Carbolite PTC 12/20/150 User Manual

CONTENTS

section page

Installation, Operation &

Maintenance Instructions

1200°C Thermocouple Calibration Furnace

type PTC 12/20/150

This manual is for the guidance of operators of the above Carbolite products

and should be read before the furnace is connected to the electricity supply.

This manual should supply all the information required for safe and trouble-

free furnace operation. Information on controller operation is included.

MF11 – 3.08

Instrument switch: when the instrument switch is operated the temperature

control circuit is energised.

Heat Light: the adjacent light glows or flashes to indicate that power is

being supplied to the elements

DANGER of electrical shock– read any warning printed by this symbol.

DANGER – hot surface. Read any warning printed by this symbol.

WARNING: all surfaces of a furnace may be hot.

DANGER – read any warning printed by this symbol.

PTC

1.0 SYMBOLS & WARNINGS

1.1 Switches and Lights

1.2 Warning Symbols

2 MF11 – 3.08

PTC

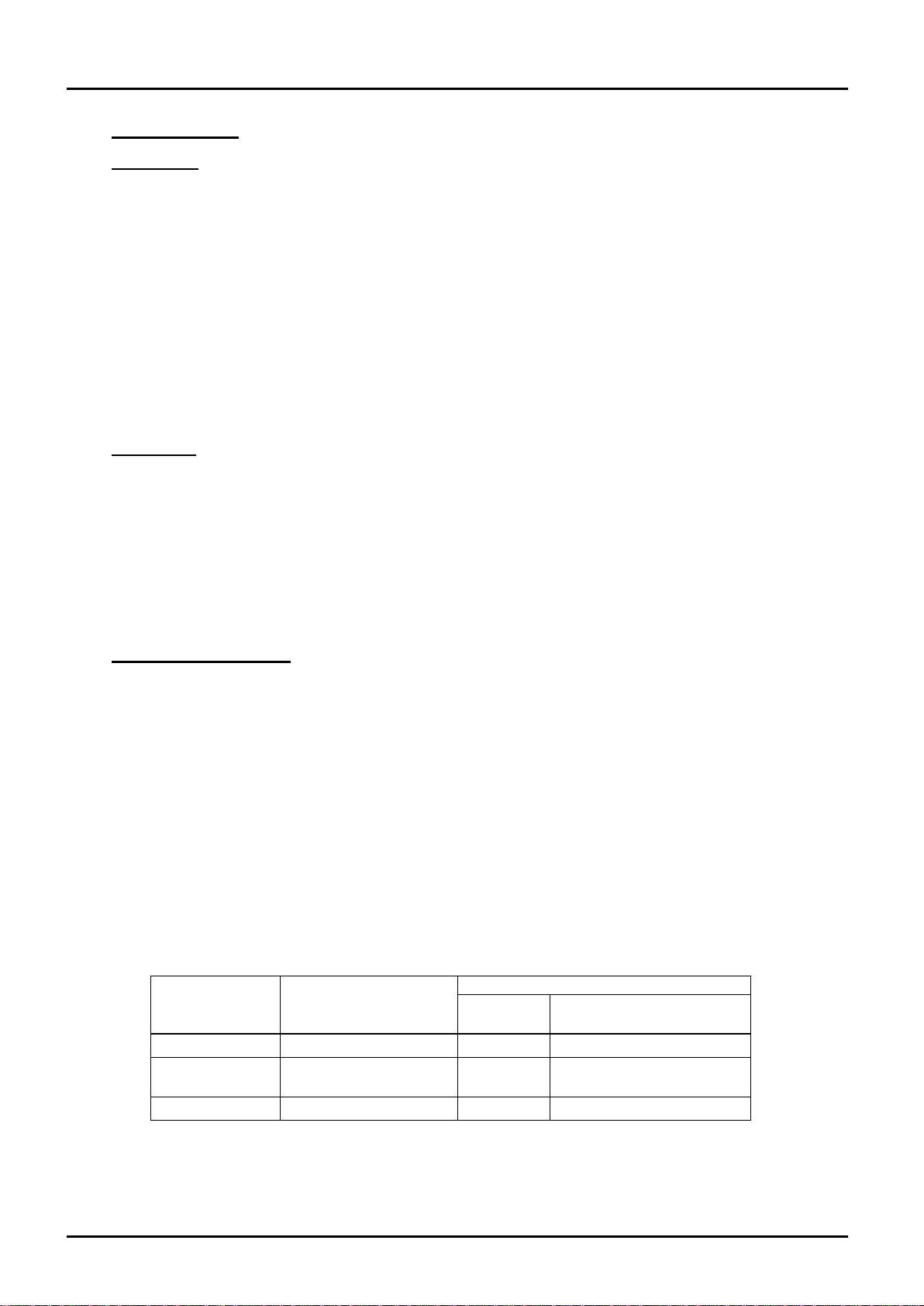

supply type

Cable colour

Terminal

label

LiveNeutral

Reversible or Live-Live

Brown

L

to live

to either power conductor

Blue

N

to neutral

to the other power

conductor

Green/Yellow

PE

to earth

to earth

2.0 INSTALLATION

2.1 Unpacking

Unpack the furnace and remove the transit clamp from the working end of the furnace as follows:

- loosen the locking nut on the central clamp bolt;

- turn the bolt clockwise with a screwdriver to release the force on the clamping device;

- remove the two screws which hold the transit clamp to the furnace;

- carefully withdraw the transit clamp;

- retain the clamp.

If at any time the furnace is returned for repair or otherwise subject to arduous travel, refit the

transit clamp. The furnace must be cold before the clamp is fitted.

NOTE: This product contains Refractory Ceramic Fibre (better described as Alumino Silicate

Wool) for precautions and advice in handling this material see the ‘Repairs and Replacements’

section.

2.2 Setting Up

Underneath the furnace is a dual voltage switch. Set this correctly for the supply to be used: 115V

for 110-120V, 230V for 220-240V.

Ensure that there is free space around the furnace. Do not obstruct any of the vents: they are

needed to keep the controls cool.

Ensure that the furnace is placed in such a way that it can be quickly switched off or disconnected

from the electrical supply - see below.

Do not place the furnace on an inflammable surface.

2.3 Electrical Connections

The furnace requires a single-phase A.C. supply with earth (ground). The supply may be Live to

Neutral non-reversible, Live to Neutral with reversible plug, or Live to Live. Check that the

supply voltage is compatible with the voltage on the furnace rating label, and that the voltage

switch referred to above is correctly set.

The furnace is internally fused at 10 Amps. A 110-120V supply should be fused externally at 10

Amps. A 220-240V supply should be fused externally at 5 Amps.

In the event of the furnace being used on 230V when the voltage switch is set to 115V, a fast-blow

fuse protects the circuit. This is located in a panel mounted holder adjacent to the voltage switch.

The furnace is supplied with a plug-in cable which may be wired directly to an isolator which

operates on both conductors, or fitted with a line plug which may be quickly disconnected from the

supply. The isolator or the plug should be within easy reach of the operator. The supply must

incorporate an earth (ground).

Connect the supply as follows:

MF11 – 3.08 3

125mm

thermocouple

tip

PTC

3.0 OPERATING INSTRUCTIONS

3.1 Operating Cycle

The furnace is fitted with an instrument switch. The switch cuts off power to the controller.

Connect the furnace to the electrical supply.

Operate the instrument switch to activate the temperature controller. The controller becomes

illuminated and goes through a short test cycle. Set the temperature as required - see section 4.0.

As the furnace heats up the Heat light glows steadily at first and then flashes as the furnace

approaches the desired temperature. For further information on temperature control see section 4.0.

To turn the furnace off, set the Instrument switch to it’s off position; the controller display will go

blank. If the furnace is to be left off unattended, isolate it the electrical supply.

3.2 General Operating Notes

Heating element life is shortened by use at temperatures close to maximum. Do not leave the

furnace at high temperature when not required. The maximum temperature is given on the furnace

rating label and on the back page of this manual.

Light weight ceramic fibre insulation can easily be marked by accidental contact. Some fine cracks

may be visible on the surface of the insulation, or may develop in the surface of the chamber due

to the progressive shrinkage of the insulation materials. Cracks are not usually detrimental to the

functioning or the safety of the furnace.

3.3 Operator Safety

Ceramic materials used in furnace manufacture become electrically conducting at high

temperature.

The furnace incorporates a Heater Switch on the control panel which safely interrupts the heating

element circuit. Use this switch when inserting anything into the furnace chamber which might

touch the interior. Do not rely upon the instrument switch for this purpose.

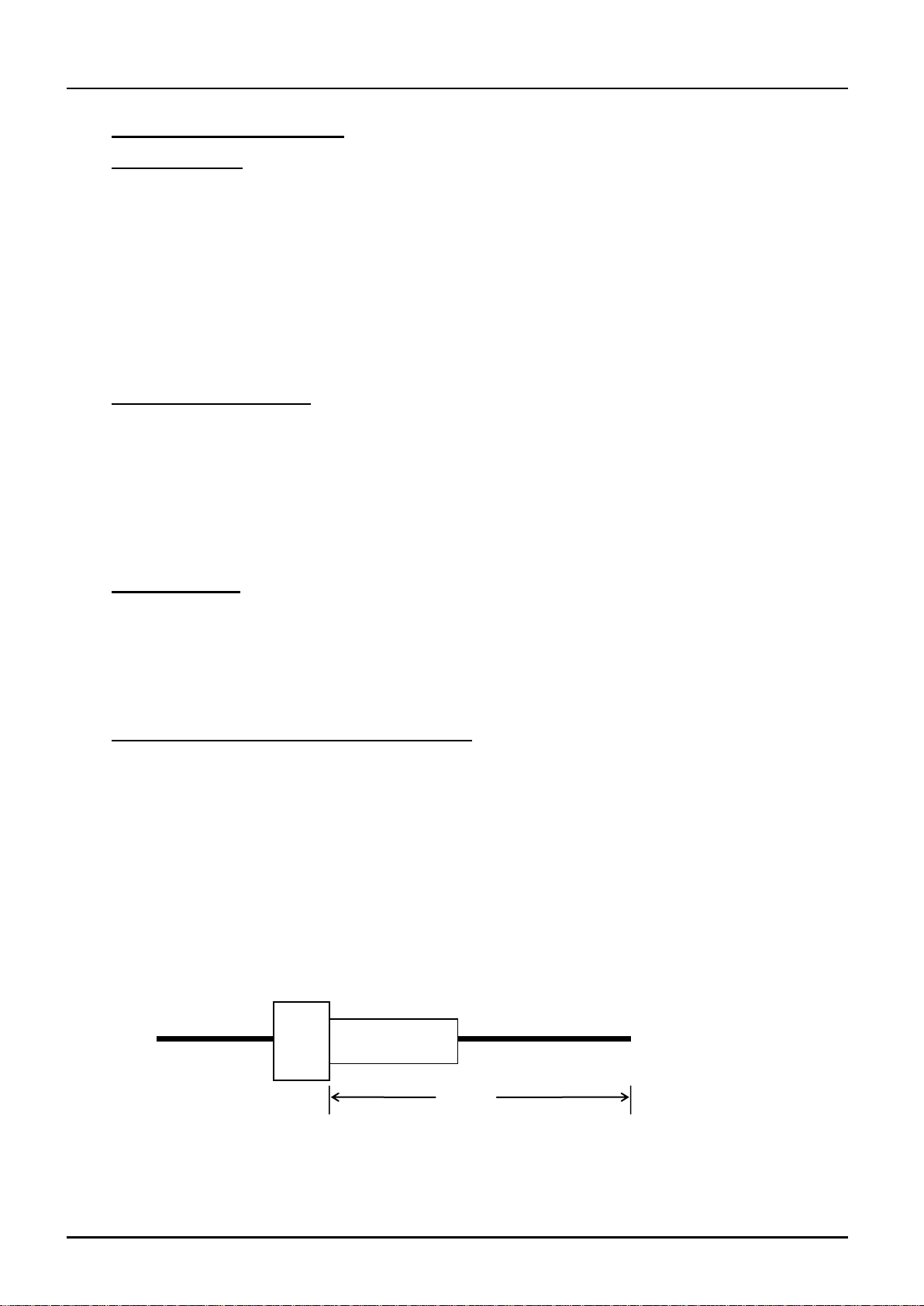

3.4 Instructions for Use as a Calibration Furnace

The PTC 12/20/150 is designed for calibration by the comparison method, which consists of

comparing the thermocouple under test with a reference thermocouple. This reference

thermocouple can have traceability to national standards, either if it is ordered with this

requirement, or by getting it independently calibrated.

In the PTC 12/20/150 the reference thermocouple is built in and has its own indicator marked

Reference Temperature. It is located within the work tube such that its tip is positioned close to

that of the thermocouple to be tested in the part of the tube which has the most uniform

temperature.

The thermocouple to be calibrated should be passed through an end plug with a suitable size hole,

with the tip 120 to 130mm from the step in the plug.

If thermocouples with different outer diameters are to be calibrated then end plugs with different

4 MF11 – 3.08

size holes should be used. These may be ordered from Carbolite. The maximum recommended

PTC

diameter is 7.5mm - larger diameters may experience too much heat conduction and give an

incorrect calibration.

Insert the thermocouple and end plug and support the cold end to ensure that the assembly lines up

with the axis of the furnace tube.

Switch on the instrument switch and set the desired temperature on the controller. Allow the unit

to warm up and stabilise. The reference temperature may be slightly lower than the control

temperature so adjustment can be made to the control setting to bring the reference temperature to

the exact temperature if desired; allow it to stabilise.

Either the output of the thermocouple or an indicated temperature can be checked against the

reference temperature and any error noted. This error can now be used to correct any readings

taken by the thermocouple. The noted error is the calibration of the thermocouple. Remember to

include the reference thermocouple error in calculating the calibration - see the reference

thermocouple certificate.

The calibration should be made at temperatures at which the thermocouple is to be used. If it is to

be used over a range of temperatures then calibrate it at a number of points over the range (for

example at every 100°), and plot a graph of error against temperature. A curve drawn through the

points can then be used to find the error at any temperature.

MF11 – 3.08 5

Loading...

Loading...