Carbolite RHF 14/3, RHF 15/3, RHF 16/3, RHF 14/8, RHF 15/8 Instruction Manual

...

C

Installation, Operation &

Maintenance Instructions

1400°C - 1600°C Chamber Furnaces

RHF models: 3 litre - 35 litre

This manual is for the guidance of operators of the above Carbolite products and

should be read before the furnace is connected to the electricity supply.

ONTENTS

Section page

1.0 Symbols & Warnings 2

2.0 Installation 2

3.0 Operation 4

4.0 Maintenance 6

5.0 Repairs & Replacements 8

6.0 Fault Analysis 11

7.0 Circuit Diagrams 12

8.0 Fuses & Power Settings 14

9.0 Specifications 16

Manuals are supplied separately for the furnace controller

(and overtemperature controller when fitted).

Please read the controller manuals before operating the furnace.

MF07 – 3.05

Supply Light: when the furnace is connected to the electrical supply the

Heat Light: the adjacent light glows or fl

ashes to indicate that power is

DANGER of electrical shock

–

read any warning printed by this symbol.

DANGER

–

hot surface. Read any warning printed by this symbol.

DANGER

–

read any war

ning printed by this symbol.

RHF

1.0 SYMBOLS & WARNINGS

1.1 Switches and Lights

light in the adjacent switch glows

1.2 Warning Symbols

being supplied to the elements

WARNING: all surfaces of a furnace may be hot.

2.0 INSTALLATION

2.1 Unpacking & Handling

When unpacking or moving the furnace always lift it by its base. Never lift it by the door. Use two

or more people to carry the furnace where possible. Remove any packing material from the door

gear and furnace chamber before use.

2.2 Siting & Setting Up

Place the furnace in a well ventilated room, away from other sources of heat, and on a surface

which is resistant to accidental spillage of hot materials. Do not mount the furnace on an

inflammable surface.

Ensure that there is free space around the furnace. Do not obstruct any of the vents in the control

section: they are needed to keep the controls cool.

Ensure that the furnace is placed in such a way that it can be quickly switched off or disconnected

from the electrical supply - see below.

If the chimney is supplied unfitted, then fit it into the hole in the top of the furnace case. If the

furnace is to be used to heat substances which emit fumes, then a fume extraction duct of about

150mm inlet diameter may be placed directly above the chimney outlet. Do not make a sealed

connection to the furnace chimney as this causes excessive airflow through the chamber and

results in poor temperature uniformity.

2 MF07

RHF

2.3 Heating Elements

The Silicon Carbide elements are VERY FRAGILE and are packed separately. Fit them according to

the instructions in section 5.7.

2.4 Electrical Connections

Connection by a qualified electrician is recommended.

Models RHF 14/3, 15/3, 16/3 and 14/8 may be ordered for single phase use or for two phases out

of a three phase supply with neutral. All other models may be ordered for single phase use or for

three phase with or without neutral. The furnace must be connected only to the type and voltage of

the supply for which it was ordered.

Check the furnace rating label before connection. The supply voltage should agree with the voltage

on the label, and the supply capacity should be sufficient for the amperage on the label.

The supply should be fused at the next size equal to or higher than the amperage on the label. A

table of the most common fuse ratings is also given in section 8.1 of this manual. Where a supply

cable is present there are internal supply fuses; in this case customer fusing is preferred but not

essential.

Furnace with supply cable: either wire directly to an isolator or fit with a line plug.

Furnace without supply cable: a permanent connection to a fused and isolated supply should be

made to the internal terminals after temporary removal of the furnace back panel.

Connection by line plug: the plug should be within reach of the operator, and should be quickly

removable.

Connection to isolating switch: this should operate on both conductors (single phase) or on all live

conductors (three phase), and should be within reach of the operator.

The supply MUST incorporate an earth (ground).

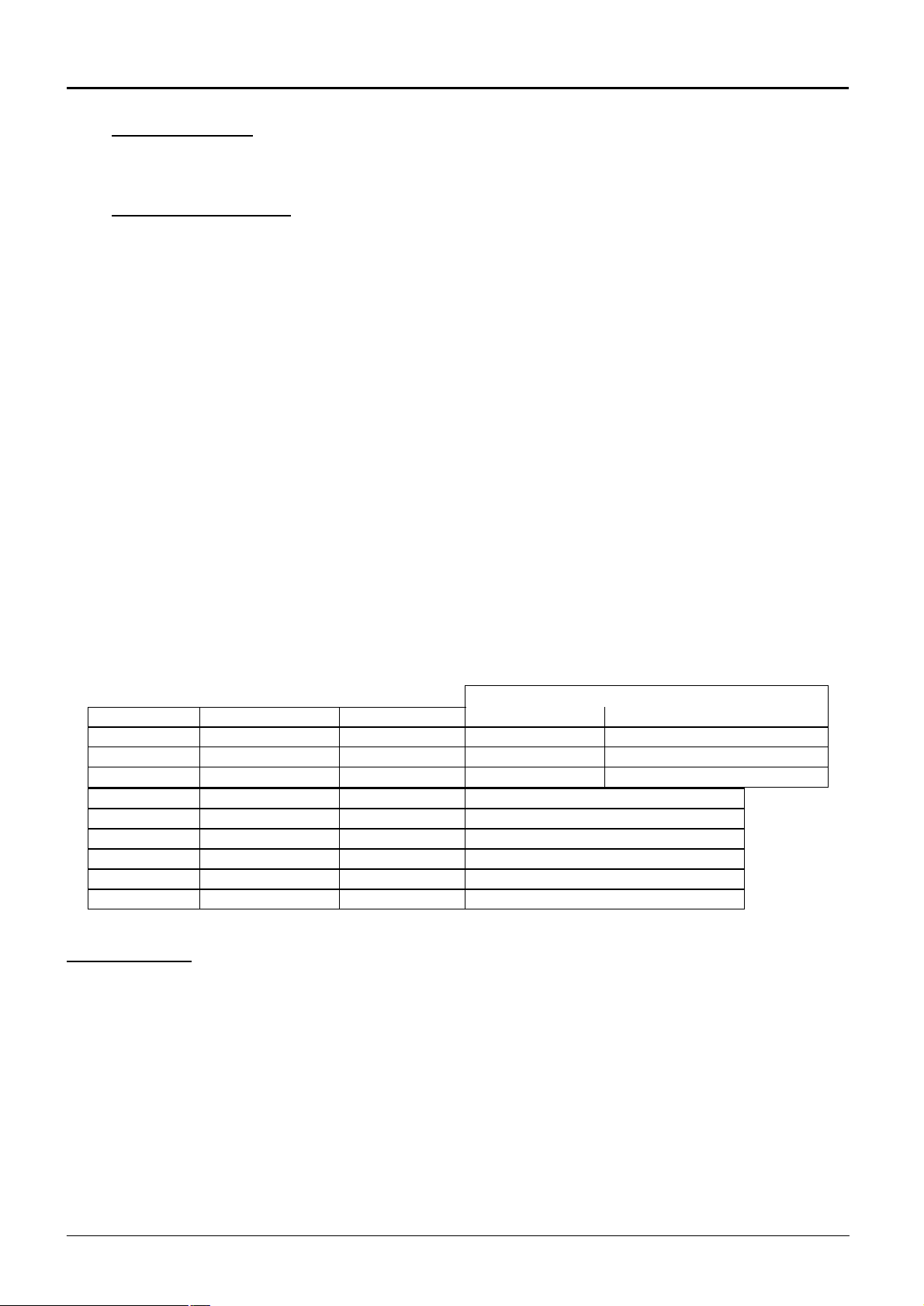

ELECTRICAL CONNECTION DETAILS

Supply Terminal label Cable colour

1-phase

N Blue To neutral to the other power conductor

PE Green/Yellow To earth (ground) to earth (ground)

supply Terminal label Cable colour

2- or 3-phase

L2 Black to phase 2

L3 Black to phase 3 except 2-phase

N Light Blue to neutral except delta

PE Green/Yellow to earth (ground)

L Brown To live to either power conductor

L1 Black to phase 1

Live-Neutral Reversible or Live-Live

supply type

Technical Notes

The furnaces covered by this manual have electronically controlled power limits. Do not attempt to

calculate the Amps from the Wattage. High break capacity fuses should be used. Avoid fast-blow

fuses and magnetic trip circuit breakers - consult Carbolite if in doubt.

Two-phase models use two phases out of a 3-phase+neutral supply. One phase is unused. The

neutral current is equal to the current in one of the used phases.

Model RHF 16/35 has unequal phases: L1 and L2 have 4 heating elements and L3 has 2 elements.

In 4-wire configuration, one phase takes half the current of the other two, and the neutral also takes

this half-amount (see also section 8.1).

MF07 3

RHF

3.0 OPERATION

The instructions for operating the temperature controller are given in a separate manual.

If the furnace is fitted with a time switch, see also the supplementary manual MS03.

If cascade control is fitted, see the supplementary manual MS07.

3.1 Operating Cycle

The furnace is fitted with a combined Supply light and Instrument switch. The light is on

whenever the furnace is connected to the supply. The switch cuts off power to the control circuit.

Connect the furnace to the electrical supply. The Supply light should glow.

Operate the instrument switch to activate the temperature controller; the O position is off, the

I position on. The controller becomes illuminated and goes through a short test cycle.

Close the furnace door and adjust the temperature controller (see controller manual).

Overtemperature option only. If the overtemperature controller has not yet been set as required, set

it and activate it according to the instructions in the appropriate manual.

Unless a time switch is fitted and is off, the furnace starts to heat up. The Heat light(s) glow

steadily at first and then flash as the furnace approaches the desired temperature or a program

setpoint.

Overtemperature option only. If the overtemperature trip operates then an indicator in the

overtemperature controller flashes, and the heating elements are isolated. Find and correct the

cause before resetting the overtemperature controller according the instructions supplied.

To switch the furnace off, set the Instrument switch to O. If the furnace is to be left off, isolate it

the electrical supply.

3.2 General Operating Advice

Heating element life is shortened by use at temperatures close to maximum. Do not leave the

furnace at high temperature when not required. The maximum temperature is shown on the

furnace rating label and on the back page of this manual.

When heating large objects, in particular poor conductors, avoid shielding the thermocouple from

the heating elements. The thermocouple is intended to sense the temperature near the heating

element, but if a large object is placed in the chamber it may record the average temperature of the

object and the elements, which can lead to overheating of the elements. Allow large objects to gain

heat at a lower temperature and then reset the controller to a temperature close to the desired

maximum.

When heating materials which produce smoke or fumes, the chimney must be correctly fitted and

unobstructed. Otherwise, soot can accumulate in the chamber and could possibly cause an

electrical breakdown of the heating element.

If the furnace is used to heat materials which emit smoke or fumes, regularly heat it up to

maximum temperature for one hour without load to burn away the soot.

Materials such as case hardening compounds and other reactive salts may penetrate the furnace

chamber lining and attack the insulation, or the elements, causing premature failure. Use of a

hearth tile may be advisable: please consult our technical department.

4 MF07

RHF

3.3 Use of Probes

Any metal object used to probe into the furnace chamber while the furnace is

connected to the supply must be earthed (grounded). This applies in particular to

metal sheathed thermocouples, where the sheaths must be earthed. The refractory

material of the chamber lining becomes partly conducting at high temperatures, and

the electric potential inside the chamber can be at any value between zero and the

supply voltage. Unearthed probes can cause serious electric shock.

3.4 Atmospheres

When an optional gas inlet is fitted there is a label near the inlet saying "INERT GAS ONLY". In

practice inert or oxidising gases may be used, but not combustible or toxic gases. Chamber

furnaces are not gas tight, so it should be understood that gas usage may be high, and that the

chamber is likely always to contain some air. Residual oxygen levels of 1% are to be expected.

3.5 Operator Safety

The furnace incorporates a safety switch which interrupts the heating element circuit when the

door is opened. This prevents the user touching a live heating element, but also prevents the

furnace from heating up if the door is left open. The operation of this switch should be checked

periodically – see section 4.1.2.

Avoid burns: furnace surfaces can be hot. Before you remove a hot object from the furnace make

sure you have a safe place to put it down.

MF07 5

Loading...

Loading...