Operating Instructions

Temperature Controller

Type 302P4

English

MC22-GB – v1.01

MC22 -GB-v1.01

Contents

1 Introduction to the Controller and Manual 3

1.1 Using This Manual 3

1.2 302P - Controller 3

1.3 PID Control 3

2 Basic Operation 4

2.1 Controller Layout 4

2.2 Keys 5

3 Quick Start Guide 5

3.1 Home Display 5

3.2 Selecting a program 6

3.3 Starting the program Cycle 6

3.4 Program Cycle 6

3.5 Program Hold and Cancel 6

3.6 Understanding Operator Levels 6

4 Programming 10

4.1 Program Parameters 10

4.2 Program editing 11

4.3 Creating a program 13

4.4 Enter Program Edit level 13

4.5 Programming 14

4.6 Program Review 16

4.7 Exit Program level 16

4.8 Running a program 17

4.9 Program Status 18

4.10 Program End Feature 19

4.11 Program Example 20

5 Enhanced Mode 21

5.1 Customer Calibration 22

6 Navigation Diagram 25

7 Controller Fault 26

7.1 Fault Code Diagnostic Table 26

8 Glossary of Terms 26

2

302P Controller

MC22-GB-V1.01

1 Introduction to the Controller and Manual

1.1 Using This Manual

This manual aims to explain how to set up and operate the Carbolite 302P controller; it must

be read in conjunction with the product main manual.

Due to the complex nature of furnace control the use of technical terms throughout this

manual is unavoidable. Explanations of these terms can be found in the ‘Glossary of Terms’

at the back of this manual.

This manual covers the operation of:

1.2 302P - Controller

The 302P is a digital temperature controller which uses PID algorithms to give excellent

temperature control when properly set. This controller can store 4 programs of 4 ramp/dwell

segments. Programs 1,2& 3 are protected by password and program 4 is open to edit.

1.3 PID Control

The 302P4 controller use PID (Proportional, Integral, Derivative) temperature control. This

type of control uses a complex mathematical control system to adjust the power being sent

to the elements and to hold the furnace or oven at the desired temperature.

3

Introduction

MC22 -GB-v1.01

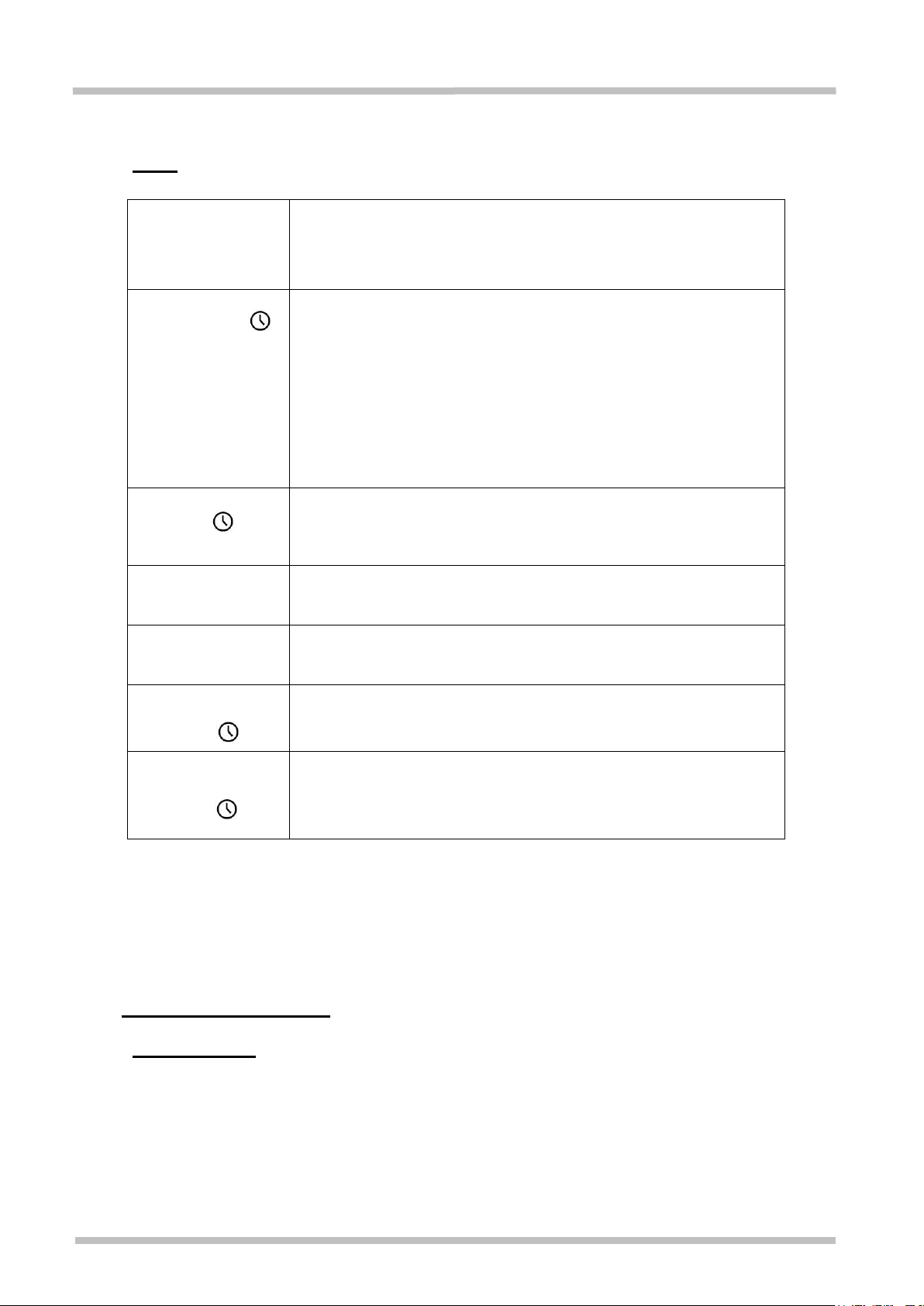

Power Output

Indicator Lamp

Setpoint

Temperature

(Lower Display)

Measured

Temperature

(Upper Display)

Run Indicator Lamp

Run Key

Down Key

Function Key

Up Key

Up Key

Up Key

2 Basic Operation

2.1 Controller Layout

4

MC22-GB-V1.00

Function Key

The Page key is used to:

Scroll down parameters.

Store modified parameters.

Review program parameters in basic operation mode.

Run Key

The Run key is used to:

Start the program cycle when pressed for more than

1.5 seconds.

Hold program cycle when pressed for more than 1.5

seconds while program is running.

Stop program when pressed for more than 5 seconds

while program is running or in hold.

Scroll up parameters in set up operator mode or

configuration mode.

Function + Run

When pressed simultaneously for more than 3 seconds is

used to:

Start the procedure to select operating mode.

Arrow Keys

The arrow keys are used:

individually to adjust the selected parameters.

Down + Function

+

When pressed simultaneously:

are used to enable “lamp test” in Basic mode

Down + Run

When pressed simultaneously:

Used to reach minimum value during parameter

modify

Up + Run

When pressed simultaneously:

Used to reach maximum value during parameter

modify

2.2 Keys

Basic Operation

Note: In operator set up mode, if a parameter is selected and no further action is taken, the

display will time out and revert back to the home display in its working level after

approximately 1 minute.

3 Quick Start Guide

3.1 Home Display

When switched on, the controller goes through a short lamp test routine and then displays

the process value in the upper display and “rdy” in the lower display. This is known as the

“Home Display”.

5

Quick Start Guide

MC22 -GB-v1.01

3.2 Selecting a program

With basic operator mode selected OP.b (see section 3.6) press the function key once to

display nprG in the lower display and the program number in the upper display. Select the

required program number using the Down or Up After selection press the function key

to store the parameter.

3.3 Starting the program Cycle

To start the program the “Run” button must be pressed and held down for 1.5 seconds.

After 1.5 seconds the lower run indicator lamp will be lit continually and the displays will

show the program setpoint (PSP); lower display, process value (PV); upper display.

3.4 Program Cycle

Once the program has been started, the heat light (situated below the power switch) and the

upper power output indicator lamp will initially display a long pulse at a continuous cycle

rate, these display pulses will reduce within the same cycle rate, as the furnace approaches

the desired temperature or a program setpoint.

As the program is running the lower indicator lamp will be lit continuously.

When the program has finished its cycle the lower indicator lamp will be switched off and

the lower display will show End.

3.5 Program Hold and Cancel

To hold the program, the “Run” button must be pressed and held down for 1.5 seconds,

while the program is running. When the program is in hold, the lower display will flash

between the word “hoLd” and current Program set point and the lower indicator lamp will

flash continually.

To remove the hold status, the “Run” button must be pressed and held down for 1.5

seconds. After 1.5 seconds the lower display will no longer display hold and the lower

indicator lamp will be lit continually. The program will then continue from the current process

value indicated on the upper display.

To cancel a program, either while the progam is running or in the hold condition, the “Run”

button must be pressed and held down for 5 seconds. After 5 seconds the lower indicator

lamp will switch off, the lower display will show “rdy”, and the upper display will show the

current process value.

To restart the program refer to section 3.3

3.6 Understanding Operator Levels

There are three user levels in the controller; Op.b (Basic Operator Mode) OP.E (Enhanced

Mode) and OP.P (Program Edit Mode).

There are also three further engineering levels indicated by OPS, CP1 and CnF which are

factory set and not covered within this manual.

6

Quick Start Guide

MC22-GB-V1.00

Op.b (Basic Operator Mode) is for running the program only. No other parameters are

available.

OP.E (Enhanced Mode) is for calibration and address assignment. Access to these is

protected by security code =17.

OP.P (Program editing mode).provides access to programming parameters. Access to

these is protected by security code =4

To Enter OP.E (Enhanced mode) starting from Basic operator mode (OP.b).

1. From the home display press and hold the Function and Run keys

simultaneously for more than 3 seconds.

2. The display will show OPr lower display and OP.b upper display (Op.b being the

current active mode)

3. Press the Up or Down to choose OP.E

4. Press to enter selected level.

5. The word pass will be shown on the bottom display and ---- on the top display. This

will time out after 10 seconds, during this period the password should be selected

using the Up or Down

6. Press to enter the password.

7. When the correct password has been entered the upper display will flash PASS. If an

incorrect password is entered the upper display will flash Errand then return to the

home display.

Once in Enhanced mode, the parameters within this level can be accessed by pressing

page to descend the list, or run to ascend the list.

When OP.E operations have been completed, OP.b mode must be returned to manually as

outlined below.

7

Quick Start Guide

MC22 -GB-v1.01

To Enter OP.P (Program Editing Mode).

8. From the home display press and hold the Function and Run keys

simultaneously for more than 3 seconds.

9. The display will show OPr lower display and OP.b upper display (Op.b being the

current active mode)

10. Press the Up or Down to choose OP.P

11. Press to enter selected level.

12. The word pass will be shown on the bottom display and ---- on the top display. This

will time out after 10 seconds, during this period the password should be selected

using the Up or Down

13. Press to enter the password.

14. When the correct password has been entered the upper display will flash PASS. If an

incorrect password is entered the upper display will flash Err and then return to the

home display.

15. Once in the program edit mode the parameters within this mode can be accessed by

pressing page to descend the list, or run to ascend the list.

Note: There is no time out or power cycling function, whereby the instrument automatically

returns to a lower operating mode.

When OP.P operations have been completed, OP.b mode must be returned to manually as

outlined below.

To exit OP.E (Enhanced mode) or OP.P (Program Editing Mode) and return to OP.b (Basic

operator mode).

1. Return to the top level home display of the OP.E or OP.s list. This will be where the

displays show the, program setpoint (PSP) in the lower display and process value

(PV) in the upper display. This can be done either by leaving the current selected

parameter to time out after 10 seconds, or by pressing the page or Run to scroll

through the parameter list and return to the top level home display.

2. Press and hold Function and Run simultaneously for more than 3 seconds.

3. The display will show OPr lower display and OP.E or OP.P upper display (OP.E or

OP.P being the current active mode)

4. Press the Up or Down to choose OP.b

5. Press to enter selected level.

6. No password is required to enter a lower level of operation, therefore the display will

return to basic operator mode and show the, program setpoint (PSP); lower display

and process value (PV); upper display.

Check that no parameters are not available by pressing the page or run keys.

8

MC22-GB-V1.00

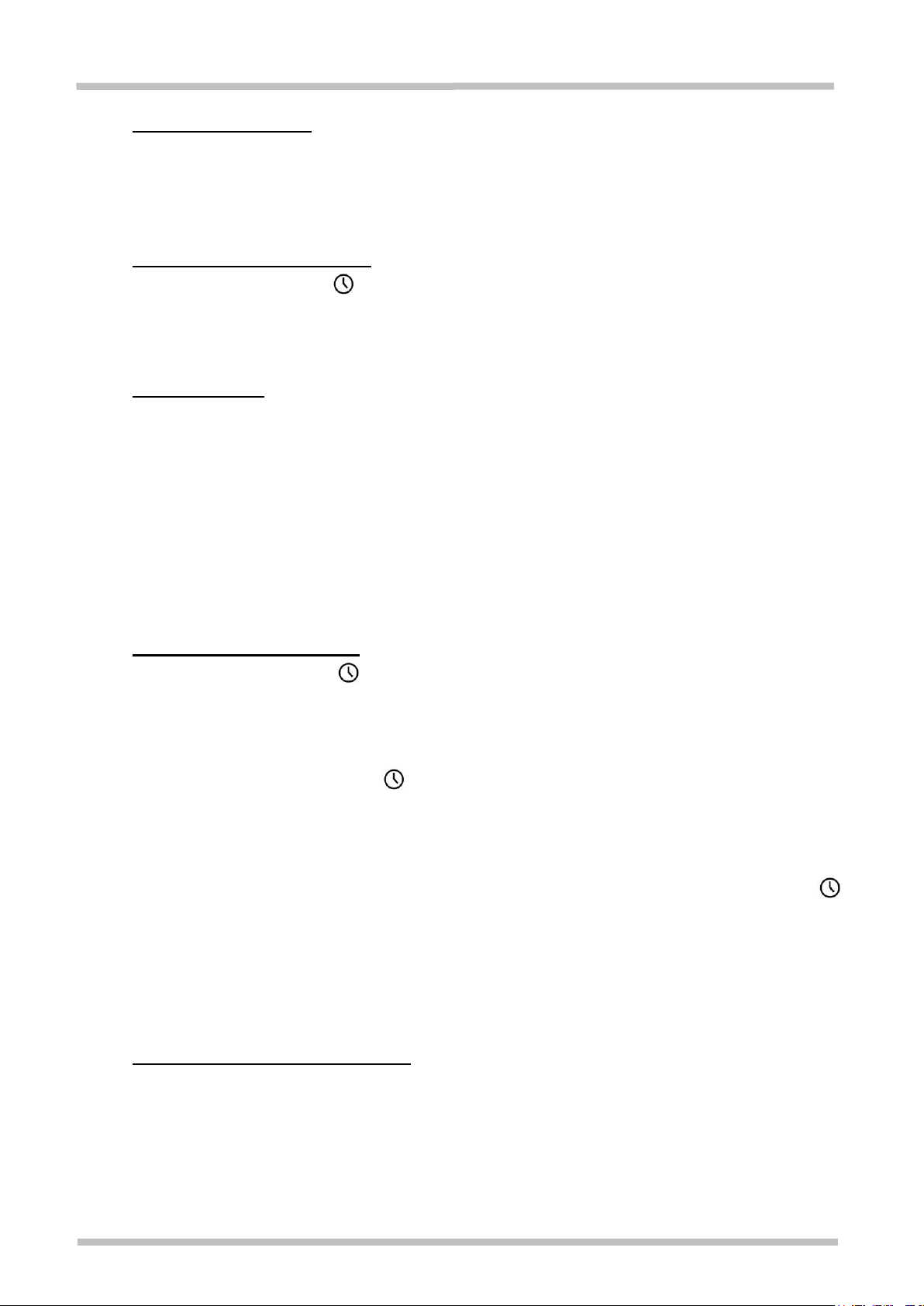

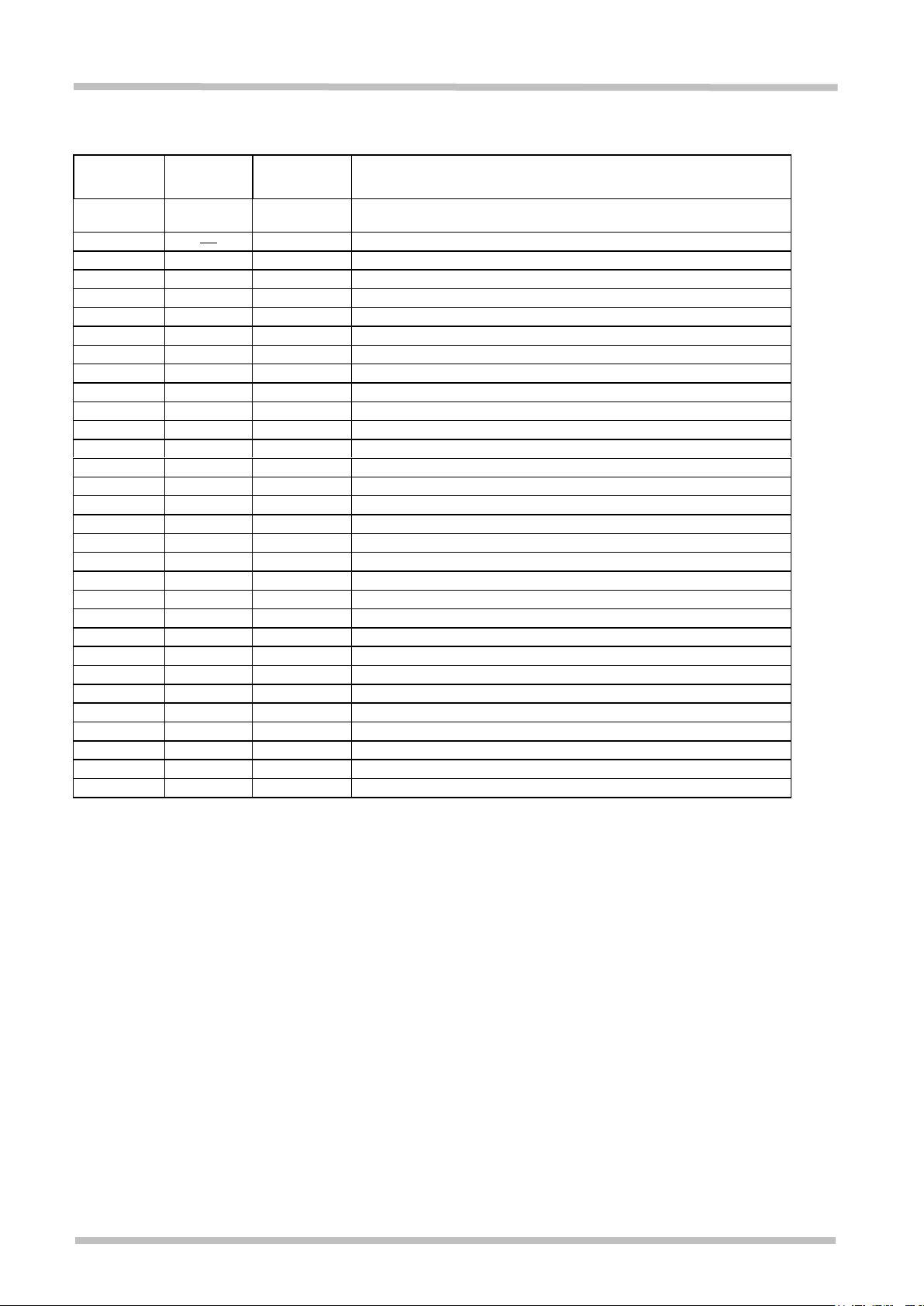

BASIC

OPR MODE

OP.b

ENHANCED

MODE

OP.E

Program

Editing Mode

OP.P

DESCRIPTION

Home Display

Home

Display

Home Display

OP

SELECTED SETPOINT

CL.ST

CUSTOMER CALIBRATION

OFST

OFFSET FOR 1 POINT CALIBRATION or COEFFICIENT “b”

SLOP

COEFFICIENT “a” (Slope)”

CAL.L

LOW POINT FOR 2 POINT CALIBRATION

OFS.L

OFFSET ON LOW POINT FOR 2 POINT CALIBRATION

CAL.H

HIGH POINT FOR 2 POINT CALIBRATION

OFS.H

OFFSET ON HIGH POINT FOR 2 POINT CALIBRATION

ADr

MODBUS ADDRESS

nPrG

SELECTED PROGRAM

SEG

SEGMENT IN EXECUTION

rT

TIME REMAINING TO THE END OF PROGRAM

r.rPt

REPETITIONS REMAINING TO THE END

rPt

TIME REMAINING UNTIL THE END

PASS

PASWORD TO EDIT PROGRAM 1,2,3

ITSP#

ITSP

INITIAL SET POINT

SP.1#

SP.1

SEGMENT 1 TARGET SET POINT

rr.1#

rr.1

SEGMENT 1 RAMP RATE TO SP 1

TH 1#

TH 1

SEGMENT 1 TIME HELD AT SP 1

SP.2#

SP.2

SEGMENT 2 TARGET SET POINT

rr.2#

rr.2

SEGMENT 2 RAMP RATE TO SP 2

TH 2#

TH 2

SEGMENT 2 TIME HELD AT SP 2

SP.3#

SP.3

SEGMENT 3 TARGET SET POINT

rr.3#

rr.3

SEGMENT 3 RAMP RATE TO SP 3

TH 3#

TH 3

SEGMENT 3 TIME HELD AT SP 3

SP.4#

SP.4

SEGMENT 4 TARGET SET POINT

rr.4#

rr.4

SEGMENT 4 RAMP RATE TO SP 4

TH 4#

TH 4

SEGMENT 4 TIME HELD AT SP 4

Rpt#

rPT

PROGRAM EXECUTION REPETITOINS

CET#

CET

CYCLE END THRESHOLD

Table showing parameters accessible in OP.b and OP.E and OP.P modes

Quick Start Guide

# NOTE: In basic mode these parameters are not alterable

9

Loading...

Loading...