CONTENTS

Section page

Installation, Operation &

Maintenance Instructions

Combustion Tube Furnaces

CFM models

This manual is for the guidance of operators of the above Carbolite products and

should be read before the furnace is connected to the electricity supply.

Manuals are supplied separately for the furnace controller

(and overtemperature controller when fitted).

Please read the controller manuals before operating the furnace.

MF10 - 3.08

Instrument switch: when the instrument switch is operated the temperature

control circuit is energised.

Heat Light: the adjacent light glows or flashes to indicate that power is

being supplied to the elements

DANGER of electrical shock– read any warning printed by this symbol.

DANGER – hot surface. Read any warning printed by this symbol.

WARNING: all surfaces of a furnace may be hot.

DANGER – read any warning printed by this symbol.

Heat Switch: the switch disconnects power to the heating elements; unless

this switch is off there is a danger of electric shock when inserting objects

into the furnace

CFM

1.0 SYMBOLS & WARNINGS

1.1 Switches and Lights

1.2 Warning Symbols

2 MF10 - 3.08

CFM

2.0 INSTALLATION

2.1 Unpacking & Handling

When unpacking or moving the furnace always lift it by its base. Do not lift it by the end panels or

by the internal insulation. Use two people to carry the furnace where possible. Remove any

packing material from inside the furnace before use.

NOTE: This product contains Refractory Ceramic Fibre (better described as Alumino Silicate

Wool) for precautions and advice in handling this material see the ‘Repairs and Replacements’

section.

2.2 Siting

Place the furnace in a well ventilated room, away from other sources of heat, and on a surface

which is resistant to accidental spillage of hot materials. Do not mount the furnace on an

inflammable surface.

Ensure that there is free space around the furnace. Do not obstruct any of the vents in the control

section: they are needed to keep the controls cool.

Ensure that the furnace is placed in such a way that it can be quickly switched off or disconnected

from the electrical supply - see below.

2.3 Setting Up

The furnace is typically used for sulphur and chlorine test in accordance with BS1016 parts 6 & 7,

ASTM D 3177-75; ISO 351 & 609. Please refer to the appropriate documentation. This manual

only gives general guidance common to tube furnaces.

Fit any work tube(s) ordered into place.

If a metal work tube is being used in the furnace, ensure that it is earthed, and that it is mounted so

as not to touch the furnace ceramic tube or insulation. See the safety warning in section 3.5.

2.4 Heating Elements (1400°C Models)

The Silicon Carbide elements are VERY FRAGILE and are packed separately. Fit them according to

the instructions in section 5.7.

MF10 - 3.08 3

supply type

Cable colour

Terminal

label

Live-Neutral

Reversible or Live-Live

Brown

L

to live

to either power conductor

Blue

N

to neutral

to the other power

conductor

Green/Yellow

PE

to earth (ground)

to earth (ground)

CFM

2.5 Electrical Connections

Connection by a qualified electrician is recommended.

The furnaces covered by this manual require a single-phase A.C. supply with earth (ground). The

supply may be Live to Neutral non-reversible, Live to Neutral with reversible plug, or Live to

Live.

Check the furnace rating label before connection. The supply voltage should agree with the voltage

on the label, and the supply capacity should be sufficient for the amperage on the label.

The supply should be fused at the next size equal to or higher than the amperage on the label. A

table of the most common fuse ratings is also given in section 7.5 of this manual. Where a supply

cable is present there are internal supply fuses; customer fusing is preferred but not essential.

Furnace with supply cable: either wire directly to an isolator or fit with a line plug.

Furnace without supply cable: a permanent connection to a fused and isolated supply should be

made to the internal terminals after temporary removal of the furnace back panel.

Connection by line plug: the plug should be within reach of the operator, and should be quickly

removable. Connection to isolating switch: this should operate on both conductors (single phase)

or on all live conductors (three phase), and should be within reach of the operator.

Single phase: connect the supply as follows:

The supply MUST incorporate an earth (ground).

Technical Note (1400°C Models)

The 1400°C models have an electronically controlled power limit. Do not attempt to calculate the

Amps from the Wattage. High break capacity fuses should be used. Avoid fast-blow fuses and

magnetic trip circuit breakers - consult Carbolite if in doubt.

4 MF10 - 3.08

CFM

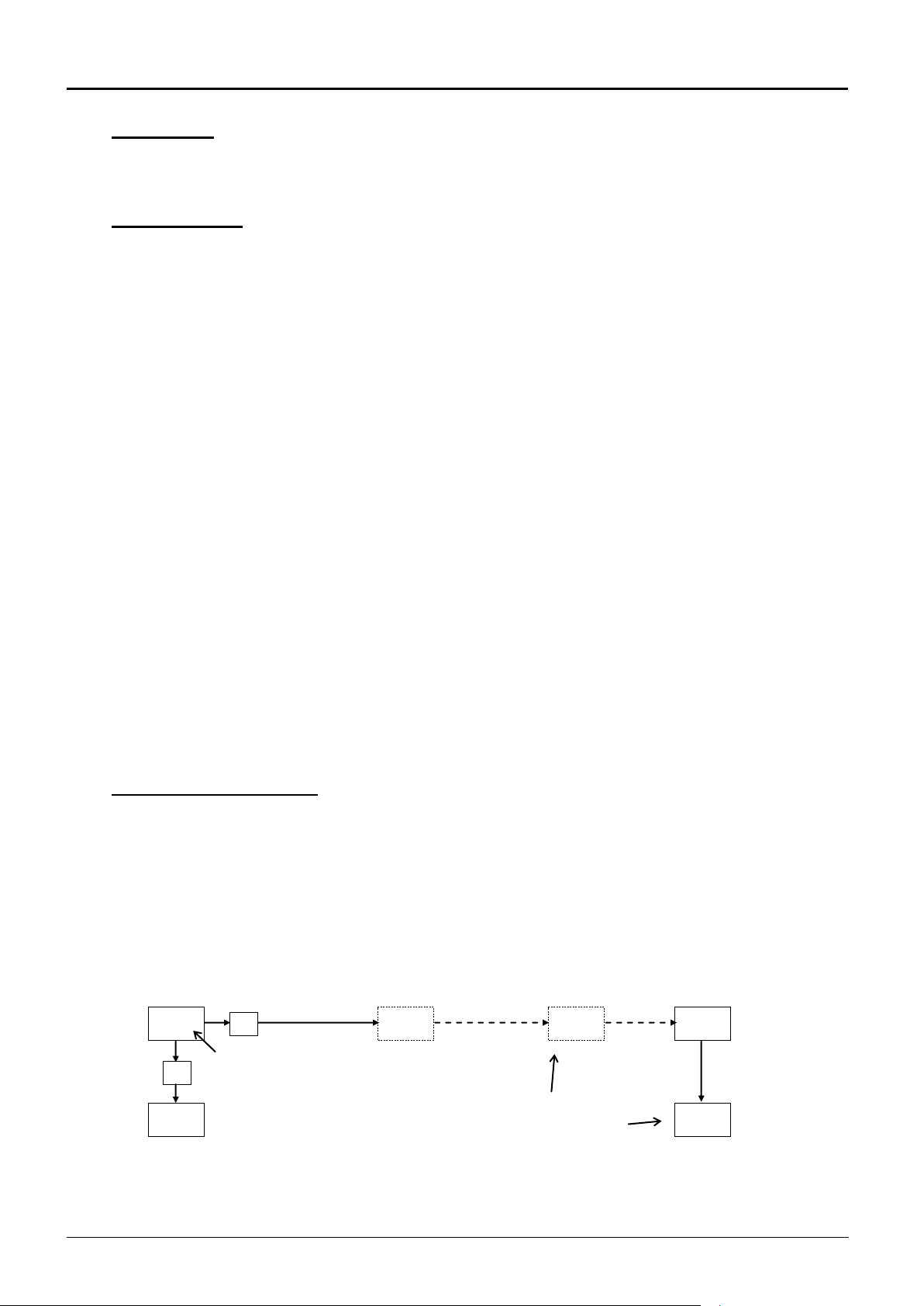

Home

List

Access

List

20.0

ACCS

OP

codE

*C

*C

output power,

read only

measured temperature;

use / to access

setpoint

for factory access to

lists and parameters

not available to the

operator

3.0 OPERATION

The instructions for operating the temperature controller are given in a separate manual.

If the furnace is fitted with a time switch, see also the supplementary manual MS03.

3.1 Operating Cycle

If the furnace has an auxiliary heater, see also section 3.2.

The furnace is fitted with an Instrument switch. The switch cuts off power to the control circuit.

There is also a Heater switch which can be used to disconnect power to the elements.

Connect the furnace to the electrical supply.

Operate the instrument switch to activate the temperature controller. The controller becomes

illuminated and goes through a short test cycle. Adjust the temperature controller (see controller

manual).

Overtemperature option only. If the overtemperature controller has not yet been set as required, set

it and activate it according to the instructions in the appropriate manual.

Switch on the Heater switch, located on the instrument panel.

Unless a time switch is fitted and is off, the furnace starts to heat up. The Heat light(s) glow

steadily at first and then flash as the furnace approaches the desired temperature or a program

setpoint.

Unless a time switch is fitted and is off, the furnace starts to heat up. The Heat light(s) glow

steadily at first and then flash as the furnace approaches the desired temperature or a program

setpoint.

Overtemperature option only. If the overtemperature trip operates then an indicator in the

overtemperature controller flashes, and the heating elements are isolated. Find and correct the

cause before resetting the overtemperature controller according the instructions supplied.

To switch off power to the heating elements, use the Heater Switch .

To turn the furnace off, set the Instrument switch to it’s off position; the controller display will go

blank. If the furnace is to be left off unattended, isolate it the electrical supply.

3.2 Auxiliary heater (if fitted)

The auxiliary heater is controlled by an independent temperature controller, which is affected by

the same instrument switch as the main controller. Note that a time switch (if fitted) may not

switch off the auxiliary heater, depending on other options ordered.

Set the auxiliary heater's temperature controller after setting the main controller, as given in

section.

Auxiliary heater controller navigation diagram:

MF10 - 3.08 5

Loading...

Loading...