humiFog direct

User manual

READ CAREFULLY IN THE TEXT!

Integrated Control Solutions & Energy Savings

NO POWER

& SIGNAL

CABLES

TOGETHER

ENG

IMPORTANT WARNINGS:

The humidiers manufactured by CAREL are advanced products, whose

operation is specied in the technical documentation supplied with the

product that can be downloaded, even prior to purchase, from the website

www.carel.com. Every product made by CAREL Industries, in relation to

its advanced level of technology, requires a qualication/ conguration /

setup phase in order to best full your specic application. The lack of such

phase of study, as indicated in the manual, can cause the nal product to

malfunction, of which CAREL cannot be held responsible. The client (builder,

developer or installer of the nal equipment) assumes all responsibility and

risk relating to the conguration of the product in order to achieve the

expected results in relation to the specic nal installation and/or equipping.

In this case, subject to specic agreements, CAREL acts as a consultant for

the success of the installation / start-up / use of the machine, but in no case

does it accept liability for proper operation of the humidier and of the nal

plant, should the warnings and recommendations in this manual or in any

other technical documentation of the product not be followed. In particular,

in addition to the obligation to observe the above mentioned warnings and

recommendations for proper use of the product, we recommend paying

attention to the following warnings:

• DANGER ELECTRIC SHOCK: The humidier includes live electrical

parts. Disconnect the power supply before accessing internal parts, in

case of maintenance and during installation.

• DANGER WATER LEAKS: The humidier automatically and constantly

sucks in/drains quantities of water. Malfunctions in the connections or

humidier may cause leaks.

WARNING:

DISPOSAL:

The humidier consists of metal parts and plastic parts. With reference to

the European Parliament and Council Directive 2002/96/EC issued on 27

January 2003 and the related national implementation legislation, please

note that:

1. WEEE cannot be disposed of as municipal waste, said waste must be

collected separately;

2. the public or private waste collection systems dened by local

legislation must be used. Moreover, the equipment can be returned

to the distributor at the end of its working life when buying new

equipment;

3. the equipment may contain hazardous substances: the improper use

or incorrect disposal of such may have negative eects on human

health and on the environment;

4. the symbol (crossed-out wheeley bin) shown on the product or

on the packaging and on the instruction sheet indicates that the

equipment has been introduced onto the market after 13 August

2005 and that it must be disposed of separately;

5. in the event of illegal disposal of electrical and electronic waste, the

penalties are specied by local waste disposal legislation.

Warranty for materials: 2 years (from the manufacture date, excluding

consumables).

Certication: the quality and safety of CAREL products are guaranteed by

CAREL’s ISO 9001 certied design.

• Environmental and power supply conditions must conform to the

values specied on the product rating labels.

• Only qualied personnel who are aware of the necessary precautions

and able to perform the required operations correctly may install,

operate or carry out technical service on the product.

• Only water with the characteristics indicated in this manual must be

used.

• All operations on the product must be carried out according to the

instructions provided in this manual. Any uses or modications that are

not authorised by the manufacturer are considered improper. CAREL

Industries declines all liability for any such unauthorised use.

• Do not attempt to open the system in ways other than those described

in this manual.

• Observe the standards in force in the place where the humidier is

installed.

• Keep the humidier out of the reach of children and animals.

• Do not install and use the product near objects that may be damaged

when in contact with water (or condensate). CAREL Industries declines

all liability for direct or indirect damage following water leaks from the

humidier.

• Do not use corrosive chemicals, solvents or aggressive detergents to

clean the inside and outside parts of the humidier, unless specically

indicated in the user manual.

• Do not drop, hit or shake the humidier, as the inside parts and the

linings may be irreparably damaged.

CAREL adopts a continuous development policy. Therefore, CAREL

reserves the right to carry out modications and improvements to any

product described in this document without prior notice. The technical

data in the manual can undergo modications without forewarning. The

liability of CAREL in relation to its own product is governed by CAREL

general contract conditions published on the website www.carel.com

and/or by specic agreements with clients; in particular, within the limits

set by the applicable law, in no way will CAREL, its employees or its branch

oces/aliates be responsible for any lack of earnings or sales, loss of

data and information, cost of replacement goods or services, damage to

objects or persons, work interruptions, or any direct, indirect, accidental,

patrimonial, coverage, punitive, special or consequential damage in any

way caused, be they contractual, out-of-contract, or due to negligence

or other responsibility originating from the installation, use or inability of

use of the product, even if CAREL or its branch oces/aliates have been

warned of the possible damage.

3

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

4

Contents

ENG

1. GENERAL DESCRIPTION AND MODELS 7

1.1 General description ...................................................................................................7

1.2 Operating principle .................................................................................................7

1.3 Cabinet part numbers ..............................................................................................8

1.4 Hose part numbers ....................................................................................................8

1.5 Blower unit part numbers......................................................................................8

1.6 Main components ......................................................................................................9

1.7 Dimensions and weights.....................................................................................10

1.8 Packaging and shipment ....................................................................................10

1.9 IP rating and standards .........................................................................................10

2. CABINET INSTALLATION 11

2.1 Positioning ....................................................................................................................11

2.2 Cabinet water connections ...............................................................................11

2.3 Cabinet electrical installation ...........................................................................12

2.4 Changing the oil cap .............................................................................................13

3. DISTRIBUTION SYSTEM INSTALLATION 13

3.1 Blower unit installation .........................................................................................13

3.2 Mounting single blower units on the wall / ceiling ...........................14

3.3 Mounting double blower units on the ceiling ......................................15

3.4 Blower unit electrical connection ..................................................................15

4. ELECTRONIC CONTROLLER SET UP AND

CONNECTIONS 16

4.1 Remote ON/OFF signal connection .............................................................16

4.2 Analogue signal from the main probe and limit probe in .................

the rst zone ...............................................................................................................16

4.3 Analogue signal from the main probe and limit probe in the ........

second zone ................................................................................................................16

4.4 Analogue signal from an external controller .........................................17

4.5 Digital signal from humidistat or external controller ......................17

4.6 Serial or Ethernet communication ................................................................17

4.7 Alarm relay output ..................................................................................................17

4.8 Unit status digital output ....................................................................................17

4.9 Production percentage analogue outputs ..............................................18

9. WIRELESS PROBES, INSTALLATION AND

CONFIGURATION 36

9.1 Type of installation and wireless probe electrical connections .....36

9.2 Wireless probe installation .................................................................................36

10. ALARM TABLE 37

11. MAINTENANCE 40

11.1 Routine maintenance ............................................................................................40

11.2 Special maintenance ............................................................................................40

11.3 Pump maintenance ................................................................................................ 40

11.4 50 hour oil change warning ..............................................................................41

11.5 Notication, maintenance warning, reset hour counter .................41

11.6 Blower spare parts ...................................................................................................41

11.7 Cabinet spare parts .................................................................................................42

12. APPENDIX 43

12.1 Single-zone cabinet wiring diagram ............................................................43

12.2 Two-zone cabinet wiring diagram ................................................................ 44

12.3 Datasheets ....................................................................................................................45

5. STARTUP AND USER INTERFACE 19

5.1 Graphic terminal .......................................................................................................19

5.2 Start-up ...........................................................................................................................19

5.3 Touch display ..............................................................................................................20

5.4 Remote installation of the touch display ..................................................24

6. OPERATION OPTIONS 25

6.1 Main menu and overview of functions ...................................................... 25

6.2 Control ............................................................................................................................26

6.3 Functions .......................................................................................................................27

6.4 Congurations ...........................................................................................................28

7. MASTER/SLAVE NETWORK OF HUMIDIFIERS 30

7.1 Description of the Master/Slave system ....................................................30

7.2 Network switch for Master/Slave connection ........................................30

7.3 Type of Master/Slave system installation ..................................................30

7.4 Master/Slave system conguration ..............................................................31

8. CONNECTIVITY 33

8.1 Webserver .....................................................................................................................33

8.2 Supervisor connection ......................................................................................... 34

8.3 List of Modbus parameters ................................................................................34

8.4 List of BACnet parameters ..................................................................................35

5

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

6

1. GENERAL DESCRIPTION AND MODELS

ENG

1.1 General description

humiFog Direct is a direct humidier for room installation. It consists

of a pumping unit (also called the cabinet) and a distribution system

(comprising blower units) to be installed directly in the room to be

humidied and cooled. The pumping unit is connected to the blower

units by high pressure hoses.

The cabinet is tted with a pump that delivers water at high pressure (70

bars) to the nozzles on the blower units, where it is atomised into very

ne droplets that evaporate spontaneously.

The cabinets are available in the single zone and two-zone version. The

latter can manage two independent zones, reading two separate signals

(from a probe or external controller).

For all models, the minimum ow rate that can be supplied by the pump

is 10% of its nominal ow rate. For this reason, it is recommended to

couple a distribution line that can atomise a ow-rate of water equal at

least to the minimum ow-rate delivered by the pump.

It is important to install the distribution system in a suitable environment

(in terms of volume, air change and operating temperature) so as to

ensure absorption of the atomised water. Carel can provide support for

calculating the required humidication load.

1.2.1 Functional diagram

7 7

1.2 Operating principle

System operation is based on a request signal from a probe (temperature

or humidity) or external controller. When operation is enabled (remote

on/o ) and at the same time there is a humidication or cooling request

signal, the system opens the ll solenoid valve and activates the pump,

which pumps the water at high pressure (70 bars). After having also

opened the outlet solenoid valve, the initial stage of operation begins,

involving washing and lling the line, after which, when the line is lled

and pressurised, the nozzles will start spraying water.

Modulation is available in PWM mode (pulse width modulation): the

controller alternates a time (set on the display) in which the outlet

solenoid valves are operation, thus atomising the water, with period in

which the outlet valves are closed and the bypass valve is open, thus

interrupting atomisation into the room.

The set point is managed directly by the electronic controller using a

proportional band (P+I) or an oset when reaching the set point.

On reaching the set point, the system stops and enters standby mode,

restarting when there is a new request. For this reason, the system should

be powered on at all times.

Key

1 Mains water line

2 Reverse osmosis system

3 Demineralised water line

4 Expansion vessel

5 humiFog Direct cabinet

6 High pressure water hoses (70 bars)

6

6

5112

8

10

33

8

12

8

Fig. 1.a

7 humiFog Direct blower units

8 Water drain point

9 On-o ball valve

10 Power supply (230V 50 Hz or 120V 60 Hz)

11

12 Mechanical feedwater lter

991 4

Electrical connection from cabinet to the blowers

7

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

D = 230 V 50 Hz

090 = 90 l/h

1.3 Cabinet part numbers

Fig. 1.b

The cabinets dier in terms of ow-rate delivered by the pump, power

supply voltage/frequency, and the capacity to control one or two

atomisation racks, managed independently from each other

U = 120 V 60 Hz

.

U A _ _ _ D _ _ 0 1

040 = 40 l/h

080 = 80 l/h

050 = 50 l/h

Part numbers available:

UA040DD101 40 l/h, 230V 50Hz, single zone

UA040DD201 40 l/h, 230V 50Hz, two zones

UA080DD101 80 l/h, 230V 50Hz, single zone

UA080DD201 80 l/h, 230V 50Hz, two zones

UA050DU101 50 l/h, 120V 60Hz, single zone

UA050DU201 50 l/h, 120V 60Hz, two zones

UA090DU101 90 l/h, 120V 60Hz, single zone

UA090DU201 90 l/h, 120V 60Hz, two zones

N.B. to manage the 230V - 60 Hz power supply a 230V-120V transformer

can be installed upstream and connected to the cabinet. The transformer

must be installed according to safety standards in force.

1 = single zone

2 = double zone

Tab. 1.a

1.5 Blower unit part numbers

Fig. 1.c

The blower units dier based on the number of nozzles, the type of

nozzles (the nozzles are already pre-assembled in the factory), power

supply voltage/frequency and the direction of spray (front or two

directions).

Nozzle size:

0 = 1.45 l/h

D = 230 V 50 Hz

U = 120 V 60 Hz

1 = 2.8 l/h

2 = 4.0 l/h

D L A _ _ _ _ _ 0 0

Number of nozzle

Part numbers available:

P/N 230 V 50 Hz BLOWERS (CE)

DLA02DF000 Front blower 3.0 l/h (2 x 1.45 l/h nozzles) 230 V 50 Hz

DLA02DF100 Front blower 5.0 l/h (2 x 2.8 l/h nozzles) 230 V 50 Hz

DLA02DF200 Front blower 8.0 l/h (2 x 4.0 l/h nozzles) 230 V 50 Hz

DLA04DF000 Front blower 6.0 l/h (4 x 1.45 l/h nozzles) 230 V 50 Hz

DLA04DF100 Front blower 11.0 l/h (4 x 2.8 l/h nozzles) 230 V 50 Hz

DLA04DF200 Front blower 16.0 l/h (4 x 4.0 l/h nozzles) 230 V 50 Hz

DLA04DB000 Double blower 6.0 l/h (4 x 1.45 l/h nozzles) 230 V 50 Hz

DLA04DB100 Double blower 11.0 l/h (4 x 2.8 l/h nozzles) 230 V 50 Hz

DLA04DB200 Double blower 16.0 l/h (4 x 4.0 l/h nozzles) 230 V 50 Hz

DLA08DB000 Double blower 12.0 l/h (8 x 1.45 l/h nozzles) 230 V 50 Hz

DLA08DB100 Double blower 22.0 l/h (8 x 2.8 l/h nozzles) 230 V 50 Hz

DLA08DB200 Double blower 32.0 l/h (8 x 4.0 l/h nozzles) 230 V 50 Hz

F = single zone (front)

B = double zone (front/back)

Tab. 1.c

1.4 Hose part numbers

The high pressure hoses (OD = 10 mm, ID = 6.4 mm) are supplied by

Carel in dierent lengths. The part numbers available are listed below.

All the hoses have with M16x1.5 female couplings with O-rings, ideal for

direct connection to the cabinet and the blower units without needing

to use sealants. Each hose kit includes an M16x1.5 nipple to be used for

coupling dierent hoses together.

Stainless steel pipes can also be used to connect the blowers to the

cabinet. The recommended outside diameter is 10 mm. This solution is

the installer’s responsibility.

Carel recommends using hoses rather than pipes.

UAKT005014 High pressure hose, L = 0.5 m

UAKT010014 High pressure hose, L = 1.0 m

UAKT020014 High pressure hose, L = 2.0 m

UAKT050014 High pressure hose, L = 5.0 m

UAKT100014 High pressure hose, L = 10 m

UAKT200014 High pressure hose, L = 20 m

Tab. 1.b

P/N 120 V 60 Hz BLOWERS

DLA02UF000 Front blower 3.0 l/h (2 1x .45 l/h nozzles) 120 V 60 Hz

DLA02UF100 Front blower 5.0 l/h (2 x 2.8 l/h nozzles) 120 V 60 Hz

DLA02UF200 Front blower 8.0 l/h (2x 4.0 l/h nozzles) 120 V 60 Hz

DLA04UF000 Front blower 6.0 l/h (4 x 1.45 l/h nozzles) 120 V 60 Hz

DLA04UF100 Front blower 11.0 l/h (4 x 2.8 l/h nozzles) 120 V 60 Hz

DLA04UF200 Front blower 16.0 l/h (4 x nozzles from 4.0l/h) 120 V 60 Hz

DLA04UB000 Double blower 6.0 l/h (4 x 1.45 l/h nozzles) 120 V 60 Hz

DLA04UB100 Double blower 11.0 l/h (4 x 2.8 l/h nozzles) 120 V 60 Hz

DLA04UB200 Double blower 16.0 l/h (4 x 4.0 l/h nozzles) 120 V 60 Hz

DLA08UB000 Double blower 12.0 l/h (8 x 1.45 l/h nozzles) 120 V 60 Hz

DLA08UB100 Double blower 22.0 l/h (8 x 2.8 l/h nozzles) 120 V 60 Hz

DLA08UB200 Double blower 32.0 l/h (8 x 4.0 l/h nozzles) 120 V 60 Hz

Tab. 1.d

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

8

1.6 Main components

ENG

17

18

power supply

230 V 50 Hz

120 V 60 Hz

21

21

22

23

20

water drain

3/4" GAS F

19

1

3

water inlet

3/4” GAS F

2

4

14

15

16

16

15

ow

and return

M16x1.5

male

2

1

11

10

1312

9

6

Cabinet water circuit

Ref. Description

1 Water inlet lter

2 Pressure reducer

3 NC ll solenoid valve

4 Low pressure gauge

5 Motor

6 Pump

7 High pressure gauge

8 High pressure sensor

9 Temperature-controlled safety valve

10 High pressure sensor

11 Temperature sensor

12 Overow valve

13 Drain solenoid valve

14 Bypass solenoid valve

15 NC ll solenoid valve

16 NO return solenoid valve

17 Fuse kit

18 pGDx display

19 Controller

20 Expansion card

21 Transformer

22 SSR

23 Cooling fan

5

Fig. 1.d

87

input / output water

Single-blower: M16 x 1.5 male

Double blower: M16 x 1.5 female

8

7

Ref. Description

1 metal support / wall bracket

2 side plastic cover

3 centre plastic cover

4 pressurised water manifold

5 nozzle

6 power LED

7 terminal block for blower power supply

8 fan

6 5 4 3 2

Fig. 1.e

1

9

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

1.7 Dimensions and weights

1.7.1 Dimensions and weights of the cabinet

93

3/4"G f

235

19

50

5050

100

347

50 50

60,5

Tab. 1.e

180

98,5

3/4"G f

80

M16x1.5M

M16x1.5M

M16x1.5M

M16x1.5M

75

310

60 60

60

805

800

630

Fig. 1.f

Dimensions Weight

630x300x800 mm

(24.8"x11.8"x31.5")

UA040-UA050 UA080-UA090

single zone two zones single zone two zones

60 kg (132 lb) 64 kg (141 lb) 64 kg (141 lb) 68 kg (149 lb)

1.7.2 Dimensions and weights of the single blowers

200

1.8 Packaging and shipment

The cabinet is packaged and delivered on a wooden pallet with a

cardboard cover. The user is responsible for moving the cabinet near the

point of operation, removing the packaging and placing it in a position

ready for the water and electrical connections.

The blowers are delivered already assembled in cardboard boxes. The user

is responsible for removing the blower from the packaging, removing the

side plastic covers so as to make the water and electrical connections,

and then replacing the plastic covers before starting the system.

1.8.1 Dimensions and weights of the packages

Fig. 1.i

Dimensions Weight

720x460x1020 mm

(28.5"x18"x40")

UA040-UA050 UA080-UA090

single zone two zones single zone two zones

64 kg (141 lb) 68 kg (149 lb) 68 kg (149 lb) 72 kg (158 lb)

Tab. 1.h

640

17,5

200

IN/OUT

940

M16X1,5

Fig. 1.g

P/N Dimensions [a x b x c] Weight

DLA02xFx00

Single blower, 2 modules

DLA04xFx00

Single blower, 4 modules

640 x 200 x 180 mm

(25 x 8 x 7 inches)

940 x 200 x 180 mm

(37 x 8 x 7 inches)

4.5 kg

(9 lb)

5.6 kg

(12 lb)

Tab. 1.f

1.7.3 Dimensions and weights of the double blowers

IN/OUT

200

640

225

200

940

Fig. 1.h

P/N Dimensions [a x b x c] Weight

DLA04xBx00

Double blower, 2 modules

DLA08xBx00

Double blower, 4 modules

640 x 200 x 400 mm

(25 x 8 x 16 inches)

940 x 200 x 400 mm

(37 x 8 x 16 inches)

M16X1,5

400

9.2 kg

(20 lb)

15.5 kg

(34 lb)

Tab. 1.g

Fig. 1.j

P/N Dimensions [L x W x H] Weight

DLA02xFx00

front blower 2 mod

DLA04xFx00

front blower 4 mod

DLA04xBx00

double blower 2 mod

DLA08xBx00

double blower 4 mod

755 x 235 x 295 mm

(30 x 9 x 12 inches)

1050 x 235 x 295 mm

(41 x 9 x 12 inches)

755 x 470 x 295 mm

(30 x 18 x 12 inches)

1050 x 470 x 295 mm

(41 x 18 x 12 inches)

5.7 kg

(12 lb)

7.4 kg

(16 lb)

11.4 kg

(25 lb)

18 kg

(39 lb)

Delivery and storage temperature must be between -10°C - 50°C and

humidity between 0% - 90% non-condensing.

1.9 IP rating and standards

The IP rating of the cabinet is IP20.

The IP rating of the blowers is IP20.

The IP rating of the blowers is not a problem for installation, as all the

components inside have a higher IP rating.

The blowers can in fact be installed in rooms with very high humidity (up

to 95% non-condensing).

The unit is compliant with the Machinery Directive.

The unit is CE marked in the 230 Vac 50 Hz version in accordance with IEC

60335-1, IEC 60335-2, EN 60335, EN 61000-6-2 (2006) and EN 61000-6-4

(2007).

The unit is UL marked in the 120 Vac 60 Hz version in accordance with

directive UL998.

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

10

2. CABINET INSTALLATION

ENG

2.1 Positioning

The cabinet, being IP20, must be installed in a closed compartment,

sheltered from the rain, water spray and direct sunlight.

The cabinet must be installed in an environment with a temperature

between 5 and 40°C.

Around 1 m clearance must be left in front of the cabinet to allow the

door to be opened and maintenance to be performed. Around 0.5 m

clearance needs to be left on both sides of the cabinet to allow space for

the water connections on the right and electrical connections on the left.

Fig. 2.a

2.1.2 Floor-standing installation

For oor-standing installation, the unit needs to rest on a raised platform

so as to allow connection of the drain hose, located on the bottom of the

cabinet (see chapter 2.2.3).

min 30 cm

Fig. 2.c

2.2 Cabinet water connections

2.1.1 Wall mounting

The cabinets can be wall-mounted or oor-standing.

In the event of wall mounting, it is recommended to use the metal frames

and screws supplied. See the distances shown in the following image for

drilling the holes and fastening the brackets.

2.2.1 Feedwater line

An expansion vessel should always be installed upstream of the cabinet,

so as attenuate variations in pressure in the feedwater line. It is also

suggested to install a mechanical lter on the feedwater line to the

cabinet (P/N ECKVESS050 for the lter vessel and P/N ECKFILT050 for the

lter cartridge). Finally, an on-o ball valve should be installed on the line

upstream of the cabinet, so as to allow for any maintenance operations

on the water circuit downstream.

Fig. 2.d

A hose with a minimum diameter Ø=1/2” should be connected upstream

of the cabinet so as to ensure the right ow-rate and pressure to the

humidier. The humidier inlet connection is 3/4” GAS F. The required

humidier inlet pressure is at least 3 bars.

Fig. 2.b

11

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

2.2.2 Feedwater characteristics

humiFog Direct requires demineralised water, so as to ensure:

• minimum maintenance;

• no blockages of the nozzles;

• no dust (the droplets that evaporate will not leave mineral salts in the

environment);

• improved hygiene.

The use of demineralised water is also required to comply with standards

UNI8883, VDI6022 and VDI3803.

humiFog Direct must only operate on demineralised water that falls

within the limits listed in the following table. Normally, these values can

be obtained by reverse osmosis or nanoltration of the feedwater.

Specic conductivity 25 - 80 µS/cm

pH 5.5 – 8.5

Total hardness (TH) 0 - 25 mg/l CaCO3

Temporary hardness 0 - 15 mg/l CaCO3

Chlorides (Cl) 0 - 10 ppm Cl

Iron + manganese (Fe + Mn) 0 mg/l

Silicon dioxide (SiO2) 0 - 1 mg/l

Chlorine ions (Cl-) 0 mg/l

Calcium sulphate (CaSO4) 0 - 5 mg/l

2.2.3 Cabinet drain connection

The drain point located at the bottom of the cabinet must be connected

externally (3/4" GAS F tting) to an open discharge with drain trap.

93

3/4"G f

2.3 Cabinet electrical installation

The cabinet must be connected to the mains by the user.

230 V 50 Hz for cabinet CE version UA***DD*01

120 V 60 Hz for cabinet UL version UA***DD*01

The connection must be compliant with local standards, using a suitablysized cable. A three-wire cable (line + neutral + earth/ground) must be

connected to the three terminals (L + N + GR).

Fig. 2.f

Cabinet terminal Power cable

L L / F (line)

N N / W (neutral)

GR GR / PE (earth)

Important: t an external power switch on the humidier power supply

line to isolate the power supply, and a TT earthing system with earth fault

current of 30 mA.

No additional wiring is required to the cabinet terminal block, except

for the power supply to the blower fans, using the terminals. For the

electrical connections from the cabinet to the blowers, see chapter 3.4.

235

Fig. 2.e

Also remember that the cabinet cannot be installed on the oor without

a support that keeps the cabinet raised by at least 20-30 cm.

2.2.4 Blower water supply line

With reference to the high-pressure hoses provided by CAREL (inside

diameter Ø = 6.3 mm), in order to ensure correct operation of the

atomisation system, the water supply line to the blowers in a single zone

must respect the following maximum lengths:

Model Rated pump

capacity [L/h]

UA040DD2** 40

UA050DU2** 50

UA040DD1** 40

UA050DU1** 50

UA080DD2** 80

UA090DU2** 90

UA080DD1** 80

UA090DU1** 90

* The values shown refer to the water circuit in a single zone and the last

blower on the line.

Contact CAREL for longer water lines.

Maximum hose length supplying

the blowers* [m]

25

50

50

100

Tab. 2.a

Fig. 2.g

2.3.1 Fuses

The following table lists the technical specications of the fuses supplied

for the dierent cabinets:

Fuse Single-zone cabinet Two-zone cabinet

F1 1 A (upstream of the transformer) 1 A (upstream of the transformer)

F2 1 A (upstream of the transformer) 1 A (upstream of the transformer)

F3 4 A (downstream of the transf.) 1 A (upstream of the transformer)

F4 1 A (upstream of the transformer)

F5 4 A (downstream of the transf.)

F6 4 A (downstream of the transf.)

UA0*0DD*** (50 Hz)

Tab. 2.b

Fuse Single-zone cabinet Two-zone cabinet

F1 2.5A (upstream of the transformer) 2.5A (upstream of the trans-

former)

F2 2.5A (upstream of the transformer) 2.5A (upstream of the transf.)

F3 4 A (downstream of the transf.) 2.5A (upstream of the transf.)

F4 2.5A (upstream of the transf.)

F5 4 A (downstream of the transf.)

F6 4 A (downstream of the transf.)

UA0*0DU*** (60 Hz)

Tab. 2.c

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

Fuses F1, F2, F3*, F4* are installed in the fuse carriers (Fig. 2.h).

Fuses F3, F5*, F6* are installed on the top surface of the corresponding

transformers (components no. 17 in Fig. 1.d).

* indicates the P/N for the fuse on the two-zone cabinet.

12

Fig. 2.h

2.4 Changing the oil cap

During installation, before starting the unit, remember to replace the red

oil cap (A) on the pump with the yellow one (B) supplied. The red cap is

closed and is only used for transport. The yellow cap has a vent opening

and is used for normal operation of the system. The yellow cap is supplied

inside the cabinet, tied to the high pressure gauge (see the image below).

A

B

ENG

Fig. 2.i

3. DISTRIBUTION SYSTEM INSTALLATION

3.1 Blower unit installation

The humiFog Direct system works by connecting the cabinet to a

number of blower units installed directly in the room to be humidied

and/or cooled.

The following simple rules must be kept in mind when installing the

blower units:

• the minimum ow-rate that can be atomised in the room is 8 l/h

(irrespective of the size of the pump). The minimum number of blower

units must therefore be dened based on the number and size of the

chosen nozzles.

The maximum numbers of blower units that can be connected to a

cabinet are:

• 12 blower units with 2 nozzles

• 6 blower units with 4 nozzles

• 3 blower units with 8 nozzles

The blower units must be suitably positioned so as to allow complete

absorption of the sprayed water. Consequently it is recommended to

install the blowers a due distance apart, at a sucient height from the

oor and with free space at the front without obstacles.

0.5 ÷ 1m

≥ 5m

≥ 4m

light light

≤ 10°

SI

SI NO

SI NO

NO

≥ 5m

≤ 4m

The blower units can be mounted either on the wall or on the ceiling.

For a correct installation, see the example in Fig. 3.a or contact Carel for

dierent temperature and humidity conditions.

13

≤ 10°

rH = 40% T = 25 °C

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

SI NO

Fig. 3.a

ENG

The blower unit installation procedure is as follows:

1. Unpack the blower unit from the box it was delivered in. The blower

units are delivered fully assembled.

2. Remove the side plastic covers cover from the blower. Unscrew the

long screws on the side using a screwdriver. Make sure to keep the

screws, as they will be needed again for assembly at the end.

3. Mount the blower unit on the metal support. See paragraph 3.2 for

details.

4. Connect the water line to the inlet on the blower units (M16x1.5). See

paragraph 3.3 for details.

5. Electrically connect the blower units to the cabinet, which supplies

power and controls operation of the fans. See paragraph 3.4 for

details.

6. Complete blower assembly by repositioning the side plastic covers

removed previously, and xing them with the same screws as

removed at the beginning.

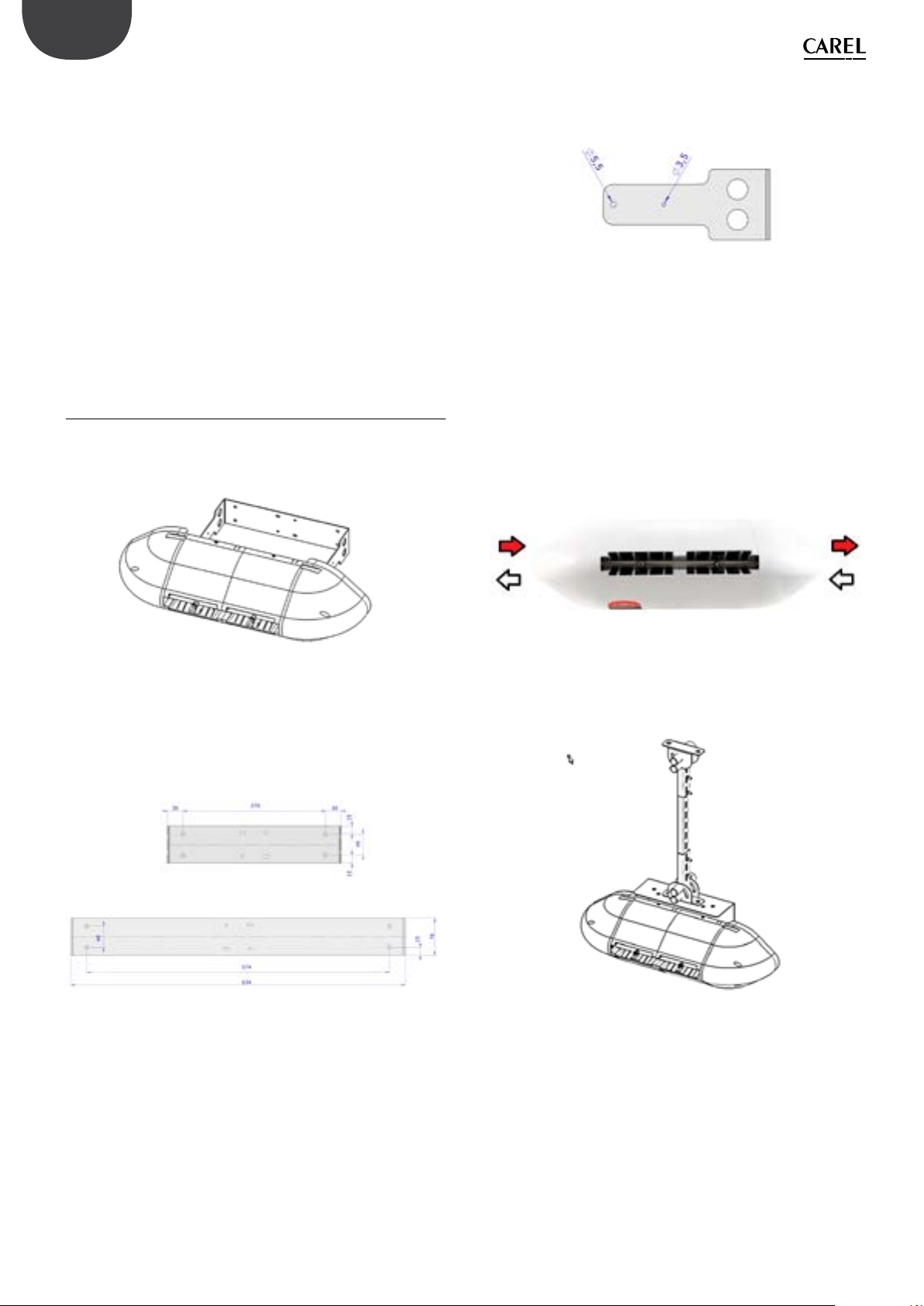

3.2 Mounting single blower units on the wall / ceiling

The single blower units (P/N DLA%F) are designed to be installed on a

vertical wall using a special metal support to be xed to the wall using

screws. Check that the wall is made from suitable material and is able to

support the weight of the blower unit (concrete, not plasterboard).

Then attach the blower to the protrusions on the wall-mounting support

bracket.

Fix the blower unit to the bracket using the screws supplied in a bag

inside the packaging.

Fig. 3.e

When tightening the rst screw (M6 self-tapping in Ø=5.5 mm holes),

slightly loosen the screws on the ring clamps that support the nozzle

manifold, so as to be able to turn it and free up space to continue

mounting the unit. Tighten one screw on the right and one screw on

the left.

Then tighten the third screw (M4 self-tapping in Ø=3.5 mm hole) on

the right-hand side of the blower (opposite the terminal block). When

tightening this screw, the angle of the blower can be adjusted between

-10°/-5°/0°/+5°/+10° from horizontal, using one of the ve small holes

provided.

Then make the water connections, connecting the feedwater line

either on the right or left of the blower, and the water return line on the

opposite side.

Fig. 3.b

First remove the blower unit from the packaging and take o the side

plastic covers. Remove the blower unit from the steel bracket on the rear.

Rest the bracket against the wall in the position where the blower will be

installed, and then drill four holes in the wall, using the steel bracket as

the drilling template.

Fig. 3.c

Fig. 3.d

After having drilled the holes in the wall, x the metal support using

anchor screws (not supplied).

Fig. 3.f

Finally, t the two cable glands and complete the electrical wiring, as

described in paragraph 3.4.

Carel also provides an additional kit (including a special plate bent at 90°)

for mounting single blower units on the ceiling.

Fig. 3.g

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

14

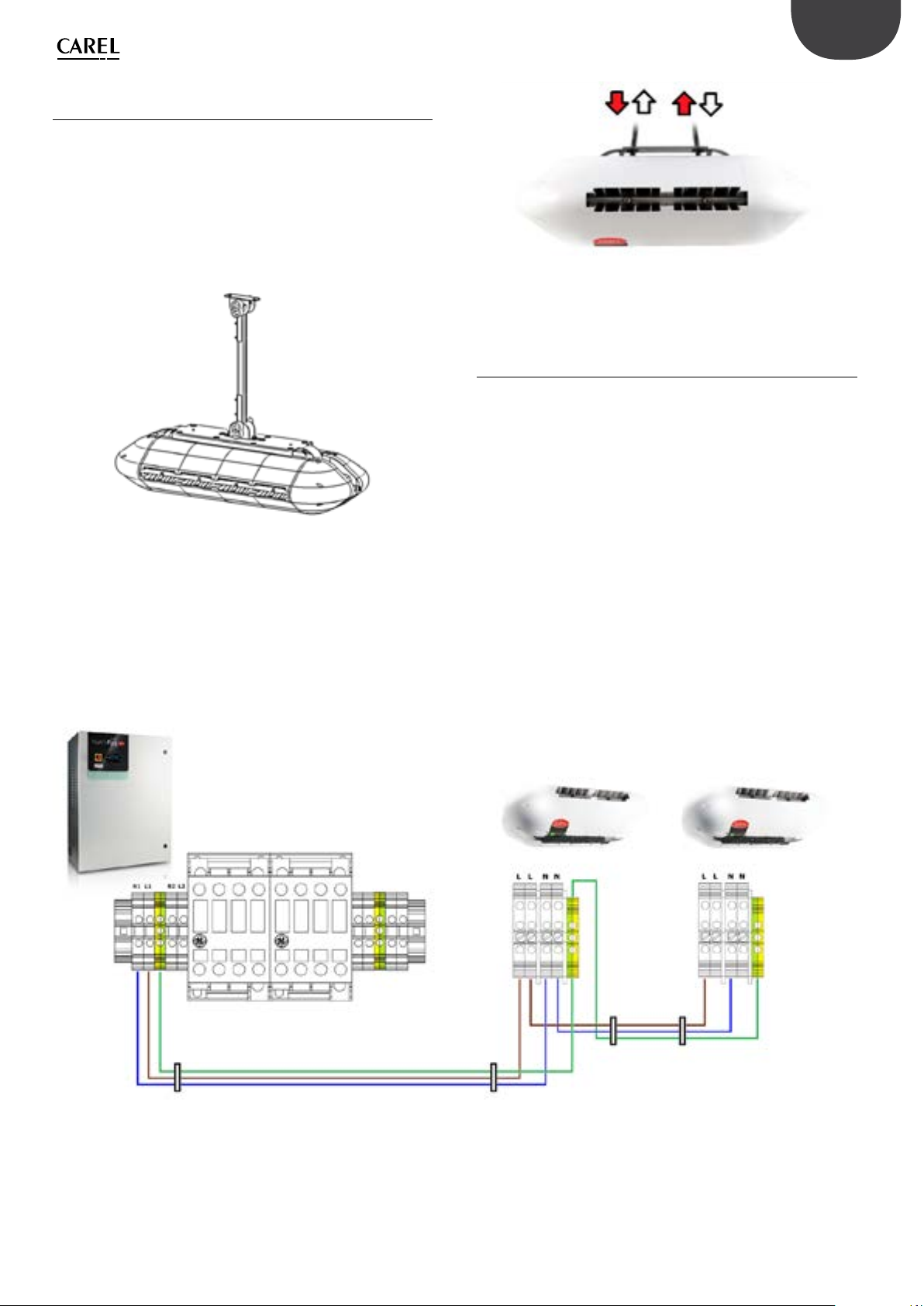

3.3 Mounting double blower units on the ceiling

The double blower units (P/N DLA%B) are designed to be installed on

the ceiling by anchoring them to a metal support that can support their

weight and the vibrations due to the pressurised water. To mount the

blower unit, use the special attachments provided on the unit’s metal

structure.

Carel provides additional kits with everything needed to complete

installation easily. Make sure to carefully choose the point where the

vertical support bar will be anchored. The support bar must not be longer

than 1 metre, so as to avoid excessive bending and vibrations.

Fig. 3.h

After installing the blower, make the water connections by connecting

the feedwater and return lines to the two pipes provided on the top of

the blower. The feedwater/return lines can be connected either to the

right or left.

ENG

Fig. 3.i

Finally, t the two cable glands and complete the electrical wiring, as

described in paragraph 3.4.

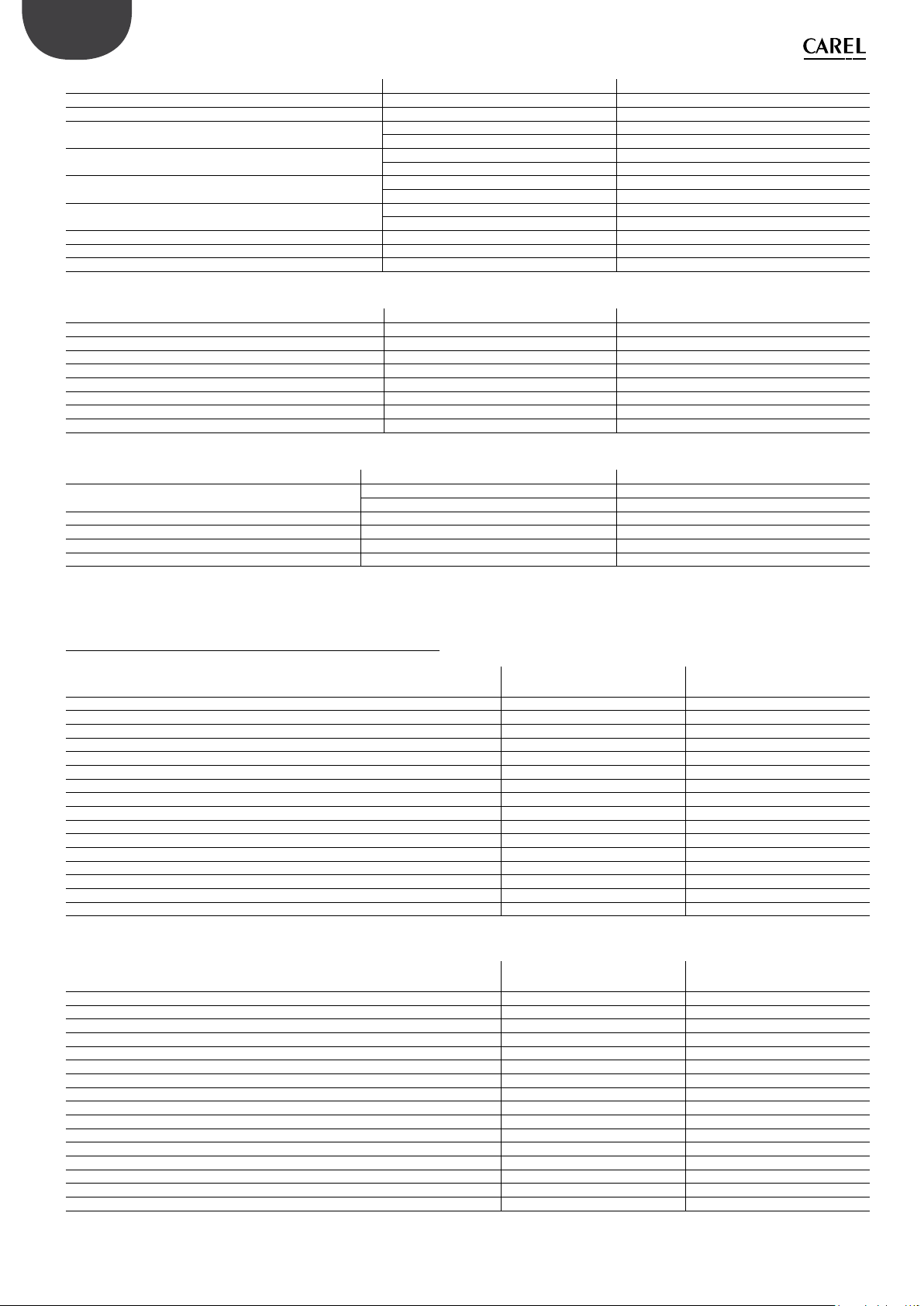

3.4 Blower unit electrical connection

The blower units must be electrically connected to the cabinet so that

they are activated only when there is a humidication request

Before electrically connecting the blower units to the cabinet, make sure

that the cable glands supplied with the cabinet and the blower units are

available. All connections to be made by the user (cabinet power supply,

blower unit power supply, probe connections, etc.) must be performed

by running the cables through the cable glands, and in accordance with

local safety standards.

Also check that the cable is the right size for the distance and voltages

used. Carel recommends an AWG14 or AWG12 cable, as shown in the

technical data at the end of the manual.

To connect power to the blower units, connect three suitably-sized wires

(line + neutral + earth) from the terminals on the cabinet (shown in the

gure) to the terminals on the blower (shown in the gure). To power

a second and subsequent blowers, start from the free terminals on of

the previous blower and connect to the terminals on the next blower, as

shown in the gure.

Fig. 3.j

Important:

• remember to run the wires through the cable glands (marked in the gure).

• check the maximum number of blower units that can be connected to each cabinet in the tables in Appendix 12 at the end of the manual.

• when connecting the line (L) and neutral (N) from the cabinet to the blower units, never reverse L and N. Reversing or crossing over the wiring may cause

short-circuits.

After having completed the wiring, close the side plastic covers again and x them using the screws. The system is now ready to operate.

15

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

4. ELECTRONIC CONTROLLER SET UP AND CONNECTIONS

After having correctly installed the cabinet and completed the water and

electrical connections, connect the signals used to interface with the

humiFog Direct humidier to the c.pHC electronic controller (and the

c.pCO controller on two-zone cabinets.

Fig. 4.a

4.1 Remote ON/OFF signal connection

The remote ON/OFF contact is used to enable operation from an external

device. It is a digital contact that can be either open or closed: when the

terminal is open, humiFog cannot operate. The contact refers to inputs 7

[GND]- 8 [digit] on terminal M2 on the c.pHC.

The remote ON/OFF contact must not be confused with the ON/OFF

signal that manages operation, described in paragraph 4.5.

The following types of probes are allowed:

• 4-20 mA, 0-20 mA current probes

• 0-10 V, 0-1 V, 2-10 V voltage probes

The analogue signal from the limit probe in the rst zone is connected to

the c.pHC controller via inputs 5 [IN a] 6 [GND] 3 [+12 Vdc] on terminal M2.

MAIN PROBE

ZONE 1

[IN a] [GND] [+15 Vdc] [IN a] [GND] [+15 Vdc]

Important: if connecting a probe with voltage signal that requires a

power supply greater than the +12 Vdc supplied to the terminal on the

c.pHC, the third wire must not be connected to input 3 [+12 Vdc] but

rather to terminal GA1 [+24 Vac], made available on the cabinet terminal

block, right above the c.pHC.

LIMIT PROBE

ZONE 1

Fig. 4.c

7 [GND]8 [digit]

Fig. 4.b

If not intending to use an external contact to start / stop the unit, leave

the terminal short-circuited (as supplied).

REMOTE ONOFF

4.2 Analogue signal from the main probe

and limit probe in the first zone

humiFog Direct can be controlled using an analogue signal (modulating)

from a main humidity or temperature probe connected to the c.pHC

electronic controller. If connected to a humidity probe, humiFog Direct

will display the relative humidity read by the probe. If connected to a

temperature probe, on the other hand, humiFog Direct will display the

temperature. Based on the probe reading and the deviation from the set

point, humiFog Direct will modulate the humidication load according

to the PWM principle (see paragraph 6.2). The following types of probes

are allowed:

• 4-20 mA, 0-20 mA current probes

• 0-10 V, 0-1 V, 2-10 V voltage probes

The analogue signal from the main probe in the rst zone is connected to

the c.pHC controller via inputs 1 [IN a] 2 [GND] 3 [+12 Vdc] on terminal M2.

4.3 Analogue signal from the main probe and limit probe in the second zone

If a second zone is used (only with UA%DD201 and UA%DU201 cabinets),

the main probe corresponding to the second zone must be connected to

the c.pCOe expansion installed under the c.pHC controller.

The following types of probes are allowed:

• 4-20 mA, 0-20 mA current probes

• 0-10 V, 0-1 V, 2-10 V voltage probes

The inputs used for the main probe are U1 [IN a] and [GND] on terminal

J2, and the power supply is taken from the +Vdc on terminal J9. The limit

probe (optional) corresponding to the second zone is connected to

inputs U2 [IN a] and [GND] on terminal J2, and the power supply is taken

from the +Vdc on terminal J9.

MAIN PROBE

ZONE 1

[IN a] [GND] [+15 Vdc] [IN a] [GND] [+15 Vdc]

LIMIT PROBE

ZONE 1

The limit probe (optional) is used for the auxiliary function to reduce

humiFog Direct humidication or cooling capacity when approaching

a set humidity or temperature threshold (on the display or external

controller). To set the threshold, select operation with limit probe on the

display. The threshold will either be a humidity or temperature value. The

limit probe can also be used without using a main probe.

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

Fig. 4.d

Important: unlike the rst zone, the connection to the c.pCOe expansion

relating to the second zone can supply power to probes that require up

to 21 Vdc.

16

ENG

4.4 Analogue signal from an ext. controller

As an alternative to the main probe, a signal from an external controller

can be used. The latter processes the request to send to humiFog Direct

via an analogue signal, which varies from 0 to 100%. humiFog will adjust

the capacity delivered proportionally to the signal received, and the

display will show the request sent as a percentage.

The following types of proportional signals are allowed:

• 4-20 mA, 0-20 mA current signals

• 0-10 V, 0-1 V, 2-10 V voltage signals

The external signal for the rst zone is connected to the c.pHC controller

via inputs 1 [IN a] and 2 [GND] on terminal M2.

The external signal for the second zone is connected to the c.pCOe

controller via inputs U1 [IN a] and [GND] on the terminal J2.

EXTERNAL SIGNAL ZONE 1

[IN a] [GND] [IN a] [GND]

The limit probes can also be associated with the external proportional

signal, and will be connected as shown in the previous paragraphs.

Fig. 4.e Fig. 4.f

EXTERNAL

SIGNAL ZONE 2

4.5 Digital signal from humidistat or external controller

The signal from the external controller can be replaced by the signal from

a humidistat, thermostat, or any external device with digital contact. In

this case, humiFog Direct will work in ON/OFF mode, either delivering

100% of ow-rate or remaining in standby. The capacity delivered can be

reduced by setting parameter P0 (the reduction is managed by PWM, see

paragraph 6.5). The electrical connection is the same as in the previous

case shown in Figure 4.e. Make sure to congure the humiFog Direct (via

the screens on the display) so that it can be controlled by an ON/OFF

signal from external controller or device.

4.6 Serial or Ethernet communication

humiFog Direct can be controlled by a supervisor that reads the humiFog

Direct parameters and sends commands. To connect a supervisor, the

RS485 serial port (terminal M12, inputs 1 [Tx/Rx-] 2 [Tx/Rx+] 3 [GND]) or

Ethernet port is used. The choice of which port to use depends on the

supervisor. Modbus and BACnet communication protocols are available

as standard: no auxiliary cards need to be tted on the c.pHC controller

The Ethernet port can also be used for the Webserver function (see

Chapter 8), so as to monitor and control humiFog Direct via a local

network, without needing a supervisor.

4.7 Alarm relay output

The digital output for communication of an alarm status is connected to

contacts 1-2-3 on terminal M6 on the c.pHC. N.C. logic is set by connecting

the two wires to contacts 1-2, while N.O. logic is set connecting the two

wires to contacts 1-3.

N.C.

ALARM RELAY

Fig. 4.h

N.O.

4.8 Unit status digital output

The c.pHC controller provides a digital output corresponding to unit status.

This is a voltage-free contact that provides the following information:

• contact closed: unit on or in standby

• contact open: unit o (OFF from keypad or from remote contact, or

no power)

The unit status digital output is available at contacts 1-2 on terminal M5

on the c.pHC.

4.9 Production percentage analogue

outputs

The c.pHC controller provides an analogue output (0-10 V) corresponding

to the percentage of production that humiFog Direct is delivering.

The output replicates the request signal relating to the corresponding

humiFog Direct zone.

The production percentage analogue outputs are connected to the

following terminals:

• zone 1: outputs 1 and 2 on terminal M8 on the c.pHC.

• zone 2: outputs U3 and GND on terminal J2 on the c.pCOe.

ETHERNET

Fig. 4.g

1 [Tx/Rx-]

2 [Tx/Rx+]

3 [GND]

SERIAL RS485

% PRODUCTION

ZONE 1

Important: when several GND contacts are wired to the same terminal

these are equivalent to each other, and can be used indierently.

17

SYSTEM

STATUS

Fig. 4.i Fig. 4.j

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

% PRODUCTION

ZONE 2

ENG

5. STARTUP AND USER INTERFACE

5.1 Graphic terminal

The 4.3” touch graphic terminal has an interface with coloured and

animated icons. The contents of the display can be scrolled up and down

simply and intuitively.

Fig. 5.a

On the right of the graphic terminal is the notication bar.

If the humidier is powered on, the notication bar is always on, even when

the display is o, and provides immediate information on humidier status.

Bar colour Bar status Humidier status

White Light on steady Unit o (o or standby)

Green Light on steady Unit in production, start-up, ll

Blue Light on steady Washing in progress

Red Light ashing Alarm on the unit

Cyan Light on steady Unit in manual mode

Yellow Light ashing Unit shutting down

Tab. 5.a

5.2 Start-up

Switch on humiFog Direct by moving the disconnect

switch on the front panel from position O to position

I.

The display shows the “humiFog Direct” logo, after which the menu

language can be chosen, from the following options:

• English

• Italiano

• Deutsch

• Français

• Español

Tap the language and ag icon with your nger to access the drop-down

menu with the options.

Configuration wizard

When starting the rst time, a wizard is provided to quickly set the main

unit parameters. There are at most 10 steps to set up the unit:

Step 1/10

Enter the humidier model.

Step 2/10

Enter the humidication load in kg/h for zone 1 and, if present, zone

2. The humidication load can be easily calculated by multiplying the

number of atomising nozzles in the zone by the ow-rate delivered by

each nozzle.

Step 3/10

Select zone 1 control mode from the options:

• ON/OFF contact (e.g. humidistat);

• External signal:

• External signal + humidity limit probe;

• External signal + temperature limit probe;

• Main humidity probe;

• Main temperature probe;

• Main humidity probe + humidity limit probe;

• Main temperature probe + temperature limit probe;

• Main humidity probe + temperature limit probe;

• Main temperature probe + humidity limit probe;

• Two main humidity probes (weighted average);

• Two main temperature probes (weighted average);

If using wireless probes, select the parameter that is shown by default

and at the end of the wizard refer to chapter “9. WIRELESS PROBES;

INSTALLATION AND CONFIGURATION”.

Step 4/10

Select zone 2 control mode. The options available are those already listed

in step 3/10.

Step 5/10

Select the type of signal from the main probe or from an external

controller to control zone 1:

• 0-10 V;

• 4-20 mA;

• 0-20 mA;

• 0-1 V;

• 2-10 V;

• NTC (temperature probe only)

Fig. 5.b

Scroll the menu with your nger.

Select the desired language and then conrm.

Fig. 5.c

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

Step 6/10

Select the type of signal from the limit probe in zone 1. The signals

available are those already listed in step 5/10.

Step 7/10

Select the type of signal from the main probe or from an external

controller to control zone 2. The signals available are those already listed

in step 5/10.

Step 8/10

Select the type of signal from the limit probe in zone 2. The signals

available are those already listed in step 5/10.

Step 9/10

Enter the set points for zone 1 and zone 2 relating to the main probe and

limit probe.

Step 10/10

Enter the system date and time.

The wizard is now nished: you can choose whether or not to display it

the next time humiFog direct is powered on. In any case, the wizard is

always accessible from the settings menu on the graphic terminal.

18

ENG

5.3 Touch display

HOME menu

The “HOME” menu includes information about the pumping station and

the zones, including current production, information on the probes and

unit status.

10

8 9

11

1

2

Pos. Function Pos. Function

1 ON/OFF quick menu 7 Notication centre

2 Set point quick menu 8 System date & time

3 Input/output quick menu 9 Scheduler status

4 System information quick menu 10 Master/Slave Network

5 Descriptive icon of zone status 11 Main menu

6 Alarm list

Fig. 5.d

5.3.1 ON/OFF quick menu

Pressing the ON/OFF quick menu icon accesses the screen for switching

the entire system or individual zones on and o. To switch on or o the

unit or zones (ON when the indicator is positioned to the right, OFF when

positioned to the left), press the button.

Message Values Meaning

Unit ON Enables the pump to operate according to zone request

Zone 1/2

(visible only

if unit ON)

The menu also contains information on the type of system start-up

control signal. To return to the home menu, press the “HOME” icon

OFF Switches the pumping unit OFF

START Enables atomisation in zone 1/2 according to the request

PAUSE Temporarily stop atomisation in zone 1/2

7

6

5

4

3

Tab. 5.b

Tab. 5.a

To return to the home menu, press the “HOME” icon

Fig. 5.f

5.3.3 INPUT/OUTPUT quick menu

Press the icon to access the menu.

The input/output dashboard oers an intuitive and real-time view of the

system operating status, the values read by the humiFog direct cabinet

probes, the status of the mechanical components in the water circuit and

the water ow path.

Mechanical component I/O dashboard

Solenoid valve

Pressure sensor

Temperature sensor

Pressure switch

Pump

Nozzles

To return to the home menu, press the “HOME” icon

symbol

(Valve closed)

(Valve open)

(Atomise ON

(Atomise OFF)

System components

FV: cabinet ll valve

BYP: bypass valve

DC: cabinet drain valve

FV1: zone 1 ll valve

DR1: zone 1 drain valve

FV2: zone 2 ll valve

DR2: zone 2 drain valve

LPS: low pressure sensor

RHP: high pressure sensor

T: water temperature sensor

HP: high pressure switch

Cabinet pump

Zone nozzles

Tab. 5.d

Fig. 5.e

5.3.2 Set point quick menu

Press the icon to access the menu. The menu is used to modify the set

point and proportional control band. Press the white number to change

the value. Enter the desired value and press the conrm button (

Title Message Values Default

Zone 1 set

(Zone 2 set)

To move from one area to another, or from one page to another, press

the right and left arrows on the display and repeat the same operations

to change the values.

Main probe set point 0-100% rH 0-40 °C 50% rH 25 °C

Main probe band 0-10% rH 0-10 °C 5% rH 2 °C

Limit probe set point 0-100% rH 0-40 °C 80% rH 15 °C

Limit probe band 0-10% rH 0-10 °C 5% rH 2 °C

).

Tab. 5.c

Fig. 5.g

To switch to display the input/output values in table form, press the right

arrow.

If using wireless probes, to display the input/output values, press the

right arrow again.

Use the slider to scroll through the table.

To return to the previous display, press

To return to the home menu, press the “HOME” icon

Fig. 5.h

19

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

Fig. 5.i

5.3.4 INFO quick menu

Press the icon to access the menu.

Menu describing humidier status, software and hardware information.

To move from one page to another, press the arrows on the right and left

of the display.

To scroll through the displayed information, press the slider.

To return to the home menu, press the “HOME” icon

5.3.7 Notification centre

Press the icon to access the notication centre.

To view the details of an individual notication, press the notication.

To return to the previous display, press

To return to the home menu, press the “HOME” icon

Fig. 5.m

5.3.8 System date and time

The system date and time is displayed.

5.3.9 Scheduler status

If enabled, the scheduler status (on/o ) is shown. Pressing the icon

accesses the scheduler section, described in the following paragraph

“5.3.16 Scheduler”.

Fig. 5.j

5.3.5 Zone status

To view more details for the single zone, on the display home page press

the white nozzle icon or use the arrows on the right and left of the display

to move from one zone to the other.

To return to the home menu, press the “HOME” icon

Fig. 5.k

5.3.6 Alarm list

Press the icon to display the alarm list.

To view the alarm log, press

To reset the alarms, press

To return to the previous display, press

To return to the home menu, press the “HOME” icon

5.3.10 MASTER/SLAVE Network

Only for single-zone cabinets, if the master/slave network is enabled for

several humidiers, the

letter M is displayed, for slave units the letter S is displayed.

Press the icon to access information from the humidier network.

The page displayed shows some of the characteristics of the individual

unit and the system.

To quickly display the IP addresses of the units making up the master/

slave network, press

To view the page with details on current production and the status of the

humidiers in the master/slave network, press the right arrow.

icon is displayed. For the master unit, the

Fig. 5.n

.

Fig. 5.l

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

Fig. 5.o

To access information on the individual humidier, press the desired unit.

20

ENG

5.3.11 Main menu

Press the icon to access the main menu.

The menu provides access to the system items that are available without

entering a password.

To return to the previous display, press

To return to the home menu, press the “HOME” icon

Fig. 5.p

Description of the menus:

Menu Description

Clock Date and time setting

Input/Output Display the analogue and digital inputs/outputs

Graphs Display historical and real-time operation of the

humidier

Functions Special and manual functions

Scheduler Manage scheduling of working time bands

Language Set the menu language

Settings Access advanced humidier conguration (Installer

password 77). Menu: E. Settings. Change unit of measure

(Imperial/International)

Tab. 5.e

5.3.12 Clock

Press the icon to access the function.

Press the text to change the desired parameters.

To return to the previous display, press

To return to the home menu, press the “HOME” icon

5.3.14 Graphs

Press the icon to access the function.

The graphs function is used to view the values of some system analogue

and digital variables over a certain time frame.

Press the zone to be viewed.

On the rst screen displayed, the real-time value of the analogue and

digital variables relating to the zone is plotted. The value of each variable

is shown numerically in the table to the right of the graphs.

To scroll through the displayed information, press the slider.

To return to the previous display, press

To return to the home menu, press the “HOME” icon

Fig. 5.r

To move from one page to another, press the arrows on the right and left

of the display.

Moving to the right, the second screen displays the history of analogue

variables for the zone.

Press the

Press the

Press the

Press the arrows under the graph to change the period displayed.

Press the

the red cursor. The value of the variables corresponding to the red cursor

is shown in the table on the right.

icon to save the graph displayed to external memory.

icon to restore the initial view.

icon to select the length of the period to be viewed.

icon to hide the variables, magnify the graph and move

Fig. 5.q

5.3.13 Input/Output

Press the icon to access the function.

The same screen is displayed, which is also accessible from the input/

output quick menu.

Fig. 5.s

Moving to the right again, the history of the system's digital variables is

displayed on the third screen.

Fig. 5.t

21

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

5.3.15 Functions

Press the icon to access the functions.

The option to select the language following a reboot or unit power on

can be enabled or disabled.

To return to the previous display, press

To return to the home menu, press the “HOME” icon

Fig. 5.u

5.3.16 Scheduler

Press the icon to access the function.

Press the

Press the

To return to the previous display, press

To return to the home menu, press the “HOME” icon

icon to activate or deactivate the scheduler function

icon to access scheduler programming

5.3.18 Settings

Press the icon to access the function.

Enter the password (installer password 77) and conrm.

To return to the previous display, press

To return to the home menu, press the “HOME” icon

Fig. 5.y

Type in the

Press the icon to update the display application from a USB pendrive

Press the

Press the

Press the

The advanced conguration is managed via a keyboard on the display

(g. 5.a).

For details on the advanced conguration screens and parameters, see

the next chapter.

icon to change the unit of measure.

icon to access the conguration wizard or factory data reset

icon to access the advanced conguration.

icon to log out.

Fig. 5.v

The display shows the weekly scheduling status, press the column with

the individual day to access programming

Fig. 5.w

Press the

arrows to move to the previous or next day. Press the

scheduler program to the next day.

icon to program the scheduler time and status. Use the

icon to copy the

87

1

2

3

Fig. 5.z

Button Function

(1) alarm list and reset any active alarms

(2) PRG return to the “main” screen

from the “main” screen, access the previous menu

(3) ESC return to the previous screen/display

access notications (from main menu only)

(4) UP cyclically scroll the screen menu, parameters and param-

eter values

from the “main” screen: access the INFO screens

(5) ENTER select and conrm

from the main menu: access the “SET” screens

(6) DOWN cyclically scroll the screen menu, parameters and param-

eter values

from the “main” screen: access the INFO screens

(7) multiple selection of the previous buttons

(8) multiple selection duration

4

5

6

Tab. 5.f

Fig. 5.x

5.3.17 Language

Press the icon to access the function.

Scroll with your nger and select the desired language.

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

5.4 Remote installation of the touch display

To install the 4.3” touch screen in a remote position, use kit P/N

HCTXDA0000. The kit comprises a touch display, a 24 Vdc power supply,

a telephone cable and a telephone splitter for simultaneous connection

of the two displays (one in the remote position and the other installed on

the humidier).

22

ENG

6. ADVANCED CONFIGURATION PARAMETERS AND

OPERATING OPTIONS

6.1 Main menu and overview of functions

When accessing with password 77, the advanced settings button is available

for accessing a series of additional submenus. Each submenu is divided into a

number of screens identied by the index shown at the top right on the display.

The table below provides a complete overview of the screens.

Menu Index Description

a. Control

b. Functions

c. Congurations

d. Network unit Dd01 Enable the humidier network using the PRG button (if enabled, the network symbol appears on the main screen)

e. Manual mode De01 Enable manual zone request, set request % and enable management of individual c.phc outputs to check operation of electro-

Da01 Set the type of control in zone 1 and the maximum production

Da02 Set the type of control in zone 2 and the maximum production

Da03 (visible if control using two main probes has been enabled)

Set the weight of the zone 1 control probes

Da04 Set the set point and band for the zone 1 main probe

Da05 Set the set point and band for the zone 1 limit probe

Da06 (visible if control using two main probes has been enabled)

Set the weight of the zone 2 control probes

Da07 Set the set point and band for the zone 2 main probe

Da08 Set the set point and band for the zone 2 limit probe

Da09 Maintenance hour counter, reset counter and maintenance warning

Da10 This is shown after 40 operating hours

The oil change counter (warning at 50 h) can be reset

Da11 Unit hour counter (not resettable)

Da12 Set unit operating hours (e.g. after replacing c.phc controller) and maintenance warning

Db01 Enable lling and set the lling time

Db02 Set washing cycle duration and frequency

Db03 Enable management of the external water treatment system

Db04 Management of advance start and delayed stop of blower fans

Db05 Export event log via USB

Db06 Export alarm log via USB

Dc01 Set the type of signal for the main humidity probe in zone 1, minimum/maximum probe reading, probe oset, enable

disconnected probe alarm and set the alarm delay

Dc02 Set the type of signal for the main temperature probe in zone 1, minimum/maximum probe reading, probe oset, enable

disconnected probe alarm and set the alarm delay

Dc03 Set the type of external signal for zone 1, minimum/maximum signal value, signal oset

Dc04 Set the NO/NC logic for the external on/o contact (humidistat)

Dc05 Set the type of signal for the humidity limit probe in zone 1, minimum/maximum probe reading, probe oset, enable

disconnected probe alarm and set the alarm delay

Dc06 Set the type of signal for the temperature limit probe in zone 1, minimum/maximum probe reading, probe oset, enable

disconnected probe alarm and set the alarm delay

Dc07 Set the type of signal for the main humidity probe in zone 2, minimum/maximum probe reading, probe oset, enable

disconnected probe alarm and set the alarm delay

Dc08 Set the type of signal for the main temperature probe in zone 2, minimum/maximum probe reading, probe oset, enable

disconnected probe alarm and set the alarm delay

Dc09 Set the type of external signal for zone 2, minimum/maximum signal value, signal oset

Dc10 Set the NO/NC logic for the external on/o contact (humidistat)

Dc11 Set the type of signal for the humidity limit probe in zone 2, minimum/maximum probe reading, probe oset, enable

disconnected probe alarm and set the alarm delay

Dc12 Set the type of signal for the temperature limit probe in zone 2, minimum/maximum probe reading, probe oset, enable

disconnected probe alarm and set the alarm delay

Dc13 (visible for single-zone cabinet)

Set wireless probes 1-4: main, limit or absent

Dc14 (visible for single-zone cabinet)

Set wireless probes 5-8: main, limit or absent

Dc15 (visible for two-zone cabinet)

Enable wireless probes 1-4 for the main/limit control function in zone 1/2

Dc16 (visible for two-zone cabinet)

Enable wireless probes 5-8 for main/limit control function in zone 1/2

Dc17 Set the percentage weight of the wireless probes

Dc18 Set humidication load in zone 1/2

Dc19 Set the pressure relief time for zone 1

Dc20 Set the pressure relief time for zone 2

Dc21 (visible for two-zone cabinet)

Set the system anti-drip time

Dc22 Set the anti-pressure return time

Dc23 Set the cabinet pressure probe osets

Dd02 Set the IP address of cabinet 1/2/3/4 in the network and check status, online/oine

Dd03 Set maximum load and grouped/balanced distribution set point

Dd04 Set cabinet rotation time (0 h = rotation disabled)

Dd05 Unit oine alarm timeout

Dd06 Disable network settings for the current unit (if Y, the network symbol is not shown on the main screen)

Dd07 Current unit production request

Dd08 Check status and production % of unit 1/2/3/4 on the network

mechanical components

De02 Manual management of contactor, ll valve FV, cabinet drain valve DR, bypass valve BYP

23

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

ENG

Steam_Pr

St

Menu Index Description

e. Manual mode De03 Manual management of zone 1 ll valve FV1, zone 1 drain valve DR1, zone 1 fans, set zone 1 production %

f. Initialisation Df01 Set the screen language

g. Supervision Dg01 (visible for single-zone cabinet)

h. Logout Exit the settings menu: request password on next access

6.2 Control

6.2.1 Modulation of production

The system modulates the atomisation of water intermittently, in PWM

mode (pulse width modulation). Within a time period of 120 seconds

(settable value), the unit will deliver pressurised water to the blower

units for atomisation by the nozzles in the room:

• for 120 seconds continuously, when there is maximum production

request;

• for a fraction of time Ton less than 120 seconds (minimum 8% of the

entire period) and proportional to the request signal, if not at the

maximum.

When atomisation stops, the pump remains active and the water is

recirculated through an internal bypass circuit in the pumping unit,

rather than being delivered to the blower units.

De04 Manual management of zone 2 ll valve FV2, zone 2 drain valve DR2, zone 2 fans, set zone 2 production %

De05 Manual management of unit status contact, alarm relay, cabinet fan, WTS contact

Df02 Change passwords for accessing the menus

Df03 Set the unit of measure (International or Imperial).

Df04 Set the unit model

Df05 Enable USB port reading for unit software update

Dg02 (visible for two-zone cabinet)

Dg03 Select supervisor protocol

Dg04 BMS supervisor port conguration: baud rate, stop bits, parity

Dg05 Ethernet supervisor port conguration: DHCP, IP address, mask, gateway, DNS. Important - these values must be provided by the

Dg06 BACnet conguration: address, maximum number of masters, maximum number of frames

Set the serial address, enable unit on/o and control from supervisor

Set the serial address, enable unit on/o and control from supervisor

local network administrator

Pmax

Steam_Pr

Pmin

OFF ON

0%

hy 2xhy 100%

Fig. 6.aa

Key:

Water_pr Pressurised water production Y External signal

P0 Max production hy Activation hysteresis

Pm Min production

Y= 0…1Vdc

0…10Vdc

2…10Vdc

0…20mA

4…20mA

Y

Tab. 6.a

Fig. 6.z

The type of control is set on the following screen:

Index Description Parameter

Type of control Set the type of control

Da01

Da02

Default: humidity (one probe)

Options: proportional to external signal,

proportional to external signal with limit

probe, On/O signal, humidity (one probe),

temperature (one probe), humidity with limit,

temperature with limit, humidity (two probes),

temperature (two probes)

Tab. 6.b

6.2.2 Proportional control to an external signal

(modulating operation)

Atomisation is proportional to the value of an external signal Y, (selectable

from the following options: 0 to 1 Vdc; 0 to 10 Vdc; 2 to 10 Vdc; 0 to 20

mA; 4 to 20 mA). The maximum production Pmax corresponds to the

maximum value of the external signal Y, and will be the humidier’s rated

production. The activation hysteresis hy is not settable by the user.

6.2.3 Autonomous control with humidity or

temperature probes

When using a main humidity control probe and an optional limit

humidity probe, atomisation is related to the % rH reading made by the

relative humidity probe and increases as the value read deviates from the

set point St. Maximum production Pmax corresponds to the case where

the humidity value, read by the probe, is BP away (proportional band)

from the set point. The activation hysteresis hy is not settable by the user.

Pmax

Pmin

ON

BP

Fig. 6.ab

Key:

Water_pr Pressurised water production Y External signal

P0 Max production hy Activation hysteresis

Pm Min production

OFF

hy

%rH

"humiFog direct" +0300073EN rel. 1.2 - 02.05.2019

24

ENG

When using a main temperature control probe and an optional limit

temperature probe, atomisation is related to the temperature reading in

°C or °F made by the probe and increases as the value read deviates from

the set point St. Maximum production Pmax corresponds to the case

where the temperature value, read by the probe, is BP away (proportional

band) from the set point. The activation hysteresis hy is not settable by

the user.

Fig. 6.ac

Key:

Water_pr Pressurised water production Y External signal

P0 Max production hy Activation hysteresis

Pm Min production

For “humidity (one probe)” or “temperature (one probe)” control, one

single main probe can be connected and congured, either wired or

wireless.

For “humidity with limit” or “temperature with limit” control, a wired

probe can be connected as the main probe and a wired probe as the

limit. If using wireless probes (maximum of four), two groups of probes

can be dened: the group of main probes and the group of limit probes.

In this case, the average will be calculated between the main probes,

depending on the dened weight, and the limit probes will also have

their own average, again depending on the dened weight.

For “humidity (two probes)“ or “temperature (two probes)” control, only a

group of main probes can be dened. Wired probes can be connected to

the main probe input (M2.1) and the limit probe input (M2.5), which will

be used as a second probe, with the average calculated. If using wireless

probes (maximum of four), only a group of main probes can be dened,

with the average calculated, depending on the dened weight.

For the connections of the signals and/or probes, see chap. 4.

6.2.4 Weighted average of the probes (installer

menu)

If using two temperature probes or two humidity probes, the humidier

controller will calculate the weighted average of the probe readings.

In this way, two probes can be used, for example humidity probes, at

opposite ends of the room, calculating the average.

Index Description Parameter

Da03

Da06

The weight of each probe should be expressed with a value from 0 to

100.

Weight of the

probes

Set the weight of the probes

Default: 100

Possible settings: 0 to 100

Step: 1

6.3 Functions

6.3.1 Filling

For correct functioning of the system there must be no air in the lines,

so as to avoid vibrations, long transients and low-quality atomisation. To

eliminate all air, the lling time must be set correctly. When starting the

system the rst time, measure the time required for the water to reach

the end of the circuit, and wait only until water visibly comes out of the

circuit. The longer the water circuit, the higher the lling time needs to

be.

Ref. Display Description Range Def UoM

Db01 En. lling When the pumping station

Duration Line lling time before start-

needs to start and the water

supply line is detected as

being empty, i.e. when rst

starting, enabling the pump,

starting again for the new

season etc., by setting the

parameter to Yes, the pump

delivers the ow-rate for