Page 1

A25 Series Warm Air Control with Manual Reset

The A25 Series Warm Air Control with Manual Reset is

designed to shut down fans, burners, dampers, etc.,

when the temperature of the sensed air becomes

greater than the controller’s setpoint.

When the sensed temperature increases to the

controller’s setpoint, the A25’s switch will open.

Manual reset is required to reclose the electrical circuit.

The A25 may be used as a high limit control in the

supply air duct (or plenum) where a lockout type

control is desired or required by local code.

FANs 125, 121

Product/Technical Bulletin A25

Issue Date 0796

Figure 1: The A25 Series Warm Air Control

with Manual Reset

Features and Benefits

❑

Trip-free Reset Lever Does not allow the reset switch to hold the contacts in a closed (on)

position

❑

Pilot Duty Electrical Rating for

up to 600 Volts Maximum

❑

Enclosed Switch Protects switch contacts from dust

❑

Rod and Tube Sensing

Element

❑

Adjustable Duct

Mounting Flange

❑

Wide Temperature Range Allows the A25 to be used with many applications

Allows direct control of high voltage motor starters

Provides maximum response and allows for a high maximum

sensing element temperature

Controls the depth of sensor insertion into the airstream;

compensates for insulation depth

© 1996 Johnson Controls, Inc.

Part 24-7664-656, Rev.—

Code No. LIT-125118

1

Page 2

pplication Overview

A

A typical application for the A25 Series Warm Air

Control with Manual Reset is to stop the operation of

air conditioning or ventilating fans upon a temperature

rise. Models A25AP and A25CP are Factory Mutual

approved for use as fire protection devices.

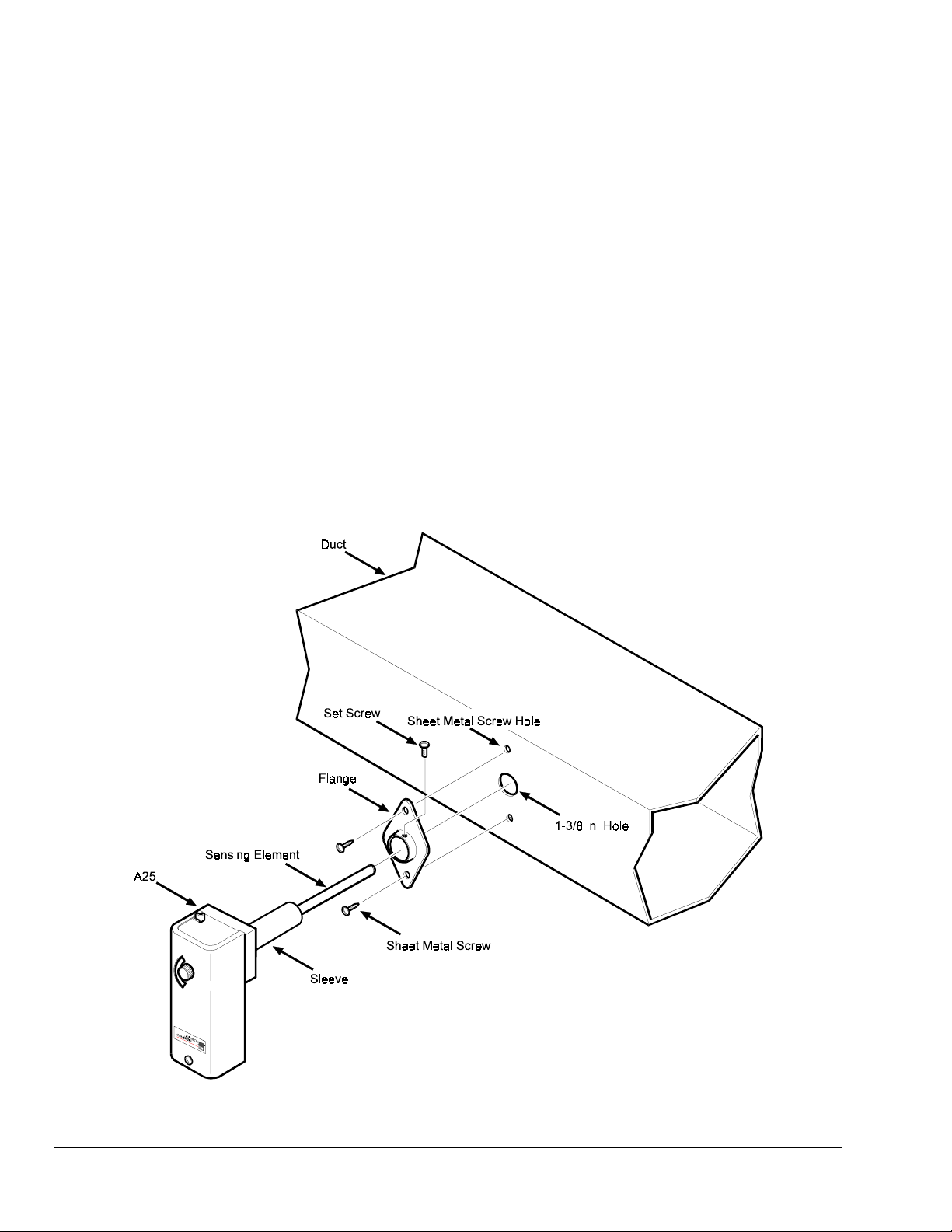

3. Using the flange as a template on the duct, mark

the location for two 1/2 in. (13 mm) No. 10 sheet

metal screws.

4. Punch (or drill) both sheet metal screw holes in the

duct at the marked locations.

5. Secure the flange to the duct with two 1/2 in.

(13 mm) No. 10 sheet metal screws provided.

nstallation

I

1. Select a mounting location for the A25 in the duct

(or plenum). The location must allow the sensing

element to sense the average temperature in the

duct.

2. Drill (or cut) a 1-3/8 in. hole in the duct at the

selected mounting location (refer to Figure 2).

6. Insert the sensing element and sleeve through the

flange installed in Step 5 (and into the duct).

7. Secure the A25 to the flange by screwing the set

screw firmly against the sleeve. Do not

overtorque the set screw.

Note: Insert the sensing element as far as possible

into the air stream without allowing it to contact

any object inside the duct. Provide at least

5-3/4 in. (14 cm) clearance between the

sensor and any other objects inside the duct.

Figure 2: Installing the A25

2 A25 Series Warm Air Control with Manual Reset Product/Technical Bulletin

Page 3

iring

W

WARNING: Shock hazard. To avoid

electrical shock or damage to

equipment, disconnect all power

before making wiring

connections.

If available, follow the instructions for the unit onto

which the A25 will be installed. Make all wiring

connections only with copper conductors and in

accordance with the National Electrical Code and local

regulations. Refer to the label inside the A25’s cover

for the maximum electrical rating.

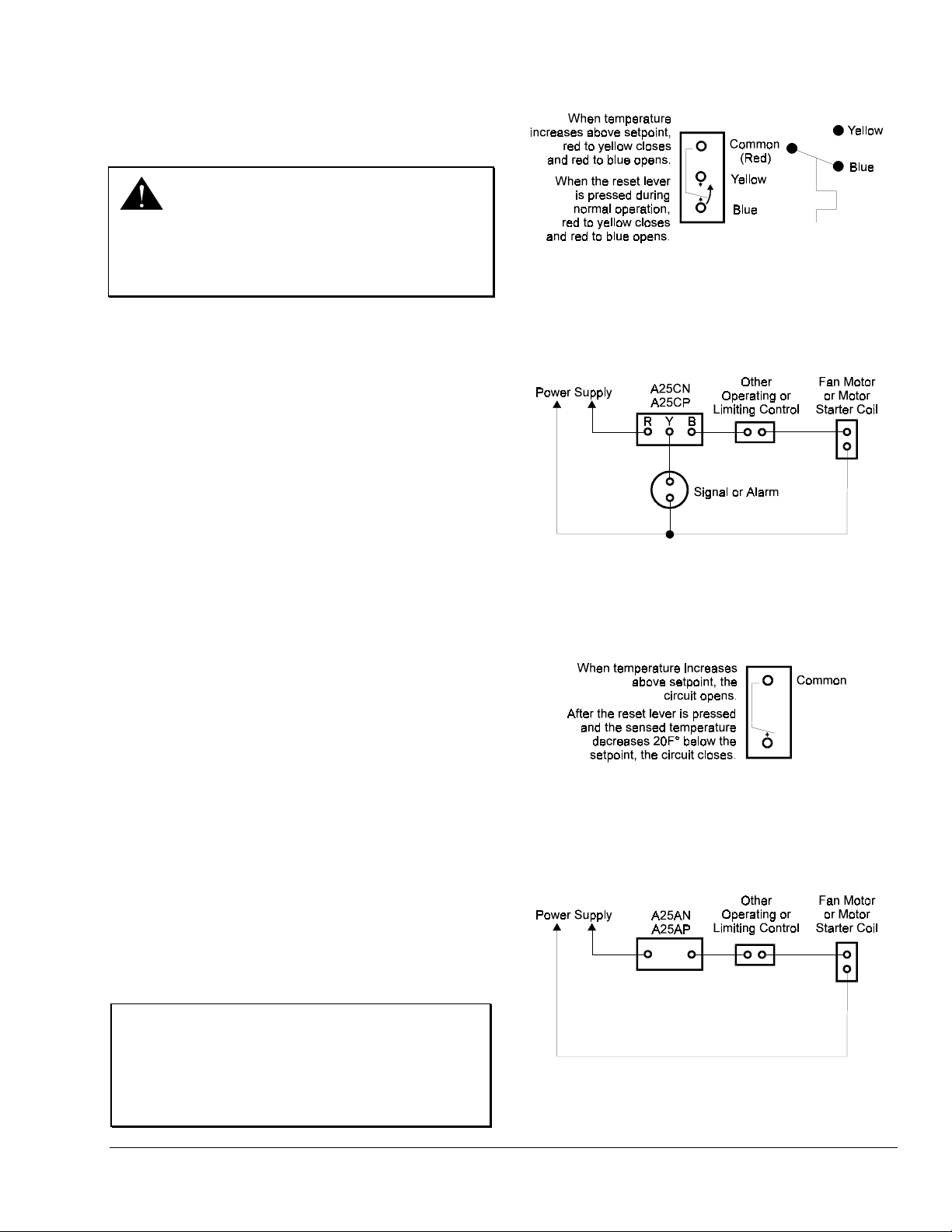

Models A25CN and A25CP

SPDT (Single Pole Double Throw) Units

The wiring terminals on the SPDT (Single Pole

Double Throw) models are color coded:

●

Red is common.

●

The red to yellow circuit closes on temperature

increase.

Figure 3: Terminal Identification for

A25CN and A25CP SPDT Models

Figure 4: Typical Wiring Diagram of

A25CN and A25CP SPDT Models

●

The red to blue circuit opens on temperature

increase.

Refer to Figures 3 and 4 for terminal identification and

typical wiring connections.

When the reset lever is pressed during normal

operation, the trip free contacts are activated, the red

to blue contact opens and the auxiliary red to yellow

contact closes. At this point, the auxiliary system

will activate.

Models A25AN and A25AP

SPST (Single Pole Single Throw) Units

When the temperature increases to above the setpoint,

the circuit opens. When the reset lever is pressed after

the sensed temperature decreases to approximately

20F° (11C°) below the setpoint, the circuit closes.

Refer to Figures 5 and 6 for terminal identification and

typical wiring connections.

IMPORTANT: Only use the terminal screws

furnished with the A25 (8-32 x

1/4 in. binder head). Use of other

screws will void warranty, may

damage switch terminals, and

result in improper connections.

Figure 5: Terminal Identification for

A25AN and A25AP SPST Models

Figure 6: Typical Wiring Diagram for

A25AN and A25AP SPST Models

A25 Series Warm Air Control with Manual Reset Product/Technical Bulletin 3

Page 4

heckout Procedure

C

O

peration

After installing the A25, perform the following

procedures. Observe at least three complete

operating cycles to verify that all components are

functioning properly. If the unit fails to checkout, refer

to the troubleshooting chart (Table 2). Do not attempt

to make adjustments.

Return Air Applications

1. After completing the installation and wiring

procedures, turn on the power to the circuit.

2. Turn the setpoint knob counterclockwise until

the A25 shuts down the system.

The A25 should lockout and the alarm or

signal (if applicable) should activate.

Note: The setpoint at shutdown should equal the

approximate duct air temperature.

3. Turn the setpoint knob clockwise to the

desired setpoint.

Nothing should happen.

4. Press the reset lever.

The system should restart and the alarm or

signal (if applicable) should shut off.

Models A25AN and A25CN

Setpoint Adjustment: Adjust the A25 setpoint by

rotating the setpoint knob (Figure 7). The setpoint

is displayed in the setpoint window.

Test Procedure:

To test (trip) the A25: Raise the temperature

at the sensor above the setpoint or lower the

setpoint below the ambient temperature.

control should lockout (trip).

To reset after test: Lower the temperature at

the sensor to 20F° (11C°) below the setpoint or

raise the setpoint to 20F° (11C°) above the

ambient temperature. Press the reset lever.

The A25 should reset (closing the circuit).

Reset Procedure: Verify that the temperature has

dropped to 20F° (11C°) below setpoint. Press the

reset lever to reset the A25 (closing the circuit).

The

Supply Air Applications

1. After completing the installation and wiring

procedures, turn on the power to the circuit.

2. Raise the supply air temperature to the

setpoint temperature.

Note: The supply air temperature can be raised

by simulating a fan failure or restricting the

return air flow.

3. When the system shuts down, determine the

temperature at the A25 sensing element.

The temperature reading should closely

approximate the A25’s setpoint at which the

system is shut down and (if applicable) the

alarm or signal is activated.

4. Return the system to normal operation by

re-establishing air flow or by restarting the fan.

5. Press the reset lever.

The system should restart and the alarm or

signal (if applicable) should shut off.

Figure 7: Models A25AN and A25CN

4 A25 Series Warm Air Control with Manual Reset Product/Technical Bulletin

Page 5

Models A25AP and A25CP

Setpoint Adjustment: Loosen the cover screw

(Figure 8) and remove the cover. Adjust the

setpoint by rotating the adjusting screw. When

adjusted, re-install the cover. Tighten cover screw.

Test Procedure:

To test (trip) the A25: Raise the temperature

at the sensor above the setpoint or lower the

setpoint below the ambient temperature.

control should lockout (trip).

To reset after test: Lower the temperature at

the sensor to 20F° (11C°) below the setpoint or

raise the setpoint to 20F° (11C°) above the

ambient temperature. Press the reset lever.

The A25 should reset (closing the circuit).

Reset Procedure: Verify that the temperature has

dropped 20F° (11C°) below setpoint. Press the

reset lever to reset the A25 (closing the circuit).

imensions

D

The

Figure 8: Models A25AP and A25CP

Figure 9: A25 Dimensions, in./mm

A25 Series Warm Air Control with Manual Reset Product/Technical Bulletin 5

Page 6

epairs and Replacement

R

Do not make field repairs. For a replacement control,

contact your nearest Johnson Controls representative.

Table 1: Ordering Information

Item Product Code

Number

A25 Series Warm Air

Control with Manual Reset

roubleshooting

T

A25AN-1

A25AP-1

A25CN-1

A25CP-1

Table 2: Troubleshooting Chart

Symptom Problem Solution

The A25 is not sensing properly.

The system does not operate.

A25 does not lockout upon a

temperature rise beyond the setpoint.

The A25 does not sense the correct air

temperature.

A25 will not reset.

Product

Description

SPST, opens on temperature rise, setpoint knob adjustment.

SPST, opens on temperature rise, concealed screwdriver adjustment,

Factory Mutual approved.

SPDT, setpoint knob adjustment.

SPDT, concealed screwdriver adjustment, Factory Mutual approved.

The sensing element may not be

extended into the airstream or the

sensing element is contacting an object

inside of the duct (or plenum).

Incorrect switch connections or improper

wiring.

Damaged sensor.

The A25 is tripped.

The A25 is defective. Replace the A25.

The A25 is defective. Replace the A25.

The temperature in the duct (or plenum)

is not 20F° (11C°) below the setpoint.

Insert the sensing element as far as

possible into the airstream without

allowing it to contact any object inside the

duct (or plenum).

Ensure that the wiring connections follow

the wiring diagrams in the

Check connections.

Replace the A25.

Reset the A25.

Check system for overheating or fire.

Wiring

section.

6 A25 Series Warm Air Control with Manual Reset Product/Technical Bulletin

Page 7

Notes

A25 Series Warm Air Control with Manual Reset Product/Technical Bulletin 7

Page 8

pecifications

S

Product

Range

Electrical Ratings Volts, AC 120 VAC 208 VAC 240 VAC 277 VAC

Ambient Temperature

(Maximum)

Conduit Opening

Switch

Cover Finish

High Limit Dial Stop

Material

Mounting

Reset

Sensing Element

Shipping Weight

Wiring Connections

Agency Listing

* FLA = Full Load Amps; LRA = Locked Rotor Amps. Values are equivalent to a 1 HP motor rating in accordance with UL353.

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these specifications,

consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products.

A25AN-1 SPST, opens on temperature rise, setpoint knob adjustment.

A25AP-1 SPST, opens on temperature rise, concealed screwdriver adjustment,

Factory Mutual approved.

A25CN-1 SPDT, setpoint knob adjustment.

A25CP-1 SPDT, concealed screwdriver adjustment, Factory Mutual approved.

25 to 215°F (-4 to 102°C)

Motor FLA*

Motor LRA*

Noninductive A

Case 104°F (40°C)

Element 300°F (149°C)

7/8 in. (22 mm) diameter hole for 1/2 in. conduit

Snap-acting contacts in dust protected enclosure

Gray baked enamel

125°F

Case 0.063 in. (1.6 mm) galvanized steel

Cover 0.025 in. (0.64 mm) cold rolled steel

Flange for flat surface

Positive, trip-free reset mechanism (manual reset 2 operation). Control can be reset when

the temperature drops 20F° (11C°) below the dial setting.

Bi-metal rod and tube construction

Individual pack 1.8 lb. (0.8 kg)

Overpack of 12 units 23 lb. (10.4 kg)

Screw-type terminals

UL Recognized: File MP640, Guide MBPR

CSA Certified: File LR948, Class 4813 02

Factory Mutual Approved (Models A25AP and A25CP only): Class 3545

16 9.2 8 96 55.2 48 16 16 16 16

Pilot Duty: 125 VA at 24/600 VAC

Controls Group

507 E. Michigan Street

P.O. Box 423

Milwaukee, WI 53201 Printed in U.S.A

8 A25 Series Warm Air Control with Manual Reset Product/Technical Bulletin

Loading...

Loading...