Carbolite 3216P1, 3216P5 User Manual

Operating Instructions

Temperature Controller

Type 3216 P1 P5

English

MC18-GB – v1.04

MC18-GB – v1.04

2

3216 Controller

MC18-GB – v1.04

Contents

1 INTRODUCTION TO THE CONTROLLER AND MANUAL 4

1.1 USING THIS MANUAL 4

1.2 PID CONTROL 4

2 BASIC OPERATION 5

2.1 CONTROLLER LAYOUT (HOME DISPLAY) 5

2.2 KEYS 5

3 QUICK START GUIDE 6

3.1 OPERATION AS A SIMPLE CONTROLLER 6

3.2 CHANGING THE SET POINT 6

3.3 USING THE CONTROLLER 6

3.4 UNDERSTANDING USER LEVELS 6

4 SETTING UP THE CONTROLLER 8

4.1 MAXIMUM OUTPUT POWER SETTING 8

4.2 CUSTOMER ID. 8

4.3 UNITS 8

4.4 LANGUAGE 8

4.5 SCROLLING TEXT 8

4.6 CUSTOMER CALIBRATION 9

4.7 HOLDBACK 10

5 PROGRAMMING 10

5.1 CREATING A PROGRAM 10

5.2 RUNNING A PROGRAM 12

5.3 PROGRAM STATUS 12

5.4 PROGRAM EXAMPLE 14

6 OPTIONS 15

6.1 DIGITAL COMMUNICATIONS – RS232 15

6.2 DIGITAL COMMUNICATIONS – RS485 15

6.3 COMMS ADDRESS 16

6.4 ALARM OPTION 16

6.5 REMOTE INPUT AND OUTPUT (ANALOGUE COMMUNICATIONS) 16

7 NAVIGATION DIAGRAMS 16

7.1 3216P1 & 3216P5 17

8 CONTROLLER FAULT 18

8.1 FAULT CODE DIAGNOSTIC TABLE 18

9 GLOSSARY OF TERMS 18

3

Introduction

MC18-GB – v1.04

1 Introduction to the Controller and Manual

1.1 Using This Manual

This manual aims to explain how to set up and operate the Eurotherm 3216 series of

controllers; it must be read in conjunction with the product main manual.

Due to the complex nature of furnace or oven control the use of technical terms throughout

this manual is unavoidable. Explanations of these terms can be found in the ‘Glossary of

Terms’ at the back of this manual.

This manual covers the operation of:

1.1.1 3216P1 - Controller/Programmer

The 3216P1 is a digital temperature controller which uses PID algorithms to give excellent

temperature control. This controller can store and run a single program of 8 ramp/dwell

segments. The 3216P1 can also be used as a simple temperature controller.

1.1.2 3216P5 - Controller/Programmer

The 3216P5 is a digital temperature controller which uses PID algorithms to give excellent

temperature control. This controller can store up to 5 programs of 8 ramp/dwell segments.

The 3216P5 can also be used as a simple temperature controller.

1.2 PID Control

The 3216 series of controllers use PID (Proportional Integral Derivative) temperature

control. This type of control uses a complex mathematical control system to adjust the

power being sent to the elements and to hold the furnace or oven at the desired

temperature.

4

MC18-GB – v1.04

2 Basic Operation

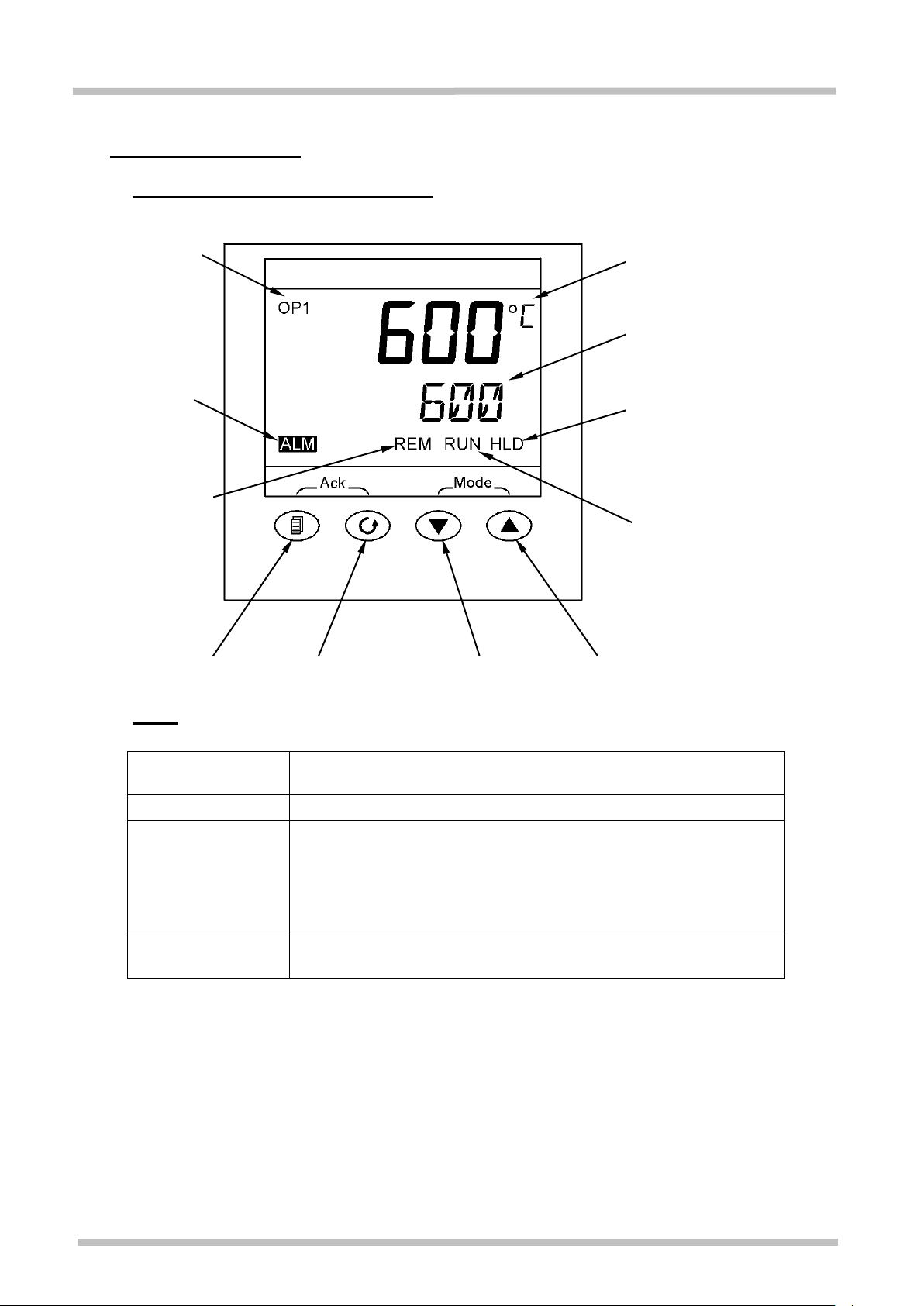

Page Key

The Page key is used to access level 2 when held down

for 3 seconds.

Scroll Key

The Scroll key is used to scroll through the parameters.

ACK

Page + Scroll

When pressed simultaneously the ACK function is used

to:

Return to the Home Menu.

Acknowledge an alarm if activated.

Reset a program after the program has ended

Arrow Keys

The arrow keys are used individually to adjust the

selected parameters and in combination to run a program

Power Output

Indicator

Scroll Key

Down Key

Up Key

Alarm

Indicator

Hold Indicator

Setpoint

Temperature

Measured

Temperature

Run Indicator

Remote

Indicator

(When configured)

Scroll Key

Page Key

2.1 Controller Layout (Home Display)

Basic Operation

2.2 Keys

Note: If a parameter is selected and no further action is taken, the display will time out and

revert back to the home display in its working level after approximately 1 minute

5

Quick Start Guide

MC18-GB – v1.04

3 Quick Start Guide

3.1 Operation as a simple controller

When switched on, the controller goes through a short test routine and then shows the

measured temperature (PV = Process Value) in the upper part of the display, and below it,

the set temperature (Set Point).

3.2 Changing the Set Point

Press Up or Down to select the required SP. If the SP is higher than the measured

temperature, the OP1 indicator will illuminate in the top left corner of the display, indicating

that the controller is calling for power (giving an output).

The controller will immediately attempt to reach the set temperature and then maintain it.

3.3 Using The controller

The parameters in the controller are first shown by a short code (mnemonic). After 5

Seconds a description of the parameter will scroll once along the display and then revert

back to the mnemonic. The scrolling text can be interrupted at any time by a single press of

any of the buttons, but will not scroll again until the parameter is returned to. In this manual

the mnemonic will be shown first, followed by the scrolling text in brackets;

e.g. Prog <program number>

3.4 Understanding User Levels

There are two user levels in the controller; Level 1(Operator) and Level 2 (Supervisor).

Level 1 (Operator) is for the day to day operation of the controller. These parameters are

not protected by a security code.

Level 2 (Supervisor) provides access to additional parameters. Access to these is protected

by a security code

To Enter Level 2

1. Press and hold the page key for 3 seconds.

2. The display will show Leu 1 GOTO

3. Release the page Key

4. Press the Up or Down to choose LEu 2 (level 2)

5. Press the Up or Down to enter the code (Level 2 Code = 9).

If the correct code is entered, PASS should momentarily be displayed and then revert to the

level 2 home display (See Section 5.3)

If an incorrect code is entered the display reverts back to Level 1 home display (See Section

5.3)

6

Loading...

Loading...