Cardiovascular Systems, Inc. DIAMONDBACK 360 Peripheral Orbital Atherectomy System Exchangeable Series, DIAMONDBACK 360 Instructions For Use Manual

_______________________________________ _____________

DIAMONDBACK 360

®

Peripheral Orbital Atherectomy

System Exchangeable Series

Including the Orbital Atherectomy Device, Handle, Orbital

Atherectomy Cartridge, Saline Pump, VIPERWIRE ADVANCE®

Peripheral Atherectomy Guide Wire, and VIPERWIRE

ADVANCE® with FLEXTIP Peripheral Atherectomy Guide Wire

Instructions for use

_______________________________________ _____________

Caution: Federal Law (USA) restricts this device to sale by or on the order of a

physician.

The following are trademarks of Cardiovascular Systems, Inc.:

CSI®, Cardiovascular Systems®, DIAMONDBACK 360®, VIPERWIRE®, VIPERWIRE

ADVANCE®, VIPERWIRE ADVANCE® with FLEXTIP, VIPERSLIDE®, GlideAssist

®

Explanation of Symbols on Package Labels

Refer to the package labels to see which symbols apply to specific products.

Lot number

Model number

Consult IFU www.csi360.com (USA) (Symbol appears in blue when

placed on the device itself)

Caution: Consult IFU www.csi360.com (USA)

Do not reuse.

Do not re-sterilize

Sterilized with Ethylene Oxide

Manufacturer

Use by

Maximum guide wire tip diameter

Maximum guide wire shaft diameter

Guide wire length

Caution: Federal law (USA) restricts this device to sale by or on

the order of a physician.

Contains phthalates

Explanation of Symbols on the Saline Pump

Low saline red LED indicator

Start button and pump ON green LED indicator

Pump status yellow LED indicator

Prime button

Type CF Applied Part

Slow Blow Type T Fuse

Explanation of Symbols on the Handle

Prime button

Low speed button

Medium speed button

High speed button

Rotate Symbol

Eject Symbol

Non-continuous use; spin cycles of 30 seconds on, 30

seconds off with maximum spin time of ≤ 8 minutes per

cartridge using no more than three cartridges per handle

Table of Contents

1. System Description................................................................................................ 1

2. System and Component Descriptions ................................................................... 1

3. Indications for Use ................................................................................................. 9

4. Contraindications ................................................................................................... 9

5. Restrictions .......................................................................................................... 10

6. Warnings ............................................................................................................. 10

7. Precautions ......................................................................................................... 11

8. Storage and Handling .......................................................................................... 13

9. Adverse events .................................................................................................... 13

10. Clinical Trials Summary ....................................................................................... 14

11. Equipment, Setup, and Test ................................................................................ 14

12. OAS Directions for Use ....................................................................................... 22

13. Specifications ...................................................................................................... 32

14. OAS Pump Declaration of Conformity ................................................................. 34

15. EMC Declaration ................................................................................................. 34

16. FCC ..................................................................................................................... 37

17. Disclaimer of Warranty ........................................................................................ 37

Appendix A. System Troubleshooting ........................................................................... 39

Appendix B. Introducer, Guide Sheath, or Guide Catheter Size .................................... 44

Appendix C. Maximum Orbit and Resulting Lumen Diameter ....................................... 46

Appendix D. Orbit Performance .................................................................................... 48

1

1. System Description

The Cardiovascular Systems, Inc. (CSI) DIAMONDBACK 360 Peripheral Orbital Atherectomy

System (OAS) Exchangeable Series is a minimally invasive, catheter-based OAS designed for

improving luminal diameter in patients with peripheral arterial disease (PAD). PAD is caused by

the accumulation of plaque in the arteries of the leg or foot and reduces blood flow that may

lead to pain, tissue loss, and eventual foot amputation, leg amputation or death. This system

treats a broad range of plaque types in the lower limbs and reduces or removes occlusive

material by using a spinning, orbiting diamond-coated crown, within peripheral arteries, in order

to restore lumen patency.

The OAS consists of a hand-held CSI DIAMONDBACK 360 Orbital Atherectomy Device (OAD),

the CSI Saline Pump (OAS pump), the CSI VIPERWIRE ADVANCE Peripheral Atherectomy

Guide Wire (guide wire) or CSI VIPERWIRE ADVANCE with FLEXTIP Peripheral Atherectomy

Guide Wire (guide wire), and the CSI VIPERSLIDE Lubricant (lubricant).

The Exchangeable Series allows for multiple treatment options by offering a variety of

cartridges, with different crown sizes, for use with a single handle. The Exchangeable Series

OAS cartridges are intended to provide variable crown sizes during a procedure. The cartridges

should be utilized for the treatment of multiple lesions to achieve full-leg revascularization. The

following Exchangeable Series package options are available:

• OAD - handle, cartridge, and saline line

• Handle-only with a saline line

• Cartridge-only

2. System and Component Descriptions

2.1. Orbital Atherectomy Device (OAD) Description

The OAD is a hand-held, over-the-wire device consisting of a handle, a cartridge, and a

saline line (Figure 1). The cartridge includes a sheath-covered drive shaft and a

diamond-coated crown. The diamond coating on the crown provides an abrasive surface

with which to reduce or remove occlusive material within peripheral arteries. The handle

includes control buttons for operating the OAD and contains the motor and electronics

that power the rotation of the drive shaft. The GlideAssist feature facilitates advancing

and retracting the OAD crown over the guide wire.

Warning: The device is designed to track and spin only over the CSI Peripheral

VIPERWIRE ADVANCE Guide Wire or the VIPERWIRE ADVANCE with FLEXTIP Guide

Wire. Do not use any other guide wire with this device.

Select a crown size according to the crown’s ability to cross the lesion within the minimum

proximal reference vessel diameter at the treatment site. See Table 1, Table 2, and

Table 3 for available crown sizes. See Appendices C and D for orbit performance.

2

3

Table 1: Micro Crowns

Model Number

Type

Crown Size

Shaft

Length

Nose

Length*

DBP-EX-125MIC145

DBP-CART-125MIC145

OAD

Cartridge

1.25 mm

145 cm

7 mm

DBP-EX-125MIC75

DBP-CART-125MIC75

OAD

Cartridge

1.25 mm

75 cm

7 mm

*Nose length is the length of the drive shaft from the crown to the distal tip of the shaft.

Table 2: Solid Crowns

Model Number

Type

Crown Size

Shaft Length

Nose Length*

DBP-EX-125SOL75

DBP-CART-125SOL75

OAD

Cartridge

1.25 mm

75 cm

7 mm

DBP-EX-125SOL145

DBP-CART-125SOL145

OAD

Cartridge

1.25 mm

145 cm

7 mm

DBP-EX-150SOL145

DBP-CART-150SOL145

OAD

Cartridge

1.50 mm

145 cm

10 mm

DBP-EX-200SOL145

DBP-CART-200SOL145

OAD

Cartridge

2.00 mm

145 cm

30 mm

DBP-EX-125SOL200

DBP-CART-125SOL200

OAD

Cartridge

1.25 mm

200 cm**

10 mm

DBP-EX-150SOL200

DBP-CART-150SOL200

OAD

Cartridge

1.50 mm

200 cm**

10 mm

DBP-EX-175SOL180

DBP-CART-175SOL180

OAD

Cartridge

1.75 mm

180 cm**

30 mm

*Nose length is the length of the drive shaft from the crown to the distal tip of the shaft.

**180 cm and 200 cm length devices are intended to accommodate patient anatomy and physician

preferred access methodology, for example radial access. See Section 10.3 Initiating the Atherectomy

Procedure.

Table 3: Classic Crowns

Model Number

Type

Crown Size

Shaft

Length

Nose

Length*

DBP-EX-150CLA145

DBP-CART-150CLA145

OAD

Cartridge

1.50 mm

145 cm

15 mm

DBP-EX-200CLA145

DBP-CART-200CLA145

OAD

Cartridge

2.00 mm

145 cm

20 mm

*Nose length is the length of the drive shaft from the crown to the distal tip of the shaft.

4

Figure 1. OAD - includes the handle, cartridge, and saline line

______________________________________________________________________

Cartridge

A. Nose length

B. Crown

C. Saline sheath

D. Rotation grips

E. Saline line port connector

Handle

F. Crown advancer knob

G. On/Off button

H. Cartridge eject button

I. Speed buttons and indicators

J. Brake light indicator

K. Prime button

L. Guide wire brake lever

M. Electrical power cord

Saline line

N. Saline line port connector

O. Injection port

P. Saline tubing positioners

Q. Saline tubing

5

R. Saline bag spike

OAD Features:

• On/Off Button to control when the crown starts and stops

• 3 speed control buttons with LED indicators to select the crown rotation speed

• Saline prime button

• 15 cm crown advancement with travel measurement indicators

• Ability to lock crown advancer knob to maintain crown position relative to handle

• Manual guide wire brake to restrict both the rotational and axial movement of the

guide wire with a LED indicator

• Eccentrically-mounted, diamond-coated crown that provides an abrasive surface with

which to reduce or remove occlusive tissue

• GlideAssist to facilitate advancing and retracting the OAD crown over the VIPERWIRE

guide wire.

• Ability to separate the cartridge from the handle to allow the use of multiple cartridges

in one case

• Crown advancement measurement indicators

• Able to load guidewire through proximal end of OAD

6

2.2. Package Contents: OAD, Handle, Or Cartridge

2.2.1. OAD

The OAD and accessories are supplied sterile and are for single-use only. Each

package contains:

• OAD (fully assembled – one handle and one cartridge)

• Saline line (connects the OAD to the OAS pump)

2.2.2. Handle

The handle and accessories are supplied sterile and are for single-use only. Each

package contains:

• One handle

• Saline line (connects the OAD to the OAS pump)

2.2.3. Cartridge

The cartridge is supplied sterile and is for single-use only. Each package contains:

• One cartridge

2.3. OAS Pump Description

The OAS pump provides the saline pumping mechanism and power to the device. The

small, reusable, and portable OAS pump attaches to a standard five-wheel rolling

intravenous (IV) pole (Figure 2) and plugs in to a wall power outlet. The OAS pump

includes a built-in, audible 25 second spin time notification, system power and priming

buttons, and status indicators.

7

Figure 2. OAS Pump

______________________________________________________________________

A. IV pole screw clamp

B. IV pole (not included)

C. Low saline level sensor and connector cord

D. Control panel

E. OAS Pump door

F. OAD connection

______________________________________________________________________

2.4. OAS Pump Package Contents

The OAS pump and accessories are supplied non-sterile. Each package contains:

• OAS Pump with attached IV pole screw clamp

• Power cord

• Low saline level sensor and connector cord

2.5. VIPERWIRE ADVANCE Peripheral Guide Wire Description

The guide wire is a smooth, stainless steel wire, with a silicone coating, and a radiopaque

distal spring tip (Figure 3). The guide wire allows for proper positioning of the OAD crown

within peripheral arteries and provides a center of rotation for the OAD drive shaft. The

guide wire torquer is a small, plastic accessory, packaged with the guide wire, and

provides a gripping surface for manipulating the guide wire, if desired. Guide wires are

available in a variety of spring tip diameters (Tables 4 and 5).

8

Figure 3. Guide wire

______________________________________________________________________

A. Distal spring tip

______________________________________________________________________

Table 4 VIPERWIRE ADVANCE Peripheral 0.014” Guide Wires

OAD Device

Shaft Length

Compatibility

Model Number

Guide wire

Spring Tip

Diameter

Guide

wire

Length

75 and 145 cm

VPR-GW-14

0.014”

335 cm

75 and 145 cm

VPR-GW-17

0.017”

335 cm

180 and 200 cm

VPR-GW-EL14

0.014”

475 cm

180 and 200 cm

VPR-GW-EL18

0.018”

475 cm

Table 5 VIPERWIRE ADVANCE with FLEXTIP Peripheral 0.014”Guide Wire

OAD Device

Shaft Length

Compatibility

Model Number

Guide wire

Spring Tip

Diameter

Guide

wire

Length

75 and 145 cm

VPR-GW-FT14

0.014”

335 cm

75 and 145 cm

VPR-GW-FT18

0.018”

335 cm

75 and 145 cm

VPR-GW-FLEX14

0.014”

335 cm

75 and 145 cm

VPR-GW-FLEX18

0.018”

335 cm

180 and 200 cm

VPR-GW-ELFLEX14

0.014”

475 cm

180 and 200 cm

VPR-GW-ELFLEX18

0.018”

475 cm

9

2.6. VIPERWIRE ADVANCE Peripheral Guide Wire Package Contents

The guide wire and guide wire torquer are packaged separately from the OAD, are

supplied sterile and are for single-use only. Each VIPERWIRE ADVANCE package

contains:

• Five (5) guide wires

• Five (5) torquers

2.7. Lubricant Description

VIPERSLIDE Lubricant reduces friction between the OAD drive shaft and the guide wire.

It is packaged separately from the OAD.

Note: Please refer to the VIPERSLIDE Lubricant IFU prior to starting the atherectomy

procedure.

3. Indications for Use

The DIAMONDBACK 360 Peripheral Orbital Atherectomy System Exchangeable Series is a

percutaneous orbital atherectomy system indicated for use as therapy in patients with occlusive

atherosclerotic disease in peripheral arteries and who are acceptable candidates for

percutaneous transluminal atherectomy.

The OAS supports removal of stenotic material from artificial arteriovenous dialysis fistulae (AV

shunt). The system is a percutaneous orbital atherectomy system indicated as a therapy in

patients with occluded hemodialysis grafts who are acceptable candidates for percutaneous

transluminal angioplasty.

4. Contraindications

Use of the OAS is contraindicated in the following situations:

• The guide wire cannot be passed across the peripheral lesion.

• The system cannot be used in coronary arteries.

• The target lesion is within a bypass graft or stent.

• The patient has angiographic evidence of thrombus; thrombolytic therapy must be

instituted prior to atherectomy.

• The patient has angiographic evidence of significant dissection at the treatment site. The

patient may be treated conservatively to permit the dissection to heal before treating the

lesion with the OAS.

10

5. Restrictions

The OAS should only be used by physicians who are experienced in peripheral angioplasty at

their institutions and trained on the use of the OAS. Contact a CSI representative for information

on training.

6. Warnings

• Do not use the OAD in a vessel that is too small for the crown. The reference vessel

diameter at the treatment area must be at least 2.00 mm in diameter for the 1.25mm micro

crown.

• If mechanical failure of the OAD occurs before or during the atherectomy procedure,

discontinue use immediately. Do not attempt to use a damaged OAD or other system

component. Use of damaged components may result in system malfunction or patient injury.

• Do not use the OAD during spasm of the vessel.

• Only use the approved CSI VIPERWIRE ADVANCE 0.014-inch (0.3556 mm) × 335-cm

guide wires for 75cm and 145 cm length CSI crown and shaft configurations. Only use the

approved CSI VIPERWIRE ADVANCE 0.014-inch (0.3556 mm) x 475 cm guide wires for

180 cm and 200 cm length CSI crown and shaft configurations. See Table 4 and Table 5 for

the appropriate guide wire to use based on the OAD shaft configuration. Follow CSI’s

instructions related to guide wire use.

• Do not continue treatment if the guide wire or the OAD becomes sub-intimal.

• Immediately stop use if the OAD stalls. Review for complications and mechanical failure if a

stall condition occurs. Do not change to a higher speed if the OAD stalls.

Note: If a stall occurs, the On/Off button is inactive for five seconds. If the On/Off

button is pressed during this five second lockout period, the lockout period will begin

again.

• Performing treatment in vessels or bifurcations that are excessively tortuous or angulated

may result in vessel damage.

• Always use fluoroscopy when advancing the guide wire to avoid misplacement, dissection,

or perforation. The OAD tracks over the guide wire, so it is imperative that the guide wire be

initially placed through the stenotic lumen and not in a false channel.

• Do not inject contrast while OAD crown is spinning. OAD failure or patient harm may occur.

• Handle the OAD and guide wire carefully. A tight loop, kink, or bend in the guide wire may

cause damage and system malfunction during use.

• Never operate the OAD without normal saline and lubricant solution. Flowing saline and

lubricant solution is required for cooling and lubricating the OAD during use to avoid

overheating and permanent damage to the OAD and possible patient injury.

• The crown at the distal tip of the OAD operates at very high speeds. Do not allow body parts

or clothing to come into contact with the crown. Physical injury or entanglement may occur.

• Never advance the orbiting crown to the point of contact with the guide wire spring tip. Distal

detachment and embolization of the tip may result.

11

• Always advance the orbiting, abrasive crown by using the crown advancer knob. Never

advance the orbiting crown by advancing the shaft or handle. Guide wire buckling may

occur, and perforation or vascular trauma may result.

• Always keep the crown advancing or retracting while it is at high rotational speeds. Do not

allow the crown to remain in one location for more than 2–3 seconds. Maintaining the crown

in one location while it is orbiting at high speeds may lead to excessive tissue removal.

• Do not start or stop orbiting of the crown when tight in a lesion.

• Never force the crown when rotational or translational resistance occurs; vessel perforation

may occur. If resistance to motion is noted, retract the crown and stop treatment

immediately. Use fluoroscopy to analyze the situation.

• When treating chronic total occlusion (CTO), create a channel at low or medium speed

before traversing the lesion at high speed. Crossing the CTO on high speed may cause the

shaft and/or guide wire to fracture as a result of excessive force.

• While advancing the crown through the introducer sheath/guide catheter, do not activate

crown rotation. The crown must not spin while located within the introducer sheath/guide

catheter.

• The maximum travel of the crown advancer knob—and therefore the shaft tip—is 15 cm.

Moving the crown advancer knob forward moves the shaft tip an equal distance toward the

guide wire spring tip. When moving the crown advancer knob, make sure there is sufficient

distance between the guide wire spring tip and the distal end of the shaft (10 cm minimum).

If the distance between the shaft tip and the guide wire spring tip is insufficient, the shaft tip

may damage the guide wire spring tip and result in dislodgement of the guide wire spring tip.

Use contrast injections and fluoroscopy to monitor movement of the shaft tip in relation to

the guide wire spring tip.

• Do not prolapse or bend the guide wire core. If the spring tip becomes prolapsed, keep the

bend/prolapse contained within the spring tip section only. A prolapsed or bent guide wire

core can result in damage to the guide wire or OAD.

• The system should not be used on children or pregnant women.

• Do not re-use or re-sterilize the OAD. If the OAD is re-used, the OAD may not function as

intended and serious infection, leading to potential harm and/or death, may occur.

• Do not spin the crown in GlideAssist, with the guide wire brake lever in the unlocked

position, without first securing the guide wire by holding it with fingers or by using the guide

wire torquer. If using the guide wire torquer, ensure that it is securely fastened to the guide

wire before starting to spin the crown. Failure to secure the guide wire when the brake is

unlocked could allow the guide wire to spin while in GlideAssist mode which may result in

patient harm.

7. Precautions

• If the sterile packaging appears damaged or shelf life has expired, do not use the product.

• Do not flip contents of trays into the sterile field as damage may occur. Components within

trays must be carefully removed and placed into sterile field to avoid damage.

12

• Follow standard hospital atherectomy policies and procedures, including those related to

anticoagulation and vasodilator therapy.

• Radiographic equipment for fluoroscopy should be used to provide high-resolution images.

Guide wires and catheters should only be manipulated under fluoroscopy.

• Because of the torque responsiveness of CSI-approved guide wires, they are more difficult

to handle than other commercially available guide wires used in peripheral angioplasty.

Exercise care when using these guide wires.

• Use only normal saline and lubricant solution as the infusate. (Drugs such as vasodilators are

added to the infusate at the physician’s discretion). The OAD may malfunction if contrast or

other substances are injected into the OAD infusion port.

• Do not operate the OAD without recommended lubricants at the manufacturers’ recommended

concentration. Maximum speeds may not be achieved without lubricants.

• Ensure the OAD strain relief remains straight during atherectomy treatment.

• To relieve compression in the driveshaft, lock the crown advancer knob at 1cm from the full

back position, advance device over the wire to a position proximal from the lesion, deploy

the guide wire brake, then unlock the crown advancer knob and move it fully proximal. If the

OAD is started with existing compression in the driveshaft, it may result in the crown

springing forward.

• If 1:1 motion is not observed between the crown advancer knob and the crown, retract and

re-advance the crown into the lesion. Repeat retracting and advancing the crown into the

lesion until 1:1 movement is observed. If the knob and the crown are not moving together,

the crown may be driven into the lesion with too much force and may result in the crown

springing forward on exiting the lesion.

• When moving the eccentric diamond-coated crown back and forth across the lesion, employ

a series of intermittent treatment intervals and rest periods.

• Rest periods are recommended after 30-second treatment intervals, with a maximum total

treatment time of 8 minutes per cartridge.

• Monitor the saline fluid level during the procedure. Normal saline and lubricant solution

infusion is critical to OAD performance.

□ Do not kink or crush the saline tubing. Flow of saline will be reduced.

□ Check the saline tubing and connections for leaks during the procedure.

• Do not allow fluid to leak onto electrical connections of the OAS pump.

• Do not detach the cartridge from the handle when the OAD is over the guide wire. Kinking

of the guide wire and/or not being able to reconnect the cartridge and the handle may occur.

• Do not track only the cartridge into the patient and then attempt to connect the handle.

Kinking of the guide wire and/or not being able to reconnect the cartridge and the handle

may occur.

• Do not attempt to load a guide wire with a crossing profile >0.014” through the proximal end

of the OAD. Guide wire with a crossing profile >0.014” will not fit through the internal

components of the OAD.

• Do not attempt to remove the cartridge from the handle when spinning.

13

8. Storage and Handling

8.1. Storage

Store all system components at room temperature and in a clean environment away

from magnets and sources of electromagnetic interference (EMI).

Do not store ViperSlide Lubricant above 25°C (77°F). Do not freeze ViperSlide

Lubricant. Refer to the ViperSlide Lubricant IFU prior to starting the atherectomy

procedure.

8.2. Handling

• All system and Exchangeable Series components are intended to be used in typical

operating room/catheterization laboratory environments.

• Additional components should be on hand in the event of damage to any of the

components or to component packaging.

• Do not reuse or resterilize the OAD, handle, cartridge, guide wire, guide wire torquer,

or lubricant as these components are designed for single-use only.

• Do not use the OAD, handle, cartridge, or the guide wire if their sterile package

barriers are compromised or damaged.

• Do not resterilize any component after exposure of the component to body tissue or

body fluids.

• Do not use the OAD, handle, cartridge, or OAS pump if any of them were dropped

onto a hard surface, from a height at or greater than 12 in (30 cm), as these

components may be damaged and may fail to operate properly.

• Do not use any system components after their use-by date.

• Do not use Viperslide Lubricant if it is exposed to temperatures outside the range

indicated on the package labels.

9. Adverse events

Potential adverse events that may occur and/or require intervention include, but are not limited

to:

• Allergic reaction to medication/media/OAD components

• Amputation

• Anemia

• Aneurysm

14

• Bleeding complications which may require transfusion

• Cerebrovascular accident (CVA)

• Death

• Distal embolization

• Entry site complications

• Hemolysis

• Hypotension/hypertension

• Infection

• Myocardial infarction

• Pain

• Pseudoaneurysm

• Restenosis of treated segment that may require revascularization

• Renal insufficiency/failure

• Slow flow or no reflow phenomenon

• Thrombus

• Vessel closure, abrupt

• Vessel injury, including dissection and perforation that may require surgical repair

• Vessel spasm

• Vessel occlusion

10. Clinical Trials Summary

See www.CSI360.com for clinical trial information

11. Equipment, Setup, and Test

11.1. Equipment

In addition to the OAS components, equip the operating room with the following:

• Introducer, guide sheath, or guide catheter - see Appendix B for sizing

recommendations

• Standard IV pole with five wheels and a 20 inch diameter base

• 1000 mL bag of normal saline

• Fluoroscopic imaging equipment

• Standard hospital grade, electrical wall outlet

• Other equipment, as needed, for interventional procedures

11.2. OAS Pump Set Up

1. Use the IV pole screw clamp to attach the OAS pump to a standard IV pole making

sure to attach the OAS pump to the IV pole at a distance not greater than 60 in (153

cm) from the floor to the top edge of the OAS pump.

15

2. Hang the low saline level sensor and cord, by the closed loop, from the horizontal

arm of the standard IV pole.

3. Plug the low saline level sensor connector into the back of the OAS pump (Figure ).

Figure 4. Plug in the low saline level sensor_________________

____________________________________________________

4. Verify that the power cord is connected to the back of the OAS pump.

5. Insert the other end of the power cord into the electrical wall outlet.

Warning: To avoid risk of electric shock, this equipment must only be connected to a

supply mains with protective earth.

Warning: Ensure the power cord connection to the OAS pump and the on/off switch is

accessible at all times.

Caution: Do not allow fluid to leak onto electrical connections of the OAS pump.

11.3. Preparing the Bag of Saline and Lubricant

Ensure that the OAS pump is powered off by pressing the Master Power switch on

the back of the OAS pump to off and ensure that no LEDs are illuminated on the OAS

pump control panel (

16

1. Figure 5).

17

Figure 5. OAS Pump control panel

______________________________________________________________________

A. Low saline red LED indicator

B. Prime button

C. Start button and green LED indicator

D. Status yellow LED indicator

______________________________________________________________________

2. Prepare a full 1000 mL bag of normal saline solution with lubricant. Refer to the

VIPERSLIDE Lubricant Instructions for Use for lubricant preparation instructions.

3. Hang the prepared saline bag with lubricant from the low saline level sensor on the

standard IV pole.

Caution: Do not use glass bottles for the saline solution with lubricant or hang

multiple saline bags from the low saline level sensor as this will disable the Low Saline

Information signal.

11.4. OAD Set Up

Carefully remove the OAD (or individual OAD handle and cartridge) from the tray(s) and

set onto a stable surface.

Note: Removal of the OAD from the packaging by tipping the tray and allowing the OAD

to fall out can result in damage to the OAD or ancillary devices underneath the OAD.

11.4.1. Connect the Cartridge to the Handle

18

If the handle and cartridge are not pre-connected, perform the following:

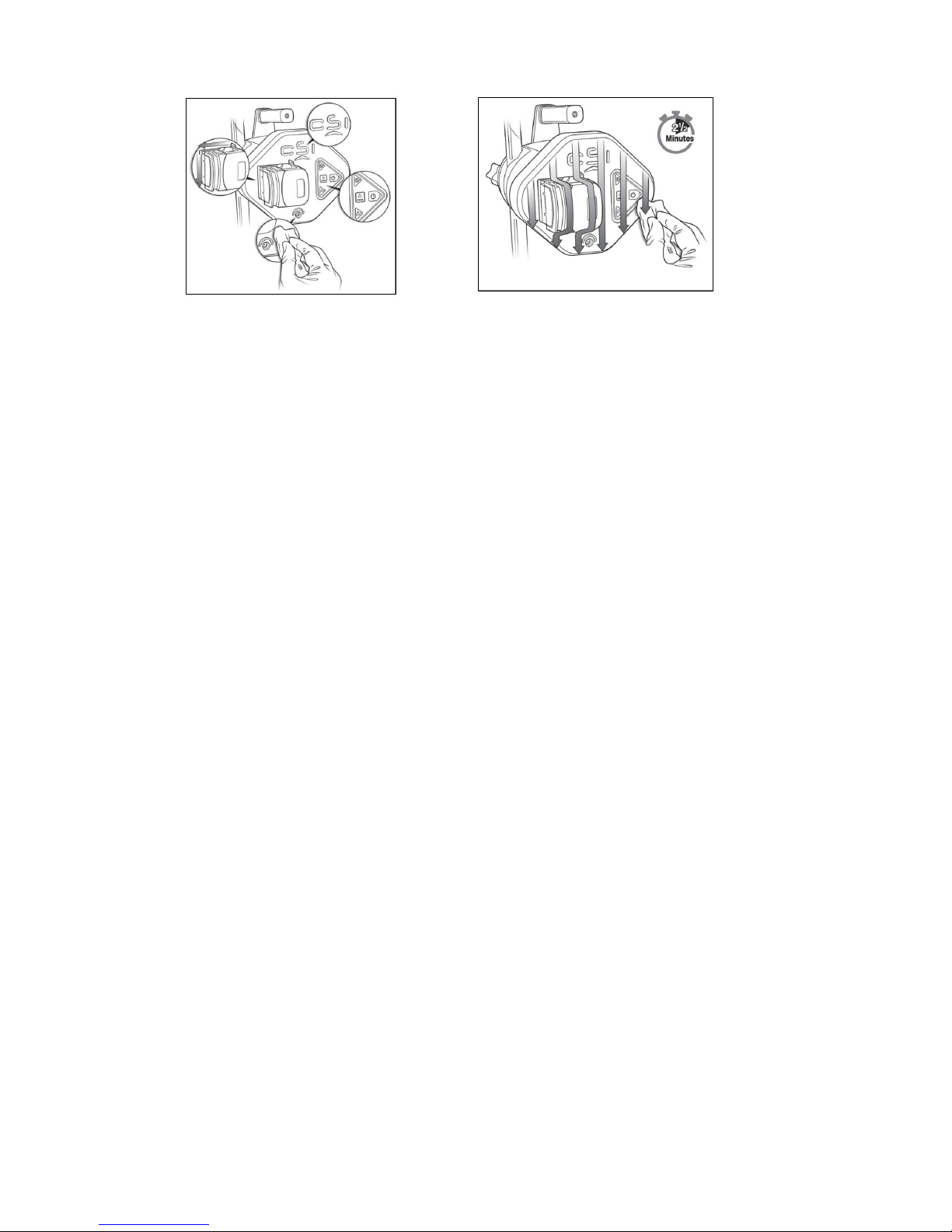

1. Insert the cartridge into the handle, see Figure 6.

Figure 6. Cartridge Insertion

2. Rotate the cartridge to lock it to the handle. Two tactile, audible clicks indicate

that the cartridge is locked, see Figure 7. If the crown advancer knob cannot

move, ensure that the cartridge is fully rotated.

Figure 7. Cartridge Rotation.

19

Figure 8. Assembled OAD.

11.5. Connecting the OAD to the OAS Pump

Remove the sterile saline tubing from the OAD package and pass the saline bag spike

end of the saline tubing out of the sterile field. Connect the other end of the saline tubing

luer to the device luer. Additionally, pass the OAD power cord out of the sterile field.

Perform the following:

1. Connect the saline tubing to the saline bag with lubricant using standard institution

procedures.

2. Open the door, located on the front of the OAS pump, by rotating the door in the

direction of the arrow (Figure 9).

3. Place the saline tubing over the pump rollers so that the tubing positioners align with

the top and bottom V-guides on the pump (Figure 9).

20

Figure 9. Placing the saline tubing within the OAS Pump

______________________________________________________________________

A. Saline tubing positioners

B. Saline tubing

C. V-guides

D. OAS Pump door

______________________________________________________________________

4. While closing the door, verify that there is no pinching of the saline tubing and ensure

that there is slack in the saline tubing between the OAS pump and saline bag with

lubricant.

5. Verify that the saline tubing is properly inserted into the saline tubing V-guides and

that there are no kinks or damage to the saline tubing.

6. Press the Master Power switch, on the back of the OAS pump, and verify that the red

or yellow LED is illuminated on the OAS pump control panel.

7. Connect the OAD power cord to the OAS pump (Figure 10).

Figure 10. Connect the OAD power cord to the OAS pump____________

8. Remove the driveshaft from the dispenser coil.

9. Purge air from the OAD and the saline tubing as follows:

21

a. Verify that the saline tubing is connected to the OAD.

b. Press the green Start button on the OAS pump control panel to start saline flowing

through the saline tubing. Verify that the green LED illuminates.

c. Press and hold the Prime button on the OAS pump control panel to purge air from

the saline tubing. Continually pressing the Prime button will pump saline through

the tubing at an increasing flow rate. Releasing the Prime button will decrease the

flow to the low flow rate after two seconds.

d. Verify that saline is exiting from the OAD sheath near the crown.

e. Continue priming to ensure there are no air bubbles within the saline tubing and

use standard hospital procedures to aspirate or purge air from the lines.

f. After verifying there are no air bubbles within the saline tubing, discontinue

priming.

11.6. Testing the OAD

11.6.1. Testing OAD Crown Advancement

Before inserting any portion of the OAD into the body, ensure that axial

movement of the OAD crown advancer knob will produce smooth travel of the

crown.

Caution: Do not spin the crown during this test.

1. Ensure that the crown advancer knob is in the unlocked position as this will

allow free axial travel of the crown advancer knob.

2. While visually monitoring the crown, slowly move the crown advancer knob

in a back and forth motion. The maximum travel of the crown advancer knob,

and the corresponding maximum travel of the shaft tip, is 5.9 inches (15 cm).

11.6.2. Optional: Testing OAD Crown Rotation

This test is optional, but is performed chronologically after testing crown

advancement.

Note: Hold the guide wire firmly during the test. When the test is complete, the

OAD is ready for use and the guide wire can be inserted through the introducer,

guide sheath, or guide catheter.

1. Push the crown advancer knob fully proximal, away from the nose of the

handle, and release the guide wire brake before threading the guide wire

through the OAD drive shaft.

2. Grasp the proximal end of the guide wire and thread the guide wire through

the opening in the OAD drive shaft distal tip.

22

Caution: Do not operate the OAD if there is a bend, kink, or tight loop in the

guide wire. A bend, kink, or tight loop in the guide wire may cause damage

to and malfunctioning of the OAD during use.

3. Continue feeding the guide wire into the OAD drive shaft until the guide wire

appears at the rear of the OAD.

4. Lock the guide wire in place by pressing down on the guide wire brake lever

as the crown will not spin if the guide wire brake is unlocked.

5. Verify that saline is still flowing freely out of the saline sheath tip. Verify that

the saline tubing is properly connected to the saline bag, that the saline

tubing routes correctly through the saline tubing guides, and that the saline

tubing is properly connected to the OAD.

6. Hold the OAD sheath a few centimeters from the crown while making sure

that the crown is not in contact with any objects. Verify there is no pinching of

the OAD sheath at any time during OAD operation.

7. Press and release the On/Off button located on top of the crown advancer

knob to activate crown rotation. The OAD is preset to low speed, and the

illuminated LED on the OAD will indicate that the OAD is operating at low

speed.

8. Check that the flow of saline is increasing and that the shaft and crown are

beginning to spin.

9. Immediately press and release the On/Off button to stop the shaft and crown

from spinning and to complete the test.

11.7. Initiating the Atherectomy Procedure

1. Gain vessel access using the physician’s preferred methodology.

2. Access the treatment site with an appropriately sized introducer, guide sheath, or

guide catheter.

Note: For radial access, use a preferred guide catheter or guide sheath of an

appropriate length.

3. Use angiography to locate, visualize, and evaluate the lesion.

4. If desired, use the thumb and index finger to gently impart a slight curve or J-shape to

the distal spring tip of the guide wire.

5. If use of the guide wire torquer is desired, attach the torquer to the guide wire by

holding the distal end of the torquer and rotating the proximal end counterclockwise to

tighten.

6. Approach and cross the lesion, with the guide wire, using the physician’s preferred

methodology.

23

12. OAS Directions for Use

12.1. Performing the Atherectomy Procedure

1. Ensure that the OAD guide wire brake lever is open (in the up position).

2. Lock the crown advancer knob at 1 cm from the fully proximal position.

3. While keeping guide wire placement stationary, advance the OAD drive shaft over the

guide wire and through the hemostasis valve.

4. Under direct visualization, gently advance the OAD crown over the guide wire to a

position approximately 1 cm proximal to the lesion. Verify that the OAD distal tip is

not within the lesion when the crown and drive shaft begin to spin.

(Optional) Use the GlideAssist feature to facilitate advancing the OAD crown over

the VIPERWIRE guide wire.

Warning: Spinning the crown using GlideAssist can be done with the OAD guide

wire brake lever in either the locked or unlocked position. If using GlideAssist with

the guide wire brake in the unlocked position, the guide wire must be held using

either fingers or the guide wire torquer. If using the guide wire torquer, ensure that it

is securely fastened to the guide wire before starting to spin using GlideAssist.

a. Enable GlideAssist mode by pressing and holding the low speed button. Release

the button once the low speed light begins to slowly blink. The slowly blinking

light indicates GlideAssist mode is enabled.

b. Ensure the guide wire is secure by locking the guide wire brake or by holding

the guide wire with either fingers or the guide wire torquer.

c. Press and release the On/Off button on top of the crown advancer knob to

activate crown rotation. The low speed light will rapidly blink indicating the crown

is spinning in GlideAssist mode.

d. Stop the OAD crown rotation by pressing and releasing the On/Off button on top

of the crown advancer knob. The low speed light will slowly blink indicating the

OAD is no longer spinning but continues to be in GlideAssist mode.

e. Disable GlideAssist mode by pressing and immediately releasing any speed

button while the crown is not spinning. The low speed light will stop blinking, yet

remains illuminated indicating the OAD is now in treatment mode.

Note: If the brake configuration is changed from either the locked or unlocked

position while spinning in GlideAssist mode, the crown will automatically stop

spinning yet the OAD will remain in GlideAssist mode.

5. Inject contrast medium through a port in the hemostasis valve to verify that the size of

the crown is compatible with the treatment area diameter (see Appendix C).

6. Verify that the guide wire spring tip is distal to the lesion and is not in danger of

coming in contact with the advancement of the spinning crown and drive shaft tip.

7. Push down on the guide wire brake lever to engage the guide wire brake. The crown

will not spin if the guide wire brake is not locked.

24

8. Unlock and move the crown advancer knob to the fully proximal position to relieve

any compression in the driveshaft.

9. Press and release the On/Off button on top of the crown advancer knob to activate

crown rotation. The OAD is preset to low speed, and the illuminated LED on the OAD

will indicate that the device is operating at low speed.

10. Audibly verify that the OAD drive shaft and crown are orbiting at a stable speed.

11. Slowly advance the crown advancer knob to begin atherectomy of the lesion at a

travel rate between 1 mm per second and 10 mm per second. Using imaging,

continually verify that the crown and the crown advancer knob are moving 1:1 with

one another. Ensure that the OAD handle remains horizontal during the procedure to

minimize saline leakage from the OAD.

12. Using a series of intermittent treatment intervals and rest periods, slide the crown

advancer knob to move the crown back and forth across the lesion always returning

to the proximal side of the lesion when the interval set is complete.

Warning: Once the OAD has reached full speed (as indicated by a stable pitch), do

not allow the orbiting crown to remain in one location as it may lead to vessel

damage. Continue to maintain a travel rate between 1 mm per second and 10 mm

per second.

A rest period of 30 seconds, is recommended for every 30 seconds of treatment, with

a maximum treatment time of 8 minutes per cartridge. The OAS pump will emit a

beep after every 25 second interval of treatment time. Use contrast injections through

the introducer, guide sheath, or guide catheter only during rest periods to

fluoroscopically evaluate results.

Warning: Maximum total treatment time should not exceed 8 minutes per

cartridge. If maximum total treatment time is exceeded, the OAD shaft, crown, and

VIPERWIRE guide wire may begin to exhibit signs of wear and result in a device

malfunction and possible injury to the patient.

13. If reduction of the stenosis is not adequate, perform one of the following:

• Continue to treat the lesion by moving the crown back and forth across the lesion

per the instructions above.

• Increase the rotational speed of the crown by using the crown rotation speed

buttons on the handle of the device.

14. Evaluate the reduction of the stenosis

15. Perform a final angiogram.

12.1.1. Load a Guidewire through the Proximal End of the OAD

Guidewires with crossing profile <0.014” can be loaded through the proximal end of

the OAD.

25

1. Ensure the OAD brake is unlocked and the device is not spinning.

2. If the OAD is in the patient, keep the pump power on.

3. If there is a guidewire in the OAD, remove the guidewire from the proximal end

of the OAD.

4. A 4 French dilator may be inserted into the green strain relief to aid insertion of

the guidewire. Insert the new guidewire through the proximal strain relief.

Warning: The device is designed to track and spin only over the CSI

Peripheral VIPERWIRE ADVANCE Guide Wire or the VIPERWIRE ADVANCE

with FLEXTIP Guide Wire.

CAUTION: Do not attempt to load a guide wire with crossing profile >0.014”

through the proximal end OAD. Guide wire with crossing profile >0.014” will

not fit through the internal components of the OAD.

12.1.2. Exchanging the Cartridge

Note: Each handle can only accept up to three different cartridges. The

Exchangeable Series device has not been tested clinically for extended use in a

single lesion.

To Exchange the cartridge, perform the following:

1. Stop the spinning crown and drive shaft by pressing and releasing the On/Off

button on top of the crown advancer knob.

2. Retract the OAD sheath and drive shaft, from the introducer, guide sheath, or

guide catheter, while monitoring and maintaining guide wire position.

3. Once the OAD drive shaft and sheath are fully retracted, power off the OAS pump

by pressing the green Start button on the OAS pump control panel to stop saline

from flowing through the saline tubing and verify that the green LED, on the OAS

pump control panel, is not illuminated.

4. Disconnect the saline tubing from the cartridge and set aside for use with the next

cartridge.

5. Disconnect the cartridge from the handle:

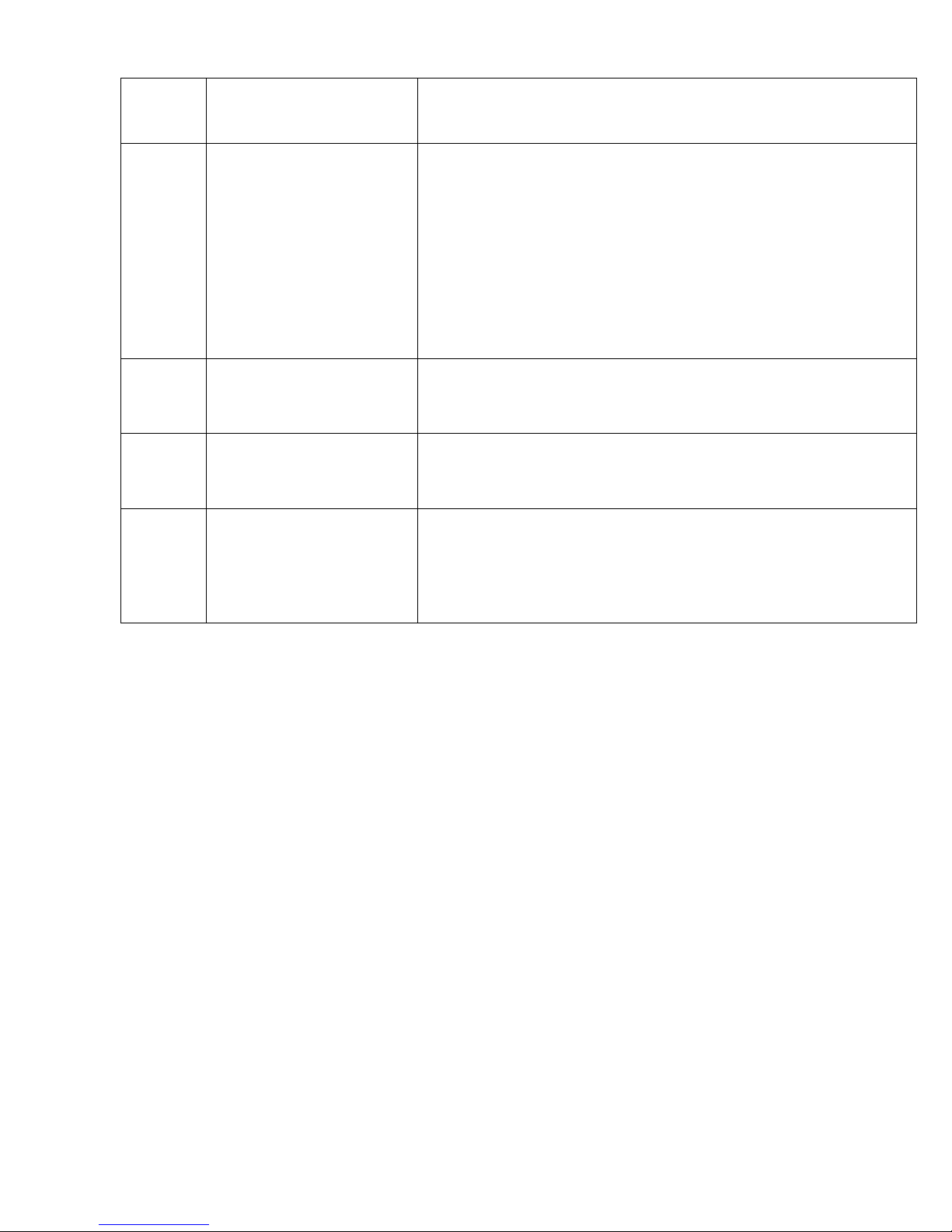

a) Slide the crown advancer knob to the most distal position on the handle. The

yellow button will align with the rotate symbol on the handle, see Figure 11.

26

Figure 11. Cartridge Exchange

b) Rotate the cartridge and then pull it partially out of the handle until it stops.

The yellow button will now align with the eject symbol on the handle, see

Figure 12.

Figure 12. Cartridge Rotation

c) Press and hold the yellow button while pulling on the cartridge until it is fully

removed from the handle, see Figure 13.

27

Figure 13. Cartridge Removal

6. Obtain a new cartridge and follow the steps described in 11.4 to connect the new

cartridge to the handle.

Note: The cartridge is for single-use only and cannot be used with any other

handles once it is used with the original handle.

7. Connect the saline line to the new cartridge

8. Press the green Start button on the OAS pump control panel to start the saline

flowing through the saline tubing and verify that the green LED illuminates.

9. Purge the air from the new cartridge.

10. Test the OAD crown advancement per the instructions in Section 11.6.1.

11. Load the OAD drive shaft over the CSI guide wire.

12.1.3. Replacing the Bag of Saline and Lubricant

The low saline level sensor triggers an audible information signal every 5 seconds,

for a total of 30 seconds, if there is less than 200 mL (+/- 100 mL) remaining in the

bag of saline and lubricant during a treatment period. If the low saline level sensor

triggers during a rest period, only the red low saline LED is illuminated. Perform the

following to replace the bag of saline and lubricant:

1. Ensure that the OAS pump is stopped by pressing the green Start button on the

OAS pump control panel and verify that the green LED, on the OAS pump control

panel, is not illuminated.

2. Prepare a new 1000 mL bag of normal saline solution with lubricant. Refer to the

VIPERSLIDE Lubricant Instructions for Use for lubricant preparation instructions.

3. Remove the low bag of saline and lubricant from the low saline level sensor on

the IV pole.

4. Hang the new bag of saline and lubricant from the low saline level sensor on the

standard IV pole.

28

Caution: Do not use glass bottles for the saline solution with VIPERSLIDE

Lubricant or hang multiple saline bags from the low saline level sensor as this will

disable the Low Saline Level Sensor.

5. Remove the bag spike from the empty bag of saline and Lubricant and spike the

new bag of saline and lubricant.

6. Power on the OAS pump by pressing the green Start button on the OAS pump

control panel.

7. Ensure that no air is present in the saline tubing.

12.1.4. Replacing the OAD

Caution: Do not reuse cartridges from the existing handle to the new replacement

handle. Replace the entire OAD with both a new handle and a new cartridge.

If the OAD (handle plus cartridge) needs replacing, perform the following:

1. Stop the spinning crown and drive shaft by pressing and releasing the On/Off

button on top of the crown advancer knob.

2. Disconnect the OAD power cord from the OAS pump.

3. Leave the introducer, guide sheath, or guide catheter and the guide wire in place,

release the guide wire brake on the OAD, and retract the OAD sheath and drive

shaft, from the introducer, guide sheath, or guide catheter, while monitoring and

maintaining guide wire position.

4. Power off the OAS pump by pressing the green Start button on the OAS pump

control panel to stop saline from flowing through the saline tubing and verify that

the green LED, on the OAS pump control panel, is not illuminated.

5. Disconnect the saline tubing from the OAD currently in use and set aside for use

with the replacement OAD.

6. Obtain a new replacement OAD and carefully remove the new replacement OAD

from the package.

Note: Removal of the OAD from the packaging by tipping the tray and allowing

OAD to fall out can result in damage to the OAD or ancillary devices underneath

the OAD.

7. First, connect the existing saline tubing to the new replacement OAD, then

connect the new replacement OAD power cord to the OAS pump.

8. Press the green Start button on the OAS pump control panel to start the saline

flowing through the saline tubing and verify that the green LED illuminates.

9. Purge the air from the OAD.

29

10. Load the new replacement OAD drive shaft over the existing guide wire.

11. Test the OAD crown advancement per the instructions in Section 11.6.1.

12.2. Completing the Atherectomy Procedure

To complete the atherectomy procedure, perform the following:

1. While the crown is spinning, retract the crown and drive shaft proximal to the lesion.

2. Stop the spinning crown and drive shaft by pressing and releasing the On/Off button

on top of the crown advancer knob.

3. Carefully remove the OAD drive shaft and crown from the introducer, guide sheath,

or guide catheter.

(Optional): Use the GlideAssist feature to facilitate retracting the OAD crown over

the guide wire.

Caution: Do not spin while retracting the crown within a guide catheter or touhy.

Damage to the guide catheter, touhy, and/or OAD may occur.

4. Press the green Start button on the OAS pump control panel to stop saline from

flowing through the saline tubing and verify that the green LED is not illuminated.

Turn off the OAS pump at the Master Power switch on the back of the OAS pump.

5. Disconnect the OAD power cord from the OAS pump.

6. Disconnect the saline tubing from the OAD and remove the saline tubing from the

OAS pump.

7. Remove and dispose of the guide wire and introducer, guide sheath, or guide

catheter according to standard hospital procedures.

8. Treat the puncture site according to standard interventional procedure protocol.

Note: The OAD, guide wire, and lubricant are designed for single-use only and

should not be reused or re-sterilized.

30

12.3. Disposal of the OAD

The OAD is designed for single use and should not be reused or resterilized. Discard the

OAD and saline tubing according to standard hospital protocol.

Certain states may have additional requirements for disposal of certain batteries. Please

verify your state’s requirements for disposal of CR lithium coin cells (CR2032 or

equivalent) prior to disposal.

California, USA Only: Perchlorate Material – special handling may apply. See

www.dtsc.ca.gov/hazardouswaste/perchlorate

12.4. Maintaining the OAS pump

The OAS pump does not require routine maintenance, periodic maintenance, or

calibration. The OAS pump has been designed to function for 875 hours minimum, with

350 hours of minimum OAD use, which equates to 5 years. Contact CSI Customer

Service if there are questions about OAS pump function or performance.

12.4.1. Cleaning the OAS Pump

Clean the OAS pump immediately after each use by following the steps below:

Caution: Ensure that the OAS pump is powered off at the Master Power switch

on the back of the pump and disconnect the OAS pump from wall power before

cleaning the pump.

Caution: Do not immerse the OAS pump into fluids. Do not use solvents or

abrasive cleaners to clean the OAS pump as these may damage the OAS pump

and OAS pump components.

Caution: Completely dry the OAS pump before reconnecting the OAS pump to

wall power and powering on the OAS pump.

1. Prepare an enzymatic detergent, such as Enzol

®

, per manufacturer’s

directions.

2. Thoroughly wipe down the pump, using a clean soft cloth that has been

dampened with the prepared detergent, until all visible soil is removed.

3. Thoroughly rinse the pump using a clean soft cloth that has been dampened

with lukewarm tap water.

4. Dry the pump using a clean, soft cloth and, if available, filtered, pressurized

air at ≤40 psi.

31

12.4.2. Disinfecting the OAS Pump

Disinfect the OAS pump after each use by following the steps below:

1. Verify no debris is present after pump has been cleaned and rinsed with

enzymatic detergent. Repeat the above cleaning procedure if any debris

continues to be visible.

2. Put on a pair of disposable protective gloves. Check the expiration date on

container and remove a fresh moist Super Sani-Cloth®. Wring excess

solution from the wipe, ensuring it is saturated, but not dripping. Discard

wipes as they become dry.

3. Disinfect the front pump face, ensuring that all the indicated surfaces are

completely covered with solution during the wiping process for a total of 2 ½

minutes to ensure an adequate “dwell” time. Dwell time means the number

of minutes that a product must be in contact with the surface, and remain

wet, in order to assure proper efficacy, or effectiveness to kill organisms.

Surfaces must not become dry at any point during disinfection. Refer to

the following steps for surfaces to be wiped:

a. Open the pump head cover (see Figure 14).

b. Thoroughly wipe the edge of the pump head cover all along the closure

seam on both sides (see Figure 15 and Figure 16 below).

Figure 14. Open pump head cover Figure 15. Wipe closure seam. Figure 16. Wipe Closure Seam

4. Thoroughly wipe the seams and crevices of the pump head cover, around

the edges of the lettering, around the button area, and around the power

outlet (see Figure 17). Thoroughly wipe all surfaces of the front face of the

pump (see Figure 18). Continue to keep all surfaces wet for a minimum of

two and a half minutes. Discard the wipes.

32

Figure 17. Thoroughly wipe these areas Figure 18. Wipe all surfaces of front face

12.5. Returning System Components

Contact CSI Customer Service if system components need to be returned. See the back

of this Instruction for Use for CSI contact information.

33

13. Specifications

13.1. OAD Specifications

Parameter

Value

Electrical cable length:

OAD to OAS pump

3.4 m (11 ft.)

Electrical connector type

(OAD power)

Type CF applied Part –DC barrel

(48 V DC)

Fluid connector type

Polycarbonate Luer fitting

Saline line tubing length

(from pump to OAD port)

3.2 m (10.5 ft.) minimum

Visual alerts

Speed and brake indicators

Sterilization

Ethylene oxide (EtO) cycle

Storage conditions

Room temperature in a clean

environment away from magnets

and sources of electromagnetic

interference (EMI).

Operating conditions

Typical operating

room/catheterization laboratory

environment (10-30°C)

Operating life: Cartridge

8 minutes of total therapy time

Operating life: Handle

24 minutes of total therapy time

Water Ingress Protection

IPX1: Protection against water

ingress

Approximate saline flow

rate for 145 cm (4 Fr) OAD

7 mL/min to 16 mL/min

Approximate saline flow

rate for 145 cm (5 and 6

Fr) OAD

10 mL/min to 30 mL/min

Approximate saline flow

rate for 75 cm (4 Fr) OAD

10 mL/min to 23 mL/min

Approximate saline flow

rate for 200 cm (5 Fr) OAD

10 mL/min to 34 mL/min

Approximate saline flow

rate for 180 cm (5 Fr) OAD

16 mL/min to 35 mL/min

34

OAS Pump Specifications

Parameter

Value

Depth

<30.6 cm (12.0 in)

Height

20.3 cm (8.0 in)

Width

25.4 cm (10.0 in)

Weight

<5.0 kg (11 lbs)

Electrical cable length:

OAS pump to electrical

outlet

6.1 m (20 ft.)

Master Fuse

250 V 4A SLOW BLOW (Type T)

External housing

ABS Plastic

Electrical connector type

(Main Power)

Mains Power Plug (100–240 V AC @

50–60 Hz)

Audible information

signals

Audible information signal for

approximately every 25 sec of OAD

spin time.* Audible information signal

every 5 sec for a total of 30 sec when

the saline level falls below 200 mL

during a treatment period.

Visual alerts

Start button

Low Saline Information Signal when

≤200 mL (± 100 mL) remaining out of

a 1000-mL bag of saline

Storage conditions

Room temperature in a clean

environment.

Operating conditions

Typical operating

room/catheterization laboratory

environment (10-30°C)

Operating life

875 hours minimum, with 350 hours

of therapy minimum or 5 years

Water Ingress Protection

IPX1: Protection against water

ingress

* Timer resets when crown spinning stops.

35

13.2. VIPERWIRE ADVANCE Guide Wire Specifications

VPR-GW 14

VPR-GW-17

VPR-GW-FT14

VPR-FLEX14

VPR-GW-FT18

VPR-FLEX18

VPR-GW-EL-14

VPR-ELFLEX14

VPR-GW-EL18

VPR-ELFLEX18

Guide Wire

Length

335 cm

335 cm

335 cm

335 cm

475 cm

475 cm

Guide Wire

Coating

Silicone

Silicone

Silicone

Silicone

Silicone

Silicone

Core wire

diameter

.014”

.014”

.014”

.014”

.014”

.014”

Core wire

material

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Spring Tip

Length

3 cm

3 cm

3 cm

3 cm

3 cm

3 cm

Spring Tip

Diameter

.014”

.017”

.014”

.018”

.014”

.018”

Spring Tip

Material

Platinum/

Tungsten

Platinum/

Tungsten

Platinum/

Tungsten

Platinum/

Tungsten

Platinum/ Tungsten

Platinum/ Tungsten

Spring Tip

Shape

Straight

Straight

Straight

Straight

Straight

Straight

14. OAS Pump Declaration of Conformity

CSI declares that the peripheral system is in conformity with the requirements of: IEC 60601-

1. The OAS pump is compatible for use in a standard catheter laboratory environment.

15. EMC Declaration

Medical electrical equipment needs special precautions regarding electromagnetic

compatibility (EMC). Install and use medical electrical equipment according to the EMC

information below:

• Do not have portable and/or mobile radio-frequency (RF) communications equipment

within close proximity of medical electrical equipment as portable and mobile RF

communications equipment can affect medical electrical equipment.

• Ensure that power frequency magnetic fields are at levels characteristic of a typical

commercial or hospital environment.

• Under an EMC phenomena the OAS may stop operation, and may require user

intervention to recycle the power to resume operation.

The Orbital Atherectomy System has been tested to IEC 60601-1-2. The Orbital Atherectomy

System has been tested to Immunity and Emission Test Levels of a Professional Healthcare

36

Facility Environment. The OAS is Group 1 (Therapy ME Equipment and Systems) and

therefore must meet CISPR 11 Class A. The Orbital Atherectomy System performance may be

impaired by close proximity interference from RFID equipment and other common emitters like:

diathermy, lithotripsy, and electrocautery.

Note: The Emissions characteristics of this equipment make it suitable for use in industrial

areas and hospitals (CISPR 11 class A). If it is used in a residential environment (for which

CISPR 11 class B is normally required) this equipment might not offer adequate protection to

radio-frequency communication services. The user might need to take mitigation measures,

such as relocating or re-orienting the equipment.

Essential Performance of the Exchangeable Product:

• System starts, runs, stops at the operator’s discretion and recovers in a controlled

manner from external upsets.

Emissions

Emissions

Standard

Test

Compliance

Level

Electromagnetic environment Guidance

IEC 60601-1-2

RF Emissions

CISPR 11

Group 1

The orbital atherectomy device

uses RF energy only for its

internal function. Therefore, its

RF emissions are very low and

are not likely to cause any

interference in nearby electronic

equipment.

IEC 60601-1-2

RF Emissions

CISPR 11

Class A

The orbital atherectomy device is

suitable for use in all locations

other than those located in

residential environments and

those directly connected to a

low-voltage power supply

network that supplies buildings

used for domestic purposes.

IEC 60601-1-2

Harmonics, IEC

61000-3-2

Class A

IEC 60601-1-2

Flicker, IEC

61000-3-3

Complies

37

Immunity

Immunity

Standard

Test

Test Level

Compliance Level

IEC 60601-1-2

Electrostatic

Discharge (ESD),

IEC 61000-4-2

±8 kV contact

±2, ±4, ±8, ±15 kV

air

±8 kV contact

±2, ±4, ±8, ±15 kV air

IEC 60601-1-2

Radiated RF, IEC

61000-4-3

3 V/m

80 MHz to 2.7 GHz

3 V/m

80 MHz to 2.7 GHz

IEC 60601-1-2

Radiated RF,

Proximity Fields,

IEC 61000-4-3

Tested to levels

specified in Table 9

of IEC 60601-12:2014

Complies to levels of Table

9

IEC 60601-1-2

Electrical Fast

Transient / Burst,

IEC 61000-4-4

± 2 kV for

power supply

lines

± 1 kV for

input/output

lines

± 2 kV for

power supply

lines

± 1 kV for

input/output

lines

IEC 60601-1-2

Surge, IEC 610004-5

± 2 kV line

to ground

± 1 kV line

to line

± 2 kV line

to ground

± 1 kV line

to line

IEC 60601-1-2

Conducted

Disturbances RF,

IEC 61000-4-6

3 Vrms 150 kHz to

80 MHz

6 Vrms ISM bands

3 Vrms 150 kHz to 80 MHz

6 Vrms ISM bands

IEC 60601-1-2

Power Frequency

50/60 Hz Magnetic

Field, IEC 61000-48

30 A/m, 50 / 60 Hz

30 A/m, 50 and 60 Hz

IEC 60601-1-2

Voltage Dips and

Interruptions, IEC

61000-4-11

100 % dip for 0.5

cycle; 0°, 45°, 90°,

135°, 180°, 225°,

270°, 315°

100% dip for 1

cycle

30% dip for 25

cycles

100% dip for 5

seconds

100% dip for 0.5

cycle; 0°, 45°, 90°, 135°,

180°, 225°, 270°, 315°

100% dip for 1 cycle

30% dip for 25

cycles

100% dip for 5

seconds

AIM 7351731

ISO 14223

65 A/m, 134.2 kHz

65 A/m

AIM 7351731

ISO/IEC 14443-3

(Type A)

7.5 A/m, 13.56

MHz

7.5 A/m

AIM 7351731

ISO/IEC 14443-4

(Type B)

7.5 A/m, 13.56

MHz

7.5 A/m

38

AIM 7351731

ISO/IEC 15693 (ISO

18000-3 Mode 1)

5 A/m, 13.56 MHz

5 A/m

AIM 7351731

ISO 18000-3 Mode

3

12 A/m, 13.56 MHz

12 A/m

AIM 7351731

ISO/IEC 18000-7

3 V/m, 433 MHz

3 V/m

AIM 7351731

ISO/IEC 18000-63

Type C

54 V/m, 860 – 960

MHz

54 V/m

AIM 7351731

ISO/IEC 18000-4

Mode 1

54 V/m, 2.45 GHz

54 V/m

Radio

RFID Transceiver Specifications

FCC ID

2AMME-EX1000

Frequency

13.56 MHz

Receiver bandwidth

14 kHz

Effective Radiated Power

55 mW maximum

Standard

ISO/IEC 15693

Modulation

ASK

16. FCC

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Cardiovascular Systems, Inc. has not approved any changes or modifications to this device by

the user. Any changes or modifications to the device could void the user's authority to operate

the equipment.

17. Disclaimer of Warranty

Although Cardiovascular Systems, Inc. (CSI) uses reasonable care in the manufacture of its

devices, they are used in difficult environment within the human body with many biological

differences between individual patients. CSI has no control over the conditions under which

this device is used, condition of the patient, methods of administration or handling after the

device leaves CSI’s possession. THEREFORE, CSI DISCLAIMS ALL WARRANTIES

WHETHER EXPRESSED OR IMPLIED, WRITTEN OR ORAL, INCLUDING BUT NOT

LIMITED TO ANY WARRANTIES OF MERCHANTABILITY OF FITNESS FOR A

PARTICULAR PURPOSE. CSI DOES NOT WARRANT EITHER FOR A GOOD EFFECT OR

AGAINST ALL ILL EFFECT FOLLOWING ITS USE. CSI (INCLUDING ITS AFFILIATED

ENTITIES, OWNERS, DIRECTORS, OFFICERS, EMPLOYEES, AGENTS AND VENDORS)

39

SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

LOSS, DAMAGE, OR EXPENSE ARISING FROM OR RELATED TO THE USE OF THIS

DEVICE.

No person has authority to bind CSI to any representation, warranty, or liability except as set

forth in this Disclaimer of Warranty.

CSI may, at its sole discretion, replace any device that is determined to have been out of

specification at the time of shipment.

The exclusions, disclaimers, and limitations set forth in this Disclaimer of Warranty are not

intended to, and shall not be construed as to, contravene mandatory provisions of any

applicable law or regulation. If any part of this Disclaimer of Warranty is held to be illegal or

unenforceable by a court of competent jurisdiction, the part shall be modified so as to be

enforceable to the maximum extent possible. If the part cannot be modified, then that part may

be severed and the other parts of this Disclaimer of Warranty shall remain in full force and

effect.

40

Appendix A. System Troubleshooting

If issues with the OAS pump or OAD cannot be resolved in each of the situations below,

replace the recommended part and continue with the procedure. Contact CSI Customer

Service for returning OAS components. See the back of these instructions for use for CSI

contact information.

Issue

number

Issue

Solution

1

The OAS pump will

not power on and no

LEDs are

illuminated on the

OAS pump control

panel

1. Ensure that the power cord is properly inserted into

the power module on the back of the OAS pump and

that the power cord is connected to a functioning wall

power outlet.

2. Ensure that the Master Power switch, on the back of

the OAS pump, is in the on position.

3. Contact CSI Customer Service at the phone number

on the back of this instructions for use to return to

CSI.

2

The OAS pump will

not pump saline

1. Ensure that the OAS pump is properly powered on –

see Issue number 7.

2. Ensure that the saline bag and saline tubing (i.e. bag

spike) are properly connected with no kinks and a

sufficient amount of saline is in the saline bag such

that the low saline level sensor is not active and the

red LED on the OAS pump control panel is not

illuminated.

3. Ensure that the saline tubing is routed correctly

through the OAS pump saline tubing guides and that

the OAS pump saline tubing door is closed.

4. Ensure that the yellow LED is off and the green LED

is illuminated. If the green LED is not illuminated,

press the green Start button and verify that the yellow

LED is off and that the green LED illuminates.

5. If the green LED is flashing while the yellow LED is

illuminated, press the green Start button twice and

verify that the yellow LED is off and that the green

LED illuminates.

6. If the OAS pump does not restart after completing the

above mentioned steps, press the Master Power

switch to power off the OAS pump. Wait a few

seconds and press the Master Power switch to power

41

Issue

number

Issue

Solution

on the OAS pump. Verify that the OAS pump powers

on.

3

The OAS pump was

running, but has

stopped pumping

and the yellow LED

is illuminated

1. Verify the OAD power cord is connected to the OAS

pump.

2. Press the Master Power switch, on the back of the

OAS pump, to power off the OAS pump. Wait five (5)

seconds and press the Master Power switch to

power on the pump.

4

All three LEDs on

the front panel of

the OAS pump

remain illuminated

1. Press the Master Power switch, on the back of the

OAS pump, to power off the OAS pump. Wait a few

seconds and press the Master Power switch to

power on the pump.

2. Contact CSI Customer Service at the phone number

on the back of this instructions for use.

5

After OAS pump

power up, all three

LEDs on the front

panel of the OAS

pump blink three

times and there is

an audible

notification signal

three times.

1. Contact CSI Customer Service at the phone number

on the back of this instructions for use.

6

The low saline level

sensor (red LED) is

illuminated

Note: The OAS pump will stop pumping saline and

supplying power to the OAD 30 seconds after the low

saline level sensor activates while the OAD is

spinning, as indicated by an audible information

signal every 5 seconds.

1. If there is less than 200 mL of saline left in the bag of

saline and lubricant, replace the bag with a new 1000

mL bag of normal saline and lubricant solution.

2. Ensure that the bag of saline and lubricant is hanging

freely from the saline bag open hook and that the low

saline level sensor cord is properly inserted into the

connector on the sensor and the connector on the

back of the OAS pump.

3. Verify that the red low saline LED on the OAS pump

control panel turns off and either the yellow LED or

the green LED illuminates. If the yellow LED

42

Issue

number

Issue

Solution

illuminates, press the Start button on the OAS pump

and verify that the green LED illuminates.

7

OAD speed LED

indicators are

blinking sequentially

(Low, Medium,

High)

1. Verify the cartridge is installed correctly.

2. If the cartridge is installed correctly, replace the

cartridge. If the LEDs continue to blink with the new

cartridge, replace the handle.

8

All OAD Speed

indicator LEDs blink

simultaneously

1. Discontinue treatment.

2. Press the green start button on the OAS pump to turn

off OAD power. Press the green start button on the

OAS pump to supply power to the OAD.

3. If the OAD LEDs continue to blink simultaneously,

replace the OAD.

9

All speed indicator

LEDs on the OAD

handle remain

illuminated

1. Immediately discontinue treatment and replace the

OAD.

10

Blood is backing up

into the OAD

1. Immediately discontinue treatment, but leave the

OAS pump running.

2. Verify that the saline tubing is properly connected to

the saline bag, that the saline tubing is routed

correctly through the OAS pump saline tubing guides,

and that the saline tubing is properly connected to

the OAD.

3. If the saline tubing is properly connected and blood

continues to back into the OAD sheath, replace the

cartridge.

11

The crown does not

spin.

1. Check that the brake is locked and brake LED is

illuminated. Note: the brake does not need to be

locked to use GlideAssist.

2. Verify that the OAS pump and OAD are receiving

power with green LEDs illuminated.

3. Press the OAD on/off button to start device.

4. If the device has power, but does not spin, replace

cartridge.

43

Issue

number

Issue

Solution

12

Crown rotational

speeds are variable

and will not stabilize

1. Immediately discontinue treatment, but leave the

OAS pump running.

2. Verify that saline is flowing. Verify VIPERSLIDE

Lubricant is present in the saline bag. See the

VIPERSLIDE Lubricant Instructions for Use for

information.

3. Verify that the saline tubing is properly connected to

the saline bag, that the saline tubing is routed

correctly through the OAS pump saline tubing guides,

and that the saline tubing is properly connected to

the OAD.

4. Verify that the crown advancer knob moves

smoothly.

5. Retract the crown proximal to the lesion. Using a

travel rate between 1 mm per second and 10 mm per

second, continue treatment on low speed.

6. If rotational speeds will not stabilize, replace the OAD

or guide wire.

13

The crown is not

moving one-to-one

with the crown

advancer knob

During start up in the vessel:

1. Verify the Tuohy valve is not over-tightened.

2. Verify the crown advancer knob moves smoothly.

3. Retract the crown advancer knob until the crown

moves with the knob.

While spinning:

1. Immediately discontinue treatment, but leave the

OAS pump running.

2. Verify the Tuohy valve is not over-tightened.

3. Verify that the crown advancer knob moves

smoothly.

4. Retract the crown advancer knob until the crown

moves with the knob.

5. Verify that contrast media injections were not above

400 psi or occurred during crown spinning.

6. Engage and disengage the lesion using a travel rate

between 1 mm per second and 10 mm per second

while maintaining one-to-one crown to advancer knob

movement.

14

The crown stops

spinning during the

procedure

1. Immediately discontinue treatment, but leave the

OAS pump running.

2. Check to ensure that the OAS pump power cord is

connected to the back of the OAS pump and that the

OAD power cord is connected to the OAS pump.

44

Issue

number

Issue

Solution

3. Check that the OAS pump green LED OAS pump on

light is on and that the OAD green LED light is on. If

the OAS pump green LED is flashing, press the

pump start button twice.

4. Verify that saline is flowing.

5. Check that the OAD guide wire brake lever is in the

down/locked position with brake LED illuminated.

6. Retract the crown proximal to the lesion.

7. Use fluoroscopy to analyze the situation prior to