CONTENTS

Section page

Installation, Operation &

Maintenance Instructions

Annealing Ovens

TLD models

This manual is for the guidance of operators of the above Carbolite products

and should be read before the oven is connected to the electricity supply.

Manuals are supplied separately for the temperature controller

(and overtemperature controller when fitted).

Please read the controller manuals before operating the oven.

MF18 – 3.06

Instrument switch: when the instrument switch is operated the temperature

control circuit is energised.

DANGER of electrical shock– read any warning printed by this symbol.

DANGER – hot surface. Read any warning printed by this symbol.

WARNING: all surfaces of an oven may be hot.

DANGER – read any warning printed by this symbol.

TLD

1.0 SYMBOLS & WARNINGS

1.1 Switches and Lights

1.2 Warning Symbols

1.3 Introduction

Reproducible annealing of thermoluminescent dosimeters is essential to maintain constant

sensitivity and low background readings.

Use of the Carbolite TLD Annealing Oven ensures that the best results are consistently obtained.

The fan assisted air recirculating system eliminates the temperature gradients encountered in

simple gravity convection ovens. The risk of errors arising due to non-reproducible annealing is

greatly reduced by the automatic program controller.

The Carbolite annealing oven is supplied as a complete self contained unit. The front opening side

hinged door gives access to the work chamber which is fitted with two shelves. The air

recirculating fan draws air from the back of the chamber and passes it over the heating elements.

The reheated air is then returned to the chamber on all four sides. The temperature programmer is

conveniently located in the base of the equipment below the oven chamber.

2 MF18 – 3.06

TLD

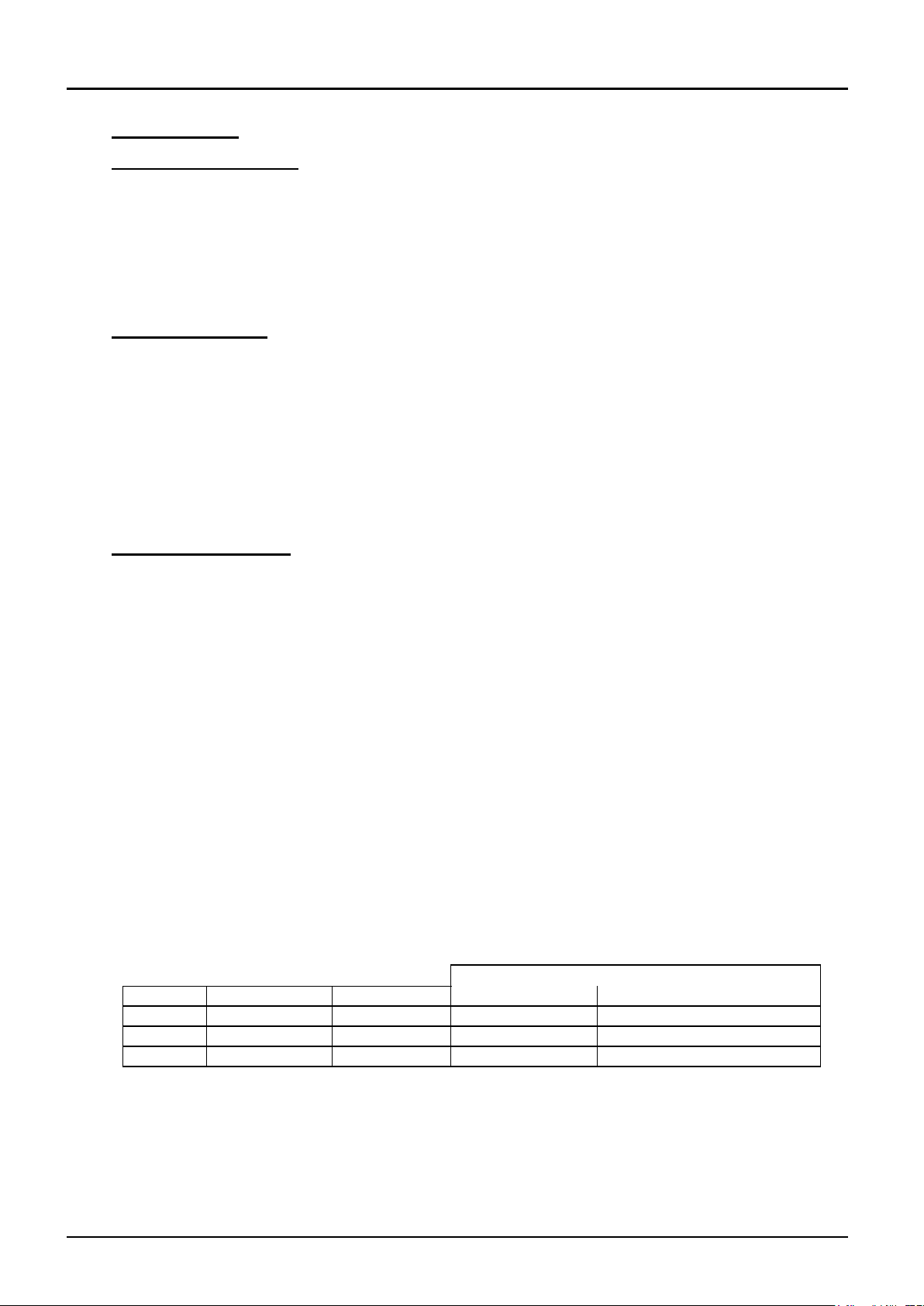

CONNECTION DETAILS

supply type

Supply

Terminal label

Cable colour

Live-Neutral

Reversible or Live-Live

1-phase

L

Brown

To live

to either power conductor

N

Blue

To neutral

to the other power conductor

PE

Green/Yellow

To earth (ground)

to earth (ground)

2.0 INSTALLATION

2.1 Unpacking & Handling

Lift the unit by its base. Do not use the door or any other projecting cover or component to support

the equipment when moving it. Use two people to carry the oven where possible. Remove any

packing material from the inner chamber before use.

NOTE: This product contains Refractory Ceramic Fibre (better described as Alumino Silicate

Wool) for precautions and advice in handling this material see the ‘Repairs and Replacements’

section.

2.2 Siting & Setting Up

Place the oven on a level surface.

Ensure that there is free space around the oven. Ensure that any vents in the oven are not obscured.

During the operation of the oven hot air is exhausted from the vent on the top of the oven while

the cooling blower is in operation; there must be clearance of at least 500mm between the top of

the oven and any surface which must be made of non-combustible material.

Ensure that the oven is placed in such a way that it can be quickly switched off or disconnected

from the electrical supply - see below the top of the oven and the ceiling of the room. Always

ensure that the vent on the top of the oven is free to open.

2.3 Electrical Connections

Connection by a qualified electrician is recommended.

The oven is manufactured for use on a single phase supply, which may be Live to Neutral non-

reversible, Live to Neutral reversible or Live to Live.

Check the Oven rating label before connection. The supply voltage should agree with the voltage

on the label, and the supply capacity should be sufficient for the amperage on the label.

The supply should be fused at the next size equal to or higher than the amperage on the label. A

table of the most common fuse ratings is also given in section 8.1 of this manual. Where a supply

cable is present there are internal supply fuses; customer fusing is preferred but not essential.

Oven with supply cable: either wire directly to an isolator or fit with a line plug.

Oven without supply cable: a permanent connection to a fused and isolated supply should be made

to the internal terminals after temporary removal of the oven back panel.

Connection by line plug: the plug should be within reach of the operator, and should be quickly

removable.

Connection to isolating switch: this should operate on both conductors and should be within reach

of the operator.

The supply MUST incorporate an earth (ground).

MF18 – 3.06 3

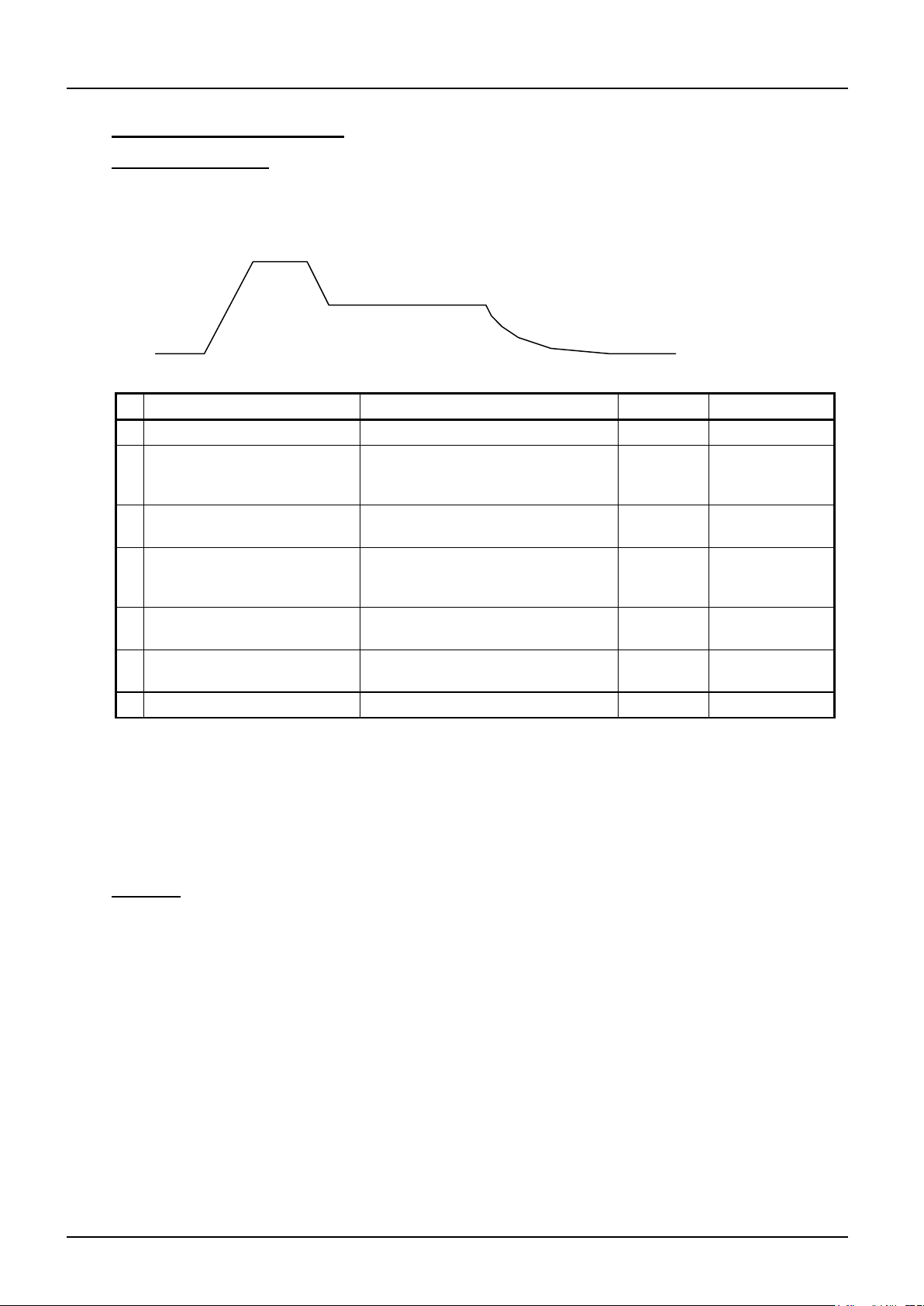

function

initial setting

program

1

Start.

2

Heat at a controlled rate.

heat up at 480°C/hour to 300°C

SEG.n 1

tGt

rAtE

rmP.r

300°C

8°C per min

3

Dwell for a preset period.

dwell at 300°C for 1 hour

SEG.n 2

dweLL

1 hour

4

Cool at a controlled rate.

Cool to 80°C assisted by inlet

blower

SEG.n 3

tGt

rAtE

rmP.r

80°C

20°C per min

5

Dwell for a preset period.

80°C for 12 hours

SEG.n 4

dweLL

12 hours

6

Cool naturally to room

temperature.

SEG.n 5

SteP

0°C

7

Finish.

SEG.n 6

End

1

2 3 4

5

6

7

TLD

3.0 OPERATING INSTRUCTIONS

3.1 Operating Program

The program consists of the stages shown in the graph below. The rates of temperature rise, dwell

temperature and dwell times are all adjustable by the user. The general format of the program is

installed at the manufacturing stage, with initial values as shown in the table below.

This program causes the oven to heat up at 480°C per hour to a temperature of 300°C. The

temperature remains at 300°C for 1 hour. At the end of the 1 hour the setpoint changes to 80°C

and the oven cools down as quickly as possible to this temperature. The rate of cooling is quite fast

because of the air inlet blower which is incorporated in the oven. When the chamber temperature

reaches 80°C the second dwell period starts and the oven remains at 80°C for 12 hours. At the end

of 12 hours the heaters are switched off and the oven cools naturally to room temperature.

3.2 Controls

The instructions for operating the temperature controller are given in a separate manual.

The oven is fitted with an instrument switch. The switch cuts off power to the controller(s).

The circulation fan operates when the instrument switch is switched on.

Connect the oven to the electrical supply.

Operate the instrument switch to activate the temperature controller. The controller becomes

illuminated and goes through a short test cycle.

Adjust the temperature – see the controller manual.

Overtemperature Option: If the overtemperature controller has not yet been set as required, set it

and activate it according to the instructions in the appropriate manual.

The oven starts to heat up according to the set program.

4 MF18 – 3.06

Loading...

Loading...