Carbolite MTT 12/38/850 User Manual

CONTENTS

Section page

Operating & Maintenance

Instructions

“MTT 12/38/850”

Combustion Tube Furnace

for Carbon-14 & Tritium Analysis

This manual covers the operation of the furnace only.

See also the Process Manual.

This manual should supply all the information required for safe and trouble-

free furnace operation. Information on controller operation is included.

MF38 – 3.07

Instrument switch: when the instrument switch is operated the temperature

control circuit is energised.

Heat Light: the adjacent light glows or flashes to indicate that power is

being supplied to the elements

DANGER of electrical shock– read any warning printed by this symbol.

DANGER – hot surface. Read any warning printed by this symbol.

WARNING: all surfaces of a furnace may be hot.

DANGER – read any warning printed by this symbol.

Heat Switch: the switch disconnects power to the heating elements; unless

this switch is off there is a danger of electric shock when inserting objects

into the furnace

MTT

1.0 SYMBOLS & WARNINGS

1.1 Switches and Lights

1.2 Warning Symbols

2 MF38 – 3.07

MTT

CONNECTION DETAILS

supply type

Supply

Terminal label

Cable colour

Live-Neutral

Reversible or Live-Live

1-phase

L

Brown

To live

to either power conductor

N

Blue

To neutral

to the other power conductor

PE

Green/Yellow

To earth (ground)

to earth (ground)

2.0 INSTALLATION

2.1 Unpacking & Handling

When unpacking or moving the furnace always lift it by its base or by both ends of the main body.

Never lift it by its work tube or the surrounding insulation. Use two people to carry the furnace.

Remove any packing material before use.

Place the furnace in a well ventilated room, away from other sources of heat, and on a surface

which is resistant to accidental spillage of hot materials. Do not mount the furnace on an

inflammable surface.

Ensure that there is free space around the furnace. Do not obstruct any of the vents in the control

section: they are needed to keep the controls cool.

Ensure that the furnace is placed in such a way that it can be quickly switched off or disconnected

from the electrical supply - see below.

NOTE: This product contains Refractory Ceramic Fibre (better described as Alumino Silicate

Wool) for precautions and advice in handling this material see the ‘Repairs and Replacements’

section.

2.2 Electrical Connections

Connection by a qualified electrician is recommended.

The furnace is supplied for use on a single phase A.C. supply, normally 220-240V. The supply

may be Live to Neutral non-reversible, Live to Neutral reversible or Live to Live. Check the

furnace rating label before connection.

220-240V model: the supply should be fused at 13A or 16A. Internal fuses of 12.5A are fitted. See

section 7.2.

The furnace should either be connected directly to an isolator which operates on both conductors,

or be fitted with a line plug. An isolator should be within easy reach of the operator; a line plug

should be quickly removable.

The supply must incorporate an earth (ground).

MF38 – 3.07 3

Furnace end of cable

RS232 Cable: furnace to PC

Computer end of cable

female 25-pin (9-pin)

9-pin (25-pin) male

Tx

2 (3)

3 (2)

Tx

Rx

3 (2)

2 (3)

Rx

Com

7 (5)

5 (7)

Com

7,8 (4,5)

Link together

1,4,6 (6,8,20)

Link together

RS485 cable: furnace to furnace

female 25-pin (9-pin)

25-pin (9-pin) female

2 (3)

2 (3)

+

3 (2)

3 (2)

+

Com

7 (5)

7 (5)

Com

RS422: furnace to furnace

female 25-pin

25-pin female

Rx+

3

3

Rx+

Rx

16

16

Rx

Com

7

7

Com

Tx+

12

12

Tx+

Tx

13

13

Tx

MTT

2.3 Connection to a Computer

This furnace is normally fitted with RS485 3-wire communications on the main controller only.

For information, RS232 and 5-wire connections are also shown below. This section does not apply

if the digital communication facility is not fitted.

If the RS232 option is supplied, then the furnace is fitted with one subminiature D-socket

connected to the controller comms module. RS232 is suitable for direct connection to a personal

computer (PC), using a “cross-over” cable as follows (the linked pins at the computer end are

recommended but may not be necessary). The cable is usually 25-pin at the furnace end and 9-pin

at the computer, but other alternatives are shown in parentheses.

If an RS485/422 option is supplied, then the furnace is fitted with two D-sockets. Connection

between products is by “straight” cable as follows:

If a boxed KD485 RS485/422 to RS232 converter is supplied, then the connection cable from

furnace to KD485 should be a “straight” cable, the same as the furnace-to-furnace cable. The

connection between the KD485 and the PC should be a “crossover” cable, the same as the Furnace

to PC cable. Note that the internal wiring of the KD485 box for the 5-wire (RS422) system

includes a cross-over.

4 MF38 – 3.07

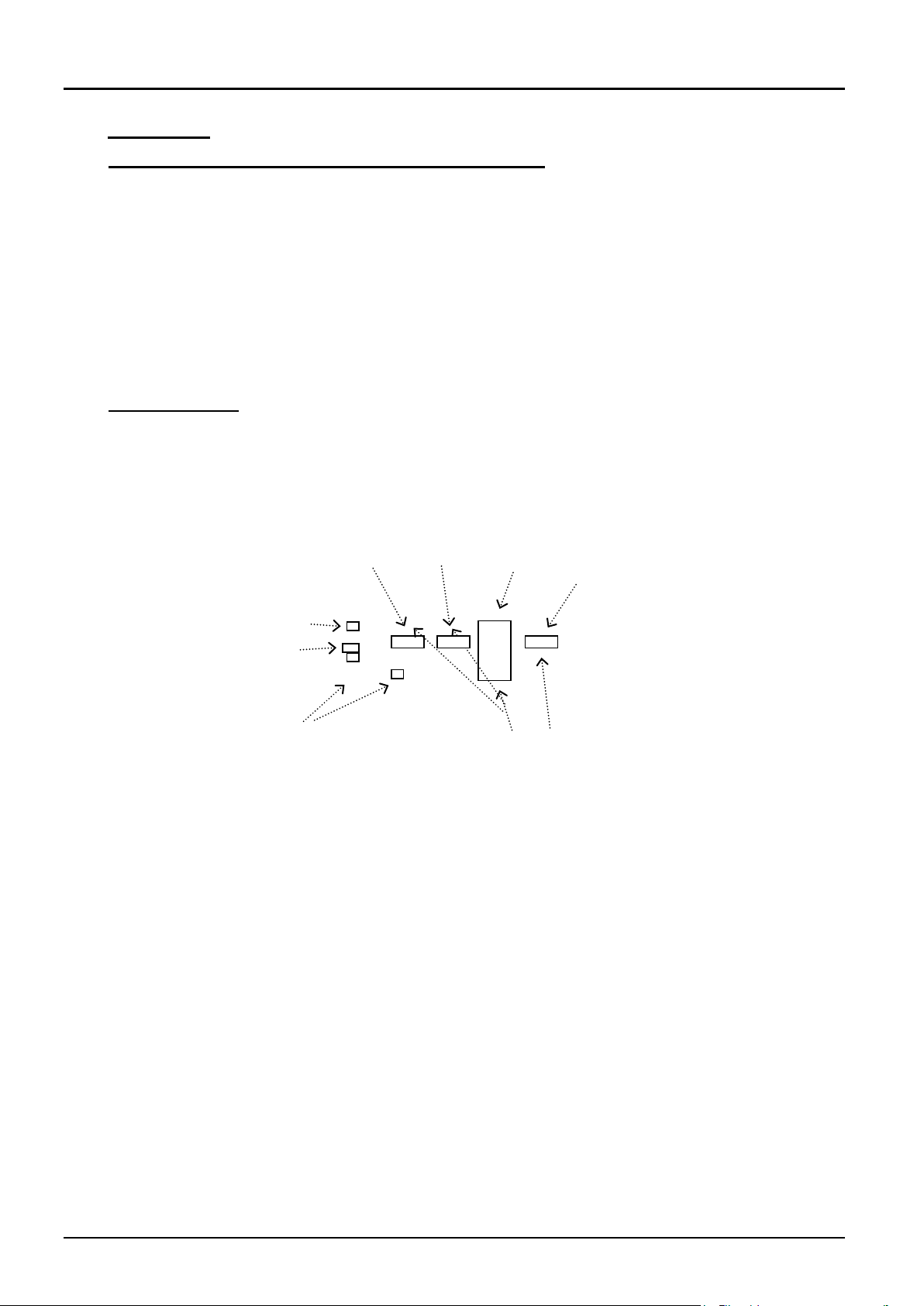

MTT

heat lights

instrument switch

Controllers

heater switch

Zone 2

overtemp

Zone 1

overtemp

Zone 2

catalyst

Zone 1

control

3.0 OPERATION

3.1 “MTT 12/38/850” – two zone combustion tube furnace.

The furnace is based on the Carbolite model MTF 12/38/400, but has two independent zones,

giving twice the heated length in total. The two zones are wound on a single ceramic tube (38/46 x

900mm long); each zone is approximately 400mm length. The zones are separated by

approximately 10mm because of the requirement for separate overtemperature systems.

The extended control box type CBT is used for the base.

The zones are independently controlled. Each has independent overtemperature which acts only on

its own zone.

This manual only describes furnace operation. For all other details about the use of this furnace as

a special model for Carbon-14 & Tritium analysis see the separate process Instructions.

3.2 Operating Cycle

The furnace is fitted with an instrument switch. The switch cuts off power to the controllers and

also to the heating elements via a contactor. There is also a Heater switch which can be used to

disconnect power to the elements without switching off the controllers. Heat lights indicated when

controlled power is being supplied to the elements. The instrument layout is as follows:

Operate the instrument switch to activate the temperature controller. The controller becomes

illuminated and goes through a short test cycle.

Set the temperature controllers to the desired setpoint or program - see the supplementary

controller manual.

If the overtemperature controllers have not yet been set as required, set them and activate them

according to the instructions in the supplementary manual for the overtemperature controller.

Switch on the Heater switch, located on the instrument panel. The furnace starts to heat up. The

Heat lights glow steadily at first and then flash as the heating zones approach the desired

temperature or a program setpoint.

If an overtemperature trip operates then an indicator in the overtemperature controller flashes, and

the corresponding heating element is isolated. Find and correct the cause before resetting the

overtemperature controller according the instructions in the supplementary manual.

To switch off power to the heating elements, use the Heater Switch. To switch the furnace off, use

both the Heater switch and the Instrument switch. If the furnace is to be left off unattended, isolate

it from the electrical supply.

MF38 – 3.07 5