gaSteam 45/90/180

pHC control

User manual

LEGGI E CONSERVA

QUESTE ISTRUZIONI

READ AND SAVE

THESE INSTRUCTIONS

L’installazione del prodotto deve obbligatoriamente

comprendere la connessione di messa a terra,

usando l’apposito morsetto giallo-verde in morsettiera.

Non utilizzare il neutro come connessione a terra.

The product must be installed with the earthconnected,

using the special yellow-green terminal on the terminal

block. Do not use the neutral for the earth connection.

Le produit doit être installé avec la connexion terre

branchée, en utilisant la signalisation et les bornes

spécifiques (jaune/vert) à la mise à la terre.

Ne pas utiliser le neutre comme mise à la terre.

Das Produkt muss geerdet werden. Verwenden Sie

hierfür den gelb-grün Anschluss an der Klemmleiste.

Verwenden Sie nicht den Null-Leiter für die Erdung.

La instalación del producto debe obligatoriamente

incluir la conexión de la toma de tierra,

utilizando el borne amarillo/verde del regletero.

No utilizar el neutro como conexión a tierra.

Warning!

3gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

IMPORTANT WARNINGS

BEFORE INSTALLING OR HANDLING THE AP PLIANCE PLE ASE CAREFULLY READ AND FOLLOW THE

INSTRUCTIONS AND SAFETY STANDARDS DESCR IBED IN THIS MANUAL AND I LLUSTRATED BY THE

LABELS ON TH E MACHINE.

This humidifi er produces non-pressurised steam by means of a heat exchanger powered by a gas burner

immersed in the water contained in the boiler. The steam produced is used to humidify environments or

industrial processes, using special distributors.

The quality of the water used affects the process of evaporation, and as a result the appliance may be

supplied with untreated water, as long as this is drinkable, demineralised or treated with a softener

(see Characteristics of the supply water). The evaporated water is automatically replaced using a fi lling

valve.

This appliance has been designed exclusively to directly humidify rooms or ducts, using a distribution

system, as long as the installation, use and maintenance operations are carried out according to the

instructions contained in this manual and on the labels applied internally and externally.

The conditions of the environment, the fuel and the power supply voltage must comply with the specifi ed values.

All other uses and modifi cations made to the device that are not authorised by the manufacturer are

considered incorrect.

Liability for injury or damage caused by the incorrect use of the device lies exclusively with the user.

Please note that the machine is connected to the gas mains, contains powered electrical devices and hot

surfaces.

All service and/or maintenance operations must be performed by specialist and qualifi ed personnel who

are aware of the necessary precautions and are capable of performing the operations correctly and in

accordance with the safety standards and legislation in force, with specifi c reference to:

1. Italian law 1083/71: “Safety standards relating to the use of gaseous fuel”;

2. Italian Law no.46/90: “Safety standards relating to systems in buildings”;

3. Presidential Decree no. 447, December 6, 1991: “Regulations to law no. 46, dated March 5,

1990, on safety relating to systems in buildings”;

4. Italian Law 10/91: “Regulations to the national plan for energy savings and the development of

renewable sources of energy”.

Disconnect the machine from the mains power supply before accessing any internal parts.

The local safety standards in force must be applied in all cases.

Disposal of the parts of the humidifi er: The humidifi er is made up of metallic and plastic

parts.

In reference to European Community directive 2002/96/EC issued on 27 January 2003 and

the related national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and such waste must be collected and disposed of

separately;

2. the public or private waste collection systems defi ned by local legislation must be used. In addition,

the equipment can be returned to the distributor at the end of its working life when buying new

equipment.

3. the equipment may contain hazardous substances: the improper use or incorrect disposal of such

may have negative effects on human health and on the environment;

4. the symbol (crossed-out wheeled bin) shown on the product or on the packaging and on the instruction sheet indicates that the equipment has been introduced onto the market after 13 August 2005

and that it must be disposed of separately;

5. in the event of illegal disposal of electrical and electronic waste, the penalties are specifi ed by local

waste disposal legislation.

Warranty on materials: 2 years (from the date of production, excluding the consumable parts, such as

the cylinder).

Certifi cation: the quality and safety of CAREL products are guaranteed by CAREL’s ISO 9001 certifi ed

design and production system, as well as the TÜV, CE

and ETL marks.

5gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

Content

1. GENERAL CHARACTERISTICS OF THE MAIN CONTROL BOARD - PHC 7

2. CONTROL SIGNALS FROM THE FIELD 8

2.1 Humidity or temperature control .......................................................................................................8

2.2 Pin strip position on the board for probe confi guration ..............................................................10

2.3 Using other brand probes ................................................................................................................10

3. AUXILIARY CONTACTS 11

3.1 Alarm contact..........................................................................................................................................11

3.2 Dehumidifi cation contact ...................................................................................................................11

3.3 Remote terminal/supervisor systems ..............................................................................................11

3.4 Checks ......................................................................................................................................................11

4. STARTING, CONTROL AND SHUTTING DOWN 12

4.1 Starting the appliance ...........................................................................................................................12

4.2 Manually draining the boiler ..............................................................................................................14

4.3 The pGD0 graphic display (CAREL code: PGD0PH0F00) ...........................................................14

4.4 The main “menu” ................................................................................................................................15

5. “MAIN “MENU” - AUXILIARY FUNCTIONS 18

“SERVICE” (“MAINTENANCE”) SUBMENU 18

5.1 “SERVICE” - information on the fi rmware ......................................................................................18

5.2 “SERVICE” - display the operating hours ........................................................................................18

5.3 Manually draining the cylinder ...............................................................................................18

5.4 Procedure for testing the electrical parts ........................................................................................19

6. READING AND SETTING THE PARAMETERS 20

6.1 Reading and setting the set point .....................................................................................................20

6.2 Reading and setting the control parameters - reading the measurements ............................20

6.3 “Rotation” of the steam request between the two burners (UG180 only) .............................23

7. CONFIGURATION PARAMETERS 24

7.1 Reading and setting the confi guration parameters - “USER” submenu ...................................24

7.2 Confi guring the control mode ............................................................................................................24

7.3 Humidity control with humidistat .....................................................................................................24

7.4 Unit of measure ....................................................................................................................................24

7.5 Confi guring the ambient humidity (or temperature) probe ......................................................24

7.6 Confi guring the limit humidity probe ..............................................................................................25

7.7 Initial auto-test ........................................................................................................................................25

7.8 Setting the pre-purge speed and calibrating the fan speed ........................................................25

7.9 Water supply with REVERSE OSMOSIS system .............................................................................26

7.10 Setting the maximum ratio between the water fi lled and the water drained for dilution ..26

7.11 Preheating .............................................................................................................................................26

7.12 Antifreeze ..............................................................................................................................................27

7.13 Reversing the logic of the alarm relay .............................................................................................27

7.14 Options - drain due to inactivity ......................................................................................................28

7.15 Setting the production ramp .............................................................................................................28

7.16 Setting the fan speed for minimum and rated production .......................................................28

7.17 Setting the minimum production ....................................................................................................29

7.18 Options .................................................................................................................................................29

8. ALARMS, TROUBLESHOOTING 30

8.1 Alarms ....................................................................................................................................................30

8.2 Alarm management and signals .......................................................................................................30

9. OPERATING PRINCIPLE, CONTROL AND OTHER FUNCTIONS 32

9.1 Operating principle ..............................................................................................................................32

9.2 Control principles .................................................................................................................................32

6

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

10. OTHER FUNCTIONS 34

10.1 Measuring the conductivity of the supply water .........................................................................34

10.2 Flue gas discharge temperature measurement ..........................................................................34

10.3 Automatic draining ............................................................................................................................34

10.4 Antifoam procedure ............................................................................................................................34

10.5 Dehumidifi cation request signal .....................................................................................................34

10.6 Automatically emptying the cylinder due to extended inactivity .............................................34

10.7 Automatic reset from no water ........................................................................................................34

10.8 Repeating the humidity request .......................................................................................................35

10.9 Automatic procedure to unblock the fl oating level sensor ........................................................35

7

U

Z

AL

O

T

S

Y

1U

2U 3U 4U 5U 6U

7U

8U 9U 10U 11U 12U 13U 14U

1T

2

T 3T 4T

5

T 6T 7T 8T

9

T 10T 11T 12T

1

3T

1

4

T

1

Y

2Y

3

Y

4Y

5

Y 6Y

7

Y 8

Y

9

Y

1S 2S

3S 4S 5

S 6S

7S

8S 9S 10S 11

S 12S 13S 14S

L

1

L

2

GN D

1

O

2

O

3O

4

O 5

O

6O

7

O

8

O 9

O

1Z 2Z 3Z 4

Z

5

Z 6Z 7Z 8Z 9

Z

10Z 11Z 12

Z

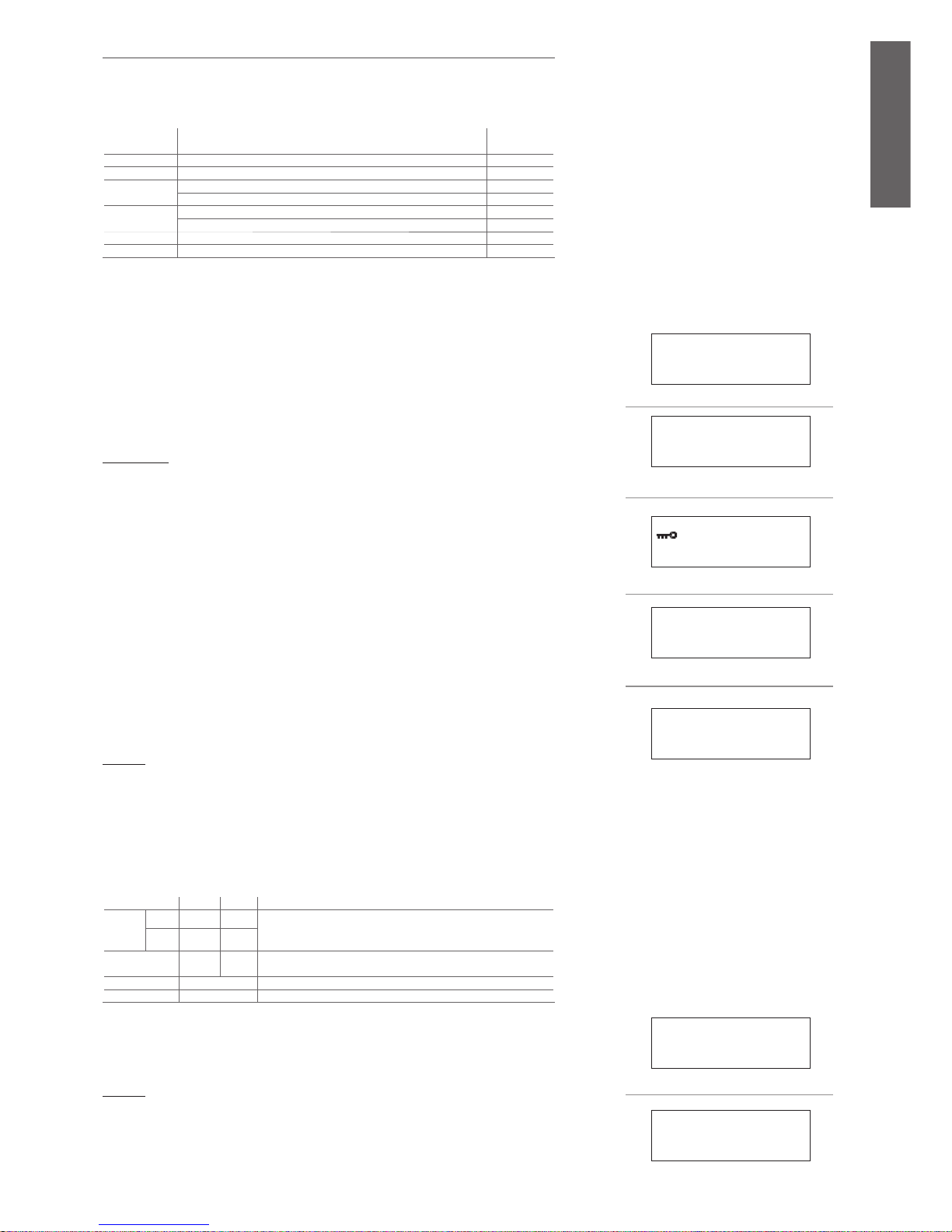

Fig. 1.a

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

1. GENERAL CHARACTERISTICS OF THE MAIN CONTROL BOARD - PHC

This is a microprocessor electronic controller based on the pGE technology developed by CAREL for the

management of all models of humidifi er.

It is made up of two electronic boards, positioned one on top of the other and connected together by

pin strip.

• bottom board - “main control board”: connected to the pGE board with the microprocessor and the

clock card, as well as the serial card;

• top board, or “expansion board”.

The pHC is designed to run the control program, and is fi tted with the set of terminals required for

connection to the controlled devices (for example: valves, power contactors) and to the fi eld (probes,

external controller).

The program and the parameters are saved in FLASH MEMORY, meaning the data is safe even in the

event of a power failure (without the need for a backup battery).

The pHC can be connected to pLAN (pCO Local Area Network) and tLAN networks.

The pLAN network is made up of a series of controllers and terminals that interact with one another.

Each controller in the pLAN network can exchange information at high speed. Up to 31 units, either pHC

controllers or terminals, can be connected, for the rapid exchange of information.

tLAN communication is available with I/O expansion modules or the PST display (3 or 4 digit).

Connection to the supervisor/telemaintenance serial line on the RS485 standard is ensured by fi tting the

pHC with optional cards, using the CAREL, Modbus® or ECHELON®, RS232 and GSM communication

protocols.

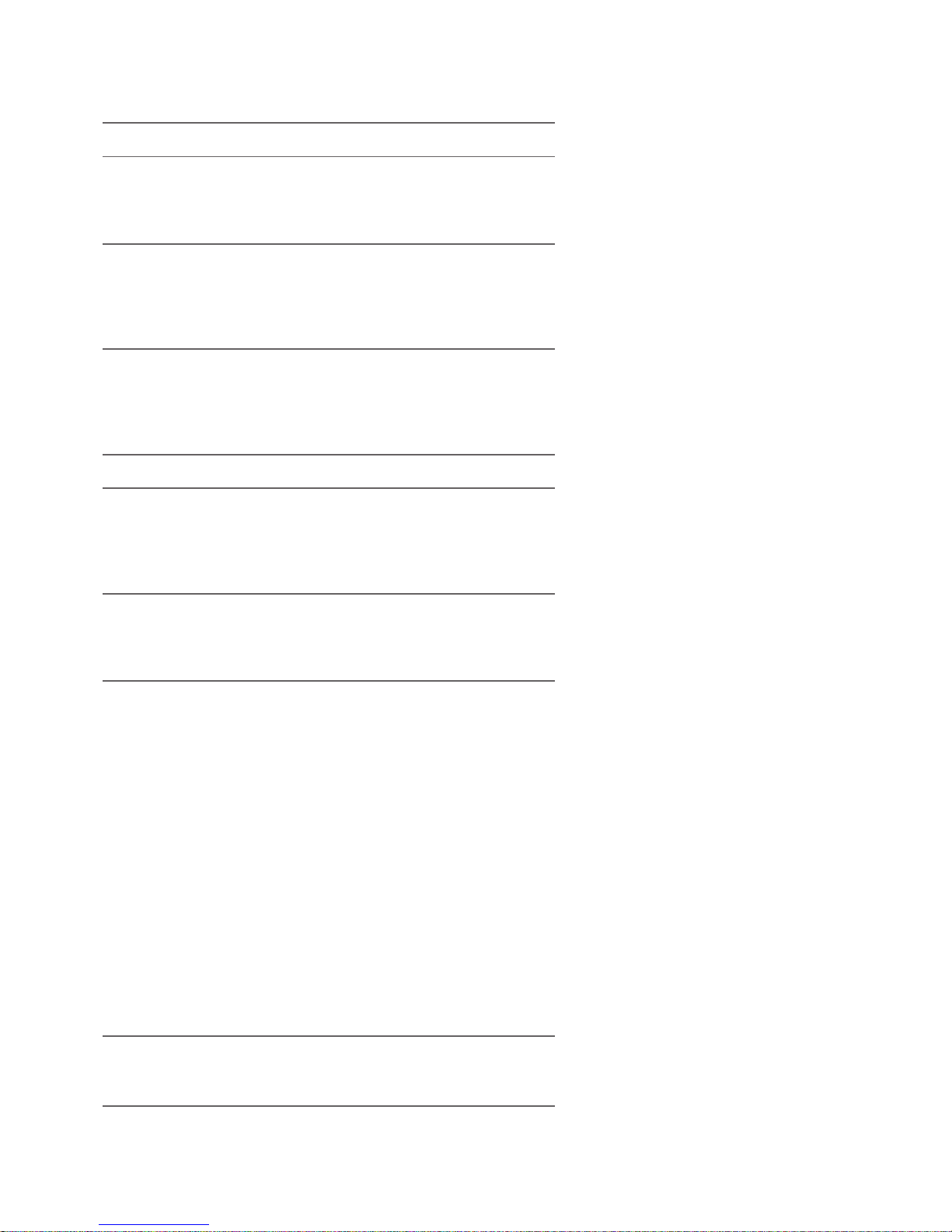

Terminal block

8

H

CR

CR

7U

Remote

ON/OFF

Action

ON/OFF

8U 9U 10U

a

H H

7U 8U 9U 10U

b

CR

7U 8U 9U 10U

c

Remote

ON/OFF

Action

ON/OFF

Remote

ON/OFF

Action

ON/OFF

Fig. 2.a

Fig. 2.b

R

CR

Fig. 2.c

External regulator

OUT

REF

1U

2U

3U

7U

8U

CR

Fig. 2.d

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

2. CONTROL SIGNALS FROM THE FIELD

2.1 Humidity or temperature control

The humidifi er with humidity control action can be connected to a remote supervisor using optional

cards. It can be controlled in the following four different ways (for further details, see chap. 9):

a) Type C control: ON/OFF

The humidifi er is operated by a mechanical humidistat H, by a voltage-free remote contact CR, or by a

combination of the two, which must be connected to terminals 7U, 8U, 9U and 10U on terminal block U

in the electrical panel.

The diagrams in Fig. 2.b show the connections to be made in the case of:

a) operation controlled by a simple enabling contact (CR);

b) operation by external mechanical humidistat (H);

c) a combination of the two.

b) Type P control:

proportional control, with signal sent by an external controller.

The steam production is managed by an external controller R, which sends the controller a humidity

request signal; the controller can be programmed to receive one of the following proportional signals

(see par. 9.2.2):

• voltage: 0 to 1 Vdc; 0 to 10 Vdc; 2 to 10 Vdc;

• current: 0 to 20 mA, 4 to 20 mA.

The reference (zero) of the external controller must be connected to the GND terminal (2U) and the

control signal to terminal B1 on terminal block U.

To avoid unstable control, the earth of the external controller must be connected to the earth of the

controller.

This type of control can also be used with an enabling contact (CR) connected to the “Remote ON/OFF”

terminal.

9

HT

CR

Fig. 2.e

CR

HT CH

Fig. 2.f

HT

1U

2U

3U

4U

5U

6U

7U

8U

out H

M

+ (G)

HT

out H

M

+ (G)

CH

out H

M

+ (G)

a

b

CR

1U

2U

3U

4U

5U

6U

7U

8U

CR

Fig. 2.g

TT

CR

Fig. 2.h

TT

out T

M

+ (G)

1U

2U

3U

4U

5U

7U

8U

CR

Fig. 2.i

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

c) Type H control:

humidity control with ambient relative humidity probe (and outlet limit probe, if required).

With this confi guration (see Fig. 2.e) the main control board, connected to a humidity probe HT,

performs a complete control action according to the humidity measured.

An outlet humidity limit probe (see Fig. 2.f) can also be connected: with this confi guration, the main

control board, connected to a humidity probe HT, performs a complete control action, while also limiting

the steam production according to the relative humidity value in the outlet duct, measured by the probe

CH.

The diagrams shown in Fig. 2.g indicate the connection to be made using CAREL probes, with:

• just one relative humidity probe (a);

• an outlet humidity limit probe (b).

CAREL PROBES AVAILABLE...

...for rooms ...for air ducts ...for special applications

ASWH100000 ASDH100000 ASPC230000

ASDH200000 ASPC110000

Table 2.a

The controller can also be connected to non-CAREL probes (see paragraph 2.3.)

HT: CAREL relative humidity probe;

CH: CAREL outlet relative humidity probe.

d) Control for steam baths:

temperature control with room temperature probe

The humidifi er is connected to a temperature probe TT (see Fig. 2.h), and performs a complete

control action according to the temperature measured inside the controlled environment.

Fig. 2.i shows the connection of the CAREL probe model ASET03001, with a range of measurement

-30T90°C. The recommended CAREL probes have a 0 to 1 volt output, and therefore the range

of reading must be set (see par. 7.5). The control signal must be connected to 1U, and the earth

reference is GND (2U).

The controller can also be connected to non-CAREL active probes (see par. 2.3).

TT: CAREL temperature probe.

10

1

2

3

1

2

3

JS5

JS5

JS4

JS4

3

3

1

1

2

2

Main board A in the

pHC controller

1

2

3

JS4

JS4

123

JS3

JS3

JS3

JS4

1

2

3

Expansion board B on

the pHC controller

1

2

3

4

5

6

Fig. 2.j

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

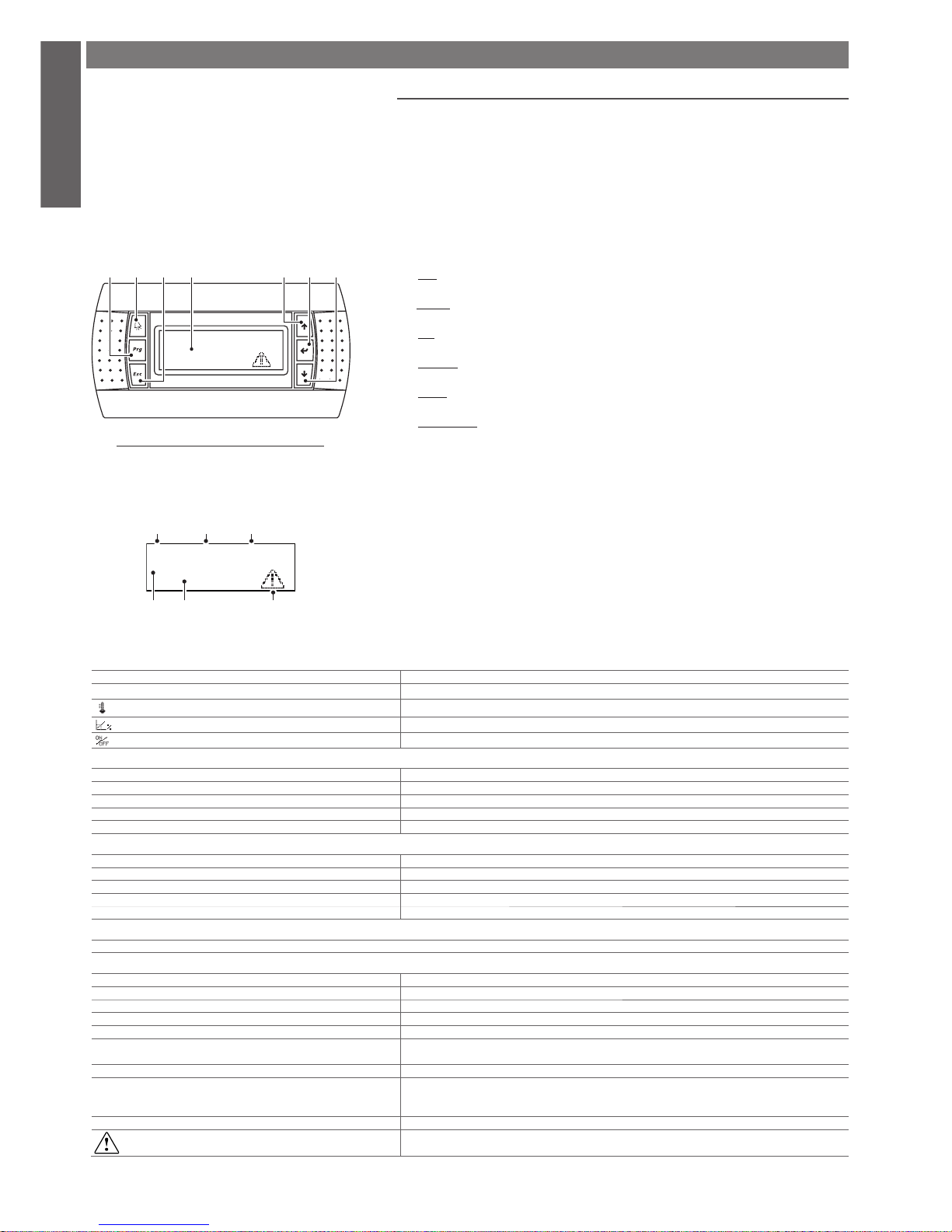

2.2 Pin strip position on the board for probe confi guration

1 room probe confi guration

2 limit probe confi guration

3 0 to 10 Vdc

4 all but 0 to 10Vdc

5 tachymetric 2

6 safety thermostat 2

2.3 Using other brand probes

Different brand probes can also be used, with the output signals (see par. 7.3) selectable from the

following standards:

• voltage: 0 to 1 Vdc, 0 to 10 Vdc, 2 to 10 Vdc;

• current: 4 to 20/ 0 to 20 mA.

In addition, the minimum and maximum values of the signal must be set (see par. 7.5).

A 15 Vdc power supply is available for the probes.

The control signals must be connected:

• for the control probe HT (or TT) to terminal 1U, the earth reference for which is GND (2U);

• for the limit probe CH to terminal 5U, the earth reference for which is GND (6U);

• for the current probe to terminal 4U, the earth reference for which is GND (6U).

Important warnings:

• To avoid unstable control, the earth of the probes or the external controllers must be connected to the

earth on the appliance’s controller.

• For the operation of the humidifi er, the terminals corresponding to the “remote ON-OFF” signal must

be connected to an enabling contact or jumpered (default solution). If these terminals are not connected, all the internal and external devices managed by the controller are disabled, with the exception

of the drain pump, limited to the drain cycle due to extended inactivity (see par. 10.5).

11

70

80

90

C

NO

NC

Fig. 3.a

13U

14U

NC

C

Fig. 3.b

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

3. AUXILIARY CONTACTS

3.1 Alarm contact

The humidifi er controller is fi tted with a voltage free contact for the remote alarm signal (one or more

events).

The alarm contact is connected via terminals 70, 80 and 90, as shown in Fig. 3.a.

electrical specifi cations connection to the alarm contact

250 Vac; Imax: 8A resistive 2A inductive removable terminal block as per Fig. 5.13

Table 3.a

3.2 Dehumidifi cation contact

When the humidifi er is used as in case c) in paragraph 2.1 (relative humidity control), a contact (NO,

voltage-free) can be used to activate an external dehumidifi cation device; in this case, the humidifi er can

provide complete control over the ambient relative humidity. The dehumidifi cation contact is connected

via terminals 13U, 14U on terminal block U, as shown in Fig. 7.7. For further details, see chapter 7.14.

See table 3.a.

3.3 Remote terminal/supervisor systems

The humidifi er controller can be connected to up to three pGD user terminals, one of which fi tted as

standard on board the unit, and 2 optional terminals that can be located up to 200m away.

The controller can also be connected to a supervisory system via RS485, RS232 serial lines or FTT10 LON

using the optional cards shown in the following table.

optional cards characteristics supported protocols

PCO2004850 used for the direct interface of the controller to an

RS485 network

CAREL, Modbus

PCO200MDM0 used for the direct interface of the controller to an

RS232 network with an external modem

CAREL for remote

connections

PCO20000F0 used to interface of the controller to an FTT10 LON

network, when suitably programmed

LON-Echelon

Table 3.b

Connection is also possible to TREND systems using a board sold directly by TREND.

3.4 Checks

The following conditions represent correct electrical connection:

• the rated voltage of the appliance corresponds to the mains voltage;

• the fuses installed are suitable for the line and the power supply voltage;

• mains disconnecting switch has been installed so as to be able to disconnect power to the humidifi er;

• the electrical connections have been performed as shown in the diagrams;

• the power cable is secured to the tear-proof cable clamp;

• terminals 7U-8U are jumpered or connected to an enabling contact;

• the earth of any non-CAREL probes is connected to the earth on the controller;

• if the appliance is controlled by an external controller, the earth of the signal is connected to the earth

of the controller.

12

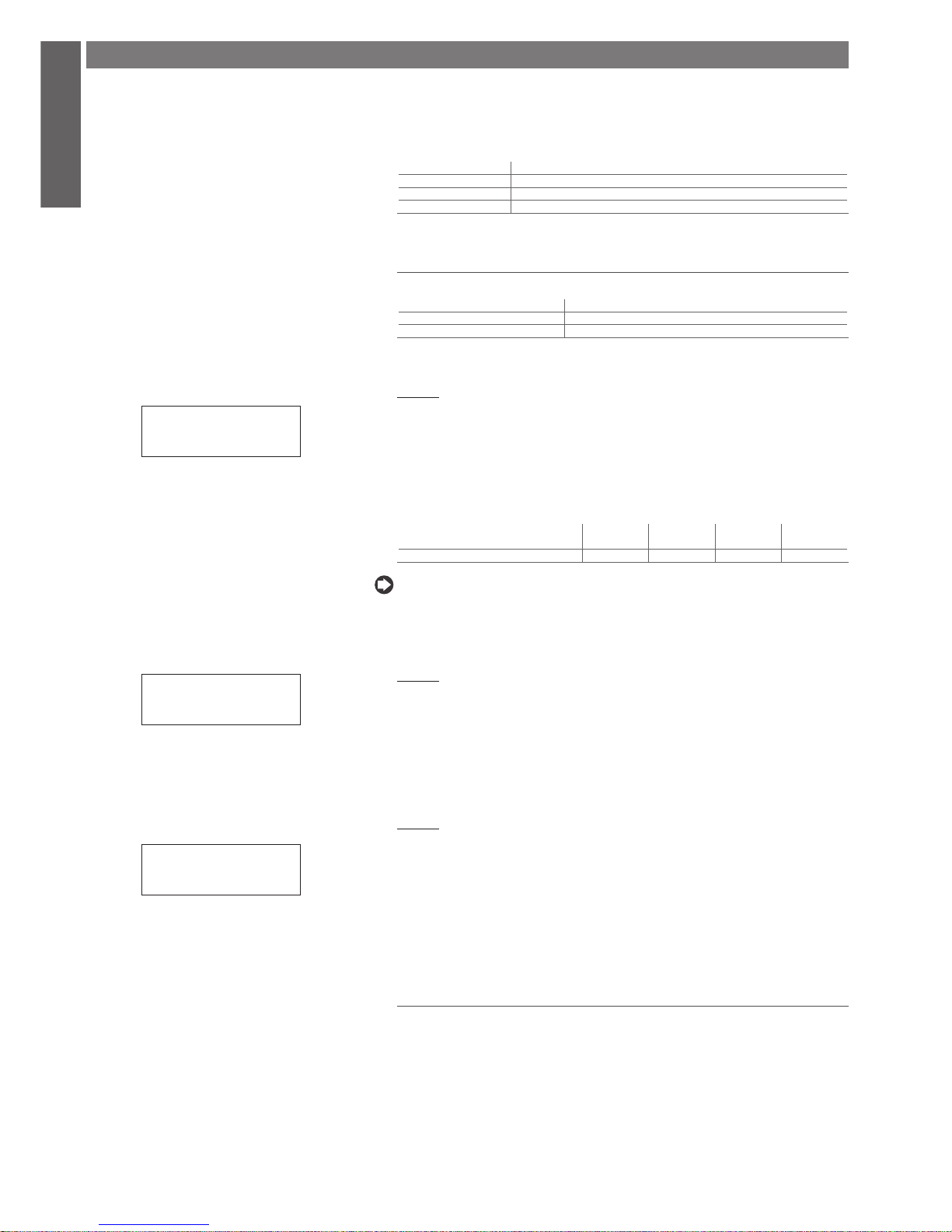

1 5 63 72 4

rH 100.0%

Off by Keyboard

50.0%rH

Fig. 4.a

321

4 5 6

rH 100.0%

Setp.

Off by Keyboard

50.0%rH

Fig. 4.b

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

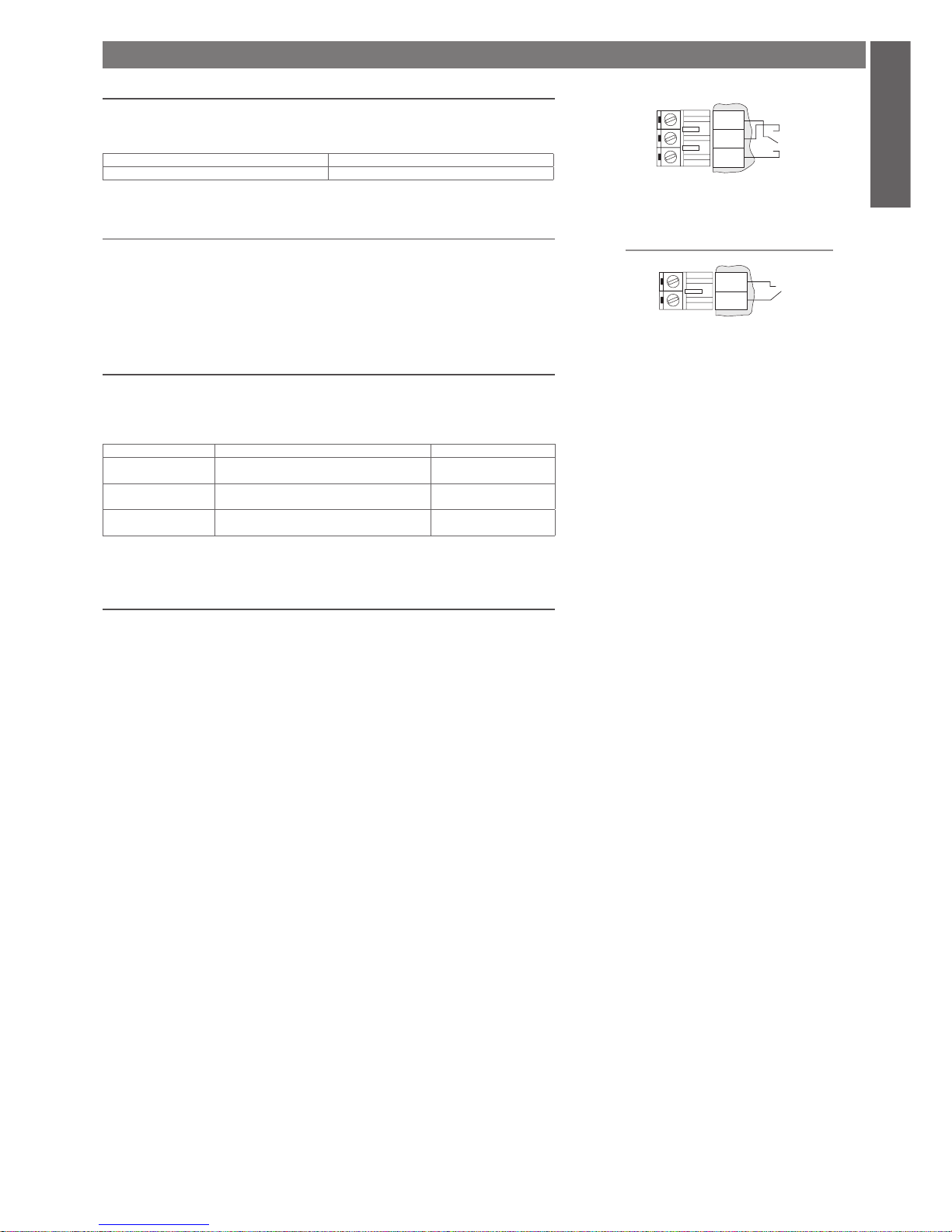

4.3 The pGD0 graphic display (CAREL code: PGD0PH0F00)

The pGD0 graphic display is an electronic device, compatible with the previous PCOI/PCOT terminals,

used for the complete management of the graphics, by displaying icons (defi ned at an application

software development level) and international fonts, in two dimensions: 5x7 and 11x15 pixels.

The application software only resides on the pHC board; the terminal does not need any additional

software during operation.

In addition, the terminal allows a wide range of operating temperatures (-20T60°C) and guarantees a

high index of protection (IP65).

The pGD0 graphic display (20 columns x 4 rows) is backlit.

4.3.1 Front panel

1. “PRG” button: programming button

Accesses the humidifi er confi guration maintenance and menu;

2. “Allarme” button: alarm button

Used to display and reset any alarms present;

3. “ESC” button: button to return to the “main screen”;

4. Graphic display, 4 rows x 20 columns: Displays the icons and texts for the user interface;

5. “UP arrow” button: scrolls the various screens on the pGD and changes the values of the confi gura-

tion parameters;

6. “ENTER” button: used, where possible, to scroll the individual rows in the confi guration screens and

to access the individual confi guration parameters;

7. “DOWN arrow” button.

For convenience, the pages on the display are called “screens”.

The screens may contain text messages, small pictures, variable values (read and write).

In this case too, for convenience, the variable values (read or write) are called “fi elds”.

4.3.2 Main screen

Main screen” refers to the screen that appears during the normal operation of the humidifi er.

This screen displays the main aspects relating to the operation of the humidifi er.

For example, the screen shows the general humidifi er operating status, the control mode selected, the

humidity value read by the probes, or an indication if any alarms are active.

The following table lists all the possible information shown on the main screen (Fig. 4.b).

Control mode fi eld

display mode

rH

type H control

type T control

type P control

type C control

Signal applied fi eld

display mode

Humidity value read by the ambient probe type H control

Temperature value read by the ambient probe type T control

Value as a % applied by the external controller to input “B1” on the pHC type P control

Production value as a percentage of the target type C control

Unit of measure fi eld

display mode

% type H control

°C (°F) type T control

% type P control

% type C control

Set point fi eld

This row displays the set point. Only shown in H or T control mode

General operating status fi eld

display description

Off from the keypad Unit off. Unit switched off from the keypad

Off from Superv. Unit off. Unit switched off via supervisor

Disabled Unit on. Humidifi er disabled via the keypad

No request Unit on. No steam request

Pr. 000.0 kg/h Unit on. Total steam fl ow-rate currently produced in (kg/h or lb/h). Visible only when the unit is on, the

humidifi er is enabled for operation and humidity is requested.

Remote off Unit on. Steam production stopped by the opening of the “Remote ON/OFF” contact

Alarms Unit on. The production in both cylinders has been stopped by a shutdown alarm. This is displayed for a few

moments, after which the message “No Request” is displayed, as, following a shutdown alarm, the humidity

request is forced to zero.

display description

The alarm icon appears when an alarm or pre-alarm condition is present in one of the two cylinders.

Press the Alarm button to check and if necessary reset the alarm (see par. 8.1)

Table 4.a

4. STARTING, CONTROL AND SHUTTING DOWN

13

clock

Time 10:54

Date 20/02/04

Day Friday

Fig. 4.c

Clock update

Time 10:54

Date 20/02/04

Fig. 4.d

Clock

password

0000

Fig. 4.e

Scheduler

Humidif. on-off No

Set point No

Fig. 4.f

Scheduler

On-off timezones No

Humid.timezones Yes

Fig. 4.g

Humid. on-off

Mon:F3 Tue:F3 Wed:F3

Thu:F3 Fri:F3 Sat:F3

Sun:F3

Fig. 4.h

Humid. on-off

Mon:F1 Tue:F1 Wed:F1

Thu:F1 Fri:F1 Sat:F2

Sun:F4

Fig. 4.i

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

4.4 The main “menu”

The main “menu“ offers the user or the installer the possibility to modify all the desired parameters. It is

accessed by pressing the “PRG” button, Fig. 4.e.p.

Use the UP and DOWN arrows to scroll the rows in the menu.

The description of the individual items are listed in the following table.

fi eld description level of

accessibility

set Enable operation. Set the control parameters. free

user Set the confi guration parameters with access by password. password

service Access the operations reserved for the installer or service personnel. password

Information on the fi rmware free

clock System clock. Set free

Set the time bands password

alarm log Alarm log free

unit on-off Unit ON/OFF free

Table 4.b

As regards the description of the control and confi guration parameters (“Set” and “User” items) refer to

par. 6.2.2.

The “Unit ON-OFF” item has already been analysed in par. 4.3.6 (“Start unit from keypad”).

4.4.1 “Clock” submenu

Entering the “clock” submenu, the user can access the clock (useful for the timed start-up of the humidifi er) and the date, Fig. 4.c.

Setting the clock

The clock can be set using the “UP” and “DOWN” buttons in the following screen, Fig. 4.d.

To set the clock:

• press the “ENTER” button to move the cursor to the fi eld to be changed;

• change the value using “UP” and “DOWN”;

• press the “ENTER” button to confi rm.

Setting the time bands

This important function is used to automatically set the operation of the humidifi er during the days of

the week.

These settings are accessed after entering the password “0077”, Fig. 4.j, which opens the time band

activation screen, Fig. 4.f.

There are two possible settings:

• timed humidifi er On/Off operation;

• timed humidity set point control.

In addition, both functions can be enabled to work at the same time.

4.4.3 Timed humidifi er ON/OFF operation

This function can be used to set humidifi er on and off times specifi cally and separately for each day of

the week. Once the humidifi er is on, the production of humidity depends only on the control parameters

set (see par. 6.2.2) and the humidity measured.

Sequence:

• to activate this type of setting, go to the screen shown in Fig. 4.g and set the fi eld on the right of “Onoff timezones” to “Yes”;

• press “ENTER” to confi rm.

This then activates the following time band control screens. To display these, position the cursor (using

“ENTER”) at the top left and then press “UP” and “DOWN”.

Four different time bands can be selected:

ON-OFF bands

time band

ON OFF

description

F1 F1-1 09:00 13:00 the humidifi er remains on (the values in the table are the default

values. These can be modifi ed by moving the cursor to the values and

using the “UP” or ”DOWN” button).

F1-2 14:00 21:00z

F2 14:00 21:00 the humidifi er remains on (the values in the table are the default

values, which can be modifi ed.)

F3 Always ON Humidifi er always on

F4 Always OFF Humidifi er always off

Table 4.c

Once the time bands have been set, the bands then need to be enabled for each day. An example of the

screen is shown to the side.

Sequence:

• use the “ENTER” button to move the cursor to the time band for the day in question;

• use the “UP” and “DOWN” buttons to choose one of the 4 time bands seen in Table 4.3;

• press “ENTER” to confi rm and move to the next value.

An example of a setting is shown to the side.

14

Scheduler

On-off timezones No

Humid.timezones Yes

Fig. 4.j

Set point

ON SET

Z1: 00:00 000.0%

Z2: 00:00 000.0%

Fig. 4.k

Set point

ON SET

Z3: 00:00 000.0%

Z4: 00:00 000.0%

Fig. 4.l

Set point

ON SET

Z1: 08:30 050.0%

Z2: 12:30 040.0%

Fig. 4.m

Set point

ON SET

Z3: 13:30 050.0%

Z4: 18:00 030.0%

Fig. 4.n

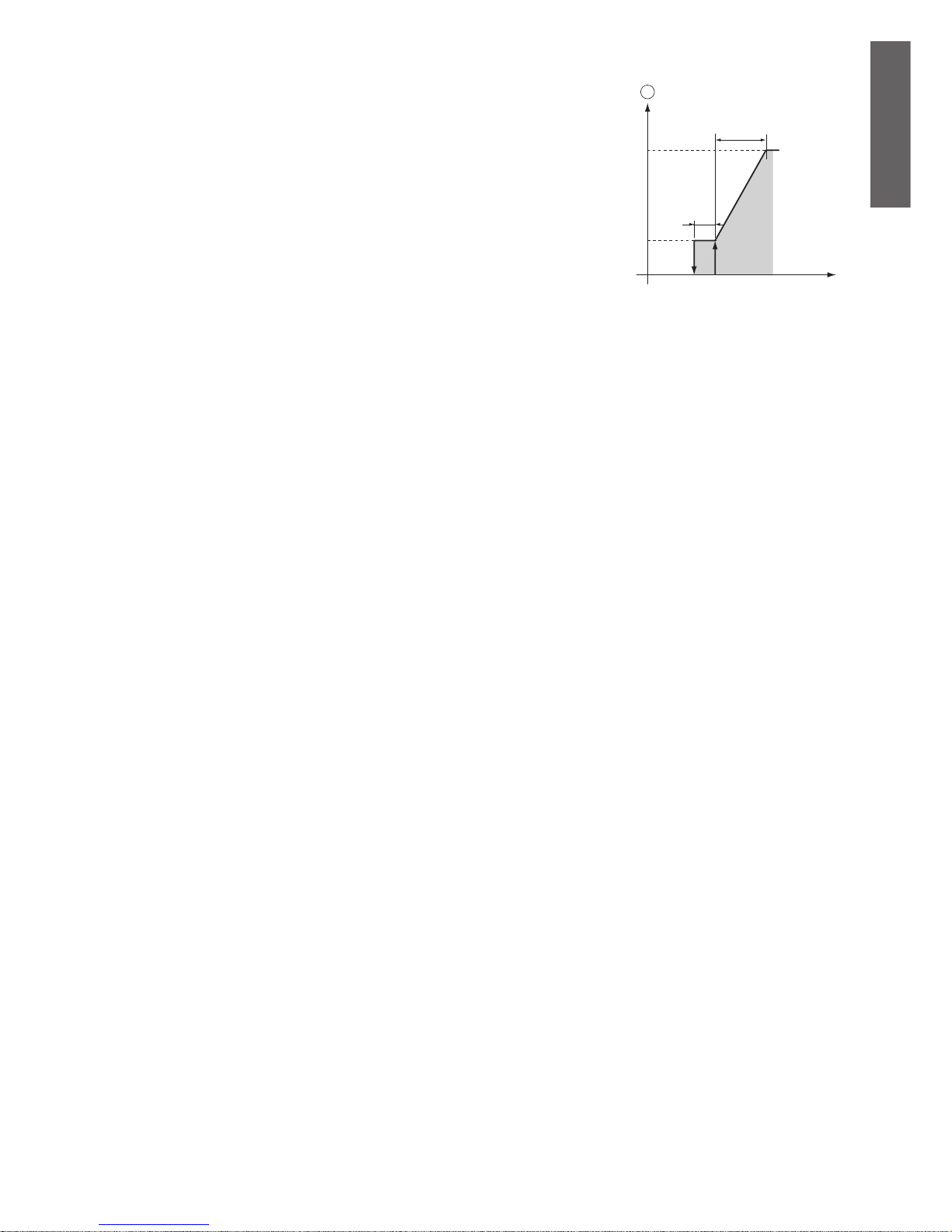

00:00 08:30 12:30 13:30 18:00

Set %

Fig. 4.o

Scheduler

Humidif. on-off Yes

Set point Yes

Fig. 4.p

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

4.4.3 Timed set point control

With this type of control, the humidity H (or temperature T) set point can be varied during the day.

Up to 4 switching points can be set, with both the time and new set point. This setting is valid for every

day of the week.

Sequence:

• move to the screen shown to the side and set the fi eld to the right of “Humid. timezones” to “Yes”;

• press “ENTER” to confi rm.

This then activates the following control screens for the set point switching points (position the cursor

using “ENTER” at the top left and then press “UP” and “DOWN”).

To set the switching points, go to the following two screens.

Setting the switching points:

• press “ENTER” to move the cursor to the fi eld to be changed;

• use the “UP” and “DOWN” buttons to set the desired time and the new humidity set point that will

take effect from that moment on;

• press “ENTER” to confi rm and to go to the next fi eld.

For example, if the two screens are set as shown to the side, the trend of the set point during each day

of the week will be as shown in the example.

- Combined control

The activation of both control modes is used to set both the humidifi er ON/OFF times and the set point

values during the day. To do this, both the values in the fi elds on the screen to the side must be set to

“Yes”.

This will enable all the subsequent screens for setting the time bands and the set point.

4.4.4 Alarm log

The humidifi er memory can record the alarms that are activated during the life of the humidifi er.

The memory saves up to 200 events, and information is available both on the type of alarm and on

the date and time it occurred. To access the alarm log, simply go to the “Alarm log” submenu (“History

Alarms”). Use the “UP” and “DOWN” buttons to scroll all the events that have been saved (the number

of the event is shown in the top right of the screen).

An example of a screen is shown to the side.

15

OFF

Fig. 4.q

Fig. 4.q.a

1

0

ON

Fig. 4.r

Fig. 4.s

Language: ENGLISH

UP/DOWN to change

ENTER saveexit

025

Fig. 4.t

rH 100.0%

Setp. 50.0%rH

Off by keyboard

Fig. 4.u

Menu

. Unit On-Off

> Set

. User

Fig. 4.v.a

Menu

. Alarm History

> Unit On-Off

. Set

Fig. 4.v.b

Unit status:

Off by Keyboard

- Press ENETR to -

- switch on -

Fig. 4.v.c

rH 100.0%

Setp. 50.0%rH

Disabled

Fig. 4.v.d

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

4.4.5 Shutting down

When shutting down the appliance at the end of the season or alternatively for maintenance on the

electrical parts and/or water circuit, the humidifi er should be placed out of service.

NOTE: empty the cylinder before shutting down the humidifi er to prevent fouling.

Sequence:

• open the mains disconnecting switch on the power line to the humidifi er;

• move the rocker switch to 0 (see Fig. 4.z) and check that the display on the controller is off;

• close the shut-off tap on the water line to the humidifi er.

To empty the cylinder when shutting down, refer to par. 5.3.

In the event of a malfunction with the pump, or a malfunction with the electrical parts, the boiler can be

emptied manually using the manual drain tap, see the fi gure to the side.

4.1 Starting the appliance

Staring for the fi rst time

When the humidifi er is started for the fi rst time, the AUTO-TEST procedure should be run (see par 7.7),

which automatically checks the main functions of the unit (fi ll, drain and control of the level sensor).

If enabled, the AUTO-TEST procedure starts whenever the electronic controller is switched on.

Nonetheless, the AUTO-TEST procedure can be disabled (see par. 7.7).

4.1.1 Start-up procedure and sequence

I – 0 switch: ON/OFF (Fig. 4.a).

After having closed the disconnecting switch in the power line to the humidifi er, switch on the appliance

by moving the rocker switch to position “I”.

The start-up sequence then begins, which includes an initial phase followed by the operation of the

appliance.

After the switch has been moved to the On position, the graphic display shows the screens in the

sequence described in the fi gures below.

1. Start power supply, system boot (around 10 seconds)

Nothing is displayed, Fig. 4.s.

2. Language setting (around 30 seconds)

In this phase, the user has 30 seconds to change the language (see par. 4.3.10), Fig. 4.t.

To pass directly to the next phase, press the “ESC” button.

3. Operating phase, main screen Fig. 4.u.

4.1.2 Main functions

STARTING THE UNIT FROM THE KEYPAD

Switch the unit on from the keypad. After the start-up sequence, the humidifi er is not yet ready to

operate, and the main screen appears as in Fig. 4.d.

To start the unit, proceed as follows:

1. Select the MENU

a. press the “PRG” button. The “Menu” screen is displayed, Fig. 4.v.a;

b. scroll with the “DOWN” arrow until moving the cursor to the “UNIT ON-OFF” fi eld, Fig. 4.e.b;

2. Enable

a. press the “Enter” button. The following screen is displayed, shown in Fig. 4.v.c;

b. press “Enter”. The following main screen is automatically displayed, as shown in Fig. 4.v.d.

At this stage, the system is on and the operation of the humidifi er can be started (see the next par.).

16

Humidif.enabled: NO

Burners Sequence:

Parallel

Seq. hyster.: 5.0%

Fig. 4.v.e

Humidif.enabled: O

Burners Sequence:

PARALLEL

Seq. hyster.: 5.0%

Fig. 4.v.f

rH 100.0%

Setp. 50.0%rH

Fig. 4.v.g

Control Params

%rH Set P. 50.0%

Max.Prod. 70.0%

%rH Different. 5.0%

Fig. 4.v.h

Control Params.

%rH Set P. 50.0%

Max. Prod. 70.0%

%rH Different. 5.0%

Fig. 4.v.i

Control params.

%rH Set P. 60.0%

Max.Prod. 70.0%

%rH Different. 5.0%

Fig. 4.v.j

Control Params.

Temp Set 40.0 °C

Temp Diff. 5.0 °C

Fig. 4.v.k

Quick set

Humidifier On

Max Prod. 70.0%

Fig. 4.v.l

Quick set

Humidifier On

%rH Set P. 50.0%

Max Prod. 70.0%

Fig. 4.v.m

Quick set

Humidifier On

Temp Set P. 40°C

Max Prod. 70.0%

Fig. 4.v.n

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

ENABLE OPERATION - START/STOP STEAM PRODUCTION

Once the unit is on, the “enable” function effectively starts the humidifi er.

Subsequently, steam production is related solely to the humidity request or the presence of an alarm or

a remote OFF signal.

If the humidifi er is not enabled for operation, the main screen appears as in Fig. 4.v.d.

- Enabling operation:

1. Select the MENU

a. Press “PRG”. The “Menu” screen is displayed, Fig. 4.v.b;

b. Scroll with the “DOWN” arrow until highlighting the “Set” row, Fig. 4.v.a;

c. Press “Enter”. The screen shown in Fig. 4.v.e is displayed;

2. Start the unit

a. Press the “Enter” button to move the cursor to the fi eld to be modifi ed, Fig. 4.v.f;

b. Press “UP” or “DOWN” to change the value. The screen shown in Fig. 4.v.g is displayed;

c. Press “ENTER” to confi rm.

Note that in the main screen the term “Disabled” no longer appears, Fig. 4.v.g.

At this stage, the humidifi er is ready to produce steam.

NOTE: the production of steam now depends only on the control parameters selected (see par. 6.2.3)

and the signal applied (humidity or temperature probe or signal from external controller).

- Disabling operation

Similarly to as described in the previous paragraph, the operation of the humidifi er can be stopped,

disabling the unit.

The sequence is the same, but rather set the “Humidif. enabled” variable to “NO”.

MODIFYING THE MAXIMUM PRODUCTION ALLOWED AND THE SET POINT

The maximum production allowed can be modifi ed in all control modes.

The set point, on the other hand, can only be modifi ed in the control modes where this is featured (see

par. 6.1).

Both the parameters are modifi ed in the following sequence:

1. Select the MENU

a. Press “PRG”. The “Menu” screen is displayed, Fig. 4.v.b;

b. Scroll with the “DOWN” arrow until highlighting the “Set” row, Fig. 4.v.a

c. Press “Enter”. The screen shown in Fig. 4.v.e is displayed;

2. Access and modify the control parameters

a. Using the “UP” or “DOWN” buttons, move to the screen shown in Fig. 4.v.h;

b. Using the “ENTER” button, move to the fi eld to be modifi ed, Fig. 4.v.i;

c. Using the “UP” and “DOWN” buttons, change the value and press “ENTER” to confi rm, Fig. 4.v.j.

NOTE: it can be seen that with this sequence, the humidity differential can also be changed, in the

modes where featured.

If temperature control mode has been set, the screen shown in Fig. 4.v.k is displayed.

QUICK ACCESS TO THE SET POINT PARAMETERS SCREEN

The previous screen can be accessed quickly, from the main screen, by pressing the PRG button:

• in C control mode: ON/OFF and P control mode: Ext. Controller, pressing PRG displays the screen

shown in Fig. 4.v.l;

• in H control mode: with or without limit probe, Fig. 4.v.m;

• in T control mode: the screen shown in Fig. 4.v.n is displayed.

17

rH 40.0%

Setp. 50.0%rH

Pr. 130.0 kg/h

Fig. 4.z.o

Menu

. Unit On-Off

> Set

. User

Fig. 4.z.p

Menu

. User

> Maintenance

. Clock

Fig. 4.z.q

CAREL S.p.A.

Code :FLSTDmGST0

Vers.:1.0b10 06/09/04

Language: English

Fig. 4.z.r

CAREL S.p.A.

Code :FLSTDmGST0

Vers.:1.0b10 06/09/04

Language: taliano

Fig. 4.z.s

Language: English

UP/DOWN to change

ENTER saveexit

025

Fig. 4.z.t

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

INDICATING THE ALARM STATUS

If an alarm is present, the display shows the alarm icon.

In the event of alarms, the alarm button lights up.

If the causes disappear, the alarm button fl ashes until the alarm is reset.

For the description of the alarms refer to chap. 8.

SETTING THE LANGUAGE

The language can be set to English or Italian.

The sequence is listed below:

a. Press “PRG”. The “Menu” screen is displayed, Fig. 4.v.p;

b. Using the “DOWN” button, move to the “service” fi eld, Fig. 4.v.q;

c. Press “ENTER”, Fig. 4.v.r.

d. Press “ENTER” to move the cursor to the language fi eld and change the setting using the “UP” or

“DOWN” arrows, Fig. 4.v.s;

e. Press “ENTER” to confi rm.

The language can also be set during the “start-up sequence” (par. 4.3.1): in fact, when the following

screen appears, the language can be set by simply pressing one of the two “UP” or “DOWN” arrows,

and then pressing the “ENTER” button to save the change.

NOTE: The default language is English.

18

Control Params

%rH Set P. 50.0%

Max.Prod. 70.0%

%rH Different. 5.0%

Fig. 5.a

Control params.

Temp Set. 30.0 °C

Temp Diff. 5.0 °C

Fig. 5.b

Control Params

Limit Set 100.0 %rH

Limit Diff. 5.0 %rH

Fig. 5.c

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

5. READING AND SETTING THE PARAMETERS

The confi guration and control parameters are grouped into two sets:

1. LEVEL 1 - set point and control parameters

2. LEVEL 2 - confi guration parameters

Each parameter has the following attributes:

name text identifying the parameter

range limit values for the setting of the parameter

default factory setting of the parameter value

unit of measure symbol displayed for the unit of measure used for the parameter

Table 5.a

5.1 Reading and setting the set point

The set point can be read on the main screen, appearing in the fi eld to the right of the text “Set P.”

control mode display in the fi eld to the right of “Set P.”

Type H humidity set point

Type T temperature set point

Table 5.b

5.1.1 Setting the ambient humidity set point

Sequence:

• go to the main screen and press “PRG”;

• enter the “SET” submenu;

• scroll the screens to reach the one shown on the left;

• press “ENTER” to move the cursor to the fi eld to the right of “rH Set P”;

• press “UP” and “DOWN” to change the value;

• press “ENTER” to confi rm.

Characteristics and range of the set point:

unit of

measure

default value

(1)

min. limit max. limit

humidity setting (H control) % rH 50.0 0.0 100.0

Table 5.c

WARNING: the outlet humidity set point, relevant to the limit probe, is saved by the parameter “Limit

Set” (see par. 6.2.2).

5.1.2 Setting the temperature set point

Questa operazione è possibile solo se è stata attivata la modalità di regolazione T.

Sequence:

• go to the main screen and press “PRG”;

• press “ENTER” to move the cursor to the fi eld to the right of “Temp Set.”;

• press “UP” and “DOWN” to change the value;

• press “ENTER” to confi rm.

5.1.3 Setting the outlet humidity set point

The outlet humidity set point can only be set if H control mode with outlet limit has been activated (see

the paragraph “Setting the control mode”, par. 7.2).

Sequence:

• go to the main screen and press “PRG”;

• enter the “SET” submenu;

• scroll the screens to reach the one shown on the left;

• press “ENTER” to move the cursor to the fi eld to the right of “L set point”;

• press “UP” and “DOWN” to change the value;

• press “ENTER” to confi rm.

5.2 Reading and setting the control parameters - reading the

measurements

5.2.1 Reading the measurements and the main parameters

The measurements and the main parameters can be displayed very simply by scrolling the screens that,

staring from the main screen (par. 4.3.3), are accessed by pressing the “UP” and “DOWN” buttons.

These screens contain the values listed in the table on the opposite page.

19

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

display unit of measure accessibility description

steam: kg/h or lb/hr total steam fl ow-rate

Amb. Hum: %rH in H control mode humidity measured in the room

Set P. %rH ambient humidity set point

Amb. T: °C (°F) in T control mode room temperature

Set T.: °C (°F) room temperature set point

Set P. Lim.: %rH in H control mode + limit set point at the outlet

Humid. Limit: %rH relative humidity at the outlet

Prod.Bur1: kg/h or lb/hr current production of burner 1

Fan 1: RPM speed of fan 1

Prod.Bur2: kg/h or lb/hr current production of burner 2 (UG180)

Fan 2: RPM speed of fan 2 (UG180)

Preheat Set: °C (°F) preheating set point (if preheating is not enabled, “N.A.” is displayed)

Antifreeze Set: °C (°F) antifreeze set point (if not enabled, “N.A.” is displayed)

Conductivity µS/cm conductivity of the mains supply water

Flue gas temperature

Burner 1:

Burner 2:

°C (°F) fl ue gas temperature

Table 5.d

Scroll the screens until reaching the “Menu password” request. Enter the password “77” to access a

series of screens that provide information normally reserved for the installer or service personnel. To

enter the password, simply:

• press “ENTER” to move the cursor to the “0000” fi eld;

• press “UP” or “DOWN” to enter the number “0077”;

• press “ENTER” to confi rm.

The information included on these screens is listed in the following table.

text option description

gaSteam status see Table. 4.a similar to the status that appears on the main screen

Burner 1 (2) status On combustion active

Off combustion not active

Alarm alarm

activity: Off burner not active

Production steam production in progress

Preheat preheating in progress

Pre-purge pre-purge in progress

Antifreeze antifreeze in progress

Speed: fan speed (rpm)

Table 5.e

5.2.2 Setting the control parameters

The control parameters are the values corresponding to the ambient humidity control (or temperature)

control process.

To access these parameters, scroll the screens present under the “SET” submenu.

Control parameters

display range default UOM accessibility description

Burner sequence,

UG180 only

Parallel, Parallel always Operating mode (see Chap. 9 Operating principles)

Series

Seq. hyster.: UG180

only

0 to 20.0 5.0 % always hysteresis for the shutdown/ignition of the burners

only in series or parallel burner sequence with

rotation (see “setting the operating sequence of the

two burners”) UG180

Max. prod. 25.0 to 100.0 UG045/90 UG180 if

sequence”= parallel and

rotation not enabled

70.0 % always Maximum production of the humidifi er as a

percentage

For the concept of rotation see par. 6.3 “Options”

Note: for the minimum limit for this parameter - see

par. 5.17 “setting the production”

12.5 to 100.0 only UG180 if “boiler

sequence”= series

%rH Set P. 0 to 100.0 50 % in H control mode and H control

mode with outlet limit

Humidity set point

%rH Differential 2.0 to 20.0 5.0 % Humidity differential

Limit Set (%rH set point) to 100.0 80.0 % only in H control mode with

outlet limit

Outlet humidity set point

L. Diff. 2.0 to 20.0 5.0 % Outlet humidity differential

Temp Set 0 to 50.0 30.0 °C only in T control mode Temperature set point

32.0 to 122.0 86.0 °F Temperature differential

Temp Diff. 2.0 to 19.9 5.0 °C

35.6 to 68 41.0 °F

Low 0 to 100.0 10.0 % in H control mode and H control

mode with outlet limit

Low humidity alarm threshold

High 0 to 100.0 90.0 % High humidity alarm threshold

High 0 to 100.0 100.0 %rH only in H control mode with

outlet limit

High outlet humidity alarm threshold

Low 0 to (high threshold) 0 °C only in T control mode Low temperature alarm threshold

32.0 to (high threshold) 32.0 °F

High (low threshold) to 60.0 60.0 °C High ambient temperature alarm threshold

(low threshold) to 140.0 140.0 °F

20

100%

bD; bD/2

100%; 50%

bD; bD/2

100%; 50%

“Min. Prod”

(bD)

100%

1

2

4

2

3

bD

100%

bD

100%

2

5

Fig. 5.d

bD/2

H

100%50%

bD/2 ≥ 50% - hyst

bD/2 ≤ 50% - hyst

bD; bD/2

bD; bD/2

bD; bD/2

100%; 50%

100%; 50%

bD; bD/2

100%; 50%

100%; 50%

hyst

P**; P**/2

P*; p*/2

P*=P**

100%50%

100%50%bD

100%50%

1

2

3

5

2

3

6

7

2

1

2

100%50%

50%

bD

bD/2

bD/2

bD

100%

4

2

hyst

Fig. 5.e

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

5.2.3 Setting the “operating sequence of the two burners” (UG180 only)

The gaSteam 180 manages the operation of the two burners so that in stable operation these produce

180 kg/h of steam.

Ideally, the gaSteam 180 can be considered as two separate humidifi ers, each with its own burner, and

able to produce up to 90 kg/h.

The two systems are managed based on the setting of the “Burner Sequence” parameter, seen in the

table above.

• “PARALLEL” mode: the steam request is divided equally between the burners. In this case, therefore,

the steam production provided by the two burners is the same.

• “SERIES” mode: (also called “sequential”): if the steam request is less than 50% of the rated

production, only one burner is operated. Only if the request exceeds the 50 % does the other burner

start.

As each burner must operate so that the corresponding “ideal” humidifi er produces a minimum (25%

for natural gas; 33% for butane-propane) of the “ideal” fl ow-rate of 90 kg/h, “SERIES” mode naturally

offers a wider overall range of modulation of steam production.

• PARALLEL mode: the minimum possible production is 45 kg/h;

• SERIES mode: the minimum production is 22.5 kg/h

Example of PARALLEL mode

Key

1 production burner 1; total

2 total request

3 production burner 2; total

4 2% in P control; 0.1xP0 in H/T control

5 total production

Key

1 production burner 1; total

2 total request

3 production burner 2; total

4 total production

5 H= 2% in P control; 0.1xP0 in H/T control

6 hyst= “Seq.Hyster” parameter (def: 5.0%, range:

0-20.0%)

7 P*= 100% - 2*hyst - bD

P**= 100% - bD

It can be seen that an hysteresis is required in the intermediate burner On/Off zone, which is managed

by the “Seq. Hyster.” parameter seen in the previous table.

Example of SERIES mode

21

bD/2

100%

bD; bD/2

2*bD; bD

00%; 50%

bD; bD/2

100%; 50%

100%50%bD

bD

1

2

1

2

bD

bD/2

100%

100%50%bD

bD/2

50%

3

2

hyst

hyst

Fig. 5.f

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

To offer a wider range of modulation in parallel mode, the concept of “ROTATION” has been introduced

(see OPTIONS - Rotation of the request between the burners).

If ROTATION is active, in PARALLEL mode too one burner is started fi rst, while the other remains off

until the steam request is between 12.5% and 25%. Above 25%, both burners start operating in parallel

mode.

Key

1 production burner 1; total

2 total request

3 production burner 2; total

5.3 “Rotation” of the steam request between the two burners

(UG180 only)

parameter name options default

Burner rotation NO ROTATION No Rotation

AT START

IN PRODUCTION

Table 5.g

Description

In normal operation, depending on the humidity request and the control mode selected (series or parallel), the control logic automatically calculates how much energy must be generated by each burner/fan

system.

The rotation of the request consists in periodically reversing these production references.

The rotation of the request ensures, in the long term, similar operating hours for the two burners in the

gaSteam, with the consequence of not only having more uniform wear on the combustion systems, but

also a more uniform accumulation of lime-scale deposits on the two exchangers.

Two types of rotation are available:

• IN PRODUCTION: this is rotation by time, that is, whenever the difference in operating hours between

the two burners reaches 10 hours, the production references are reversed.

• AT START: whenever that the steam production ends, when following request is received, the burner

with the less operating hours always starts fi rst, along as the difference in operating hours has

exceeded 10 h.

Note: the difference of 10 h can be modifi ed. The parameter is called “Time Diff.” and is displayed on

the same screen as the “Burner rotation” only if one of the two rotation modes is enabled.

22

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

6. CONFIGURATION PARAMETERS

6.1 Reading and setting the confi guration parameters - “USER”

submenu

The confi guration parameters are used to set the operating modes of the controller, that is, assign the

essential functions of the humidifi er.

These parameters are normally managed by the installer or the service personnel, and therefore a

password is required to access the screens that contain these parameters.

To access these screens, the sequence is:

• press “PRG”;

• enter the “user” submenu;

• when the “User Password” is requested, enter the number “77”.

To change the parameters in the same screen, proceed as follows:

• press “ENTER” to position the cursor on the desired parameter;

• press “UP” or “DOWN” to change the value;

• press “ENTER” to confi rm and access the next parameter.

The type and meaning of these parameters are listed in the following paragraphs.

6.2 Confi guring the control mode

This parameter can be used to choose between 5 different control modes, listed in the table below.

parameter name display description (for a detailed description see chap. 7)

Type of control H: Probe %rH H control (default) Humidity control with probe in the room

H: Probe %rH + Limit H control Humidity control with room probe and limit probe

P: Ext. Control P control Proportional control with signal sent by an external controller

T: Temp. Control T control Temperature control with probe in the room

C: ON/OFF C control Humidity control with humidistat

Table 7.a

7.3 Humidity control with humidistat

Humidity control with humidistat.

parameter name display

Probe type

(not accessible in C control mode: ON/OFF)

0 to 1V (default)

0 to 10V

2 to 10V

0 to 20mA

4 to 20mA

NTC

0 to 135 ohm

Table 7.b

7.4 Unit of measure

Select the unit of measure, between metric and imperial.

parameter name display

Unit of measure °C-kg/h (default)

°F - lb/hr

Tab. 7.c

7.5 Confi guring the ambient humidity (or temperature) probe

This is used to set the minimum value, maximum value and the offset for the probe used in the room.

screen name parameter name range default accessibility UOM

H control T control

Confi g. Amb. Probe (not accessible in C control

mode: ON/OFF)

Min. 0 to (Max. ) 0.0 %rH °C

Max. (Min) to 100 100.0 %rH °C

Offset -10.0 to 10.0 0.0 %rH °C (or °F)

Table 7.d

NOTE for T control: the setting of the minimum and the maximum values for the probe is only in

degrees centigrade.

The offset, on the other hand, being linked to the difference between the reading made by the probe

and by a reference thermometer, depends on which unit of measure has been selected.

For example, if having selected imperial measurements: if based on the measurements made it is clear

that the value read by the probe is normally 2°F higher than the reading made by a reference

thermometer, to correct the error set the offset to -2.0°F).

23

Burners rotation:

NO ROTATION

Autotest: NO

Fig. 6.a

Burners rotation:

NO ROTATION

Autotest: YES

Fig. 6.b

Softened water

NO (normal/demin.)

Forced drains 2

- Press ALARM -

Fig. 6.c

Insert calorific

power:

37.9x1000 Kj/m3

- Press Alarm -

Blower speed

Pre-purge 3450RPM

Manual 3000RPM

Fig. 6.d

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

6.6 Confi guring the limit humidity probe

This is used to set the minimum value, maximum value and the offset for the limit probe.

screen name parameter name range default UOM

Confi g. Limit Probe (accessible only in H control mode with

outlet limit)

Type 0 to 1 V 0 to 1 V

0 to 10 V, 2 to 10 V, 0 to 20 mA, 4 to 20 mA, NTC

Min. 0 to (Max.) 0.0 %rH

Max. (Min) to 255 100.0 %rH

Offset -10.0 to 10.0 0.0 %rH

Table 6.e

6.7 Initial auto-test

This is an automatic procedure used to check the correct status of the fi ll valve and the drain pump and

the correct operation of the fl oat present in the level sensor.

• the boiler is fi lled until reaching the highest level of the level sensor;

• after which a drain cycle is performed until reaching the lowest level of the level sensor.

All this takes place without igniting the burners.

The auto-test must fi rst be enabled.

To enable/disable the auto-test procedure, go to the “USER” submenu, enter the password “77” and go

to the screen shown in Fig. 7.a.

Move the cursor to “Auto-test” and use the UP/DOWN arrows to set “YES”.

NOTE: The auto-test is only performed if the humidifi er is enabled for production, “Humid.

Enabled=Yes” and if the controller is enabled from the keypad This function is useful for service or when

fi rst starting the appliance.

IMPORTANT: In these conditions, the auto-test occurs whenever the controller is switched off an on

again. To avoid the auto-test being performed whenever the controller is switched on, it is recommended to disable the function.

6.7.1 End Autotest: softened water mode

At the end of the autotest the screen shown to the side is displayed, used to enable/disable operation

with softened water and set the number of evaporation cycles between two drain for dilution cycles.

• pressing “ALARM” confi rms the settings displayed and exits the screen;

• pressing “ENTER” positions the cursor in the fi eld that is used to enable or disable the mode, by

pressing the “UP” or “DOWN” buttons;

• pressing “ENTER” again moves to the fi eld for setting the number of cycles, “UP” and “DOWN” change

the value.

• pressing “ENTER” again and then “ALARM” confi rms the values set and exits the screen.

IMPORTANT: The value set by default for the number of evaporation cycles between two drain cycles

(Force drain cycles) is the value recommended by the manufacturer.

To change this setting without causing operating problems, contact qualifi ed personnel.

6.7.2 End Autotest: setting the heat value of the supply gas

After exiting the “Softened water” screen, the screen shown to the side is displayed, (Fig. 7.c) which

prompts the user to set or confi rm the HHV of the supply gas in Kj/m3. This option is required as the

value varies considerably between the geographical regions where the humidifi er is installed. The heat

value is provided by the gas company.

• pressing “ALARM” confi rms the value displayed and exits the screen;

• pressing “ENTER” allows the value to be set using the “UP” and “DOWN” buttons;

• pressing “ENTER” again confi rms the value set and then pressing “ALARM” exits the screen.

IMPORTANT: The value set determines the correct operation of the humidifi er. Contact qualifi ed

personnel before changing it.

6.8 Setting the pre-purge speed and calibrating the fan speed

NOTE: These operations must be carried out by qualifi ed personnel.

The pre-purge speed is indicated in “RPM” and is normally set by the manufacturer based on the

characteristics of the combustion system and the gas.

To modify this parameter, go to the following screen and change the “Pre-purge” parameter.

During service, it may also be useful to check if the fan speed measured with a stroboscope coincides

with the speed set via SW. The “Manual” parameter can be used to force a desired speed for performing

the test.

24

Pre-heating:

DISABLED

Set PreHeat: 80.0 °C

Fig. 7.e

Pre-heating:

TEMP. +%rH

Set PreHeat: 80.0 °C

Fig. 6.f

100%

24

Max Prod

hyst hyst

1

ON

OFF

3

100%

Max Prod

diff hyst

ON

OFF

Set Prerisc

hy

11

33

24

Fig. 6.g

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

6.9 Water supply with REVERSE OSMOSIS system

The gaSteam is a humidifi er suitable for operation on demineralised water, which reduces the phenomena of saline deposits and fouling inside the boiler and on the walls of the exchangers.

In this regard, the water pipe can be connected to a reverse osmosis system for demineralising the water.

The rated water fl ow to the installation must be equal to the fl ow-rate of the solenoid valve fi tted.

6.10 Setting the maximum ratio between the water fi lled and the

water drained for dilution

During normal operation, the gaSteam periodically performs drain cycles, called drain “for dilution”,

followed by refi lling with supply water. These drain cycles have the fundamental task of reducing the

high conductivity of the water inside the boiler due to the continuous concentration of salts during the

repeated fi ll/evaporation cycles.

The control logic calculates how many fi ll/evaporation cycles must be completed before performing

the dilution, based on the conductivity of the supply water. Normally, if the supply water is not very

conductive, the drain cycles for dilution are performed less frequently. With this type of water, therefore,

the number of fi lls between two successive drain cycles for dilution can be very high.

This number therefore needs to be limited.

To do this, use the “Max ratio fi ll/drain” parameter, under the screen seen in the previous paragraph.

The default value is 10.

6.11 Preheating

The preheating function is used to keep the water above a temperature set by the user when no steam is

requested. Preheating thus speeds up the return to the steam production when next requested.

There are three options:

1. Preheating disabled;

2. Preheating enabled: operation by temperature + restriction on %rH

In the classic mode, preheating is controlled depending on the water temperature and is activated

according to the value read by the humidity (in H control) or temperature probes (in T control) or the

signal applied (in P control). This is enabled by setting “TEMP. + %rH” for the preheating options present

in the screen shown in Fig. 7.f.

Preheating is activated depending on the humidity value measured by the probe and by the operating

mode set.

In C mode (ON/OFF), preheating is never activated.

In P mode (proportional), preheating is activated and deactivated depending on the signal applied to the

room probe input.

By default, preheating is activated when the signal applied exceeds 3%, while it is deactivated when it

falls below 1% (see Fig. 7.g).

In humidity control mode preheating is activated when the relative humidity falls below the “humidity

set point + preheating offset - hysteresis” and is deactivated when it rises above the “humidity set point

+ preheating offset” (see Fig. 7.g).

The values of the preheating offset and hysteresis parameters can be changed from the default values.

These must be as follows:

Preheating offset: Range= 2.0 - 20.0 [°C] ; Default= 3.0 [°C]

Hysteresis: Range= 2.0 - 5.0 [°C] ; Default= 2.0 [°C]

Graph of Proportional Mode Graphic of Control Mode

Key

1 production %

2 signal applied to probe 1 input

3 preheating

4 probe rH1

25

Hyst= 2,5 °C

100

bD

hyst

1

2

3

4

Fig. 6.h

Set Nofrost

7 °C

Max Prod

Min Prod

diff. 3 °C

hyst= 5 °C

1

2

Fig. 6.i

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

Once preheating is activated, the heating is modulated by the systems (burners + fans) depending on

the water temperature measured by the NTC probe and the “preheating set point” (see Fig. 7.h).

The preheating set point temperature is a parameter with a range 70T-90°C and a default equal to 80°C.

Key

1 Reference % for the burner

2 temperature

3 Fixed differential of 20°C

4 preheating temperature (def.: 80°C)

3) Preheating enabled: operation with temperature control only

In this case, preheating is always enabled, that is, it is not activated depending on the humidity value or

the temperature measured by the external probe.

The reference for the combustion systems only depends on the water temperature measured by the

NTC probe and by the preheating set point, as illustrated in the previous graph.

This option is enabled by choosing the “ONLY TEMPERATURE” option in the previous screen (Fig. 7.f).

6.11.1 Preheating on request

Setting preheating to “ON REQUEST”, that is, whenever a humidity request causes the burner to ignite,

means that the temperature of the water inside the boiler is checked, and if this is lower than the set

value, the humidifi er will heat the water to this value before actually responding to the request. In this

way, even with quite moderate requests and with cold water, steam production will start relatively

quickly.

6.12 Antifreeze

The antifreeze option can be very useful in applications that feature the installation of the gaSteam

outdoors, especially in colder countries where there is the real risk that, if no steam is requested, the

water inside the boiler might freeze.

For this reason, an option that can be enabled by the user

has been added that starts heating the water if

the temperature measured by the NTC probe is too low.

The humidifi er must be activated and continuously connected to the power and gas supplies, excluding

any interruptions.

The antifreeze function acts as displayed in the following graph.

Key

1 reference % for the burner

2 NTC temperature

6.13 Reversing the logic of the alarm relay

Normally, the alarms that stop the humidifi er energise the coil in the alarm relay.

This logic can be reversed, so that the coil remains energised when no alarm is present, and is de-energised when an alarm is activated.

To do this, set the following parameter:

screen name parameter name range default

Options Al. Relay ENERGISED ENERGISED

NOT ENERGISED

Table 6.f

26

%rH

Dehum Set

Dehumid

ON

OFF

Dehumid Diff.

Fig. 6.j

Control Params

DeHum. set 100.0%

DeHum.diff. 5.0%

Fig. 6.k

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

6.14 Options

Drain due to inactivity

The drain due to inactivity is used to completely empty the water from the humidifi er if the cylinder does

not produce steam for a period set by parameter, which by default is 3 days.

By default, the drain due to inactivity is enabled.

It can be disabled by setting the parameter in the following table.

screen name parameter name range default

Options Drain for inactivity Y,N Y

Table 6.g

In addition, the value of the parameter relating to the period of inactivity can be changed, available by

scrolling the screens.

The parameter is:

screen name parameter name range default UOM

Options Days of inactivity 1 to 199 3 d (days)

Table 6.h

Warn when exceeding maintenance hour limit

The gaSteam features a limit to the number of operating hours of the humidifi er, beyond which it is

recommended to perform maintenance (see the par. on MAINTENANCE).

In this case, a “maintenance request” alarm is sent.

Nonetheless, this alarm can be disabled, by setting the “Maint. warning” parameter to “N”.

screen name range default UOM

Maint. warning Y, N Y h (hours)

Table 6.i

Dehumidifi cation

The dehumidifi cation function is only possible if terminals 13U - 14U on terminal block U are connected

electrically to a dehumidifi er (see par. 3.2).

By default, dehumidifi cation is not enabled.

During normal operation, dehumidifi cation may occur only if the following conditions are satisfi ed:

1. the dehumidifi cation option is enabled;

2. the ambient humidity probe is connected;

3. the humidifi er has not been disabled by “Remote ON/OFF”;

If these conditions are satisfi ed, the dehumidifi cation process is activated depending on the humidity

measured, based on the “dehumidifi cation set point” and “dehumidifi cation differential” parameters, as

shown in the graph to the side.

To activate the dehumidifi cation function, the following parameter needs to be enabled:

screen name parameter name range default

Options Dehumidify Y, N N

Table 6.j

Once dehumidifi cation has been enabled, the “set point” and “differential” parameters can be modifi ed.

To do this, go to the following screen, under the “SET” submenu.

The characteristics of these parameters are listed below:

screen name parameter name range default UOM

Control Param DeHumid. set (humidity set point) to 100.0 100.0 %

DeHumid.diff. 2.0 to 19.9 5.0 %

Table 6.k

Manually set the conductivity of the supply water and set the conductivity alarm thresholds

The conductivity of the supply water, as well as normally being monitored to prevent excessively conductive water from entering (“High conductivity alarms” - see “Alarms”), is also useful for determining the

limit of fi ll/evaporation cycles between two drain cycles for dilution.

As the conductivity of the water is directly responsible for the accumulation of salts inside the boiler.

To change these two limits, set a parameter that, if not equal to zero, takes the place of the conductivity

read by the conductivity meter. The lower this parameter, the higher the limit values described above. By

default the parameter is set to zero.

The limit values for the high conductivity warning and alarm can also be set on the same screen.

The screen has the following characteristics:

screen name parameter name range default UOM

Conductivity Forced (B4) 0 to 2000 (*) 0 uS/cm

Pre-Al (B5) 0 to (B6) 1000 uS/cm

Alarm (B6) (B5) to 2000 1250 uS/cm

Table 7.l

(*): supply water conductivity:

• b4= 0: the controller uses the conductivity measured automatically by the conductivity meter;

• b4= 1 to 4: the value set corresponds to the number of evaporation cycles between two drain for dilution

cycles: each “b4” evaporation cycles one drain to dilute cycle is performed;

• b4> 4: the controller uses the value of b4 as the conductivity and IGNORES the value measured by the

conductivity meter.

Note: to the side of the above parameters there may be the codes B4, B5 and B6, which indicate the

name of the parameter that was normally used with the gaSteam 40, 45 and 90.

27

Options

Time (b9)

Min.Pr.-100 0min

Fig. 6.l

Blower speed

for produuction:

Min.: 1800RPM

Nominal: 5150RPM

Fig. 6.m

Burner minimum

production: 25%

Fig. 6.n

Mostra masch.lingua

allo start-up? Y

Abilita supervisore

on-off? N

Fig. 6.o

ENGLISH

gaSteam pHC CONTROL +030220534 - rel. 1.2 - 15.05.2006

6.15 Setting the production ramp

During operation, the steam request may change depending on the readings of the probes or the signal

from the external controller.

The speed at which the humidifi er shifts to the new request can be slowed down by setting the parameter (formerly parameter b9 in the old gaSteam models 40, 45, 90) that is located in the screen shown to

the side.