Carbolite BLF 18/21 User Manual

CONTENTS

Section page

Installation, Operation &

Maintenance Instructions

1700-1800°C Bottom Loading Furnaces

BLF 17/3 to BLF 18/21

This manual is for the guidance of operators of the above products and

should be read before the furnace is connected to the electricity supply.

Manuals for the furnace controller and overtemperature controller are

supplied separately.

Please read the controller manuals before operating the furnace.

MF23 – 3.11

Instrument switch: when the instrument switch is operated the temperature

control circuit is energised.

Heat Light: the adjacent light glows or flashes to indicate that power is

being supplied to the elements

DANGER of electrical shock– read any warning printed by this symbol.

DANGER – hot surface. Read any warning printed by this symbol.

WARNING: all surfaces of a furnace may be hot.

DANGER – read any warning printed by this symbol.

BLF

1.0 SYMBOLS & WARNINGS

1.1 Switches and Lights

1.2 Warning Symbols

2 MF23 – 3.11

separately packed items

Most

models

BLF 17/8

Elements

6 9 Element clamps

6

18

Element clips *

12

18

Braids* *

1 set

1 set

Separators

6

9

* or combined clips and braids may be supplied

EHF /3 transit clamps

BLF

2.0 INSTALLATION

2.1 Unpacking & Handling

When unpacking or moving the furnace always lift it by its base. The furnace contains a

transformer and is heavy: use two or more people to carry it. Some models may alternatively be

lifted by fitting lifting bolts to captive threads in the top of the case.

Remove any packing material.

NOTE: This product contains Refractory Ceramic Fibre (better described as Alumino Silicate

Wool) for precautions and advice in handling this material see the ‘Repairs and Replacements’

section.

2.2 Siting & Setting Up

Place the furnace in a well ventilated room, away from other sources of heat, and on a surface

which is resistant to accidental spillage of hot materials. Do not mount the furnace on an

inflammable surface.

Ensure that there is free space around the furnace. Do not obstruct any of the vents in the case:

there are cooling fans in the case which must not be obstructed.

Ensure that the furnace is placed in such a way that it can be quickly switched off or disconnected

from the electrical supply - see below.

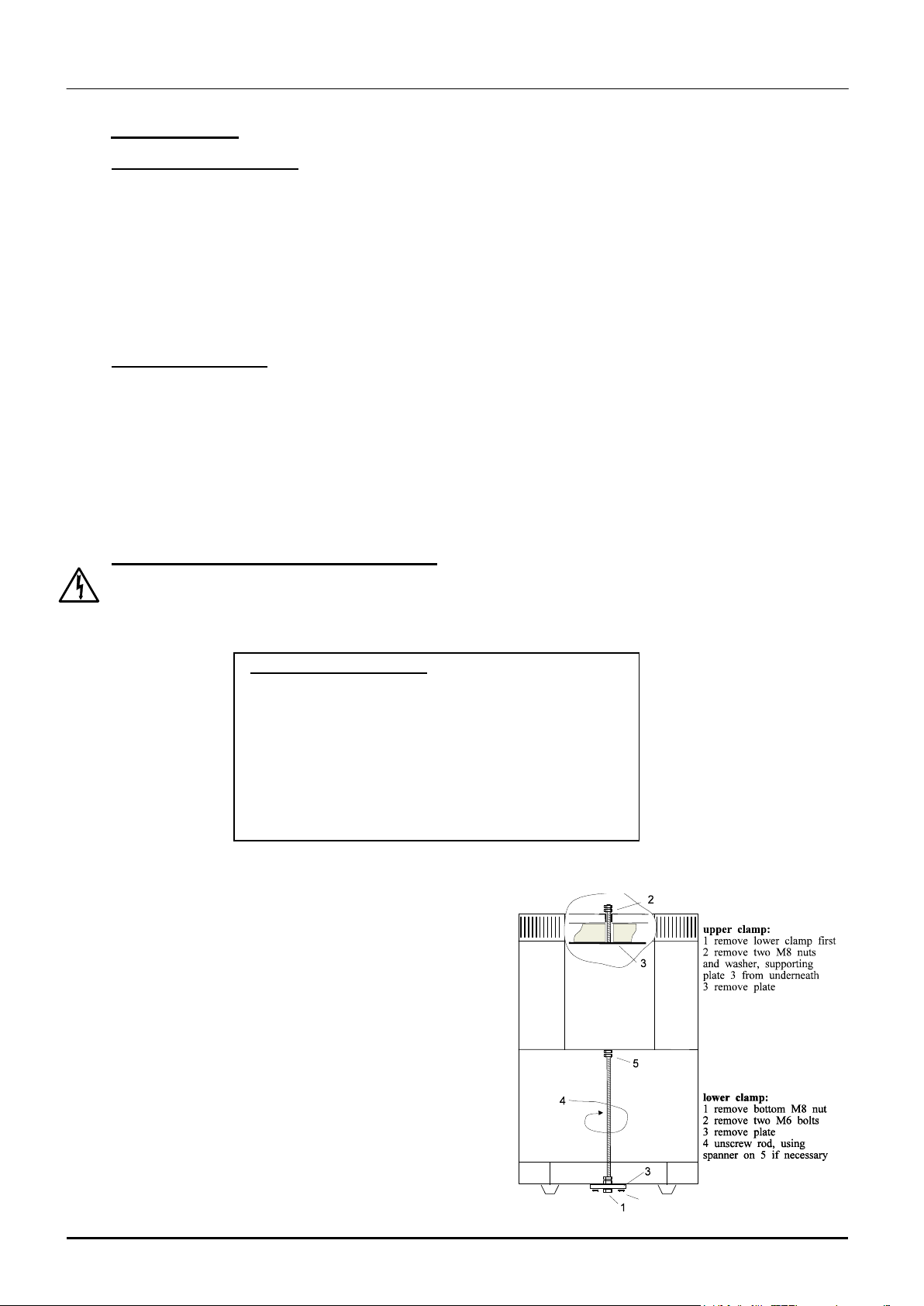

2.3 Fitting the Chimney & Heating Elements

Wear eye protection when handling the heating elements. See the warning in section 5.6.

The Molybdenum Disilicide elements are EXCEPTIONALLY FRAGILE and are packed

separately, together with other items as shown in the list.

Transit Clamps – dependent on model: the example

shown here is for the 3 litre models; remove any

transit clamps as shown. Fit the ceramic chimney to

the hole that exits the top of the chamber. Most

models are supplied with an insulation piece to fit

around the chimney; fit this insulation. For the BLF

18/8 the insulation is positioned under the roof

support frame and will need moving into position

once the transit clamp is removed.

Remove the complete top access panel using the

hidden screws in holes in the top of the panel:

loosen the screws two turns and remove the panel

Fit the heating elements vertically into the chamber.

Handle the elements with great care. The

installation of these elements is described later in

this manual.

MF23 – 3.11 3

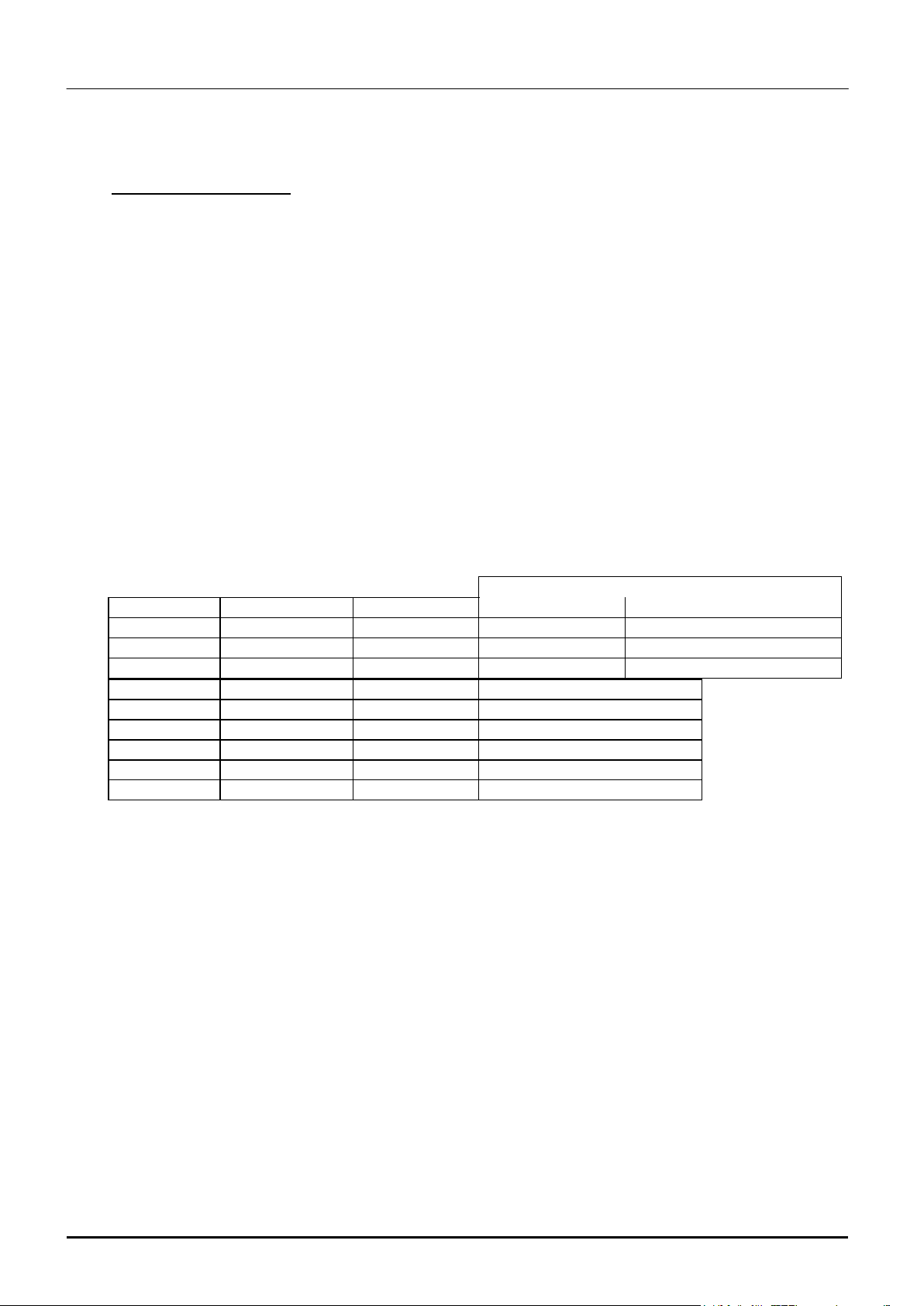

CONNECTION DETAILS

supply type

Supply

Terminal label

Cable colour

Live-Neutral

Reversible or Live-Live

1-phase

L

Brown

To live

to either power conductor

N

Blue

To neutral

to the other power conductor

PE

Green/Yellow

To earth (ground)

to earth (ground)

supply

Terminal label

Cable colour

3-phase

L1

Black

to phase 1

L2

Black

to phase 2

L3

Black

to phase 3

N

Light Blue

to neutral except delta

PE

Green/Yellow

to earth (ground)

BLF

Connect the aluminium braids securely as indicated in the element installation instructions.

2.4 Electrical Connections

Connection by a qualified electrician is recommended.

The 3 litre models are designed for single phase electrical supplies with or without neutral. Larger

models are designed for 3-phase use.

The voltage or range of voltages on which the furnace may be operated is given on the furnace

rating label. Check that the supply voltage is compatible with the voltage on the label, and that the

current capacity is sufficient for the amperage on the label, before connection to the supply. A

table of the most common ratings is given in section 8.5 of this manual.

Supply cables may be fitted to special order; when fitted, supply-rated fuses are internally fitted,

and the cable may be directly wired to an isolator or fitted with a line plug. Where no supply cable

is fitted there are no internal supply-rated fuses, and a permanent connection should be made from

a fused and isolated supply to the internal terminals after temporary removal of the furnace back

panel.

The supply point must be within reach of the furnace operator and must incorporate either an

isolating switch which operates on both conductors (single phase) or on all live conductors

(two/three phase), or a quickly removable plug.

The supply MUST incorporate an earth (ground).

DO NOT connect a furnace ordered for three phase use to a single phase supply or to the wrong

type of three phase supply.

4 MF23 – 3.11

BLF

3.0 OPERATION

The instructions for operating the temperature controller are given in a separate manual.

If the furnace is fitted with a time switch, see also the supplementary manual MS03.

If cascade control is fitted, see the supplementary manual MS07.

3.1 Operating Cycle

The furnace is fitted with an Instrument switch. The switch cuts off power to the controllers and

contactor.

Connect the furnace to the electrical supply. The cooling fans should automatically operate.

Check the hearth control switch for correct operation. The spring return switch stops the hearth in

any position, but over-travel is automatically limited. Load the furnace and raise the hearth.

Operate the instrument switch to activate the temperature controller. The controller becomes

illuminated and goes through a short test cycle.

Adjust the temperature controller – see the controller manual.

Set the overtemperature controller to a temperature a little (say 15°C) above the maximum setpoint

of program temperature, according to the instructions in the appropriate manual.

Unless a time switch is fitted and is off, the furnace starts to heat up. The Heat light glows brightly

at first, more dimly as the furnace temperature approaches a program setpoint.

If the overtemperature trip operates then an indicator or message in the overtemperature controller

flashes, and the heating elements are isolated. Find and correct the cause before resetting the

overtemperature controller according to the instructions supplied.

To switch the furnace off, set the Instrument switch to off. The case cooling fans remain on and the

chamber can be unloaded. Leave the fans on until the furnace cools to below 300°C. If the furnace

is to be left off unattended, isolate it from the electrical supply.

3.2 General Operating Advice

Heating element life is shortened by use at temperatures close to maximum. Do not leave the

furnace at high temperature when not required. The maximum temperature is shown on the furnace

rating label and on the back page of this manual. The furnace can be cycled between room

temperature and maximum without a detrimental effect on element life.

On first installing the elements, and on subsequent element replacement, run the furnace at 1500°C

for an hour to create a protective glaze on the element surface.

The thermocouple is intended to sense the temperature near the heating element, but if a large

object is placed in the chamber it may record the average temperature of the object and the

elements, which can lead to overheating of the elements. Allow large objects to gain heat at a

lower temperature and then reset the controller to a temperature close to the desired maximum.

The furnace elements are very susceptible to mechanical shock. Take care when loading or

unloading the furnace chamber. Opening the hearth at high temperatures is not recommended, but,

if it is necessary, keep the hearth lowered for as short a period as possible. The insulation cools

quickly and may crack through thermal shock. Note, though, that the insulation material is

susceptible to some surface cracking arising from high temperature cycling; such cracking is not

detrimental to the performance of the furnace.

Lightweight ceramic fibre insulation can easily be marked by accidental contact. Some fine cracks

may be visible on the surface of the insulation, or may develop in the surface of the chamber due

to the progressive shrinkage of the insulation materials. Cracks are not usually detrimental to the

functioning or the safety of the furnace.

MF23 – 3.11 5

Loading...

Loading...