Page 1

CHT3

CHT3

Original Operating Instructions

Original Operating Instructions

CHT3-1 / CHT3-2 / CHT3-A

CHT3-1 / CHT3-2 / CHT3-A

CHT3-V / CHT3-N / CHT3-S

CHT3-V / CHT3-N / CHT3-S

Page 2

Table of Contents

Safety........................................................................................... 3

General safety.......................................................................... 3

Notes and symbols used.......................................................... 3

Personnel qualifications............................................................ 5

Intended use............................................................................. 5

Reasonably foreseeable misuse.............................................. 5

Technical specifications................................................................6

Connection options................................................................... 6

Connection plan........................................................................ 8

Drilling pattern...........................................................................9

Dimensional drawing.............................................................. 10

General description.................................................................... 11

Assembly....................................................................................12

Recommended screw types................................................... 13

Maximum dimensions of the screws...................................... 13

Maintenance...............................................................................13

Maintenance operations......................................................... 13

Clean CHT3............................................................................ 14

Disassembly............................................................................... 14

Disposal......................................................................................15

Options....................................................................................... 15

Manual updates..........................................................................15

Imprint.........................................................................................16

Product description / Product description.................................. 17

Page 3

This manual has been written for technicians/installers and

operators and should be kept for future reference. Read these

operating instructions carefully and make sure that you have fully

understood the contents before installing or working with the CHT3.

TIP

Metric and imperial measurements are used in drawings.

Imperial measurements are marked with [ ].

Safety

General safety

All work on electrical systems or operating equipment may only

be carried out by a specially qualified electrician according to the

applicable electrotechnical regulations.

The safety of the system in which the SENSORswitch is integrated

is the responsibility of the operator.

Notes and symbols used

Warning notes in relation to personal injury / material damage are

formulated according to the "SAFE” principle. This means they

contain information on the type and source of the hazard, potential

consequences as well as how to avoid and avert danger. The

following hazard classifications apply in the safety notes:

DANGER

Danger designates a hazardous situation, which,

if ignored, will lead to death or serious injury. The

symbol next to the warning indicates the type

and source of the danger.

Page 4

WARNING

Warning designates a hazardous situation,

which, if ignored, may lead to death or serious

injury. The symbol next to the warning indicates

the type and source of the danger.

CAUTION

Caution designates a hazardous situation, which,

if ignored, may lead to injury. The symbol next to

the warning indicates the type and source of the

danger.

NOTICE

Notice designates a situation, which may cause material

damages and impair the product’s function if attention is not

paid.

TIP

Tip provides additional useful information about the handling of

the product.

Symbol Meaning

4

■

Avoiding and adverting danger in the warning note

►

Instructions for action

All instructions to be followed within a procedure are

always listed in chronological order.

List

Page 5

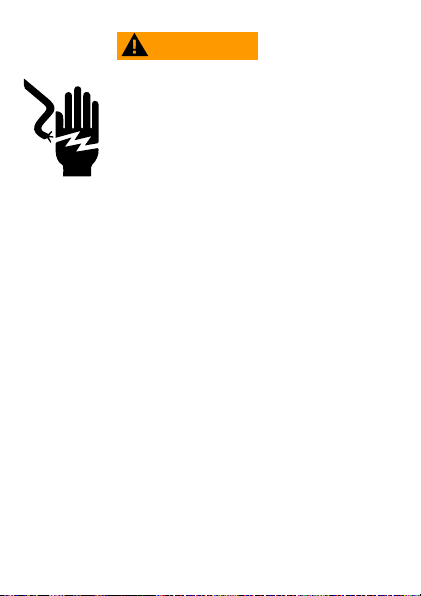

WARNING

Improper work on electrical systems!

Electric shock can result in death or lifethreatening injuries.

4

Before working on electrical systems,

disconnect them from their voltage supply

and secure them against being switched on

again.

4

Work on electrical installations should be

carried out only by qualified personnel in

compliance with local and national electrical

regulations and specifications.

Personnel qualifications

A qualified electrician is a person with suitable technical training,

expertise and experience as well as knowledge of relevant

standards, who can evaluate the work assigned to them

correspondingly and recognize potential risks.

Intended use

The SENSORswitch is intended for use in accordance with the

items listed here, the values from the “Technical specifications”

chapter and the product description.

■

Only connect the product to a limited energy source as per IEC

61010 or an NEC class 2 power supply unit.

■

Source current < 4 A at maximum operating voltage.

Reasonably foreseeable misuse

The switch is not suitable for:

•

use as a foot switch.

•

use in potentially explosive atmospheres.

•

use with inductive loads without a free-wheeling diode.

•

use as a safety component as per directive 2006/42/EC.

Page 6

Technical specifications

Operating voltage 24 V (16.8 to 32 V)

Load current max. 400 mA

Output pulse

dynamic

static

Reverse polarity protection Protection of all cables/lines

Short circuit protection Protected against short circuit and

Voltage drop max. 3 V at 400 mA

Power consumption at 24 V

with signal tone

with vibration

with signal tone and vibration

Operating temperature

dynamic

static

Degree of protection IP Front IP69K

Type of actuation Capacitive

Actuation force No actuation force required

max. altitude 2000 m above sea level

Relative air humidity max. 95%, non-condensing

approx. 300 ms

Corresponds to operating time

overload

max. 30 mA

max. 70 mA

max. 130 mA

max. 200 mA

-30 °C (-22 °F) … +80 °C (176 °F)

0 °C (32 °F) … +55 °C (131 °F)

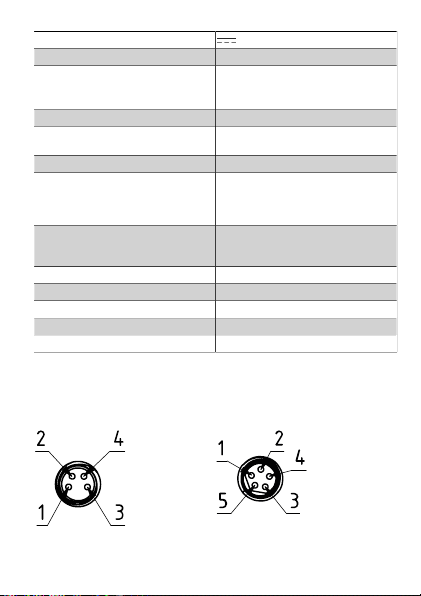

Connection options

Plug

CHT3-_5_ …

Plug M8, 4-pin

CHT3-_5_ …

Plug M8, 5-pin

Page 7

CHT3-_6_ …

Plug JST 2.54, 4-pin

CHT3-_6_ …

Plug JST 2.54, 5-pin

CHT3-_1_ …

Plug AMP 6.3, 4-pin

CHT3-_8_ …

Plug M12, 4-pin

CHT3-_4_ …

Plug AMP 6.3, 4-pin

CHT3-_8_ …

Plug M12, 5-pin

Strands

CHT3-_7_ …

200 mm single strands with wire end ferrules

Wire end ferrules with plastic collars DIN 46228

Wire cross-section strands 0.25 mm

2

Page 8

Connection plan

+VDC

+VDC / LED1

PNP-NO

0V

3

4

2

1

LED1

LED2

brown

white

black

blue

Load

+VDC

0V / LED1

NPN-NO

0V

3

2

4

1

load

LED1

LED2

brown

black

white

blue

LED1

LED2

+VDC / LED1

+VDC / LED2

PNP-NO

0V

+VDC

3

4

2

5

1

brown

white

grey

black

blue

Load

PNP-NO, 4-pin

NPN-NO 4-pin

PNP-NO 5-pin

Page 9

Drilling pattern

CHT3-2 CHT3-V

V-assembly

Page 10

CHT3-1 CHT3-S CHT3-N CHT3-A

A-assembly

Dimensional drawing

Exemplary presentation, plug M8, 4-pin

Page 11

General description

The supplied SENSORswitch can have options that differ from

those shown in this manual. This does not affect the function. The

SENSORswitch is equipped with different color LEDs to indicate

operating conditions. The LEDs are actuated differently depending

on the pin configuration.

Page 12

Assembly

Requirements: Mounting surface is level and clean.

► Disconnect the system from its voltage supply and secure it

against being switched on again.

► Set the desired position of the SENSORswitch and provide a

center hole of minimum Ø 50 mm to maximum Ø 58 mm.

TIP

The product description will indicate whether an A- or Vassembly is involved.

► Position the SENSORswitch (B) in the A- or V-assembly, align

centered and vertically and mark holes (C).

► Select the diameter of the holes according to the recommended

screw type and start drilling.

► Connect the SENSORswitch (B) electrically according to the

connection plan.

► Install the SENSORswitch (B) with the recommended screws.

The screw head must not deform the mounting flange (B).

► Place cover ring (A) with

groove (D) downward and

press close to the button

surface. The cover ring

must be flush with the entire

button surface.

NOTICE

Mineral grease and oils can attack the plastic of the button!

4

Do not use grease or oils to apply the cover ring (A).

Page 13

Recommended screw types

■

DIN EN ISO 1207 M4

■

DIN EN ISO 7045 M4

■

DIN EN ISO 1481 Ø3.9 mm

■

DIN EN ISO 7049 Ø3.9 mm

Maximum dimensions of the screws

The drawing shows the

maximum dimensions of the

screws.

Maintenance

Maintenance operations

Carry out the following maintenance operations at the specified

intervals.

Page 14

Maintenance operation as needed annually

Clean the button surface X

Check cables for intactness and firm

fit

Check screw connections for

tightness

NOTICE

Solvents contained in cleaning agents can attack the

plastic of the button!

4

Clean the surface of the button with a neutral cleaning agent

or a damp microfiber cloth.

X

X

Clean CHT3

Switch off the SENSORswitch for cleaning to prevent unintentional

actuation.

NOTICE

Solvents contained in cleaning agents can attack the

plastic of the button!

4

Clean the surface of the button with a neutral cleaning agent

or a damp microfiber cloth.

Disassembly

► Disconnect the system from its voltage supply and secure it

against being switched on again.

► Insert the flat head screwdriver into the groove (D) on the cover

ring (A) and remove the cover ring with the screwdriver via lever

action.

► Loosen the screw connections and disconnect the electrical

connection.

Page 15

Disposal

Different types of electrical and electronic components must be

recycled according to their type. All applicable statutory, state and

local laws and regulations must be complied with.

Options

Braille characters Relief

Color variations

RAL 1023 RAL 7035 RAL 9017 RAL 3020 RAL 5017 RAL6024

Scan QR code for more information

or visit our website cht3.captron.de.

Manual updates

CAPTRON reserves the right to make changes to the contents of

this manual as needed. The most current version can be found on

our website. www.captron.com .

Page 16

Imprint

The operating instructions have been authored and published by

CAPTRON Electronic GmbH

Johann-G.-Gutenberg-Straße 7

82140 Olching – Germany

Tel.: +49 (0)8142 - 44 88 - 160

sales@captron.com

www.captron.com

Copyright 2020

CHT3 1.2

Page 17

Product description / Product

Product description / Product description

description

Loading...

Loading...