compactSteam

Electrode Steam Humidifier

Umidificatore a vapore per ambienti residenziali

User manual

Manuale d’uso

Integrated Control Solutions & Energy Savings

User manual

compactSteam +030222070 - rel. 1.4 - 05.09.2017

3

Close the cylinder clamp

Warning

If present, remove the following items:

Remove before installing

Remove before installing

Remove before installing

Remove before installing

Remove before installing

4

compactSteam +030222070 - rel. 1.4 - 05.09.2017

WARNINGS

DISPOSAL

The CAREL Industries humidiers are advanced products, whose operation is

specied in the technical documentation supplied with the product or can be

downloaded, even prior to purchase, from the website www.carel.com. Each

CAREL Industries product, in relation to its advanced level of technology, requires

setup/conguration/programming/commissioning to be able to operate in

the best possible way for the specic application. The failure to complete such

operations, which are required/indicated in the user manual, may cause the nal

product to malfunction; CAREL Industries accepts no liability in such cases.

The customer (manufacturer, developer or installer of the nal equipment)

accepts all liability and risk relating to the conguration of the product in order

to reach the expected results in relation to the specic nal installation and/

or equipment. CAREL Industries may, based on specic agreements, acts as a

consultant for the installation/commissioning/use of the unit, however in no

case does it accept liability for the correct operation of the humidier and the

nal installation if the warnings or suggestions provided in this manual or in

other product technical documents are not heeded. In addition to observing

the above warnings and suggestions, the following warnings must be followed

for the correct use of the product:

• DANGER OF ELECTRIC SHOCK

The humidier contains live electrical components. Disconnect the power

supply before accessing inside parts or during maintenance and installation.

• DANGER OF WATER LEAKS

The humidier automatically and constantly lls/drains certain quantities of

water. Malfunctions in the connections or in the humidier may cause leaks.

• DANGER OF BURNS

The humidier contains high temperature components and delivers steam

at 100°C/ 212°F.

Warning:

The humidier is made up of metal parts and plastic parts. In reference to

European Union directive 2002/96/EC issued on 27 January 2003 and the related

national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and such waste must be

collected and disposed of separately;

2. the public or private waste collection systems dened by local legislation

must be used. In addition, the equipment can be returned to the distributor

at the end of its working life when buying new equipment;

3. the equipment may contain hazardous substances: the improper use or

incorrect disposal of such may have negative eects on human health and

on the environment;

4. the symbol (crossed-out wheeled bin) shown on the product or on the

packaging and on the instruction sheet indicates that the equipment has

been introduced onto the market after 13 August 2005 and that it must be

disposed of separately;

5. in the event of illegal disposal of electrical and electronic waste, the penalties

are specied by local waste disposal legislation.

Warranty on the materials: 2 years (from the date of production, excluding

consumables).

Approval: the quality and safety of CAREL S.P.A. products are guaranteed by the

ISO 9001 certied design and production system, as well as by the

mark.

• The installation of the product must include an earth connection, using the

special yellow-green terminal available in the humidier.

• The environmental and power supply conditions must conform to the values

specied on the product rating labels.

• The product is designed exclusively to humidify rooms either directly or

through distribution systems (ducts).

• Only qualied personnel who are aware of the necessary precautions and

able to perform the required operations correctly may install, operate or carry

out technical service on the product.

• Only water with the characteristics indicated in this manual must be used for

steam production.

• All operations on the product must be carried out according to the instructions

provided in this manual and on the labels applied to the product. Any uses

or modications that are not authorized by the manufacturer are considered

improper. CAREL Industries declines all liability for any such unauthorized use.

• Do not attempt to open the humidier in ways other than those specied in

the manual.

• Observe the standards in force in the place where the humidier is installed.

• Keep the humidier out of the reach of children and animals.

• Do not install and use the product near objects that may be damaged when

in contact with water (or condensate). CAREL Industries declines all liability

for direct or indirect damage following water leaks from the humidier.

• Do not use corrosive chemicals, solvents or aggressive detergents to clean

the inside and outside parts of the humidier, unless specically indicated in

the user manual.

• Do not drop, hit or shake the humidier, as the inside parts and the linings

may be irreparably damaged.

CAREL Industries adopts a policy of continual development. Consequently,

CAREL reserves the right to make changes and improvements to any product

described in this document without prior warning. The technical specications

shown in the manual may be changed without prior warning.

The liability of CAREL Industries in relation to its products is specied in the

CAREL Industries general contract conditions, available on the website www.

carel.com and/or by specic agreements with customers; specically, to the

extent where allowed by applicable legislation, in no case will CAREL Industries,

its employees or subsidiaries be liable for any lost earnings or sales, losses of data

and information, costs of replacement goods or services, damage to things or

people, downtime or any direct, indirect, incidental, actual, punitive, exemplary,

special or consequential damage of any kind whatsoever, whether contractual,

extra-contractual or due to negligence, or any other liabilities deriving from the

installation, use or impossibility to use the product, even if CAREL Industries or

its subsidiaries are warned of the possibility of such damage.

compactSteam +030222070 - rel. 1.4 - 05.09.2017

5

ENGLISH

6

compactSteam +030222070 - rel. 1.4 - 05.09.2017

Contents

1. COMPACTSTEAM OPERATION 9

1.1 Operating stages ...................................................................................................................................9

1.2 Cylinder life ............................................................................................................................................10

2. MODELS 11

3. INSTALLATION 12

3.1 Positioning ...............................................................................................................................................12

3.2 Assembly .................................................................................................................................................12

3.3 Characteristics of the supply water ..................................................................................................14

3.4 Drain water .............................................................................................................................................14

3.5 Water connections ................................................................................................................................14

3.6 Steam distribution .................................................................................................................................15

3.7 Electrical connections ...........................................................................................................................18

3.8 Power wiring...........................................................................................................................................18

3.9 Control wiring ........................................................................................................................................18

3.10 On/off operation ..................................................................................................................................19

3.11 Modulating operation .........................................................................................................................20

3.12 Connecting the CLIMA humidistat ..................................................................................................20

3.13 Wiring connections .............................................................................................................................20

ENGLISH

4. STARTING 21

4.1 Checks when starting ............................................................................................................................21

4.2 CompactSteam control device ...........................................................................................................21

4.3 Starting compactSteam ........................................................................................................................21

4.4 Starting with a new cylinder ............................................................................................................... 21

5. COMPACTSTEAM OPERATION 22

5.1 Displaying information .........................................................................................................................22

5.2 Setting the maximum steam production .........................................................................................22

5.3 Manual drain cycle ................................................................................................................................22

5.4 Resetting the hour counter .................................................................................................................23

5.5 Alarms ......................................................................................................................................................23

6. TROUBLESHOOTING 24

7. MAINTENANCE 25

7.1 Periodical checks ....................................................................................................................................25

7.2 Cylinder maintenance ...........................................................................................................................25

7.3 Spare parts ..............................................................................................................................................26

8. TECHNICAL SPECIFICATIONS 27

compactSteam +030222070 - rel. 1.4 - 05.09.2017

7

8

compactSteam +030222070 - rel. 1.4 - 05.09.2017

1. COMPACTSTEAM OPERATION

Range of isothermal humidifiers for steam production in rooms. The steam is produced from the water

contained in the cylinder (connected to the mains). The water boils and evaporates due to the electric

current generated by two immersed electrodes in the cylinder.

1.1 Operating stages

• the humidifier opens the fill valve (1) connected to the main water supply;

• the water flows through the hose (2) to the tank (3), the flow restrictor (4) controls the filling speed;

• when the tank is full, the water overflows into the hose (6) and starts filling the cylinder (5);

• once the level of water in the cylinder has been reached, the humidifier closes the fill valve (1);

• the current generated by the immersed electrodes in the cylinder (7) heats the water until it boils;

• the steam exits the cylinder through the outlet (8) and - depending on the model of humidifier - is

distributed directly into the room (using a fan), or into the duct (via a steam line).

Note:

• if the water in the cylinder exceeds the level sensor (9), the humidifier opens the drain pump (11)

and drains the excess quantity;

• if the current generated in the cylinder reaches excess levels, the humidifier opens the drain pump

(11) and drains the quantity of water required to restore the level of current;

• before emptying the humidifier activates the tempering valve (10) to cool the water to 60°C/140°F;

• the humidifier automatically controls the quantity of mineral salts dissolved in the water by activating

the fill (1) and drain (11) pumps;

• the cylinder is fitted with a filter (12) to prevent the mineral debris from blocking the drain pump (11);

• if the humidifier is in standby and does not produce steam for more than 3 days (72 hours), the

water in the cylinder is automatically emptied;

• the fill tank (3) is connected to an overflow hose (13) to prevent contact between the mains water

and the water in the cylinder;

• the current running through the cylinder is controlled by the current transformer connected to the

electrodes (7).

8

7

5

12

Key

1 fill valve

2 fill hose

3 fill tank

4 flow restrictor

5 cylinder

6 cylinder fill hose

7 immersed electrodes

8 steam outlet

9 level sensor

10 tempering valve

11 drain pump

12 water drain filter

13 overflow hose

DP

11

9

HL

water drain

Fig. 1.a

DT

10

3

EVF

water fill

13

2

6

4

1

ENGLISH

A

Tab. 1.a

B

C

D

No. Description

E

F

A cylinder steam generator

B steam blower (optional)

C user interface/display

D On/Off button

E fill and tempering valves

F drain pump

Tab. 1.b

compactSteam +030222070 - rel. 1.4 - 05.09.2017

Fig. 1.b

9

ENGLISH

Cylinder life

1.2 Cylinder life

Basic information

The plastic cylinder containing the electrodes is the heart of the humidifier. In the cylinder, during operation, the water is

boiled to produce steam. As the steam does not carry away the minerals dissolved in the water, the concentration of these

increases in proportion to the quantity of steam generated; in addition, some of the salts (above all calcium and magnesium

bicarbonates) tend to foul the electrodes until these are electrically insulated. When a part of the electrodes is covered by lime

scale, the level of the water in the cylinder is raised so that a new section of clean electrodes can conduct the current. At the

end, the electrodes will be completely covered with lime scale and will no longer be able to conduct the current required to

produce steam. The humidifier controller can measure such low levels of current between the electrodes, and signalling that

the life of the cylinder is coming to an end by displaying alarm code E6. Several factors affect the life of the cylinder, which

may range from 500 to 2000 operating hours.

Cylinder life and characteristics of the water

The characteristics of the water, which vary very depending on the site in question, significantly affect the life of the cylinder.

The main characteristics are the quantity of minerals dissolved in the water and their composition. If, for example, the

content of calcium and magnesium bicarbonates is high, significant deposits form and consequently the life of the cylinder is

shortened. If on the other hand the water contains a considerable percentage of chlorides, corrosion may occur, with possible

electric discharges between the electrodes.

Cylinder life and humidity load

Humidity load demands have an effect on cylinder life. Normal installations where humidity capacity is properly sized require

only intermittent periods where full humidifier capacity is required. This allows the water level in the cylinder to be increased

only as electrode segments become insulated by lime scale, which tends to maximise cylinder life.

In certain installations that require constant operation at full capacity, cylinder life is reduced because the water level in the

cylinder is generally much higher, and the electrodes become covered with lime scale more quickly. Installations like this may

result in a cylinder life of less than 1000 hours. Consequently, it is extremely important to correctly size the capacity of the

humidifier in relation to the required humidity load.

Maximum production

Fig.1.c

20%100%

Cylinder life and maximum production

Another factor affecting cylinder life is the maximum production setting. A higher production rate will result in a shorter

cylinder life, and vice-versa. For this reason, models CH*05***** are preset with a maximum production of 70% of the rated

value. Figure 1.c shows the relationship between the maximum steam production and cylinder life.

10

compactSteam +030222070 - rel. 1.4 - 05.09.2017

2. MODELS

Two versions of compactSteam humidifiers are available:

Duct steam distribution Direct room distribution

ENGLISH

Fig.2.a

compactSteam is made in various models that differ in terms of capacity (kg of steam produced per

hour) and voltage (the voltage depends on the national grid). Each model is identified by a 10-character

alphanumeric code. The meaning of each character is shown below:

CH m ss c v xx r

CH means compactSteam Humidifier and is fixed;

m = model: 0 for injection in the duct, F for direct room distribution;

ss = rated steam flow in kg/h (see the table on page 27 for the complete list with the rated steam flow);

c = type of control: V = ON/OFF or 0 to 10 Vdc proportional control;

v = power supply: 1 = 110 VAC single-phase, 2 =230 VAC single-phase;

xx = customisation or xH = complete package (compactSteam + CLIMA);

r = version.

Examples:

CH002V1001: compactSteam for injection in the duct (m = 0), rated steam flow 5.5 pounds/hour /

2.5kg/h (ss = 02), 110 VAC single-phase (v = 1), not customised, (xx = 00), version 1

(r = 1, with drain pump)

Note: Some models may not be available in all countries.

Fig.2.b

compactSteam +030222070 - rel. 1.4 - 05.09.2017

11

A

A

Duct steam distribution

B

C

3. INSTALLATION

3.1 Positioning

• The compactSteam unit is designed for wall-mounting;

• to ensure correct steam distribution, position the humidifier near the point of steam distribution

A

F

E

steam;

• make sure the humidifier is vertical, leaving the minimum clearances (see Fig.3.a and Tab. 3.a for the

installation of the duct model and Fig. 3.b and Tab. 3.b for the room model) to ensure safety and

allow for the necessary maintenance operations.

A

B

ENGLISH

C

D

E

F

Direct room distribution

D

C

A

B

C

D

D

Millimetres Inches

150 mm 6“

150 mm 6“

150 mm 6“

150 mm 6“

600 mm 24“

max. 0.2

B

Millimetres Inches

150 mm 6“

1500 mm 60“

1800 mm 72“

600 mm 24“

Fig. 3.a

Tab. 3.a

Fig. 3.b

Tab. 3.b

3.2 Mounting

Removing the front cover

The front cover is fastened to the body unit using four Phillips head screws located in the four corners of

the unit. Use a screwdriver to unscrew the four screws on the cover as shown in Fig. 3.d, then remove

the cover by simply pulling it outwards (Fig. 3.e). To replace the cover, perform the same operations in

the reverse order.

Be careful not to over-tighten the screws.

Dimensions of the unit (for all models):

B

C

Millimetres Inches

A

B

C

Empty weight

Packaged weight

Weight installed + water

341 mm 13.4”

204 mm 8.1”

600 mm 23.7”

Kilograms Pounds

8 kg 18 lbs

10 kg 22 lbs

12 kg 26 lbs

Fig. 3.c

Tab. 3.c

Fig. 3.d

Fig. 3.e

12

compactSteam +030222070 - rel. 1.4 - 05.09.2017

Fastening to the wall

Instructions for fastening to the wall:

1. drill the holes in the wall according to the drilling template supplied;

2. fasten compactSteam to the wall using the screws and the anchors supplied.

Fig 3.f shows the measurements in mm (inches in brackets) for wall-mounting.

TOP

256

[10 1/8]

128

[5]

128

[5]

40

[1 5/8]

24

60

[7/8]

[2 3/8]

54

[2 1/8]

65

[2 1/2]

9

[3/8]

48

[1 7/8]

[1 5/8]

[2 3/4]

ø 40

69

[1 1/8]

ENGLISH

ø 30

448

[17 5/8]

38,5

[1 1/2]

[2 3/8]

98,5

[3 7/8]

70

[2 3/4]

600

[23 5/8]

94

[3 5/8]

[2]

ø 50

[7/8]

16

[5/8]

81

[3 1/4]

78

[3 1/8]

ø 23

[7/8]

37

[1 1/2]

ø 23

35

[1 3/8]

53

[2 1/8]

36

[1 3/8]

61

[2 3/8]

50

[2]

60

BOTTOM

compactSteam +030222070 - rel. 1.4 - 05.09.2017

Fig. 3.f

102

[4]

13

99

[3 7/8]

62

[2 1/2]

3.3 Characteristics of the supply water

The humidifier must be supplied with water with the following characteristics:

• pressure between 20psi and 110psi or 0.1 and 0.8 MPa (1 and 8 bar);

• temperature between 33°F and 104°F or 1°C and 40°C;

• flow-rate minimum of 0.45 L/min or 0.12gpm;

• connection type

• hardness no greater than 40°fH (equal to 400 ppm of CaCO

• conductivity: from 100 to 1250 μS/cm;

• absence of organic compounds.

The characteristics of the supply-water must fall within the following limits:

¾” G (see chap. 8 ‘‘Technical specifications’);

);

3

ENGLISH

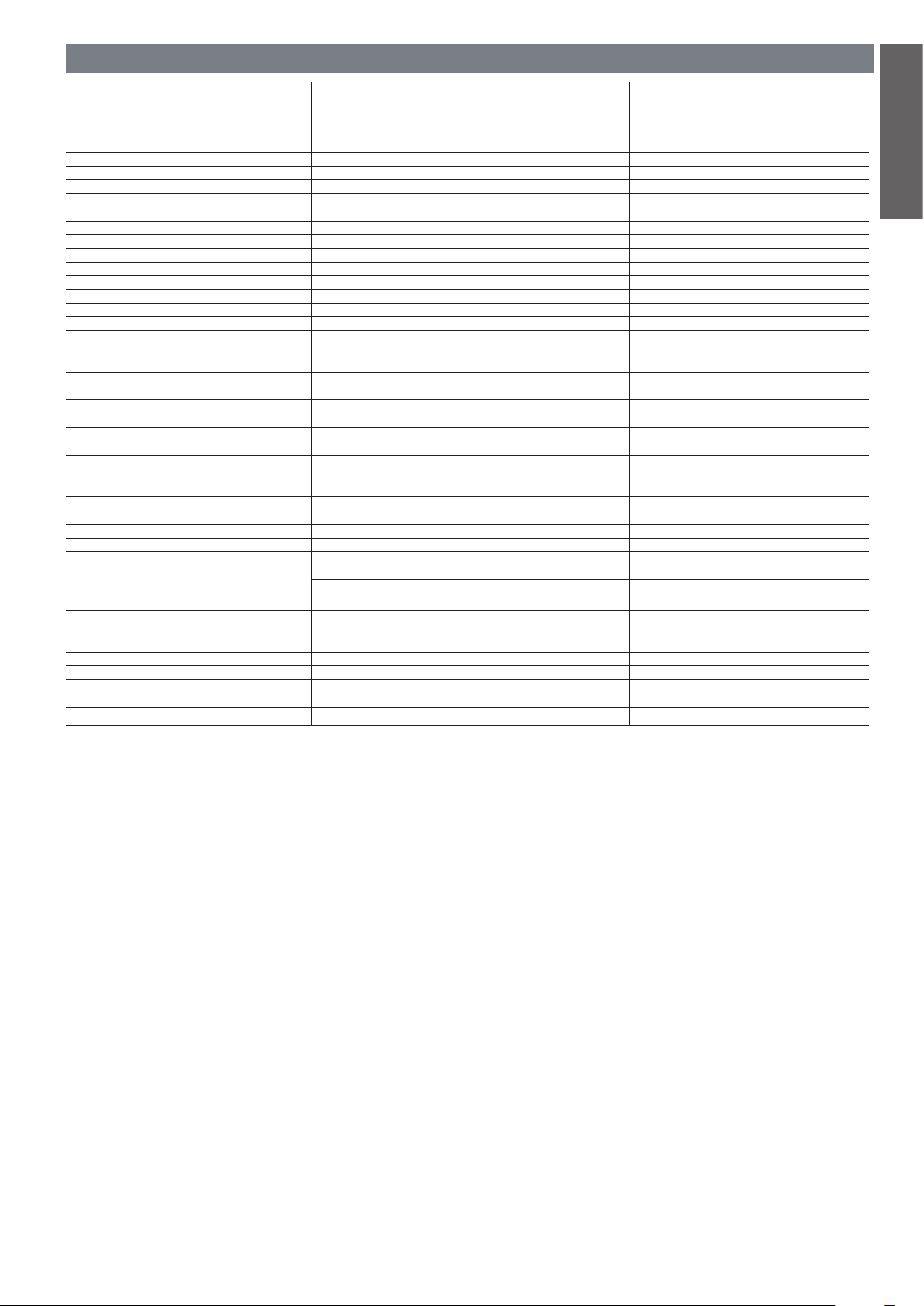

supply water characteristics unit of

measure

normal

water

water with low

salt content

min. max. min. max.

Hydrogen ions (pH) 7 8.5 7 8.5

Specific conductivity at 20 °C (σ

Total dissolved solids (c

Dry residue at 180 °C (R

Total hardness (TH) mg/l CaCO

) mg/l (1) (1) (1) (1)

R

) mg/l (1) (1) (1) (1)

180

Temporary hardness mg/l CaCO

Iron + Manganese mg/l Fe+Mn = 0.2 = 0.2

Chlorides ppm Cl

) μS/cm 350 1250 100 350

R, 20 °C

100 (2) 400 50 (2) 16 0

3

60 (3) 300 30 (3) 100

3

-

= 30 = 20

Silica mg/l SiO2 = 20 = 20

Residual chlorine mg/l Cl

Calcium sulphate mg/l CaSO4 = 100 = 60

= 0.2 = 0.2

2

Metallic impurities mg/l 0 0 0 0

Solvents, thinners, detergents, lubricants mg/l 0 0 0 0

Tab. 3.d

(1)

= values depend on the specific conductivity; in general:

CR ≅0.93 * σ

(2)

= not less than 200% of the chloride content in mg/l CL

(3)

= not less than 300% of the chloride content in mg/l CL

R, 20 °C

; R

180

≅0.65 * σ

R, 20 °C

-

-

There is no reliable relationship between hardness and conductivity of the water.

Important

do not treat the water with softeners, this may cause the entrainment of foam, affecting the operation of

the unit;

do not add disinfectants or anticorrosive compounds to the water, as these are potential irritants;

the use of well water, industrial water or water from cooling circuits and, in general, any potentially

chemically or bacteriologically contaminated water is not recommended.

IMPORTANT: When installation is completed, flush

the supply hose for around 30 minutes by piping

water directly into the drain, without sending it into the

humidifier. This will eliminate any scale or processing

residues that may block the drain pump and cause

foam when boiling.

3.4 Drain water

• this contains the same substances dissolved in the supply water, however in higher quantities;

• it is cooled to 60°C / 140°F by mixing it with supply water;

• it is not toxic and can be drained into the sewerage system.

3.5 Water connections

Before proceeding make sure that the humidifier is disconnected from the main power supply.

Connection to the main water supply

Install a manual valve upstream of the installation to be able to cut off the water supply, as illustrated in Fig.

3.h. Connect the humidifier to the main water supply using a hose capable absorbing water hammer, to

avoid damaging the fill valve. The hoses are identified by the following CAREL codes: FWH3415000 (1.5 m

/4ft long), FWH3 430000 (3 m /9.5ft long ). Alternatively, a hose with a minimum inside diameter of 6 mm

/ 1/4” can be used. If soft polymer tubing is used, secure this to the wall to prevent it from detaching from

the fill connector and this avoiding water leaks. The threaded fill valve fitting is located at the bottom of the

humidifier (see Fig. 3.g). Remember that the fill valve is fitted with a filter that requires periodical cleaning.

Make sure there is sufficient clearance for maintenance. The water line can be connected either through the

holes at the rear (so that these remain hidden behind the unit) or through the holes at the bottom of the unit.

14

compactSteam +030222070 - rel. 1.4 - 05.09.2017

Water drain

As well as the connection to the main water supply, compactSteam also requires connection to a drain

pipe for emptying the water in the cylinder whenever necessary. The drain tubing can be connected from

the rear (as shown in Fig. 3.i) or from the bottom of the unit using the elbow connector supplied (Fig.

3.g and 3.h).

The characteristics of the drain line are shown in Tab. 3.e.

The drain tubing must have a minimum inside diameter of 32 mm (1-1/4”) and must be secured to the

humidifier drain outlet without requiring additional support. The drain tubing must have a minimum slope

of 5°, and a drain trap must be installed to prevent the return of odors, as illustrated in Fig. 3.h and 3.i.

In addition, a funnel should be used to interrupt continuity in the drain line and prevent flooding inside

the unit.

The compactSteam unit is fitted with a tempering valve that, opening at the same time as the pump, adds

cold water to the drain line, thus ensuring a maximum temperature of the drain water of 60°C /140°F.

Fill valve and filter

Instant drain flow 50Hz

Instant drain flow 60Hz

Rated connection diameter

Drain temperature

25 l/min / 6,6 gpm

26,2 l/min / 7 gpm

32 mm / 1-1/4”

60 °C / 140 °F

4

Tab. 3.e

Water drain

Fig. 3.g

ENGLISH

Key:

1 Supply

2 Manual valve

3 External filter (recommended)

4 Drain funnel

5 Drain

6 Water fill hose

(FWH3415000 or FWH3430000)

6

1

2

min. 5°

3

5

Fig. 3.h Fig. 3.i

3.6 Steam distribution

Steam injection in the duct

The maximum static pressure allowed in the duct is 950 Pa (95 mm water column /3.7” W.C.)

The compactSteam duct models can be used with the plastic nozzle shown in Figure 3.j (CAREL code

SDPOEM00**) for the injection of steam in the duct. The dimensions are shown in Table 3.f. These

distributors can be fitted horizontally or vertically (hole facing upwards).

Installing the CAREL SDPOEM00** jet distributors (see Fig.3.j)

- make a series of holes on the wall according to the distributor drilling template (included in the

packaging);

- insert the distributor with the steam opening inside the duct; fasten the flange using 4 screws.

B

B

A

A

A

A

B

C

1

H

G

E

D

F

2

I

I

H

G

F

1

4

5

A 31.5 mm 12.4”

B

C

D

E

F

G

H

I

1

2

2

Millimetres Inches

50 mm 1.96”

56 mm 2.20”

57.5 mm 2.26”

100 mm 3.93”

Ø 8 mm Ø 0.31”

Ø 22 mm Ø 0.86”

Ø 30 mm Ø 1.18”

12 or 22 mm 0.47 or 0.87”

Steam inlet

Condensate outlet

Tab. 3.h

compactSteam +030222070 - rel. 1.4 - 05.09.2017

Fig. 3.j

15

Alternatively, a stainless steel distributor for ducts can be used (CAREL code DP0**D22R0):

ENGLISH

Key to Fig. 3.j:

steam inlet (ØA)

1

condensate drain (ØB)

2

flange gasket

3

screw max diameter. “M5 / (3/16”) (see instruction

4

sheet supplied with the distributor)

22 mm (7/8”)

ØA

10 mm (3/8”)

ØB

58 mm (2 1/4”)

ØY

35 mm (1 3/8”)

Ø

68 mm (2 11/16”)

X

STEAM CYLINDER HOSE ADAPTER

1

3

2

X

4

A

X

B

Models

• DP035D22R0: l = 332 mm / 13 1/16” (models CH001 to CH003 only);

• DP045D22R0: l = 438 mm / 17 1/4” (for all models, CH001 to CH005).

Installing the CAREL DP0**D22R0 linear distributors (see Fig. 3a.j):

• make a series of holes on the wall according to the distributor drilling template (included in the

packaging);

• insert the distributor with the steam holes facing upwards;

• fasten the flange using 4 screws.

Important: to allow the condensate to return through the drain connection, fit the distributor at a slight

incline (at least 2°, see Fig. 3.l).

l

Y

°2

Fig. 3a.j

Tab. 3.g

Fig. 3.k

Condensate drain hose

During operation some of the steam may condense, causing a decline in efficiency and noise (gurgling).

To drain the condensate, connect a drain hose (CAREL code 1312353APG) with a drain trap and a

minimum slope of 5° to the bottom of the humidifier (see Fig. 3.L). The condensate hose should run

through the hole located at the top of the fill tank inside the humidifier, as illustrated in Fig 3.k.

IMPORTANT WARNING: for correct operation, the drain trap should be filled with water before starting

the humidifier.

Steam hose

• make the connection between the humidifier and distributor using a hose (it is recommended to use

the steam hoses supplied by CAREL, code 1312360AXX). Unsuitable hoses may weaken and crack

causing steam leaks;

• avoid the formation of pockets or traps where condensate may form;

• avoid choking the hose due to tight bends or twisting.

fasten the end of the hose to the connectors on the humidifier and the steam distributor using metal

clamps (not supplied), so that these do not detach due to the high temperature.

To connect to the cylinder hose steam use the adapter code CHKADAP000.

WARNING: the length of the hose must not exceed 4 m / 13ft.

16

compactSteam +030222070 - rel. 1.4 - 05.09.2017

A

Figure 3.l shows an example of correct and incorrect installation of the steam hose and condensate drain

hose.

≥20%

3 m (10 FT max.)

1.5 m (5 FT max.)

≥20% ≥20%

steam outlet hose

Note:

• The minimum slope of the steam outlet hose in the upwards section must be 20%;

• The minimum slope of the steam outlet hose in the downwards section must be 5% ;

• The maximum length of the hose is 4 m / 13ft.

gentle bend

≥5%

obstacle

1.5 m (5 FT max.)

no condensate drain

≥5%

condensate

drain

1.5 m (5 FT max.)

horizontal section

0 m (3 FT max.)

Typical installation if the

unit is above the steam

distributor

condensate drain with trap

Note: the height of the trap must exceed the static pressure

of the tubing

≥20%

condensate

drains

YES

ENGLISH

radius too tight

kinked

sag

no trap

no slope

sag without drain

Fig. 3.l

ROOM steam distribution

compactSteam can distribute the steam directly into the room being humidified. For direct humidification,

both the compactSteam with built-in blower (CAREL code CHF*******) and the duct model (code

CH0*******) can be used, the latter connected to a remote room blower (code VRDCHA1000 for 110 Vac

models, and VRDCHA2000 for 230 Vac models).

The following drawing (Fig 3.m) shows the minimum distance that must be observed when installing the

remote steam blower, so as to avoid burning and the condensation of steam on objects such as lights,

electrical equipment, cold surfaces, etc. For further details on the installation and use of the blower, see

the corresponding manual.

sag without drain

NO

no condensate drain

30%

compactSteam +030222070 - rel. 1.4 - 05.09.2017

C

Fig. 3.m

B

Millimetres Inches

A

B

C

150 mm 6“

1500 mm 60“

600 mm 24“

Tab. 3.h

17

Fig. 3.n Fig. 3.o

3.7 Electrical connections

Before proceeding with the electrical connections:

• make sure that the humidifier is disconnected from the main;

• check that the unit’s power supply voltage corresponds to the value indicated on the rating plate

inside the electrical panel.

(Note: The tolerance allowed on the rated voltage is -15% +10%);

• the humidifier power line must be fitted with a disconnect switch and fuses to protect against short

circuits (to be fitted by the installer).

Note: To avoid unwanted interference, the power cables should be kept separate from any control

wiring. All the wiring must comply with the national and local electrical standards in force.

ENGLISH

Fig. 3.p

Code Power supply

(single phase)

CH*01V1001 110Vac 56/60Hz 1.6 3.5 1.15 10.50 2.5 mm

CH*02V1001 110Vac 56/60Hz 2.5 5.5 1.8 0 16.40 6 mm

CH*01V2001 230Vac 50/60 hz 1.6 3.5 1.15 5.0 1.5 mm

CH*03V2001 230Vac 50/60 hz 3.2 7 2.31 10.0 2.5 mm

CH*05V2001 230Vac 50/60 hz 5.4 12 3.89 16.9 6 mm

Note: Some models may not be available in all conutries.

Steam output

(kg/h)

To connect the humidifier to the mains:

• once the power cables have been run into the unit, use the cable clamps illustrated in Fig 3.n to

secure them in the correct position;

• connect the power cables to the terminal block at the bottom left of the control module, as illustrated

in Fig. 3.o;

• connect the yellow-green wire to the earth terminal on the unit located on the metal support plate

under the control module.

Tab. 3.i shows the electrical data (power supply voltages) for each model of humidifier.

Steam output

(Ibs/hr)

Power (kW) Current (A) Power cables External fuse (A)

3.9 Control wiring

3.8 Power wiring

2

AWG12 16

2

AWG10 32

2

AWG14 10

2

AWG12 16

2

AWG10 32

or breaker

Tab. 3.i

Fig. 3.q

On compactSteam, steam production is controlled by an external signal:

• in on/off mode, a simple contact (for example a humidistat) enables/disables steam production;

• in proportional mode, the humidifier produces a quantity of steam that is directly proportional to the

0 to 10 V signal generated by an external control device.

The compactSteam unit can be connected to any simple or automatic humidistat, as well as safety

devices such as limit humidistats, air flow switches and remote ON/OFF switches. To connect the

external control devices, run the cables through the bottom of the unit until reaching the top of the

control module, and secure them with the cable clamp (see Fig. 3.n). The terminal blocks for the control

wiring are located at the top right of the control module (see Fig. 3.q and 3.r)

IMPORTANT NOTE: Select the correct type of control signal on the keypad (see paragraph 5.1.1)

before connecting the control wiring.

Fig. 3.r

18

compactSteam +030222070 - rel. 1.4 - 05.09.2017

3.10 On/Off operation

The diagrams shown in the figures on the side indicate the connections to be performed on the terminal

block in the following situations:

Fig 3.s operation controlled by a simple voltage-free remote enabling contact,

indicated as CR;

Fig 3.t operation controlled by an external mechanical humidistat, indicated as H;

Fig 3.u a combination of the above.

Remote enabling contact (fig.3.s)

Remove the jumper between terminals AB-AB and connect the voltage-free remote contact (CR) in series

to terminals AB-AB; terminals IN-GND must be jumpered. When contact AB-AB is closed, the humidifier is

enabled for operation; if the contact is open, steam production stops immediately.

Fig. 3.s

ENGLISH

External humidistat without enabling (fig. 3.t)

Connect the external humidistat between terminals IN-GND and leave the jumper in position between

terminals AB-AB. DO NOT apply any voltage to AB-AB. If the IN-GND contact is closed, steam production

starts, while if it is open steam production stops after 5 s.

External humidistat with enabling (fig. 3.u)

Connect the external humidistat between terminals IN-GND. Remove the jumper between terminals ABAB and connect any limit devices, air flow switches or remote contacts (CR) in series to terminals AB-AB.

Steam production only starts when both contacts, AB-AB and IN-GND, are closed. If contact AB-AB is open

steam production stops immediately, while if IN-GND is open production stops after 5 s.

Interlock between compactSteam for ducts and the system fan controller

In duct applications, compactSteam starts steam production only if there is an external call for humidity

(humidistat closed) and the system fan is on. The system fan communicates with compactSteam via the

remote input AB-AB.

The following sequence of events must be true for compactSteam to produce steam:

• External humidistat close (= steam demand)

• FAN-EXT contact closed by compactSteam, to start the system fan

• Input AB-AB closed, indicating that the fan has started (= enable steam production)

compactSteam can be connected to an air flow switch (that is, a device that senses the flow of air generated

by the fan in the duct). This flow sensor should be connected to the remote enabling input (terminals

AB-AB) in series with a limit humidistat (normally closed).

When the flow sensor is connected to compactSteam, steam production is only enabled if air flow is

measured inside the duct.

N2

G ND

N1

AB

AB

G ND

IN

N2

G ND

N1

AB

AB

G ND

IN

Fig. 3.t

C R (1)

H

Fig. 3.u

H

(1): external switch

Fan symbol

• Off: no call (IN-GND = open), regardless of whether or not production is enabled (AB-AB = open or

closed);

• Flashing: call present (IN-GND = closed), awaiting production to be enabled (AB-AB = open);

• On steady: call present (IN-GND = closed) and production enabled (AB-AB = closed).

Note:

• When enabled (AB-AB = closed), the symbol goes off 30 s after the production call is no longer present

(IN-GND = open);

• When the production call is present (IN-GND = closed), the symbol goes off 60 s after production is

disabled (AB-AB = open).

compactSteam +030222070 - rel. 1.4 - 05.09.2017

19

3.11 Modulating operation

Connect the external 0 to 10 V modulating control device between terminals IN-GND as shown in Fig. 3.v.

Then connect any safety switches (limit device, air flow switch, remote on/off) in series to terminals AB-AB.

If no safety switches are used, install a jumper between AB-AB. DO NOT apply any voltage to AB-AB.

Steam production is modulated from 20% to 100% of the maximum production, proportionally to the

signal provided by the external controller.

Fig. 3.v

3.12 Connecting the CLIMA humidistat

The Clima humidistat is used to automatically control the humidity in the room. The humidistat can

enable/disable the humidifier based on two time bands (day and night), and can control humidification in

two different modes: proportional control and ON/OFF control.

For the installation and the connection of the Clima device, see the corresponding instruction sheet,

provided inside the packaging with the humidistat.

ENGLISH

3.13 Wiring connections

Terminal Function Electrical specifications

L1-L2-EARTH Power supply and earth connections Power supply (110 Vac single-phase 50/60 Hz or 230 Vac single-phase 50/60 Hz)

KEY Programming port Connection to a programming device or supervisor

AB-AB Remote enabling input Normally open external contact; Rmax= 300 Ohm; Vmax= 33 Vdc; Imax= 6 mAdc;

humidifier enabled = contact closed

IN-GND Control signal input If 0 to 10 V set:

Input impedance 10 kOhm

If ON/OFF set (default): Vmax = 33 Vdc, Imax = 5mA, Rmax = 300 Ohm

NC-C-NO NC alarm contact

250 V; 8 Amp max. with resistive load; 4 Amp max. with inductive load

C common alarm contact

NO alarm contact

NO-C External fan relay 250 V; 8 Amp max. with resistive load; 4 Amp max. with inductive load

24-GND Power supply for external humidistat Power supply for external humidistat, 24 Vac; 2 Watts

Tab. 3.l

EMBEDDED

BLOWER

KEY FOR PROGRAMMING PORT:

EVF = FILL VALVE

DP = DRAIN PUMP

DT = DRAINTEMPERING VA LVE

HL =HIGH-LEVEL SENSOR

STEAM

BOILER UNIT

DP

Control device wiring diagram

KEY

ALARM

EXT FAN

AB N1 GND N2

AB

IN GND

NC C NO

NO C

24Vac GND

KEYBOARD

HL

N

EVF

HL

2

ON-OFF

BOTTON

4

EXTERNAL FUSED

DISCONNECT TO BE

INSTALLED(NOT

SUPPLIED) RESPECT

LOCAL CODES

WATER

OUTLET

DT

EVF

WATER

INLET

DP

N

F

INT

FAN

E1

E2

6

8

L1 L2

POWER SUPPLY

(110VAC1-PHASE 50-60HZ

OR

230VAC 1-PHASE 50-60HZ)

CONNECTED

TO GROUND

PROGRAMMING

PORT

AIR PRESSURE SWITCH

HUMIDISTAT

ALARM

EXTERNAL DUCT FAN

24VAC FOR

EXTERNAL

HUMIDISTATS

20

Fig. 3.z

compactSteam +030222070 - rel. 1.4 - 05.09.2017

4. STARTING

IMPORTANT WARNING:

1. Before starting, make sure there are no water leaks, and that the electrical components are dry;

2. Do not connect the power supply if the humidifier is damaged or even partially wet!

When installation is completed, flush the supply hose for around 30 minutes by piping water directly into the

drain, without sending it into the humidifier; this will eliminate any scale or processing residues that may cause

foam when boiling.

4.1 Checks when starting

Before starting the humidifier, check that:

• The water supply is connected, the line has been flushed and the taps are open.

• The drain is connected as explained in the paragraph 3.5 (flood prevention funnel and drain trap under the unit).

• The power supply is connected in accordance with the instructions, the laws in force and the rating labels

on the unit.

• The power fuses are installed and intact.

• Any air flow switch is wired to open if there is no air flow.

• Any limit humidistat is wired to open if the humidity increases above the set value.

• All the wire connectors on the unit are tight.

• The steam and condensate hoses are installed correctly, without kinks or twisting, and are correctly sloped in

compliance with the manual.

4.2 CompactSteam control device

The compactSteam control device features an LCD that, using icons and numbers, displays the operation of the

system:

1 Steam production as a % of rated capacity

2 Active alarm icon

3 Instant current flow in amperes (default display)

4 Steam production in progress

5 Cylinder fill in progress

6 Foam detected inside the cylinder

7 Water inside the cylinder

8 Cylinder drain in progress

9 Red LED: alarm

10 Yellow LED: power supply

11 Green LED: operation

12 Drain button for manually emptying the cylinder and confirming the values set for the parameters

13 On/Off button

14 “Reset” button to reset alarms and access the parameters

15 Level of steam production: 33%, 66%, 100%

16 Fan relay active

4.3 Starting compactSteam

• Press the START button (13), the unit starts and the display shows a sequence of characters. Once this

initialisation phase has ended, the yellow power LED comes on and the compactSteam unit is ready to operate.

• If there is demand for humidity, compactSteam delivers power to the electrodes in the cylinder, and the

green LED comes on, indicating that operation has started.

16

15

11

14

ENGLISH

1

2

3

4

5

6

7

8

10

9

12

4.4 Starting with a new cylinder

When starting with a new cylinder, the cylinder cleaning cycle should be run, as follows:

1. Turn compactSteam off.

2. Turn compactSteam on again, while holding the two buttons, “reset/sel” and “drain”, until the display

shows“00” and the wrench symbol

3. Then hold the “reset/sel” button to scroll the numeric parameters on the display. Hold “reset/sel” for a few

seconds until the display shows “04”.

WARNING: If the value selected is higher than “04” do not confirm, but rather press “reset/sel” until the

display returns to normal operating mode and start again from point 1

4. Press “drain” for at least 1 second: the cleaning cycle start.

During the cylinder cleaning cycle appears the PC signal (pre-cleaning) in the display, the electrodes are

powered and the cylinder is filled with water until one of the following conditions occurs:

• The level of the water reaches the maximum level sensor;

• the phase current is equal to 20 A.

Once one of these events occurs, the cylinder is completely emptied, with the electrodes off (the pump and

the tempering valve are activated for 3 minutes). The water used for washing is heated to help eliminate any

residues and traces of dirt.

CAREL Industries recommends that at least two cleaning cycles should be performed when starting with a new

cylinder. Once the cleaning has ended, the humidifier starts normal service.

IMPORTANT WARNING: When the humidifier starts with a new or empty cylinder, it may take a long time (a

number of hours) for the water in the cylinder to reach the concentration of minerals required to achieve rated

steam production.

compactSteam +030222070 - rel. 1.4 - 05.09.2017

flashes; then release the two buttons.

13

Fig. 4.a

21

ENGLISH

5. COMPACTSTEAM OPERATION

5.1 Displaying information

The information shown on the display during the normal operation of compactSteam is the instant current

in amperes running between the electrodes. To display other information, press and hold the “reset/sel”

button until the display shows the required information. When holding the button, every 2 seconds the

display will scroll between the current, the percentage (%) of steam production, the hour counter and

then the current again (Fig. 5.a).

Fig. 5.a

1. Instant current: this is the current that flows through the water to make it boil (default display).

2. percentage (%) of steam production: this is the steam production (proportional to the current),

expressed as a percentage of rated production.

3. hour counter: this counts the operating hours of the cylinder (it should be set to zero when

replacing the cylinder). The value is expressed in tens of hours, so for example when the display

shows 13, the real number of operating hours is between 130 and 139.

Selecting the type of signal

NOTE: Select the type correct of control signal on the keypad before connecting the control wiring.

Proceed as follows:

To select the type of control signal proceed as follows:

1. Turn compactSteam off.

2. Turn compactSteam on again, while holding the two buttons, “reset/sel” and “drain”, until the display

shows“00” and the wrench symbol flashes; then release the two buttons.

3. Then hold the “reset/sel” button to scroll the numeric parameters on the display. Hold “reset/sel” for a

few seconds until the display shows “02”.

WARNING: If the display shows a value higher than “02” do not confirm, but rather press “reset/sel”

until the display returns to normal operating mode and start again from point 1.

4. Press the “drain” button for at least 1 second to confirm the value: the display will show “P1” for 1

second and then the value of parameter P1 currently set will be displayed alongside.

5. Pressing “reset/sel” switches the value of P1 between “0” and “1”:

0 = humidistat;

1 = external 0 to 10 V modulating signal

6. Press the “drain” button for at least 1 second to confirm the new value of parameter P1 and return

to normal operating mode.

7. Turn compactSteam off: now the control wiring can be connected.

Note: If no selection is made within 3 s, the software automatically returns to normal operating mode.

5.2 Setting the maximum steam production

To adapt the compactSteam to the specifications characteristics of the environment, the maximum steam

production can be set between 20% and 100% of rated production, in steps of 5%. To set the maximum

steam production:

1. Turn compactSteam off.

2. Turn compactSteam on again, while holding the two buttons, “reset/sel” and “drain”, until the

display shows“00” and the wrench symbol

3. Then hold the “reset/sel” button to scroll the numeric parameters on the display. Hold “reset/sel”

for a few seconds until the display shows “01”.

WARNING: If the display shows a value higher than “01” do not confirm, but rather press “reset/sel”

until the display returns to normal operating mode and start again from point 1

4. Press “drain” for at least 1 second to confirm the value: the display shows “P0” for 1 second and

then the value of parameter P0 currently set will be displayed alongside.

5. Pressing “reset/sel” scrolls the value of P0 from 20% to 100% in steps of 5%

6. Press the “drain” button for at least 1 second to confirm the new value of parameter P0 and return

to normal operating mode.

Note: If no selection is confirmed within 3 s, the software automatically returns to normal operating

mode.

flashes; then release the two buttons.

5.3 Manual drain cycle

Holding the “drain” button on the front of the unit activates the manual cylinder drain cycle. Hold the

button until the cylinder is empty.

22

compactSteam +030222070 - rel. 1.4 - 05.09.2017

5.4 Resetting the hour counter

The hour counter must be set to zero whenever the cylinder is replaced, so as to cancel and restart the

maintenance timer:

1. Turn compactSteam off.

2. Turn compactSteam on again, while holding the two buttons, “reset/sel” and “drain”, until the display

shows“00” and the wrench symbol

flashes; then release the two buttons.

3. Then hold the “reset/sel” button to scroll the numeric parameters on the display. Hold “reset/sel” for a

few seconds until the display shows “03”.

WARNING: If the display shows a value higher than “03” do not confirm, but rather press “reset/

sel” until the display returns to normal operating mode and start again from point 1

4. Press “drain” for at least 1 second to confirm the value: the hour counter is immediately reset and

compactSteam returns to normal operating mode.

Note: If no selection is confirmed within 3 s, the software automatically returns to normal operating

mode.

5.5 Alarms

In the event of alarms, the red LED flashes, the alarm relay closes, activating the remote signal (if installed)

and the alarm code flashes on the display.

There are two types of alarms: warnings and shutdown alarms. The former can be deleted by pressing the

“reset/sel” button for 2 s, while the latter are displayed until maintenance is performed. Multiple alarms

flash in sequence, alternating with the main display.

The table below (Tab. 5.a) shows all the alarm codes, with a description of the problems that cause these

and the actions required to restore normal operation.

Display Description Action Red LED Alarm relay Notes

- EE

E0

E1

E2

E3 Cylinder almost exhausted, already used for

E4

E5

E6

E7

E8 Cylinder lifetime expired (3000 hours) Unit Disabled: Reset the hour counter (read

E9

Remote ON/OFF open Unit disabled OFF OFF Jumper terminals AB-AB

Internal memory error Contact the service centre ON ON Have the unit reprogrammed by the service

Control board configuration not valid Unit disabled ON ON Have the unit reprogrammed by the service

High current alarm Unit disabled ON ON 1) Turn off;

Low production, low conductivity of the supply

water or excessive foam/lime scale in the

cylinder

2000 hrs

Fill alarm, water not filling or fill too slow (the

current does not increase within the set time)

Drain alarm, cannot perform the drain (the

current does not decrease within the set time)

Cylinder exhausted (critical performance) The signal is reset automatically if

Foam detected Press the “reset/sel” button for 1 second to

High temperature of the control device (above

80°C / 176°F)

Unit disabled.

Press the “reset/sel” button for 1 second to

delete the alarm

Press “reset/sel” key for 1 seconds to reset. Off Off Change cylinder (not urgent)

Press the “reset/sel” button for 1 second to

delete the alarm; otherwise, the signal will

be automatically reset every 10 minutes until

the supply water is available again.

Press the “reset/sel” button for 1 second to

delete the alarm

compactSteam can satisfy demand,

otherwise turn the unit off and on again.

delete the alarm

chap. Resetting the hour counter”)

The signal is automatically reset if the

temperature falls below 80 °C / 176 °F.

ON ON Check the conductivity of the supply water and

ON ON 1) Check the water supply and the fill valve; 2)

ON ON 1) Make sure the drain pump is not blocked

OFF OFF Replace the cylinder (urgent)

OFF OFF If the problem persists, perform a number of

On On Change the cylinder.

OFF OFF Replace the control device.

centre

centre

2) Check the connections;

3) Check the cylinder (no bridges of lime

scale between the electrodes);

4) Check that the electrodes are not shorted.

if necessary replace the cylinder with the low

conductivity version.

Check for any leaks from the drain pump;

3) Make sure the filter on the fill solenoid

valve is not blocked (Fig. 3.g);

4) Check that the steam outlet is not working

against excessive backpressure,

preventing

the flow of water into the cylinder by

gravity;

5) Check that the steam outlet hose is not

choked or that there are no pockets of

condensate;

6) Check that the power cables are

connected to the cylinder.

2) Check that there are no blockages in the

drain connection.

cleaning cycles (see chapter 4.4 “Starting with a

new cylinder”)

ENGLISH

Tab. 5.a

compactSteam +030222070 - rel. 1.4 - 05.09.2017

23

6. TROUBLESHOOTING

Problem Cause Solution

The humidifier does not start 1. No electrical power

The humidifier does not start 1. Remote ON/OFF contact open

The humidifier fills with water without

producing steam

ENGLISH

The humidifier wets the duct 1. Distributor not installed correctly (too near the top of the duct

The humidifier wets the floor below 1. Humidifier drain blocked

2. Humidifier ON/OFF switch in position 0 (off)

3. Control connectors badly connected

4. Broken fuses

5. Controller fault

2. The humidistat has not been connected correctly

3. Humidistat fault

4. Control signal not compatible with the type set (see note 5.11)

5. Value measured by the sensor/sensors higher than the

corresponding set point

1. High steam backpressure

2. Fill valve filter blocked

3. Minerals in the fill tank

4. Leaks from the drain pump

or the condensate return is blocked)

2. System oversized

3. Humidifier active when the fan in the duct is off

2. The supply water or overflow circuit has leaks

3. The condensate drain hose pipe does not carry the water to

the tank

4. The steam hose is not fastened to the cylinder correctly

1. Check the protection devices upstream from the humidifier and

the presence of power

2. Close the ON/OFF switch: position I (on)

3. Check that the connectors are properly inserted in the terminal

block

4. Check the condition of the fuses

5. Check that this is activated and the correct voltage is connected

1. Close the ON/OFF contacts (terminals AB-AB)

2. Check the external connections

3. Replace the humidistat

1. Check that the steam hose is not twisted or curved downwards,

thus trapping the condensate

2. Clean the fill valve filter

3. Clean the fill tank

4. Check the voltage on the drain pump and/or replace the drain

pump

1. Check that the steam distributor is installed correctly

2. Decrease the set steam production

3. Check the connection of the device (flow switch or differential

pressure switch) slaving the humidifier to the fan in the duct

1. Clean the drain circuit and the fill tank

2. Check the entire water circuit

3. Check the correct position of the condensate drain hose in the

drain tank

4. Check the fastening of the hose clamps on the steam outlet

Sparks form inside the cylinder a few hours

after starting

The cylinder fills with water and drains

continually, without producing steam

1. The supply water contains considerable quantities of iron,

copper or other conductive contaminants.

1. The minerals have formed a bridge between the electrodes.

2. Backpressure from the steam hoses or the duct.

3. The flow controller on the fill valve is broken or not calibrated.

4. High conductivity of the water.

5. Excessive foam forms.

1. If using a softener, check the salts used. If these contain additives,

stop use, rinse all the lines and use non-softened water.

2. Check the electrodes in the cylinder to make sure they have not

been damaged during transport.

1. Replace the cylinder.

2. Check if the steam hoses have twists or sags that may trap the

condensate.

3. Replace the fill valve.

4. Consider using a mixture of demineralised water and untreated

water.

5. Check the cylinder and replace it if exhausted.

Tab. 6a

24

compactSteam +030222070 - rel. 1.4 - 05.09.2017

7. MAINTENANCE

7.1 Periodical checks

• After one hour of operation: check for any water leaks.

• Every fortnight or after no more than 300 operating hours: check for any water leaks and check the

general operation of the cylinder. Check that during operation no sparks form between the electrodes.

• Every three months or after no more than 1000 operating hours: check operation, check for any water

leaks and, if necessary, replace the cylinder. Check for any blackened parts of the cylinder. If there are

blackened parts in the cylinder, check the condition of the electrodes and, if necessary, replace the c ylinder.

• Every year or after no more than 2500 operating hours: replace the cylinder.

IMPORTANT: ALWAYS DISCONNECT THE POWER SUPPLY BEFORE PERFORMING ANY MAINTENANCE

OPERATIONS

IMPORTANT: Always disconnect the power supply before touching the cylinder in the event of water leaks,

as the water may be carrying current.

7.2 Cylinder maintenance

The life of the cylinder depends on several factors, including: the quantity and type of minerals present in

the water, the correct operation and sizing of the humidifier, the capacity, as well as regular and careful

maintenance.

IMPORTANT WARNINGS:

The humidifier and the cylinder contain live electrical components and very hot surfaces. All service and/

or maintenance operations must be carried out by expert and qualified personnel who are aware of the

necessary precautions. Before performing any operations on the cylinder, make sure that the humidifier is

disconnected from the power supply. Remove the cylinder from the humidifier only after having drained it

completely using the “manual drain” procedure described in paragraph 5.3. Check that the model and the

power supply voltage of the new cylinder correspond to the data shown on the rating plate.

Replacing the cylinder

IMPORTANT WARNING:

The cylinder may reach high temperatures. Let it cool down before touching it or wear protective gloves.

To replace the cylinder:

• Completely drain the cylinder, holding the “drain” button until the cylinder is empty;

• Turn the humidifier off and disconnect the mains power supply;

• Remove the cover;

Version with injection in the duct:

• Remove the steam hose from the cylinder;

• Lift up the cylinder support bracket and lift it out of the unit (Fig. 7.a);

• Disconnect the steam hose adapter from the cylinder and lift the cylinder out of the unit.

• Disconnect the wiring from the top of the cylinder (Fig. 7.b);

• Install the new cylinder in the humidifier, performing the same operations in the reverse order.

Version with room distribution:

• Unscrew the 2 bolts on the built-in fan;

• Lift up the cylinder support bracket to release it (Fig. 7.a);

• Disconnect the blower from the cylinder and lift the cylinder out of the unit;

• Disconnect the wiring from the top of the cylinder (Fig. 7.b);

• Install the new cylinder in the humidifier, performing the same operations in the reverse order.

WARNING: THE THREADED NUTS THAT FASTEN THE ELECTRICAL CABLES TO THE CYLINDER MUST

BE TIGHTENED TO 5 Nm ± 10% (44 in-lb ± 10%) TORQUE TO AVOID THE RISK OF FIRE (Fig. 7.c).

ENGLISH

Fig. 7.a

1

2

3

4

Fig. 7.b

Key:

1) Grey cap

2) Top nut

3) Power terminal

4) Retainer

7.3 Maintenance of the other components in the water circuit

IMPORTANT WARNING:

• The power supply must be always disconnected when performing maintenance on the humidifier.

• Do not use detergents or solvents to clean the plastic components;

• Lime scale can be removed using a solution of vinegar or diluted acetic acid and a soft brush; rinse

the cylinder completely with fresh water.

Cleaning the fill and drain tempering valve

1. disconnect the power cables and remove the pipes;

2. remove the valve and check the condition of the inlet filter;

3. clean with solution of vinegar or diluted acid and soft brush;

4. rinse with fresh water;

5. replace if necessary.

Cleaning the drain pump

1. disconnect the power cables and remove the pipes;

2. take out the screws and remove the drain pump;

3. clean drain pump with solution of vinegar or diluted acid and soft brush;

4. rinse the pump with fresh water;

5. replace if necessary.

compactSteam +030222070 - rel. 1.4 - 05.09.2017

Fig. 7.c

25

ENGLISH

12

15

Cleaning the fill tank:

Clean the tank from any mineral deposits and check that the water can flow freely from the tank to the

drain through the drain valve. Cleaning the supply, fill and overflow hoses: make sure these are clean

and not blocked and replace if necessary.

IMPORTANT WARNING: After having replaced or checked the water circuit, make sure the components

have been connected correctly and the right gaskets have been fitted. Restart the humidifier and run a

number of cleaning cycles (between 2 and 4, see paragraph 4.4 “Starting with a new cylinder”), then

make sure there are no water leaks.

7.4 Spare parts

Item Component code Description

5

1 CYLINDERS SEE TABLE 7.b

12

2 CHM05V2001 CONTROL MODULE 5.4 kg/h 230V WITH DRAIN PUMP

4

6

CHM03V2001 CONTROL MODULE 3.2 kg/h 230V WITH DRAIN PUM

CHM01V2001 CONTROL MODULE 1.6 kg/h 230V WITH DRAIN PUMP

CHM02V1001 CONTROL MODULE 2.5 kg/h 110V WITH DRAIN PUMP

CHM01V1001 CONTROL MODULE 1.6 kg/h 110V WITH DRAIN PUMP

1

3

8

14

Fig. 7.d

10

2

11

7

9

12

3 CHKSW16000 ON-OFF SWITCH FOR COMPACTSTEAM

4 CHKFAN1000 FAN KIT 110V

CHKFAN2000 FAN KIT 230V

5 CHKFILT000 FAN FILTER

6 CHKDIST000 STEAM DISTRIBUTOR KIT

7 CHKFV01001 FILL SOLENOID VALVE + DRAIN TEMPERING 110 V FOR DRAIN PUMP

CHKFV02001 FILL SOLENOID VALVE + DRAIN TEMPERING 230 V FOR DRAIN PUMP

8 CHKDP01000 KIT FOR DRAIN PUMP 110V

CHKDP02000 KIT FOR DRAIN PUMP 230V

9 CHKD900000 TUBING TO CONNECT TO DRAIN 90°

10 CHKFT00000 FILL TANK + PLUG FOR DRAIN PUMP

15 CHKDT0000 DRAIN TANK + PLUG FOR DRAIN PUMP

11 CHKTR00001 ROOM TUBING KIT FOR DRAIN PUMP

CHKTD00001 DUCT TUBING KIT FOR DRAIN PUMP

12 CHKSCREW00 COVER FASTENING SCREWS

14 CHKBT00001 BOTTOM TANK FOR DRAIN PUMP

CHKCAB0000 WIRING KIT FOR UNIT WITH DRAIN PUMP

MCH2004850 RS485 KIT

98C425C001 RS232 - RS485 SERIAL CONVERTER

CHKADAP000 STEAM CYLINDER HOSE ADAPTER

Tab. 7.a

CYLINDERS

Cylinders (item 1) Rated steam flow Vac single-phase

CY0S1A0000 3.5 lbs/h 1.6 kg/h 110 normal 350-1250 Default in compactSteam

CY0S1A0000 3.5 lbs/h 1.6 kg/h 110 low 100-350

CY0S1A0000 5.5 lbs/h 2.5 kg/h 110 normal 350-1250 Default in compactSteam

CY0S1A0000 5.5 lbs/h 2.5 kg/h 110 low 100-350

CY0S1B0000 3.5 lbs/h 1.6 kg/h 230 normal 350-1250 Default in compactSteam

CY0S1C0000 3.5 lbs/h 1.6 kg/h 230 low 100-350

CY0S1B0000 7 lbs/h 3.2 kg/h 230 normal 350-1250 Default in compactSteam

CY0S1C0000 7 lbs/h 3.2 kg/h 230 low 100-350

CY0S1C0000 12 lbs/h 5.4 kg/h 230 normal 350-1250 Default in compactSteam

CY0S1D0000 12 lbs/h 5.4 kg/h 230 low 100-350

KITCY0FG00 Internal filter and gasket valid for all cylinders

26

Supply water conductivity (µS/cm)

Notes

Tab. 7.b

compactSteam +030222070 - rel. 1.4 - 05.09.2017

8. TECHNICAL SPECIFICATIONS

Instant steam production;

voltage-phase-frequency, kW

Steam outlet diameter 22 mm

Outlet pressure limits (Pa/mmWC/PSI /inWC) 950 Pa/95 mm WC/0.014 PSI / 3.7 in WC Duct only

Dimensions (mm / inch) 600 x 341 x 204 mm (24” x 14” x 8”) (Height x Width x Depth)

Weight empty/packaged/installed with water 8/10/12 kg

IP IP20

Power cables 12 AWG

Power relay 2 x 30 A On board

Earth connection

Type of water introduced Drinking water Do not use demin. or softened water

Range of conductivity 100-1250 μS/cm Special cylinders for cond. < 350

Water fill connection ¾” G Adapter to ¾” FPS

Instant water fill flow-rate 0.6 l/min 0.16 gpm

Drain connection 32 mm (1.25”) Adjustable from horizontal to vertical.

Drain water temperature < 60°C

Drain flow 50Hz l/min (gpm) max. 25 l/min

Drain flow 60Hz l/min (gpm) max. 26.2 l/min

Built-in fan flow 120 m³/h

ambient operating temp.

°C (°F)

ambient operating humidity

(% rH)

storage temperature °C (°F) -10…70 (14…158)

probe inputs (general

features)

remote enable input voltage-free contact; max. resistance 300 Ω; Vmax= 33 Vdc; Imax= 6 mAdc;

alarm relay outputs (general

features)

External Relay 250 V 8 A with resistive load (4 A max with inductive load)

Alimentazione per umidostato esterno Alimentazione elettrica per umido stato esterno 24Vac ;2Watt

Serial communication RS485

1.6 kg/h (3.5 lbs/h): 110 Vac single-phase 50/60 Hz. 1.18 kW

1.6 kg/h (3.5 lbs/h): 230 Vac single-phase 50/60 Hz. 1.18 kW

2.5 kg/h (5.5 lbs/h): 110 Vac single-phase 50/60 Hz. 1.86 kW

3.2 kg/h (7 lbs/h): 230 Vac single-phase 50/60 Hz. 2.36 kW

5.4 kg/h (12 lbs/h): 230 Vac single-phase 50/60 Hz. 4.05 kW

18/22/26 lbs.

Screw

< 140°F

(max. 6.6 gpm)

(max. 7 gpm)

71 cfm

50 dB

1…40 (33.8…104)

10…60

If programmated: ON_OFF (Default):

Vmax=33Vdc, Imax=5mA, Rmax=300 Ohm

If programmated 0…10V:

input impedence 10Kohm

umidificatore abilitato= contatto chiuso.Richiede una connessione esterna

250 V 8 A with resistive load (4 A max with inductive load)

Notes

From rear or bottom of unit.

Drain tempering device

Direct distribution in room only

ENGLISH

Tab. 8.a

Limited warranty

All products manufactured by CAREL Industries are guaranteed to the original purchaser to be free

from defects in materials and workmanship in the course of normal and reasonable use for a period of

2 years from the date of shipment. The humidifier spare parts are guaranteed for 90 days from the date

of the invoice. The components replaced under warranty are guaranteed for the remaining duration of

the original warranty or for 90 days, whichever is longer, as long as the product has been installed and

operated in accordance with all appropriate manuals and wiring diagrams, and started up by a qualified

CAREL Industries technician. Any product or part that is found to be defective will, at the option of

CAREL Industries be replaced or repaired. CAREL Industries reserves the right to inspect any part or

installation before replacing or repairing defective parts. After startup of the product, labour for repairs

or replacement of parts is not covered by this warranty. Replacement of routinely replaceable parts such

steam cylinders and gaskets are not covered by this warranty. CAREL Industries assumes no liability for

consequential or inconsequential damage, or damage due to negligence or improper use. Under the

terms of this warranty, the original purchaser may have certain legal rights and other rights, which may

vary from state to state. The warranty is void if the product is damaged due to negligence, mishandling

or improper use, or if the product label is missing. CAREL Industries shall repair or replace the products

within two (2) months of receiving the returned goods.

CAREL reserves the right to modify or change its products without prior warning.

compactSteam +030222070 - rel. 1.4 - 05.09.2017

27

28

compactSteam +030222070 - rel. 1.4 - 05.09.2017

Manuale d’uso

compactSteam +030222070 - rel. 1.4 - 05.09.2017

3

Qualora presenti, rimuovere i seguenti elementi:

Chiudere il fermo del cilindro

Avvertenza

Rimuovere prima di installare

Rimuovere prima di installare

Rimuovere prima di installare

Rimuovere prima di installare

Rimuovere prima di installare

4

compactSteam +030222070 - rel. 1.4 - 05.09.2017

AVVERTENZE

Gli umidicatori CAREL Industries sono prodotti avanzati, il cui funzionamento

è specicato nella documentazione tecnica fornita col prodotto o scaricabile,

anche anteriormente all’acquisto, dal sito internet www.carel.com. Ogni

prodotto CAREL Industries, in relazione al suo avanzato livello tecnologico,

necessita di una fase di qualica/congurazione/programmazione anché

possa funzionare al meglio per l’applicazione specica. La mancanza di tale

fase di studio, come indicata nel manuale, può generare malfunzionamenti nei

prodotti nali di cui CAREL Industries non potrà essere ritenuta responsabile.

Il cliente (costruttore, progettista o installatore dell’equipaggiamento nale)

si assume ogni responsabilità e rischio in relazione alla congurazione del

prodotto per il raggiungimento dei risultati previsti in relazione all’installazione

e/o equipaggiamento nale specico. CAREL Industries in questo caso, previ

accordi specici, può intervenire come consulente per la buona riuscita della

installazione/start-up macchina/utilizzo, ma in nessun caso può essere ritenuta

responsabile per il buon funzionamento dell’umidicatore ed impianto nale

qualora non siano state seguite le avvertenze o raccomandazioni descritte

in questo manuale o in altra documentazione tecnica del prodotto. In

particolare, senza esclusione dell’obbligo di osservare le anzidette avvertenze

o raccomandazioni, per un uso corretto del prodotto si raccomanda di prestare

attenzione alle seguenti avvertenze:

• PERICOLO SCOSSE ELETTRICHE

L’umidicatore contiene componenti sotto tensione elettrica. Togliere

l’alimentazione di rete prima di accedere a parti interne o in caso di

manutenzione e durante l’installazione.

• PERICOLO PERDITE D’ACQUA

L’umidicatore carica/scarica automaticamente e costantemente quantità

d’acqua. Malfunzionamenti nei collegamenti o nell’umidicatore possono

causare perdite.

• PERICOLO DI USTIONE

L’umidicatore contiene componenti ad alta temperatura, ed eroga vapore

a 100°C/ 212°F.

Attenzione:

• L’installazione del prodotto deve obbligatoriamente comprendere una

connessione di terra, utilizzando l’apposito morsetto di colore giallo-verde

presente nell’umidicatore.

• Condizioni ambientali e tensione di alimentazione devono essere conformi ai

valori specicati nelle etichette ‘dati di targa’ del prodotto.

• Il prodotto è progettato esclusivamente per umidicare ambienti in modo

diretto o mediante sistemi di distribuzione (condotte).

• Installazione, utilizzo e manutenzione devono essere eseguite da personale

qualicato, consapevole delle precauzioni necessarie e in grado di eettuare

correttamente le operazioni richieste.

• Per la produzione di vapore si deve utilizzare esclusivamente acqua con

caratteristiche indicate nel presente manuale.

• Tutte le operazioni sul prodotto devo essere eseguite secondo le istruzioni

contenute nel presente manuale e nelle etichette applicate al prodotto. Usi

e modiche non autorizzati dal produttore sono da considerarsi impropri.

CAREL Industries non si assume alcuna responsabilità per tali utilizzi non

autorizzati.

• Non tentare di aprire l’umidicatore in modi diversi da quelli indicati nel

manuale.

• Attenersi alle normative vigenti nel luogo in cui si installa l’umidicatore.

• Tenere l’umidicatore fuori dalla portata di bambini e animali.

• Non installare e utilizzare il prodotto nelle vicinanze di oggetti che possono

danneggiarsi a contatto con l’acqua (o condensa d’acqua). CAREL Industries

declina ogni responsabilità per danni conseguiti o diretti a seguito di perdite

d’acqua dell’umidicatore.

• Non utilizzare prodotti chimici corrosivi, solventi o detergenti aggressivi

per pulire le parti Interne ed esterne dell’umidicatore, salvo non vi siano

indicazioni speciche nei manuali d’uso.

• Non fare cadere, battere o scuotere l’umidicatore, poiché le parti interne e di

rivestimento potrebbero subire danni irreparabili.

CAREL Industries adotta una politica di continuo sviluppo. Pertanto si riserva

il diritto di eettuare modiche e miglioramenti a qualsiasi prodotto descritto

nel presente documento senza preavviso. I dati tecnici presenti nel manuale

possono subire modiche senza obbligo di preavviso.

La responsabilità di CAREL Industries in relazione al proprio prodotto è regolata

dalle condizioni generali di contratto CAREL Industries pubblicate nel sito

www.carel.com e/o da specici accordi con i clienti; in particolare, nella misura