP20/IP44

PS20012204110 POWER+ 12 A, 200-240 Vac 1PH, IP20 PEC

A

PS20015204110 POWER+ 15 A, 200-240 Vac 1PH, IP20/IP44 PEC

A

PS20018404110 POWER+ 18 A, 380-480 Vac 3PH, IP20/IP44 PEC

A

PS20012204100 POWER+ 12 A, 200-240 Vac 1PH, IP20

A

PS20015204100 POWER+ 15 A, 200-240 Vac 1PH, IP20/IP44

A

PS20018404100 POWER+ 18 A, 380-480 Vac 3PH, IP20/IP44

A

PSACH10100 Coil for POWER+ 18 A

A

M E2V**CS1C0 Electronic expansion valve E2V**C 1313 S.

M E2VSTA03*0 Unipolar stator coil with cable *m

M E2VFIL0100 Filter kit for valve E2VBSF (conn. diam. 12 ODF) 10 pcs

M SPKT00H8C0 Press.Trasd. 4-20 mA 0...120 barg (0...1740 psig) sealed gage

M SPKT00D8C0 Press.Trasd. 4-20 mA 0...150 barg (0…2175 psig) sealed gage

A SPKT00L1S0 Press.Trasd. 0-5V 0…90 barg sealed gage packard 1/4 gas F

M SPKC002310 Cable AWG 3 wires l=2m for SPKT packard vulcanised - IP67

M NTC0**HT41 IP55, ** m cable, 0T150 °c, multiple package (10 pcs)

M NTC0**HF01 IP67, ** m cable, fast reading NTC probe strap-on plastic

O NTC0**WH01 Wh NTC sensor IP68 -50T105 cable **m

A PGDEH31FX0 pGDe terminal Hecu LOGO, pLAN version

A PLD00GFP00 PLDPro LCD neutral, 132x64 pixels, pLAN version

M S90CONN00* Connection cable between terminal and pCO

O PCOS004850 Opto-isolated RS485 serial connection card for pCO sistema

O PCOS00S030 Fastening bracket for RS485/Lon/RS232 serial card

Key:

M mandatory

(mandatory)

connector kit, no BMS, FLSMTDMCUTU

connector kit, no BMS, with plastic cover, FLSMTDMCUTU

connector kit, no BMS, FLSMTDMCUTU

connector kit, no BMS, with plastic cover, FLSMTDMCUTU

Steel high pressure without electrical coil

8-28V packard 1/4 gas male

8-28V packard 1/4 gas male

2

, l=*m

Tab. 1.a

A mandatory /

alternative

O optional

Hecu CO2 system example

Supervisor

RS485 max 5 unit

Fig. 1.a

7

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

2. INSTALLATION

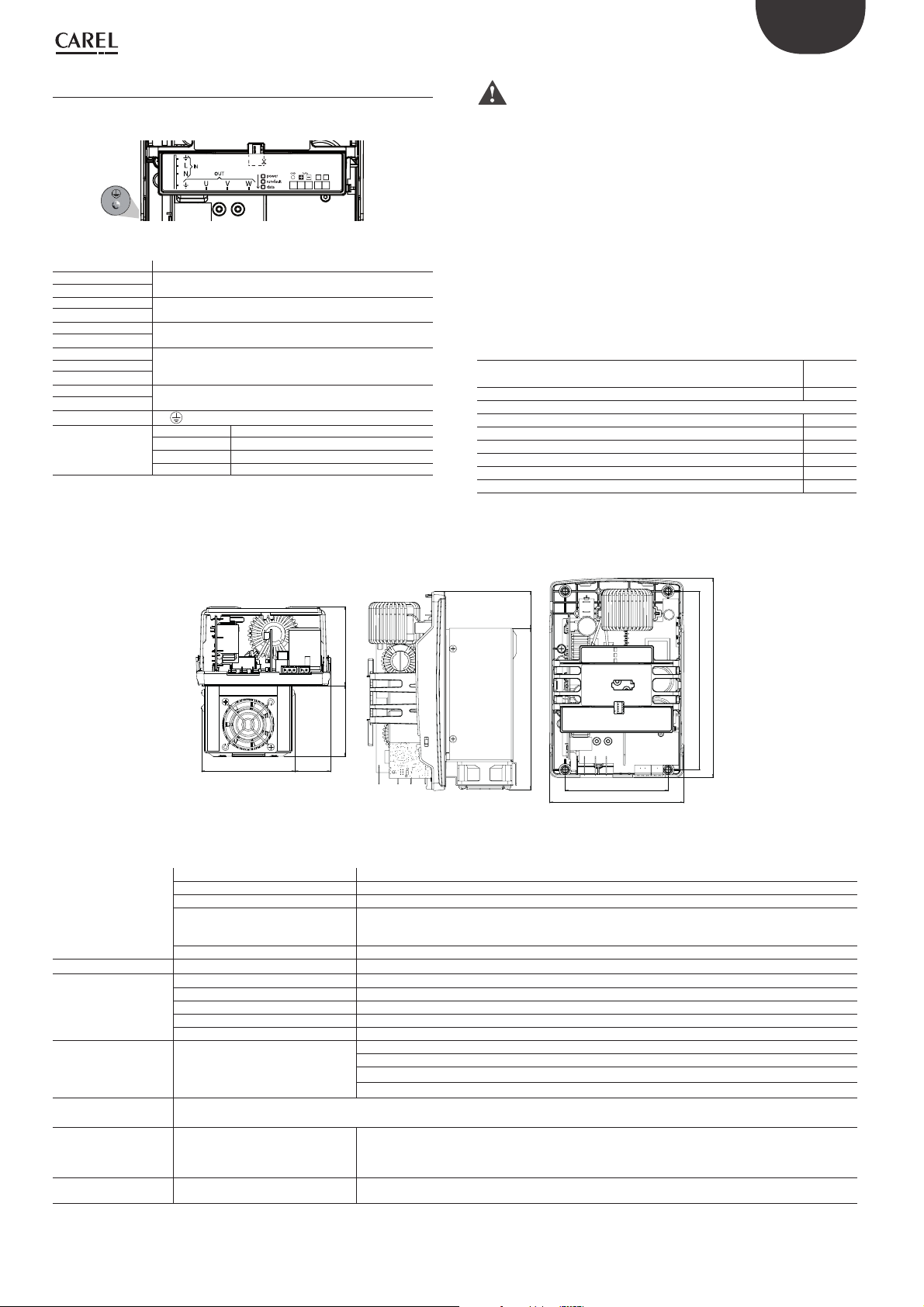

2.1 Main board: description of the terminals

For further details on the electrical and mechanical specifi cations, see

technical leafl et +050001590

Vout

RX-/TX-

J10

J15

J16

J17

J18

J19

J20

J21

J22

J23

J24

J11

J12

J14

J9

RX+/TX+

GND

RX-/TXRX+/TX+

GND

RX-/TXRX+/TX+

GND

N01

NC1

C1

Out2

C2

Out3

C2

Out4

C2

Out5

C2

C2

V-IN

Out6

C6

Out7

C7

Out8

C8

1

2

3

4

5b

- for UP2B*: 24 Vac +10%/-15% 50/60 Hz,

G0

28 to 36 Vdc +10%/-15%;

J1

U1

U2

J2

U3

GND

U4

U5

+Vdc

J3

+5VR

GND

U6

U7

+Vdc

J4

+5VR

GND

U8

U9

U10

J5

+Vdc

+5VR

GND

GND

Y1

J6

Y2

Y3

DI1

DI2

J7

DI3

DI4

GND

15

J13

J8

- for UP2A*: 230 Vac 50/60 Hz, +10%/-15%;

G

Fig. 2.a

Key:

1 Power 230 Vac for version with transformer (UP2A*********)

Power 24 Vac for version without transformer (UP2B*********)

2 Universal channels 9 Alarm digital output

3 Analogue outputs 10 pLAN serial connection

4 Digital inputs 11 BMS2 serial connection

5a Valve 1 output 12 Fieldbus serial connection

5b Valve 2 output 13 Connection for PLD terminal

6 Switching digital relay outputs 14 Dipswitch for settings

7 Voltage input for outputs 2, 3, 4, 5 15 BMS1 RS485 serial card

8 Digital outputs with voltage signal 16 Green power LED

Digital

inputs

Analogue

outputs

Type: digital inputs with voltage-free contacts

Number of digital inputs (DI): 4

Type: 0 to 10 Vdc cont., PWM 0 to 10 V 50 Hz synch. with power supply,

PWM 0 to 10 V frequency 100 Hz, PWM 0 to 10 V frequency 2 kHz

Number of analogue outputs (Y): 3

Universal

channels

Analogue/digital conversion bits: 14

Type of input selectable from application: NTC, PT1000, PT500, PT100, 4 to

20 mA, 0 to 1 V, 0 to 5 V, 0 to 10 V, voltage-free contact **

Type of output selectable from application: PWM 0/3.3 V 100 Hz

synchronous with power supply PWM 0/3.3 V 100 Hz, PWM 0/3.3 V 2 kHz,

0 to 10 V analogue output Maximum current 2 mA

Number of universal channels (U): 10

Precision of passive probe reading: ± 0.5 C across entire temperature

range; Precision of active probe reading: ± 0.3% across entire voltage

range; Output precision: ± 2%

Digital

outputs

Group 1, Switchable power R1: NO 1(1)A

Group 2, Switchable power R3, R4, R5: NO NO 2(2)A

Group 3, Switchable power R6, R7, R8: NO 6(6)A

Maximum switchable voltage: 250Vac

Switchable power R2 (SSR case mounting): 15 VA 110/230 Vac

The relays in the same group have basic insulation between each other

and therefore must have the same power supply

Relays belonging to diff erent groups have reinforced insulation and

consequently a diff erent power supply can be used

Unipolar

valve

outputs

Maximum power for each valve: 7 W

Type of control: unipolar

Valve connector: 6-pin, fi xed sequence

Power supply: 12 Vdc ±5%

Maximum current: 0.3 A for each winding

Minimum winding resistance: 40 Ω

Maximum cable length: 2 m

** max. 6 x 0 to 5 V rat. and 4 x 4 to 20 mA probes

14

12

11

13

5a

16

10

9

8

7

6

Tab. 2.a

Electrical and mechanical speci cations of the controller

Power supply:

230 Vac, +10…-15% UP2A*********;

24 Vac +10%/-15% 50/60 Hz,

28 to 36 Vdc +10…-15% UP2B*********;

Maximum power input: 25 VA

Insulation between power supply and controller

• 230 Vac model: reinforced

• 24 Vac model: reinforced guaranteed by power transformer

Maximum voltage of connectors J1 and J16 to J24: 250 Vac;

Minimum size of digital output wires: 1.5 mm

Minimum size of all other connector wires: 0.5 mm

2

2

Power supplied

Type: +Vdc, +5VR, Vout for external power supplies

+Vdc: 26 Vdc ±15% for 230 Vac model power supply (UP2A*********),

21 Vdc ±5% for 24 Vac model power supply (UP2B*********)

Max current available +Vdc: 150 mA total, taken from

all connectors, protected against short circuits

+5 VR: 5 Vdc ± 2%; maximum available current 60 mA, total

taken from all connectors, protected against short circuits

Vout: 26 Vdc ±15% for 230 Vac model power supply (UP2A*********),

21 Vdc ± 5% Maximum current available (J9): 100 mA

Product speci cations

Program memory (FLASH): 7 MB

Log memory: 4 MB

Internal clock precision: 100 ppm

Removable battery: Lithium button, CR2430, 3 Vdc

Battery lifetime: minimum 8 years

Terminal connections available

Type: all pGDe terminals with dedicated connector J15, PLD with

dedicated connector J10

Max distance for pGDe terminal: 2 m via telephone connector J15, 50

m via AWG24 shielded cable

Maximum number of connectable terminals: one pGDe series terminal

on J15 or J14; one PLD terminal on connector J10, selecting the tLAN

protocol on card dipswitches

Communication lines available

Type: RS485, Master for FieldBus1, Slave for BMS 2, pLAN

No. and type of lines available:

1 line, not opto-isolated on connector J11 (BMS2).

1 line, not opto-isolated on connector J9 (FieldBus), if not used by the

PLD terminal on connector J10.

1 line, not opto-isolated on connector J14 (pLAN), if not used by the

pGDe terminal on connector J15.

1 optional line (J13), selectable from the Carel options available

Max. connection cable length: 2 m via unshielded cable, 500 m via

AWG24 shielded cable

Maximum connection length

Universal digital inputs and anything else not specifi ed: less than 10 m

Digital outputs: less than 30 m

Serial lines: see specifi cations in the corresponding sections

Operating conditions

Storage: -40T70 °C, 90% rH non-cond.

Operation: -40T70 °C, 90% rH non-cond.

Physical speci cations

Dimensions: 13 DIN rail modules, 228 x 113 x 55 mm

Ball pressure test: 125 °C

Other speci cations

Environmental pollution: level 2

Ingress protection: IP00

Class according to protection against electric shock: to be incorporated

into Class I and/or II equipment

PTI250 for PCB insulation; PTI175 for other materials

Period of stress across the insulating parts: long

Type of action: 1C; 1Y for SSR versions

Type of disconnection or microswitching: microswitching

Heat and fi re resistance category: category D (UL94 - V2)

Immunity against overvoltages: category II

Software class and structure: Class A

Do not touch or tamper with the device when powered

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

8

ENG

2.2 10A single-phase inverter

For further details on the electrical and mechanical specifi cations, see

technical leafl et +0500076IE

-DC

+DC

J2

J1

C

1

Fig. 2.b

Description of the terminals:

Ref. Description

L, N

earth conn. (*)

U, V, W

earth conn. (*)

-DC

+DC

J1-1 C

J1-2 NO

J2-3 0 V

J2-5 Tx/RxJ3-6 PTC

J3-7 24 Vdc

E

F (LED)

(*) The earth connections inside the controller are electrically connected together

and to the PE.

Single-phase power input

Motor output

DC bus output

Relay output (green connector)

RS485/ModBus® connectionJ2-4 Tx/Rx+

PTC input (black connector)

PE

POWER (green) drive powered

RUN/FAULT (green/red) drive running / active alarm

DATA (yellow) communication active

NO

2 3 4 5 6 7

J3

PTC

24Vdc

Tab. 2.b

CE conformity:

2006/95/EC

EN 61800-5-1: Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

2004/108/EC

EN 61800-3, ed. 2.0: Adjustable speed electrical power drive systems. EMC requirements, including specifi c test methods.

EN61000-3-2: Electromagnetic compatibility (EMC) Part 3-2: Limits for harmonic

current emissions (equipment input current <= 16A per phase).

EN61000-3-12: Electromagnetic comp. (EMC) Part 3-12: Limits - Limits for harmonic current emissions (equipment input current > 16 A and <=75 A per phase).

Rated values

The following table shows the rated input current and output current

values, as well as the specifi cations for sizing the cables (cross-section,

maximum length) and the fuses. The values refer to an operating

temperature of 60°C and a switching frequency of 8 kHz, unless otherwise

specifi ed.

PSD10102BA

Rated input current at 230 V

Fuse or type B circuit breaker

Power cable size

Rated output current

Rated output power at 230 V

Maximum total dissipation

Maximum dissipation on the heat sink

Min. motor cable size

Max. motor cable length

17 A

25 A

4 mm

10 A

3.8 kW

270 W

150 W

2.5 mm

5 m

2

2

Tab. 2.d

Dimensions

6 87,1

4,8

78

Important: before carrying out any maintenance, disconnect the

drive and the control circuits from the power supply by moving the main

system switch to “off ”. Once having powered down the drive, wait at least

5 minutes before disconnecting the electrical cables;

Main technical speci cations

Operating temperature -20T60°C

Humidity < 95% RH non-condensing

Environmental pollution level Max 2

Input voltage 200 - 240V ± 10%, 50 - 60Hz, 1~

Output voltage 0 - Input voltage

Output frequency 0 - 500 Hz

Maximum length 5 m

Switching frequency 4, 6, 8 kHz

Protection functions

Frequency resolution 0.1 Hz

Inputs

Outputs

Serial input

24 Vdc auxiliary power supply Double insulation, 10% precision, 50 mA max

Maximum length 100 m shielded cable

Ingress protection IP00

Drive: short circuit, overcurrent, earth fault, overvoltage and undervoltage, overtemperature

Motor: overtemperature and overload (150%

Inom for 1 minute)

System: loss of communication

1 motor protection input: PTC temp. or voltage-free contact, maximum current 10 mA,

maximum length 25 m.

1 relay: programmable output, voltage-free

contact: 240 Vac, 1 A

RS485, Modbus® protocol, max baud rate 19200

bit/s

Tab. 2.c

177,6 40,9

197

Fig. 2.c

4,8

65,7 7,3 7,5

102,8 39,3

138

88

Ø5

M5

113,412,6 4

7055,8

6,9

209,5

9

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

2.3 12-16 A single-phase, 18-24 A threephase inverter

For further details on the electrical and mechanical specifi cations, see

technical leafl et +0500048IE

C1

C2

F

E

L1/LL2/N L3UVW

Fig. 2.d

Description of the terminals:

Ref. Description

L1/L, L2/N, L3

earth conn. (*)

L1/L, L2/N

earth conn. (*)

U, V, W

earth conn. (*)

C1, C2

1.2 Relay output

30 V

5 Tx/Rx6 PTC input

7 24 Vdc

80V

9 STOa Safety digital input - Safe Torque

10 STOb

E

F (LED)

(*) The earth connections inside the controller are electrically connected together

and to the PE.

(**) To enable the drive to operate, apply a voltage of 24 Vac/Vdc to the Safe Torque

Off digital input. The polarity is indiff erent for direct current power supply.

Three-phase power input

Single-phase power input

Motor output

Terminals not used in PSD10**2 **, for optional DC choke on

PSD10184** and PSD10244**

PE

POWER (green) drive powered

RUN/FAULT (green/red) drive running / active alarm

DATA (yellow) communication active

1 2 345 678910

RS485/ModBus® connection4 Tx/Rx+

Auxiliary voltage

Off (**)

CE conformity:

2006/95/EC

EN 61800-5-1: Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

2004/108/EC

EN 61800-3, ed. 2.0: Adjustable speed electrical power drive systems. EMC requirements, including specifi c test methods.

EN61000-3-2: Electromagnetic compatibility (EMC) Part 3-2: Limits for harmonic

current emissions (equipment input current <= 16A per phase).

EN61000-3-12: Electromagnetic comp. (EMC) Part 3-12: Limits - Limits for harmonic

current emissions (equipment input current > 16A and <=75A per phase).

Rated values

The following table shows the rated input current and output current

values, as well as the specifi cations for sizing the cables (cross-section,

maximum length) and the fuses. The values refer to an operating

temperature of 60°C and a switching frequency of 8 kHz, unless otherwise

specifi ed.

model

Rated input current at 230 V

Fuse or type B circuit breaker

Power cable size

Rated output current

Rated output power at 230 V

Maximum total dissipation

Maximum dissipation on the heat sink

Min. motor cable size

Max. motor cable length

PSD10122A0 PSD10162A0

22 A 28 A

32 A 40 A

4 mm

2

6 mm

2

12 A 16A

4.5 kW 6 kW

330 W 450 W

190 W 250 W

2.5 mm

2

2.5 mm

2

5 m 5 m

Tab. 2.f

model

Rated input current at 400 V 3PH

Fuse or type B circuit breaker

Power cable size

Rated output current

Rated output power at 400 V 3PH

Maximum total dissipation

Maximum dissipation on the heat sink

Min. motor cable size

Max. motor cable length

18A 3PH 24A 3PH

23 A 30 A

32 A 40 A

4 mm

2

6 mm

2

18A 24A

10.5 kW 14 kW

320 W 485 W

250 W 380 W

4 mm

2

4 mm

2

5 m 5 m

Tab. 2.g

Dimensions

173

127

Main technical speci cations

Reference technical document

Operating temperature -20T60°C

Humidity < 95% RH non-condensing

Environmental pollution level Max 2

Input voltage 200 - 240V ± 10%, 50 - 60Hz, 1~

Output voltage 0 - Input voltage

Output frequency 0 - 500 Hz

Maximum length 5 m

Switching frequency 4, 6, 8 kHz

Protection functions

Frequency resolution 0.1 Hz

Inputs

Outputs

Serial input

24 Vdc aux. power supply Double insulation, 10% precision, 50 mA max

Maximum length 100 m shielded cable

Ingress protection IP20

+0500048IE

Drive: short circuit, overcurrent, earth fault, overvoltage and undervoltage, overtemperature

Motore: overtemperature and overload (150%

Inom for 1 minute)

System: Safe Torque OFF input, loss of communication

1 motor protection input: PTC temp. or voltage-free contact, maximum current 10 mA,

maximum length 25 m.

1 relay: programmable output, voltage-free contact: 240 Vac, 1 A

RS485, Modbus® protocol, max baud rate 19200

bit/s

Tab. 2.e

268

240

24,6

24,6

86

12

27,9

2660

70,8

33,2

71,3

Fig. 2.e

26 2675

192,3

131

M5

80

82

190

289,2

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

10

ENG

~

2.4 12 A single-phase inverter PSD2

For further details on the electrical and mechanical specifi cations, see

technical leafl et +0500120IE

cut this area and access to DIP switches

to set the ID (network) address

E

Fig. 2.f

Description of the terminals:

Ref. Description

L, N Single-phase power input

(*)

PE

U, V, W Motor output

(*)

PE

-DC DC bus output

+DC

GND (0V)

Tx/Rx+

Tx/RxSTO1 STO safety input

STO2

E

F (LED)

(*)

The earth connections inside the drive are wired together and to the PE.

Spade connectors

Spade connectors

Spade connectors

RS485/ModBus® connection

3-pin plug-in terminals

2-pin plug-in terminals

Earth screw

PE

POWER (green) drive powered

RUN (green) drive running

FAULT (red) drive alarm

DATA (yellow) communication active

3 4 5 6 7

STO

A B

Tab. 2.h

Important:

• before carrying out any maintenance, disconnect the drive and the

control circuits from the power supply by moving the main system

switch to “off ”. Once having powered down the drive, wait at least 5

minutes before disconnecting the electrical cables;

• always make sure that the motor has come to a complete stop. Freely

rotating motors may generate dangerous voltages across the Power+

terminals, even when this is not powered;

Rated values

The following table shows the rated input current and output current

values, as well as the specifi cations for sizing the cables (cross-section,

maximum length) and the fuses. The values refer to an operating

temperature of 60°C and a switching frequency of 8 kHz, unless otherwise

specifi ed.

PSD10102BA

Rated input current at 230 V 19.2 to

Fuse or type B circuit breaker

Power cable size

Rated output current

Rated output power at 230 V

Maximum total dissipation

Maximum dissipation on the heat sink

Min. motor cable size

Max. motor cable length

16 A

25 A

4 mm

12 A

3.8 kW

270 W

150 W

2.5 mm

5 m

Tab. 2.i

2

2

Dimensions

103 39.3

Main technical speci cations

Environmental conditions

Power supply

Motor output

Functions

Control unit

Inputs

Outputs DCbus power supply

Storage temperature -40T60°C

Operating temperature -20T60°C

Humidity < 95% RH non-condensing

Altitude

Environmental pollution level 3

Input voltage 200 - 240V / 105 -125V ± 10%, 50/60Hz, 1~

Output voltage 0 - Input voltage

Output frequency 0 - 500 Hz

Frequency resolution 0.1 Hz

Maximum cable length see paragraph 5.1

Switching frequency 4, 6, 8 kHz

Protection functions

Each drive must be connected in the network via Modbus® to a CAREL pCO or other manufacturer’s controller that manages the drives with Master/

Slave logic.

STO (Safe Torque Off )

for auxiliary devices

40.9177.7

87.1

197

220

78

113.4

148

Fig. 2.g

Maximum allowed: 2000 m above sea level

Up to 1000 m asl without derating

Derating in terms of maximum output current: 1% /100m

Drive: short circuit, overcurrent, earth fault, overvoltage and undervoltage, overtemperature

Motor: overload (150% Inom for 1 minute), stall

System: loss of communication,

Safety: STO (Safe Torque Off ), locked rotor

Voltage-free contact input, reinforced insulation (12 V SELV circuit):

open contact voltage: <24 V

closed contact current: 40 mA typical

max. cable length 25 m

395 Vdc ± 10 Vdc, 1.9 A max for PS2**122***** models;

max. cable length 1 m - shielded cable, minimum cross-section 1 mm

2

11

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

Interface

data connection

Serial data connection

Insulation Reinforced (24 V SELV circuit)

RS485, Modbus® protocol, maximum baud rate 19200 bit/s - typical resistance in reception 96 KΩ (equal to

1/8 load unit, i.e. 1/256 of the maximum load applicable on the line)

Maximum length 100 m shielded cable

Ingress protection IP00

Ball pressure test temperature 125°C

Construction Device to be incorporated

Type of automatic action PS200122***0* and PS200122***S* Functional

PS200122***1* and PS200122***P* Safety

Pulse voltage 4 kV (overvoltage category III)

Conformity

to standards

Low voltage directive

CE

Compatibility directive

electromagnetic

2014/35/EU

IEC 60730-1, IEC 60335-1 (sections 29 and 30), IEC 60335-2-34 (sections 19.101 and 19.103)

2014/30/EU

EN 61800-3, ed.2.0: Adjustable speed electrical power drive systems. EMC requirements, including specifi c

test methods.

EN61000-3-2: Electromagnetic compatibility (EMC) Part 3-2: Limits - Limits for harmonic current emissions

(equipment input current <= 16 A per phase).

EN61000-3-12: Electromagnetic compatibility (EMC) Part 3-12: Limits - Limits for harmonic current emissions

(equipment input current > 16 A and <=75 A per phase).

UL UL 60730-1, UL 60335-1 (sections 29 and 30), UL 60335-2-34 (sections 19.101 and 19.103)

2.1 15 A 1 PH and 18 A 3 PH inverter PSD2

For further details on the electrical and mechanical specifi cations, see

technical leafl et +0500125IE

L3

L2

L1

C1

C2

E

UVW

GND

Tx/Rx

+

Fig. 2.h

Description of the terminals:

Ref. Description

L3, L2, L1 Three-phase power supply

(*)

(*)

U, V, W

C1 Optional external choke

C2

GND GND (0 V ) RS485/ModBus® connection

+ Tx/Rx+

- Tx/RxA STO safety digital input (**)

B

E

F (LEDS) POWER (green) drive powered

Motor output

three-pin plug-in connector

2-pin plug-in connector

earth screw

PE

RUN (green) drive running

FAULT (red) drive alarm

DATA (yellow) communication active

(*) The earth connections inside the controller are wired together and to the PE.

(**) Voltage-free digital input: if not used, short-circuit with a jumper.

Note: RS485 and STO connections have reinforced insulation from

the power supply.

F

power

run-fault

data

STO

A B

-

Tab. 2.k

Tab. 2.j

• for a fi xed installation, according to local regulations in force, a circuit

breaker may be required between the power supply and the drive;

• the drive must be connected to earth: the earth cable must be sized

for the maximum fault current, which will normally be limited by fuses

or a circuit breaker.

Rated values

The following table shows the rated input current and output current

values, as well as the specifi cations for sizing the cables (cross-section,

maximum length) and the fuses. The values refer to an operating

temperature of 60°C and a switching frequency of 8 kHz, unless otherwise

specifi ed.

model 15A 1PH 18A 3PH

Rated input current at 230 V (400 V 3 PH)

Fuse or type B circuit breaker

Power cable size

Rated output current

Rated output power at 230 V (400 V 3 PH)

Maximum total dissipation

Maximum dissipation on the heat sink

Min. motor cable size

Max. motor cable length

26 to 23 A

32 A 32 A

4 mm

15 A 18 A

5 kW 10.5 kW

320 W 320 W

235 W 250 W

4 mm

5 m 5 m

18.5 to

16.5 A

2

2

4 mm

4 mm

2

2

Dimensions (mm)

8782

131

136

269.2

240 24.6

289,2

316

Important:

• in the European Union, all units that incorporate the drive must

comply with the Machinery Directive 2006/42/EC. Specifi cally, the

manufacturer of the unit is responsible for installing a main switch and

conformity to standard EN 60204-1;

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

12

24.6

Fig. 2.i

80

172

192,3

213

Main technical speci cations

~

~

Environmental conditions Storage temperature -40T60°C

Power supply

Motor output

Functions

Control unit

Inputs

Interface

connection

data

Other

Standards

compliance

Operating temperature -20T60°C

Humidity < 95% RH non-condensing

Altitude

Environmental pollution level 3

Input voltage

Output voltage 0 - Input voltage

Output frequency 0 - 500 Hz

Frequency resolution 0.1 Hz

Maximum cable length see paragraph 5.1

Switching frequency 4, 6, 8 kHz

Protection functions

Each drive must be connected in the network via Modbus® to a CAREL pCO or other manufacturer’s controller that manages the drives with

Master/Slave logic.

STO (Safe Torque Off )

Serial data connection

Insulation Reinforced (24 V SELV circuit)

Maximum length 100 m shielded cable

Ingress protection IP00

Ball pressure test temperature 125°C

Construction Device to be incorporated

Type of automatic action PS2********0* and PS2********S* models: Type 1 (functional control)

Pulse voltage 4 kV (overvoltage category III)

Low voltage directive

CE

Electromagnetic compatibility directive

Maximum allowed: 2000 m above sea level

Up to 1000 m asl without derating

Derating in terms of maximum output current: 1% /100m

PS2**183*****, PS2**243*****: 200 - 240Vac -10%/ +10%, 50 - 60Hz, 3 ~

PS2**184*****, PS2**244*****: 380 - 480Vac -10%/ +10%, 50 - 60Hz, 3 ~

Drive: short circuit, overcurrent, earth fault, overvoltage and undervoltage, overtemperature

Motor: overload (150% Inom for 1 minute), stall

System: loss of communication,

Safety: STO (Safe Torque Off ), locked rotor

Voltage-free contact input, reinforced insulation (24 V SELV circuit):

open contact voltage: <24 V

closed contact current: 40 mA typical

max. cable length 25 m

RS485, Modbus® protocol, maximum baud rate 19200 bit/s

Typical reception resistance 96 KΩ, equal to 1/8 of unit load, i.e. 1/256 of maximum load applicable on

the line

PS2********1* and PS2********P* models: Type 2 (safety control)

2014/35/EU

IEC 60730-1, IEC 60335-1 (sections 29 and 30), IEC 60335-2-34 (sections 19.101 and 19.103)

2014/30/EU

EN 61800-3, ed.2.0: Adjustable speed electrical power drive systems. EMC requirements, including

specifi c test methods.

EN61000-3-2: Electromagnetic compatibility (EMC) Part 3-2: Limits - Limits for harmonic current emissions (equipment input current <= 16 A per phase).

EN61000-3-12: Electromagnetic compatibility (EMC) Part 3-12: Limits - Limits for harmonic current emissions (equipment input current > 16 A and <=75 A per phase).

ENG

UL

UL 60730-1, UL 60335-1 (sections 29 and 30), UL 60335-2-34 (sections 19.101 and 19.103). See chap. "UL requirements for installation".

Network address

The confi guration and programming of the Power+ drive, as well as the

run/stop commands and speed reference, are managed by a CAREL pCO

controller or by any BMS (Building Management System) via RS485 serial

connection with Modbus® protocol. The ModBus® network address can

be set from 1 to 246, and this number comprises the basic address set by

parameter, and the address set by the 4 dipswitches inside the drive, from

0 to 15. By changing the basic address, it is possible to cover the entire

range of addresses.

Mod. add. Description Def Min Max UOM R/W

32 Basic address 1 1 232 - R/W

120 Network address - 1 246 - R

121 Dipswitch address - 0 15 - R

Tab. 2.m

Important:

any changes to the device’s serial address, either on the dipswitches or via

the parameter, will only be eff ective when next powering on or resetting

the device.

The confi guration of the address set manually by the dipswitches on the

drive is shown below.

Tab. 2.l

Important: Before accessing the dipswitches, power off and wait for

the LEDs to go off .

Dipswitch address

Dipswitches

1234

OFF OFF OFF OFF 0

ON OFF OFF OFF 1

OFF ON OFF OFF 2

………… …

ON ON ON ON 15

Dipswitch

address

Tab. 2.n

Warning: if the address set by the dipswitches is between 0 and 14,

the network address is the sum of the basic address and the dipswitch

address, while baud rate and parity are set by the corresponding

parameters.

If the dipswitch address is set to 15, communication mode is set to:

• 19200 bit/s; no parity; 2 stop bits; network address 1

regardless of the value of the corresponding parameters.

It is recommended to avoid setting the dipswitch address to 15 as a

normal confi guration.

1

234

Fig. 2.j

ON

OFF

13

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

2.5 Unipolar E2V valves for R744

44.0

D

B

43.0

G

ØE In

ØE Out

G

C

ØF In

ØF Out

(in 0.51 out 0.71 inch)

ID 13/OD 18 mm

(in 0.51 out 0.71 inch)

10 mm (0.39 inch)

Ø39

Ø16

A

Valve type A B C D E F G

E2V**CS1C* 125.8mm (4.95 inch) 82.3 mm (3.24inch) 52.3 mm (2.06 inch) 53.3 mm (2.10 inch) ID 13/OD 18 mm

CAREL E2V-C operating speci cations CAREL E2V-U stator

Compatibility R22, R134a, R404A, R407C,R410A, R744, R507A, R417A Reference technical document +050001440

Maximum working

up to 140 barg (2030 PSIg) Power supply voltage 12 V

pressure (MWP)

Maximum operating

pressure diff erential

up to 120 bars (1740 PSI)

for E2V24CS0** and E2V24CS1** 85 bars (1233 PSI)

Drive frequency 50 Hz

(MOPD)

PED Gr. 2, art. 3, par. 3 Phase resistance (25 °C) 40 Ohms ± 10%

Refrigerant temperature -40T70 °C (-40T158 °F) Ingress protection IP67

Room temperature -30T70 °C (-22T158 °F) Connections 6 pin, cable length: 2 m

Contact CAREL for diff erent operating conditions or alternative refrigerants. Complete closing / control steps 500 / 480

2.6 Pressure probes (SPKT00**8C0)

C

uscita

out

A

non utilizzato

not used

Technical speci cations

reference technical document +050000596

power supply 8-28 Vdc, ±20%

output 4 to 20 mA

mechanical fi tting ¼” male gas (with circular gasket, resistant to

water and oil)

operating temp. -40T100°C

storage temp. -20T100°C

fl uid temp. (average) -20T100°C

linearity ± 1% FS (0 to 50 °C) temperature compensated

± 2% FS (0 to 80 °C); ± 4% FS (-40 to 100 ° C)

ingress protection IP67 with connector plugged in

Fig. 2.a

B

alimentazione

supply

shock 20 g* sinusoidal, 11 msec

vibrations 5 to 2000 Hz / 10 g /, X/Y/Z axes / 20 g sen 11

ms

Description of codes and models

Part number Pressure psi Pressure bars Mod. over

SPKT00D8C0 0 2175 0 150 Male 4360 300 7680 530 IP67

SPKT00H8C0 0 1740 0 120 Male 4360 300 7680 530 IP67

Note: (1): with connector plugged in; all sensors are sealed gauge

4 mA 20 mA 4 mA 20 mA psi bar psi bar

range

Burst

pressure

IP

(1)

environmental poll. level normal

insulation at 50 V ≥ 10 MΩ

response time (0 to 99%) < 10 msec

EMC EN 61000-6-1 - 4 / EN 61326-2-3

electrical connections Packard Plug

tightening force 12-16 Nm

Compatible with all types of refrigerant

Note: FS = MAX output - MIN output

Tab. 2.o

2.7 Temperature probes

Models NTC***HP00 NTC***HT41 NTC***HF01

Reference technical document +030220655 +030220655 +030220655

Operating range -50T105 °C in air / -50T50 °C in fl uid 0T150 °C in air -50T105 °C

Connections Stripped wire terminals, dimensions: 5±1

mm

Sensor NTC 10 kΩ ±1% at 25 °C Beta 3435 NTC 50 kΩ ±1% at 25 °C Beta 3977 R(25 °C)= 10 kOhm 1%; Beta 3435

Dissipation factor (in air) approx. 3 mW/°C approx. 3 mW 3 mW

Thermal constant over time (in air) approx. 25 s approx. 30 s approx. 50 s

Sensor ingress protection IP67 IP55 IP67

Sensor housing Polyolefi n High temperature polyester dim. 20x5 mm Thermoplastic with fi xing tie

Class of protection against electric shock Basic insulation for 250 Vac Basic insulation for 250 Vac Basic insulation for 250 Vac

Heat and fi re resistance cat. Flame retardant In accordance with CEI 20-35 UL/HB cable

• inside showcase temperature • discharge temperature

Tab. 2.p

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

Stripped wire terminals, dimensions:

6±1mm

14

Stripped wire terminals, dimensions:

6±1mm

• evaporation temperature

• gas cooler outlet temperature

2.8 General connection diagram

ENG

Inverter 15A (1 PH)

Inverter 12/16A (PSD1)

L2/N L3 U V W

L1/L

LKN

(*)

(*)

PE

White

White

Green

Green

Black

(*)

Black

White

Green

(*)

White

(*)

Black

Black

Green

HP switch

Fuse or

MCB

PAY ATTENTION

TO THE POWER SUPPLY!

Power supply

- for ECU70*: 230 Vac 50/60 Hz, +10%/-15%;

- for ECU80*: 24 Vac +10%/-15% 50/60 Hz,

28 to 36 Vdc +10%/-15%;

Analog Input

B1

Suction press. probe

B2

Gas cooler press. probe

B3

Suction temp. probe (CAREL NTC)

B4

Discharge temp. probe (CAREL NTC-HT)

B5

Gas cooler temp. probe (CAREL NTC)

B9

Discharge only LT probe

Parallel suct. probe (LT)

B10

Receiver probe (MT)

0...10 Vdc Fan

Analog Output (0-10V)

Digital Input (free voltage)

Inverter 18/24A (3 PH)

Inverter 12A

Inverter 10A (PSD1)

-DC

+DC

to power+, MPXPRO, Ultracella

N

L

LN

pGDe Terminal pLD PRO

+

GND STO

345 67

HPV valve

Digital Output

(POWERED)

Digital Output

(NOT POWERED)

-

PTC

Klixon

boss

J13

PE

High press

switch

2

1

ON

J10

J11

J12

J14

J16

J17

J18

J19

J20

J21

J22

J23

J24

K

OFF

J9

+

GND STO

-

M

3

to HECU controller

G

G0

J1

U1

U2

U3

GND

U4

U5

+Vdc

+5VR

GND

U6

U7

+Vdc

+5VR

GND

U8

U9

U10

+Vdc

+5VR

GND

GND

(A01) Y1

(A02) Y2

(A03) Y3

DI1

DI2

DI3

DI4

GND

PTC Klixon

HECU conguration

supervisory system

J2

J3

J4

J5

J6

J8

J7

DIP2=OFF

DIP1=ON

RS485 serial card

to connect

RPRV valve

L

N

UVW

Fuse or

M

MCB

3

L

N

Vout

RX-/TXRX+/TX+

GND

RX-/TXRX+/TX+

GND

RX-/TXRX+/TX+

GND

N01

Fan 1

NC1

C1

Out2

C2

Out3

C2

Out4

C2

Out5

C2

C2

V-IN

N06

C6

N07

C7

N08

C8

Fig. 2.k

(*) The 4-20 mA pressure probes must be connected with the white to Ux and the black to + Vdc, green is not used

(**) 230 Vac SSR output, maximum switchable power 15 VA

Important: If the PEC version inverters (with class B software structure) are not used, the thermal protection devices for overload and high pressure

must act directly on the compressor actuator, and must therefore be wired in series with the compressor contactor coil control. For the types of cable to be

used, see the power+ manual ( +0300094EN).

I/O selection tables (example for MT unit)

Analogue inputs Digital inputs Analogue outputs Digital outputs

Suction temperature High pressure alarm Modulating fans Fan 1

Discharge temperature Low pressure alarm Fan 2

Outside temperature BLDC compressor alarm Equalising solenoid valve

Gas cooler outlet temperature Fan alarm

Suction pressure Remote ON-OFF

Gas cooler pressure

Receiver pressure

15

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

C

2.9 Functional diagrams

There are two confi gurations, one for medium temperature applications

and one for low temperature applications. The main diff erence involves

the double suction line required for low temperature applications; in this

case, the RPRV (fl ash gas) valve is optional.

There are other alternative confi gurations that require a system to inject

oil via an EEV (using an external driver) or capillary tube.

1. Medium temperature con guration

The confi guration defi ned for medium temperature applications involves

Hecu CO2 managing a DC compressor, with up to 2 on-off fans, an

electronic expansion valve for gas cooler pressure control (HPV) and an

electronic expansion valve for managing receiver pressure (RPRV). The

serial network allows monitoring and interaction with up to 5 evaporators

equipped with MPXPRO or UltraCella controllers, and a CAREL EEV

electronic expansion valve.

HPV

T

OUT, GT

2

P

REC

E

P

T

Technology

T

P

Check

GC

valve

DIS

RPRV

2

35 barg

2

By-pass

SUC

SUC

up to 5

2. Low temperature con guration

The confi guration defi ned for low temperature applications involves

Hecu CO2 managing two DC compressors (LT/DC and parallel), with up

to 2 on-off fans, an electronic expansion valve for gas cooler pressure

control (HPV) and an optional electronic expansion valve for managing

receiver pressure (RPRV). It should be noted that in this confi guration, the

RPRV (fl ash gas) valve is optional, as receiver pressure control is managed

by the parallel compressor.

The serial network allows monitoring and interaction with up to 5

evaporators equipped with MPXPRO or UltraCella controllers, and a

CAREL EEV electronic expansion valve.

HPV

T

OUT, GT

2

P

T

Technology

Check

GC

valve

DIS

By-pass

L1: PAR

T

SUC

P

P

T

Technology

SUC

Check

valve

DIS

DIS

35 barg

By-pass

P

REC

L2: LT

T

SUC

P

SUC

2

Fig. 2.l

Symbol Description

TSUC Suction temperature

PSUC Suction pressure

TDIS Discharge temperature

Tout,GC Gas cooler temperature

PGC Gas cooler pressure

PREC Receiver pressure

2

up to 5

2

Fig. 2.m

Symbol Description

TS,LT Suction temperature LT

PS,LT Suction pressure LT

TD,LT Discharge temperature LT

PD,LT Discharge pressure LT

TS,PAR Suction temperature PAR

PS,PAR Suction pressure PAR

TD,PAR Discharge temperature PAR

Tout,GC Gas cooler temperature

PGC Gas cooler pressure

PREC Receiver pressure

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

16

3. Serial network con guration

Hecu CO2 is fi tted with a built-in RS485 Fieldbus serial port and optional

RS485 BMS serial port. The RS485 Fieldbus serial line can be connected

to 2 Power+ inverters and up to 5 MPXPRO/UltraCella controllers. The

addresses are defi ned as shown in the following table. To simplify

commissioning with the default settings, it is recommended to set the

MPXPRO/UltraCella controllers with consecutive addresses, starting

from address 11. The following table shows the default values of serial

addresses for the connected MPXPRO/UltraCella controllers.

Device Address Device Address

Power+ 1 MPXPRO/UltraCella 3 13

Power+ 3 MPXPRO/UltraCella 4 14

MPXPRO/UltraCella 1 11 MPXPRO/UltraCella 5 15

MPXPRO/UltraCella 2 12

Serial address 3 is used for the parallel compressor inverter when this is

featured in the LT application.

Note: For LT units, the two inverter addresses must be 1 and 3. To

set these addresses (1 and 3), the corresponding dipswitches are set to 0

and 2, which when added to the basic address (1) will give the fi nal

addresses 1 and 3 (see the paragraph "Network address" on page 13).

ENG

1

3

Supervisory

system

Fieldbus - Modbus® RS485

C1

C1

C2

C2

PE

L1/L L2/N L3 U V W

F

12 345678910

C1

C1

C2

C2

PE

L1/L L2/N L3 U V W

F

12 345678910

max 5 units

RX-/TX-

RX+/TX+

GND

Vout

RX-/TX-

RX+/TX+

GND

OFF

J9

J11

J12

ON

1

2

J10

J1

J14

J16

J17

J18

J19

J20

J21

J22

J23

J24

J13

RPRV valve

J2

J3

J4

J5

J6J8J7

High

voltage

master

AUX

11

MPXPRO

High

voltage

master

AUX

12

MPXPRO

master

13

EVDEVO EVDEVOmaster

14

Fig. 2.n

Note: system communication is only compatible with MPXpro SW.

Important:

• A possible short circuit on the Fieldbus serial line will compromise

operation of the system compressor.

• As there is no software control on the connected device (MPXpro,

Ultracella), make sure during confi guration to set these correctly,

based on the physical address selected on the evaporator controller.

• To set the power+, MPXpro and UltraCella addresses, see the

corresponding manuals.

Important: The system is only compatible with MPXpro SW revision

≥ 4.0 and UltraCella SW revision ≥ 2.0

17

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

2.10 Installation

For installation proceed as follows, with reference to the wiring diagrams:

• before performing any operations on the control board, disconnect

the main power supply by turning the main switch in the electrical

panel OFF;

• avoid touching the control board, as electrostatic discharges may

damage the electronic components;

• the index of protection required for the application must be ensured

by the manufacturer of the cabinet or by suitable assembly of the

controller;

• if there are several condensing units connected to the same electrical

panel, use a B or B+ residual current device when the compressors

are controlled by inverter; these protection devices must always be

installed always upstream of any AC/A/F RCDs (see the fi gure below):

Wh

OK

Tipo

AC/A/F

Tipo

AC/A/F

IΔn≥300 mA

IΔn≤100 mA

NO

S

Tipo

B/B+

kHz

IΔn≥30 mA

• use cable ends suitable for the corresponding terminals. Loosen each

screw and insert the cable ends, then tighten the screws and lightly

tug the cables to check correct tightness;

• separate as much as possible the probe and digital input cables from

cables to inductive loads and power cables, so as to avoid possible

electromagnetic disturbance. Never run power cables (including the

electrical panel cables) and probe signal cables in the same conduits;

• do not install the probe cables in the immediate vicinity of power

devices (contactors, circuit breakers, etc.);

• reduce the path of probe cables as much as possible, and avoid spiral

paths that enclose power devices.

Important: Class A software structure: the thermal protection

devices for overload and high pressure must act directly on the

compressor actuator, and must therefore be wired in series with the

compressor contactor coil control.

Note: serial connection starts from terminal J10 on Hecu CO2 and

runs through the power+ inverter and all the MPXPRO controllers

installed on the refrigerated units. The maximum number of MPXPRO

controllers is 5, the limit for this application.

The following recommendations must be observed:

• connect the two twisted wires to the Tx/Rx+ and Tx/Rx- terminals;

• connect the single wire to the GND terminal;

• connect the shield to earth at one end only;

• use a shielded cable (e.g. Belden 3106A - AWG 22);

• For supervisor serial network connection only: connect a 120 Ω

terminating resistor between the Tx/Rx+ and Tx/Rx- terminals on the

last controller in the network (the one furthest away from Hecu).

Earth

Fig. 2.o

• connect any digital inputs, Lmax = 10 m;

• connect the temperature and pressure probes, Lmax = 10m;

• connect the electronic expansion valve cable the connectors J17 and

J21;

• connect the inverter serial communication cable to terminal J10 (if

featured);

• connect the PGDe terminal (required for commissioning) to connector

J17;

• connect the power supply to the controller and the inverter, where

featured;

• program the controller using the guided commissioning procedure:

see the chapter on “Commissioning”.

• connect the electrical loads to the relay outputs only after having

programmed the controller. Carefully evaluate the maximum ratings

of the relay outputs as indicated in the Technical specifi cations;

• connect the supervisor serial line to the optional BMS RS485 card.

Important: avoid installing the controllers in environments with

the following characteristics:

• relative humidity greater than 90% or with condensation;

• strong vibrations or knocks;

• exposure to water sprays;

• exposure to aggressive and polluting atmospheres (e.g.: sulphur and

ammonia gases, saline mist, smoke) which may cause corrosion and/

or oxidation;

• strong magnetic and/or radio frequency interference (thus avoid

installation near transmitting antennae);

• exposure to direct sunlight and the elements in general.

Device

1

AWG 20/22

Signals (+/-)

GND

Device

2

Device

n

Important: the following warnings must be observed when

connecting the controllers:

• incorrect connection to the power supply may seriously damage the

controller;

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

18

3. USER INTERFACE

ENG

3.1 Graphic terminal

The Hecu CO2 user interface is the pGDE terminal, in the panel or builtin version. The functions associated with the 6 buttons on the pGDE

terminal are the same on all screens, and are described in the table.

Functions of the 6 buttons

Button Associated function

(ALARM) Displays the list of active alarms and accesses the alarm log

Used to enter the main menu tree

Returns to the higher level screen

(UP) Scrolls a list upwards or increases the value highlighted by the

(DOWN) Scrolls a list downwards or decreases the value highlighted by

(ENTER) Enters the selected sub-menu or confi rms the set value

The LEDs associated with the buttons have the following meaning.

Meaning of the LEDs

LED Button Meaning

Red

Yellow

Green

cursor

the cursor

Tab. 3.a

Flashing: active and unacknowledged alarms

Steady: acknowledged alarms

Hecu CO2 on

Hecu CO2 powered

Tab. 3.b

Menu screen

An example of the menu screens is shown in the fi gure:

Fig. 3.b

The selected item number is shown in the top right corner. The

buttons are used to select the desired menu item, while

selected item.

&

accesses the

Parameter display/setting screen

An example of a parameter display/setting screen is shown in the fi gure,

which highlights the fi elds and icons used:

1

2

3

3.2 Description on the display

There are three basic types of screens shown to the user:

• Main screen

• Menu screen

• Parameter display/setting screen

Main screen

The main screen is the screen that the Hecu CO2 software automatically

returns to 5 minutes after the last button was pressed. An example of a

main screen is shown in the fi gure, which highlights the fi elds and icons

used:

1

2

3

4

5

Fig. 3.a

1 Time and date

2 Main values

3 Unit status (unit off ) or compressor and fan status (unit on)

4 Active alarm signals and manual operation status

5 Access to further information screens (menu branch Aa) by pressing ENTER

.

Fig. 3.c

1 Menu branch identifi er

2 Screen identifi er

3 Parameters

The screen identifi er uniquely identifi es the menu branch and the

screen: the fi rst characters indicate the menu branch, while the last two

alphanumeric digits identify the screen inside the menu; for example,

screen Bab01 is the fi rst screen in menu Bab

Note:

• The information shown on the main screen varies according to

the system confi guration and the control value used (pressure or

temperature).

19

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

4.1 Main menu

4. MENU DESCRIPTION

To navigate the menu tree, use the following

buttons:

• & : navigate sub-menus, screens and

ranges of values and settings;

• : confi rm and save the changes made;

• : return to the previous menu

A.Unit Status

B.Input/Output

C.Compressors

D.Condensers

E.Evaporators

F.Other

functions

G.Configurations

H.Safety

a.Main Info

b.Setpoint

c.ON/OFF

a.Status a.Dig.In.

b.Manual man. a.Dig.Out

c.Test a.Dig.Out

a.MT/LT compr.

b.PAR compr.(ONLY LT)

a.Oil a.I/O status

b.defrost a.I/O status

c.Economizer a.I/O status

d.Injection a.I/O status

e.Heat recovery a.I/O status

f.Gen. functions a.Stages

g.Chillbooster a.I/O status

h.Transcritical a.I/O

i.DSS a.I/O status

a.Clock a.Time bands

b.Language

c.BMS

d.Fieldbus

e.Password

a.History

b.Prevent

c.Alarm configuration

b.Analog In.

c.Dig.Out

d.Analog Out

b.Analog Out

c.usc.BLDC

d.vacuum

b.Analog Out

a.I/O status

Regulation

b.

c.Op. hours

d.Energy save

e.Alarms

f.Configuration

g.Advanced

a.I/O status

b.Regolation

c.EEV

d.Energy save

e.Alarms

f.Configuration

g.Advanced

a.Stato I/O

b.Configuration

c.Regulation

d.EVD driver

b.Settings

b.Settings

c.info

b.Regulation

b.Regulation

b.Regulation

b.Modulation

c.Alarms

d.Time bands

e.I/O status

b.Regulation

b.Settings

c.EVOsettings

b.settings

b.Settings

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

I.Info

L.Setup

20

a.Pre-configuration not available

b.Wizard

c.Advanced config. not available

d.Default

5. COMMISSIONING

ENG

5.1 Guided commissioning procedure

Hecu CO2 can be setup the fi rst time from the pGDe or pLDpro user

terminal. If the controller has not yet been confi gured, the user terminal

shows the fi rst screen in a guided confi guration procedure, called the

wizard. Otherwise, the same menu can be accessed from branch: L Setup

>> b.wizard.

The main parameters needed for general confi guration are shown one at

a time. The wizard screens are all numbered in the top right corner; the

following explanations refer to this number. To go from one screen to the

next press È, to return to the previous screen press Ç.

Screen Lb01: indicates the type of system, medium or low temperature.

Screen Lb02: change unit of measure from SI (°C, barg) to Imperial (°F,

psig).

Screen Lb03: indicates the type and number of compressors.

Screen Lb08: indicates the compressor control set point and diff erential

set as default by CAREL based on the type of application and the

refrigerant. The type of control is always proportional and integral,

and when exiting the wizard, control will be fi xed set point only until

confi guring communication with the cabinets, when the fl oating suction

pressure set point can be enabled.

Screen Lb91: indicates the number of fans. A maximum of two fans can

be selected.

Screen Lb04: indicates the type of modulating device associated with

the compressor selected in the previous screen.

Screen Lb05: indicates the BLDC compressor model and the power+

inverter serial address (always = 1). This is used to understand whether

the inverter is on and connected via serial with Hecu.

Screen Lb06: indicates whether the connected model of inverter is

compatible and if so automatically downloads some typical compressor

parameters to the inverter. The parameters can also be written manually

by selecting “Yes” for Write default.

Screen Lb92: indicates the type of fans, ON-OFF, modulating PWM or

0-10 V.

Screen Lb95: indicates gas cooler control based on temperature.

Screen Lb96 Lb97: indicates the type of control and the working set

point and diff erential for the fans.

Screen Lb99: indicates which valves have been installed on the unit for

management of CO2, and the type

Screen Lb3a: indicates the end of the wizard procedure. Pressing ENTER

ends the procedure, and the system will be confi gured based on the

options selected.

Screen Lb07: indicates compressor control based on pressure and the

corresponding refrigerant.

Important: wait a few seconds for the automatic default value

download procedure to be completed.

21

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

ENG

6. FUNCTIONS

6.1 Unit ON/OFF

The unit can be switched on and off as follows:

• User terminal

• Supervisor

• Digital input

On-off from the user terminal and the confi guration parameters are

available under the main menu, branch Ac

On-off from the supervisor and from the digital input and start-up after a

blackout (with specifi c delay, to avoid continuous starts and stops in the

event of instability in the power supply) need be enabled.

On-off from the digital input is equivalent to an enabling signal, that is, if

the digital input is Off the unit cannot be switched on in any other way,

while if it is On, the unit can be switched on or off in any other way, with

the same priority (the most recent has precedence, whatever the origin),

as shown in the fi gure:

Digital Input

User interface

Supervisor

Unit On/O

Fig. 6.a

Note: certain special conditions or functions in the Hecu CO2

software require the unit to be powered off :

• Confi guration of certain parameters: e.g. inputs/outputs, confi guration

of compressors, inverter parameters.

• Installation of default parameters

• Manual management

Manual con guration

Hecu CO2 automatically downloads the optimised parameters for each

model of compressor at the end of the wizard procedure.

If the model of compressor is changed or the power+ is replaced, the new

system can be confi gured manually under Compressors Æ Advanced

Æscreen Cag01.

Hecu CO2 and power+ must be powered and connected via serial; the

address of power+ must be 1 (default).

The type of compressor is selected from the list of available compressors;

the number of motor poles and the correct model of power+ are defi ned

automatically.

Select YES for Set defaults and press ENTER.

If the model of power+ (as read by power+) is the same model or larger

than the power+ selected based on the type of BLDC compressor, the

default values can be written and Hecu CO2 can control the compressor.

Otherwise, the message "Not compatible" will be shown.

Envelope management

The envelope is the set of operating points in which a compressor can

operate safely for an indefi nite time. This can be represented graphically

by drawing the limits inside which the operating conditions must be

maintained. The fi gure shows the envelope for the Toshiba DY/RY series

compressors.

6.2 BLDC compressor

A maximum of 2 BLDC compressors can be managed using the Power+

inverter. The type of compressor is selected under Compressors Æ

Confi guration (Cag01).

The BLDC compressor is managed via Modbus and works only if

connected to a CAREL power+ inverter. If there is no communication

with the inverter, the compressor will not be able to operate.

Below is the list of compressors that are currently available:

Medium and low temperature with PSD1 (R744)

Compressor HPV RPRV Inverter Capacity

TOSHIBA DY30 E2V09CS1C0 E2V11CS1C0 PSD101021A 0.3 - 2.8 kW

TOSHIBA DY45 E2V11CS1C0 E2V14CS1C0 PSD1012200 0.5 - 4.2 kW

TOSHIBA DY67 E2V14CS1C0 E2V18CS1C0 PSD1016200 0.7 - 6.3 kW

TOSHIBA RY100 E2V18CS1C0 E2V24CS1C0 PSD1018400 1.0 - 8.8 kW

Medium and low temperature with PSD2 (R744)

Compressor HPV RPRV Inverter Capacity

TOSHIBA DY30 E2V09CS1C0 E2V11CS1C0 PS200122041*0 0.3 - 2.8 kW

TOSHIBA DY45 E2V11CS1C0 E2V14CS1C0 PS200122041*0 0.5 - 4.2 kW

TOSHIBA DY67 E2V14CS1C0 E2V18CS1C0 PS200152041*0 0.7 - 6.3 kW

TOSHIBA RY100 E2V18CS1C0 E2V24CS1C0 PS200184041*0 1.0 - 8.8 kW

* =0: no PEC version; * =1: PEC version

Note: go to ksa.carel.com to check the updated list of compressors

available, with reference to the “DC compressor availability table”

+050001835.

E2VSTA0310 unipolar stator Tevap. = -10°C

E2VSTA0310

unipolar stator

TGC = 32°C

Tab. 6.a

Tevap. = -10°C

TGC = 32°C

Tab. 6.b

Discharge

pressure

Pd max

Pd min

Ps min Ps max

Fig. 6.b

The envelope limits consist of:

Suction

pressure

• Minimum and maximum discharge pressure

• Minimum and maximum suction pressure

• Minimum and maximum compression ratio (CR)

• Maximum current drawn by the compressor

The operating conditions are defi ned by:

• Suction pressure

• Discharge pressure

• Discharge temperature

• Rotation speed (rps)

The maximum discharge pressure can be limited due to construction

requirements of the circuit; in this case, a limit will be applied to the

maximum discharge temperature. The shape of the envelope can change

as compressor speed varies, and with this the operating conditions that

are considered safe for the compressor. It is therefore possible that a

certain pair of operating pressures is considered safe (inside the envelope)

at a certain speed, and unsafe (outside of envelope) at another speed.

Hecu CO2 +0300085EN rel. 2.2 - 07.05.2019

22

ENG

If the operating conditions are close to the envelope limit or outside

of this, the controller applies corrective actions in an attempt to keep

the operating point inside the limits specifi ed by the manufacturer. It

is therefore possible that in such cases, the actual compressor speed

does not correspond to the cooling capacity request of the temperature

controller, that superheat is not maintained at the set point, or that the

discharge pressure is not kept at the optimal value. If the operating

conditions remain outside of the envelope for a time exceeding the alarm

threshold (screen Cag55, default 60 s), the compressor is stopped and an

out-of-envelope alarm is signalled.

3

2

9

Discharge pressure

1

8

5

6

7

Suction pressure

Fig. 6.c

The following zones are defi ned (see Figure 6.e):

1. Inside the envelope 6. Low compression ratio

2. High compression ratio 7. Low diff erential pressure

3. High discharge pressure 8. Low discharge pressure

5. High evaporation pressure 9. Low evaporation pressure

Compressor prevent function:

by managing the envelope, compressor "Prevent" actions can be applied

to attempt to avoid shutdown due to the high discharge pressure and

temperature thresholds.

The settings are made on the following screens:

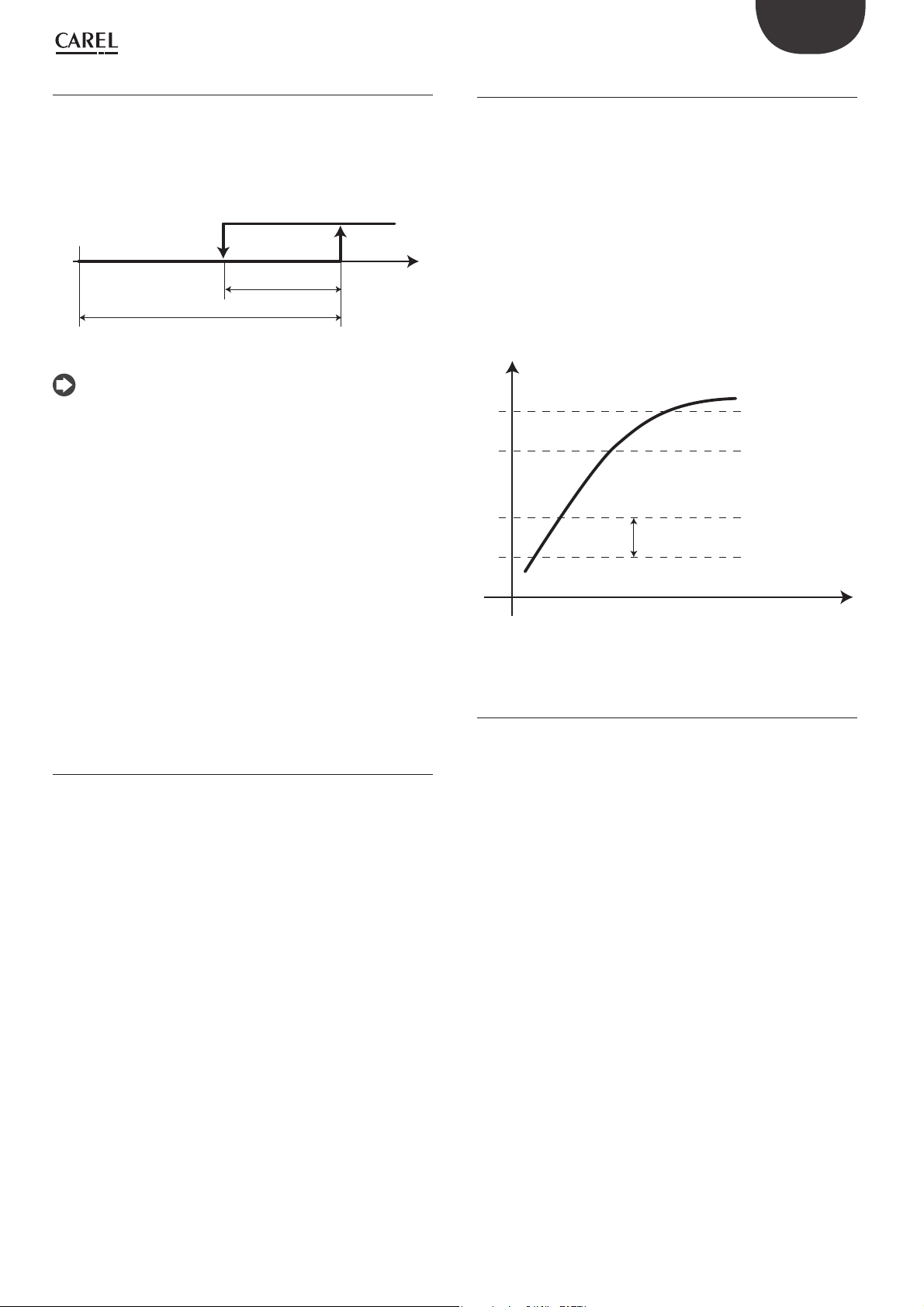

Timers

The timers include a minimum On time, a minimum Off time and a

minimum time between two consecutive starts.

These parameters can be set on screen Caf35:

The logic is described in the following graph:

Comp

ON

OFF

min ON

time

min OFF

time

min time to start

same compressor

Fig. 6.d

time

10s

Force compressor OFF: