CONTENTS

page section

Installation, Operation &

Maintenance Instructions

1700-1800°C Tube Furnaces

types VST 17/--

This manual is for the guidance of operators of the above Carbolite products

and should be read before the furnace is connected to the electricity supply.

Manuals for the furnace controller and overtemperature controller are

Please read the controller manuals before operating the furnace.

supplied separately.

LMF32C-1.07

Heat Light: the adjacent light glows or flashes to indicate that power is

being supplied to the elements.

DANGER of electrical shock– read any warning printed by this symbol.

DANGER – hot surface. Read any warning printed by this symbol.

WARNING: all surfaces of a furnace may be hot.

Instrument switch: when the instrument switch is operated the

temperature control circuit is energised.

1700° Tube

1.0 SYMBOLS & WARNINGS

1.1 Switches and Lights

1.2 Warning Symbols

2 LMF32C – 1.07

Separately packed

items

VST 17/--/250

Elements

6

Element clamps

12

Element clips

12

Braids

1 set

Element insulators

6

1700° Tube

2.0 INSTALLATION

2.1 Unpacking & Handling

When unpacking or moving the furnace always lift it by its base. Never lift it by its work tube or

the surrounding insulation, or by any protruding parts. These furnaces or the attached control

boxes contain transformers and are heavy: use two or more people to carry them.

NOTE: This product contains Refractory Ceramic Fibre (better described as Alumino Silicate

Wool) for precautions and advice in handling this material see the ‘Repairs and Replacements’

section.

2.2 Siting & Setting Up

Place the furnace in a well ventilated room, away from other sources of heat, and on a surface

which is resistant to accidental spillage of hot materials. Do not mount the furnace on an

inflammable surface.

Ensure that there is free space around the furnace. Do not obstruct any of the vents in the case:

there are cooling fans in the case which must not be obstructed.

Ensure that the furnace is placed in such a way that it can be quickly switched off or disconnected

from the electrical supply - see below.

2.3 Removal of Packing Material

VST: Open the furnace and check and remove any packing,

2.4 Fitting the Heating Elements

Wear eye protection when handling the heating elements. See the warning in section 4.7.

Wear face mask: see section 4.2.

The Molybdenum Disilicide elements are EXCEPTIONALLY FRAGILE and are packed separately,

together with other items:

Fit the heating elements vertically into the chamber, handling with great care. Installation

instructions are given later in this manual in section 4.7.

Connect the aluminium braids securely as indicated in the element installation instructions.

2.5 Fitting the Thermocouples

The thermocouples are enclosed in ceramic sheaths which fit downwards through the insulation in

holes approximately 10mm. Each hole has a nearby terminal block.

Fit the sheaths into the holes. Fix the sheaths in place using a self-tapping screw through the wire

in the nearby hole.

Insert the thermocouples and connect them to the terminal blocks. The leg of the thermocouple

with a blue paint mark is the negative. The negative side of the connecting cable is marked with a

double number (e.g. 11).

2.6 Electrical Connections

Connection by a qualified electrician is recommended.

LMF32C – 1.07 3

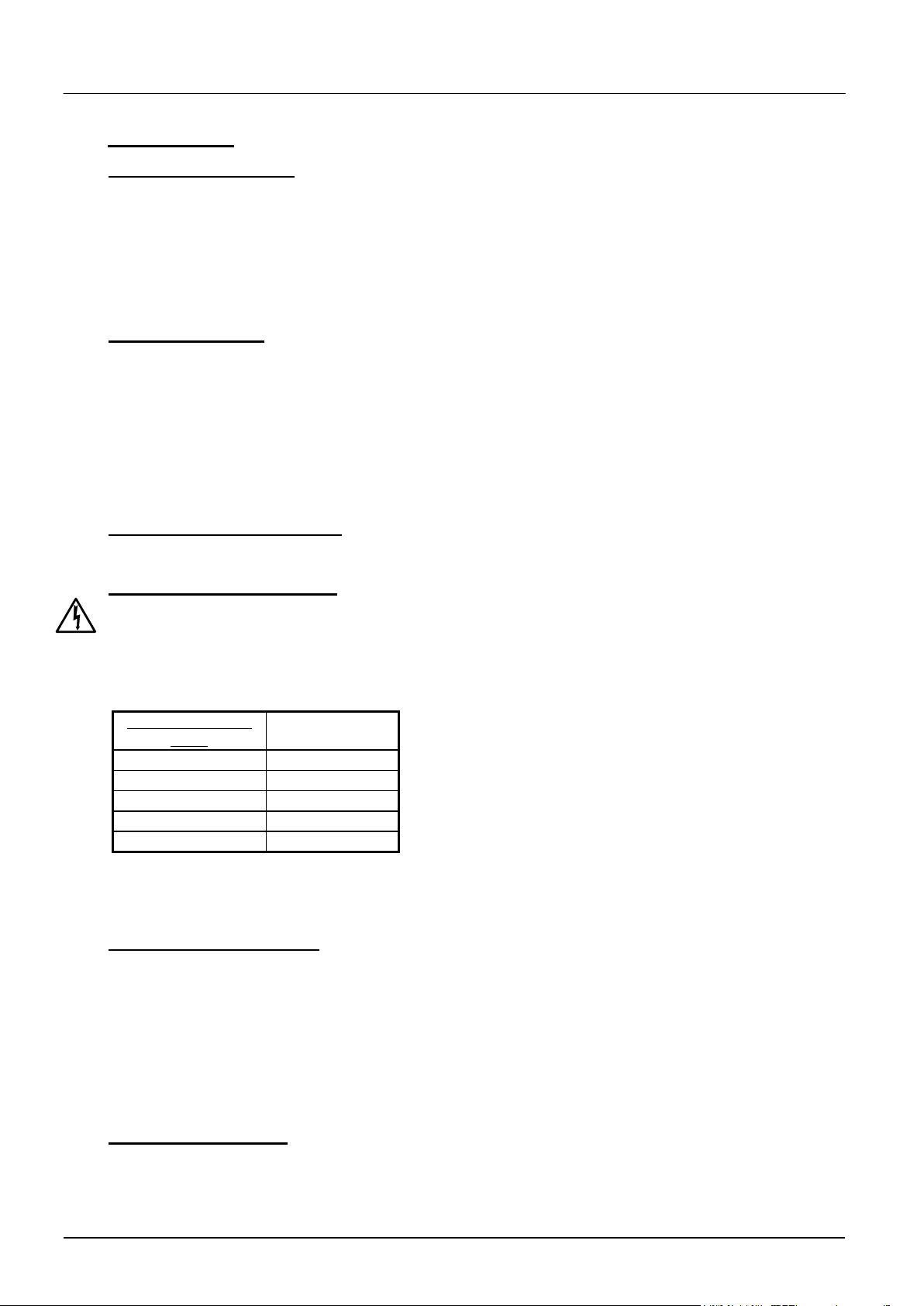

CONNECTION DETAILS

supply type

Supply

Terminal label

Cable colour

Live-Neutral

Reversible or Live-Live

1-phase

L

Brown

To live

to either power conductor

N

Blue

To neutral

to the other power conductor

PE

Green/Yellow

To earth (ground)

to earth (ground)

1700° Tube

These models are designed for single phase electrical supplies with or without neutral. The furnace

must be connected only to the type and voltage of supply for which it was ordered.

The voltage or range of voltages on which the furnace may be operated is given on the furnace

rating label. Check that the supply voltage is compatible with the voltage on the label, and that the

current capacity is sufficient for the amperage on the label, before connection to the supply. A

table of the most common ratings is given in section 7.1 of this manual.

The supply point must be within reach of the furnace operator and must incorporate either an

isolating switch which operates on all live conductors, or a quickly removable plug.

The supply MUST incorporate an earth (ground).

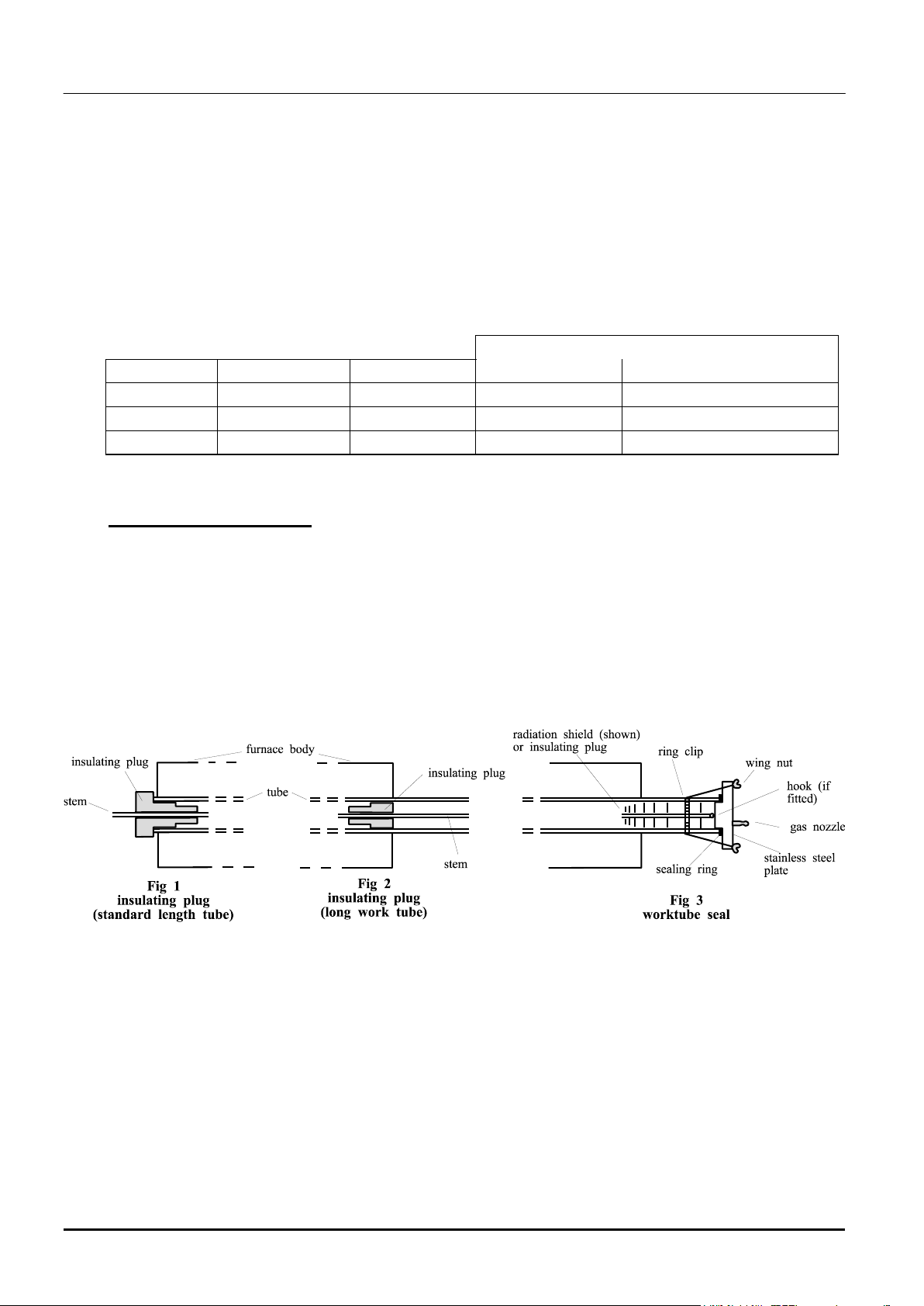

2.7 Tube Fittings (if ordered)

For optimum temperature uniformity, insulating plugs should be placed in the tube ends as shown

in fig.1. With a long work tube, the stem of the plug assembly should line up with the end of the

tube as in fig.2. Alignment of radiation shields is similar to that of plugs.

If stainless steel seals with gas inlets are supplied they are to be fitted as shown in fig.3; the stem

of any insulating plug or radiation shield should touch the seal.

If heavy fittings are to be clamped to the end of an extended work tube they can increase the

bending stress at the centre of the tube. Support such fittings in such a way that expansion of the

tube is allowed.

4 LMF32C – 1.07

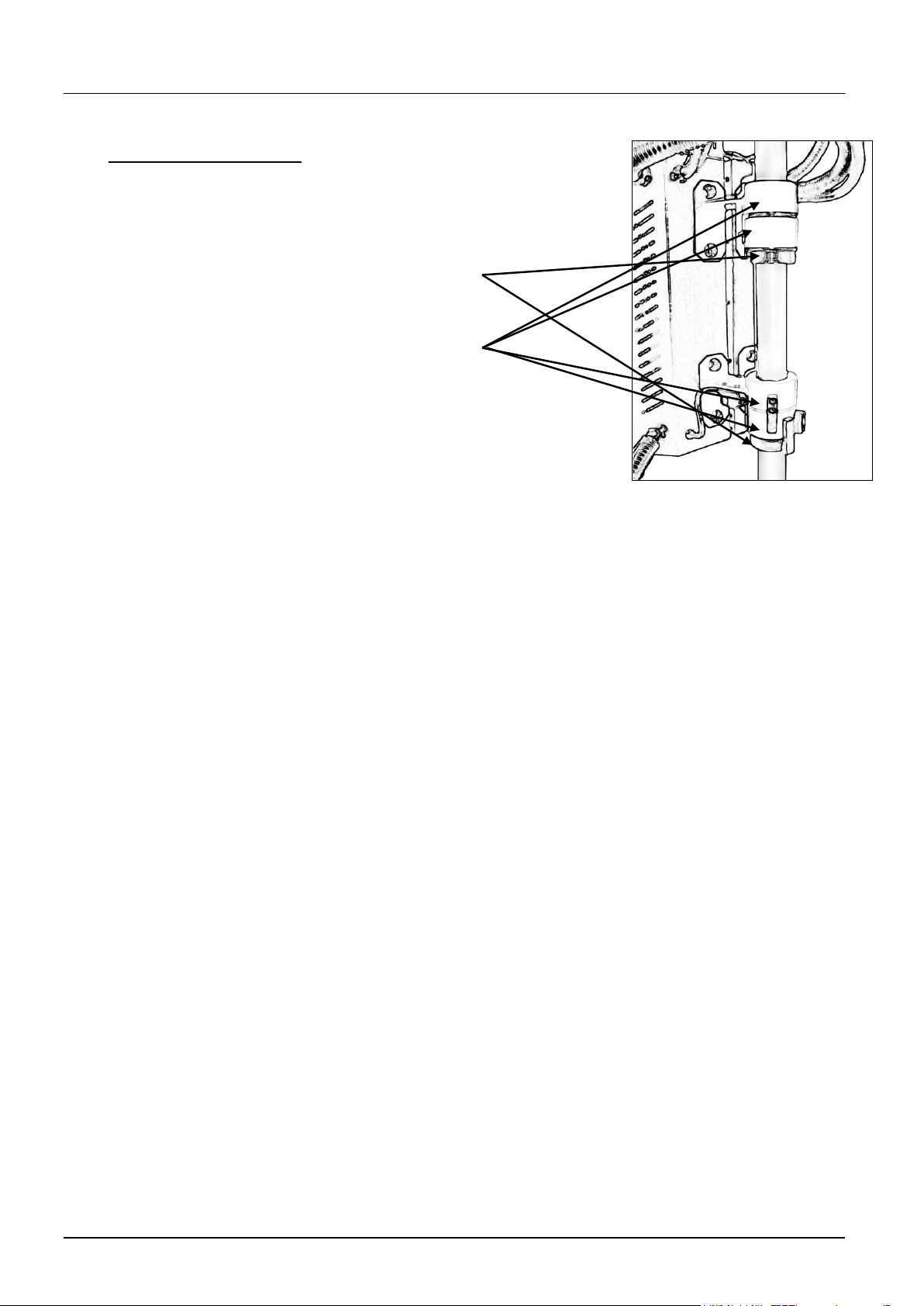

support collars

thrust bushes

1700° Tube

2.8 VST Height Adjustment

If the VST model is disassembled or adjusted it is important to note

that the two collar stops should both be fitted, and that the thrust

bushes (bearings) should be in place.

LMF32C – 1.07 5

Loading...

Loading...