Carbolite 3508 P1, 3508P10, 3508P25 Operating Instructions Manual

1 MC19-1.22

Operating Instructions

Temperature Controller

Type 3508

English

Ack

3508

1200

EUROTHERM

23

RUN/HOLD

RUN/HLD

OP1

°C

%

96.0

A/MAN

3508 Controller

2

MC19-1.22

Note: For the purposes of this manual the Eurotherm 3504 range is functionally identical to

the 3508 range.

3508 Controller

3

MC19-1.22

Contents

1.1 Using This Manual 4

1.2 PID Control 4

2 Basic Operation 5

2.1 Controller Layout (Home display) 5

2.2 Keys 5

3 Quick Start Guide 6

3.1 Operation as a simple controller 6

3.2 Changing the Setpoint 6

3.3 Resetting the programmer 6

3.4 Operating the current program 6

3.5 Understanding User Levels 6

4 Setting up the controller 8

4.1 Maximum output power setting 8

4.2 Customer ID. 8

4.3 Units 8

4.4 Language 8

5 Programming 9

5.1 Programming Notes 9

5.2 Holdback 9

5.3 Wait Segments 10

5.4 Program Cycling 10

5.5 Creating a Program 11

5.6 Running a Program 12

5.7 To pause (hold) a program 12

5.8 To stop and reset a program 12

5.9 To run a different program (P10 and P25) 12

5.10 Program Status 13

5.11 Power Failure Recovery 13

5.12 Alarms 14

5.13 Program Example 1 14

5.14 Program Example 2 16

6 Options 17

6.1 Digital Communications – RS232 17

6.2 Digital Communications – RS485 17

6.3 Comms Address 17

6.4 Alarm Option 18

6.5 Remote Input and Output (Analogue Communications) 18

6.6 Program segment output 18

7 Navigation Diagrams 19

7.1 Operator Level 1 - No Program Running 19

7.2 Operator Level 1 - Program Running 20

7.3 Supervisor Level 2 21

8 Controller Fault 22

8.1 Fault Code Diagnostic Table 22

9 Glossary of Terms 22

3508 Controller

4

MC19-1.22

Introduction to the Controller and Manual

1.1 Using This Manual

This manual aims to explain how to set up and operate the Eurotherm 3508 series of

controllers; it must be read in conjunction with the product main manual.

Due to the complex nature of furnace or oven control the use of technical terms throughout

this manual is unavoidable. Explanations of these terms can be found in the ‘Glossary of

Terms’ at the back of this manual.

This manual covers the operation of:

3508 P1 – Controller/Programmer

The 3508 P1 is a digital temperature controller which uses PID algorithms to give excellent

temperature control when properly set. This controller can store and run a single program of

up to 20 segments. The 3508P1 can also be used as a simple temperature controller.

3508P10 – Controller/Programmer

The 3508 P10 is a digital temperature controller which uses PID algorithms to give excellent

temperature control when properly set. This controller can store 10 programs of up to 50

segments each. Programs can be run individually or linked by a Call parameter as subprograms or to form single long programs. The 3508P10 can also be used as a simple

temperature controller.

3508P25 – Controller/Programmer

The 3508 P25 is a digital temperature controller which uses PID algorithms to give excellent

temperature control when properly set. This controller has a maximum of 500 segments or

25 programs; each program has a maximum of 50 segments. For example a 3508P25 could

store 10 programs with 50 segments or 25 programs with 20 segments. Programs can be

run individually or linked by a Call parameter as sub-programs or to form single long

programs. The 3508P25 can also be used as a simple temperature controller.

The 3508 does not contain a real-time calendar.

1.2 PID Control

The 3508 series of controllers use PID (Proportional Integral Derivative) temperature

control. This type of control uses a complex mathematical control system to adjust the

power being sent to the elements and hold the furnace or oven at the desired temperature.

Basic Operation

5 MC19-1.22

2 Basic Operation

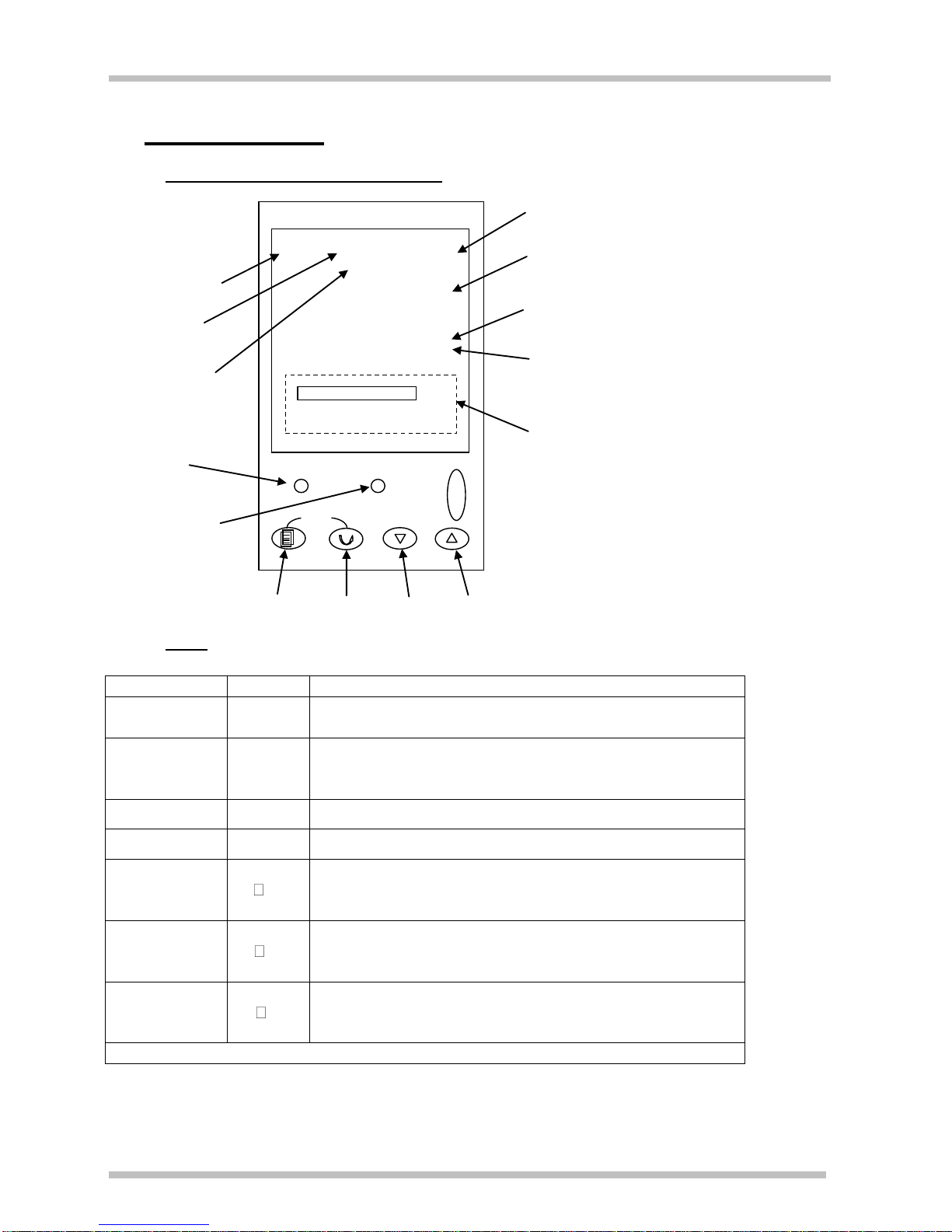

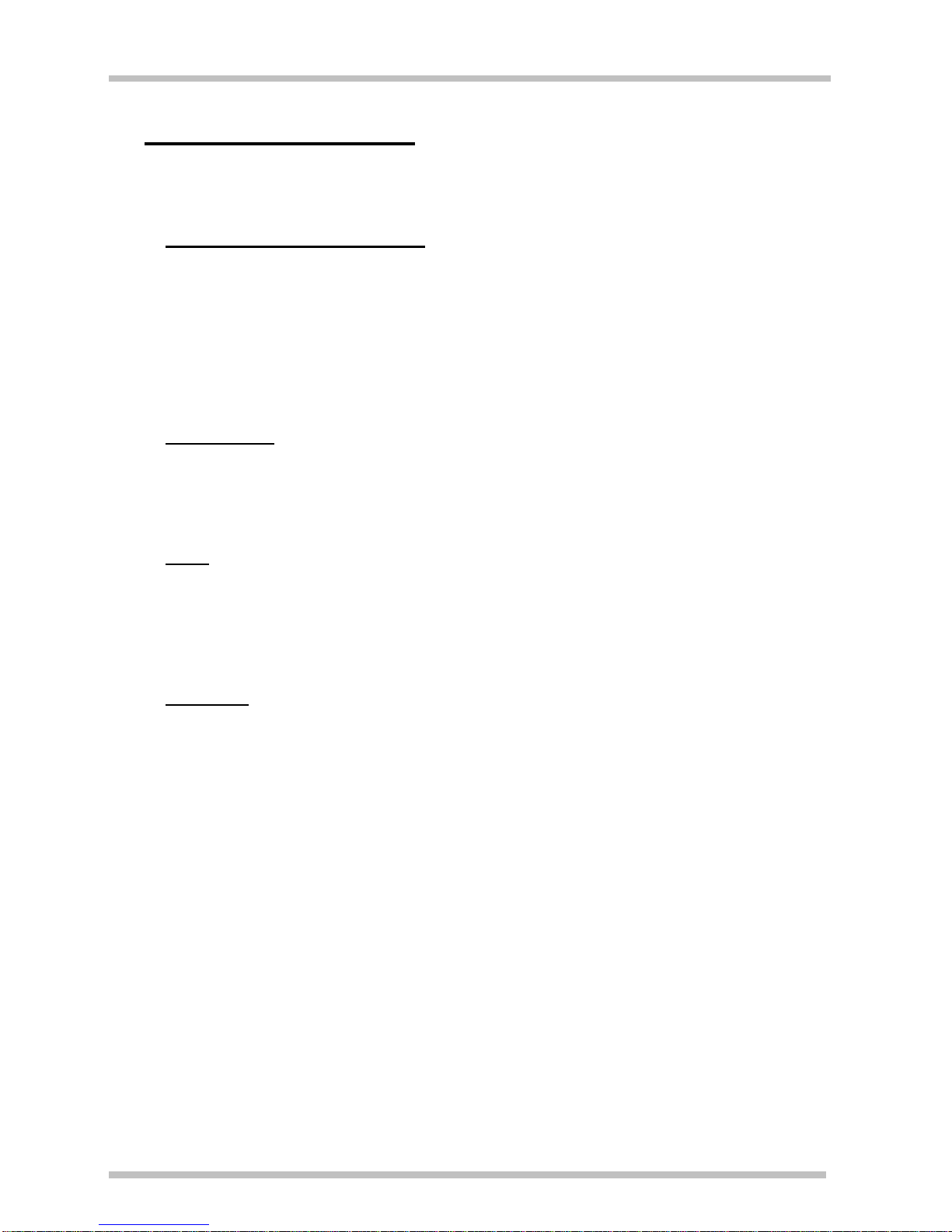

2.1 Controller Layout (Home display)

2.2 Keys

A/Man

-

Disabled

RUN/HOLD

-

Runs, Holds or Resets the current program. Hold

down for 3 seconds to Reset.

Page key

Scrolls through the page headings. Hold down for 3

seconds to access further levels, pass codes are

required.

Scroll key

Scrolls through parameters listed on pages.

Arrow keys

&

Adjust parameter values

Page and

scroll

together

+

Press together to return to the home display or to

acknowledge an alarm

Page and up

arrow

together

+

Press together quickly to scroll back up the page

headings

Scroll and up

arrow

together

+

Press together quickly to scroll back up a parameter

list

Pressing any other combination of keys together has no effect

Note: If no keys are pressed for 1 minute, the display returns to Home.

Power output

indicator

Measurement units

Measured temperature

Program Setpoint temperature (PSP)

when a program is running

Power output

percentage

Program status

indicators.

Setpoint temperature (SP)

when basic controlling

Not used

Page

Scroll

Down

Up

Runs, Holds,

Resets the current

program

OP1

°C

23

1200

%

96.0

RUN HLD

EUROTHERM

A/MAN

RUN/HOLD

3508

Ack

ALM

Alarm indicator

Quick Start Guide

6 MC19-1.22

3 Quick Start Guide

3.1 Operation as a simple controller

When switched on the controller goes through a short test routine and then shows the

measured temperature. Below it is shown the setpoint temperature (SP) and percentage of

power output.

3.2 Changing the Setpoint

Press up down to select the required SP. If the SP is higher than the measured

temperature, the OP1 indicator will illuminate at the top of the display, indicating that the

controller is calling for power (giving an output).

The controller will immediately attempt to reach the set temperature and maintain it.

3.3 Resetting the programmer

To reset the programmer to simple controller mode, press RUN/HOLD for 2 seconds.

3.4 Operating the current program

To avoid unwanted heating at the end of a program, set the SP temperature to zero

before running a program.

Ensure the programmer is reset to simple controller mode before starting a program,

by pressing RUN/HOLD for 2 seconds.

To start the program, press RUN/HOLD twice, RUN will light up on the display.

The displayed Program Setpoint (PSP) follows ramps, dwells and steps as the program

runs. The SP temperature of the controller does not apply when a program is running.

To pause the program, press RUN/HOLD.

To stop the program and return to simple controlling (reset), press RUN/HOLD for 2

seconds.

When the program ends, the programmer will either:

Automatically reset to operation as a simple controller.

Dwell at the last temperature of the program (with the RUN indicator flashing), until

the operator presses RUN/HOLD for 2 seconds to manually reset, or presses

RUN/HOLD once to restart the program.

Turn power to the elements down to zero.

3.5 Understanding User Levels

There are two levels in the controller; Level 1(Operator) and Level 2 (Supervisor).

Level 1 (Operator) is for the day-to-day operation of the controller and parameters are not

protected by a security code. There are 3 pages at this level. Page 1, Customer Identity,

can only be altered in level 2. Page 2 shows the current program status. Page 3 is for

writing and viewing programs.

Level 2 (Supervisor) provides access to additional parameters and access to these is

protected by a security code. A further 4 pages are accessible in this level as follows;

Customer identity, Control Output Hi percentage, Units.

To Enter Level 2:

1. Press and hold page for 3 seconds. The display will show “Access Goto Level 1”

Quick Start Guide

7

MC19-1.22

2. Press up to select level 2. After a short pause the display will show “Access Pass

code”.

3. Press up or down to enter the pass code 9, Pass is momentarily displayed. After

a short pause the display will return to home, the controller is now in level 2.

When Level 2 operations have been completed the supervisor must return to Level 1

manually. It is not necessary to enter a code when going from a higher level to a lower level.

To Return to Level 1:

1. Press and hold page for 3 seconds. The display will show “Access Goto Level 2.

2. Press down to go to level 1. After a short pause the display will revert to home, the

controller is now in level 1.

Quick Start Guide

8 MC19-1.22

4 Setting up the controller

Before using the controller (or during its lifetime) certain parameters may have to be set,

depending on specific requirements. To do this the Controller must be set to supervisor

Level 2, see section 3.5.

4.1 Maximum output power setting

Press page until Control Output Hi is displayed. Press up or down to adjust the value.

Depending on the furnace or oven model, the maximum power output setting may be

accessible or locked.

For Silicon Carbide heated furnaces the parameter is accessible to allow compensation for

element ageing. Refer to the product manual for details.

In many models the maximum power output setting depends on the supply voltage, refer to

the product manual for details.

4.2 Customer ID.

A furnace or oven identity number can be entered if required. This may be used to identify

one of many units, for production or quality control systems.

Press page until Customer Identity is displayed. Press up or down to select a number.

4.3 Units

Press page until Units is displayed. Press up or down to select:

C Celsius

F Fahrenheit

K Kelvin

4.4 Language

The text on the 3508 can be shown in different languages, this can only be set at the factory

and therefore must be specified at the time of placing an order.

Loading...

Loading...