Carbolite nanodac User Manual

The contents of section 4 onward are extracted from Eurotherm

nanodac manual HA030554/8 February 2014

for nanodac versions 5.00 and later

Sections not relevant to use in Carbolite products have been removed.

There is a possibility of references to notes that are not included.

For full operating instructions the nanodac manual is available on the

product tools DVD

Operating Instructions

nanodac™ recorder/controller/programmer

MC27 v1.04

Contents

1. NANODAC PASSWORD SECURITY ......................................................................................... 3

2. LOGIN ................................................................................................................................... 3

3. CASCADE ............................................................................................................................... 5

4. OPERATION ........................................................................................................................... 7

4.1 INTRODUCTION ................................................................................................................................................ 7

4.1.1 Display Screen ....................................................................................................................................................................... 7

4.1.2 Navigation Pushbuttons ........................................................................................................................................................ 7

4.1.3 On Screen Help...................................................................................................................................................................... 8

4.2 PROCESS VARIABLE DISPLAY .......................................................................................................................... 9

4.2.1 Alarm Icons ........................................................................................................................................................................... 9

4.2.2 Status Bar Icons ................................................................................................................................................................... 10

4.2.3 Breaks in recording .............................................................................................................................................................. 12

4.3 TOP LEVEL MENU ........................................................................................................................................... 13

4.3.1 Home .................................................................................................................................................................................. 13

4.3.2 Configuration ...................................................................................................................................................................... 13

4.3.3 Go to View .......................................................................................................................................................................... 14

4.3.4 History ................................................................................................................................................................................ 17

4.3.5 Faceplate Cycling on/off ...................................................................................................................................................... 17

4.3.6 Operator Notes ................................................................................................................................................................... 17

4.3.7 Demand Archiving ............................................................................................................................................................... 17

4.3.8 Login ................................................................................................................................................................................... 19

4.4 DISPLAY MODES ............................................................................................................................................. 21

4.4.1 Vertical Trend ...................................................................................................................................................................... 21

4.4.2 Horizontal Trend mode ........................................................................................................................................................ 22

4.4.3 Vertical Bargraph mode ....................................................................................................................................................... 22

4.4.4 Horizontal Bargraph mode .................................................................................................................................................. 23

4.4.5 Numeric mode .................................................................................................................................................................... 23

4.4.6 Alarm panel ......................................................................................................................................................................... 24

4.4.7 Control Loop1/Loop2 ........................................................................................................................................................... 25

4.4.8 Cascade Display Mode ......................................................................................................................................................... 26

4.4.9 Programmer Display Mode .................................................................................................................................................. 27

4.4.10 Promote List .................................................................................................................................................................. 38

4.4.11 Modbus Master display mode ......................................................................................................................................... 39

4.4.12 EtherNet/IP display mode ............................................................................................................................................... 42

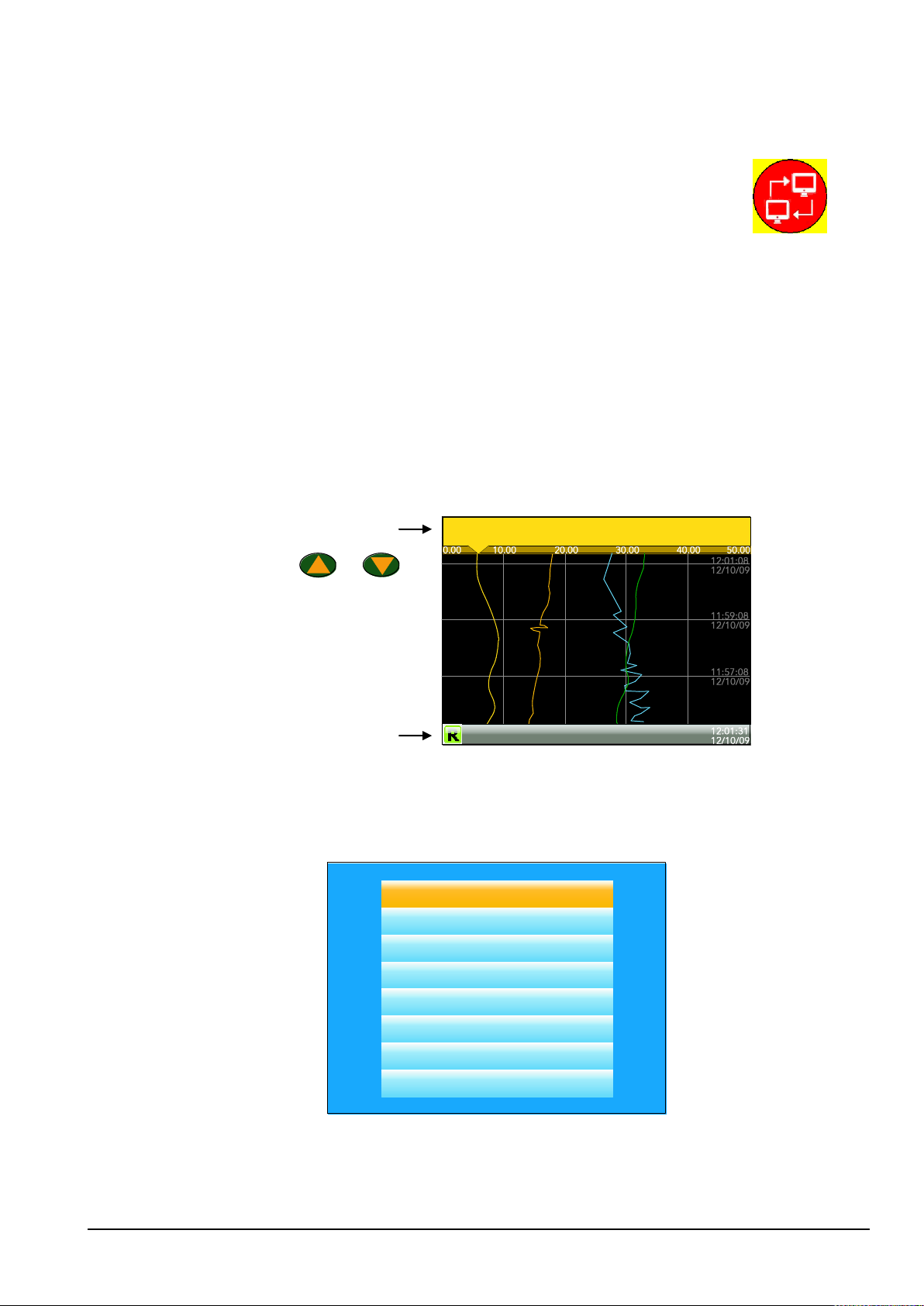

4.5 TREND HISTORY ............................................................................................................................................. 48

4.5.1 Navigation .......................................................................................................................................................................... 48

4.5.2 History Options Menu .......................................................................................................................................................... 49

4.6 TEXT ENTRY .................................................................................................................................................... 50

4.6.1 Numeric keyboard ............................................................................................................................................................... 50

4.6.2 USB keyboard ..................................................................................................................................................................... 50

5. CONFIGURATION ................................................................................................................. 51

5.1 NETWORK MENU ............................................................................................................................................ 51

5.1.1 Interface .............................................................................................................................................................................. 52

5.1.2 Archiving ............................................................................................................................................................................. 53

5.1.3 FTP Server ........................................................................................................................................................................... 55

5.1.4 Modbus TCP ........................................................................................................................................................................ 56

5.2 GROUP CONFIGURATION ............................................................................................................................... 57

5.2.1 Group Trend configuration .................................................................................................................................................. 57

5.2.2 Group Recording configuration ............................................................................................................................................ 58

6. ITOOLS ................................................................................................................................ 59

6.1 iTools CONNECTION ....................................................................................................................................... 60

6.1.1 Ethernet (Modbus TCP) communications ............................................................................................................................. 60

6.1.2 Direct Connection ................................................................................................................................................................ 62

6.2 SCANNING FOR INSTRUMENTS ...................................................................................................................... 63

6.3 PARAMETER EXPLORER ................................................................................................................................. 64

6.3.1 Parameter explorer detail .................................................................................................................................................... 65

6.3.2 Explorer tools ...................................................................................................................................................................... 66

1 MC27 –EN–1.04

nanodac™

6.3.3 Context Menu ..................................................................................................................................................................... 66

6.4 WATCH/RECIPE EDITOR ...................................................................................................... 67

6.4.1 Creating a Watch List ........................................................................................................................................................... 67

6.4.2 Watch Recipe toolbar icons ................................................................................................................................................. 68

6.4.3 Watch/Recipe Context Menu ............................................................................................................................................... 68

6.5 PROGRAMMER OPTION ..................................................................................................... 69

6.5.1 Segment parameter editing ................................................................................................................................................ 69

6.5.2 Digital Event display ............................................................................................................................................................ 71

6.5.3 Program parameters ............................................................................................................................................................ 71

6.5.4 Adding and deleting segments. ............................................................................................................................................ 72

6.5.5 Loading and Saving programs ............................................................................................................ 73

6.5.6 Toolbar icons ................................. 73

6.5.7 Context menus ..................................................................................................................................................................... 74

6.5.8 Programmer menu ............................................................................................................................................................... 75

6.5.9 Two channel programs ......................................................................................................................................................... 76

6.5.10 To Set Up OEM Security .................................................................................................................................................. 77

7. USER WIRING ...................................................................................................................... 80

7.1 COUNTER EXAMPLE ....................................................................................................................................... 81

8. USB DEVICES ....................................................................................................................... 84

8.1 MEMORY STICK .............................................................................................................................................. 84

8.2 BAR CODE READER ........................................................................................................................................ 84

8.3 USB KEYBOARD ............................................................................................................................................. 84

9. APPENDIX A: TECHNICAL SPECIFICATION ........................................................................... 85

9.1 RECORDER SPECIFICATION............................................................................................................................. 85

9.2 ANALOGUE INPUT SPECIFICATION................................................................................................................ 86

10. APPENDIX B TUNING CONSIDERATIONS ........................................................................... 88

10.1 Autotune ......................................................................................................................................................... 88

10.1.1 Relative Cool Gain in Well Lagged Processes .................................................................................................................. 94

11. APPENDIX C: REFERENCE .................................................................................................... 97

12. APPENDIX E: WEB SERVER ................................................................................................ 103

12.1 Browsers ........................................................................................................................................................ 103

12.2 Connecting to the Internet.............................................................................................................................. 103

12.3 Denied Page ................................................................................................................................................... 103

12.4 Error Message ................................................................................................................................................ 103

12.5 Home Page .................................................................................................................................................... 104

12.6 About Page .................................................................................................................................................... 104

12.7 Contact Page .................................................................................................................................................. 104

12.8 Bar Graph Page .............................................................................................................................................. 105

12.9 Line Graph Page ............................................................................................................................................. 106

12.10 Numeric Page ............................................................................................................................................ 107

12.11 Alarm Summary Page ................................................................................................................................ 107

12.12 Message Summary Page ............................................................................................................................ 108

12.13 Promote Page ............................................................................................................................................ 108

12.14 Historical Line Page ................................................................................................................................... 109

12.15 Status Icons ............................................................................................................................................... 110

12.16 DHCP Support ........................................................................................................................................... 110

12.17 Network Protocols ..................................................................................................................................... 110

12.18 Languages ................................................................................................................................................. 110

13. APPENDIX F: LABVIEW DRIVER .......................................................................................... 111

13.1 Application Example 1 - Heat/Cool Control ..................................................................................................... 111

13.2 Application Example 2 - Program Load by Program Number ........................................................................... 114

13.3 Full driver capabilities list ................................................................................................................................ 115

MC27 –EN– 1.04 2

nanodac™

1. Nanodac password security

While in Logged out mode the control loop can be viewed but no alterations can be made. The

program page can be viewed but no change in status or editing of the program can be made.

Various chart pages can be viewed along with said history for charts. Operator notes can be

viewed and written to charts and message log.

Password codes: Operator level: 9

Password codes: Supervisor level: 5

Password codes: Engineer level: 95

While in Operator mode all of the above is available plus you can change the set point of the

control loop. Change the status of the program (i.e. Run, Hold or Reset).Edit, store, and load or

delete a program. Carry out a demand archive to a device and choose what device said archive

should be sent to (USB or FTP server). See main manual for details.

While in Engineer mode the following can be change: Time; Date; Communication setting.

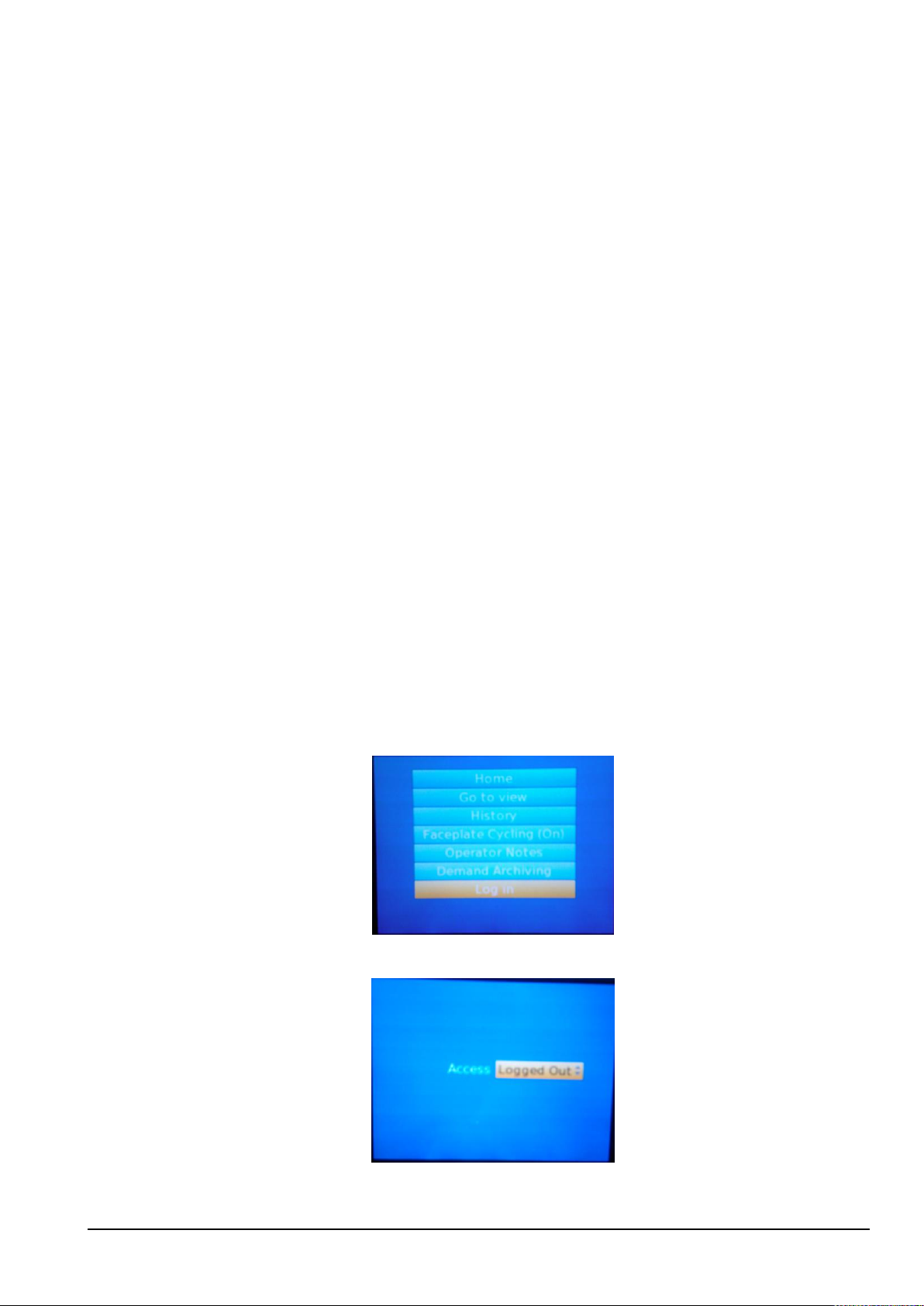

2. Login

LOG IN Procedure for the Eurotherm Nanodac Controller/Programmer

Switch on the Instrument. Also refer to section 4.3.8.

To run a program you must ‘log in’. To log in follow the instructions below.

Press the Home button (Left hand button) to bring up the LOG IN screen as shown below.

Highlight the Log in by using the Up/Down arrows (right hand buttons).

Press the Scroll button (2nd button from the LHS) to move to the access screen as shown below.

3 MC27 –EN–1.04

nanodac™

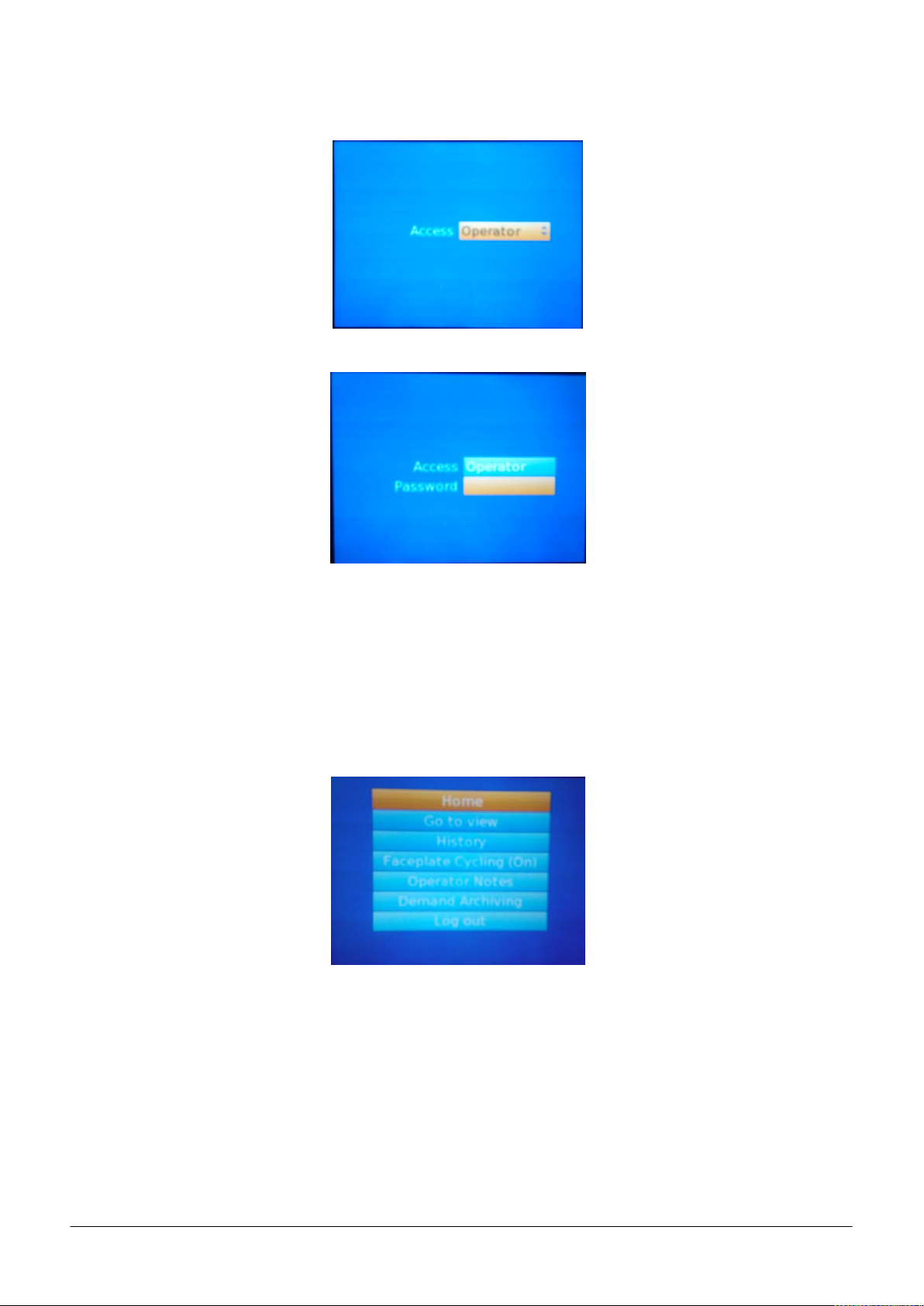

Use the arrow UP/DOWN buttons to select the operator mode as shown below.

Press the Scroll button to accept the operator mode as shown below.

A password is now required for the Operator mode. The password to be used “9”. Press the

Scroll key to bring up the keyboard and use the UP/DOWN arrows to select the numeric tab and

then number “9”.

Press the scroll button to accept the password number “9”.

Press the Home page (Left hand button).

“CANCEL – NO – YES” will appear and select “YES” using the arrow UP/DOWN buttons.

Press the Scroll key.

Note that LOGIN has now changed to LOG OUT as shown below. This is normal and correct.

Press any button to return to the home page (default page). It will now be possible to select and

highlight the boxes in the program page and select “RUN” to run a program.

MC27 –EN– 1.04 4

nanodac™

3. Cascade

3.1. PRINCIPLE OF CASCADE CONTROL

When cascade control is fitted, the Load Loop in the Nanodac senses the temperature of the

workload, and the Element Loop in the Nanodac senses the element temperature. Depending on

the oven or furnace model, the Load Thermocouple may be in a fixed position, or may be movable.

The Element Thermocouple is fixed in a predetermined position near the heating elements

If movable, the Load Thermocouple should be placed as near as possible to the work to be heated.

The Load Loop communicates with the Element Loop, calling for heat according to the load

temperature and the current program or setpoint. The Element Loop regulates the heat according

to element temperature and the requests from the Load Loop.

The element temperature could, in principle, vary between the furnace or oven maximum and

minimum, regardless of the working temperature of the load. In practice, the cascade control

system is configured to limit the element temperature to a band around the load temperature,

typically of ±500 C of the setpoint temperature.

The Load Loop is always accessible to the operator. The Element Loop may or may not be located

out of sight inside the control compartment. If the Element Loop is visible to the operator, the

display may be disregarded.

In a three-zone furnace for which the “three zone cascade” option has been ordered there are

three Element Controllers, all receiving the same control instructions from the Load Controller

3.2. OPERATION

The operator may ignore all the complications of the system, and program the Load Loop

according to the standard instructions for that controller. Home display is top view (Load Loop)

bottom view (Element loop). By pressing page, separate views of load and element loops will

show.

The Element Loop should never be adjusted. Note that the elements usually run at a higher

temperature than the load.

Because the details of the customer’s cascade application (in particular the nature of the load) are

generally not known, the feed forward parameter (Cascade Trim) is made easily accessible on the

cascade trim page. (Refer to instrument operating instructions). Its default setting is ±500 C. If

overshoot of the load temperature occurs – often a problem at low temperatures – then Cascade

Trim can be reduced in order to limit the amount of overshoot. If Cascade Trim is reduced too

much, however, the load may not reach the desired temperature. If the load does not reach the

desired temperature or is slow in the final stages, Cascade Trim can be increased: a maximum of

750 C is suggested.

When attempting to control at very low temperatures it can become a problem to achieve stable

control because of excessive power being supplied during heating. The available power can be

limited using the power limit parameter OP.Hi, and make a note of the original settings before

adjusting. The manual for the furnace or oven may also list standard settings for this parameter.

The parameter is normally set to 100% and contact Carbolite Engineering if this value needs to be

amended.

3.3. CAUTION

If the Load Thermocouple is removable, leave it in the furnace or oven chamber

whenever possible.

Operating with the Cascade Control active and with the Load Thermocouple in

an unheated position (such as lying on the work bench) may cause the furnace

or oven to heat up to its maximum temperature, wasting power and possibly

shortening element life.

5 MC27 –EN–1.04

nanodac™

3.4. OVER-TEMPERATURE CONTROL

Where over-temperature control is fitted, it normally protects against failure of the control system or

of a component such as a power control relay. The over-temperature controller must be set at a level

higher than the greatest element temperature, typically 15°C above maximum.

If the working temperature is less than the maximum temperature, then it may be possible to set the

over-temperature limit as follows:

Working Temperature + Cascade trim high (eg 50) +15°C

Example: for working at 800°C in a 1200°C furnace, the over-temperature limit could be set to

800+50+15=865°C.

MC27 –EN– 1.04 6

nanodac™

Faceplate

Main display

screen

Status area

Home

Configuration

Go to View

History

Faceplate Cycling (On)

Operator Notes

Demand Archiving

Log Out

4. OPERATION

On power up a default or custom splash screen appears and remains visible whilst the

unit is initialising. If during this process a network broadcast storm is detected, the

unit stops, displaying a network failure icon until the broadcast storm has cleared,

after which the initialisation process resumes.

4.1 INTRODUCTION

The operator interface consists of a display screen and four push buttons.

4.1.1 Display Screen

The display screen is used both to display channel information (in one of a number of display modes), and

to display the various configuration screens which allow the user to setup the recorder to display the

required channels, to set up alarms and so on. Display modes are described in Section 4.4 below;

configuration is described in Section 5

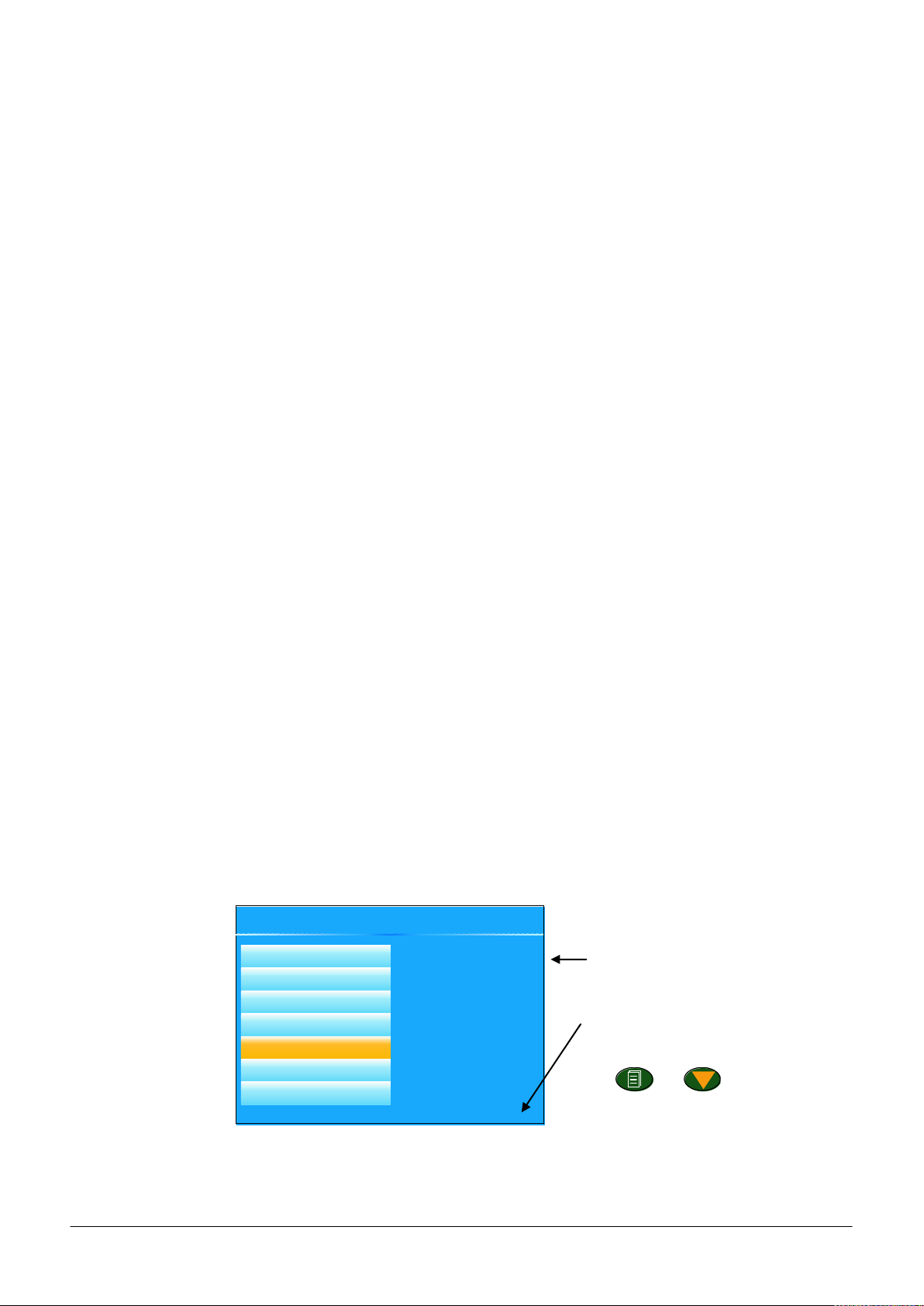

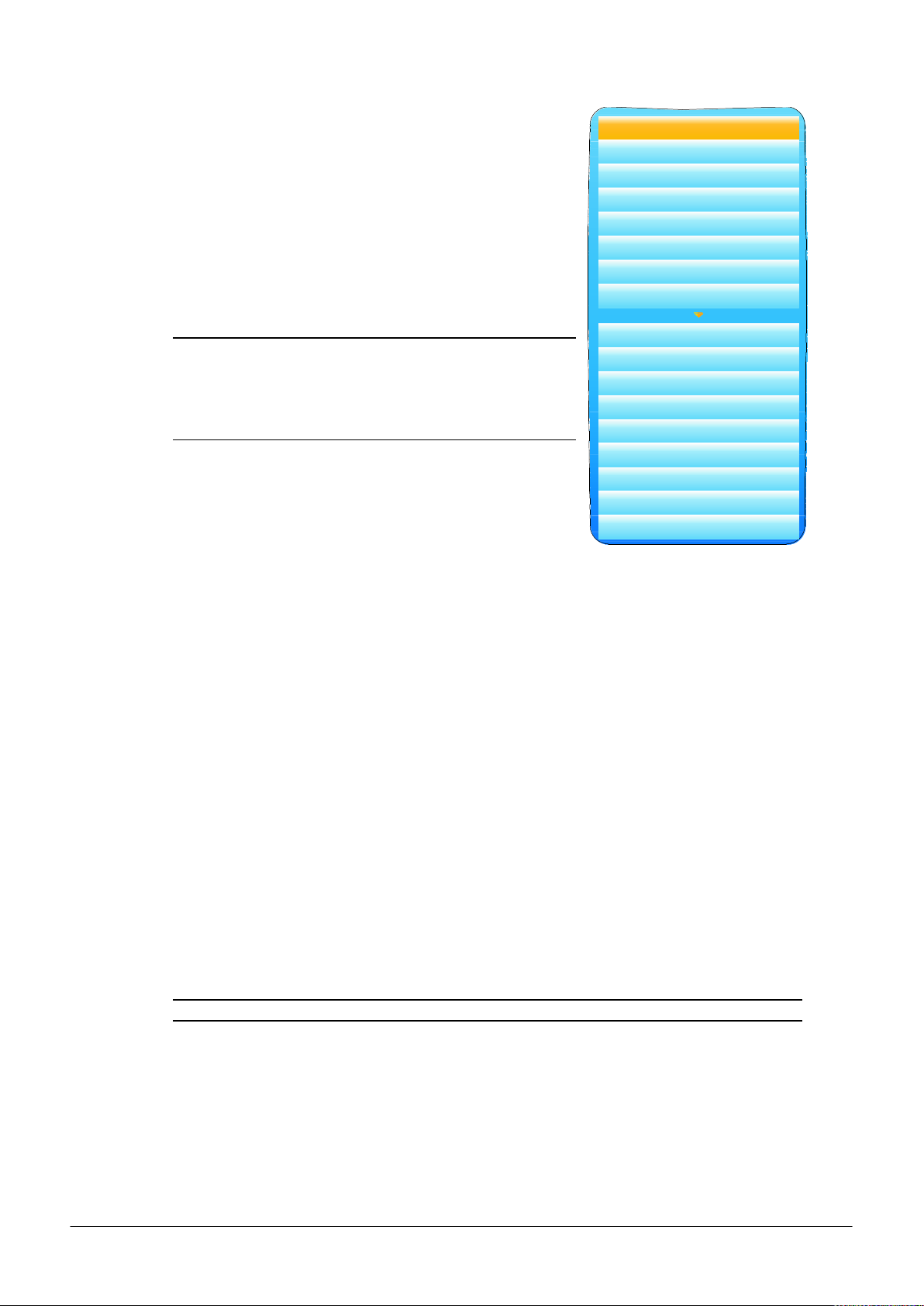

In display mode, the screen is split horizontally into three areas (figure 1.1.1)

1. a faceplate giving channel details.

2. the main display screen showing channel traces etc.

3. the status area, displaying instrument name, the current time and date and any system icons.

Figure 1.1.1 Display mode screen (vertical trend)

In configuration mode, the entire display screen is devoted to the selected configuration menu.

4.1.2 Navigation Pushbuttons

7 MC27 –EN–1.04

There are four navigation buttons, called ‘Page’, ‘Scroll’, ‘Lower’ and ‘Raise’ located below the screen. The

general properties of these buttons are described in the remainder of this section, but some have

additional, context sensitive functions, which, for the sake of clarity are not described here but in the

relevant sections (e.g. ‘Message summary’) of the manual.

Figure 1.1.2 Top level menu (Engineer level access)

nanodac™

On-screen help.

(Use the Page button with

the down arrow to access

hidden text at the bottom of

the screen)

Logic (2 Input(

Logic (8 Input)

Multiplexor

Math (2 Input)

Timer

User Values

Alram Summary

The timer function block

offers a universal timer

which may be

re-configured between

single pulse outputs and

re-triggering

outputs. Timer types are:

On pulse on-timer.

+

Select confiuguration menu

Navigation Pushbuttons (Cont.)

PAGE BUTTON

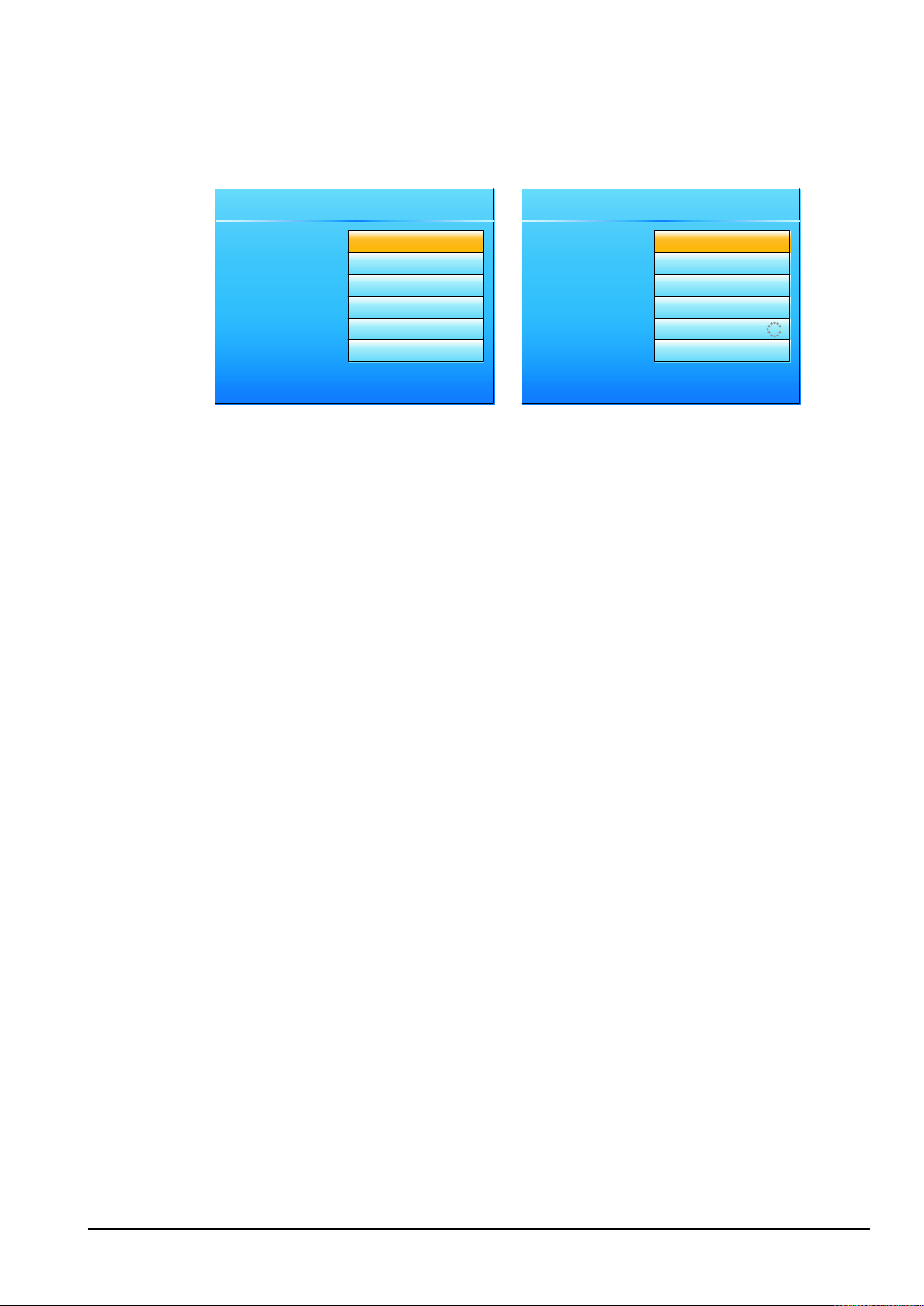

From any non-configuration page, pressing this push button causes the top level menu (figure 1.1.2) to

appear. The figure shows the menu for a user logged in with ‘Engineer’ level access. Other access levels

may have fewer menu items.

Within configuration pages, the Scroll button can be used as an enter key to select lower menu levels. In

such cases the page button is used to reverse this action, moving the user up one menu level per

operation.

SCROLL BUTTON

From trending pages, operation of the scroll push-button scrolls through the channels enabled in the

group. The Faceplate cycling ‘Off’ selection can be used to keep a particular channel permanently

displayed, and the scroll pushbuttons can then be used to select channels manually.

In configuration pages, the scroll key operates as an ‘enter’ key to enter the next menu level associated

with the highlighted item. Once the lowest menu level is reached, operation of the scroll key allows the

value of the selected item to be edited by the relevant means (for example, the raise/lower keys, or a

keyboard entry).

The ‘Page’ key is used to move the user back up the menu structure, until the top level menu is reached,

when the scroll key can be used again to return to the Home page.

The scroll button is also used to initiate user wiring as described in Section 7

RAISE/LOWER BUTTONS

Within trending displays, the Raise and Lower keys can be used to scroll through the enabled display

modes in the sequence: vertical trend, horizontal trend, vertical bargraph, horizontal bargraph, numeric,

vertical trend... and so on.

Within configuration pages, these pushbuttons act as cursor keys, allowing, for example, the user to

highlight menu items for selection using the scroll button, and in many cases allowing the user to select

one from a number of alternative values within menu items. These keys are also used to navigate through

the virtual keyboards and number pads used to enter text or numeric strings.

4.1.3 On Screen Help

The top level configuration menu includes contextual help text on the right-hand half of the screen.

Mostly this text fits within on screen height. Where this is not the case, the text can be moved up or down

the screen by holding the Page button operated whilst using the up and down arrows to move the text.

The down arrow moves the text upwards on the screen; the up arrow moves it downwards.

MC27 –EN– 1.04 8

Figure 1.1.3 On-screen help (typical)

nanodac™

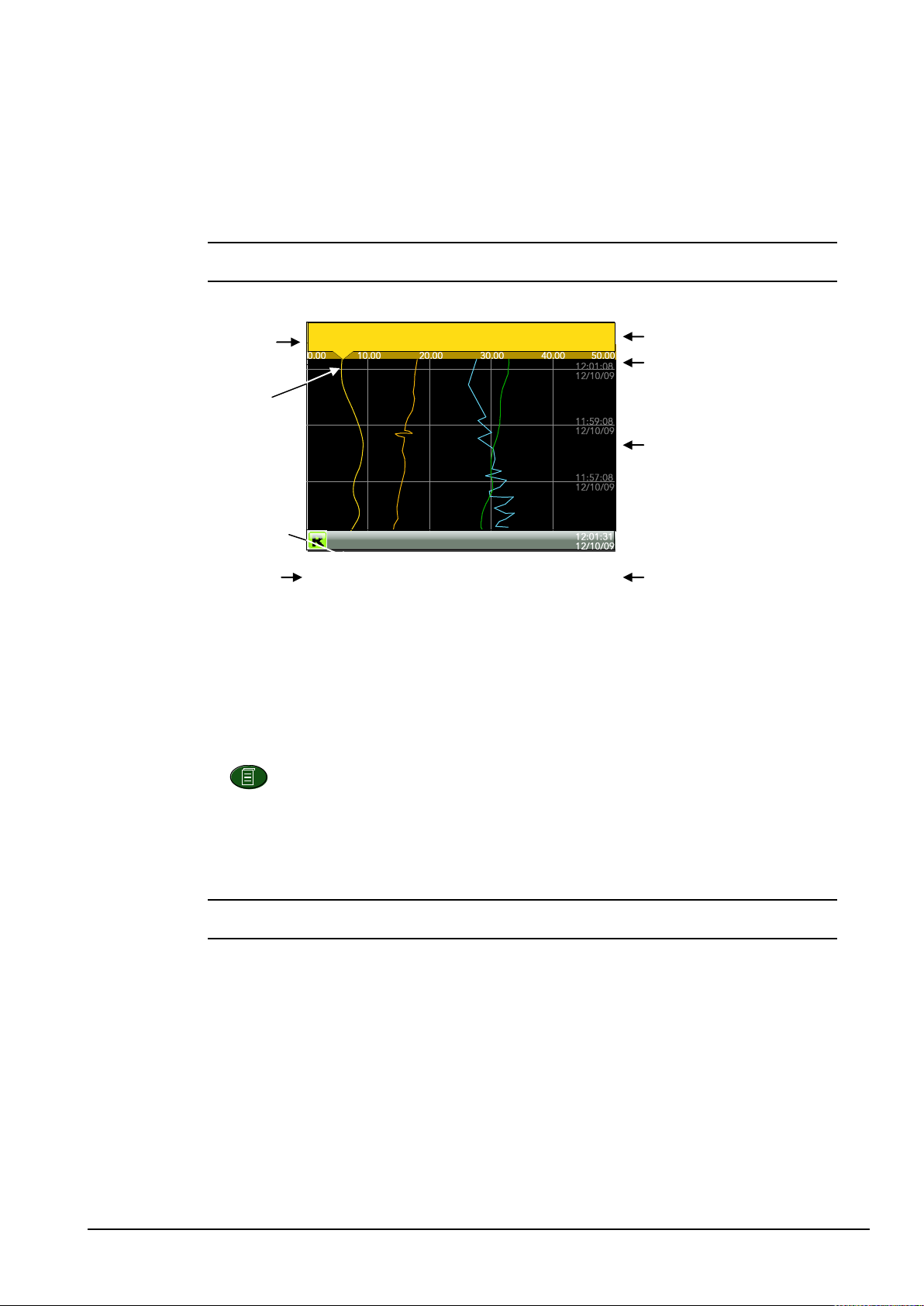

Current point value and units

Current point scale

Time/date stamps

Current time/date

Current point

name

Current point

‘pen’

Instrument name

Recording status

Channel 1

6.

23

Inst name

4.2 PROCESS VARIABLE DISPLAY

As discussed above, the operator interface consists of a display screen and associated push buttons. The

display screen shows process variables in one of a number of formats, or operational details (notes or

alarm history for example), or configuration details for use in setting up the recorder to produce the

required displays and history formats. The remainder of section four discusses the process variable

displays, alarm displays and so on; configuration details are to be found in Section 5.

Note: Some of the items below can be selected for use only by users with a suitable permission

level as set up in the ‘Instrument’ ‘Security’.

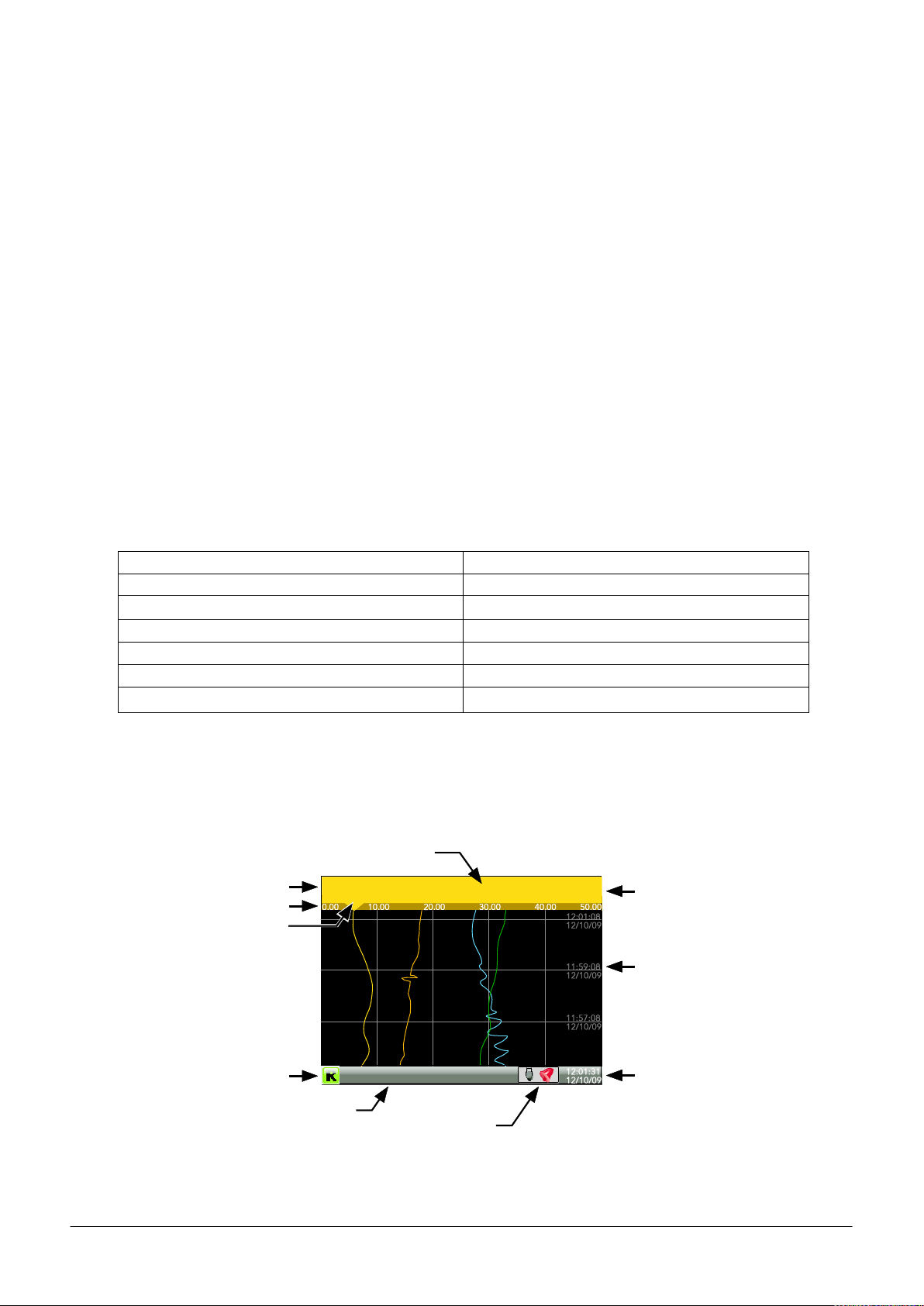

Figure 1.2 below, depicts a typical trend display and gives details of the various areas of the display page.

Figure 1.2 Typical display screen (Vertical trend)

Figure 1.2 shows a vertical trend page. Operating the Raise/Lower push-buttons allows the user to scroll

through the other display modes: Horizontal trend, Vertical bargraph, horizontal bargraph, numeric,

vertical trend... and so on. All these display modes are described in Section 4.4, below.

A display mode can also be selected from the Top level menu ‘Go To View’ item which appears when the

‘Page’ key is operated.

The scroll button can be used to scroll through the points in the group, overriding the ‘Faceplate Cycling’

on or off selection

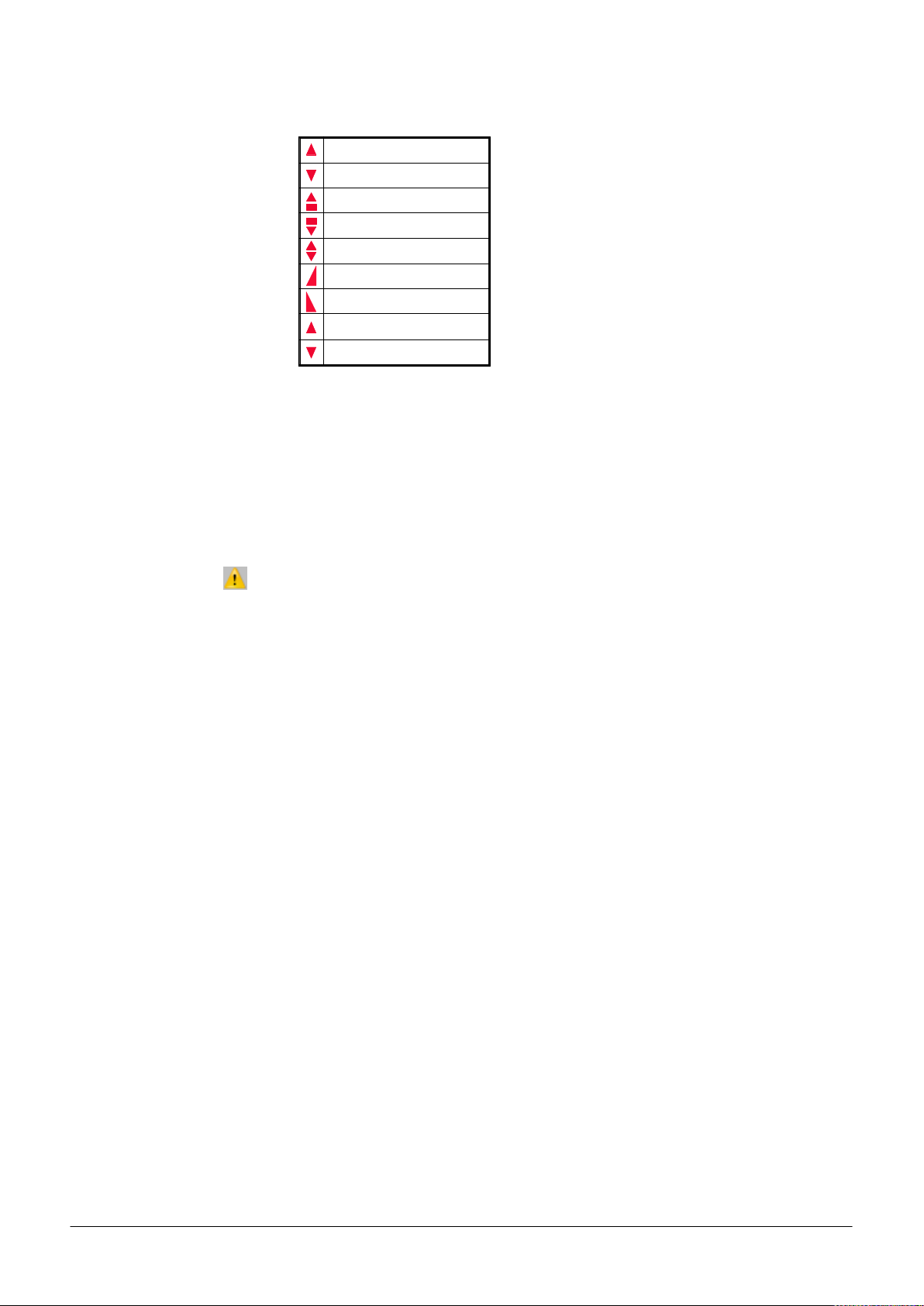

4.2.1 Alarm Icons

Note:

Trigger alarms do not display threshold marks or bars, or faceplate symbols

The alarm icons shown below appear in some display modes. The icons on a channel faceplate show the

status of that channel’s alarm(s), as follows:

Icon is flashing alarm is active but unacknowledged or it is an Auto alarm which is no longer

active but which has not been acknowledged

Icon steadily illuminated the alarm is active and has been acknowledged.

Alarm thresholds and deviation alarm bars appear for horizontal and vertical trend modes. For deviation

bars, the bar stretches from (Reference - Deviation) to (Reference + Deviation). Vertical and Horizontal

bargraph modes display only absolute alarm symbols.

9 MC27 –EN–1.04

nanodac™

Absolute High

Absolute Low

Deviation High

Deviation Low

Deviation Band

Rising Rate of change

Falling Rate of change

Digital High

Digital Low

Alarm Icons (Cont.)

4.2.2 Status Bar Icons

The following items can appear in a dedicated window immediately to the left of the time and date, at the

bottom right-hand corner of the display. The width of this window expands as the number of icons

increases, and the instrument name is truncated, as necessary, to make room.

SYSTEM ALARMS

This indicator appears, flashing, if any one or more of the alarms listed below is active. The System

Alarms summary page (accessed from ‘Go to View in the top level menu) allows the user to view such

system alarms as are active. It is not possible to ‘acknowledge’ system alarms

Archive Disabled An unattended archiving strategy has temporarily been

Archiving Failed An unattended archiving strategy has failed to complete.

Archiving Timeout A configured archiving strategy has timed out.

Battery failure Indicates that the battery is approaching the end of its useful

Broadcast Storm detected Networking is limited until the storm has passed.

Clock failure The internal clock was found to be corrupt at power up, or that

Channel error Indicates a hardware failure in the channel circuit or in the

Database failure Corrupted EEPROM or flash memory.

DHCP Server failure For units with ‘IP Type’ set to ‘DHCP’ (Network.Interface

FTP Archiving file lost A file has been deleted that had not yet been archived. Possible

FTP Archiving to slow The archive rate is too slow to prevent the internal memory

MC27 –EN– 1.04 10

Table 1.2.1 Alarm icons

disabled.

life, or that it is missing or is completely exhausted. Immediate

battery replacement is recommended (Appendix C; section C1).

the time has never been set. Time is forced to 00:00 1/1/1900.

Can be caused by battery failure, in which case a battery failure

message appears. The error is cleared by setting the time and

date.

internal cold junction temperature measurement.

configuration) this alarm occurs if the instrument is unable to

obtain an IP address from the server.

causes: Communications with the server could not be

established,; archive is disabled; archive rate too slow.

from overflowing. The recorder effectively switches to

‘Automatic’ (Section 5.1.2) to ensure that data is not lost.

nanodac™

Memory

stick fitted

Transfer in

progress

Status Bar Icons (Cont.)

FTP Primary Server Failure This error occurs if the recorder fails to establish connection

with the primary server, after two attempts. After the second

attempt fails, the recorder attempts to establish connection

with the secondary server instead. Primary and secondary

server details are entered in the Network. Archiving area of

configuration (Section 5.1.2).

FTP Secondary Server Failure This error occurs if the recorder fails to establish connection

with the secondary server, after two attempts. Primary and

secondary server details are entered in the Network.Archiving

area of configuration (Section 5.1.2).

Maths channel failure Appears if, for example, the divisor of a divide function is zero.

Media archiving file lost A file has been deleted that had not yet been archived. Possible

causes: Memory stick missing, full or write protected; archiving

has been disabled; archiving rate too slow.

Media archiving to slow The archive rate is too slow to prevent the internal memory

from overflowing. The recorder effectively switches to

‘Automatic’ (Section 5.1.2) to ensure that data is not lost.

Media full Archive storage device is full. The alarm becomes active only

when an archive is in progress.

Media missing No archive storage device present when archive attempted.

Non-volatile memory failure RAM copy of non-volatile parameters is corrupted.

Non-volatile Write Frequency warning

Recording failure (message) Message explains reason for failure.

USB overcurrent USB power fault - too much current (i.e. >100mA) is being

Wiring failure The user wiring has failed to verify, i.e. one or more wires has

One or more parameters are being written frequently to non-

volatile memory. If this continues, it may lead to ‘memory

depletion’ (i.e. the memory will no longer be able to store

values correctly). A common cause of this problem is frequent

writes over Modbus comms.

drawn by a USB device.

been detected that does not have both a source and a

destination defined. This may be the result, for example, of

power loss during a download from iTools.

11 MC27 –EN–1.04

CHANNEL ALARM

This indicator appears if any channel (including channels not in the display group) is in an alarm state. The

symbol is illuminated continuously if all alarms are acknowledged or flashes if any one or more alarms is

unacknowledged. Alarms are acknowledged from the Root menu ‘Alarm summary’ item as described in

Error! Reference source not found. or in the Channel configuration area if the user’s access permission is

appropriate.

USB

This icon appears whenever a memory stick (max. capacity 8GB) or other supported USB device (section

8) is plugged into the USB port at the rear of the recorder.

When data transfer is in progress between the instrument and the memory stick, the icon changes to a

‘busy’ version.

CAUTION

The Memory stick must not be removed while archiving (demand or automatic)

is in progress, as to do so may irreparably damage the file system of the

memory stick, rendering it unusable. It is recommended that all archiving be

suspended before the memory stick is removed.

FTP ICON

nanodac™

The FTP icon appears whenever transfer activity is taking place.

MC27 –EN– 1.04 12

nanodac™

Status Bar Icons (Cont.)

RECORD ICON

One of four icons appears at the bottom left corner of the display to indicate recording status.

Record

This indicates that the recorder is recording the items selected in the Group Recording area of

configuration (Section 5.2.2).

Stopped

This means that ‘Enable’ has been set to ‘no’ in the Group Recording area of configuration (Section 5.2.2).

Trending is not affected.

Paused (Suspended)

This means that recording has been paused by a wire to the Suspend parameter (Group Recording area of

configuration going true (high). Trending is not affected.

In Configuration

The recorder has been placed in configuration mode either at the user interface, or via iTools. Recording

is stopped until the recorder is no longer in configuration mode. For each non-recording state (Stopped,

Paused or In Configuration). A new history file is created when the unit comes out of configuration mode.

Note: For recording to be enabled, configuration status must be ‘logged out’ both at the

instrument and at iTools.

MESSAGE ICON

This ‘envelope’ icon appears when a message is generated and it remains on display until the Message

Summary is accessed, when it is removed from the display until the next new message is generated.

AUTOTUNE ICON

For instruments fitted with the Loop option, this symbol appears during the Autotune process.

4.2.3 Breaks in recording

Breaks in recording can be caused by the unit being powered down, by the user entering configuration

mode or when the recorder time is changed manually. In vertical and horizontal trend modes, a line is

drawn across the width/height of the chart to indicate that recording has been interrupted.

On power up, a red line is drawn across the chart. In ‘History’, if messages are enabled the message:

Date Time System power up

is printed on the chart, together with the configuration and security revisions.

On exiting configuration mode, a blue line is drawn on the chart and in ‘History’, if messages are enabled,

the messages:

Date Time Logged out.

Date Time Config Revision: N was N-1 (assuming a configuration change was made)

Date Time Logged in as: Engineer

appear on the chart.

When the instrument time is changed (manually - not through daylight saving action) a green line is

drawn on the chart and in ‘History’, if messages are enabled, the message:

Date Time Time/Date changed

appears on the chart.

13 MC27 –EN–1.04

nanodac™

Page key

Scroll key

Home

Configuration

Go to View

History

Faceplate Cycling (On)

Operator Nores

Demand Archiving

Log Out

Section 4.3.1

Section 4.3.2

Section 4.3.3

Section 4.3.4

Section 4.3.5

Section 4.3.6

Section 4.3.7

Section 4.3.8

4.3 TOP LEVEL MENU

This menu appears when the page key is operated from any non-configuration page. The menu items

displayed depend on the access permission of the user. One of the menu items is highlighted, and if the

scroll key is operated, then it is the highlighted item that is ‘entered’.

Figure 1.3 shows the top level menu for Engineer level access.

Figure 1.3 Top level menu

4.3.1 Home

Operating the scroll key whilst ‘Home’ is highlighted causes a return to the ‘Home’ page.

4.3.2 Configuration

Operating the down arrow key highlights the ‘Configuration’ item. Operating the Scroll key enters the

configuration submenu described in Section 5 of this manual.

Note: ‘Configuration’ appears only if the user has an appropriate access level.

MC27 –EN– 1.04 14

4.3.3 Go to View

Alarm Summary

System Alarms

Message Summary

Vertical Trend

Horizontal Trend

Vertical Bargraph

Horizontal

Bargraph

Alarm Summary

System Alarms

Message Summary

Vertical Trend

Horizontal Trend

Vertical Bargraph

Horizontal Bargraph

Numeric

Alarm Panel

Control

Control (Dual Loop)

Cascde

Programmer

Steriliser

Promote List

Modbus Master

EtherNet/IP

Alarm Panel

Control

Dual Loop

Cascade

Programmer

Steriliser

Promote List

Modbus Master

EtherNet/IP

Operating the scroll key whilst the ‘Go to view’ item is highlighted, calls the Go to view submenu (figure

1.3.3a). This allows the user to view channel alarms, system alarms, messages or to select a different

display mode.

Figure 1.3.3a Go to view submenu

Notes:

1. If an option (e.g. ‘Steriliser’) is not fitted, its display mode does not appear in the list.

2. Some display modes must be enabled in Instrument. View configuration before they become

available.

nanodac™

15 MC27 –EN–1.04

nanodac™

Page key

Scroll key

Alarm Summary

Furnace 1 temp 1 750.00 798.39

Furnace 1 temp 3 750.00 763.39

Furnace 1 temp 2 590.00 603.39

Furnace 2 temp 1 750.00 630.71

Channel descriptor

Channel ID (Alarm

number)

Alarm threshold

Channel current process value

Alarm type indicator

C

1(

2

)

C

N

C

ANC

A

Alarm Summary

Furnace 1 temp 1 750.00 798.39

Furnace 1 temp 3 750.00 763.39

Furnace 1 temp 2 590.00 603.39

Furnace 2 temp 1 750.00 630.71

C

1(

2

)

C

Acknowledge alarm?

Acknowledge alarm?

Go To View (Cont.)

ALARM SUMMARY

For each active alarm, this page displays the channel identifier with alarm number (e.g. C1(2) = channel 1;

alarm 2), the channel descriptor, the alarm threshold the current process value and an alarm type symbol.

To return to the top level menu, operate the Page key.

ALARM ACKNOWLEDGEMENT

To acknowledge an alarm from this view:

1. Use the up and down arrows to highlight the

2. Operate the scroll button. The ‘Acknowledge

3. Use the up arrow to highlight the relevant field

4. Operate the scroll key to confirm. If the alarm

SYSTEM ALARMS

Operating the scroll button whilst the ‘System Alarms’ field is highlighted displays a list of all currently

active system alarms. Status Bar Icons contains a list of system alarms and their interpretations. To

return to the top level menu, operate the Page key.

A further operation of the scroll button displays a ‘Help Information’ page, giving the reason for the

highlighted alarm.

Operate the scroll button again to return to the system alarm display.

MC27 –EN– 1.04 16

Notes:

1. The background colour to the channel ID is the same as that chosen for the channel.

2. A prefix ‘C’ in the channel ID means that this is a measuring channel; A prefix ‘V’ means that

this is a virtual channel (i.e. a totaliser, counter or maths channel)

Figure 1.3.3b Alarm summary page with acknowledge confirmation display

required alarm

alarm’ window appears.

(C2(1) in this example), or ‘All’ if all alarms are

to be acknowledged.

fails to respond, this may be due to the fact that it has been configured as a ‘Manual’ alarm, and the

trigger has not yet returned to a ‘safe’ (non-alarm) state, or it could be that the instrument is in a

logged out state.

Go To View (Cont.)

Alarm Summary

Furnace 1 temp 1 750.00 798.39

Furnace 1 temp 3 750.00 763.39

Furnace 1 temp 2 590.00 603.39

Furnace 2 temp 1 750.00 630.71

C

1(

2

)

C

AC1(2)

Acknowledge alarm?

Alarm Summary

Furnace 1 temp 1 750.00 798.39

Furnace 1 temp 3 750.00 763.39

Furnace 1 temp 2 590.00 603.39

Furnace 2 temp 1 750.00 630.71

C

1(

2

)

C

AC1(2)

Acknowledge alarm?

Message Summary

20/11/09 08:06:37 Inactive: Ch1(Al1)

20/11/09 08:06:29 Active: Ch2(Al1)

20/11/09 08:06:22 Active: Ch1(Al1)

20/11/09 08:06:19 Inactive: Ch2(Al2)

20/11/09 08:06:18 Inactive: Ch1(Al2)

20/11/09 08:06:09 Inactive: Ch2(Al1)

20/11/09 08:06:01 Active: Ch1(Al2)

20/11/09 08:05:59 Active: Ch2(Al1)

20/11/09 08:05:22 Battery flat less than 5% re

20/11/09 08:05:22 Power up

All Messages

Refresh

Exit Messages

Go to?

Summary

History

20/11/14

08:05:22

Battery flat less than 5%

remaining

To Trend History

display (Section 4.5)

Use scroll button to scroll through ‘All Messages’,

‘System’, ‘Alarm’ and ‘Power Up’. Use page

button to confirm selection

Use scroll button to return to refreshed Message

Summary page.

Use the scroll or page button to return to the top

level menu.

MESSAGE SUMMARY

Operating the scroll key whilst the ‘Message summary’ field is highlighted displays the10 most recent

messages.

Operating the scroll key whilst a message is highlighted shows the selected message in more detail (and

using the up/down keys allows the other messages to be scrolled through). Whilst in this mode, operating

the scroll key again, allows the user to choose to jump to the message’s location in trend history mode

(Section 4.5) or to return to the summary page.

By default, the interface is set up such that:

1. all message types are included

2. the up and down arrow keys cause the highlighted selection to move up or down by one message at a

time.

MESSAGE FILTERS

All Messages Causes all messages to be displayed on the screen.

System Shows only system alarms

17 MC27 –EN–1.04

Alarm Shows only channel alarms

Power up Shows only power up messages

Login/out Limits the display to Log in and Log out events.

nanodac™

Figure 1.3.3c Message summary features

nanodac™

Alarm Summary

System Alarms

Message Summary

Vertical Trend

Horizontal Trend

Vertical Bargraph

Horizontal

Bargraph

Alarm Panel

Control

Control (Dual Loop)

Cascde

Programmer

Steriliser

Promote List

Modbus Master

EtherNet/IP

Go To View (Cont.)

DISPLAY MODE SELECTION

Use the up/down arrow buttons to highlight the required display

mode. Once the required display mode is highlighted, operation of

the scroll button causes the recorder to leave the ‘Go to View’ menu

and to display channel values in the selected mode. See Section 4.4

for a description of the various display modes.

Alternatively the up and down arrow buttons can be used from any of

the display modes to cycle through the available modes in the order

listed in the figure.

Notes:

1. If an option (e.g. ‘Steriliser’) is not fitted, its display mode

is not available for selection.

2. Some display modes must be enabled in Instrument.

Display configuration before they become available.

4.3.4 History

This top level menu item allows the user to switch from real-time

trending to review mode, where channel values, messages, alarm

triggers etc. can be viewed back as far as the last significant

con.figuration change. History mode is discussed in Section 4.5

4.3.5 Faceplate Cycling on/off

For the purposes of this document the channel whose faceplate is currently displayed and whose ‘pen’

symbol is visible is called the ‘Active’ channel.

By default, the recorder scrolls through all the channels in the display group, with each channel becoming

the active channel in turn. This top level menu ‘Faceplate Cycling’ item allows the user to inhibit this

scrolling action such that the currently active channel remains active permanently, or until a manual scroll

is performed using the scroll button (or until Faceplate Cycling is re-enabled).

‘Faceplate Cycling’ is highlighted by using the up/down arrow buttons. Once highlighted, the status can

be changed from ‘On’ to ‘Off’ or vice-versa using the scroll button. Operation of the ‘Page’ button returns

the user to the trend display.

4.3.6 Operator Notes

This area allows up to 10 notes to be created when logged in as Engineer, using either the text entry

techniques described in Section 4.6, or ‘iTools’ described in Section 6. Once logged out, operating the

scroll button whilst a note is highlighted calls a selection box allowing the user either to send that note to

the chart, or to write a Custom Note.

CUSTOM NOTE

The Custom Note is written using the text entry techniques described in Section 4.6. Once the note is

complete, operation of the page button calls a confirmation display. The down arrow is used to highlight

‘Yes’, and when the scroll key is then operated, the message is sent to the chart. This custom message is

not retained for further use, so if it is required on a regular basis, it is suggested that one of the Operator

Notes 1 to 10 be configured (Engineer access level required) so that it may be used instead.

Note: Each note can contain up to 100 characters.

4.3.7 Demand Archiving

This allows a user, with a high enough access level, to archive a selected portion of the recorder history,

either to a ‘memory stick’ plugged into the USB port at the rear of the recorder (Local Archiving), or to a

pc, by means of the FTP protocol (Remote Archiving). The archived data remains in the flash memory of

the instrument. When the flash memory is full, new data causes the oldest file(s) to be discarded.

The up and down arrow keys are used to navigate to the required field.

MC27 –EN– 1.04 18

Archive To

Archive

Suspend Schedule

Cancel All

Status

Last Archive

USB

None

No

No

Complete

02/11/2011 11:37:09

Demand Archiving

Archive To

Archive

Suspend Schedule

Cancel All

Status

Last Archive

FTP Server

None

No

Complete

Connecting

02/11/2011 11:37:09

Demand Archiving

19 MC27 –EN–1.04

Demand Archiving (Cont.)

ARCHIVE MENU

Figure 1.3.7 Demand Archiving menu (Local Archiving on left; Remote Archiving on right)

Archive To With this item highlighted, the scroll button and the up/down arrows can be used

Archive In a similar way, select the archive period:

Last Day: Archive all files created in the last 24 hours.

Last Week: Archives all files created in the past seven days.

Last Month: Archives all files created in the past 31 days.

Archive All: Archives all the files in the recorder’s history.

Bring To Date: Archives all files created or updated since the ‘Last Archive’ date

Suspend Schedule When set to ‘Yes’, automatic (scheduled) archiving is stopped, once the transfer of

Cancel All When set to ‘Yes’, this cancels USB archiving activity immediately, or cancels FTP

Last Archive Shows the date and time at which the last archive (demand or automatic) was

Status For Archive to USB only

PriStatus For Archive to FTP Server only, this shows the transfer status between the

SecStatus For Archive to FTP Server only, this shows the transfer status between the

nanodac™

to select ‘USB’ or ‘FTP Server’.

For ‘USB’, the archive will be made to the rear USB memory stick. For ‘FTP Server’

the archive will be made to the Primary or Secondary server (configured in the

Network.Archive area of configuration described in Section 5.1.2. For more details

about remote archiving, see ‘Remote archiving’, below.

None: No archiving to take place. (Not editable when logged out)

Last Hour: Archives all files created within the last 60 minutes.

and time.

the current file is complete. Suspend Schedule must be set to ‘No’ again, to restart

the suspended archive. Suspend can be used to allow the memory stick to be

removed and re-fitted safely.

archiving once transfer of the current file (if any) is complete.

attempted. If a demand archive is requested, or is in operation when an automatic

archive is triggered, the automatic archive takes precedence.

‘Complete’ means that no archiving is currently taking place.

‘Transferring’ indicates that an archiving is in progress. Accompanied by an

animated circular display.

‘Suspended’ means that archiving has been suspended as requested.

instrument and the primary host computer.

instrument and the secondary host computer.

nanodac™

Demand Archiving (Cont.)

FTP SERVER ARCHIVING

This allows the archiving of recorder files to a remote computer via the RJ45 type connector at the rear of

the recorder, either directly or via a network.

In order to carry out a successful transfer:

1. Details of the remote host must be entered in the Network.Archive area of configuration (Section

5.1.2).

2. The remote computer must be set up as an FTP server. Help from the user’s IT department may be

necessary in order to achieve this. Appendix C, Section C2 to this manual suggests one way, using

Filezilla.

3. The remote computer must also be set up to respond to ‘pings’. This is because the instrument pings

the host whilst establishing connection, and if it does not receive a response the archive attempt

fails.

When accessing files using Microsoft® Internet Explorer, the address (URL) field can be in one of two

formats:

1. ftp://<instrument IP address>. This allows a user to log in as the anonymous user (if the recorder has

any account with the user name set to ‘anonymous’ with a blank password.

2. ftp://<user name>:<password>@<instrument IP address> to log in as a specific user.

For IE5 users, Microsoft® Internet Explorer displays, by default, history files only. To quit the history

folder, either uncheck the Tools/Internet Options/Advanced/Browsing/’Enable folder view for FTP sites’

option, or check the Tools/Internet Options/Advanced/Browsing/’Use Web based FTP’ option.

REVIEW SOFTWARE

‘Review’ is a proprietary software package which allows the user to extract ‘archive’ data from one or

more suitable instruments* and to present this data on a host computer, as if on a chart, or as a

spreadsheet. The host computer must be set up as an ftp server (see Appendix C section C2 for a

description of one way of doing this).

As described in the Review help system, ‘Review’ allows the user to set up a regular transfer of data (using

ftp) from connected instruments into a database on the pc, and then from this database to the chart or

spreadsheet. The chart/spreadsheet can be configured to include one or more ‘points’ from one or all

connected instruments (where a ‘point’ is an umbrella term for channel, totaliser, counter etc.).

It is also possible to archive instrument history files to a memory stick, Compact Flash card etc.

(depending on instrument type) and to use this to transfer the data to the pc.

Each type of instrument has its own remote user name and password configuration - for this instrument,

the user name and password are both ‘history.

*Suitable instruments are connected instruments, the archive files of which have the suffix ‘.uhh’.

4.3.8 Login

Login allows the user to enter a password in order to gain access to areas of the unit’s configuration which

are not available when the user is logged out.

LOGGED OUT ACCESS LEVEL

Logged out mode allows the user to select viewing mode, to view history, to view alarms, to toggle

faceplate cycling on and off, to send notes, to suspend/resume USB archiving and to access the login

process.

OPERATOR ACCESS LEVEL

In addition to the logged out features, Operator access level allows the user to acknowledge alarms, to

edit notes and to perform demand archive operations.

By default, no password is required in order to enter Operator level, but a password can be set either at

Supervisor level or at Engineer level. (See section 1)

MC27 –EN– 1.04 20

nanodac™

Record icon

Configuration

icon

Logged out

Operator

Supervisor

Engineer

Engineer Access

Access

Access

Access

Access

Password

Password

Password

Accept changes

Cancel

No

Yes

Login (Cont.)

SUPERVISOR ACCESS LEVEL

In addition to the logged out level function, this access level allows the user to view the recorder’s

configuration, and to edit some values (such as alarm thresholds). By default, there is no password

required to enter Supervisor level, but a password can be set in the Instrument area of configuration,

either at Supervisor level or at Engineer level. (See section 1)

ENGINEER ACCESS LEVEL

This allows full access to all areas of the recorder configuration. The default password is 100, but this can

be edited in the Instrument area of configuration (See section 1).

Note: recording is stopped for as long as the user is logged in at Engineer level,

even if the recorder is not being configured. This is indicated by the Record icon

at the bottom left corner of the process value display screen being replaced by

the Configuration (wrench) icon.

LOGIN PROCEDURE

From the top level menu, use the up or down arrow keys as often as necessary in order to highlight

‘Login’, and then operate the Scroll key to produce the ‘Access Logged out’ display.

Note: this procedure describes how to login to an access level with a password associated with it.

For non-password protected logins, the user needs only to select the required access level, and

press the scroll key.

21 MC27 –EN–1.04

nanodac™

Vertical trend Section 4.4.1

Cascade Section 4.4.8

Horizontal trend Section 4.4.2

Programmer (inc. future trend) Section 4.4.9

Vertical bargraph Section 4.4.3

Horizontal bargraph Section 4.4.4

Promote list Section 4.4.10

Numeric Section 4.4.5

Modbus Master Section 4.4.11

Alarm panel Section 4.4.6

EtherNet/IP Section 4.4.12

Control loop 1/2 Section 4.4.7

Faceplate

Current point name

Current point scale

Current trace ‘pen’

Recording symbol

Current point value

Time/date stamp

Current time/date

Instrument name

Status icons

To log in as Engineer (See section 1):

1. Operate the up arrow key three times, to display ‘Engineer’.

2. Press the scroll key to call the ‘alpha’ keyboard, with the letter ‘q’ highlighted.

3. Use the down arrow key three times to highlight ‘Numeric’.

4. Operate the scroll key to display the numeric keyboard (numeral ‘1’ highlighted.)

5. Use the up and down arrow keys to select the numbers and use the scroll key to enter them.

6. Use the Page key to call the confirmation display.

7. If the password entry is as required, use the up arrow twice (or the down arrow once) to highlight the

word ‘Yes’ and operate the scroll key to confirm. The top level configuration menu appears.

Otherwise, ‘Cancel’ can be used to clear the entry in order to start again, or ‘No’ can be used to quit

login.

4.4 DISPLAY MODES

The following subsections describe the various display modes available to the user. By default, the ‘Home’

display mode is ‘Vertical Trend’, but this can be edited as a part of ‘Instrument.Display’ configuration. This

configuration area also allows the user to disable one or more display modes should they not be required.

The current display mode can be chosen either by using the top level menu ‘Go to View’ item or, from any

display mode, by scrolling through the enabled modes using the up or down arrow button.

Details of the various display modes are to be found in the following subsections:

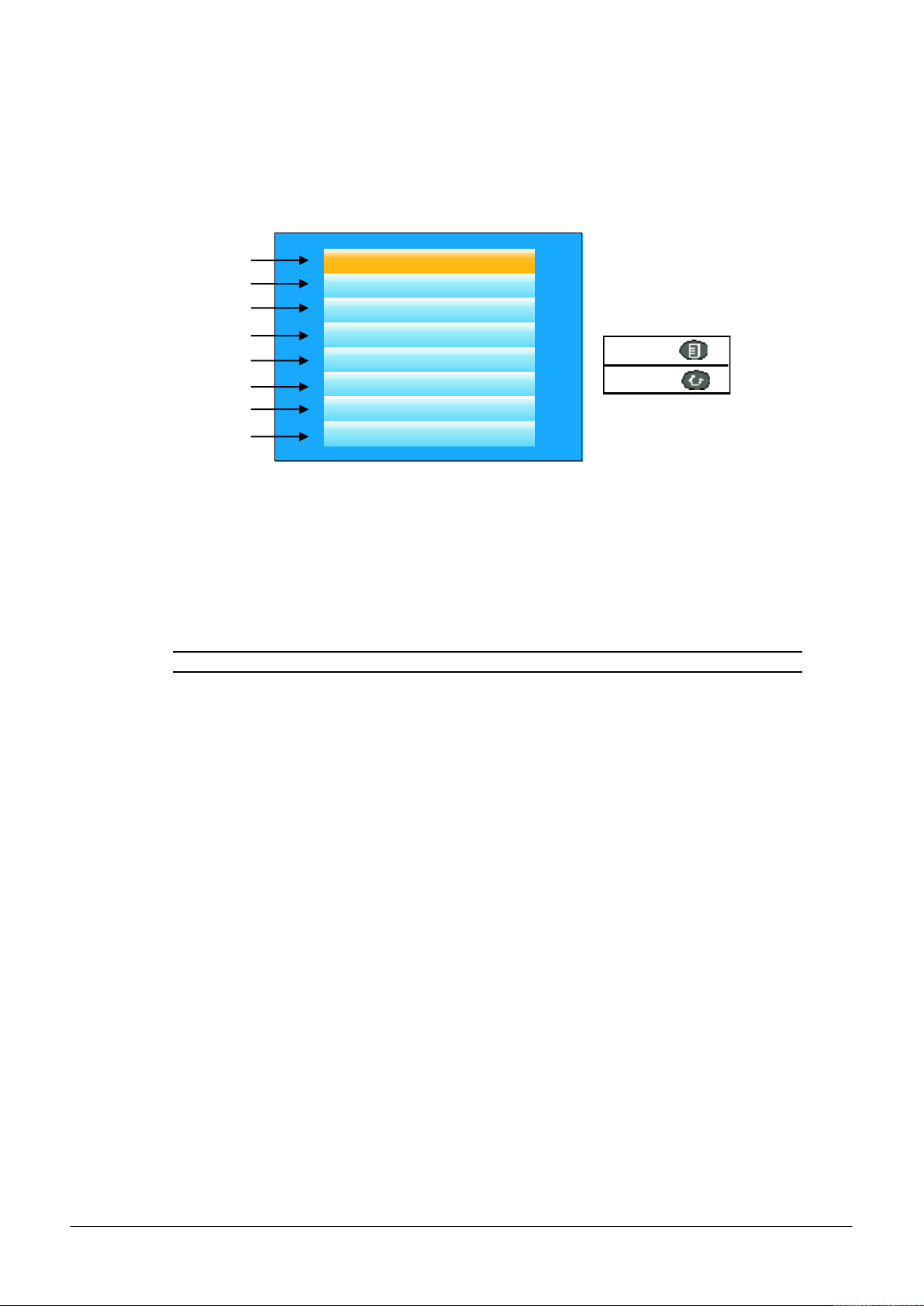

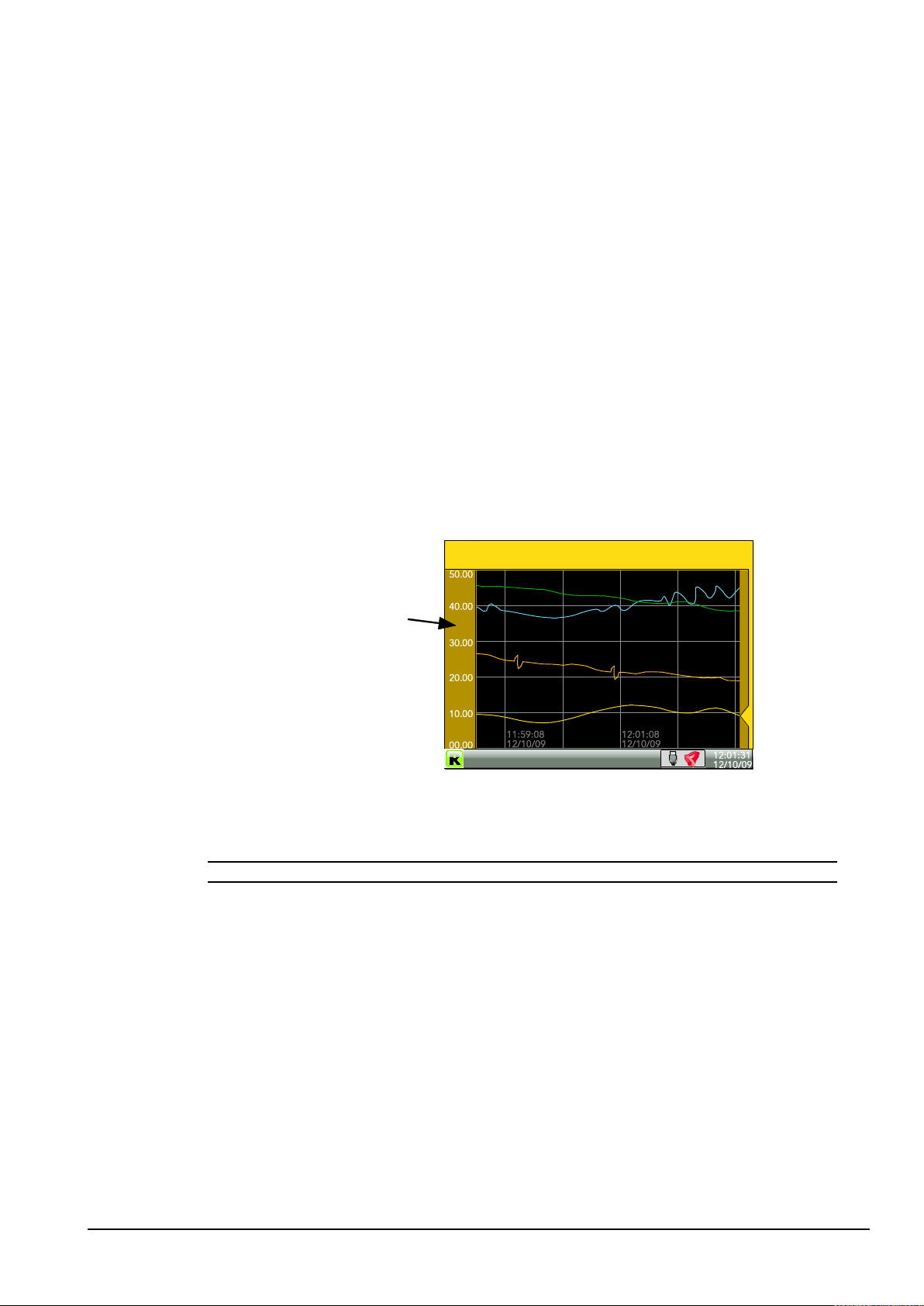

4.4.1 Vertical Trend

In this mode, channel values are traced as though on a chart rolling downwards (i.e with the latest data at

the top). The chart speed, and the number of major divisions are configured in the ‘Group.Trend’ area of

configuration (5.2.1).

Figure 1.4 Vertical trend mode display elements

MC27 –EN– 1.04 22

nanodac™

By default, after a few seconds, the

‘chart’ expands leftwards to hide the

scale.

One of the channels is said to be the ‘current’ or ‘scale’ channel. This channel is identified by its pen icon

being displayed, and by the channel descriptor, dynamic value and its scale being displayed on a

‘faceplate’ across the width of the display, above the chart.

Each channel in the Group becomes the ‘current’ channel in turn, for approximately five seconds -i.e. the

channels are cycled through, starting with the lowest numbered channel. Once the final channel in the

Group has been displayed for five seconds, the first channel is returned-to and the process repeats. This

scrolling behaviour can be enabled/disabled from the top level menu ‘Faceplate Cycling (Off)’ item

described in Section 4.3.5

.

The scroll button can be used to cycle through the channels manually in both Faceplate cycle on and off

modes.

Use of the up arrow button causes the next enabled display mode to be entered (default = horizontal

trend).

The page key calls the top level menu.

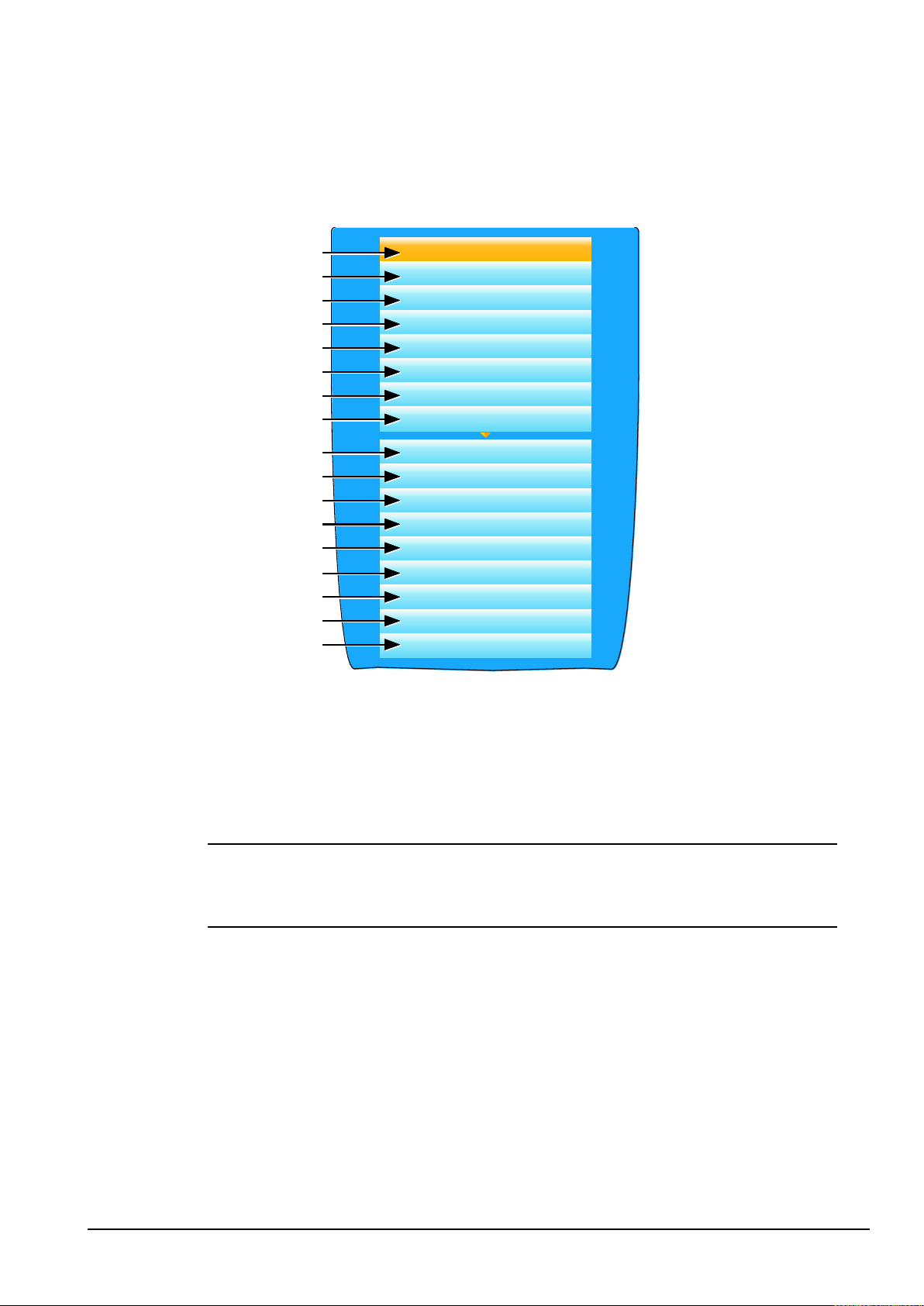

4.4.2 Horizontal Trend mode

This view is similar to the vertical trend mode described in section 3.4.1 above, except that the traces are

produced horizontally rather than vertically. Initially, as each channel appears, its scale appears at the left

edge of the display (as shown below), but in order to show the maximum amount of trend data, the scale

is overwritten after a few seconds.

Figure 1.4.2 Horizontal trend display mode

Use of the up arrow button causes the next enabled display mode to be entered (default = vertical

bargraph). Use of the page key calls the top level menu.

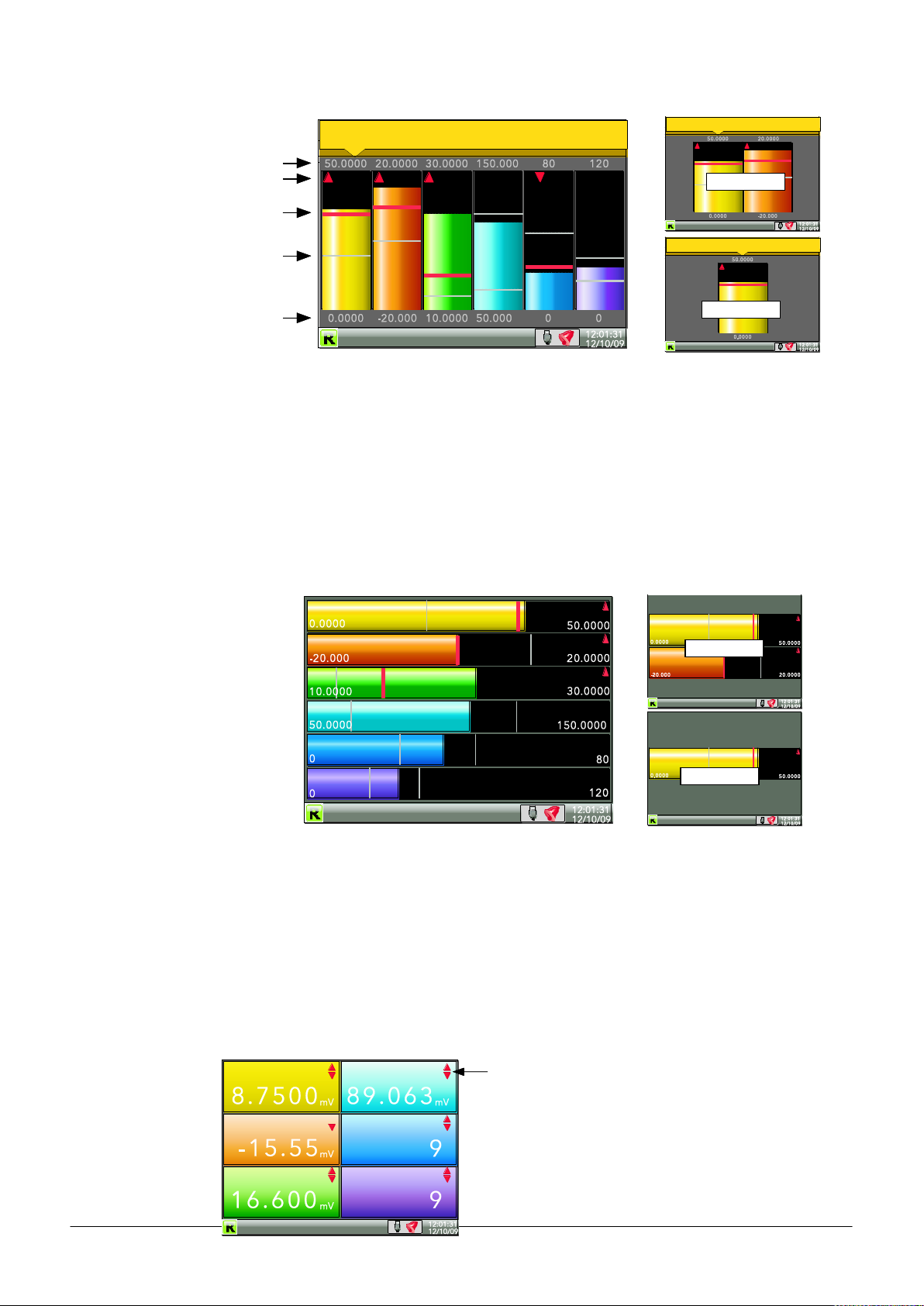

4.4.3 Vertical Bargraph mode

This display mode shows the channel values as a histogram. Absolute alarm threshold values appear as

lines across the bars, grey if the alarm is not triggered; red if the alarm is triggered. Alarm symbols appear

for active alarms.

Bargraph widths for four to six channels divide the width of the display screen equally between them. For

one and two channels, the width is fixed, and the bars are centred on the screen. Figure1.4.3 shows some

examples (not to the same scale).

23 MC27 –EN–1.04

Note: Timestamps appear to the right of the gridline to which they relate

nanodac™

Full scale value

Active alarm symbol

Alarm threshold (active)

Alarm threshold (non-active)

Zero value

2 channels

1 channel

Inst name

Furnace 1 temp 12

Channel 2

Channel 3

Channel 4

Virtual Chan 1

The scroll button

toggles the text

between point

descriptor (as shown)

and point value.

2 channels

1 channel

Alarm type indication

(table 1.2.1)

Figure 1.4.3 Vertical bargraph display mode

Use of the up arrow button causes the next enabled display mode to be entered (default = horizontal

bargraph). Use of the page key calls the top level menu.

4.4.4 Horizontal Bargraph mode

Similar to the Vertical bargraph mode described in Vertical Bargraph mode above, but includes channel

descriptors.

Figure 1.4.4 Horizontal bargraph mode

Use of the up arrow button causes the next enabled display mode to be entered (default = numeric).

Use of the page key calls the top level menu.

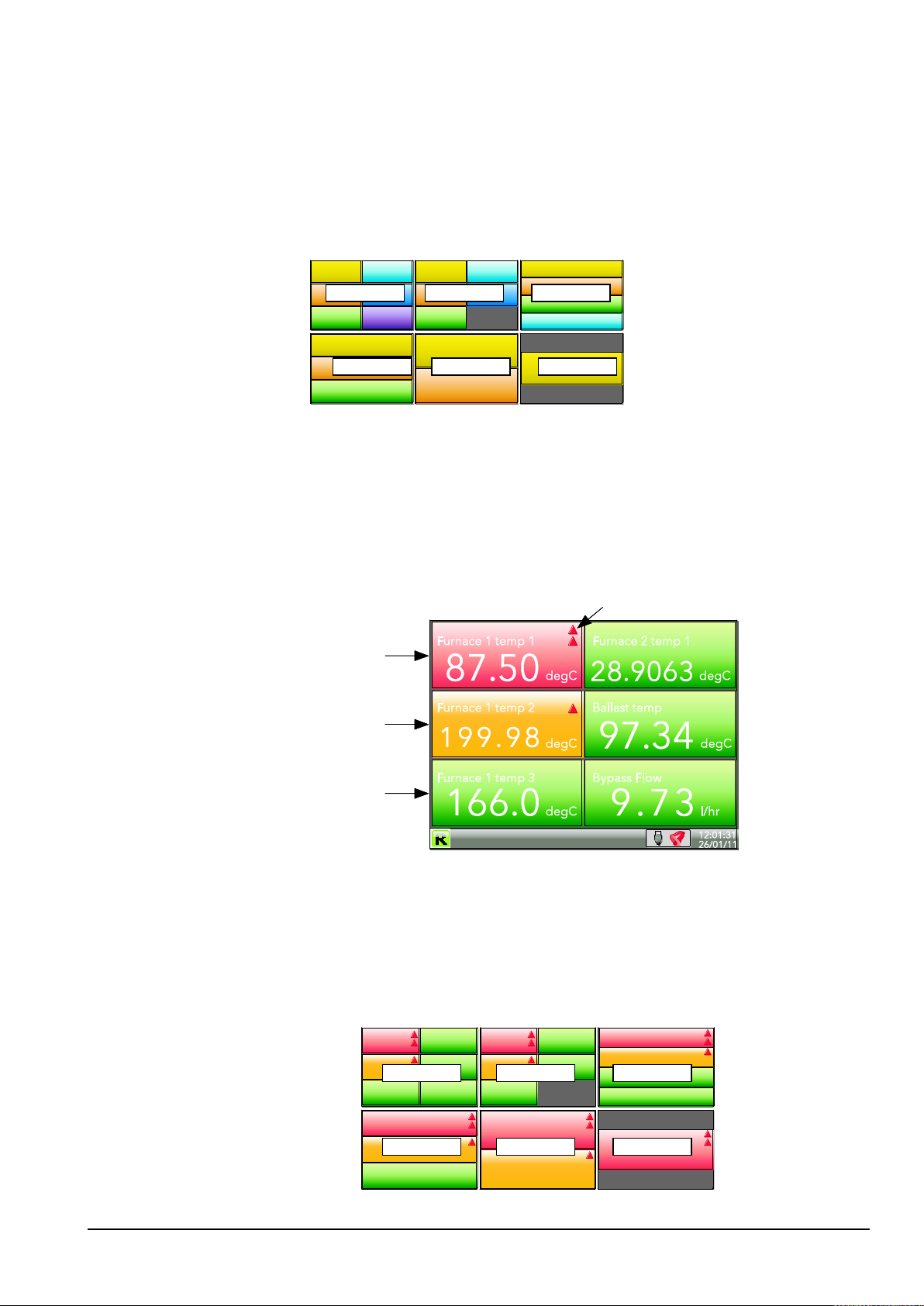

4.4.5 Numeric mode

Shows the enabled channels’ values along with their descriptors and with indications of the type(s) of

alarm configured for each channel.

MC27 –EN– 1.04 24

nanodac™

6 channels

5 channels

4 channels

3 channels

2 channels

1 channel

6 channels

5 channels

4 channels

3 channels

2 channels

1 channel

Red bar

Alarm 2 is active, or alarm 1 and

alarm 2 are both active.

Amber bar

Alarm 1 is active for this

channel, but not alarm 2

Green bar

Neither alarm 1 nor alarm two

active for this channel.

Alarm type indication (table 3.2.1)

Figure 1.4.5a Numeric display mode (six enabled channels)

The figure above shows an example where the Trend group contains six channels. Figure 1.4.5b shows

how the display appears for trend groups with fewer than six channels configured.

Figure 1.4.5b Display layout for different numbers of channels

The up arrow button returns to the vertical trend display mode; the page key calls the top level menu.

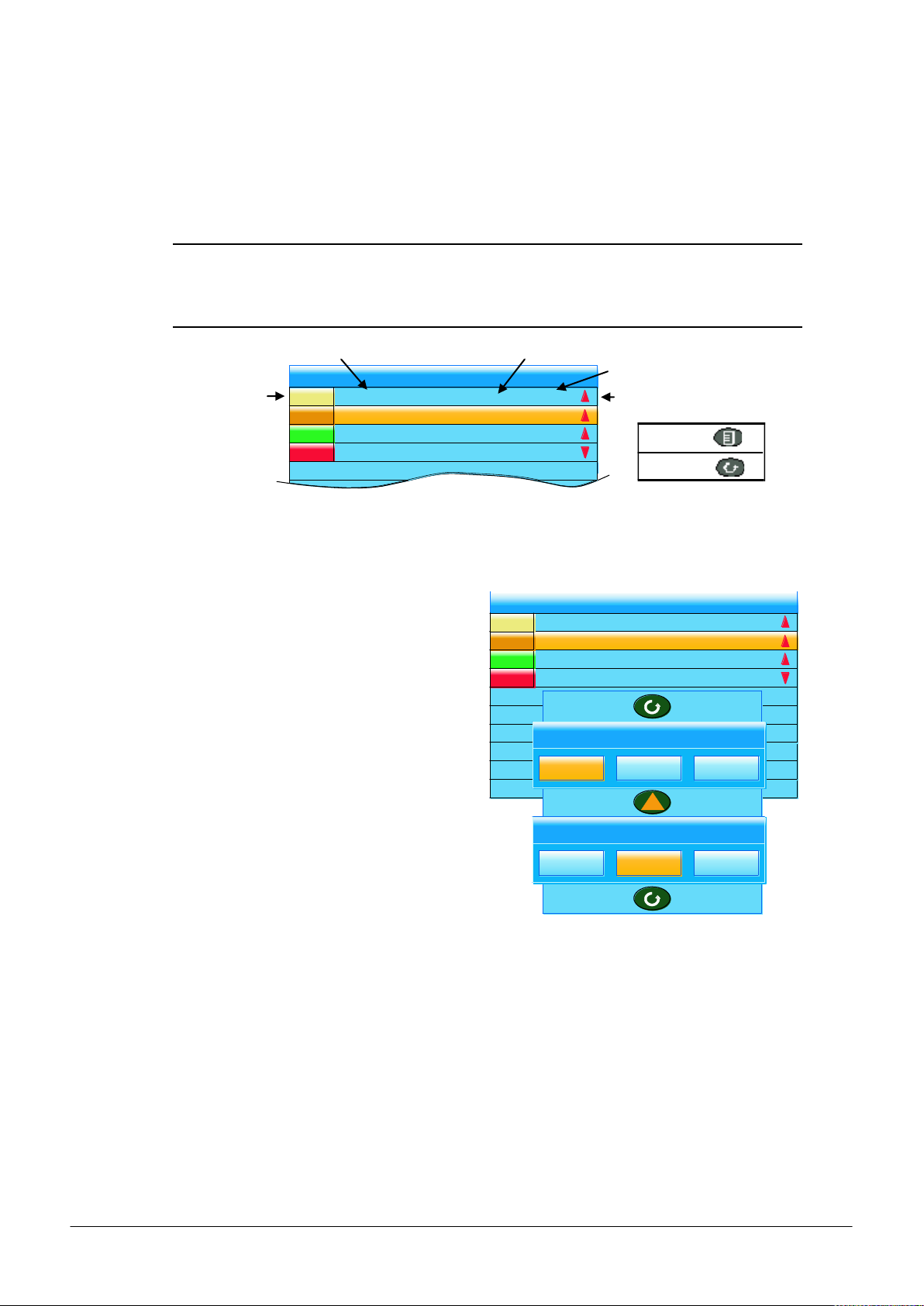

4.4.6 Alarm panel

This display appears only if enabled in the Instrument Display configuration. Alarm panel mode shows

current value and alarm status for each channel enabled in the Trend Group. The status is shown in two

ways, by the colour of the relevant bar, and by the alarm status indicators.

Figure 1.4.6a Alarm panel display (six channels)

The figure above shows an example where the Trend group contains six channels. Figure 1.4.6b shows

how the display appears for trend groups with fewer than six channels configured.

25 MC27 –EN–1.04

nanodac™

PV

wSP

Working Output

SP

SP1

Mode

PV

wSP

SP1

Mode

Man OP

SP1

Mode

Man OP

Loop 1

O

C

Loop 1

Manual

PV

wSP

Manual

Inst name

Inst name

SP1

Mode

Man OP

SP1

Mode

Man OP

SP1

Mode

Man OP

SP1

Mode

Man OP

SP1

Mode

Man OP

Figure 1.4.6b Alarm panel display layouts for trend groups with fewer than six channels

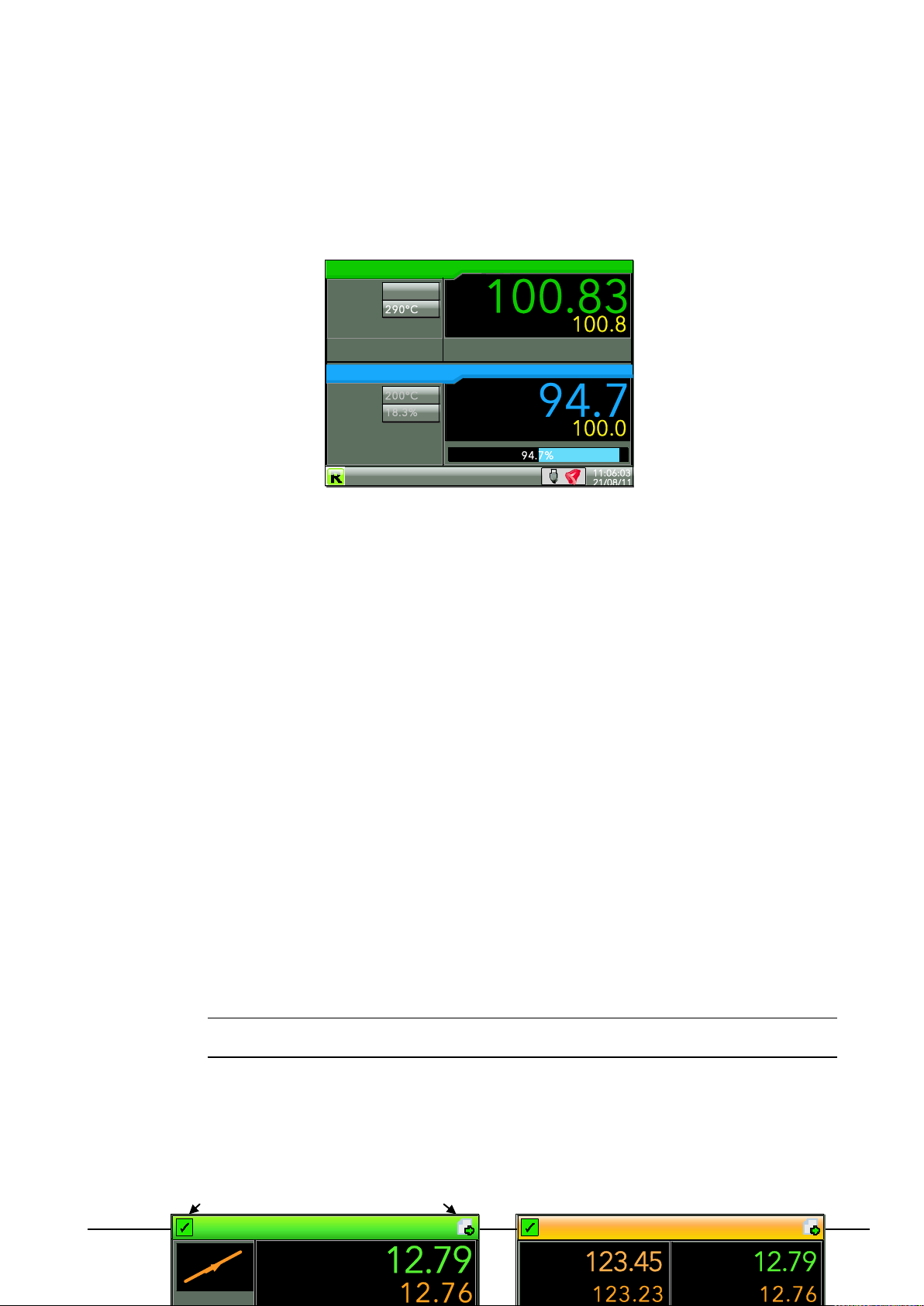

4.4.7 Control Loop1/Loop2

These displays appear only if the controller option is enabled.

The loop display modes are interactive, in that the setpoint, the Auto/Manual mode and the Manual

Output value can be edited from the user interface. Full configuration is carried out in the Loop setup

menus and a fuller description of control loops is to be found as Appendix B to this manual.

Figure 1.4.7 depicts a single loop display and the dual loop display. The up and down arrow keys are used

as normal to scroll through Loop1, Loop2 and Dual loop pages.

Figure 1.4.7 Loop displays

Note: The colours associated with the loops are those of the channels to which they are wired.

EDITING TECHNIQUES

1. With the loop page on display, operate the Scroll key. This highlights the

first editable item (SP1). The scroll order includes both loop1 and loop 2

parameters in the dual loop display.

2. Use the up and down arrow keys to select the required field for editing.

When the required field is highlighted, operate the scroll key again, to

enter edit mode.

3. Use the up/down arrows to edit the current setting.

4. Operate the scroll key to confirm the edit.

5. Select a further parameter for editing, or operate the page key to return

to normal operation.

Note: Edit permissions for Setpoint, Auto/Manual and Manual Output Access are set in the Loop

Setup configuration menu.

MC27 –EN– 1.04 26

nanodac™

Mode

Sp1

SP

Man.OP

Inst name

PV

wSP

Master

PV

Program Name (Segment name)

Program Name (Segment name)

Ramp

PV PV

Program status

Program edit

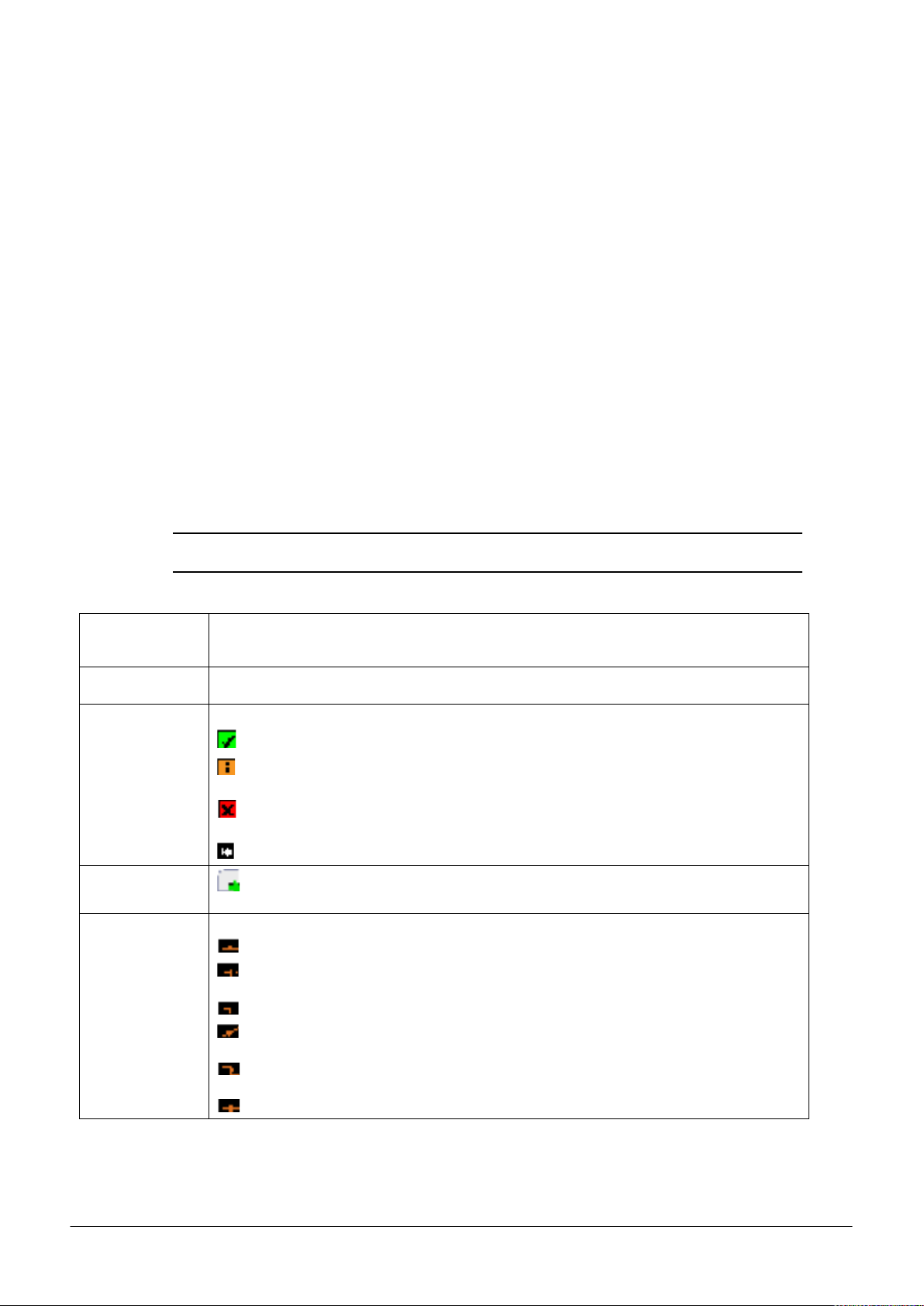

4.4.8 Cascade Display Mode

This display mode appears only if ’Cascade’ has been enabled in the Instrument.Display area of

configuration. See also Advanced Loop configuration.

Figure 1.4.8a Cascade display mode

Operating the scroll button highlights the Master ‘Mode’ field. Operating the scroll button again, enters

edit mode allowing the user to use the up/down arrow buttons to scroll through the available modes.

Once the required mode appears, a further operation of the scroll button confirms the entry and quits edit

mode.

Once out of edit mode, the down arrow key can be used to select Master ‘SP1’, Slave ‘SP’ and Slave ‘Man

OP’. The Mode selected determines how many of these items are editable by the operator.

Mode Cascade: The master loop is in auto mode and provides the slave setpoint.

Changing modes causes the slave to switch to the local slave setpoint.

Slave: A simple single loop controlling with a local setpoint.

Manual: Provides a single manual % power output.

SP1 Setpoint 1 is the primary setpoint of the controller. If the controller is in automatic

control mode, then the difference between the setpoint and the process variable

(PV) is continuously monitored by the control algorithm. The difference between

the two is used to produce an output calculated to bring the PV to the setpoint as

quickly as possible without causing overshoot.

SP The slave setpoint, either local (Manual or Slave mode) in which case it can be

edited, or supplied by the master loop (Cascade mode), in which case it is not

editable.

Man.OP The percentage output power to be applied when in Manual mode (100% = full on;

0% = off).

4.4.9 Programmer Display Mode

27 MC27 –EN–1.04

Note: The default loop names (‘Master’ and ‘Slave’) can be replaced by user-entered strings of up

to 10 characters in Advanced Loop Setup configuration.

nanodac™

Program name

This is the name of the loaded program. If the program has been modified since being saved, an asterisk (*)

appears after the name. Default background colour shown. This colour changes to that assigned to the input

channel when this is configured.

Segment name

This is the name of the current segment. If not named in Segment configuration, then the segment number

appears instead.

Program status

At the top right hand corner of the display, this can be any one of the following:

The program is running (or ran last time) without any PV ‘Alarm’ events or user intervention.

The user has intervened in the running of the program, by placing it in ‘hold’ or ‘reset’, or by advancing a

segment, or by adjusting a duration, target setpoint, ramp rate or time-to-target value.

A PV ‘Alarm’ Event has activated. A PV ‘Alarm’ Event is an absolute high/low or a deviation alarm on the PV

input.

There is no program loaded, or if a program is loaded, it has not yet run.

Program edit

This icon appears for users with appropriate access permissions, to indicate that setpoint programs can be

configured (as described in Program edit, below).

Segment type

For single channel displays, this indicates the type of segment currently being run:

Dwell. The segment value remains constant for the duration of the dwell period.

End (dwell). Displayed on completion of the program. The segment value remains at the final value until

rese

End (reset). Displayed on completion of the program. The program resets.

Ramp. The segment value ramps at a fixed rate or over a fixed period to the Target setpoint. Ramp up icon

shown; ramp down is similar but inverted.

Step. The segment value switches immediately to the new Target setpoint. Step down shown; step up

similar but inverted.

Wait. The segment value remains constant until the wait criteria are satisfied

Figure 3.4.9a Programmer displays (typical)

This display mode (if enabled - see Error! Reference source not found. allows the user to monitor the

progress of a single or dual-channel setpoint program, and if logged-in as ‘Operator*’, to reset or run the

program. The program itself is created in the Program edit page (described below) and in Programmer

configuration (Error! Reference source not found. or ‘iTools’).

*Note: Operator is the default access level - to edit, see ‘ Prog Mode Access’ in Error! Reference

source not found.)

The displays contain the following features:

MC27 –EN– 1.04 28

Loading...

Loading...