Page 1

TB 23-7-1 Carbine, Cal. .30, M1 - Cover

Click Here

This site was last updated on July 5, 2003

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Cover.html6-9-2008 14:49:24

Page 2

TB 23-7-1 Carbine, Cal. .30, M1 Table of Contents

TB 23-7-1

RESTRICTED

WAR DEPARTMENT, ORDNANCE OFFICE

WASHINGTON, MARCH 17, 1942

ORDNANCE FIELD SERVICE TECHNICAL

BULLETIN NO. 23-7-1

CARBINE, CAL. .30, M1

TABLE OF CONTENTS

Page

SECTION

I

Introduction

2 - 9

II

Operation and functioning

10 - 17

III

Disassembly and assembly

18 - 42

IV

Care, cleaning and lubrication

43 - 51

V

Immediate action and stoppages

52 - 54

VI

Organization spare parts and accessories

55 - 57

VII

Ammunition

58 - 59

VIII

Materiel affected by gas

60 - 62

IX

References

63

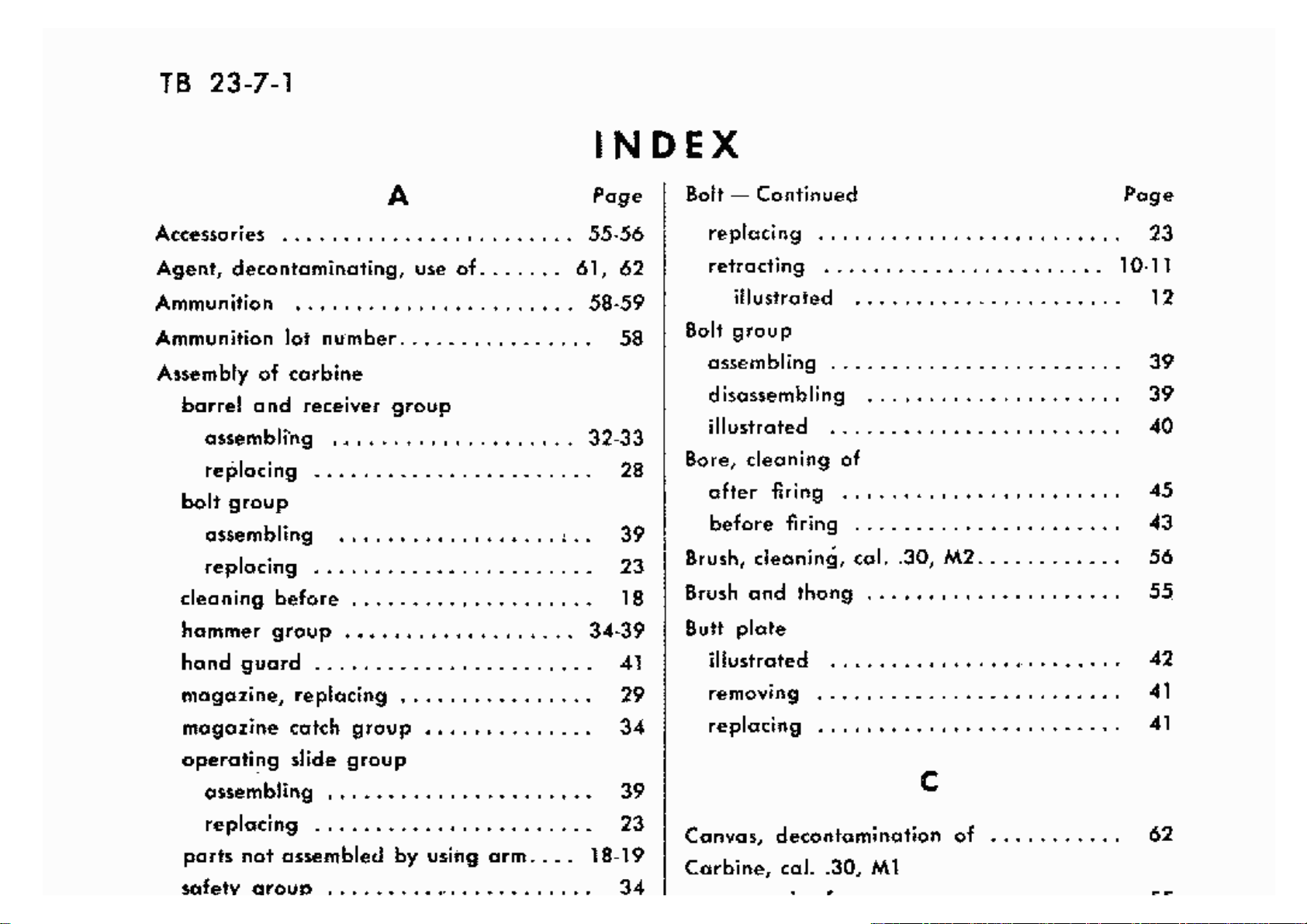

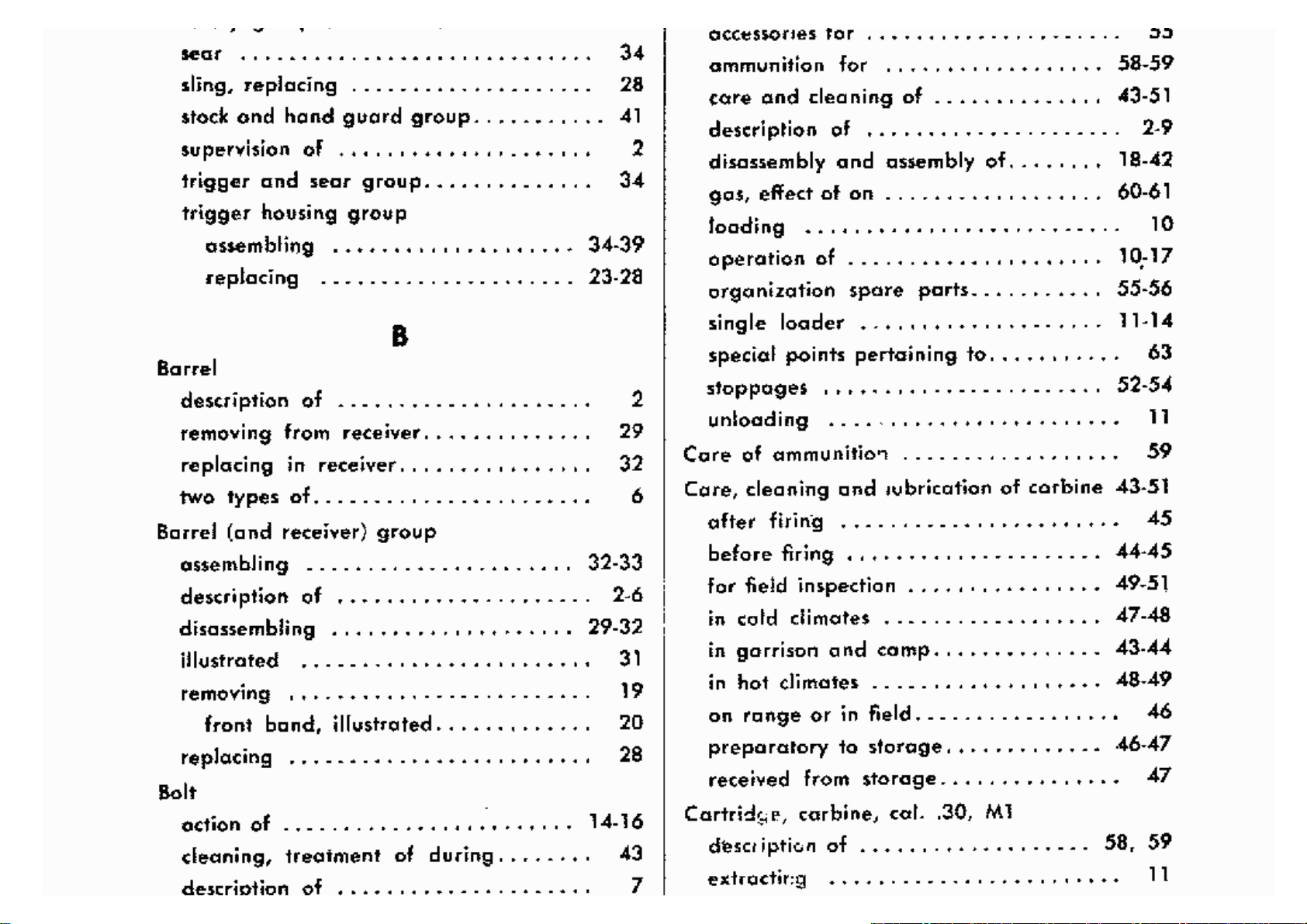

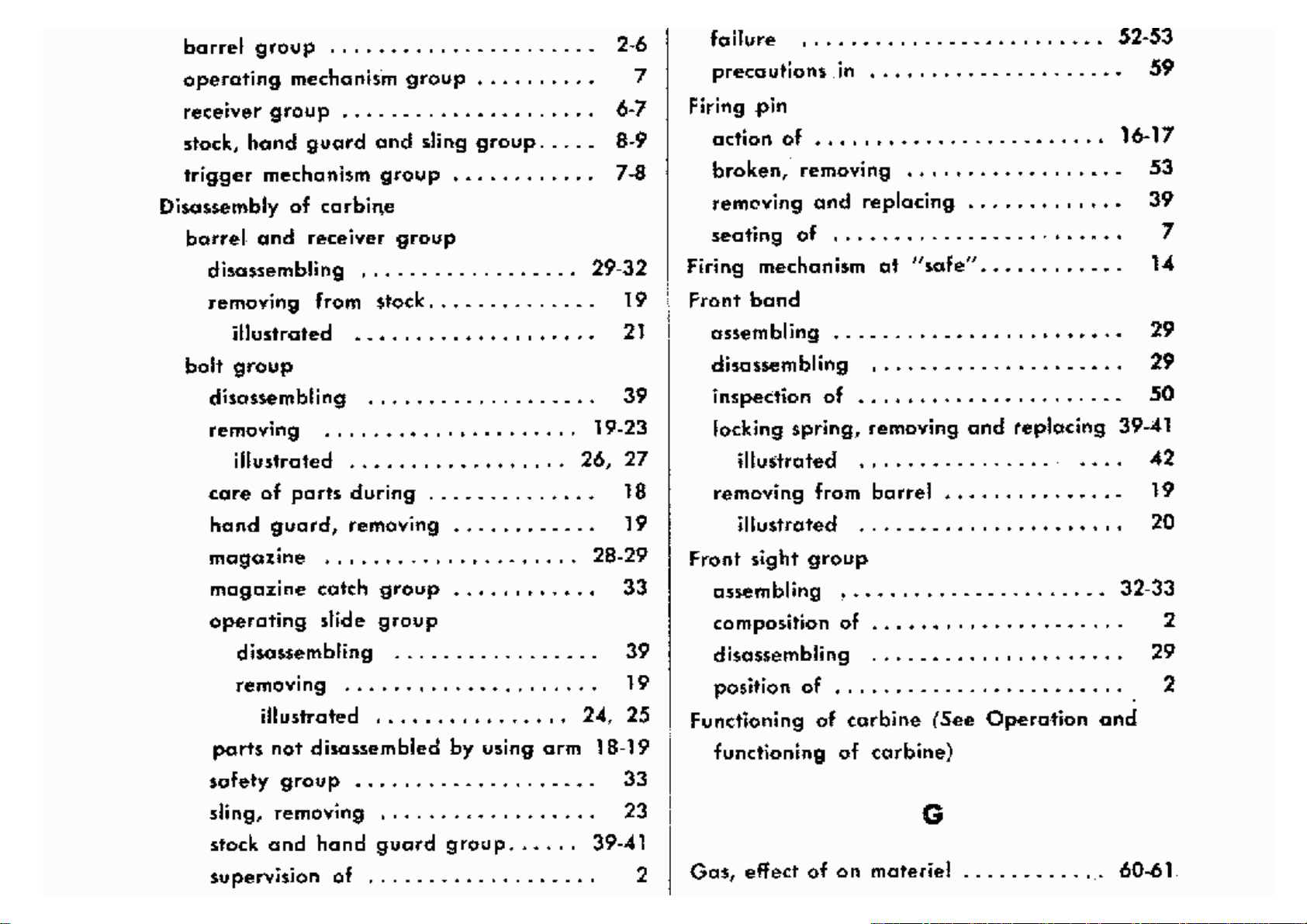

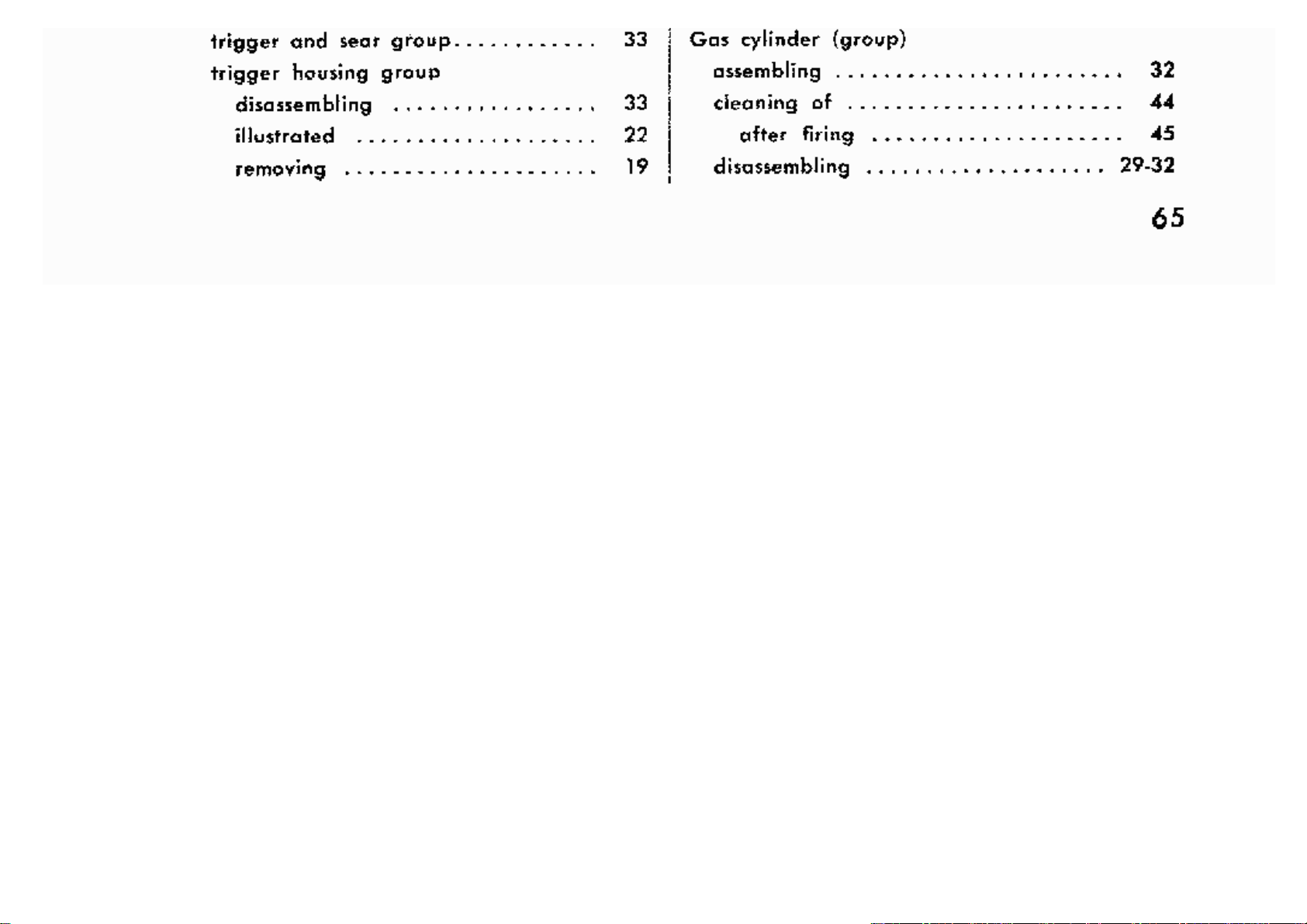

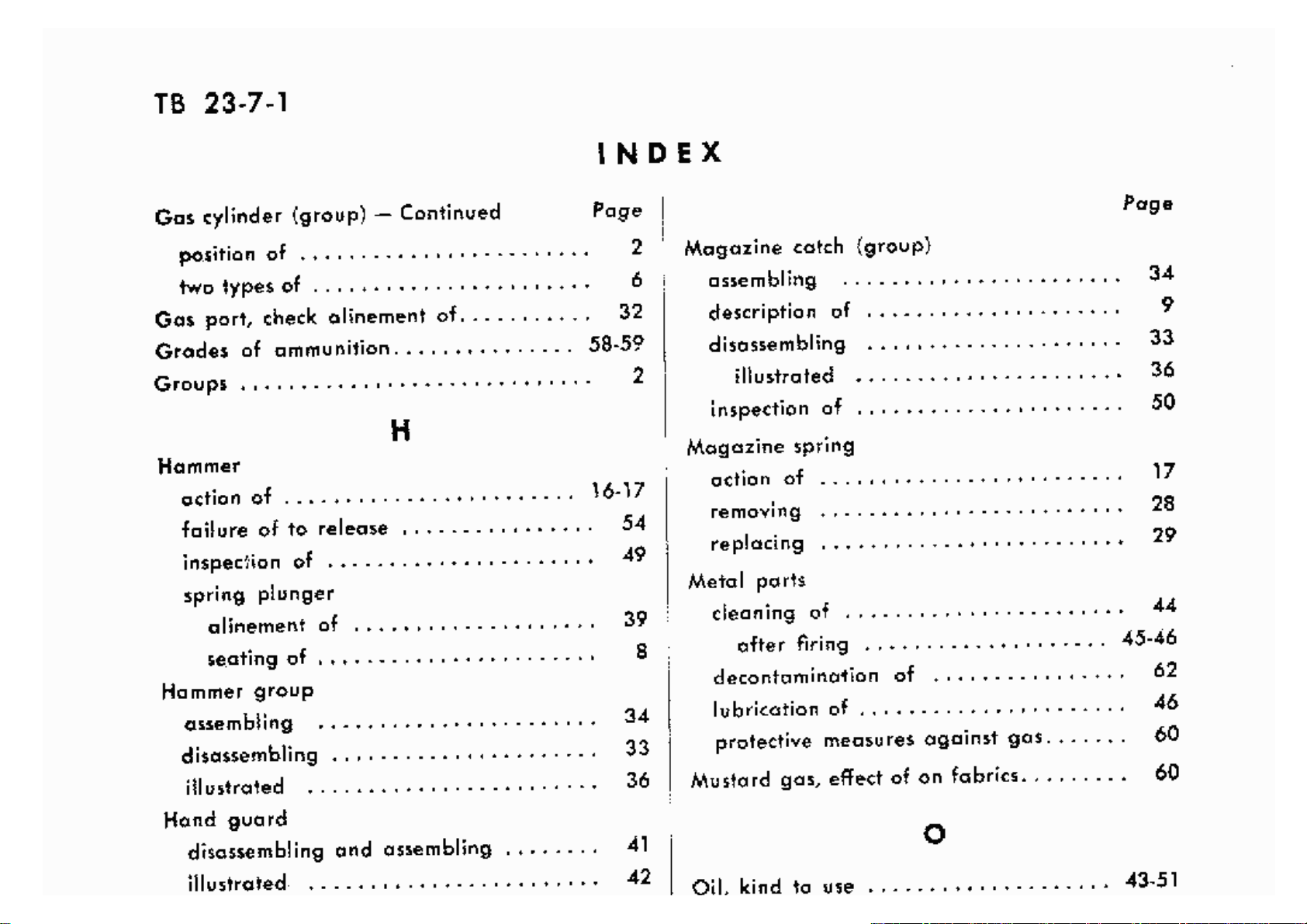

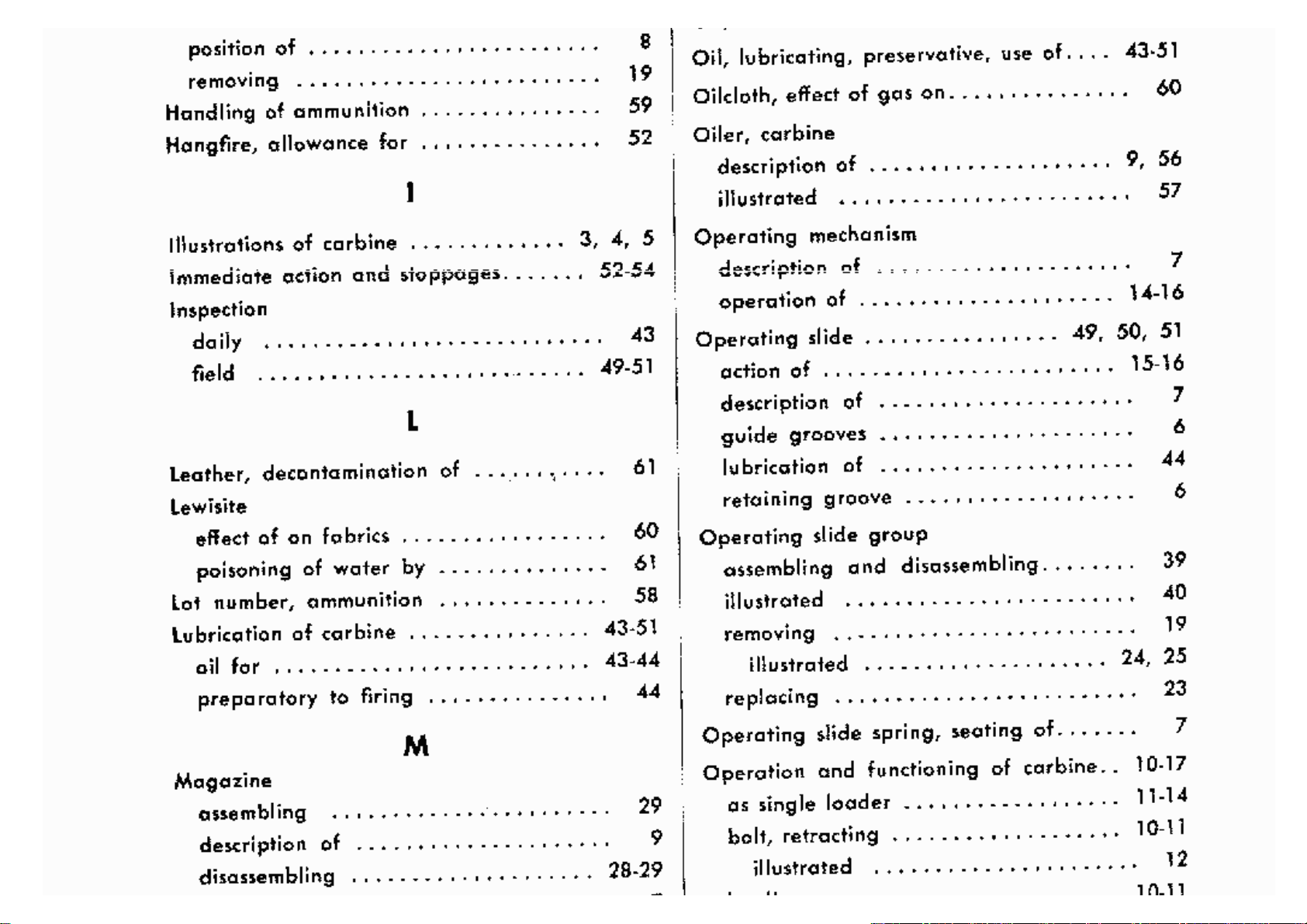

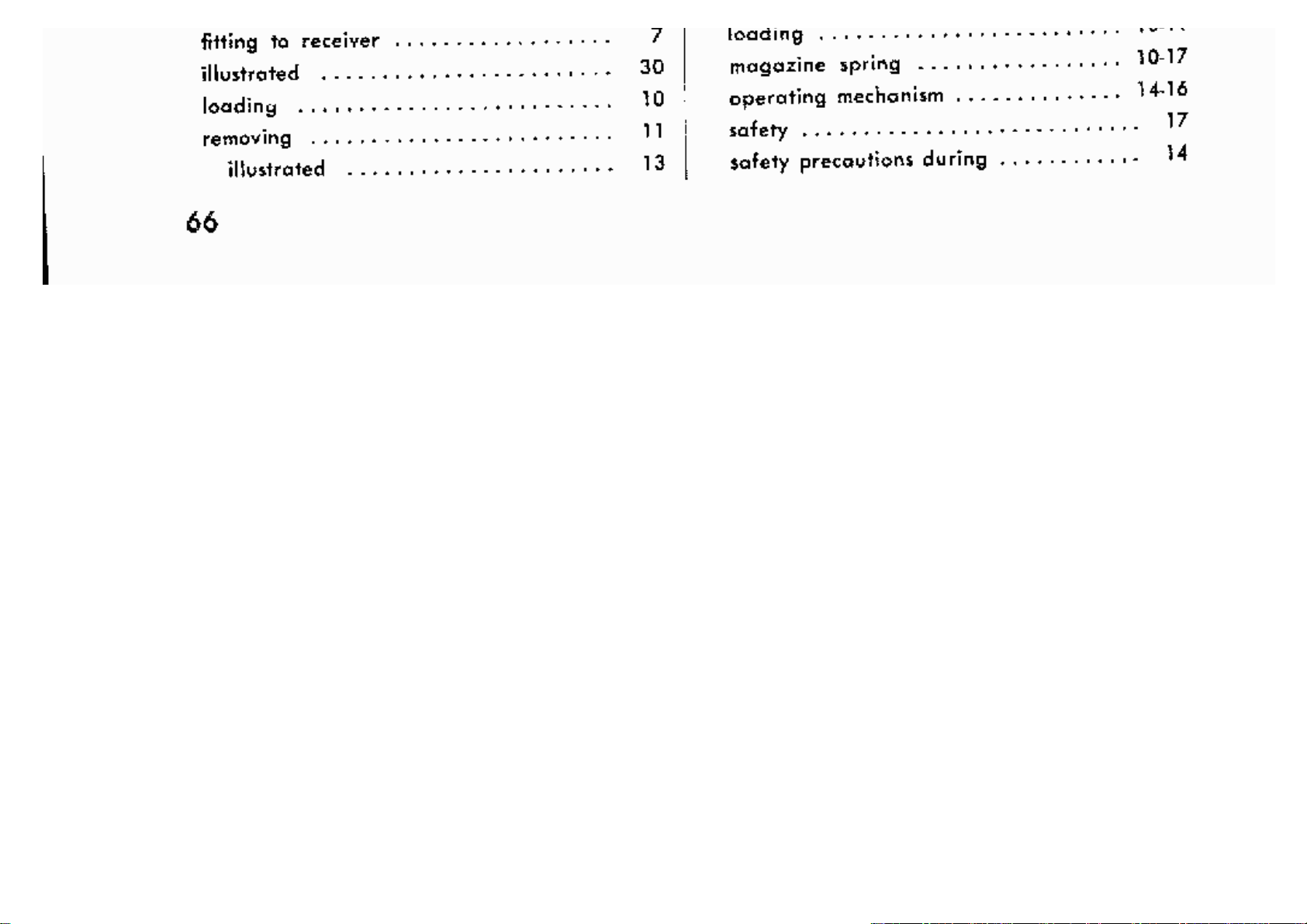

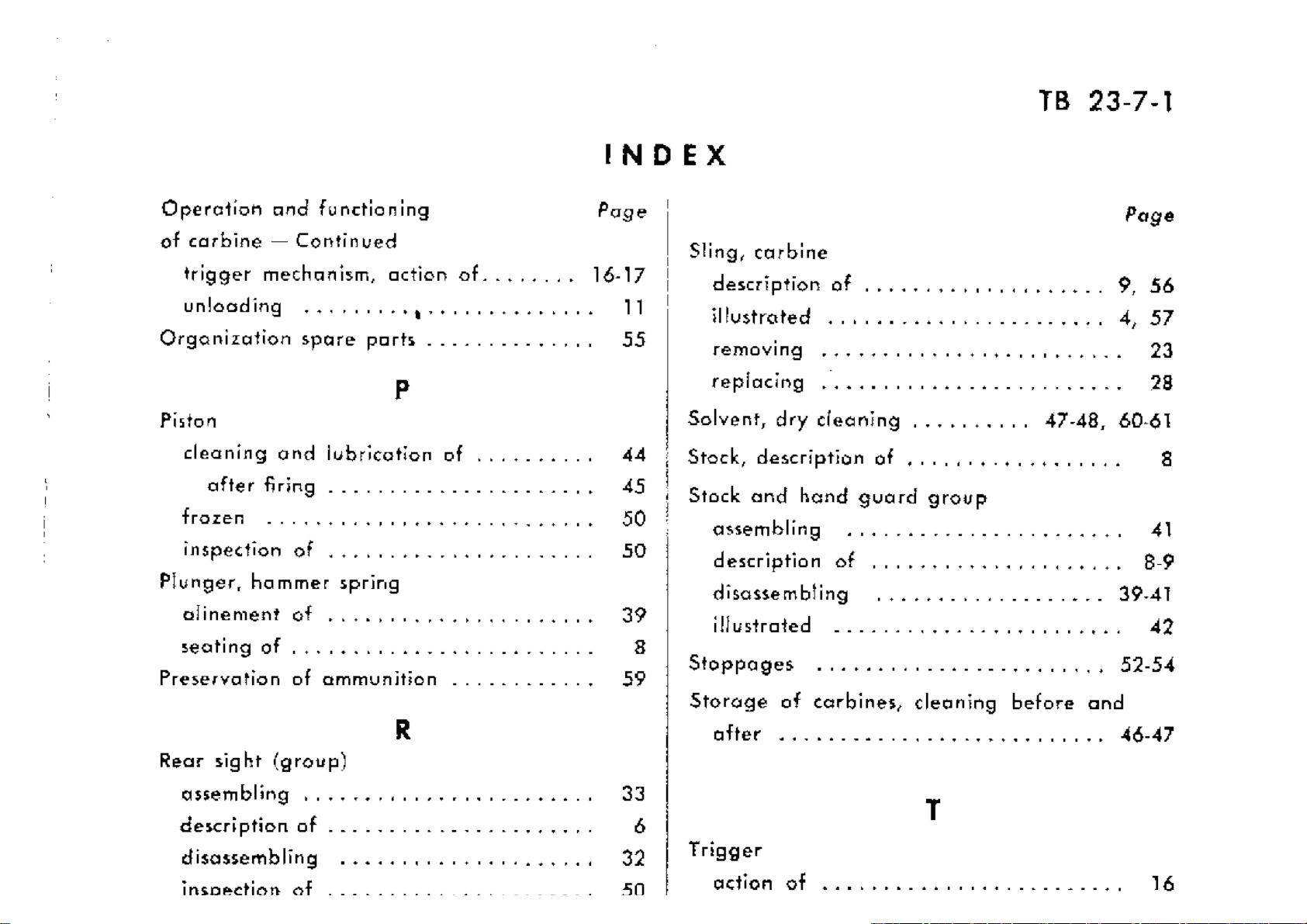

INDEX

64 - 67

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page1.html6-9-2008 14:49:26

Page 3

TB 23-7-1 Carbine, Cal. .30, M1 Section I

TB 23-7-1

CARBINE, CAL. .30, M1

SECTION I

INTRODUCTION

Paragraph

Scope 1

Description 2

Data 3

1. SCOPE. - a. This technical bulletin is published for the information and guidance of those concerned

pending the publication of FM 23-7 and TM 9-1276.

b. In addition to a description of the Carbine, Cal. .30, Ml, this technical bulletin contains information

required for the identification, use and care of the materiel and its component accessories, including available

information on ammunition.

c. Disassembly, assembly, and such repairs as may be handled using arms personnel will be undertaken

only under the supervision of an officer or the chief mechanic.

d. In all cases where the nature of the repair, modification or adjustment is beyond the scope or facilities of

the unit, the responsible ordnance service should be informed in order that trained personnel with suitable

tools and equipment may be provided, or proper instructions issued.

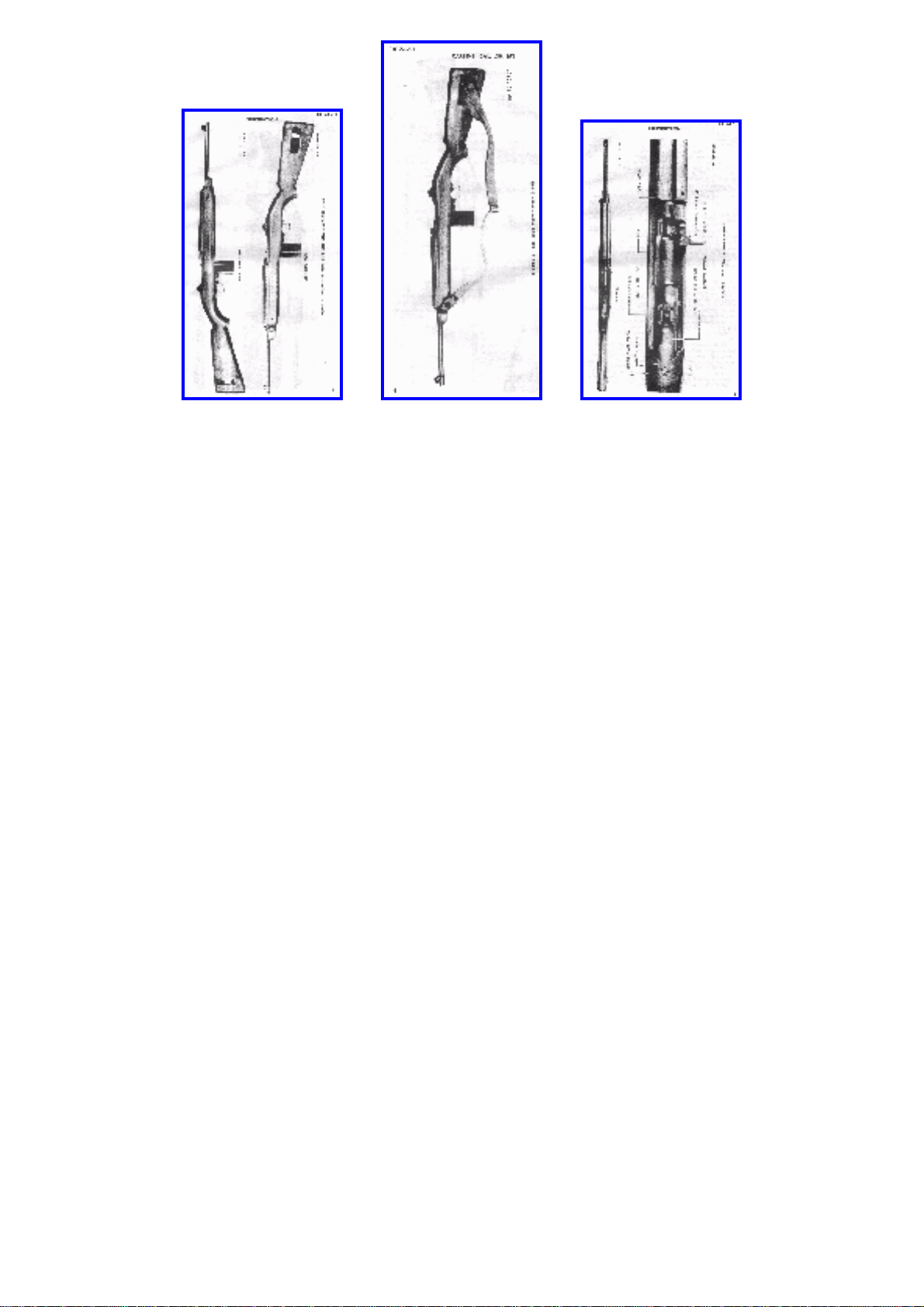

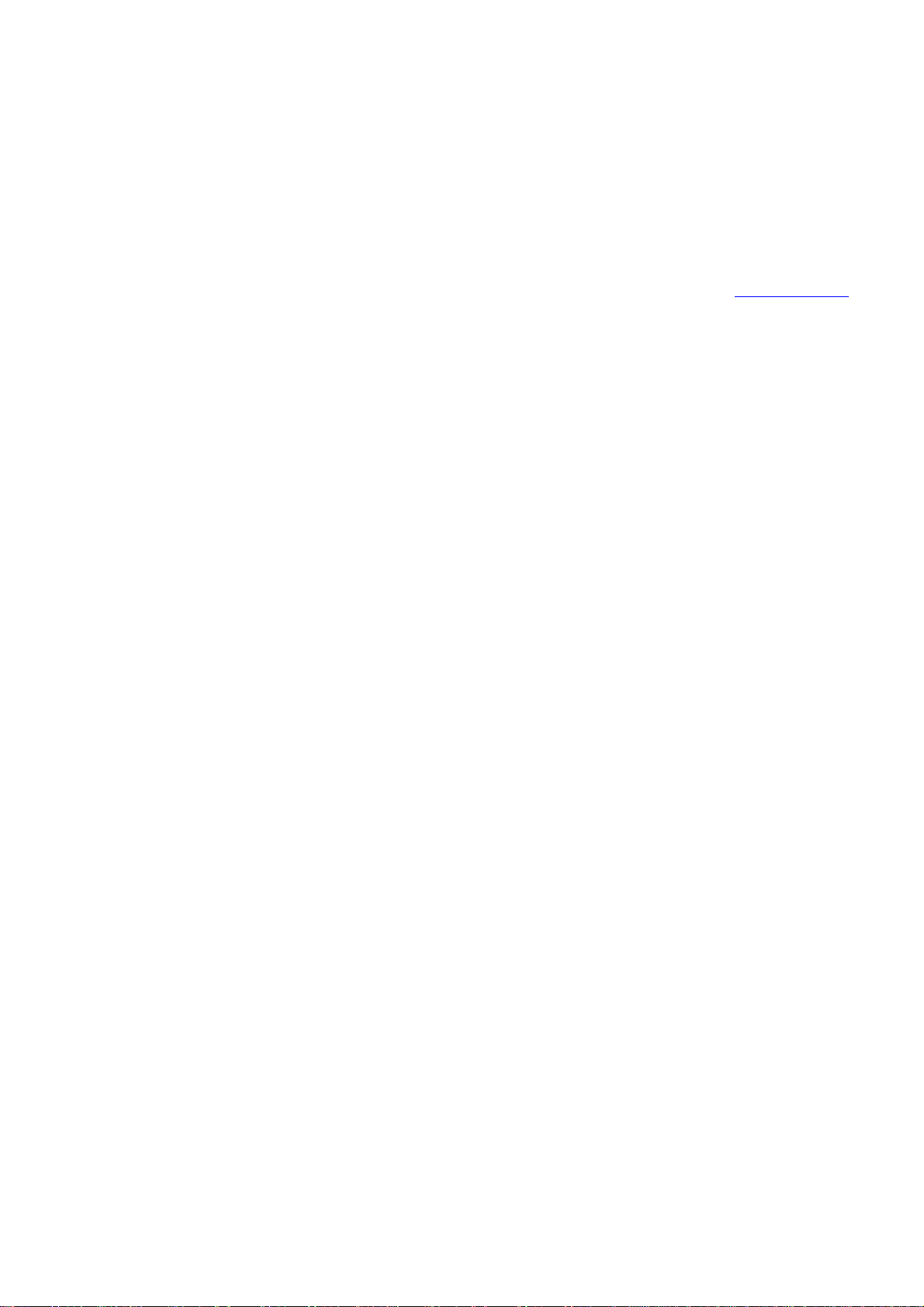

2. DESCRIPTION

. - a. The Carbine, Cal. .30, M1 (Figures 1, 2 and 3) is a gas-operated, self-loading, air-

cooled, shoulder weapon, delivering semi-automatic fire controlled by the operator. It is fed by a box

magazine containing 15 cartridges staggered in the magazine. The weapon has an over-all length of

approximately 36 inches and weighs approximately 5.80 pounds with sling and loaded magazine attached.

b. The carbine is in many ways similar in operation, functioning, and general design to the U. S. Rifle,

Cal. .30, Ml, and, in general, is composed of four main groups of assemblies and ports: the barrel and

receiver, the trigger mechanism, the operating mechanism, and the stock, hand guard and sling.

(1) Barrel group. - (a) The barrel is 18 inches tong, cylindrical and without taper for two-thirds of its

length. It is threaded into the forward end of the receiver, and in the rear face is a cut to furnish clearance for

the extractor. To the muzzle end is attached the front sight group composed of a ring body with on integral

blade positioned midway between two side wings keyed and pinned to the barrel.

(b) A gas cylinder is positioned on the underside of the barrel near the chamber and contains the piston,

locked in by the piston nut, which limits its rearward movement. A gas port is drilled at an angle through the

gas cylinder and barrel, entering the bore about 4.5 inches from the rear face of the barrel. This rearward

positioning of the gas cylinder and port makes it possible to take the gas from the bore close to the chamber,

before cooling can take place, thus minimizing carbonization.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page2.html (1 van 4)6-9-2008 14:49:29

Page 4

TB 23-7-1 Carbine, Cal. .30, M1 Section I

At this time there are two types of barrel and gas cylinder. In the first type the barrel and gas cylinder are

integral; in the second type the gas cylinder slides onto the barrel and is retained in position by a pin.

(c) On the lower sides of the barrel, to the rear of the gas cylinder,parallel guide grooves are cut, which

mate with guide lugs on the body of the operating slide to form a guideway for the operating slide and hold it

in position.In the left hand barrel groove is a relief cut, by means of which the slide body is positioned and

removed. (Refer subparagraph (3) (d) below).

(2) Receiver group. - (a) The receiver is of one piece, open at top and bottom, and contains the operating

mechanism, and to it the trigger housing (mechanism) is attached. In the inner sides of the receiver parallel

bolt guide grooves are cut, in which the bolt reciprocates and bolt lug locking apertures which are cut with a

shoulder which holds the bolt locked in the closed position when cam-rotated by the operating slide at the end

of the forward movement.

(b) On the right outer side of the receiver is the operating slide retaining groove in which the rear end

(handle) lug of the operating slide reciprocates when the slide is actuated by the piston and operatingslide

spring respectively. In the top of this groove is arelief cut, by means of which the rear end (handle) of the

operating slide is disengaged from the bolt. Slightly to the rear and below this relief cut is an aperture for

seating the operating slide stop.

(c) On the rear face of the receiver is a lug which engages in an undercut in the recoil plate (mounted in

the stock) to lock the rear end of the barrel and receiver group to the stock. Below this lug, on the underside of

the receiver, are two L-shaped lugs into which a T-lug on the rear end of the trigger housing slides and is

retained. On the forward end of the receiver is a straight tug with a pin hole which aligns with pin holes in a

mating U-lug on the forward end of the trigger housing. Through these aligned pinholes the trigger housing

retaining pin passes to hold the trigger housing in position.

(d) In the bridge of the receiver an aperture is cut with which the tong of the firing pin must mate in

order to move forward in the bolt. This mating cannot be accomplished until the bolt is rotated to the locked

position.

(e) On the top rear of the receiver is the rear sight group composed of a base (dovetailed into the

receiver), leaf, spring, and pin. The leaf is on L-shaped piece, consisting of two leaves set at right angles to

each other, each pierced with an aperture at a different height. The leaf can be rotated 90 degrees on the leaf

pin, thus positioning one or the other of the integral leaves, thereby giving sight elevations for two range

limits. This construction necessitates one leaf remaining upright at all times. When the low leaf is

perpendicular, the carbine is sighted up to 200 yards, and when the high leaf is perpendicular, up to 300 yards.

(For shot grouping at 100 and 300 yards, refer to paragraph 50 c).

(f) In the under side of the receiver is an aperture into which the magazine fits, and is retained by the

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page2.html (2 van 4)6-9-2008 14:49:29

Page 5

TB 23-7-1 Carbine, Cal. .30, M1 Section I

magazine catch positioned in the trigger housing.

(3) Operating mechanism group. - (a) The operating mechanism is composed of the bolt, the operating

slide, operating slide spring, and spring guide. The bolt operates within the receiver, and the operating slide in

its grooves on the right outside face of the receiver and lower rear faces of the barrel.

(b) The bolt contains the firing pin, extractor and ejector groups and is connected to the operating slide

by a lug on its right side, which mates with a camming aperture in the left face of the operating slide (handle).

In line with this lug, and similarly placed on each side of the bolt, are locking lugs which engage in the

receiver locking apertures already described.

(c) The extractor is of the claw type, seated in an aperture in the top of the bolt and actuated by a plunger

and spring. The ejector is seated in a well in the lower port of the bolt, locked in by the extractor, and actuated

by a spring. The firing pin is seated in a well in the center of the bolt, is locked in by the extractor and has a

tang on the rear end which blocks it from functioning until the bolt is locked, as already explained.

(d) The operating slide is composed of an integral body and (retracting)handle. The body reciprocates in

its guideways on the underside of the barrel, and the handle in its guideway in right outside face of the

receiver. The function of the slide is to move the bolt backward and forward unlocking it from, and locking it

to, the receiver at the proper time. The bolt in turn cocks the hammer on its rearward movement and feeds the

cartridge into the chamber on its forward movement. The force to accomplish these actions is supplied by the

backward thrust of the piston on the recoil stroke and the forward thrust of the loaded operating slide spring

on the counter recoil stroke. The operating slide is provided with a retracting handle for retracting the bolt. On

the shank of the handle is a lug which contains the afore mentioned bolt lug camming aperture. To the rear of

this lug is the guide lug. The operating slide spring seats in a well in the forward face of the receiver, and acts

on the operating spring guide, the forward end of which seats in an indentation in the rear face of the

operating slide (body). In the rear end of the operating slide (handle) is a stop operated by a spring. The stop

hangs the bolt when depressed and held into its retaining aperture in the operating slide (handle) guideway in

the receiver.

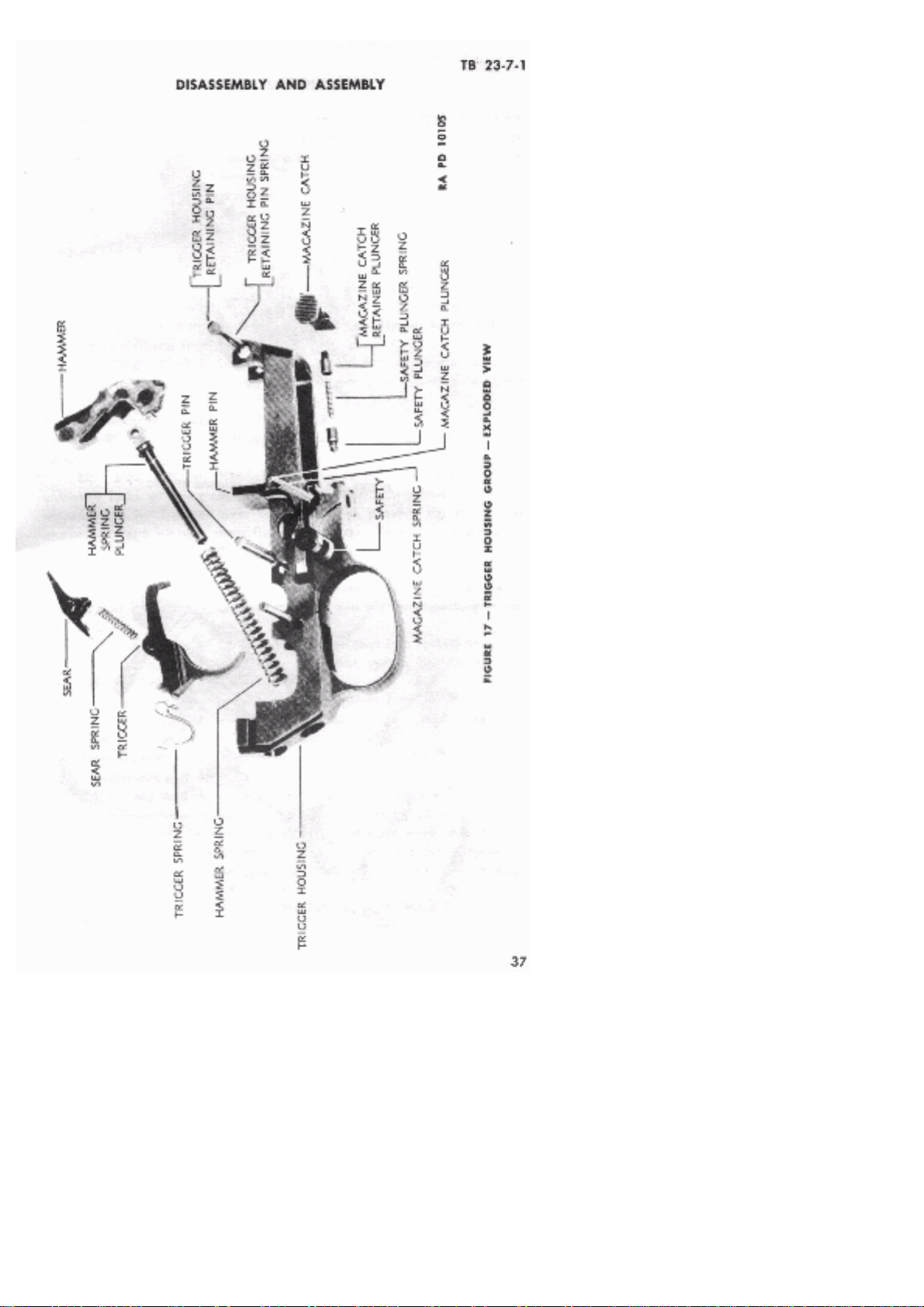

(4) Trigger mechanism group. - (a) The trigger (housing) mechanism group is composed of the trigger

housing, trigger, hammer and sear, together with their component springs and pins, and the hammer spring

plunger. The trigger housing is attached to the receiver at the rear, by means of a lug on the rear end of the

trigger housing which engages with L-shaped mating lugs on the lower rear face of the receiver. The front end

of the housing is held in position by a retaining pin passing through mating lugs on the forward end of the

receiver and trigger housing and held in position by a spring. (Refer to subparagraph b (2) (c), above).

(b) The trigger and sear rotate about the trigger pin and the hammer about the hammer pin. The hammer

spring plunger seats in a notch in the rear face of the hammer shank and extends through an aperture in the

rear of the trigger guard body, while the hammer spring bears upon the trigger housing and a collar on the

plunger. The trigger spring is a U-shaped spring which fits in a slot in the rear end of the trigger, and an

aperture in the rear end of the trigger housing. The rear end of the sear spring is seated in a well in the trigger

body, the forward end in an aperture in the rear lace of the sear.

(c) A safety is housed in the forward end of the trigger housing just forward of the bow. The safety is in

the form of a cylindrical pin with a cut so fashioned that it clears or blocks the forward end of the trigger

when the safety is pushed from side to side in its aperture. The safety is held in position by the safety plunger

and spring. On the right side of the trigger housing just ahead of the safety, is the magazine catch. This catch

functions in an aperture in the forward face of the trigger housing, and is held in engagement with two small

lugs on the magazine by the magazine catch spring and plunger. The catch, when pressed, moves laterally to

disengage it from the magazine lugs so that the magazine may be removed from the receiver.

(5) Stock, hand guard and sling group. -(a) The stock group is composed of the stock in which the

receiver and barrel are bedded, and the hand guard positioned on top of the barrel forward of the receiver. In

the rear of the aperture in which the receiver is bedded, the recoil plate is positioned. This plate is secured to

the stock by the recoil plate screw passing through the tang of the recoil plate and thence through the grip of

the stock, and threaded into an escutcheon let in to the underside of the stock grip. The recoil plate serves to

lock the rear end of the receiver to the stock as here to fore described, and to protect the wood of the stock

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page2.html (3 van 4)6-9-2008 14:49:29

Page 6

TB 23-7-1 Carbine, Cal. .30, M1 Section I

from the hammering of the recoil mechanism. A recessed butt plate is screwed to the butt end of the stock by

a wood screw.

(b) To the rear end of the hand guard a metal liner is riveted, which protrudes slightly beyond the wood

of the hand guard. This liner, when mated with an undercut in the top forward face of the receiver, secures the

rear end of the hand guard to the receiver. The forward end is secured to the barrel by the front band which

slides over the barrel and forward end of the stock and hand guard, thus securing all three together. The band

is locked in position by a locking spring and screw.

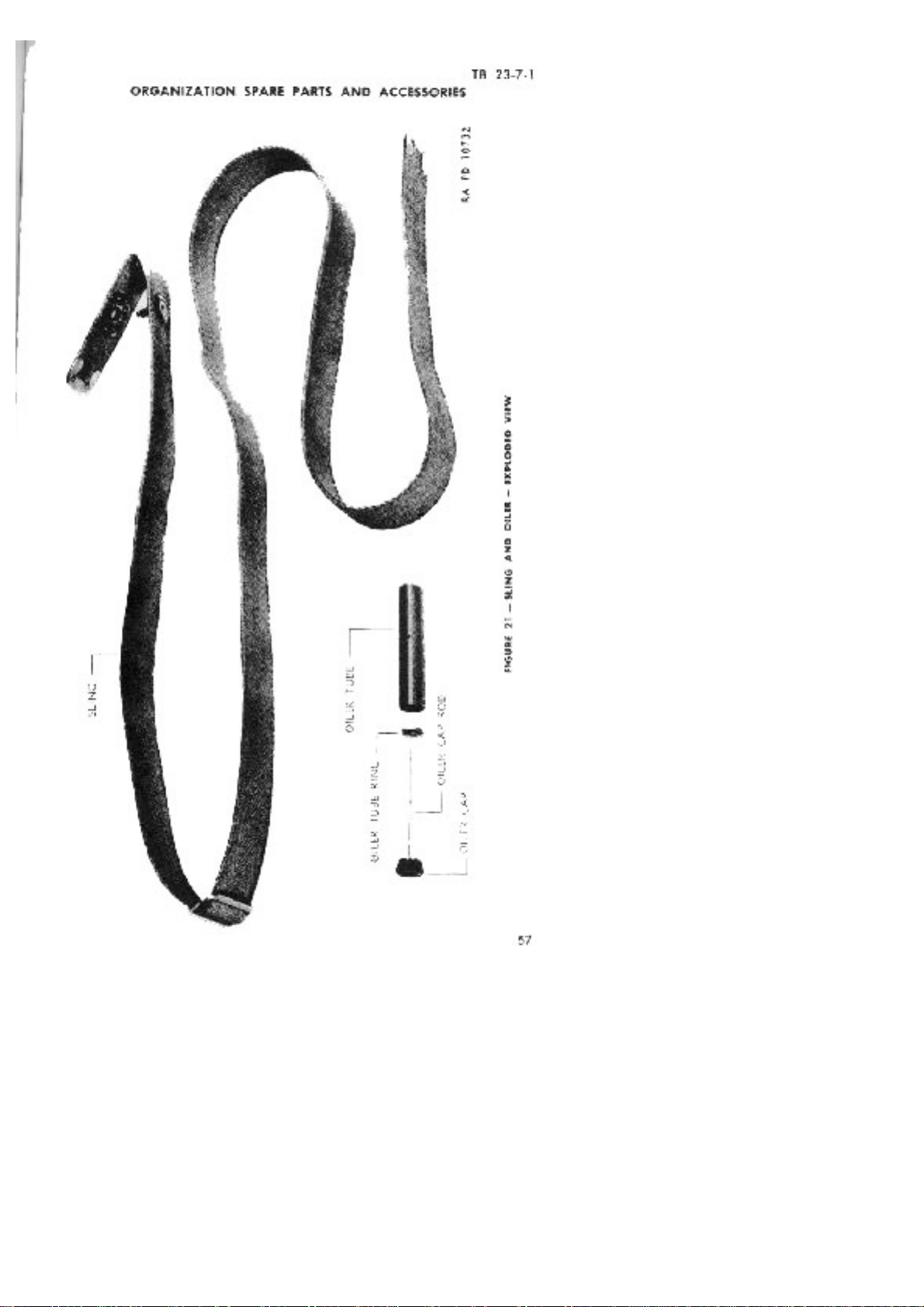

(c) A web sling is attached to a sling swivel mounted on the left side of the front band. In the rear end of

the sling a loop is formed by means of a metal button passing through two button holes in the sling (recent

style). This loop passes from the left side around the oiler, which seats in the right side of on aperture cut

through the stock near the butt. The dimensions of the aperture through which the oiler is inserted prevents it

falling out after the sling has been passed around it. Thus the oiler is held in the aperture by the sling, and acts

as an anchor pin for the rear end of the sling. To the forward end of the sling a locking buckle is attached, by

which adjustment of the sling is attained, after it has passed through the sling swivel.

NOTE: The oiler is cylindrical in shape and has a screw top to which a dropper rod is attached. It is used for

lubricating the carbine as well as to hold the sling in position.

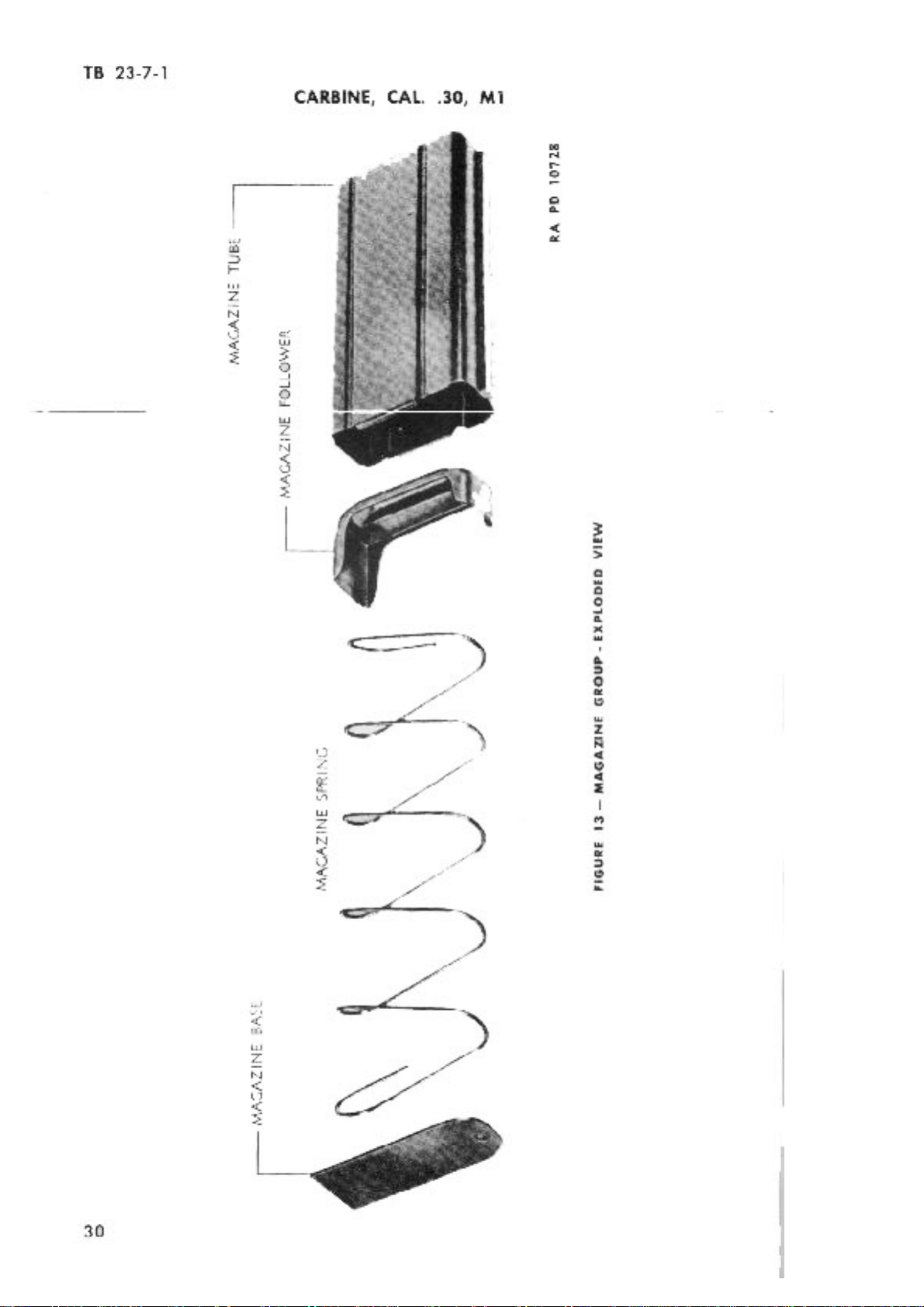

c. The magazine is composed of a tube, base, follower, and spring. When loaded, the cartridges lie

staggered in the tube and are pushed into line with the bolt, at the mouth of the tube, by the action of the

follower and the follower spring, The mouth of the tube is narrower than the body of the tube and has its lips

crimped inward. Thus one cartridge at a time is positioned and held in line with the bolt, ready to be pushed

forward and loaded into the chamber as the bolt moves forward on the counter recoil stroke.

3. DATA. --

Weight of carbine with magazine (unloaded) pounds 5.19

Weight of carbine with magazine (loaded) and sling pounds 5.80

Weight of magazine (unloaded) pounds 0.17

Weight of magazine (loaded) with 15 cartridges pounds 0.59

Weight of 100 cartridges pounds 2.79

Weight of 1 cartridge grains 1.95

Magazine capacity rounds 15

Overall length of carbine inches 36

Length of barrel inches 18

Rifling, R.H., one turn in inches 20

Grooves in barrel number 4

Sight radius inches 21.46

Trigger Pull pounds 4 - 6

Ballistics of cartridge

(Refer to Section

VII - Ammunition)

NOTE: 7000 grains equal 1 pound avoirdupois measure.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page2.html (4 van 4)6-9-2008 14:49:29

Page 7

TB 23-7-1 Carbine, Cal. .30, M1 Section II

TB 23-7-1

CARBINE CAL. .30, M1

SECTION II

OPERATION AND FUNCTIONING

Paragraph

General 4

To load the magazine 5

To load the carbine 6

To unload the carbine 7

To operate the carbine as a single loader 8

Individual safety precautions 9

Rearward movement of the operating mechanism 10

Forward movement of the operating mechanism 11

Action of the trigger mechanism 12

4 GENERAL. Operation and functioning will, for convenience, be divided into two main groups of

actions: the manual operations necessary to load, fire and unload the weapon, and the mechanical functioning

of the mechanisms when acted upon by the force generated by the expanding powder gas when the cartridge

is fired.

5. TO LOAD THE MAGAZINE. - Insert 15 cartridges into the magazine one at a time. To insert

cartridge, hold magazine in the left hand with the curved open end up and to the right. Grasp a cartridge in the

right hand between thumb and forefinger with base to the left. Insert base of cartridge in right end of opening

in top of magazine and press down with thumb against follower, forcing cartridge below lips of magazine.

Then push cartridge to left, beneath lips, until base of cartridge contacts rear of magazine tube. Grasp another

cartridge in the same manner and press down upon the first cartridge and slide the second cartridge to the left

over the first one. Continue thus until all the 15 cartridges are loaded into the clip. The cartridges will be

staggered in the magazine when it is fully loaded, with the top cartridge centered between the lips of the

magazine. If the follower does not depress smoothly, push down and release a few times. If this does not

improve the action, look for dents, rust or foreign matter in magazine tube, or for bent follower.

6. TO LOAD THE CARBINE. -- a. Insert a loaded magazine into opening in receiver with the

retaining lugs (flat face) to the rear and push it up until the magazine catch snaps into position, below the

retaining lugs on the rear face of the magazine tube. If magazine does not snap in easily, depress the catch.

Ordinarily this action should be performed with the bolt locked and the hammer let down. This makes it

possible to carry the carbine safely with loaded magazine attached, as it cannot be fired until the bolt is

retracted and allowed to close and lock.

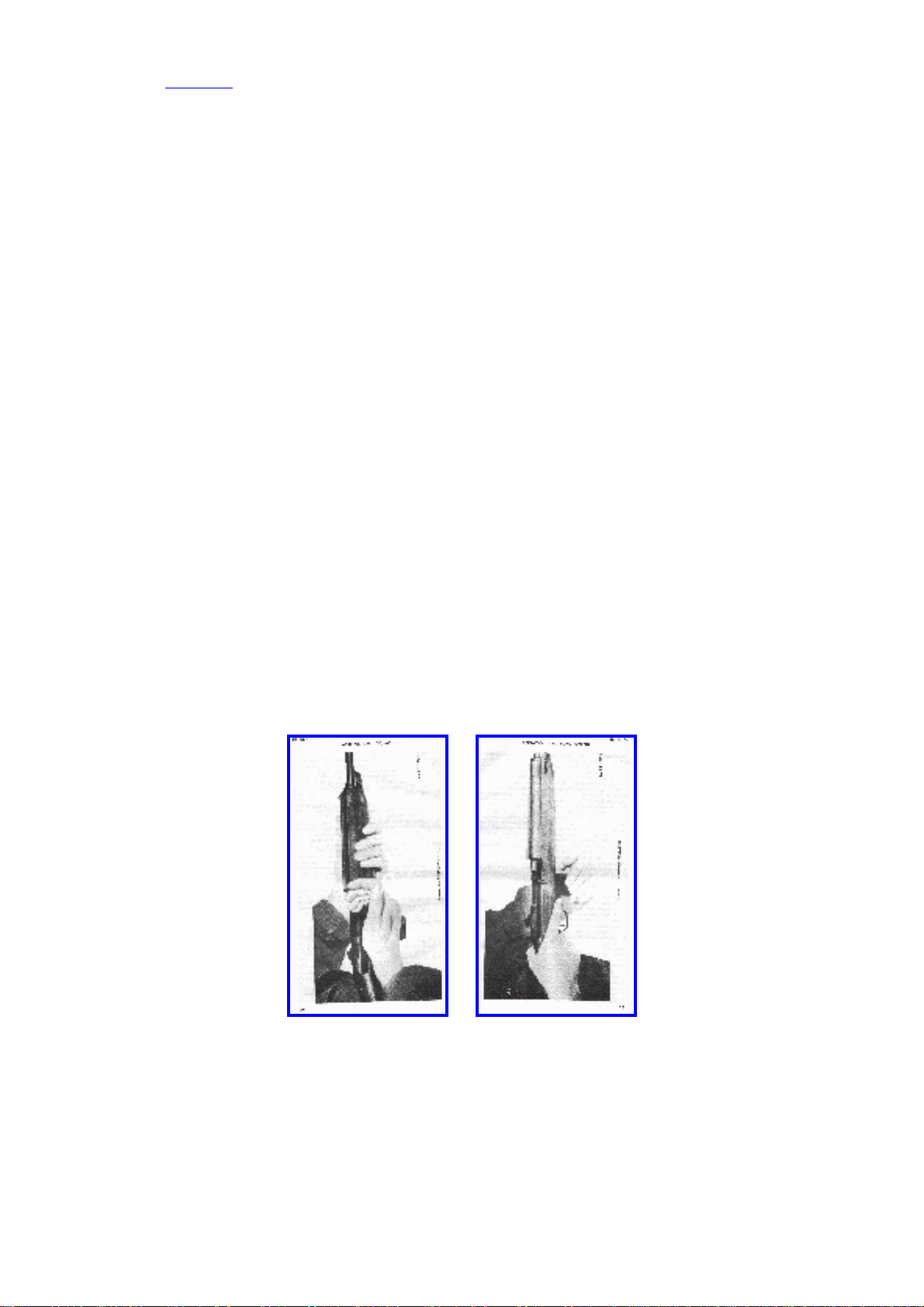

b. With loaded magazine latched in position, retract the bolt, with little finger (Figure 4), all the way to rear

by pulling back the operating slide handle, and then allow it to snap forward. Unless the bolt is fully retracted,

the sear may not be seated properly in the sear notch in the hammer. The carbine is now fully loaded with a

cartridge in the chamber and the hammer cocked. To fire the carbine it is now only necessary to pull the

trigger and thus release the hammer. When thus loaded, unless the carbine is to be fired immediately, the

firing mechanism should be placed at safe by pushing the safety all the way to the right. When thus placed at

safe, the safety must be pushed all the way to the left before the trigger can be pulled to fire the weapon (For

sight Setting refer to paragraph 2 b (2) (e)).

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page10.html (1 van 4)6-9-2008 14:49:30

Page 8

TB 23-7-1 Carbine, Cal. .30, M1 Section II

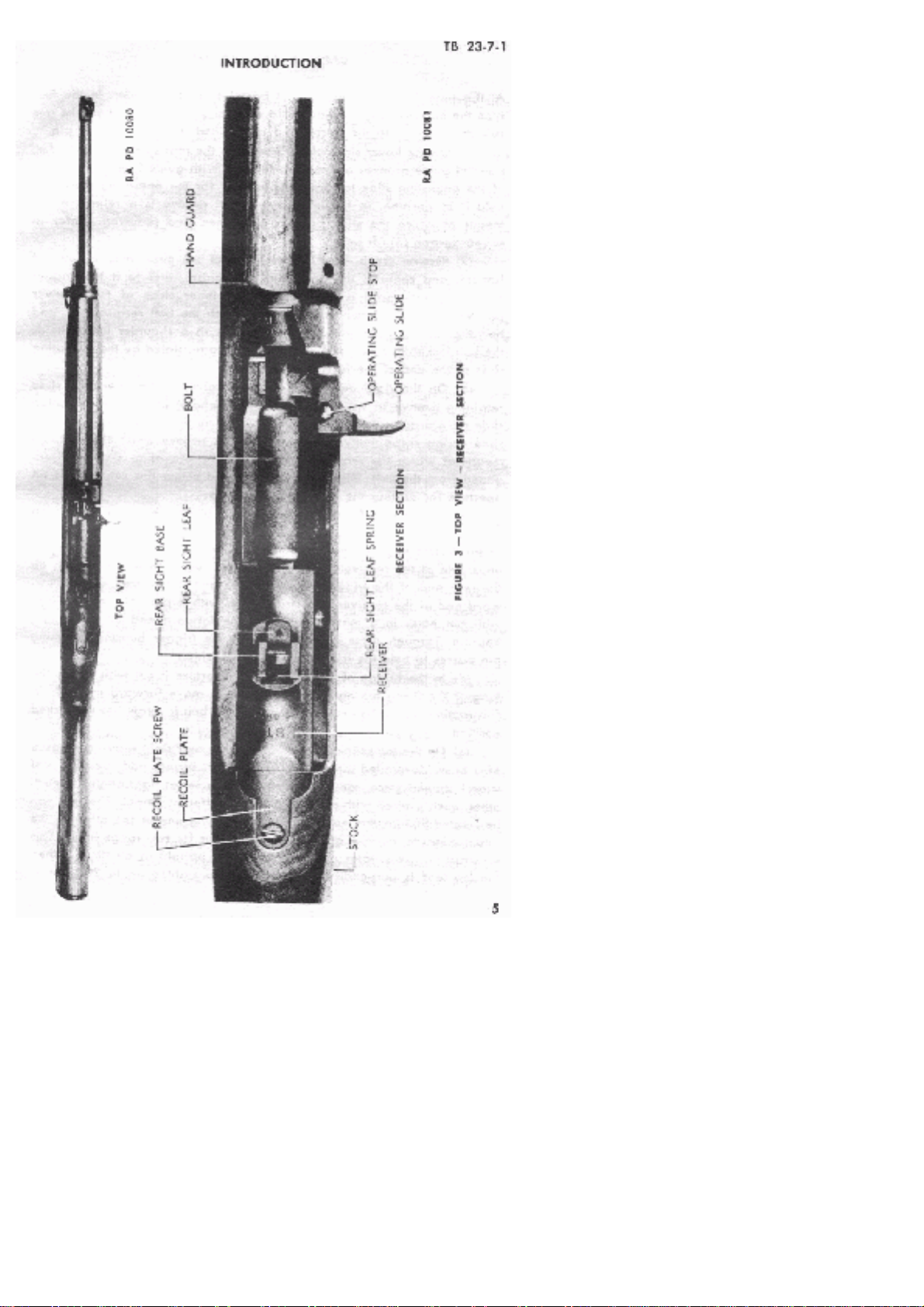

7. TO UNLOAD THE CARBINE.-- a. Press the magazine catch to the left and withdraw the magazine

from the receiver (

Figure 5). Magazine will usually fall out.

b. Retract the bolt fully by pulling back the operating slide handle. As the bolt moves to the rear it will

extract the cartridge seated in the chamber and elect it. The live cartridge case can be prevented from being

thrown clear of the receiver by the ejector, and so possibly damaged, by placing the thumb over the receiver,

thus blocking the throw of the cartridge. If cartridge is ejected freely, it should be wiped clean of foreign

matter before reloading it into the magazine. Examine chamber to see that it is empty before allowing bolt to

go forward and close. This is always a safe practice when retracting the bolt, to obviate the possibility of a

cartridge being left in the chamber. Ordinarily the bolt should be allowed to close slowly on an empty

chamber and not to snap shut.

c. When it is determined beyond doubt that the chamber is empty and with the magazine removed from the

receiver, remove the tension from the hammer spring by pulling the trigger and letting the hammer down. If

this is done while the bolt is still partly retracted, the hammer blow on the firing pin will be lessened and the

hammer will be let down easily as the bolt closes. The hammer should never be so released when there is a

loaded cartridge in the chamber.

d. To unload the chamber without withdrawing the magazine, retract the bolt, block the extracted cartridge

as explained and lift from the receiver. Before allowing the bolt to go forward, depress the top cartridge in the

magazine with the thumb so that the bolt will ride over it in closing. Allow the bolt to close slowly, watching

to see that it slides over the top cartridge and closes on an empty chamber. As a rule, however, the magazine

should be removed, unless empty, before chamber is unloaded.

8. TO OPERATE THE CARBINE AS A SINGLE LOADER.--

With empty magazine in place,

retract bolt fully and place a cartridge in the chamber. Allow bolt to close smartly so that extractor will engage

base of cartridge and bolt be rotated to full lock. Where noise is a factor, the bolt may be eased to the closed

position and the operating slide handle pressed forward at the end of the movement to insure complete locking

of the bolt. Unless carbine is to be fired immediately, the firing mechanism should be placed at safe, by

pressing safety fully to right. To unload, retract bolt fully to the rear, to eject cartridge, and examine chamber

to make sure it is empty, before allowing to close.

CAUTION: During the operation of loading and unloading and placing firing mechanism on safe, the

muzzle of the carbine should be pointed down, and care exercised to see that it is not pointing at the foot or

anything that could be damaged in case the carbine fires accidentally. Care should always be observed when

handling weapons whether loaded or unloaded.

9. INDIVIDUAL SAFETY PRECAUTIONS. --

a. Consider every carbine to be loaded until you

have examined it and proved it to be unloaded. Never trust your memory as to its condition in this respect.

b. Never point the carbine at anyone you do not intend to shoot, nor in a direction where an accidental

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page10.html (2 van 4)6-9-2008 14:49:30

Page 9

TB 23-7-1 Carbine, Cal. .30, M1 Section II

discharge may do harm.

c. Always fully unload the carbine if it is to be left where someone else may handle it.

d. Always point the carbine up when snapping the trigger after examination.

e. If it is desired to carry the carbine cocked, with a cartridge in the chamber, the trigger should be blocked

by pushing the safety to the right.

f. Under no circumstances should the hammer be let down on a partially closed bolt, with a cartridge in the

chamber.

g. Never fire a carbine with any grease, cleaning patch, dust, dirt, mud, snow, or other obstruction in the

bore. To do so may burst the barrel or blow the bolt.

h. Never grease or oil the ammunition. This may affect the ammunition, and creates a hazardous pressure

on the carbine bolt. (Refer to

paragraph 51).

i. Chamber and bore should be wiped dry of oil or grease before firing for the reason given in g and h

above.

j. See that ammunition is clean and dry. Examine all live and dummy ammunition. Turn in all cartridges

with loose bullets or which appear to be otherwise defective.

k. Do not allow ammunition to be exposed to the direct rays of the sun for any length of time. This creates

hazardous chamber pressure.

10. REARWARD MOVEMENT OF THE OPERATING MECHANISM. -- In the following

description of the mechanical functioning of the carbine, it is assumed that the carbine has lust been fired and

that there is a full or partially full magazine in the carbine.

a. As the bullet passes down the bore, propelled by the force of the expanding powder gas, it passes the gas

port in the bore. As the bullet clears the port some of the highly compressed gas, propelling it, passes through

the port into the gas cylinder and acts upon the head of the piston. The piston is driven rearward a short

distance (about ¼ inch) where it is stopped by contact with the piston nut which locks it in the gas cylinder.

The rearward motion of the piston is transferred to the operating slide, the forward face of which has been

bearing upon the rear face of the piston. The operating slide is thus driven rearward, carrying with it the bolt

with which it is engaged.

b. Before starting its rearward movement the bolt is rotated slightly through the camming action of the cam

aperture in the operating slide (handle) lug with which it is engaged. This cammed rotation disengages the

locking lugs of the bolt from the corresponding apertures in the receiver and allows the bolt to be moved to

the rear by the operating slide. During this rearward movement the operating slide compresses the operating

slide spring which seats in its well in the forward face of the receiver and through its guide bears on the rear

face of the operating slide body. The compression of this spring furnishes the power for the forward

movement of slide and bolt.

c. As the bolt moves rearward it withdraws the empty cartridge case from the chamber, gripped in the

extractor. As the forward end of the empty case clears the receiver, the ejector (in face of the bolt) which has

been held under compression against the base of the cartridge case, throws the case off the bolt and out of the

receiver.

d. While moving to the rear, the rear face of the bolt bears against the forward face of the hammer and thus

drives the hammer back and down, rotating it about the hammer pin, until the sear notch of the hammer is in

position to be engaged by the nose of the sear. At this point the nose of the sear engages in the sear notch in

the hammer and is held in engagement (due to the elongation of the pivot hole) by the pressure of the sear

spring, as the bolt rides back over the hammer, for a short distance, to the end of its rearward movement.

11. FORWARD MOVEMENT OF THE OPERATING MECHANISM.--

When the bolt has

reached the limit of its rearward (recoil) movement, it starts forward, propelled by the operating slide. The

energy for the forward (counterrecoil) movement of the slide and bolt is furnished by the operating slide

spring which was compressed (loaded) during the rearward movement of operating slide. The bolt, moving

forward, strikes the base of a cartridge which was centrally positioned in the mouth of the magazine by the

magazine follower and spring, after the bolt passed over it during the rearward movement. As the bolt

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page10.html (3 van 4)6-9-2008 14:49:30

Page 10

TB 23-7-1 Carbine, Cal. .30, M1 Section II

continues forward it pushes the cartridge out of the magazine and into the chamber of the barrel. As the bolt

slams shut on the seated cartridge, the extractor is cammed open and its claw then slips into the cannelure in

the base of the cartridge. At the same time the ejector, in the face of the bolt, is compressed against its spring

by the base of the cartridge. As the bolt moves farther forward, it is rotated by the cam in the operating slide

(handle) lug so that, upon closing, its locking lugs are in position in front of the locking shoulders of the

receiver. The tang of the firing pin is now in position to mate with the slot in the receiver and be driven

forward to fire the cartridge when the hammer is released.

12. ACTION OF THE TRIGGER MECHANISM. --

a. The recoiil off the bolt is completed so

rapidly that the operator has not usually had time to release the trigger. Thus the trigger is still in the rearward

position when the hammer is driven back and down (cocked) by the bolt on its rearward (recoil) movement. In

this rearward position, the rear end of the trigger is raised and the trigger spring compressed. The sear spring,

however, has forced the sear forward, as the (trigger) pin hole in the sear is in the form of an elongated slot.

The forward movement of the sear has caused the rear end of the sear to drop below the level of the lip on the

rear (top) of the trigger. As the hammer is forced back and down, rotating on its pin by the rearward

movement of the bolt, the lower (curved) surface of the hammer rides over the top of the sear until the sear

notch in the hammer is in position to be engaged by the sear. At this point the sear spring forces the nose of

the sear into engagement with the sear notch in the hammer. The elongated (trigger) pin hole in the sear

allows the sear to remain in engagement with the hammer even when the hammer is forced back beyond the

cocking' point by the bolt riding over it, in completing the rearward movement.

b. When the trigger is released, the trigger spring forces its rear end downward, and the hammer spring,

acting through the hammer, forces the sear to the rear. This rearward movement of the sear is made possible

by the elongated (trigger) pin hole in the sear. The release of the trigger has allowed the lip on its rear (top)

end to drop low enough for the sear to ride over, and rest upon it.

c. If the trigger is now retracted (squeezed), the rear end will rise, carrying with it the rear end of the sear

which is now resting upon it. The sear, pivoting about the trigger pin, will have its forward end forced down

and thus out of engagement with the sear notch in the hammer. The hammer is thus free to rotate about the

hammer pin. It is forced forward by the hammer spring plunger, propelled by the force of the compressed

hammer spring, and strikes the tang of the firing pin. The firing pin is thus driven forward to strike the primer

which fires the cartridge and starts a new functioning cycle.

d. In moving forward, the tang of the firing pin must clear a slot in the bridge of the receiver, which can

only be done when the bolt is fully rotated to the locked position. If the hammer should strike the firing pin

when the bolt is in any other position, the effect would be to deaden the hammer blow and to rotate the bolt

towards its locked position.

e. The carbine is provided with a safety, located in the bow of the trigger housing just forward of the

trigger. When it is positioned to the left a slot in the safety permits the forward end of the trigger to be

depressed, thus allowing the rear end to rise. If the safety is positioned to the right, the solid part of the safety

blocks the forward end of the trigger, and prevents it from being depressed. Thus the rear end cannot rise and

the hammer cannot be released.

f. The magazine is composed of a tube, base, follower and spring. The spring is positioned in the tube

between the base and the follower so that when the follower is forced towards the bottom of the tube the

spring is compressed. The compression of the spring furnishes the force for feeding the cartridges into

position at the mouth of the tube. The cartridges are loaded into the magazine tube one at a time, as described

in "To load the magazine," paragraph 5. The magazine is held in position in the bottom of the receiverby the

magazine catch as already described.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page10.html (4 van 4)6-9-2008 14:49:30

Page 11

TB 23-7-1 Carbine, Cal. .30, M1 Section III

TB 23-7-1

CARBINE, CAL. .30, M1

SECTION III

DISASSEMBLY AND ASSEMBLY

Paragraph

General 13

Removal of groups 14

Replacement of groups 15

Magazine, disassembly 16

Magazine, assembly 17

Front band, disassembly 18

Front band, assembly 19

Barrel and receiver group, disassembly 20

Barrel and receiver group, assembly 21

Trigger housing Group, disassembly 22

Trigger housing Group, assembly 23

Operating slide group, disassembly 24

Operating slide group, assembly 25

Bolt group, disassembly 26

Bolt group, assembly 27

Stock group, disassembly 28

Stock group, assembly 29

13. GENERAL. -- a. Disassembly and assembly is treated herein under two general heads:

removal and replacement of groups to the extent required for cleaning, adjustment and minor repairs,

and detailed disassembly and assembly of the component parts of each group.

b. When disassembling, attention should be paid to the position and manner of removal of groups

and parts as an aid to assembly. A group is a number of parts which either function together or are

intimately related to each other and should, therefore, be considered together.

c. Disassembled groups and parts should be placed upon a clean, flat surface and care observed to

guard against loss of pins, springs and other small parts. All parts should be thoroughly cleaned and

oiled before assembly, and the carbine lubricated and hand operated, when assembly is complete, to

test mechanisms.

d. The groups may be removed and disassembly accomplished with the tools provided and listed

in SNL B-28.

e. Disassembly, assembly, and such repairs as may be handled by using arms personnel will be

undertaken only under the supervision of an officer or the chief mechanic.

f. Disassembly of the following groups and parts are generally prohibited to the using arms:

(1) Magazine assembly.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (1 van 10)6-9-2008 14:49:38

Page 12

TB 23-7-1 Carbine, Cal. .30, M1 Section III

(2) Barrel and receiver assembly.

(3) Barrel with gas cylinder assembly.

(4) Rear sight base.

(5) Front sight.

(6) Front band assembly.

(7) Recoil plate.

(8) Operating slide assembly.

(9) Stock and hand guard assemblies.

14. REMOVAL OF GROUPS. -- a. Barrel and receiver group. -- (1) Release magazine from

receiver by pressing the magazine catch to left and withdrawing magazine downward, if it does not

fall out.

(2) Retract bolt and glance into chamber to insure that carbine is unloaded.

(3) Press sling swivel back against stock. Loosen front band by unscrewing front band screw part

way (

figure 6). (The screw may be loosened with the head of a carbine cartridge). Press forward end

of locking spring towards stock (

figure 6) and slide front band forward over front band locking

spring. The front band cannot be removed from barrel until front sight is removed.

(4) Remove hand guard by sliding it forward on barrel until the liner is disengaged from undercut

in the forward face of receiver, and then lifting it from barrel.

(5) Lift forward end of barrel and receiver group from stock (about 15 degrees) until lug at rear

end of receiver is disengaged from under retaining notch in face of recoil plate (

Figure 7). When lug

is clear, pull barrel and receiver forward and up and lift out of stock with trigger housing group

attached.

b. Trigger housing group. -- Push out trigger housing retaining pin from left side of forward end of

trigger guard until clear of lug on receiver. Pull trigger housing forward until rear lug is clear of

mating grooves in receiver, and then remove trigger housing group from receiver. Press retaining pin

home in trigger housing to prevent loss. (See

Figure 8, showing groups removed.)

c. Operating slide group (Figures

9 and 10). -- (1)Draw operating slide spring guide slightly to rear

until it is disengaged from operating slide, and then pull to right, and forward, and withdraw guide

and spring from well in receiver. Disengagement of guide may be facilitated by retracting slide part

way, then, holding spring and guide, push slide forward and remove slide as above.

(2) Draw operating slide slowly to rear until forward face of stop is in line with forward face of

top of receiver. Pull handle up and to right until guide lug is free of retaining groove in receiver. Push

body of slide forward until rear face of stop is in line with forward face of top receiver. Pull handle

up and to right until guide lug is free of retaining groove in receiver. Push body of slide forward until

rear face of stop is in line with forward face of top of receiver and rotate slide body counterclockwise,

freeing lug (by means of relief cut) from retaining guideways in barrel. Remove slide from barrel.

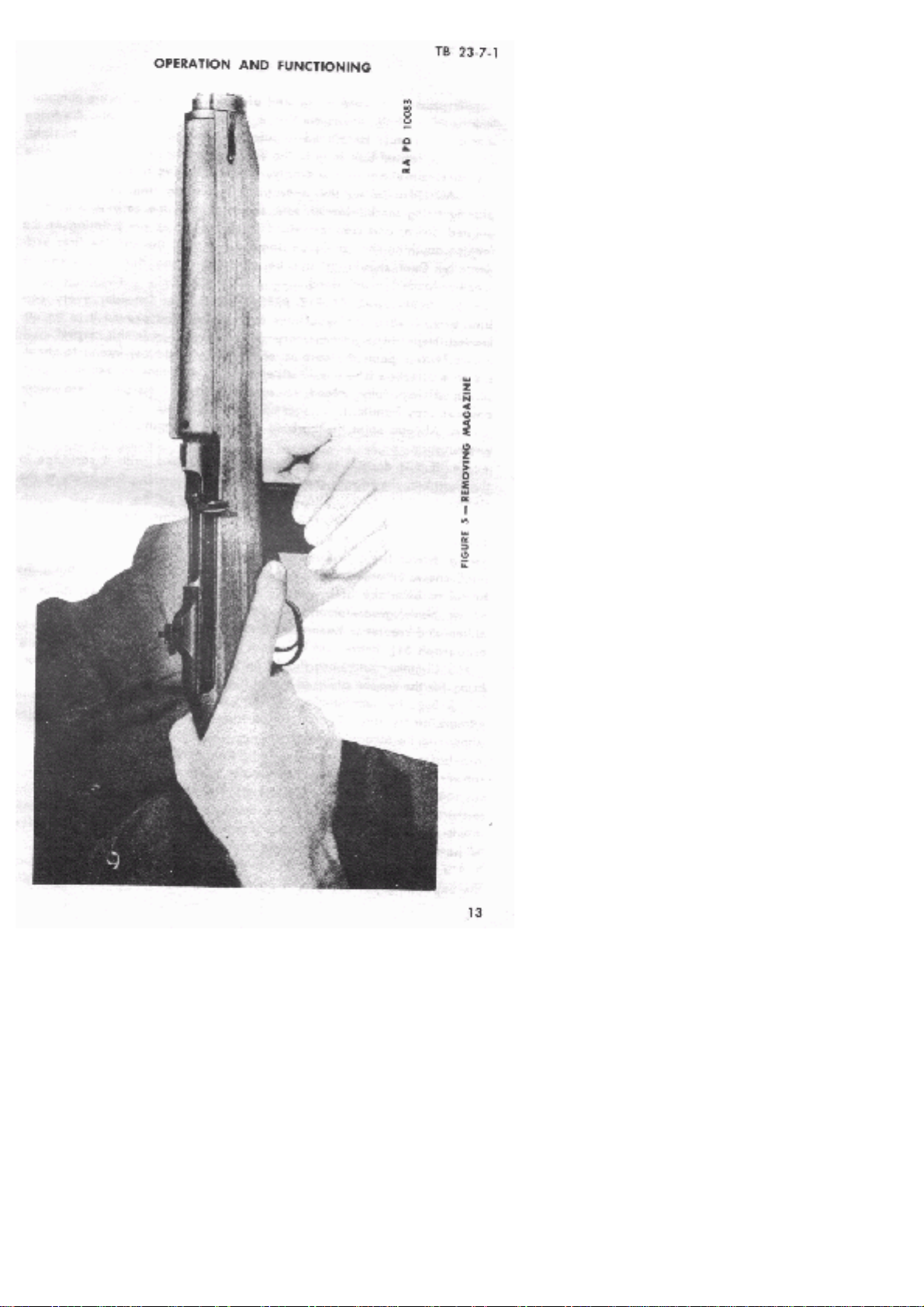

d. Bolt (Figures

11 and 12) -- Grasp bolt by cam lug and slide to rear until face of bolt is behind

locking shoulder in receiver. Rotate bolt counterclockwise, lift up to angle of about 45 degrees, and

turn bottom up. Pull bolt forward and up, out of receiver. Bolt may be removed with trigger housing

in position, but hammer must be in cocked position.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (2 van 10)6-9-2008 14:49:38

Page 13

TB 23-7-1 Carbine, Cal. .30, M1 Section III

e. Sling. -- To remove sling, unbutton rear end of sling, withdraw from around oiler, and pull oiler

to right out of aperature in stock. Unlock sling buckle and pull sling out of buckle and then out of

sling swivel. Replace oiler in its loop in sling and rebutton sling, to prevent loss of parts.

15. REPLACEMENT OF GROUPS. -- a. Bolt. -- With hammer cocked (trigger group

assembled), grasp receiver in left hand and bolt in right, top down. Insert rear of bolt, at about 45

degree angle, into rear top of receiver, and then turn bolt top up, and cam lug facing up, at an angle of

about 45 degrees. Fit left guide lug of bolt in its groove in left side of receiver and then rotate bolt

clockwise and slide forward. Bolt may be replaced with trigger housing in position, but hammer must

be in cocked position.

b. Operating slide group. -- (1) With Hammer Cocked (trigger housing group assembled), hold

body (forward end) of operating slide in the left hand and receiver in right. Place slide body against

under side of barrel so that lug on right side is seated in its guideway, and lug on left side is opposite

(mating with) relief cut in guideway in left side of barrel. Position bolt so that cam lug is in position

to enter camming aperature in left side of slide handle. Start bolt cam lug into camming aperature in

slide handle, and then rotate body of slide around barrel clockwise, until bolt lug fully enters

camming aperature in slide handle and slide body lug enters relief cut in barrel. When lugs are so

mated, push slide to rear until forward face of operating slide stop is level with forward face of rear

top of receiver, and press operating slide handle in towards receiver so that lug on handle mates with

relief cut in guideway on right side of receiver. Reciprocate slide to assure proper mating at both

ends, and with bolt.

(2) Place operating slide spring guide in spring and free end of spring in well in forward face of

receiver. compress guide against spring and, with slide fully forward, insert nose of guide head into

indentation in right rear face of slide body. Operate slide a few times to test assembly. Positioning of

guide head may be facilitated by inserting rear end of spring and guide in well in receiver then

engage forward end of spring and rear face of operating slide and retract slide part way, compressing

spring. Hold guide and spring in retracted position and move operating slide forward, then seat guide

head as above.

c. Trigger housing group. -- With bolt in forward position and hammer cocked, place flat side of

trigger housing flat upon under side of receiver with forward U-lug just ahead of lug on forward end

of receiver. Slide housing to rear so that rear T-lug mates with and slides between L-lugs on rear of

receiver, and U-lug on forward end of trigger housing mates with lug on forward end of receiver.

Align pin holes in both forward lugs and insert trigger housing retaining pin from right side so that it

is flush with both sides of U-lug. Be sure that trigger housing retaining pin spring is positioned in pin

when inserting pin. Start pin (if fully withdrawn) into hole at slight angle so as to cam the spring into

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (3 van 10)6-9-2008 14:49:38

Page 14

TB 23-7-1 Carbine, Cal. .30, M1 Section III

the hole.

d. Barrel and receiver group. -- (1) Grasp stock in right hand and barrel and receiver group in left

hand (by barrel). Insert trigger housing in aperature in top of stock and push back and down, with

barrel at an angle of about 15 degrees, until retaining lug on rear of receiver is beneath lip of retaining

aperature in face of recoil plate, and back against rear face of recoil plate. Then slowly depress

muzzle of barrel, at same time pressing to rear. If retaining lug does not cam up into aperature in

recoil plate easily, do not force, but raise muzzle again and repeat operation until lug cams easily into

aperature. Retaining aperature in recoil plate is an undercut, and retaining lug on rear of receiver has

to cam into it after nose of lug is behind undercut. If pressure is exerted before this is accomplished,

the great leverage obtained will injure the parts.

(2) When mating between lug and aperature is accomplished, lower barrel into bed in stock. Place

hand guard flat on barrel and slide to rear so that metal liner mates with and enters retaining groove in

forward face of receiver. Press hand guard fully home and slide front band over forward end of stock

and hand guard, and press back, until behind front band locking spring. Seat evenly and tighten front

band screw.

e. Sling. -- Thread free (button) end of sling through sling swivel from the rear side and then

through (unlocked) locking buckle. Place oiler in aperature in stock from right side, then thread

button end of sling around oiler from rear to front. Mate button holes and insert button. To adjust

sling, unlock buckle, pull sling through to desired length and relock buckle. (See Figure 21, showing

early type of sling. This sling has a friction type adjusting buckle and snap instead of button).

16. MAGAZINE, DISASSEMBLY. (Figure 13). -- Grasp magazine in left hand with base up and

rounded face towards the body. With left thumb press up on forward (rounded) end of magazine base

until the base can be slid to rear out of its retaining grooves in base of tube. Movement can be started

by inserting rim of cartridge or similar instrument in recess in top of base. Remove magazine spring

through opening thus obtained. Follower should not be removed unless necessary as tube may be

sprung in process. To remove: position follower at bottom of tube. Insert screw driver or similar tool

from top of tube to bear on rear end of follower and press on follower until stop flange is clear of

tube. If flange will not rotate out, press down on opposite end to assist rotation. Do not force. Grasp

flange and rotate follower out of tube.

NOTE: Magazine should not be disassembled except in emergency or for salvage.

17. MAGAZINE, ASSEMBLY. -- Insert short (curved) end of follower into rear bottom (flat)

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (4 van 10)6-9-2008 14:49:38

Page 15

TB 23-7-1 Carbine, Cal. .30, M1 Section III

side of magazine tube. Press down and rotate, until end of long side snaps under retaining flange. If

necessary insert screw driver or similar tool into top of tube to hold short end, and assist in rotation.

Do not force unduly or magazine will be distorted. Push follower to top of tube and insert magazine

spring with long side to the rear. (This permits the follower to slide easier in the tube.) Compress

spring with thumb, and slide square end of base into retaining grooves in bottom of magazine until

retained by projection on curved end, slipping inside tube. Push follower down in tube and release to

test smoothness of functioning. If follower does not slide up smoothly by spring action, tube has been

distorted and should be corrected.

18. FRONT BAND, DISASSEMBLY. -- Unscrew front band screw, remove it from band and

remove swivel. There is no further disassembly of the band as the clip and piece are spot welded

together. The front band cannot be removed from the barrel until the front sight is removed.

19. FRONT BAND, DISASSEMBLY. -- Place front band swivel between ends of front band

piece with flat side facing forward and away from front band clip. Inset screw from top through piece

and swivel and screw in part way. Do not tighten until band is assembled to stock and hand guard. If

front band has been removed from barrel it should be replaced so that the piece is towards the

muzzle.

20. BARREL AND RECIEVER GROUP, DISASSEMBLY (

Figure 14). -- a. Removing barrel

from receiver. -- The barrel should not be removed from the receiver except for replacement. To

remove, completely disassemble barrel and receiver. Wedge a hard wood block in receiver to prevent

spring of the sides and clamp receiver in a vise having leather covered jaws. Position receiver in vise

as near to end as possible and clamp only tight enough to hold securely. Place strap wrench on barrel

near receiver end and unscrew barrel anti-clockwise. (Barrel has right hand thread).

b. Front sight. -- Do not remove unless necessary, as both ends of front sight blade pin are crimped

into the body of the front sight blade and the front sight key is staked at the rear end into its keyway

in the barrel. To remove sight from barrel, punch out front sight pin and drive sight forward from

barrel, using hard wood block or brass drift. To remove key from barrel, tap lightly to rear to loosen

staking, using hard wood block or brass drift, and lift key out of keyway.

c. Gas cylinder group. -- (1) Integral type. -- Unscrew piston nut from gas cylinder. Remove nut,

elevate muzzle of barrel and slide piston out of gas cylinder. If piston will not slide out, tap cylinder

lightly with wood block. The integral type gas cylinder permits of no further disassembly.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (5 van 10)6-9-2008 14:49:38

Page 16

TB 23-7-1 Carbine, Cal. .30, M1 Section III

(2) Removable type. -- Do not remove unless necessary for replacement. Before removing

disassemble barrel and receiver and remove front sight group as described in subparagraph b above.

To remove gas cylinder: remove piston nut and piston as in (1) above, punch out retaining pin, and

drive gas cylinder forward off barrel, using hard wood block or brass drift. When driving off, make

contact with rear face of cylinder near barrel, so as to exert driving force as near parallel to barrel as

possible.

d. Rear sight. -- To disassemble rear sight group; spot a mark on rear sight base and receiver for

proper alignment upon assembly, drive out rear sight leaf pin and lift leaf and spring from sight base.

Drive out base from right to left, using block of hard wood or brass drift (dovetail tapers to right).

21. BARREL AND RECEIVER GROUP, ASSEMBLY. -- a. Replacing barrel in receiver. -- To

assemble barrel to reciever, clamp reciever in vise as described in paragraph 20 above. Start threading

by hand and then use strap wrench to screw barrel tightly into reciever. Screw barrel into reciever

(clockwise) tightly and turn until qualification marks on bottom of barrel and reciever are in line. Be

careful to start threading correctly. When assembled, flat lower surfaces of barrel and reciever should

be parallel, and extractor aperature in rear face of barrel should mate with extractor when bolt is

locked.

b. Gas cylinder. -- (1) Integral type. -- Inspect gas cylinder and port for foreign matter and wipe

clean. Insert piston in gas cylinder, head first, and screw piston nut in snugly allowing rear of piston

to protrude through nut. Shake barrel to be sure piston moves freely in gas cylinderand protrudes

sufficiently through nut (approx. ¼ inch).

(2) Removable type. -- (a) The gas cylinder must be assembled to the barrel before front sight is

assembled. Slide gas cylinder on barrel with piston aperature on under side of barrel and facing to the

rear. Aline flat sides of gas cylinder as closely as possible with flat sides of rear of barrel and drive

cylinder on barrel, using block of hard wood or brass drift, until pin holes in cylinder and pin groove

in barrel aline. Insert gas cylinder pin and drive flush with both sides of cylinder.

(b) Assemble piston to gas cylinder as described in subparagraph b (1) above.

NOTE: Gas cylinder is aligned and drilled for pin, and gas port then drilled upon manufacture. In

assembling new gas cylinder to old barrel, the alignment of the gas port should be checked.

c. Front sight.-- Place front sight key in keyway in top of barrel muzzlewith pin cut facing up. Tap

key snugly to forward end of keyway, and stake rear end of keyway to hold key in position. Slide

front sight onto barrel with sloping faces of wings facing to rear. Mate keyway with key in barrel, and

drive sight on barrel until pin hole in sight is in alignment with pin-cut in key. Insert pin and drive

through until not quite flush with either side of sight. Stake metal over both ends of pin to hold in

position.

d. Rear sight group. -- (1) If rear sight base has been removed, drive base into dovetail aperature in

rear top of reciever from the left side (dovetail tapers to the right) until aligning marks have been

made, aline rear sight base so that center line of bore (chamber) and front sight blade aline midway

between wings of rear sight base.

(2) Position leaf spring between wings of base and press down leaf upon spring until pin holes in

base and leaf aline. Insert rear sight leaf pin and drive flush. When leaf is in position, recessed face of

aperature should face to front.

22. TRIGGER HOUSING GROUP, DISASSEMBLY (

Figure 15). -- a. Hammer group. -- (1) If

hammer is not in forward position, pull trigger and ease hammer forward with thumb.

(2) Insert small punch or similar tool into hole in hammer spring guide and pull back until guide is

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (6 van 10)6-9-2008 14:49:38

Page 17

TB 23-7-1 Carbine, Cal. .30, M1 Section III

clear of notch in hammer (Figure 16); then swing guide to right to clear hammer, and ease forward

against force of spring until guide is clear of well in trigger housing. Pull guide from hammer spring.

Punch out hammer pin and remove hammer.

b. Trigger and sear group. -- Pry trigger spring until clear of seating slot in rear of trigger; then

pull forward and up and remove from aperature in trigger housing. (Trigger spring may also be

removed from the rear). Hold sear with thumb, against force of spring, and punch out trigger pin.

Invert trigger housing and shake trigger and sear group from top of trigger housing. Pull sear spring

from well in trigger.

c. Magazine catch group. -- Hold trigger housing bottom up in left hand, and with right hand insert

small punch or similar tool into hole in lower face of trigger housing just forward of the bow (

Figure

16). Engage punch ahead of magazine catch retainerplunger and pry plunger back from engagement

with magazine catch. (Hold magazine catch with left thumb so that magazine catch spring and

plunger do not fly out). Remove magazine catch and pull magazine catch plunger and spring out of

trigger housing.

d. Safety group. -- Safety cannot be removed from trigger housing until magazine catch has been

removed from trigger housing, safety spring and plunger and magazine catch retainer plunger may be

removed through forward face of trigger housing, and safety pushed out of aperature. (Magazine

catch retainer plunger and safety spring plunger are positioned on opposite ends of the safety spring).

23. TRIGGER HOUSING GROUP, ASSEMBLY (Figure 17). -- a. Safety group. -- (1) Inset

safety into its aperature ahead of trigger bow, with trigger cut facing to rear.

(2) Assemble safety spring plunger and magazine catch retainer plunger to safety spring. Insert

assembly into well in forward face of trigger housing (in magazine catch slideway). Operate safety

sufficiently to see that safety spring plunger is engaged in aperature in forward face of safety.

b. Magazine catch group. -- (1) Place magazine catch spring plunger in spring in well in right side

of trigger guard housing (just ahead of safety) with plunger facing out.

(2) Insert magazine catch into its guideway in forward face of trigger housing, from right side,

with flange facing to rear, and press to left until stopped by retainer plunger. Depress retainer plunger

into well in trigger housing and push catch to left until retaining plunger clicks into position to retain

catch in guideway. Operate safety and catch a few times to test mechanism.

c. Trigger and sear group. -- (1) Place trigger in trigger housing with long arm forward, and insert

trigger pin part way to hold in position. Insert sear spring in well in body of trigger.

(2) Place sear in position in top of trigger, with long point facing and free end of sear spring seated

in aperature in rear face of sear. Press sear back and down against force of spring until holes in

trigger housing, trigger and sear are in line and then push trigger pin all the way trhough until flush

with both sides of trigger housing.

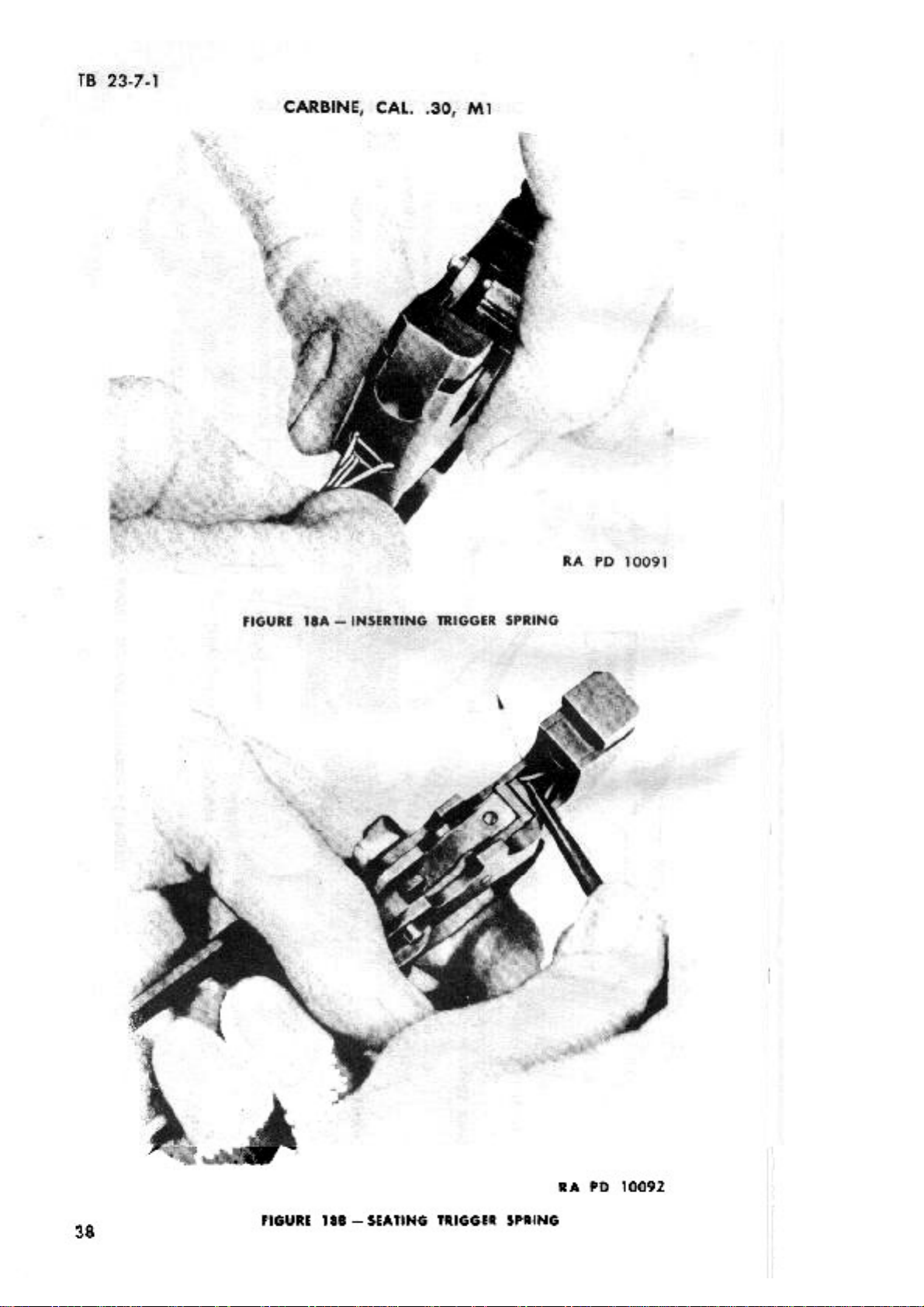

(3) With trigger in forward position, insert trigger spring from the rear (

Figure 18) into aperature

in rear face of trigger housing so that loop of spring is down and foeward, and push spring in until

loop is stopped by rear of trigger. Pry up loop so that it slips into retaining slot in top rear face of

trigger (

Figure 18). Operate trigger to test mechanism. (Trigger spring may also be reeplaced through

forward end of aperature).

d. Hammer group. -- (1) Position hammer in trigger housing with long end upand curving to rear.

Engage sear notch with sear, and press lower part of hammer back and down until pin holes in trigger

housing and hammer aline; then, insert hammer pin and position it so that there is an equal amount

protruding from either side of the trigger housing. (A new type pin, with head, is provided to position

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (7 van 10)6-9-2008 14:49:38

Page 18

TB 23-7-1 Carbine, Cal. .30, M1 Section III

the pin properly in the trigger housing. When assembling, push pin in up to shoulder.)

(2) Pull hammer slightly forward, retract trigger, and pull hammer to forward position. Insert

hammer spring plunger into hammer spring. Hold free end of spring against face of trigger housing,

central with hammer spring plunger recess, with plunger lying to right side of hammer.

(3) Insert small punch or similar tool into hole in hammer spring plunger and pull plunger back

against force of spring, guiding rear end of plunger into recess in trigger housing. When forward end

of plunger is even with rear face of hammer, press plunger to left and seat in retaining groove in base

of hammer so that hole in plunger is horizontal.

(4) Operate assembled mechanism several times to test functioning.

NOTE: Alignment of plunger and aperature in trigger housing may be facilitated, during

assembly, if spring and plunger are allowed to bear on top of the right lug protruding above the

trigger pin.

24. OPERATING SLIDE GROUP, DISASSEMBLY (

Figure 19). -- The operating slide stop is

the only removable part of the operating slide group. To remove operating slide stop, punch out

retaining pin from right side. Be careful that stop and spring do not fly out when released. Lift stop

and spring from well in operating slide.

25. OPERATING SLIDE GROUP, ASSEMBLY. -- Assemble operating slide stop spring to stop

and insert into aperature in top of slide handle with head of stop facing out. Depress stop against

force of spring and insert retaining pin from left side, and drive flush. Operate stop to test

functioning. (Nose of stop should protrude only when stop is pressed against force of spring).

26. BOLT GROUP, DISASSEMBLY (

Figure 19). -- The spindle of the extractor locks all other

components of the bolt group into the bolt. To disassemble, hold thumb over face of bolt to prevent

the ejector and extractor spring plunger from flying out when released, and punch the extractor out

from the underside of the bolt. Withdraw ejector and spring, extractor spring and plunger, and the

firing pin from the bolt.

27. BOLT GROUP, ASSEMBLY. -- a. Insert firing pin into well in rear of bolt so that tang on

rear of firing pin fits into aperature in rear end of bolt.

b. Assemble ejector spring to ejector so that it is locked in groove in ejector shank, and insert

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (8 van 10)6-9-2008 14:49:38

Page 19

TB 23-7-1 Carbine, Cal. .30, M1 Section III

ejector assembly, spring first, into ejector well in lower front face of bolt.

c. Aline cut in firing pin with extractor spindle hole in bolt. Compress ejector in well and aline cut

with that in firing pin and with extractor spindle hole. Insert hammer pin or similar pin into extractor

spindle hole, from bottom, far enough to hold ejector and firing pin in place.

d. Assemble extractor plunger spring to extractor plunger and insert, spring first, into well in

forward face of cam lug on right side of bolt.

e. Start extractor spindle into aperature hole in top of bolt and press extractor into aperature,

camming extractor plunger back into its well. Continue to press extractor home until it pushes out the

hammer (or holding) pin and seats in its aperature, flush with top of bolt. Test spring functioning of

extractor and ejector.

28. STOCK AND HAND GUARD GROUP, DISASSEMBLY (

Figure 20). -- a. Front band

locking spring. -- Insert small, straight punch in spring spindle hole in left side of forward end of

stock and drive out front band locking spring (to the right) part way; spring may then be rotated and

pulled from aperature.

b. Recoil plate. -- (1) Unscrew recoil plate screw until clear of estutcheon threads (about ¾ inch),

then withdraw from stock and recoil plate.

(2) Tap lightly on rear top face of recoil plate with a metal tool, and pull plate directly forward

out of seating aperature in stock. Do not pull up or down, because rear seating lug on plate seats in a

horizontal cut in the stock.

(3) The estutcheon should not be removed from the stock except for replacement. To remove,

thread recoil plate screw all the way into estucheon from the underside and pull estucheon out of

stock. If withdrawl is difficult, insert small straight punch from top of screw hole in stock and tap end

of screw lightly to loosen estucheon, or thread screw in from top, part way, and tap lightly, then

proceed as above.

c. Butt Plate. -- Unscrew butt plate screw and remove from stock. Tap butt plate lightly with metal

tool (to loosen) and pull to rear off stock. If butt plate is tight, do not pull off as stock is apt to be

injured. Tap on edges lightly (all the way around) until loose enough to pull from stock.

d. Hand guard. -- The liner of the hand guard assembly is rivited to the hand guard, and should not

be removed except in emergency or for salvage. To remove, file off riveted head of rivets and punch

out from the inside of hand guard.

29. STOCK AND HAND GUARD GROUP, ASSEMBLY. -- a. Front band locking spring. -insert spindle of spring into hole in right forward end of stock, and drive to left. Seat spring fully in

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (9 van 10)6-9-2008 14:49:38

Page 20

TB 23-7-1 Carbine, Cal. .30, M1 Section III

aperature in stock.

b. Recoil plate. (1) insert recoil plate into rear of reciever aperature in stock with bevel face up and

tang to rear. Recoil plate must be inserted from front to rear and held level during insertion, so that

seating lug and horizontal aperature mate. When in position, tap lightly to seat evenly and flush with

stock.

(2) If estucheon has been removed, insert small end first into aperature in under face of stock grip.

Tap in until seated level and flush with stock. Replacew recoil plate screw through top of recoil plate

and stock, thread into estucheon and draw down snugly.

c. Butt Plate. -- Place butt plate on butt and tap lightly until solidly and evenly seated on butt.

Insert screw and turn down snugly. Do not force screw as threads in wood of stock may strip.

d. Hand guard. -- If metal liner has been removed for replacement, position liner in rear face of

hand guard so that it bears evenly on wood. Insert rivets from outside and rivet against metal liner.

This should not be attempted without proper tools, or hand guard may be damaged. (Tubular rivets

are used, which require a special riveter. In emergency, a spotting punch may be used).

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page18.html (10 van 10)6-9-2008 14:49:38

Page 21

TB 23-7-1 Carbine, Cal. .30, M1 Section IV

TB 23-7-1

CARBINE, CAL. .30, M1

SECTION IV

CARE, CLEANING AND LUBRICATION

Paragraph

In garrison and camp 30

Preparatory to firing 31

After firing 32

On the range or in the field 33

Preparation of carbines for storage 34

Cleaning carbines as recieved from storage 35

Care and cleaning in cold climates 36

Care and cleaning in hot climates 37

Field inspection 38

30. IN GARRISON AND CAMP. -- a. Care and cleaning in garrison and camp include the care

of the carbine necessary to preserve its condition and appearance during the periods when no firing is

being done. Carbines in the hands of troops should be inspected daily to insure proper condition and

cleanliness. Training schedules should allow proper time for cleaning carbines on each day when

carbines are used in training. for special care in extreme climates refer to paragraphs 36 and 37.

b. (1) The bore of the carbine will always be cleaned by inserting a cleaning rod into the muzzle

end. When cleaned, with carbine fully assembled, the bolt should be held in the open position by

inserting a piece of wood between the forward face of operating slide cam lug and right rear face of

hand guard (or receiver). The operating slide stop is designed for holding the bolt in its rearmost

position, but if a cleaning rod longer than the authorized one is used the end of the rod may strike the

face of the bolt and release it. To protect the face of the bolt, a piece of rag should be stuffed into the

receiver. The magazine should be removed before cleaning the bore.

(2) To clean the bore, assemble a cloth patch to the cleaning rod and insert the rod into the bore at

the muzzle end. Move it forward and backward several times the entire length of the bore and

chamber and replace with a new patch. Repeat until a patch comes out clean. When issue patches are

not available, patches should be cut to approximately 2 ½ inches square to permit their being forced

through the bore without bending the cleaning rod. Then saturate a patch with the oil currently used

for lubrication and preservation of small arms and push it through the bore, holding the carbine, top

up, so that some of the oil will flow into the gas port. (OIL, lubricating, preservative, light, is a good

preservative when available).

CAUTION: In cleaning the bore, care must be taken not to foul the cleaning patch in the gas port.

c. To clean the screw heads and crevices, use a small cleaning brush or a small stick. To clean the

metal surfaces, wipe& with a dry cloth to remove moisture, perspiration, and dirt, then wipe with a

clean cloth containing a small quantity of OIL, lubricating, preservative, light. This protective film

will be maintained at all times. To clean the outer wood surfaces of the carbine, wipe off the dirt with

a lightly oiled cloth and clean with a soft dry one.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page43.html (1 van 7)6-9-2008 14:49:39

Page 22

TB 23-7-1 Carbine, Cal. .30, M1 Section IV

d. After cleaning and protecting the carbine as described above, place it in the gun rack without

covering and without a plug in the muzzle or bore. Muzzle covers, gun covers, rack covers, and plugs

must not be used because they cause sweating and promote rust. However, when squad rooms are

being swept, the gun racks may be covered to protect the carbines from dust. Covers must be

removed after the rooms have been swept.

31. PREPARATORY TO FIRING. -- Before firing, the following procedure will be observed to

assure the efficient functioning of the carbine. (Refer to paragraphs 36 and 37).

a. Dismount the main groups.

b. Remove all dirtand oil from bore and chamber with clean patches.

c. Remove any carbon on the piston head and in the gas cylinder.

d. Thoroughly clean and lightly oil all metal parts using OIL, lubricating, preservative, light.

e. Do not oil the bore or chamber, as hazardous chamber pressures may develop. (See

paragraph

51).

f. Lightly lubricate the following points, with a drop of oil from oiler rod.

(1) Bolt lugs (locking and cam).

(2) Bolt guideways in reciever.

(3) Cocking cam on rear of bolt, and firing pin tang recess.

(4) Operating slide spring guide.

(5) Operating slide guideways in barrel.

(6) Operating slide (handle) guideway in receiver.

(7) Contacting surface of reciever and operationg slide.

(8) Operating slide (handle) camming aperature.

(9) Piston shank.

CAUTION: Do not oil face or underside of bolt as oil may thus get into chamber of the barrel.

g. A drop of oil should occasionally be placed on the operating slide stop, magazine catch and

magazine retainer plunger, trigger pin, hammer pin and hammer plunger.

h. Lubrication should be applied lightly, as too much oil cllects grit and foriegn matter which will

cause undue abrasive wear and possible malfunction.

i. When bore and mechanism have been cleaned and oiled as described, assemble the carbine and

rub all outer surfaces with a lightly oiled rag.

32. AFTER FIRING. -- The bores of all carbines must be thoroughly cleaned by the evening of

the day on which they are fired. They should be cleaned in the same manner for the next 3 days.

(Refer to paragraphs 36 and 37).

CAUTION: Under no circumstances will metal fouling solution be used in this carbine.

a. Immediate cleaning after firing, or as soon as possible. -- Hold the carbine bottom side up, so

that no cleaning fluid (or water) will enter the gas port in the bore. Run several patches saturated with

CLEANER, rifle bore, through the bore. If rifle bore cleaner is not available, warm soapy water

(issue soap) or warm water alone should be used. Remove pache from cleaning rod and assemble the

cleaning brush to the rod end. Run brush back and forth through the bore several times while bore is

still wet. Care should be taken to insure that the brush goes all the way through the bore before the

direction is reversed, and that the chamber is thoroughly cleaned its entire length. The diameter of the

chamber in the carbine is so neat that of the bore, that additional cleaning should not be, as a rule,

necessary. After using the brush, run several wet patches through bore and chamber, removing them

from the breech end. Following this by dry, clean patches until patches come out clean and dry.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page43.html (2 van 7)6-9-2008 14:49:39

Page 23

TB 23-7-1 Carbine, Cal. .30, M1 Section IV

Saturate patch in OIL, lubricating, preservative, light, and push it through the bore and chamber,

holding the carbine, top side up, so that some of the oil will flow into the gas port in the bore.

CAUTION: In cleaning the bore care must be taken not to foul the cleaning patch in the gas port.

b. Complete cleaning. -- This cleaning should be done with the groups dismounted, and as soon as

possible after that described in subparagraph a above. If the carbine is to be fired the next day,

proceed as in paragraph 31. If the carbine is not to be fired in the next few days, repeat procedure in

subparagraph a above for 3 days. In addition, the following instructions will be observed:

(1) Gas cylinder and piston. -- After extensive firing, remove the piston. Clean out all excess

carbon from gas cylinder and from head of piston. Care should be used when removing carbon not to

scratch gas cylinder or piston unnecessarily. Check gas port in barrel after cleaning to make sure it is

free, a test piston for freedom of action in gas cylinder and through piston nut when reassembled. In

rearward position, piston should protrude about ¼ inch.

(2) Exterior surfaces. -- Wipe off the exterior of the carbine with a dry cloth to remove dampness,

dirt, and perspiration. Wipe all metal surfaces with OIL, lubricating, preservative, light, and the stock

and hand guard, with OIL, linseed, raw.

33. ON THE RANGE OR IN THE FIELD. -- The carbine must be kept clean and free from dirt

and properly lubricated with lubricating oil. To obtain its maximum efficiency the following points

must be observed. (Refer to paragraphs 36 and 37).

a. Never fire a carbine with any dust, dirt, mud, or snow in the bore.

b. Keep the chamber clean and free from oil and dirt.

c. Never leave a patch, plug, or other obstruction in the chamber or bore. Neglect of this

precaution may result in serious injury.

d. If the carbine gives indications of lack of lubrication and excessive friction, apply additional

lubricating oil to the parts listed in 31 f. Excessive friction exists if the empty cases are being ejected

to the right rear, and oil should be applied at the first opportunity as failures to feed and eject will

occur if the condition is not corrected.

e. Keep a light coating of oil on all other metal parts.

f. Remove the carbon the gas cylinder and the piston head when necessary. (Sluggish action of

carbine may indicate clogged piston).

g. In general, it should not be necessary to remove any of the parts of the carbine in the field for

cleaning, except to dismount the barrel, receiver and trigger housing group from the stock. Due to

position of gas port, the gas cylinder and piston should not require cleaning often. However, if the

mechanism becomes very dirty, the part groups may be removed from the carbine (paragraph 14) and

the necessary cleaning and lubrication accomplished.

h. During range firing, a selected and qualified man should be placed in charge of the cleaning of

carbines at the cleaning racks or tables.

34. PREPERATION OF CARBINES FOR STORAGE. -- a. OIL, lubricating, preservative,

light, is the most suitable oil for preserving the mechanism of carbines. The oil is efficient for

preserving the mechanism of carbines. This oil is efficient for preserving the polished surfaces, the

bore, and the chamber for a period of from 2 to 6 weeks, dependent on the climatic and storage

conditions. Carbines in short term storage should be inspected every five days and the preservative

film renewed if necessary.

b. COMPOUND, rust preventive, light, is a semisolid material. This compound is efficient for

preserving the polished (metal) surfaces, the bore, and the chamber for a period of 1 year or less,

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page43.html (3 van 7)6-9-2008 14:49:39

Page 24

TB 23-7-1 Carbine, Cal. .30, M1 Section IV

dependent on the climatic and storage conditions.

c. The carbines should be cleaned and prepared with particular care. The bore, all parts of the

mechanism, and the exterior of the carbines should be thoroughly cleaned and then dried completely

with rags. In damp climates, particular care must be taken to see that the rags are dry. After drying a

metal part, the bare hands should not touch that part. All metal parts should then be coated either with

OIL, lubricating, preservative, light, or rust preventive compound, depending on the length of

storage. (See a and b above). Application of the rust preventative compound to the bore of the carbine

is best done by dipping the cleaning brush in rust preventative compound and running it through the

bore two or three times. (Cleaning brush must be clean). Before placing the carbine in the packing

chest see that the bolt is its forward position and that the hammer is released. Then, handling the

carbine by the stock and hand guard only, it should be placed in the packing chest, the wooden

supports at the butt and muzzle having previously been painted with rust preventative compound.

Under no circumstances should a carbine be placed in storage contained in a cloth or other cover or

with a plug in the bore. Such articles collect moisture which causes the weapon to rust.

35. CLEANING OF CARBINES AS RECIEVED FROM STORAGE. -- a. Carbines which

have been stored in accordance with paragraph 34 will be coated with either OIL, lubricating,

preservative, light,or COMPOUND, rust preventative, light. Carbines recieved from ordnance storage

will, in general, be coated with heavy rust preventative compound. Use a light oil or SOLVENT, dry

cleaning, to remove all traces of the compound, or oil, particular care being taken that all recesses in

which springs or plungers operate are cleaned thoroughly. After using the dry cleaning solvent, make

sure it is completely removed from all parts. Then follow instructions contained in paragraph 30. If

the carbine is to be fired immediately, follow instructions contained in paragraph 31.

NOTE: Failure to clean the firing pin and the recess in the bolt in which it operates may result in

gun failure at normal temperatures, and will most certianly result in serious malfunctions if the

carbines are operated at low temperature areas, as rust preventative compound and other foreign

matter will cause the lubricating oil to congeal or frost on the mechanism.

b. Dry cleaning solvent is a petroleum distillate, of low inflammability and noncorrosive, used for

removing grease. It is generally applied with rag swabs to large parts and as a bath for small parts.

The surfaces must be thoroughly dried immediately after removal of the solvent. To avoid leaving

finger marks, which are ordinarily acid and induce corrosion, gloves should be worn by persons

handling parts after such cleaning. Dry cleaning solvent will attack and discolor rubber.

36. CARE AND CLEANING IN COLD CLIMATES. -- a. In temperatures below freezing, it is

necessary that the moving parts of the carbine be kept absolutely free from moisture. It has been

found that excess oil on the working parts will solidify to such an extent as to cause sluggish

operation or complete failure.

b. The metal parts of the carbine should be taken apart and completely cleaned with SOLVENT,

dry cleaning, before use in temperatures below 0° F. The working surfaces of parts which show signs

of wear may be lubricated by rubbing with an oiled cloth. At temperatures above 0° F, the carbine

may be oiled lightly after cleaning by wiping with a slightly oiled cloth using OIL, lubricating,

preservative, light.

c. (1) Immediately upon bringing indoors, the carbine should be thoroughly oiled, using OIL,

lubricating, preservative, light, because moisture condensing on the cold metal in a warm room will

cause rusting. After the carbine has reached room temperature, it should be wiped free of condensed

water vapor and oiled again.

http://www.geocities.com/buckrodgrs/M1/TB_23-7-1/Page43.html (4 van 7)6-9-2008 14:49:39

Page 25

TB 23-7-1 Carbine, Cal. .30, M1 Section IV

(2) If carbine has been fired, it should be thoroughly cleaned and oiled. The bore may be swabbed

out with an oily patch and when the weapon reaches room temperature, thoroughly cleaned and oiled

as prescribed in paragraph 32.