EVD ice

Superheat control

for unipolar electronic expansion valve

User manual

High Efficiency Solutions

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

ENG

WARNINGS

CAREL bases the development of its products on decades of experience

in HVAC, on the continuous investments in technological innovations

to products, procedures and strict quality processes with in-circuit and

functional testing on 100% of its products, and on the most innovative

production technology available on the market. CAREL and its subsidiaries

nonetheless cannot guarantee that all the aspects of the product and the

software included with the product respond to the requirements of the nal

application, despite the product being developed according to start-of-theart techniques. The customer (manufacturer, developer or installer of the nal

equipment) accepts all liability and risk relating to the conguration of the

product in order to reach the expected results in relation to the specic nal

installation and/or equipment. CAREL may, based on specic agreements, acts

as a consultant for the positive commissioning of the nal unit/application,

however in no case does it accept liability for the correct operation of the nal

equipment/system.

The CAREL product is a state-of-the-art product, whose operation is specied

in the technical documentation supplied with the product or can be

downloaded, even prior to purchase, from the website www.carel.com.

Each CAREL product, in relation to its advanced level of technology, requires

setup/conguration/programming/commissioning to be able to operate in

the best possible way for the specic application. The failure to complete such

operations, which are required/indicated in the user manual, may cause the

nal product to malfunction; CAREL accepts no liability in such cases.

Only qualied personnel may install or carry out technical service on the

product.

The customer must only use the product in the manner described in the

documentation relating to the product.

In addition to observing any further warnings described in this manual, the

following warnings must be heeded for all CAREL products:

• prevent the electronic circuits from getting wet. Rain, humidity and all

types of liquids or condensate contain corrosive minerals that may damage

the electronic circuits. In any case, the product should be used or stored

in environments that comply with the temperature and humidity limits

specied in the manual;

• do not install the device in particularly hot environments. Too high

temperatures may reduce the life of electronic devices, damage them and

deform or melt the plastic parts. In any case, the product should be used

or stored in environments that comply with the temperature and humidity

limits specied in the manual;

• do not attempt to open the device in any way other than described in the

manual;

• do not drop, hit or shake the device, as the internal circuits and mechanisms

may be irreparably damaged;

• do not use corrosive chemicals, solvents or aggressive detergents to clean

the device;

• do not use the product for applications other than those specied in the

technical manual.

DISPOSAL

INFORMATION FOR USERS ON THE CORRECT

HANDLING OF WASTE ELECTRICAL AND ELEC-

TRONIC EQUIPMENT (WEEE)

In reference to European Union directive 2002/96/EC issued on 27 January

2003 and the related national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and such waste must be

collected and disposed of separately;

2. the public or private waste collection systems dened by local legislation must

be used. In addition, the equipment can be returned to the distributor at

the end of its working life when buying new equipment;

3. the equipment may contain hazardous substances: the improper use or

incorrect disposal of such may have negative eects on human health

and on the environment;

4. the symbol (crossed-out wheeled bin) shown on the product or on the

packaging and on the instruction sheet indicates that the equipment has

been introduced onto the market after 13 August 2005 and that it must

be disposed of separately;

5. in the event of illegal disposal of electrical and electronic waste, the penalties

are specied by local waste disposal legislation.

Warranty on the materials: 2 years (from the date of production, excluding

consumables).

Approval: the quality and safety of CAREL INDUSTRIES products are

guaranteed by the ISO 9001 certied design and production system, as well

as by the marks (*).

All of the above suggestions likewise apply to the controllers, serial boards,

programming keys or any other accessory in the CAREL product portfolio.

CAREL adopts a policy of continual development. Consequently, CAREL

reserves the right to make changes and improvements to any product

described in this document without prior warning.

The technical specications shown in the manual may be changed without

prior warning.

The liability of CAREL in relation to its products is specied in the CAREL general

contract conditions, available on the website www.carel.com and/or by

specic agreements with customers; specically, to the extent where allowed

by applicable legislation, in no case will CAREL, its employees or subsidiaries

be liable for any lost earnings or sales, losses of data and information, costs of

replacement goods or services, damage to things or people, downtime or any

direct, indirect, incidental, actual, punitive, exemplary, special or consequential

damage of any kind whatsoever, whether contractual, extra-contractual or

due to negligence, or any other liabilities deriving from the installation, use or

impossibility to use the product, even if CAREL or its subsidiaries are warned

of the possibility of such damage.

CAUTION: separate as much as possible the probe and digital input signal

cables from the cables carrying inductive loads and power cables to avoid

possible electromagnetic disturbance.

Never run power cables (including the electrical panel wiring) and signal

cables in the same conduits.

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

3

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

Content

1. INTRODUCTION 7

1.1 Models ............................................................................................................ 7

1.2 Functions and main characteristics ............................................................. 7

1.3 Accessories ....................................................................................................... 7

2. INSTALLATION 8

2.1 Dimensions - mm (in) ................................................................................... 8

2.2 Assembly on the evaporator ........................................................................ 8

2.3 Application diagrams ...................................................................................... 9

2.4 Wiring description ......................................................................................... 10

2.5 Wiring .............................................................................................................. 10

3. USER INTERFACE 11

3.1 Keypad.............................................................................................................11

3.2 Display and visualisation ............................................................................ 11

3.3 Programming mode ..................................................................................... 11

3.4 Restore default parameters (factory) ........................................................ 11

ENG

4. COMMISSIONING 12

4.1 Commissioning procedure ......................................................................... 12

4.2 Parameters first configuration .................................................................... 12

5. FUNCTIONS 13

5.1 Control ............................................................................................................. 13

5.2 Special control function: smooth lines ..................................................... 14

5.3 Service parameters ....................................................................................... 14

6. PROTECTORS 15

6.1 Protectors ........................................................................................................ 15

7. PARAMETERS TABLE 17

8. NETWORK CONNECTION 18

8.1 RS485 serial configuration .......................................................................... 18

8.2 Network connection for commissioning via PC .................................... 18

8.3 Visual parameter manager .......................................................................... 18

8.4 Restore default parameters ......................................................................... 19

8.5 Setup by direct copy ..................................................................................... 19

8.6 Setup using configuration file .................................................................... 20

8.7 Read the configuration file on the controller ........................................ 20

8.8 Variables accessible via serial connection .............................................. 21

8.9 Control states ................................................................................................. 22

8.10 Special control states .................................................................................... 23

9. ALARMS 24

9.1 Types of alarms ..............................................................................................24

9.2 Probe alarms .................................................................................................. 24

9.3 Control alarms ............................................................................................... 24

9.4 Valve emergency closing procedure .........................................................24

9.5 Network alarm ............................................................................................... 24

9.6 Alarm table .................................................................................................... 25

10. TROUBLESHOOTING 25

11. TECHNICAL SPECIFICATIONS 26

5

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

1. INTRODUCTION

ENG

EVD ice is an electronic superheat controller for Carel unipolar expansion

valves. EVD ice has been specially designed to be installed near the valve,

directly on the refrigerant circuit, simplifying installation and making

electronic expansion valve technology available directly on board the

unit.

The plastic cover material on EVD ice guarantees total protection,

allowing the controller to operate in particularly dicult environmental

conditions, such as low temperatures and high humidity (condensation).

EVD ice can be installed directly on a unit cooler/evaporator inside a cold

room.

The controller is already tted with sensors, signal and power cables:

to complete the system, simply select the most suitable valve body

and pressure transducer for the required cooling capacity from the

compatible Carel product range.

EVD ice controls refrigerant superheat and optimises refrigerant circuit

eciency. It allows considerable system exibility, being compatible

with various types of refrigerants, in applications with refrigerators and

chiller/air-conditioners. It features low superheat protection (LowSH),

high evaporation pressure (MOP) and low evaporation pressure (LOP)

functions.

The device also has a user interface that displays the instant superheat

value at all times, signals any alarms, and above all can be used to set the

operating parameters.

When installing the controller, only three initial parameters are required

to start controlling the valve in the system:

- type of refrigerant

- operating mode (cold room, showcase, etc.)

- superheat set point.

EVD ice can easily be accessed via an RS485 serial connection (Modbus

protocol), for supervision of operating parameters and alarms in real time.

The serial connection can also be used to set the operating parameters

over a remote connection; in this case, combination with other Carel

controllers is recommended (supervisors and cold room controllers).

1.3 Accessories

Ratiometric pressure probe P/N SPKT0013P0 (-1 to 9.3 bars)

The ratiometric pressure probe specied as default for assembly is P/N

SPKT0013P0, with an operating range from -1 to 9.3 barg. Alternatively,

other probes can be installed, setting the corresponding parameter

accordingly. See the “Functions” chapter.

Fig. 1.a

1 2

P/N Type Photo nr.

SPKT0053P0 -1…4.2 barg 1

SPKT0013P0 -1…9.3 barg

SPKT0043P0 0…17.3 barg

SPKT0033P0 0…34.5 barg

SPKT00B6P0 0…45 barg

SPKT00E3P0 -1…12.8 barg

SPKT00F3P0 0…20.7 barg

SPKT00G1S0 0…60 barg 2

SPKT00L1S0 0…90 barg

Tab. 1.b

Unipolar valve body

The valve body, to be purchased separately, is assembled using the stator

supplied with EVD ice. For the part numbers, see the CAREL product

catalogue.

1.1 Models

P/N Description

EVDM011R3* EVD ice 115/230 V, E2V stator, display

EVDM011R1* EVD ice 115/230 V, E2V stator, display, Ultracap module

connector

EVDM011R4* EVD ice 115/230 V, E3V stator, display

EVDM011R2* EVD ice 115/230 V, E3V stator, display, Ultracap module

connector

(*): 0/1=single/multiple package (10 pcs)

Tab. 1.a

1.2 Functions and main characteristics

In summary:

• superheat control with LowSH, MOP, LOP functions;

• compatibility with various types of refrigerants;

• guided setup procedures rst, entering just three parameters on the

user interface: refrigerant (Gas), type of control (Mode) and superheat

set point (Superheat);

• activation/deactivation of control via digital input or remote control

via serial connection;

• controller and valve power supply incorporated (230 V/115 V);

• RS485 serial communication incorporated (Modbus protocol);

• IP65/IP67;

• operating conditions: -30T40C° (-22T104°F);

• compatible with Carel E2V and E3V single-pole valves.

Fig. 1.b

Ultracap module (P/N EVDMU**R**)

The module guarantees temporary power to the driver in the event of

power failures, for enough time to immediately close the connected

electronic valve. It avoids the need to install a solenoid valve. The module

is made using Ultracap storage capacitors, which ensure reliability in

terms of much longer component life than a module made with lead

batteries.

Fig. 1.c

From the software revision 1.7 the Smooth lines function has been

introduced.

7

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

ENG

79.4 (3.1)

92.4 (3.6)

∅

4.5 (0.2)

170 (6.7)

45.5 (1.8)

61.3 (2.4)

40.7(1.6)

19.6 (0.8)

~230 (9.1)

GAS Type

Mode

Super Heat

2.1 Dimensions - mm (in)

2. INSTALLATION

Cable (*) Length (±5%)

Power supply 500 (19.7)

RS485 500 (19.7)

Pressure probe 800 (31.5) --> E2V

1800 (70.9) --> E3V

NTC probe 1800 (70.9)

E2V/ E3V valve 600 (23.6)

Ultracap 100 (3.9)

Fig. 2.a

2.2 Assembly on the evaporator

Important:

• install EVD ice on the evaporator away from the places where

ice forms;

• connect the power and serial cables in the IP65 junction box;

• for assembly of the E2V/ E3V valve, see the “ ExV system” guide

(+030220810).

Condenser

Liquid

separator

Filter

Liquid

indicator

M

Solenoid

valve

E2V/ E3V Unipolar

expansion valve

EVD ice

Compressor

P T

(*)= for standard CAREL part numbers

EVD ice can be installed directly on the evaporator. Mark the position and

drill the holes (Ø <4.5 mm). Then tighten the fastening screws.

Fig. 2.c

WALL

NTC temp. probe

Ratiometric pressure transducer

Evaporator unit

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

Evaporator

Fig. 2.b

8

2.3 Application diagrams

WITH SOLENOID VALVE

ENG

N

L

ON / OFF

COLD ROOM

Electrical panel

Regulator

OUT

Solenoid

valve

M

COLD ROOM

IN

Evaporator

Evaporator

unit

EEV

P T

IP65

230 V input

EVD ICE

driver

230 V

N

L

COLD ROOM

OUT

Condenser

Condenser

unit

Compressor

WITHOUT SOLENOID VALVE, WITH ULTRACAP MODULE

COLD ROOM

OUT

Electrical panel

Regulator

ON / OFF

L

Fig. 2.d

COLD ROOM

Evaporator

IN

Evaporator

unit

EEV

P T

IP65

230 V input

EVD ICE

driver

230 V

L

N

EVD ICE

ULTRACAP

COLD ROOM

OUT

Condenser

Condenser

unit

N

Compressor

Fig. 2.e

9

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

ENG

digital input to start

the regulation

230 Vac

2.4 Wiring description

The driver for superheat control requires the use of an evaporation pressure

probe S1 and suction temperature probe S2, which will be tted downstream

of the evaporator, and a digital input to trigger control. Alternatively, the signal

to trigger control can be sent via a remote serial connection.

Note: input S1 is programmable. See the “Functions” chapter

The following are already wired on EVD ice:

• pressure probe and temperature probe cables;

• electronic expansion valve stator;

• Ultracap module connection cable (on models where featured);

• power and serial line cables.

The power and serial line connections are identied by the colours of

the wires.

Note: for probe installation see “Guide to EEV system”, (+03022811).

B

CAREL E V/ E V

² ³

unipolar valve

0,3 Nm

Non rimuovere

il cappuccio

di protezione A!

Do not remove

the protection cap A!

Valve stator

ULTRACAP

Module

C

NTC

A

S2

S1

GAS Type

Mode

Super Heat

A

ratiometric

pressure

transducer

D

pasta conduttiva/ conductive cream

fascetta di ssaggio/ fastening band

fascia elastica/ elastic band

EF

Fig. 0.a

marrone/ brown - L

blu/ blue - N

nero/ black - DI

Tab. 0.a

verde/ green - GND

bianco/ white - Tx/Rx+

nero/ black - Tx/Rx-

PC

1

VPM

CVSTDUM0R0

pCO

Modbus®

RS485

2

shield shield

Rif Cable Description

A ExV Unipolar electronic valve connection

B Ultracap Ultracap module connection (accessory)

C Probe S2 NTC temperature probe

D probe S1 Ratiometric pressure probe

E Power supply

L: brown Phase 230 V

N: blue Neutral 230 V

DI: black 230 V digital input to enable control

F Serial

Tx/ Rx +: white RS485 connection

Tx/ Rx -: black

GND: green

1 - Computer for conguration

2 - USB– RS485 converter (for computer)

2.5 Wiring

For installation, proceed as shown below, with reference to the wiring

diagrams and the technical specications table:

1. connect the pressure probe that suits the refrigerant. For details on

refrigerant ---> suggested pressure probe, see the chapter on

“Commissioning”;

2. connect the power cable and the digital input cable: for the maximum

length, see the technical specications;

3. power on the driver: the display will light up, and the driver will await the

commissioning parameters. See the chapter on “Commissioning”;

4. program the driver, if necessary: see the “User interface” chapter.

Note: if connecting to a serial network, see the previous diagram for

details on connecting the shield to earth.

Installation environment

Important: avoid installing the drivers in environments with the

following characteristics:

• strong vibrations or knocks;

• exposure to aggressive and polluting atmospheres (e.g.: sulphur

and ammonia fumes, saline mist, smoke) to avoid corrosion and/or

oxidation;

• strong magnetic and/or radio frequency interference (therefore avoid

installing the devices near transmitting antennae);

• exposure of the drivers to direct sunlight and to the elements in

general.

Important: the following warnings must be observed when

connecting the drivers:

• if the driver is used in a way that is not specied in this user manual,

protection cannot be guaranteed;

• incorrect power connections may seriously damage the driver;

• separate as much as possible (at least 3 cm) the probe and digital input

cables from cables to electrical loads, to avoid possible electromagnetic

disturbance. Never run power cables (including the electrical panel

cables) and probe signal cables in the same conduits;

• do not run probe signal cables in the immediate vicinity of power

devices (contactors, circuit breakers, etc.). Reduce the path of probe

cables as much as possible, and avoid spiral paths that enclose power

devices;

• *EVD ice is a controller to be incorporated into the nal equipment; it

must not be wall-mounted;

• * DIN VDE 0100: protective separation must be guaranteed between

the SELV circuits (Safety Extra Low Voltage) and the other circuits. The

requirements of DIN VDE 0100 must be complied with. To prevent

disruption of the protective separation (between the SELV circuits and

the other circuits) ensure additional fastening near the terminations.

This additional fastening must secure the insulation and not the wires.

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

10

3. USER INTERFACE

-99 --->

ENG

The user interface comprises the two-digit display and keypad with three

buttons that, pressed alone or in combination, are used to perform all the

conguration and programming operations on the driver.

2

GAS Type

Super Heat

1 2

3

1

Mode

4

Fig. 3.a

Key

1 Parameter label (for commissioning/setup)

2 Keypad

3 LED status digital input start/stop control

4 Two-digit display

blink/OFF = DI closed/open

(*) when digital input is closed the LED blinks and control is active.

During commissioning/setup, the parameter label shows the meaning

of the segments displayed in the rst digit, corresponding to the three

parameters being set:

A. GAS Type: type of refrigerant;

B. Mode: operating mode;

C. Superheat: superheat set point.

Commissioning

See the “

GAS Type

Mode

Super Heat

A. Refrigerant B. Mode (operating mode) C. Superheat set point

” chapter.

GAS Type

Mode

Super Heat

GAS Type

Mode

Super Heat

3.1 Keypad

Key Description

UP / DOWN

PRG/Set

• Increases/decreases the value of the set point or

other selected parameter

• At the end of the commissioning procedure, if

pressed for 2 s, exits the menu and control starts;

• Enter/ exit programming mode, saving the

parameters;

• Reset E8 alarm.

Tab. 2.a

123 --->

GAS Type

Mode

Super Heat

GAS Type

Mode

Super Heat

GAS Type

Mode

Super Heat

GAS Type

Mode

Super Heat

Fig. 3.b

Note: the decimal point in the digit on the right indicates the status

of the digital start/stop adjustment input. With the input closed the dot

is lit ashing.

3.3 Programming mode

The parameters can be modied using the front keypad.

Important: modify the control parameters, ONLY AFTER having

completed the guided commissioning procedure, described in chapter 4.

Modifying the Service parameters

The Service parameters include, in addition to the parameters for the

conguration of input S1, those corresponding to the network address,

probe readings, protectors and manual positioning. See the parameter

table.

Procedure:

1. press UP and DOWN together and hold for more than 5 s: the rst

parameter is displayed: P1 = probe S1 reading;

2. press UP/ DOWN until reaching the desired parameter;

3. press PRG/ Set to display the value;

4. press UP/ DOWN to modify the value;

5. press PRG/ Set to conrm and return to the parameter code;

6. repeat steps 2 to 5 to modify other parameters;

7. (when the parameter code is displayed) press PRG/Set and hold for more

than 2 s to exit the parameter setting procedure.

GAS Type

Mode

Super Heat

Fig. 3.c

3.2 Display and visualisation

During normal operation, the two-digit display shows the superheat

measure and any alarms.

The display interval for the superheat value is -5 to 55 K (-9 to 99 °F).

In general, values between -99 and 999 are displayed as follows:

1. values from 0 to 10 are displayed with decimal point and decimals;

2. values greater than 99 are displayed in two steps:

- rst, the hundreds, followed by “H”

- then the tens and units.

3. values less than -9 are displayed in two steps:

- rst the “-“sign;

- then the tens and units.

Note: if no button is pressed, after around 30 s the display

automatically returns to standard visualisation.

3.4 Restore default parameters (factory)

The driver can be reset to the default parameter values.

Procedure:

when the display is on standby, press all three buttons together . After

5 seconds, the display shows “rS”. The reset procedure can be conrmed

within 10 seconds, by pressing PRG/SET for 3 seconds. If no button is

pressed during this time, the procedure will be cancelled.

At the end the display shows two hyphens and then awaits the

commissioning parameters.

11

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

ENG

GAS Type

Mode

Super Heat

GAS Type

Mode

Super Heat

4. COMMISSIONING

Important: if the refrigerant is not available among the refrigerant

parameter options, contact CAREL service to:

1. conrm that the system: (c.pCO/Ultracella,...)+ EVD ice + CAREL electronic

expansion valve is compatible with the desired refrigerant (Gas

type=custom);

2. identify the values that dene the custom refrigerant and enter them for

parameters: “Dew a…f high/low” . See the variables accessible via

serial connection.

4.1 Commissioning procedure

Once the electrical connections have been completed (see the chapter

“Installation”) and the power supply has been connected, the operations

required for commissioning the driver depend on the type of interface

used, however essentially involve setting just 3 parameters: refrigerant,

functioning mode, superheat setpoint.

5. Press Down to move to the next parameter: Mode, indicated by the

bar in the middle;

6. Repeat steps 2,3,4,5, to set the values of the other parameters: Mode,

Superheat set point;

GAS Type

Mode

Important:

• until the commissioning procedure has been completed, control

will not be active;

• (only during commissioning) changing the gas involves changing

the value of the ratiometric probe parameter.

After powering up the driver, the display lights and the driver waits the

control parameters, indicated by the hyphens. The default parameters

are:

1. Refrigerant = R404A;

2. Type of control = multiplexed showcase/cold room

3. Superheat set point = 11 K.

Procedure:

1. The controller displays the bar at the top: refrigerant (GAS Type);

GAS Type

Mode

Super Heat

2. Press PRG/Set: the refrigerant setting is shown = 3: R404A

GAS Type

Mode

Super Heat

Super Heat

7. Press PRG/Set for 2 seconds to exit the commissioning procedure

and start control. The standard display is shown.

4.2 Parameters rst conguration

Important: ONLY DURING commissioning, changing the gas

involves changing the value of the ratiometric probe parameter; if not

specied in the table, the type of ratiometric probe is -1...9.3 barg.

Parameter/ description Def.

Gas Type = refrigerant

0 Custom

1 R22 15 R422D 28 R1234ze(-1...4.2 barg)

2 R134a 16 R413A 29 R455A (-1...12.8 barg)

3 R404A 17 R422A 30 R170 (0...17.3 barg)

4 R407C 18 R423A 31 R442A (-1...12.8 barg)

5 R410A 19 R407A 32 R447A (-1...12.8 barg)

6 R507A 20 R427A 33 R448A

7 R290 21 R245FA 34 R449A

8 R600(-1...4.2 barg) 22 R407F 35 R450A (-1...4.2 barg)

9 R600a (-1...4.2 barg) 23 R32 (0...17.3 barg) 36 R452A (-1...12.8 barg)

10 R717 24 HTR01 37 R508B (-1...4.2 barg)

11 R744 (0...45 barg) 25 HTR02 38 R452B

12 R728 26 R23 39 R513A (-1...4.2 barg)

13 R1270 27 R1234yf 40 R454B

14 R417A 41 R458A

Note: if the refrigerant is not available among the refrigerant

options, “GAS Type=refrigerant”:

1. set any refrigerant (for example R404);

2. select the type of operating mode (Mode), the superheat set point

and complete the commissioning procedure;

3. use the VPM program (Visual Parameter Manager, see the chapter

“Network connection” ) and set the refrigerant type “0= Custom” and

the parameters “Dew a...f high/low” which dene the refrigerant (see

variables accessible via serial connection);

4. start control, for example by closing the digital input contact to

enable operation.

3 =

R404A

Tab. 4.a

3. Press UP/Down to change the value

GAS Type

Mode

Super Heat

4. Press PRG/Set to save and return to the refrigerant parameter code

(bar at the top)

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

Mode = operating mode

1 Multiplexed cabinet/cold room

2 Air-conditioner/chiller with plate heat exchanger

3 Air-conditioner/chiller with tube bundle heat exchanger

4 Air-conditioner/chiller with nned coil heat exchanger

5 Reserved

6 Reserved

7 Cabinet/cold room with subcritical (R744) CO2

Superheat setpoint 11 K(20°F)

Note: consider the unit of measure (°C/°F) when setting the

superheat setpoint (Si parameter).

12

1 = Multiplexed

cabinet/

cold room

Tab. 4.b

5. FUNCTIONS

C

5.1 Control

EVD ice is a superheat controller. The type of refrigeration unit can be

selected using the “Operating mode” parameter.

ENG

Parameter/description Def.

Operating mode

1 Multiplexed cabinet/cold room

2 Air-conditioner/chiller with plate heat exchanger

3 Air-conditioner/chiller with tube bundle heat exchanger

4 Air-conditioner/chiller with nned coil heat exchanger

5 Reserved

6 Reserved

7 Banco frigo/cella con CO2 (R744) sub-critica

1 = multiplexed cabinet/

cold room

Tab. 5.a

Based on the operating mode setting , the driver automatically sets a

series of control parameters.

Operating mode PID: pro-

port. gain

1 Multiplexed cabinet/cold room 15 150 11 5 15 -50 0 50 20

2 Air-conditioner/chiller with plate heat exchanger 3 40 6 2 2,5 -50 4 50 10

3 Air-conditioner/chiller with tube bundle heat exchanger 5 60 6 2 2,5 -50 4 50 10

4 Air-conditioner/chiller with nned coil heat exchanger 10 100 6 2 10 -50 10 50 20

5 Reserved - - - - - - - - 6 Reserved - - - - - - - - 7 Banco frigo/cella con CO2 (R744) sub-critica

PID: integra-

tion time

20 400 13 7 15 -50 0 50 20

Superheat

set point

LowSH protection LOP protection MOP protection

threshold Integra-

tion time

threshold Integra-

tion time

thre-

shold

Integra-

tion time

Tab. 5.b

Superheat

The primary purpose of the electronic valve is ensure that the ow-rate

of refrigerant that ows through the nozzle corresponds to the ow-rate

required by the compressor. In this way, the evaporation process will take

place along the entire length of the evaporator and there will be no liquid

at the outlet (consequently in the branch that runs to the compressor). As

liquid is not compressible, it may cause damage to the compressor and even

breakage if the quantity is considerable and the situation lasts some time.

A low superheat temperature in fact corresponds to a situation of probable

instability due to the turbulent evaporation process approaching the

measurement point of the probes. The expansion valve must therefore

be controlled with extreme precision and a reaction capacity around

the superheat set point, which will almost always vary from 3 to 14 K.

Set point values outside of this range are quite infrequent and relate to

special applications.

Superheat control

The parameter that the control of the electronic valve is based on is

the superheat temperature, which eectively tells whether or not there

is liquid at the end of the evaporator. The superheat temperature is

calculated as the dierence between: superheated gas temperature

(measured by a temperature probe located at the end of the evaporator)

and the saturated evaporation temperature (calculated based on the

reading of a pressure transducer located at the end of the evaporator and

using the Tsat(P) conversion curve for each refrigerant).

Superheat =

(*) suction

Superheated gas

temperature

(*)

If the superheat temperature is high it means that the evaporation

process is completed well before the end of the evaporator, and therefore

ow-rate of refrigerant through the valve is insucient. This causes a

reduction in cooling eciency due to the failure to exploit part of the

evaporator. The valve must therefore be opened further. Vice-versa, if

the superheat temperature is low it means that the evaporation process

has not concluded at the end of the evaporator and a certain quantity

of liquid will still be present at the inlet to the compressor. The valve

must therefore be closed further. The operating range of the superheat

temperature is limited at the lower end: if the ow-rate through the valve

is excessive the superheat measured will be near 0 K. This indicates the

presence of liquid, even if the percentage of this relative to the gas cannot

be quantied. There is therefore un undetermined risk to the compressor

that must be avoided. Moreover, a high superheat temperature as

mentioned corresponds to an insucient ow-rate of refrigerant. The

superheat temperature must therefore always be greater than 0 K and

have a minimum stable value allowed by the valve-unit system.

Saturated evaporation

–

temperature

L

S2

S1

F

CP

S

M

E

EEV

V

P

T

Fig. 5.a

Key

CP compressor EEV electronic expansion valve

C condenser V solenoid valve

L liquid receiver E evaporator

F dewatering lter P pressure probe (transducer)

S liquid indicator T temperature probe

For the wiring, see

“Wiring description”

.

13

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

ENG

PID parameters

Superheat control uses a PID algorithm. The control output is calculated

as the sum of separate contributions: proportional and integral.

• the proportional action opens or closes the valve proportionally to

the variation in the superheat temperature. Thus the greater the K

(proportional gain) the higher the response speed of the valve. The

proportional action does not consider the superheat set point, but

rather only reacts to variations. Therefore if the superheat value does

not vary signicantly, the valve will essentially remain stationary and

the set point cannot be reached;

• the integral action is linked to time and moves the valve in proportion

to the deviation of the superheat value from the set point. The greater

the deviations, the more intense the integral action; in addition, the

lower the value of Ti (integral time), the more intense the action

will be. The integral time, in summary, represents the intensity of the

reaction of the valve, especially when the superheat value is not near

the set point.

See the “EEV system guide” +030220810 for further information on

calibrating PID control.

Par. Description Def. Min. Max. UoM

- Superheat set point

PID proport. gain 15 0 800 -

CP

PID integral time 150 0 999 s

ti

Note: when selecting the type of Mode, the PID control values

suggested by CAREL will be automatically set for each application.

LowSH: threshold 55 (99) K(°F)

11(20)

Protector control parameters

See the chapter “Protectors”.

SH_set+

Smooth_line

SH set

t

Temp. set

t

Fig. 5.b

Key

SH set Superheat set point t time

Temp.set Temperature set point

Note: the temperature setting based on the corresponding set

point is managed by the master controller, while superheat control is

managed by the EVD ice.

5.3 Service parameters

The other conguration parameters, to be set where necessary before

starting the controller, concern :

• the type of ratiometric pressure probe;

• the serial address for network connection;

• the type of unit of measure;

• enabling change in type of control (Mode);

• the number of steps (480/960) to control valve position.

5.2 Special control function: smooth lines

Note: the Smooth_line parameter is only accessible via the

supervisor.

The smooth lines function optimises evaporator capacity based on actual

cooling demand, allowing more eective and stable control. The function

completely eliminates traditional on/o control cycles, modulating

the temperature exclusively using the electronic valve; superheat set

point is controlled through a precise PI control algorithm based on

the actual control temperature. The master controller (connected via

serial to EVD mini), through dynamic management of the Smooth_line

parameter, modies the superheat set point for management of the

electronic expansion valve, from a minimum (SH_SET) to a maximum

(SH_SET + Smooth_line): this consequently acts directly on the PID

control algorithm that modies the valve position. This is useful when

the control temperature approaches the set point; the Smooth_line

parameter is used to prevent the valve from closing, by reducing the

evaporator’s cooling capacity. In order to use this function, the digital

input must be congured as BACKUP. The Smooth_line parameter thus

allows the control set point to be adjusted instantly. In the event where

there is no network connection, the Smooth_line parameter is reset so as

to resume normal control (START/STOP from digital input and SH_SET as

the superheat set point). The main eects are:

• no swings in temperature and superheat due to the set point being

reached;

• stable temperature and superheat control;

• maximum energy savings due to load stabilisation.

Par. Description Def. Min. Max. U.M.

di

Smooth_line

DI conguration

1=start/stop

2=control backup

A: superheat set point

oset for smooth lines

1 1 2 -

0 -99(-55) 99(55) K/°F

Type of pressure probe (par. S1)

S1 is used to select the type of ratiometric pressure probe.

Par. Description Def. Min. Max. UoM

S1

type of probe S1

1 = -1…4.2 barg

2 = 0.4…9.3 barg

3 = -1…9.3 barg

4 = 0…17.3 barg

5 = 0.85…34.2 barg

6 = 0…34.5 barg

7 = 0…45 barg

8 = -1…12.8 barg

9 = 0…20.7 barg

10 = 1.86…43.0 barg

11 = Reserved

12 = 0...60 barg

13 = 0...90 barg

Note: when setting the probe type, the maximum and minimum

limits for the pressure alarm are automatically dened. See “Variables

aaccessible via serial connection”.

3 1 13 -

Network address (par. n1)

See the “Network connection” chapter.

Unit of measure (par. Si)

It is possible to select the measure system of the driver:

• international (°C, K, barg);

• imperial (°F, psig).

Par. Description Def. Min. Max. UoM

Si Unit of measure: 1=°C/K/barg; 2=°F/psig 1 1 2 -

Note: the unit of measure K relates to degrees Kelvin adopted for

measuring the superheat and the related parameters.

When changing the unit of measure, all the values of the parameters

saved on the driver and all the measurements read by the probes will

be recalculated. This means that when changing the units of measure,

control remains unaltered.

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

14

ENG

Example 1: The pressure read is 20 barg this will be immediately

converted to the corresponding value of 290 psig.

Example 2: The “superheat set point” parameter set to 10 K will be

immediately converted to the corresponding value of 18 °F.

Access to the Mode (operating mode) parameter (par. IA)

To avoid accidental modication of the controller’s operating mode, it is

possible to disable the access to the corresponding parameter.

Par. Description Def. Min. Max. UoM

IA Enable operating mode modication

0/1 = yes/ no

0 0 1 -

Number of control steps (par. U3)

Total number of steps between the valve fully closed and fully open

position

Par. Description Def. Min. Max. UoM

U3 Number of valve control steps

1 / 2 = 480/960 steps

1 1 2 -

6. PROTECTORS

These are additional functions that are activated in specic situations that

are potentially dangerous for the unit being controlled. They feature an

integral action, that is, the action increases gradually when moving away

from the activation threshold. They may add to or overlap (disabling)

normal PID superheat control. By separating the management of these

functions from PID control, the parameters can be set separately, allowing,

for example, normal control that is less reactive yet much faster in

responding when exceeding the activation limits of one of the protectors.

6.1 Protectors

The protectors are 3:

• LowSH, low superheat;

• LOP, low evaporation temperature;

• MOP, high evaporation temperature;

The protectors have the following main features:

• activation threshold: depending on the operating conditions of the

controlled unit, this is set in Service programming mode;

• integration time, which determines the intensity (if set to 0, the

protector is disabled): set automatically based on the type of main

control;

• alarm, with activation threshold (the same as the protector) and

timeout (if set to 0 disables the alarm signal).

Note: The alarm signal is independent from the eectiveness of

the protector, and only signals that the corresponding threshold has

been exceeded. If a protector is disabled (null integration time), the

relative alarm signal is also disabled.

Each protector is inuenced by the proportional gain parameter (CP) of

PID superheat control. The higher is the value of CP, the more intensely

the protection will react.

Characteristics of the protectors

Protection Reaction Reset

LowSH Intense closing Immediate

LOP Intense opening Immediate

MOP Moderate closing Controlled

Tab. 6.a

Reaction: summary description of the type of action in controlling the

valve.

Reset: summary description of the type of reset following the activation

of the protector. Reset is controlled to avoid swings around the activation

threshold or immediate reactivation of the protector.

Digital input

The function of the digital input can be set by parameter:

Par. Description Def. Min. Max. UoM

di DI conguration

1=Start/Stop regulation

2=Regulation backup

Start/stop regulation:

• digital input closed: control active;

• digital input open: control in standby (see the paragraph “Control

states”).

Important: this setting excludes activation/deactivation of control

via the network. See the following function.

Regulation backup: if there is a network connection and communication

fails, the driver checks the status of the digital input to determine whether

control is active or in standby.

Note: all alarms are generated after a xed delay, as shown in the table:

Protectors Delay (s)

LowSH 300

LOP 300

MOP 600

1 1 2 -

LowSH (low superheat)

The protector is activated so as to prevent the low superheat from

causing the return of liquid to the compressor.

Par. Description Def. Min. Max. U.M.

C1 LowSH protection: threshold 5(9) -5(-9) Set point

C2 LowSH protection: integration time 15 0 800 s

When the superheat value falls below the threshold, the system enters low

superheat status, and the intensity with which the valve is closed is increased:

the more the superheat falls below the threshold, the more intensely the

valve will close. The LowSH threshold must be less than or equal to the

superheat set point. The low superheat integration time indicates the

intensity of the action: the lower the value, the more intense the action.

The integration time is set automatically based on the type of main

control.

SH

Low_SH_TH

ON

Low_SH

OFF

ON

A

OFF

D

Fig. 6.a

key:

SH Superheat A Alarm

Low_SH_TH Low_SH protection threshold D Alarm delay

Low_SH Low_SH protection t Time

B Alarm automatic reset

superheat

t

t

t

B

K(°F)

15

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

ENG

LOP (low evaporation pressure)

LOP= Low Operating Pressure

The LOP protection threshold is applied as a saturated evaporation

temperature value so that it can be easily compared against the technical

specications supplied by the manufacturers of the compressors. The

protector is activated so as to prevent too low evaporation temperatures

from stopping the compressor due to the activation of the low pressure

switch. The protector is very useful in units with compressors on board

(especially multi-stage), where when starting or increasing capacity the

evaporation temperature tends to drop suddenly. When the evaporation

temperature falls below the low evaporation temperature threshold,

the system enters LOP status and is the intensity with which the valve is

opened is increased. The further the temperature falls below the threshold,

the more intensely the valve will open. The integration time indicates the

intensity of the action: the lower the value, the more intense the action.

Par. Description Def. Min. Max. U.M.

C3 LOP protection: threshold -50

C4 LOP protection: integration time 0 0 800 s

(-58)

-85

(-121)

MOP protec.:

threshold

C(°F)

The integration time is set automatically based on the type of main

control.

Note:

• the LOP threshold must be lower then the rated evaporation

temperature of the unit, otherwise it would be activated unnecessarily,

and greater than the calibration of the low pressure switch, otherwise

it would be useless. As an initial approximation it can be set to a value

exactly half-way between the two limits indicated;

• the protector has no purpose in multiplexed systems (showcases)

where the evaporation is kept constant and the status of the individual

electronic valve does not aect the pressure value;

• the LOP alarm can be used as an alarm to highlight refrigerant leaks by

the circuit. A refrigerant leak in fact causes an abnormal lowering of the

evaporation temperature that is proportional, in terms of speed and

extent, to the amount of refrigerant dispersed.

T_EVAP

LOP_TH

superheat is no longer controlled, and an increase in the superheat

temperature. The protector will thus have a moderate reaction that tends

to limit the increase in the evaporation temperature, keeping it below the

activation threshold while trying to stop the superheat from increasing

as much as possible. Normal operating conditions will not resume based

on the activation of the protector, but rather on the reduction in the

refrigerant charge that caused the increase in temperature. The system

will therefore remain in the best operating conditions (a little below the

threshold) until the load conditions change.

Par. Description Def. Min. Max. U.M.

C5 MOP protection threshold 50

C6 MOP protection integration time 20 0 800 s

(122)

Protection LOP:

threshold

200

(392)

C(°F)

The integration time is set automatically based on the type of main

control.

When the evaporation temperature rises above the MOP threshold, the

system enters MOP status, superheat control is interrupted to allow the

pressure to be controlled, and the valve closes slowly, trying to limit the

evaporation temperature. As the action is integral, it depends directly on

the dierence between the evaporation temperature and the activation

threshold. The more the evaporation temperature increases with

reference to the MOP threshold, the more intensely the valve will close.

The integration time indicates the intensity of the action: the lower the

value, the more intense the action.

T_EVAP

MOP_TH

MOP_TH - 1

MOP

PID

ALARM

ON

OFF

ON

OFF

ON

OFF

t

t

t

LOP

ALARM

ON

OFF

ON

OFF

D

t

t

B

t

Fig. 6.b

Key:

T_EVAP Evaporation temperature D Alarm timeout

LOP_TH Low evaporation temperature protection ALARM Alarm

LOP LOP protection t Time

B Automatic alarm reset

MOP (high evaporation pressure)

MOP= Maximum Operating Pressure.

The MOP protection threshold is applied as a saturated evaporation

temperature value so that it can be easily compared against the technical

specications supplied by the manufacturers of the compressors. The

protector is activated so as to prevent too high evaporation temperatures

from causing an excessive workload for the compressor, with consequent

overheating of the motor and possible activation of the thermal protector.

The protector is very useful in self-contained units if starting with a high

refrigerant charge or when there are sudden variations in the load. The

protector is also useful in multiplexed systems (showcases), as allows all

the utilities to be enabled at the same time without causing problems

of high pressure for the compressors. To reduce the evaporation

temperature, the output of the refrigeration unit needs to be decreased.

This can be done by controlled closing of the electronic valve, implying

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

D

t

Fig. 6.c

Key:

T_EVAP Evaporation temperature MOP_TH MOP threshold

PID PID superheat control ALARM Alarm

MOP MOP protection t Time

D Alarm timeout

Important: the MOP threshold must be greater than the rated

evaporation temperature of the unit, otherwise it would be activated

unnecessarily. The MOP threshold is often supplied by the manufacturer

of the compressor. It is usually between 10 °C and 15 °C.

If the closing of the valve also causes an excessive increase in the suction

temperature (S2) above the set threshold – set via parameter (C7), not

on the display - the valve will be stopped to prevent overheating the

compressor windings, awaiting a reduction in the refrigerant charge. If

the MOP protection function is disabled by setting the integral time to

zero, the maximum suction temperature control is also deactivated.

Par. Description Def. Min. Max. U.M.

C7 MOP protection: disabling threshold

30

(86)

-85

(-121)

200

(392)

At the end of the MOP protection function, superheat control restarts

in a controlled manner to prevent the evaporation temperature from

exceeding the threshold again.

16

°C (°F)

ENG

7. PARAMETERS TABLE

Par. Description Def. Min. Max. UoM Type Carel Modbus® R/W Note

BASED (FISRT CONFIGURATION)

GAS

Refrigerant 3 0 40 - I 12 139 R/W

Type

Gas Type = Refrigerant

0 Custom

1 R22 15 R422D 28 R1234ze(-1...4.2 barg)

2 R134a 16 R413A 29 R455A (-1...12.8 barg)

3 R404A 17 R422A 30 R170 (0...17.3 barg)

4 R407C 18 R423A 31 R442A (-1...12.8 barg)

5 R410A 19 R407A 32 R447A (-1...12.8 barg)

6 R507A 20 R427A 33 R448A

7 R290 21 R245FA 34 R449A

8 R600 (-1...4.2 barg) 22 R407F 35 R450A (-1...4.2 barg)

9 R600a (-1...4.2 barg) 23 R32 (0...17.3 barg) 36 R452A (-1...12.8 barg)

10 R717 24 HTR01 37 R508B (-1...4.2 barg)

11 R744 (0...45 barg) 25 HTR02 38 R452B

12 R728 26 R23 39 R513A (-1...4.2 barg)

13 R1270 27 R1234yf 40 R454B

14 R417A 41 R458A

Mode Operating mode

1 Multiplexed cabinet/cold room

2 Air-conditioner/chiller with plate heat exchanger

3 Air-conditioner/chiller with tube bundle heat exchanger

4 Air-conditioner/chiller with nned coil heat exchanger

5 Reserved

6 Reserved

7 Cabinet/cold room with subcritical (R744) CO2

Super

Superheat set point 11

Heat

3 = R404A

1 1 7 - I 13 140 R/W

(20)

LowSH:

protection

threshold

55

(99)

(°F)

K

A 10 9 R/W

SERVICE

P1 S1 probe measurement - -85

P2 S2 probe measurement - -85

tE Evaporation temperature (converted) - -85 (-121) 200 (392) °C(°F) A 4 3 R

tS Suction temperature - -85 (-121) 200 (392) °C(°F) A 3 2 R

Po Valve opening - 0 100 % A 1 0 R

CP PID proportional gain 15 0 800 - A 11 10 R/W

ti PID integral time 150 0 999 s I 17 144 R/W

C1 LowSH protection: threshold 5(9) -5

C2 LowSH protection: integral time 15 0 800 s A 13 12 R/W

C3 LOP protection: threshold -50(-

C4 LOP protection: integral time 0 0 800 s A 15 14 R/W

C5 MOP protection: threshold 50

C6 MOP protection: integral time 20 0 800 s A 17 16 R/W

C7 MOP protection: disabling threshold 30

C8 Low suction temperature alarm threshold -50

S1 S1 probe type

Ratiometric (OUT=0…5V)

1 = -1…4.2 barg 8 = -1…12.8 barg

2 = 0.4…9.3 barg 9 = 0…20.7 barg

3 = -1…9.3 barg 10 = 1.86…43.0 barg

4 = 0…17.3 barg 11 = Reserved

5 = 0.85…34.2 barg 12 = 0…60 barg

6 = 0…34.5 barg 13 = 0…90 barg

7 = 0…45 barg

n1 Network address 99 1 99 - I 10 137 R/W

n2 Baud rate (bit/s)

0 4800, 2 stop bit, parity none 9 4800, 1 stop bit, parity even

1 9600, 2 stop bit, parity none 10 9600, 1 stop bit, parity even

2 19200, 2 stop bit, parity none 11 19200, 1 stop bit, parity even

3 4800, 1 stop bit, parity none 12 4800, 2 stop bit, parity odd

4 9600, 1 stop bit, parity none 13 9600, 2 stop bit, parity odd

5 19200, 1 stop bit, parity none 14 19200, 2 stop bit, parity odd

6 4800, 2 stop bit, parity even 15 4800, 1 stop bit, parity odd

7 9600, 2 stop bit, parity even 16 9600, 1 stop bit, parity odd

8 19200, 2 stop bit, parity even 17 19200, 1 stop bit, parity odd

(-290)

(-121)

(-9)

-85(-121) MOP

58)

LOP pro-

(122)

tection:

threshold

(86)

(-58)

-85

(-121)

-85

(-121)

3 1 11 - I 14 141 R/W

2 0 17 - I 20 147 R/W

200

(2900)

200

(392)

Superheat

set point

protection

threshold

200

(392)

200

(392)

200

(392)

barg (psig) A 6 5 R

°C(°F) A 7 6 R

K

(°F)

°C(°F) A 14 13 R/W

°C(°F) A 16 15 R/W

°C(°F) A 19 18 R/W

°C(°F) A 18 17 R/W

A 12 11 R/W

17

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

ENG

Par. Description Def. Min. Max. UoM Type Carel Modbus® R/W Note

Si Unit of measure 1=°C/K/barg ¦ 2=°F/psig 1 1 2 - I 16 143 R/W

IA Enable operating mode modication 0/1 = yes/ no 0 0 1 - I 15 142 R/W

U1 Enable manual valve positioning 0/1 = no/ yes 0 0 1 - D 11 10 R/W

U2 Manual valve position 0 0 999 step I 7 134 R/W

U3 Valve control steps: 1/2 = 480/960 steps 1 1 2 - I 11 138 R/W

U4 Valve opening at start-up (evaporator/valve capacity ratio) 50 0 100 % I 19 146 R/W

Fr Firmware release - - - - A 9 8 R

di DI conguration: 1=start/stop regulation; 2=backup regulation 1 1 2 - I 18 145 R/W

rt Reserved 1 1 1 L1 S1 alarm: Minimum pressure -1 -85(-121) S1 alarm:

H1 S1 alarm: Maximum pressure - S1 alarm:

Min press.

Max pressure

200 (392) barg (psig) A 21 20 R/W

8. NETWORK CONNECTION

barg (psig) A 20 19 R/W

Tab. 7.a

The driver can be connected via a network connection to:

1. a computer running the VPM software, for setting the parameters

before commissioning;

2. a pCO controller, loaded with the application program;

3. a PlantVisor/PlantVisorPRO supervisor, for remote monitoring and

alarm detection.

8.1 RS485 serial conguration

n1 assigns to the controller an address for serial connection to a

supervisory and/or telemaintenance system.

Par. Description Def. Min. Max. UoM

n1 Network address 1 1 99 n2 Baud rate (bit/s)

0 4800, 2 stop bit, parity none

1 9600, 2 stop bit, parity none

2 19200, 2 stop bit, parity none

3 4800, 1 stop bit, parity none

4 9600, 1 stop bit, parity none

5 19200, 1 stop bit, parity none

6 4800, 2 stop bit, parity even

7 9600, 2 stop bit, parity even

8 19200, 2 stop bit, parity even

9 4800, 1 stop bit, parity even

10 9600, 1 stop bit, parity even

11 19200, 1 stop bit, parity even

12 4800, 2 stop bit, parity odd

13 9600, 2 stop bit, parity odd

14 19200, 2 stop bit, parity odd

15 4800, 1 stop bit, parity odd

16 9600, 1 stop bit, parity odd

17 19200, 1 stop bit, parity odd

Important: all controllers connected in a serial network need to be

set with the same communication parameters.

2 0 17 -

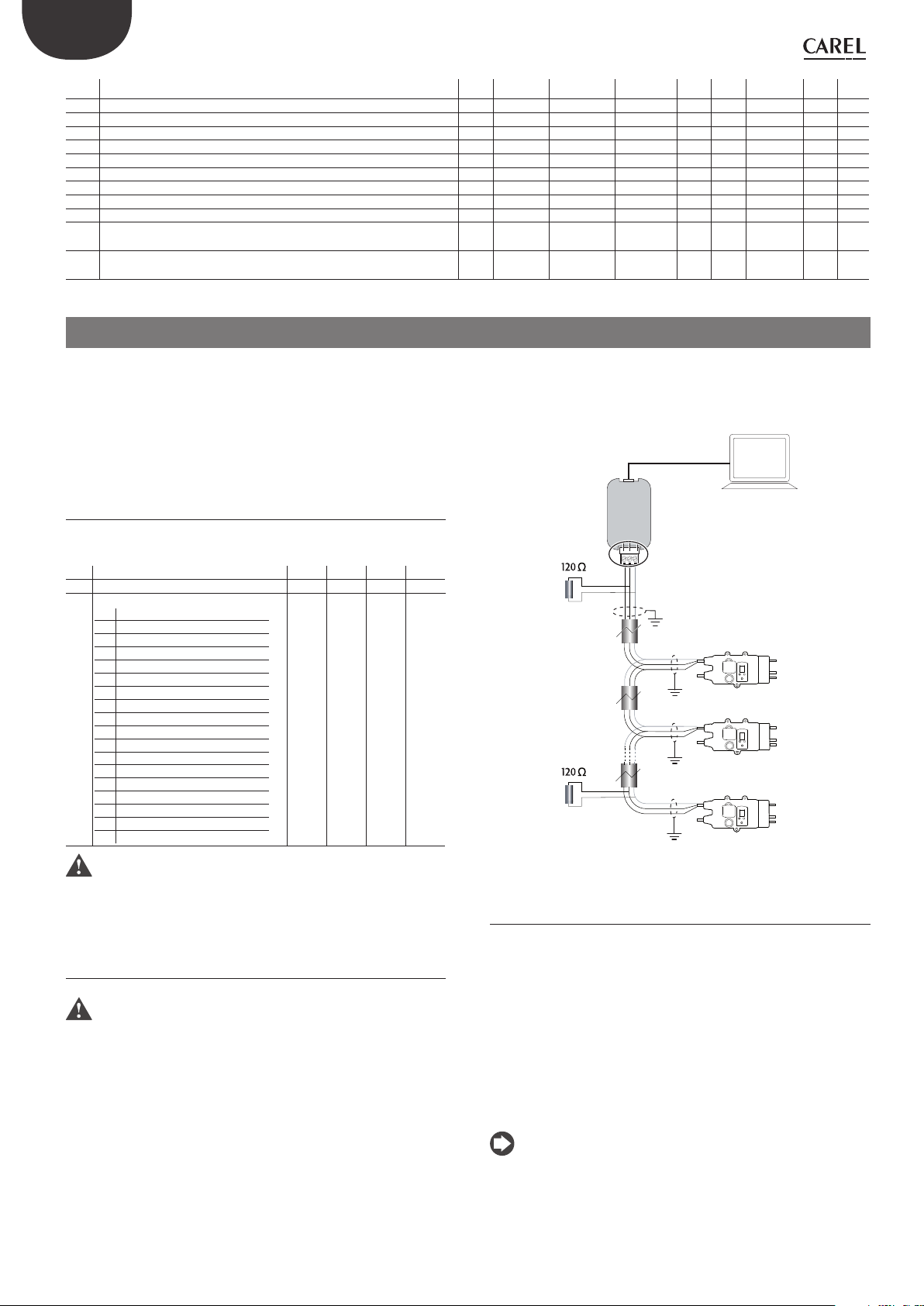

Connect the RS485 converter to controllers and make the connections

as shown in the gure. To assign the serial address, see parameter n1. See

the converter technical leaets for further information.

GND

T+

CVSTDUMOR0

*

*

USB-485

Converter

T -

shield

USB

shield

shield

shield

VPM

EVD ice 1

EVD ice 2

EVD ice ...n

Fig. 8.a

8.2 Network connection for commissioning

via PC

Warnings:

• fasten the converter properly so as to prevent disconnection;

• complete the wiring without power connected;

• keep the CVSTDUMOR0 interface cables separate from the power

cables (power supply);

• in compliance with standards on electromagnetic compatibility, a

shielded cable suitable for RS485 data transmission is used.

The RS485 converter is used to connect a computer running the VPM

software to the EVD ice driver via a serial network, for commissioning the

controllers. The system allows a maximum of 99 units, with a maximum

network length of 500 m. Connection requires the standard accessories

(RS485-USB converter, CAREL P/N CVSTDUMOR0) and a 120 Ω terminating

resistor to be installed on the terminals of the last connected controller.

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

8.3 Visual parameter manager

Go to http://ksa.carel.com and follow the instructions below. Select in

sequence:

1. “Software & Support”

2. “Conguration & Updating Softwares”

3. “Parametric Controller Software”

4. “Visual Parametric Manager”

A window will open with the possibility to download two les:

1. VPM_setup_X.Y.Z.W_full.zip: complete program;

2. X.Y.Z.W_VPM_Devices_Upgrade.zip: upgrade for supported devices;

If this is the rst installation, select Setup full, otherwise Upgrade. The

program installs automatically by running setup.exe.

Note: if choosing complete installation (Setup full), uninstall any

previous versions of VPM.

18

ENG

Programming

When opening the program, the device to be congured needs to be

selected: EVD mini. The Home page then opens, oering the choice

between starting a new project or opening an existing project. If using

the program for the rst time, choose new project.

Fig. 8.b

The following options are then available:

1. Directly access the list of parameters saved in EEPROM: select “RS485”;

The operations are performed in real time (ONLINE mode), at the top

right set network address 1 and choose the guided procedure for USB

port recognition, then go to “Device setup”;

8.4 Restore default parameters

To restore the default parameter values on the controller:

1. Establish an RS485 serial connection between the computer and the

driver. The LEDs on the USB/RS485 converter will ash;

Fig. 8.e

2. Select “Update device” and:

a. Click button (A) to open the drop-down menu;

b. Select the list of parameters corresponding to the controller’s

rmware version: “EVDMINI***.hex ”;

c. Click “Update” to load the parameters to the list and immediately

after restore the controller parameters to the default value.

C

A

B

Fig. 8.c

2. Select the model from the range based on the rmware version and list of

conguration parameters (EVDMINI0000E0X_R*.*). These operations

are performed in OFFLINE mode.

Menu

The pages marked 1) can be accessed wither Online or Oine, while

those marked 2) are Online only.

1

2

Fig. 8.d

The operations that can be performed on the pages marked 1) depend

on the rst selection made.

Note: to access the Online help press F1.

Ref. Description

Home Select operating mode

Device setup Read instant values of control

Setup summary Display the default values for the current list of parameters

Custom setup See online help.

Update device Select list of parameters and

Upload

rmware

Synoptic and

graphs

Online Oine

parameters

then Upload to controller

Select rmware and Upload -

Overview with position of

probes and probe and superheat readings in real time

Online à RS485 (rear connector)

Oine à Device model

Select Load to load a list of

project parameters (.hex), modify

and save a new project.

-

-

Tab. 8.a

3. Go to “Device setup”: the program automatically reads the default

parameters saved on the controller.

8.5 Setup by direct copy

1. On the Home page select RS485 (rear connector);

2. Go to “Device setup”;

Fig. 8.f

Fig. 8.g

Fig. 8.h

19

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

ENG

a. on the “Rapid conguration” page, set parameters “p_GAS_TYPE” =

refrigerant and “p_SUPER_MAIN_REGULATION”= type of control;

Fig. 8.i

b. on the “Conguration” page, set parameter “p_SH_SET”.

Fig. 8.j

3. Check whether there are other parameters that need to be set (see the

“Functions” chapter);

4. Finally, select “Write” to copy the parameters to the controller.

Create the conguration le

1. Select the “Device setup” page;

2. Set the parameters by double clicking, as shown in the gure:

a. on the “Rapid conguration” page, parameters “p_GAS_TYPE” =

refrigerant and “p_SUPER_MAIN_REGULATION”= type of control;

b. on the “Conguration” page, parameter “p_SH_SET”.

Fig. 8.m

3. Save the list of parameters with a new name, for example “NEW_NAME.

hex”. To load and display a list saved by the user, select “Load” and

navigate to the path where the le is saved. On the other hand,

to load a list of parameters supplied by CAREL, select “Load” and

navigate the following path:

Fig. 8.k

8.6 Setup using conguration le

On the Home page select “Device model”.

Fig. 8.l

The setup procedure comprises three steps:

1. Create the conguration le;

2. Copy the conguration le to the controller;

3. Read the conguration le on the controller.

LoadàPluginsàCommissioning EVD mini àTXTàTXT32.

Save Load

Copy the conguration le to the controller

Select “Update device” and:

a. Click button (A) to open the drop-down menu;

C

NEW_NAME.hex

Fig. 8.n

b. Select the list of parameters corresponding to the project le

created: “NEW_NAME.hex”;

c. Click “Update” to UPLOAD the parameters to the controller.

B

A

8.7 Read the conguration le on the

controller

1. Go to the “Home” page and select RS485 (rear connector);

2. Go to “Device setup” to read the list of parameters on the controller and

make sure the settings are correct.

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

20

ENG

8.8 Variables accessible via serial connection

Parameter Description Def. Min Max Type Carel Modbus® R/W Note

Reg_status Device control status 0 0 20 I 1 128 R

Machine_type_SPV Type of unit 0 0 32767 I 2 129 R

Hardware_code_SPV Hardware code 0 0 32767 I 3 130 R

EEV_Positions_steps Valve position 0 0 999 I 4 131 R

Protection_status Protector status 0 0 5 I 5 132 R

Sh_unit_power_percent Cooling capacity 0 0 100 I 6 133 R/W

Man_posit_steps Manual valve position 0 0 999 I 7 134 R/W par. U2

Start_func_test Functional test input variable 0 0 30000 I 8 135 R/W

Func_test_2 Functional test generic variable 0 -32768 32767 I 9 136 R/W

Net_address LAN serial address 99 1 99 I 10 137 R/W par. n1

EEV_steps_doubling Double valve steps 1 1 2 I 11 138 R/W par. U3

Gas_type Refrigerant 3 1 23 I 12 139 R/W Gas Type = refrig.

Super_main_regulation Main control 1 0 6 I 13 140 R/W Operating mode

Super_S1_probe_model Probe S1 3 1 11 I 14 141 R/W par. S1

Inhibit_mode_setting Enable mode parameter setting 0 0 1 I 15 142 R/W par. IA

Unity_measure Unit of measure 1 1 2 I 16 143 R/W par. Si

PID_Ti PID: integral time 150 0 999 I 17 144 R/W par. ti

Par_Digin1_Cong Digital input conguration

Start_eev_opening_ratio Valve position at start-up 50 0 100 I 19 146 R/W par. U4

Net setting Baud rate 2 0 17 I 20 147 R/W par. n2

Reset Default (*) Reset with default parameters 0 |-32768 32767 I 21 148 R/W

Ultracella signature Riservato 0 |-32768 32767 I 22 149 R/W

Control type Control type 1 1 9 I 23 150 R

Gas custom dew_a_h Dew a high -288 -32768 32767 I 24 151 R/W

Gas custom dew_a_l Dew a low -15818 -32768 32767 I 25 152 R/W

Gas custom dew_b_h Dew b high -14829 -32768 32767 I 26 153 R/W

Gas custom dew_b_l Dew b low 16804 -32768 32767 I 27 154 R/W

Gas custom dew_c_h Dew c high -11664 -32768 32767 I 28 155 R/W

Gas custom dew_c_l Dew c low 16416 -32768 32767 I 29 156 R/W

Gas custom dew_d_h Dew d high -23322 -32768 32767 I 30 157 R/W

Gas custom dew_d_l Dew d low -16959 -32768 32767 I 31 158 R/W

Gas custom dew_e_h Dew e high -16378 -32768 32767 I 32 159 R/W

Gas custom dew_e_l Dew e low 15910 -32768 32767 I 33 160 R/W

Gas custom dew_f_h Dew f high -2927 -32768 32767 I 34 161 R/W

Gas custom dew_f_l Dew f low -17239 -32768 32767 I 35 162 R/W

Net_alarm Network alarm 0 0 1 D 1 0 R all. E6

Emergency_closing_alarm Mains power failure 0 0 1 D 2 1 R all. E5

S1_alarm Probe S1 alarm 0 0 1 D 3 2 R all. A1

S2_alarm Probe S2 alarm 0 0 1 D 4 3 R all. A2

Low_sh_alarm Low_SH alarm 0 0 1 D 5 4 R all. E3

LOP_alarm LOP alarm 0 0 1 D 6 5 R all. E2

MOP_alarm MOP alarm

Low_suct_alarm Low suction temperature alarm 0 0 1 D 8 7 R all. E4

Eeprom_alarm EEPROM damaged 0 0 1 D 9 8 R all. EE

Digin1_status Digital input status 0 0 1 D 10 9 R

Manual_posit_enable Enable manual valve 0 0 1 D 11 10 R/W par. U1

Incomplete closing alarm Emergency closing not completed 0 0 1 D 12 11 R/W all. E8

Battery alarm Battery alarm 0 0 1 D 13 12 R

EVD_CAN_GO EVD regulation enable 0 0 1 D 14 13 R/W

S1_Alarm_enable S1 Probe enable 0 0 1 D 15 14 R/W

S2_Alarm_enable S2 Probe enable 0 0 1 D 16 15 R/W

EEV_Position_percent Valve opening 0 0 100 A 1 0 R par. Po

SH_SH Superheat 0 -5(-9) 55(99) A 2 1 R

Sh_Suct_temp Suction temperature 0 -85(-121) 200(392) A 3 2 R par. tS

Sh_Evap_temp Evaporation temperature 0 -85(-121) 200(392) A 4 3 R

Sh_Evap_pres Evaporation pressure 0 -20(-290) 200(2900) A 5 4 R

S1_Value Probe S1 reading 0 -85(-290) 200(2900) A 6 5 R par. P1

S2_Value Probe S2 reading 0 -85(-121) 200(392) A 7 6 R par. P2

Positioning_mode_volt 0 to 10 V input 0 0 10 A 8 7 R

Firm_release Firmware version 0 0 800 A 9 8 R par. Fr

SH_Set Superheat set point 11 Low_Sh_

PID_Kp PID: proportional gain 15 0 800 A 11 10 R/W par. CP

Low_sh_threshold Low superheat: threshold 5 -5

Low_sh_Ti Low superheat: integral time 15 0 800 A 13 12 R/W par. C2

Lop_threshold LOP: threshold -50(-58) -85(-121) MOP_th-

Lop_Ti LOP: integral time 0 0 800 A 15 14 R/W par. C4

MOP_Threshold MOP: threshold 50 LOP_th-

(*) set to 1073 to reset the parameters to default values

MOP_Ti MOP: integral time 20 0 800 A 17 16 R/W par. C6

Low_Suct_alarm_threshold Low suction temp. alarm threshold -50(-58) -85(-121) 200(392) A 18 17 R/W par. C8

Mop_Inhibition_threshold MOP: disabling threshold 30 (86) -85(-121) 200(392) A 19 18 R/W

Par_S1_Alarm_threshold_

low

Par_S1_Alarm_threshold_

high

Tctrl_rev_set Reserved - -85(-121) 200(392) A 22 21 R/W

1=Start/stop control

2=Control backup

PressureS1: alarm MIN value -1 -85(-290) Par_S1_

PressureS1: alarm MAX value 9.3 Par_S1_

1 1 2 I 18 145 R/W

0 0 1 D 7 6 R all. E1

Threshold

(-9)

reshold

Alarm_th-

reshold_low

55 A 10 9 R/W Super heat =

SH set point A 12 11 R/W par. C1

reshold

200

(392)

Alarm_th-

reshold_high

200(2900) A 21 20 R/W

A 14 13 R/W par. C3

A 16 15 R/W par. C5

A 20 19 R/W

Superheat set

point

21

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

ENG

t

t

t

t

R

P

S

A

Parameter Description Def. Min Max Type Carel Modbus® R/W Note

Pctrl_rev_set Reserved - -20(-290) 200(2900) A 23 22 R/W

SH_actual_set Reserved 0 -40(-72) 180(324) A 24 23 R

SH_Set_smooth_line Superheat Setpoint-Oset for smooth line 0 -55(-99) 55(99) A 25 24 R/W

S1_value_remote Reserved 0 -20(-290) 200(2900) A 26 25 R/W

8.9 Control states

The electronic valve controller can have six dierent control states,

each of which may correspond to a specic phase in the operation of

the refrigeration unit and a certain status of the driver-valve system. The

states are as follows:

• forced closing: initialisation of the valve position when switching the

instrument on;

• standby: no temperature control, unit OFF (at temp.);

• wait: opening of the valve before starting control, also called pre-

positioning, when powering the unit on;

• control: eective control of the electronic valve, unit ON;

• positioning: step-change in the valve position, corresponding to the

start of control when the cooling capacity of the controlled unit varies

(only EVD connected to a pCO);

• stop: of control with closing of the valve, corresponds to the end of

temperature control of the refrigeration unit, unit OFF (at temp.).

Forced closing

Forced closing is performed after the driver is powered on and corresponds

to the typical number of closing steps for CAREL E2V and E3V unipolar valves.

This is used to realign the valve to the physical position corresponding to

completely closed. The driver and the valve are then ready for control and

both aligned at 0 (zero). At power-on, rst a forced closing is performed,

and then the standby phase starts. The valve is also closed in the event of

a mains power failure if the Ultracap module is connected. In this case, the

“Forced valve closing not completed” parameter is set to 1. On restarting, if

the valve forced closing procedure is not completed successfully:

1. the Master programmable controller (pCO) will check the value of the

parameter, and if equal to 1 will decide the best strategy to adopt,

based on the application;

2. on restarting the driver positions the valve as explained in the paragraph

“Pre-positioning/start control”. The parameter is set to 0 (zero) by the

Master controller (e.g. pCO), or alternatively by pressing the PRG/

Set button on the keypad. Once the parameter has been set to 1,

the driver sets it back to 0 (zero) only if an emergency forced closing

procedure is completed successfully.

Note: lthe user can only select the resolution of the valve control

signal: 480 or 960 steps.

Par. Description Def. Min. Max. UoM

U3 Valve control steps: 1 / 2 = 480/ 960 steps 1

1 2 -

The driver calculates the valve opening based on the required capacity:

If required capacity is 100%:

Opening (%)= (Valve opening at start-up);

If required capacity is less than 100% (capacity control):

Opening (%)= (Valve opening at start-up) x (Current unit cooling

capacity), where the current unit cooling capacity is sent to the driver

via RS485 by the pCO controller. If the driver is stand-alone, this is always

equal to 100%.

Notes:

• this procedure is used to anticipate the movement and bring the valve

signicantly closer to the operating position in the phases immediately

after the unit is powered on;

• if there are problems with liquid return after the refrigeration unit starts

or in units that frequently switch on-o, the valve opening at start-up

must be decreased. If there are problems with low pressure after the

refrigeration unit starts, the valve opening must be increased.

Wait

When the calculated position has been reached, regardless of the time taken

(this varies according to the type of valve and the objective position), there

is a constant 5 second delay before the actual control phase starts. This is to

create a reasonable interval between standby, in which the variables have no

meaning, as there is no ow of refrigerant, and the eective control phase.

Control

The control request can be received by the closing of the digital input

or via network (RS485). The solenoid or the compressor are activated

when the valve, following the pre-positioning procedure, has reached

the calculated position. The following gure represents the sequence of

events for starting control of the refrigeration unit.

ON

OFF

ON

OFF

Tab. 8.b

Standby

Standby corresponds to a situation of rest in which no signals are received

to control the electronic valve: it is closed and manual positioning can be

activated. This status is normally set on the driver when the refrigeration