CaptiveAire 38APD025 Installation Manual

A38-7097

040-060 UNIT

Product

Data

a38-7096

025 UNIT WITH

LOW SOUND OPTION

GEMINI™ SELECT

38APS025-050,38APD025-100

Commercial Air-Cooled

Condensing Units with

®

PURON

Refrigerant (R-410A)

50/60 Hz

25 to 100 Nominal Tons (88 to 352 Nominal kW)

These dependable split systems

match Carrier's 40RU or 39 Series

indoor-air handlers with the versatile

outdoor 38AP condensing units for a

wide selection of commercial cooling

solutions.

• Split condensing units compatible

with ASHRAE 90.1

• Chlorine-free, non-ozone depleting

Puron refrigerant (R-410A)

• Condenser coils feature the

Novation

microchannel coil technology

• 38APS single-circuit unit has up to

3 rotary scroll compressors

• 38APD unit has up to 6 rotary scroll

compressors with 2 independent

circuits

• Standard scroll compressor units

operate as low as 33% (single

circuit) or 15% (dual circuit) of

nominal capacity

• Optional digital scroll compressors

allow incremental unloading down

to 10% (single circuit) or 5% (dual

circuit) of nominal capacity for VAV

applications

• Protection against high discharge

and low suction refrigerant

pressure, and low oil pressure

®

heat exchanger with

A38-7095

Features/Benefits

The 38AP condensing unit

offers the utmost in system

070 UNIT

configuration and control

adaptability. Its premiumquality standard components

ensure durable, efficient, and

reliable operation.

The 38AP units offer high unit EERs

(Energy Efficiency Ratios) up to 11.6

and IPLVs (integrated part load values)

up to 16.2. These units provide greater efficiency than similar units in the

marketplace, which translates into

year-round operating savings.

Copyright 2009 Carrier Corporation Form 38AP-2PD

Features/Benefits (cont)

The latest safety standards for 38AP

units are certified to UL (Underwriters

Laboratories) and CSA (Canadian

Standards Association) standards, ETL

approved.

Versatility

The 38AP Series condensing units feature up to 6 compressors and 2 refrigerant circuits, and can be matched with

a wide variety of air-handling units.

Condensing unit circuits on sizes 025050 can supply a single air handler or

2 separate air handlers. Standard units

have scroll compressors and digital

scrolls are available as an option. This

option of digital control closely matches building loads and allows fine incremental adjustments to the variance in

load.

Durable construction

All 38AP units have weatherized cabinets constructed of heavy-duty galvanized steel prepainted with corrosionresistant baked enamel. Inside and outside surfaces are protected to ensure

long life and good appearance. The

durable, galvanized steel, prepainted

components exceed the requirements

of the 500-hour salt spray test per

ASTM (American Society for Testing

and Materials) B117.

All 38AP units have Novation

exchangers with microchannel coil

technology. The microchannel heat exchanger (MCHX) coils provide longterm reliability, high performance heat

transfer, and significant savings in refrigerant charge. E-coated MCHX is

offered as an option for harsh industrial or coastal conditions.

®

heat

Reliability

The 38AP condensing units feature

highly reliable, hermetic scroll compressors. Each 38AP unit is capable of

unloading in staging sequence of scroll

compressors. Compressors are mounted on rails with vibration isolators to

provide quiet operation and reduced

component stress.

The 38AP units have single or dual

independent circuits; they provide inherent backup capability. Each circuit

is also protected by the following safety

features:

• Short-cycle protection

• Low superheat protection

• Loss of refrigerant charge

protection

• Reverse rotation protection

• Suction and discharge pressure

transducers

• High refrigerant pressure switch

(discharge)

• Circuit breakers or fuses for short

circuit protection of compressors

and outdoor fans

• Suction line accumulator for each

refrigerant circuit

Easier installation and service

The 38AP units are equipped with

hinged control-box access doors, control interface terminal boards, liquid

line shutoff valves, and suction line service valves.

Table of contents

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9,10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-14

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-71

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72-74

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75-77

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78-80

Typical Control Wiring Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . .81-84

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85-89

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90-92

2

Run Status

Service Test

Temperature

Pressures

Setpoints

Inputs

Outputs

Configuration

Time Clock

Operating Modes

Alarms

Alarm Status

ENTER

MODE

ESCAPE

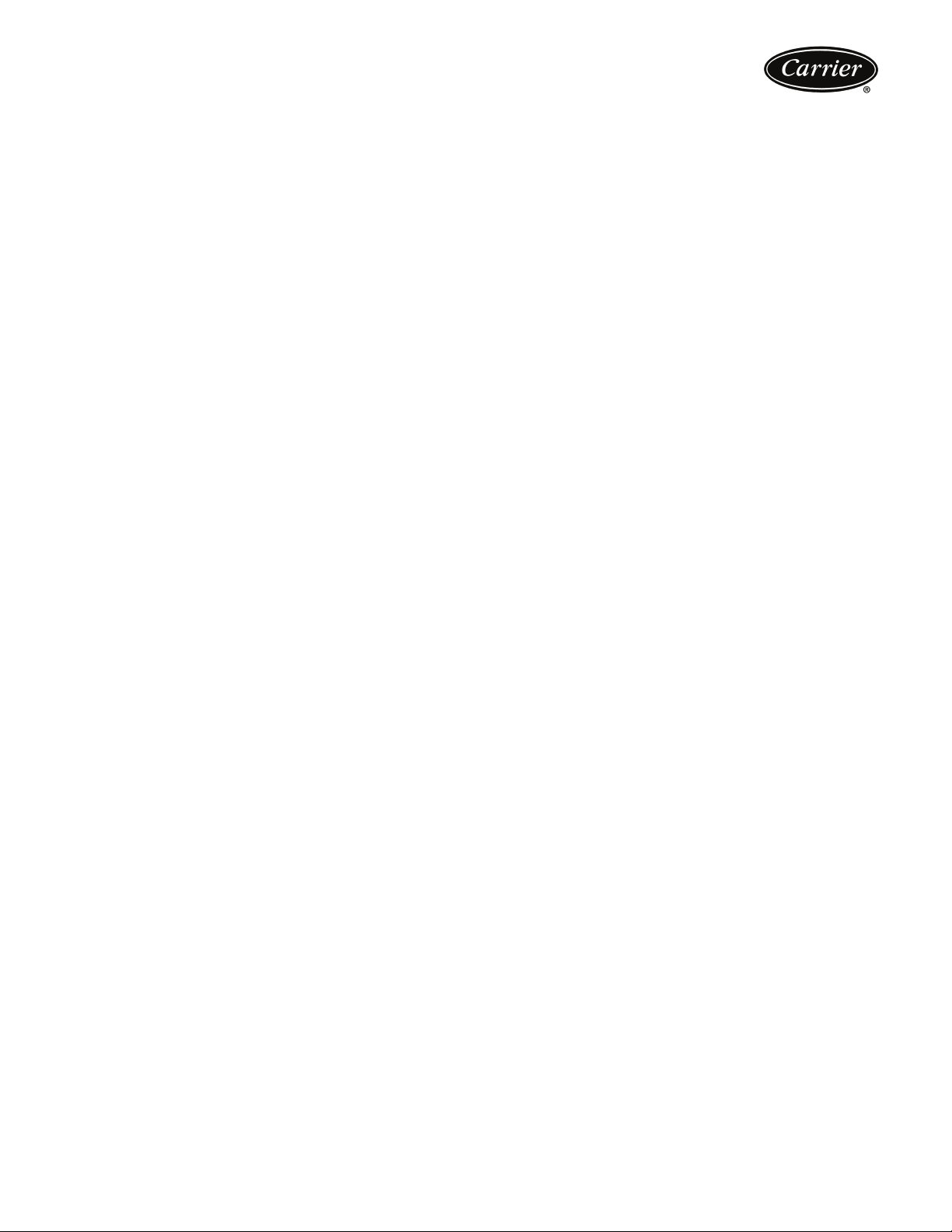

PROPELLER FAN

AEROACOUSTIC FAN

1/3 OCTAVE BAND CENTER FREQUENCY (Hz)

SOUND POWER [dB(A)]

AEROACOUSTIC™ FAN vs. PROPELLER FAN

PENETRATES BUILDING

STRUCTURE

25

40

63

130 168

250

400

630 1080

1600

2400

4000

6300

8000

90

85

80

75

70

65

60

55

50

Outputs

SCROLLING MARQUEE DISPLAY

NAVIGATOR™ DISPLAY

LOW SOUND OPTION

LOW-NOISE AEROACOUSTIC FAN

AEROACOUSTIC FAN VS PROPELLER FAN

a30-2187

a30-3162

a30-3926

NOVATION® HEAT EXCHANGER TECHNOLOGY

WITH MICROCHANNEL CONDENSER COILS

a38-7096

a30-3924

Configuration

Time Clock

Operating Modes

Alarms

E

Comfort

Link

M

O

D

E

A

larm

Run Status

Sta

tus

Service Test

Temperatures

Pressures

Setpoints

Inputs

E

S

C

N

T

E

R

TUBES

FINS

MANIFOLD

MICROCHANNELS

3

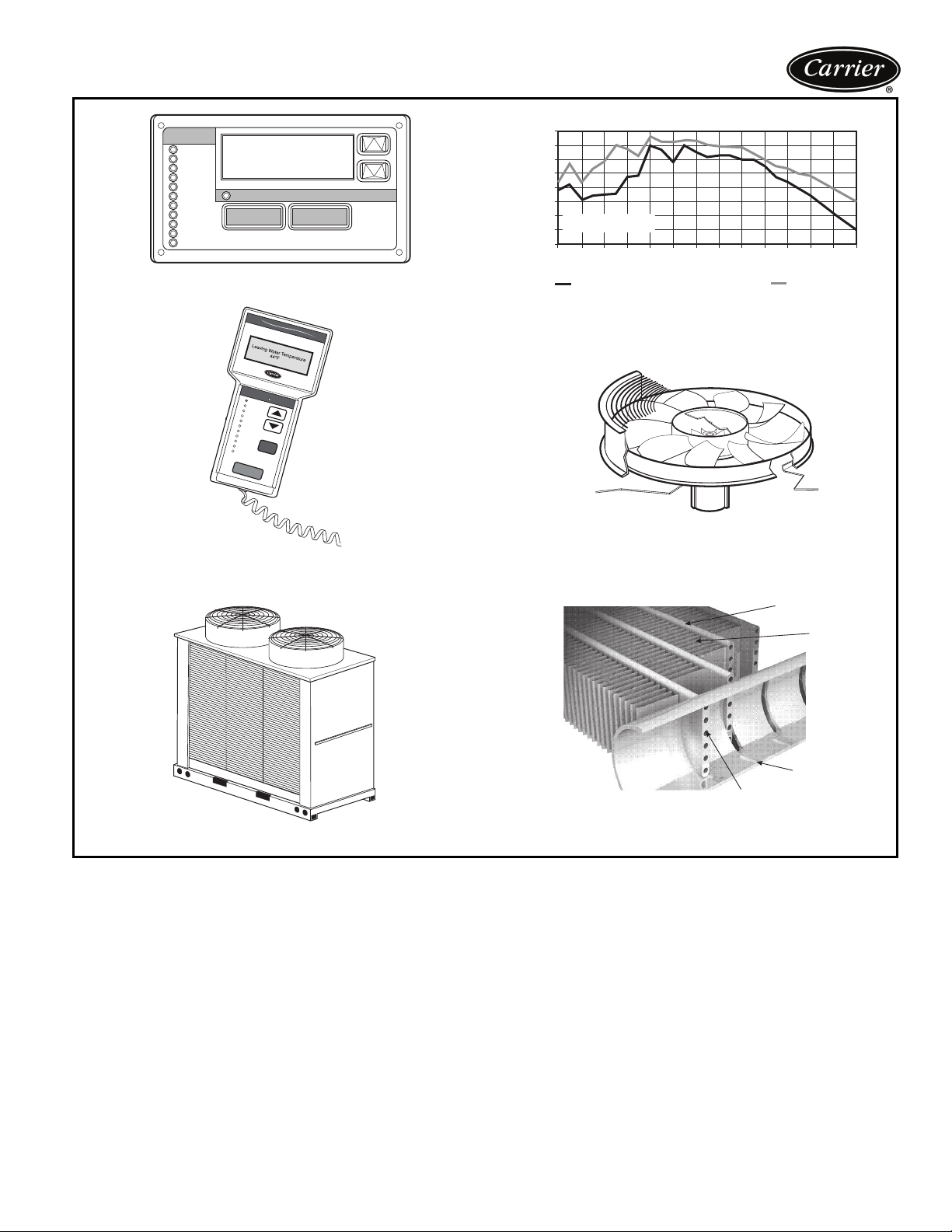

Model number nomenclature

38AP D 025 6 4 A 1 0 0 5 0

38AP – Split System Condensing Unit Packaging/Security Options

0 – Std Packaging

8 – Std Packaging, Bottom Skid

J – Bottom Skid, Top Crate, Bag

Controls/Communications Options

2 – Scrolling Marquee

3 – EMM, Scrolling Marquee

5 – No Display

Ambient/Capacity Control/

Interrupt Options

0 – Std Ambient, Std Compressor,

Std Interrupt

2 – Std Ambient, Digital Compressor,

Std Interrupt

3 – Std Ambient, Std Compressor,

High Interrupt

5 – Std Ambient, Digital Compressor,

High Interrupt

6 – Low Ambient, Std Compressor,

Std Interrupt

8 – Low Ambient, Digital Compressor,

Std Interrupt

9 – Low Ambient, Std Compressor,

High Interrupt

C – Low Ambient, Digital Compressor,

High Interrupt

Line Length Options

1 – Standard Line Length

2 – Long Line Length Check Valves

Electrical Options

0 – S

ingle Point Power, Terminal Block

1 – Single Point Power,

Non-Fused Disconnect

Refrigeration Circuit Options*

D – Dual Refrigeration Circuit

S – Single Refrigeration Circuit

Revision Level

A – Current Revision Level

ylppuS rewoP

1 – 575-3-60

2 – 380-3-60

5 – 280/230-3-60

6 – 460-3-60

9 – 380/415-3-50

Condenser Coil/Low Sound Options

4 – MCHX, No Sound Treatment

5 – E-coat, MCHX, No S

ound Treatment

C – MCHX, Low Sound Fan(s)

D – E-coat MCHX, Low Sound Fan(s)

H – MCHX, Low Sound Fan(s), Compressor Blankets

J – E-coat MCHX, Low Sound Fan(s), Compressor Blankets

Nominal Capacity – Tons (kW)

025 – 25 (88) 050 – 50 (176) 090 – 90 (317)

027 – 27 (95) 060 – 60 (211) 100 – 100 (352)

030 – 30 (106) 070 – 70 (246)

040 – 40 (141) 080 – 80 (281)

LEGEND

*38APS units available in sizes 025-050 only.

Quality Assurance

Certified to ISO 9001:2000

EMM — Energy Management Module

MCHX — Microchannel Heat Exchanger

a38-7100.eps

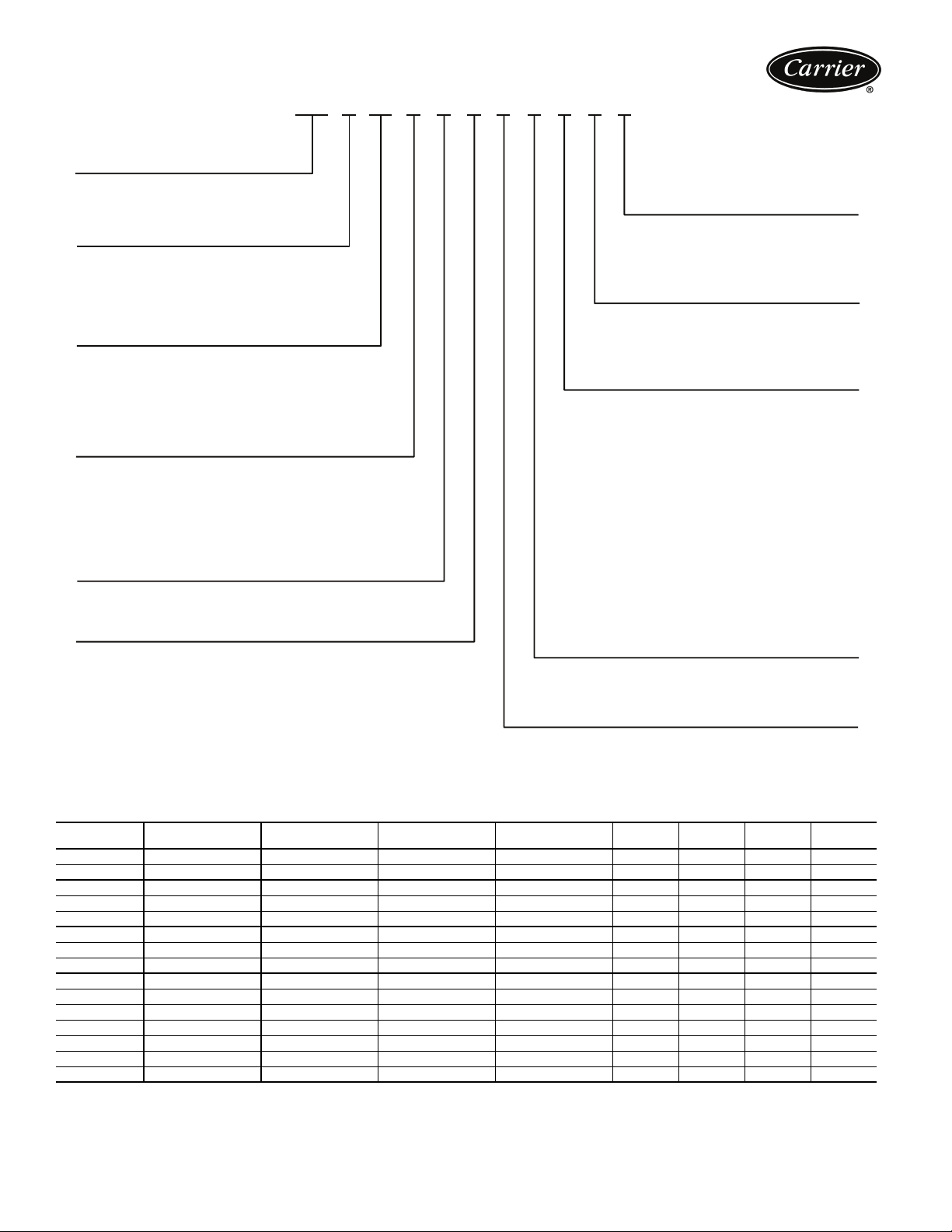

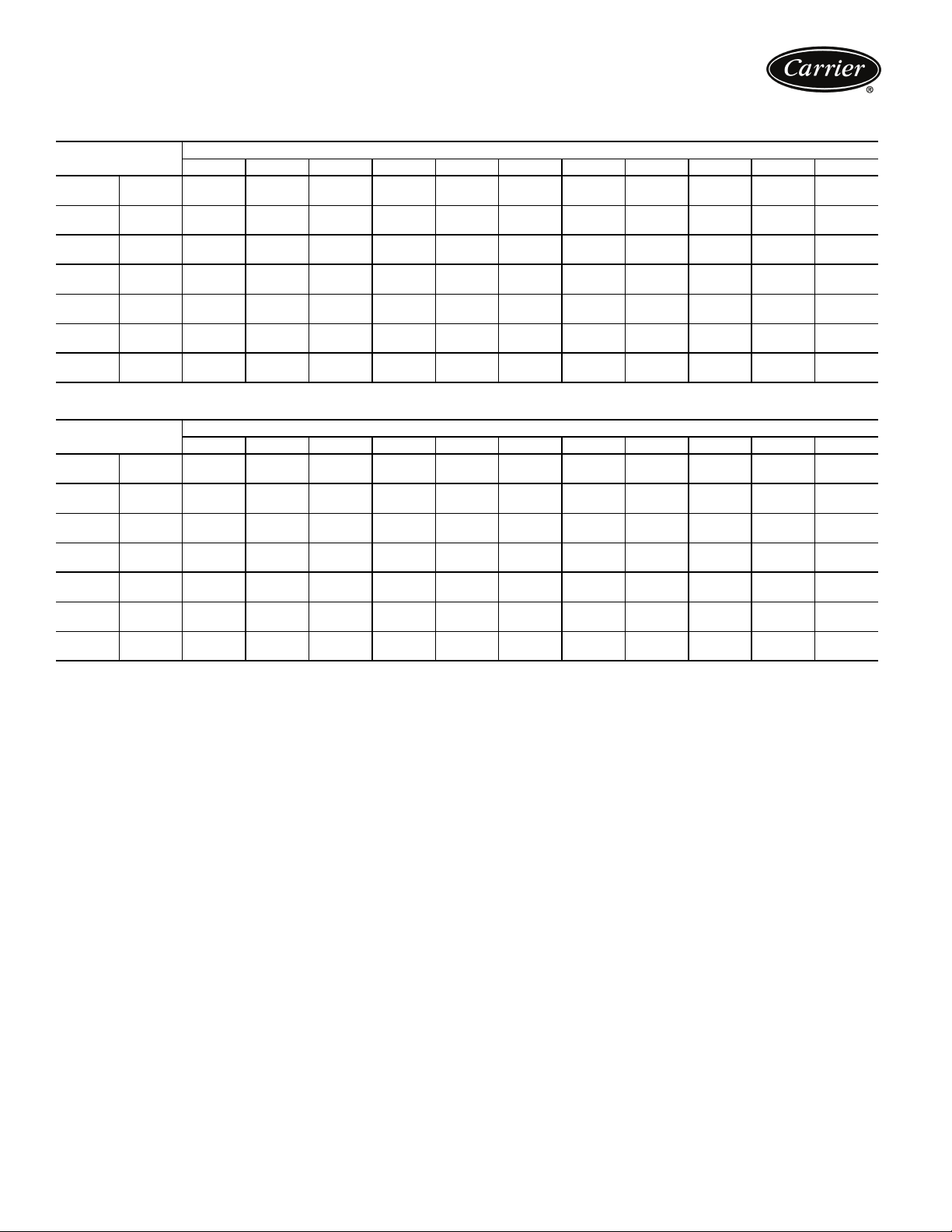

Capacity ratings

UNIT SIZE

38APS025 24.0 84.3 19.9 69.9 11.0 11.6 14.4 15.5

38APD025 24.0 84.3 19.9 69.9 11.0 11.6 13.1 14.1

38APS027 26.6 93.4 22.1 77.6 10.9 11.5 14.7 15.7

38APD027 26.6 93.4 22.1 77.6 10.9 11.5 14.0 14.7

38APS030 31.1 109.2 25.8 90.6 10.8 11.4 14.3 15.2

38APD030 31.1 109.2 25.8 90.6 10.8 11.4 12.8 13.6

38APS040 39.8 139.8 33.0 115.9 11.6 12.1 16.2 17.4

38APD040 39.2 137.7 32.5 114.1 11.5 12.0 15.3 16.4

38APS050 48.1 168.9 39.9 140.1 11.1 11.7 15.0 15.9

38APD050 50.0 175.6 41.5 145.7 10.8 11.3 14.9 15.9

38APD060 58.3 204.7 48.4 170.0 11.1 11.7 14.5 15.5

38APD070 67.3 236.4 55.9 196.3 11.0 11.4 15.7 16.7

38APD080 78.0 273.9 64.7 227.2 11.1 11.5 15.6 16.6

38APD090 87.4 306.9 72.5 254.6 11.3 11.8 15.3 16.4

38APD100 96.0 337.2 79.7 279.9 11.1 11.6 15.0 16.0

EER — Energy Efficiency Ratio

IPLV — Integrated Part Load Value

4

CAPACITY NOMINAL

TONS (60 Hz)

LEGEND NOTES:

38AP UNIT CAPACITY RATINGS

CAPACITY NOMINAL

kW (60 Hz)

CAPACITY NOMINAL

TONS (50 Hz)

CAPACITY NOMINAL

1. Unit performance is rated in accordance with ARI (Air Conditioning and

2. Ratings are based on 45 F (7.2 C) saturated suction temperature and 95 F

kW (50 Hz)

Refrigeration Institute) Standard 365.

(35 C) outside-air temperature, and include suction line losses.

EER

(60 Hz)

(50 Hz)

EER

IPLV

(60 Hz)

IPLV

(50 Hz)

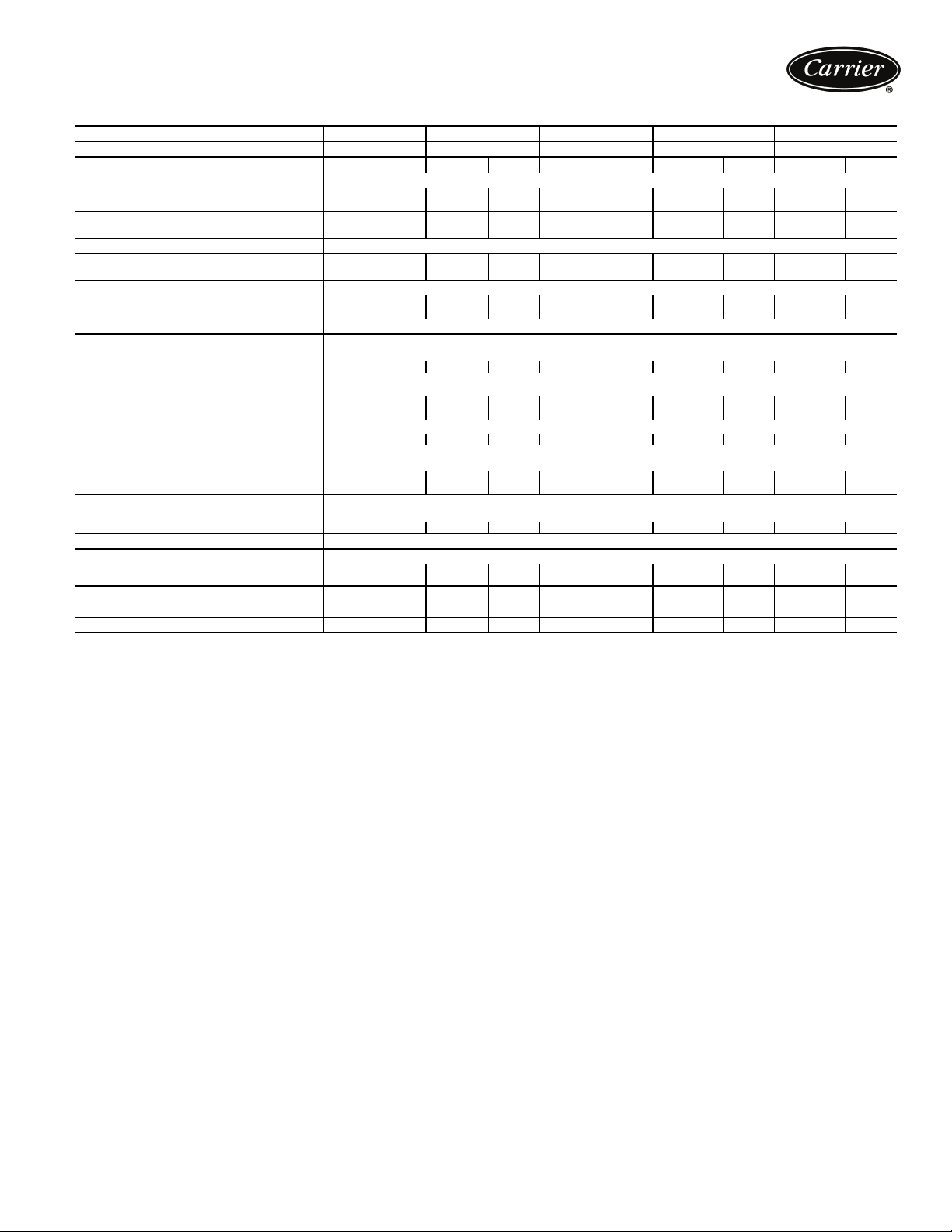

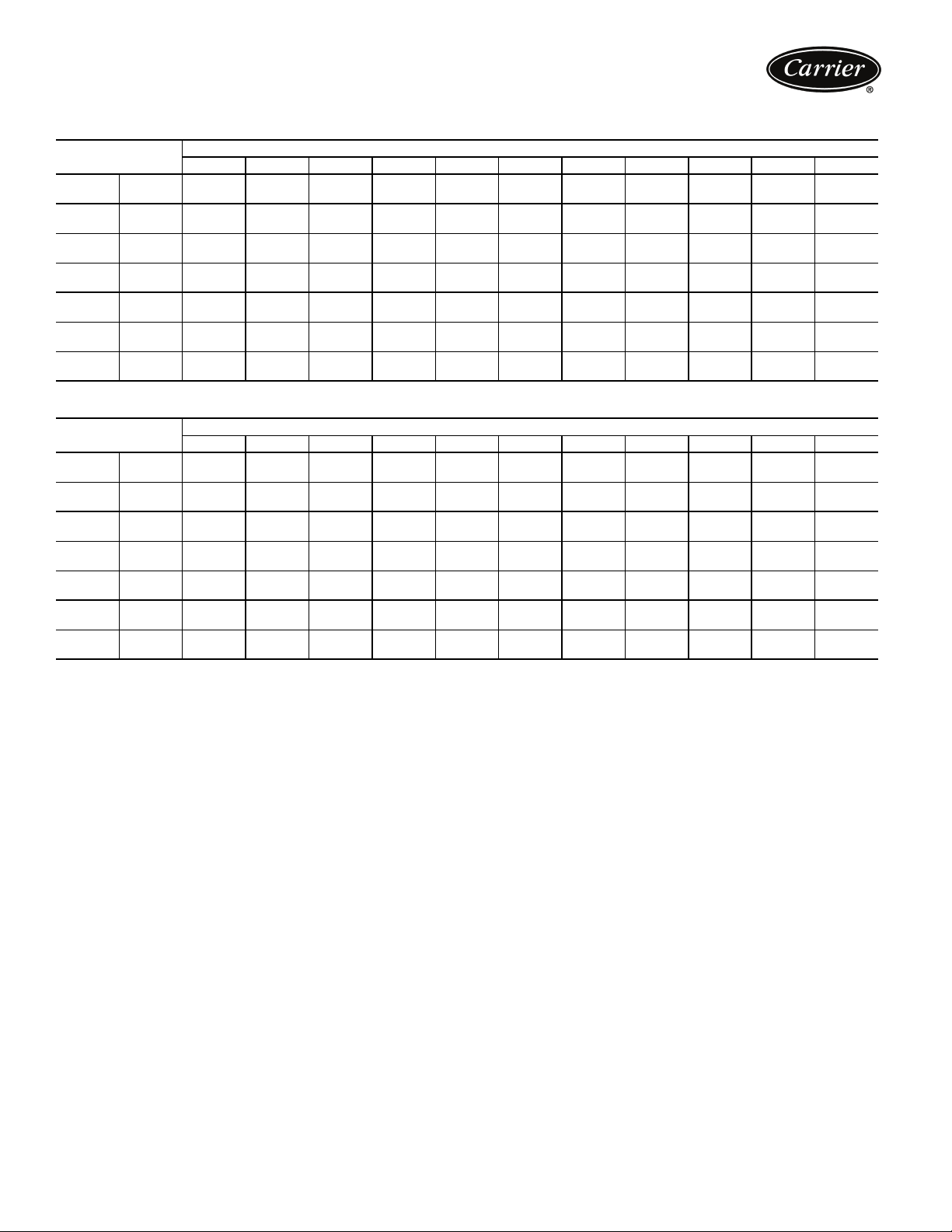

Physical data

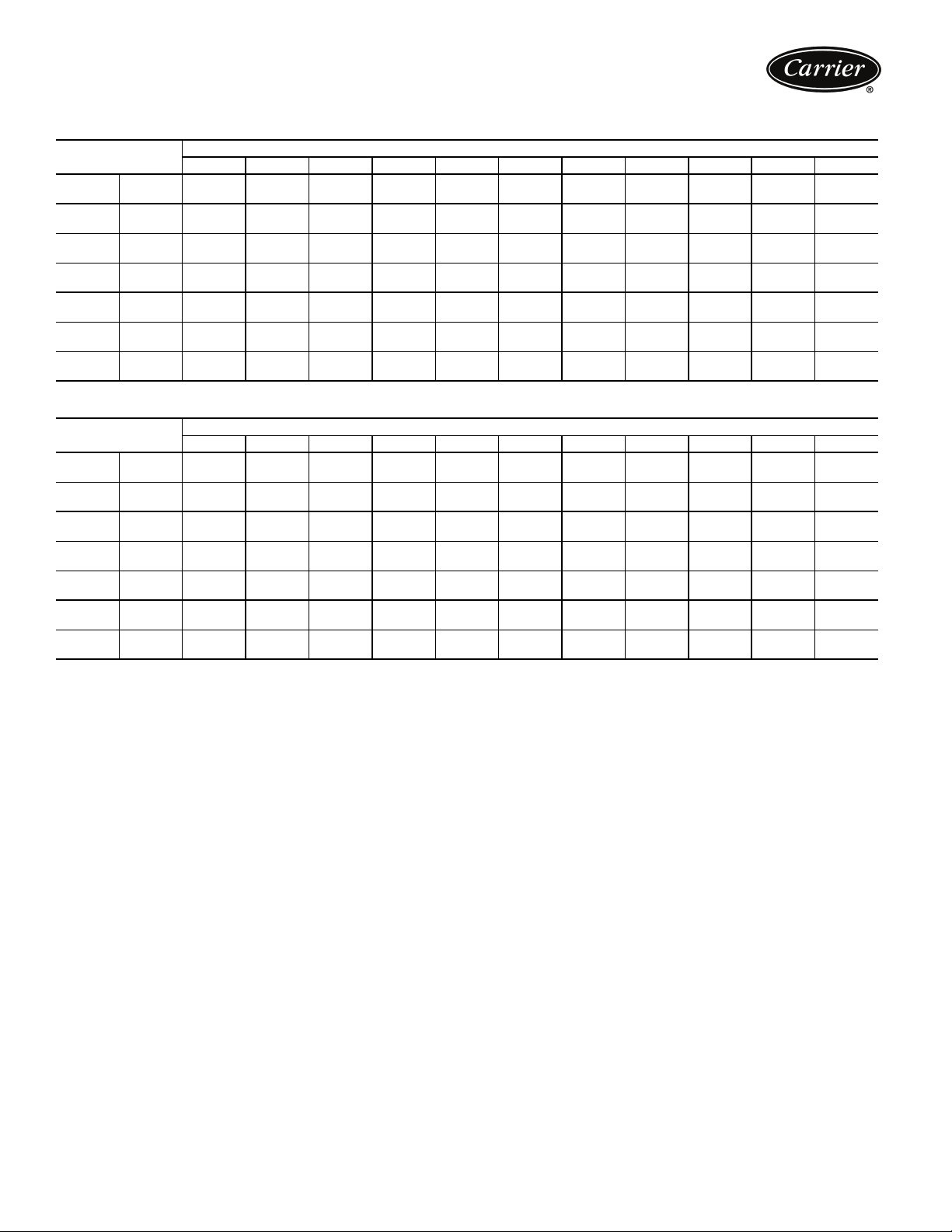

38AP025-050 UNITS — ENGLISH

NOMINAL CAPACITY, 50/60 Hz (tons) 21/25 23/27 25/30 33/40 42/50

38AP UNIT SIZE 025 027 030 040 050

CIRCUIT Dual Single Dual Single Dual Single Dual Single Dual Single

OPERATING WEIGHTS (lb)

Standard 1095 1077 1258 1240 1264 1246 2094 1968 2120 1977

With Low Sound Option 1131 1113 1294 1276 1300 1282 2148 2022 2174 2031

APPROXIMATE REFRIGERANT CHARGE,

TYPICAL (lb)*

28 24 30 26 30 26 52 40 52 40

NITROGEN SHIPPING CHARGE 15 psig

COMPRESSOR

hp (Qty) (CKT A/CKT B)

CAPACITY STEPS

Standard 222222 4 3 4 3

Digital Option 22 22 22 22 22 22 44 33 44 33

11 (2) 11 (2) 13 (2) 13 (2) 15 (2) 15 (2) 10 (2)/

8.5 (2)

13 (3) 11 (2)/

13 (2)

15 (3)

CRANKCASE HEATER (W) (each compressor) 90

CONDENSER FANS

Standard Propeller Type - Direct Drive

Quantity 222222 3 3 3 3

RPM 1140 (60 Hz), 950 (50 Hz)

Diameter (in.) 30

Total Watts (60 Hz) 3300 3300 3300 3300 3300 3300 4200 4200 4200 4200

Total Watts (50 Hz) 2750 2750 2750 2750 2750 2750 3500 3500 3500 3500

Low Noise

Quantity 222222 3 3 3 3

RPM

Diameter (in.) 30

Total Watts (60 Hz) 2750 2750 2750 2750 2750 2750 3500 3500 3500 3500

Total Watts (50 Hz) 2300 2300 2300 2300 2300 2300 2900 2900 2900 2900

CONDENSER COIL MCHX Type

No. Coils per Circuit 1

sq ft 27.1 27.1 33.9 33.9 33.9 33.9 67.8 67.8 67.8 67.8

Shrouded Axial Fan - Direct Drive

850 (60 Hz), 700 (50 Hz)

TEMPERATURE RELIEF Fusible Plug on Liquid Lines of Each Circuit - 210 F

CONNECTIONS (in.) ODF (CKT A/CKT B)

Suction Line 1

Liquid Line

3

/8 / 13/815/813/8 / 13/815/813/8 / 13/815/

5

/8 / 5/

5

5

/

8

/8 / 5/

8

5

5

/

8

/8 / 5/

8

8

15/8 / 15/

8

7

5

/

8

/8 / 5/

21/

8

8

15/8 / 15/

8

7

5

/

8

/8 / 5/

21/

8

8

8

7

/

8

MAXIMUM HEIGHT FOR 3° F SUBCOOLING (ft)† 75 75 75 75 75 75 75 75 75 75

CAPACITY PER CIRCUIT (%) (CKT A/CKT B) 50/50 100 50/50 100 50/50 100 54/46 100 48/52 100

MINIMUM UNIT CAPACITY (%) 50 50 50 50 50 50 23 33 23 33

LEGEND

MCHX — Microchannel Heat Exchanger

ODF — Outside Diameter, Female

*Typical operating charge with 25 ft of interconnecting piping. Operating charge is

approximate for maximum system capacity. Unit is factory supplied with nitrogen

holding charge. Refrigerant charge for dual circuit units is the total for both

circuits.

†Maximum vertical separation between evaporator coil and condensing unit if con-

densing unit is below the evaporator.

NOTE: Refer to Loading Sequences tables in Application Data section on page 85

or contact Application Engineering for detailed capacity step data.

5

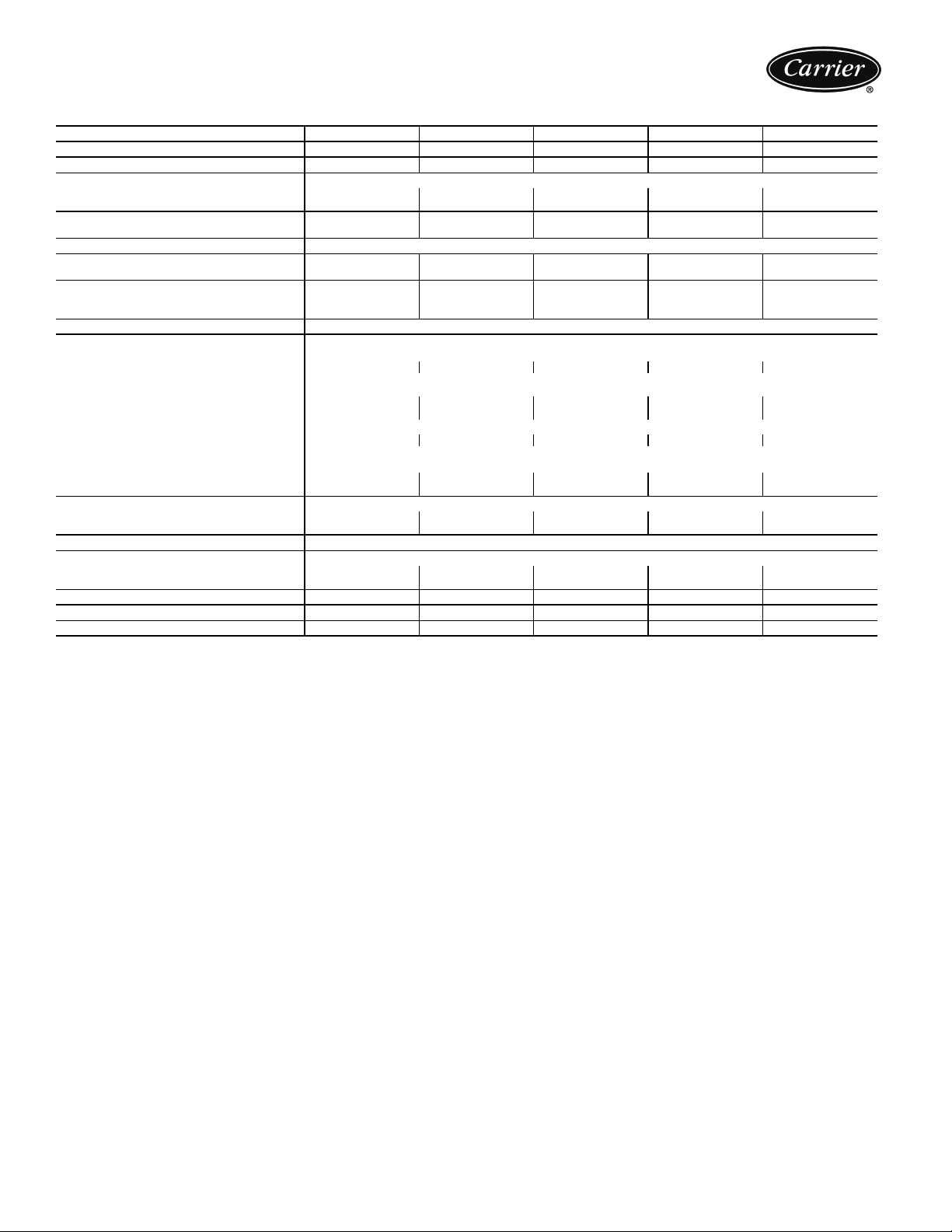

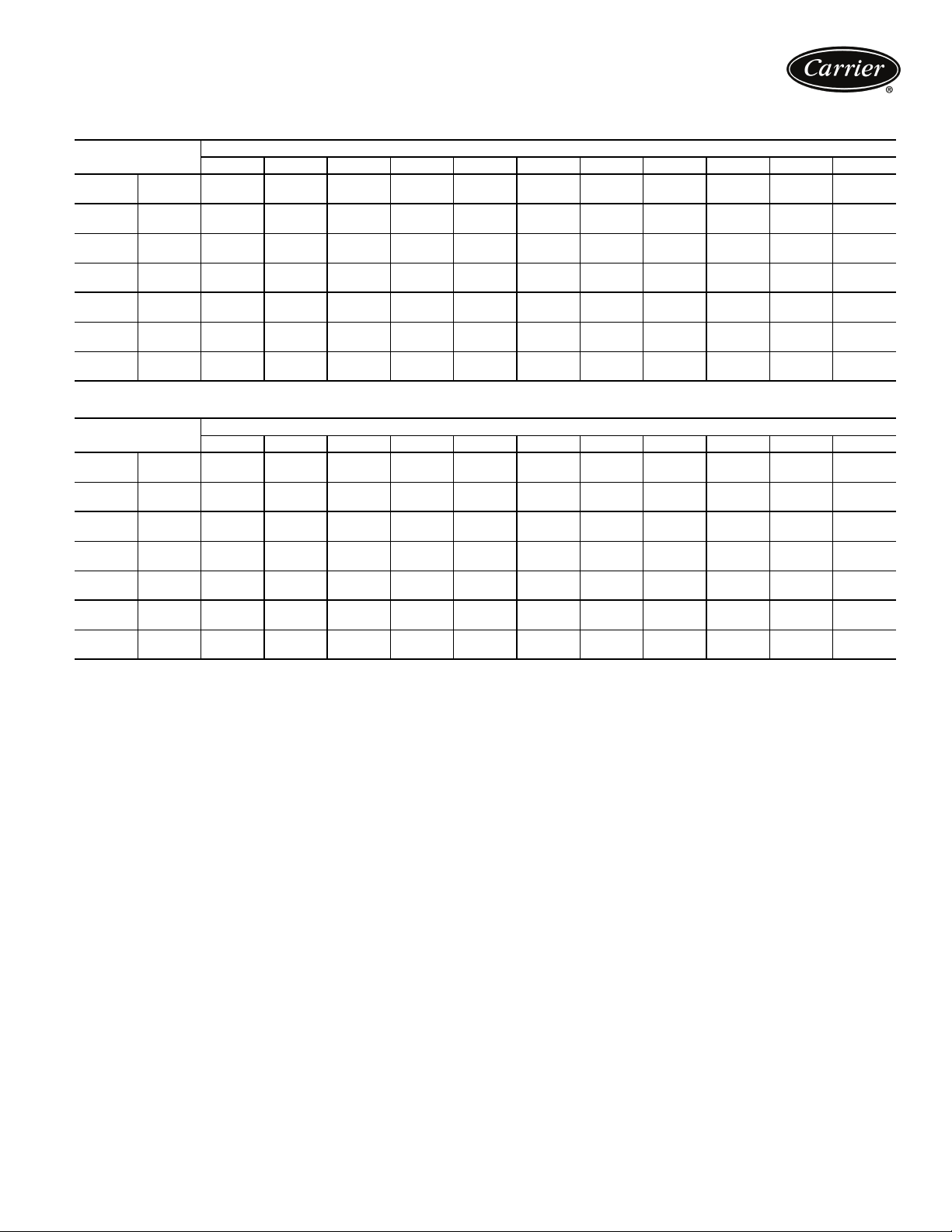

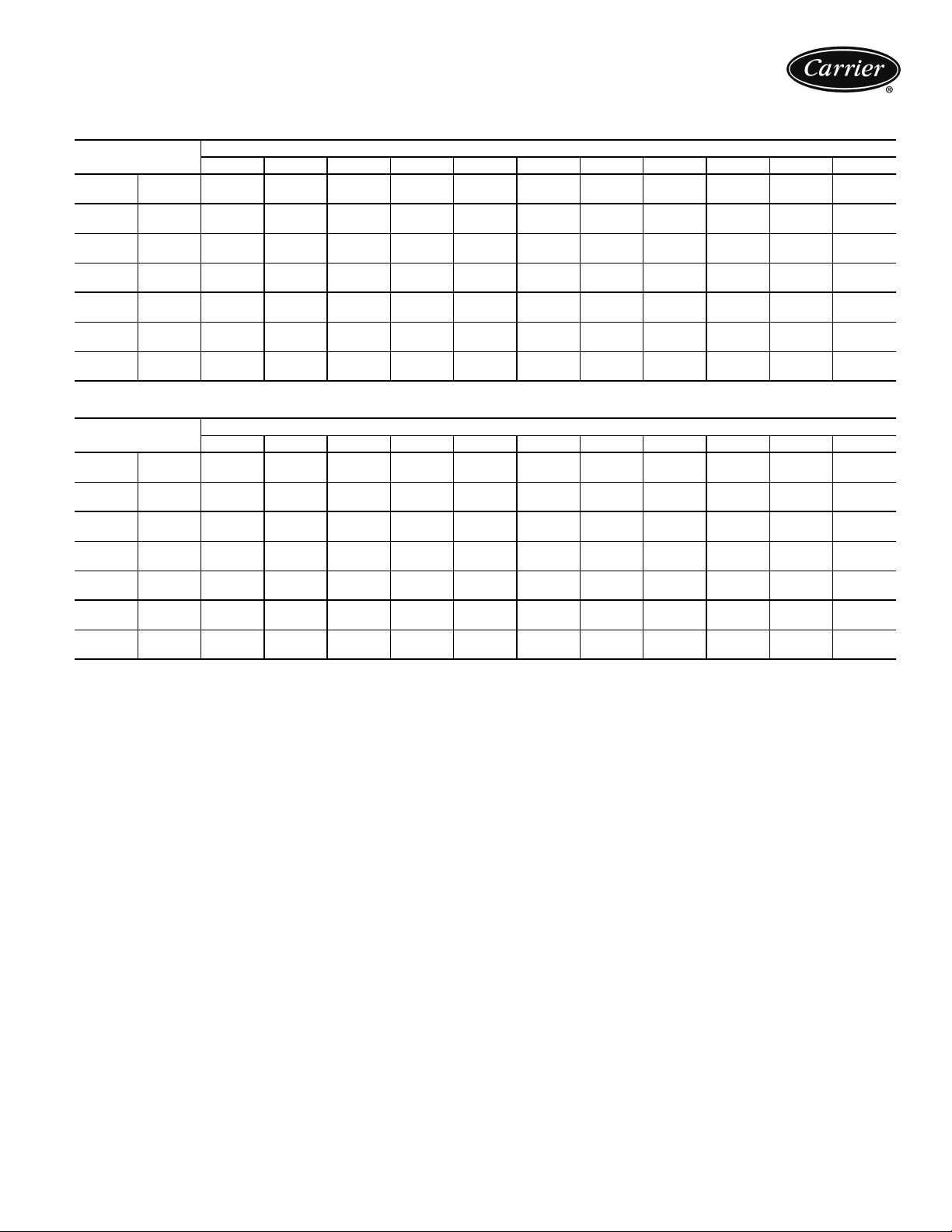

Physical data (cont)

38AP060-100 UNITS — ENGLISH

NOMINAL CAPACITY, 50/60 Hz (tons) 50/60 58/70 67/80 75/90 83/100

38AP UNIT SIZE 060 070 080 090 100

CIRCUIT Dual Dual Dual Dual Dual

OPERATING WEIGHTS (lb)

Standard 2227 2450 2610 2835 2844

With Low Sound Option 2299 2522 2700 2943 2952

APPROXIMATE REFRIGERANT CHARGE,

TYPICAL (lb)*

60 70 78 96 100

NITROGEN SHIPPING CHARGE 15 psig

COMPRESSOR

hp (Qty) (CKT A/CKT B)

CAPACITY STEPS

Standard 45566

Digital Option 44 55 55 66 66

13 (2)/15 (2) 15 (2)/11 (3) 15 (2)/15 (3) 13 (3)/15 (3) 15 (3)/15 (3)

CRANKCASE HEATER (W) (each compressor) 90

CONDENSER FANS

Standard Propeller Type - Direct Drive

Quantity 44566

RPM 1140 (60 Hz), 950 (50 Hz)

Diameter (in.) 30

Total Watts (60 Hz) 6200 6000 7500 9000 9000

Total Watts (50 Hz) 5150 5000 6250 7500 7500

Low Noise

Quantity 44566

RPM

Diameter (in.) 30

Total Watts (60 Hz) 5200 5000 6250 7500 7500

Total Watts (50 Hz) 4300 4150 5200 6250 6250

CONDENSER COIL MCHX Type

No. Coils per Circuit 1 2 2 to 3 3 3

sq ft 67.8 99.6 124.5 149.4 149.4

Shrouded Axial Fan - Direct Drive

850 (60 Hz), 700 (50 Hz)

TEMPERATURE RELIEF Fusible Plug on Liquid Lines of Each Circuit - 210 F

CONNECTIONS (in.) ODF (CKT A/CKT B)

Suction Line 15/8 / 15/

Liquid Line

5

/8 / 7/

8

8

15/8 / 21/

7

/8 / 7/

8

8

15/8 / 21/

7

/8 / 7/

8

8

21/8 / 21/

7

/8 / 7/

8

8

21/8 / 25/

7

/8 / 7/

8

8

MAXIMUM HEIGHT FOR 3° F SUBCOOLING (ft)† 75 75 75 75 75

CAPACITY PER CIRCUIT (%) (CKT A/CKT B) 46/54 47/53 40/60 46/54 50/50

MINIMUM UNIT CAPACITY (%) 23 24 20 15 17

LEGEND

MCHX — Microchannel Heat Exchanger

ODF — Outside Diameter, Female

*Typical operating charge with 25 ft of interconnecting piping. Operating charge is

approximate for maximum system capacity. Unit is factory supplied with nitrogen

holding charge. Refrigerant charge for dual circuit units is the total for both

circuits.

†Maximum vertical separation between evaporator coil and condensing unit if con-

densing unit is below the evaporator.

NOTE: Refer to Loading Sequences tables in Application Data section on page 85

or contact Application Engineering for detailed capacity step data.

6

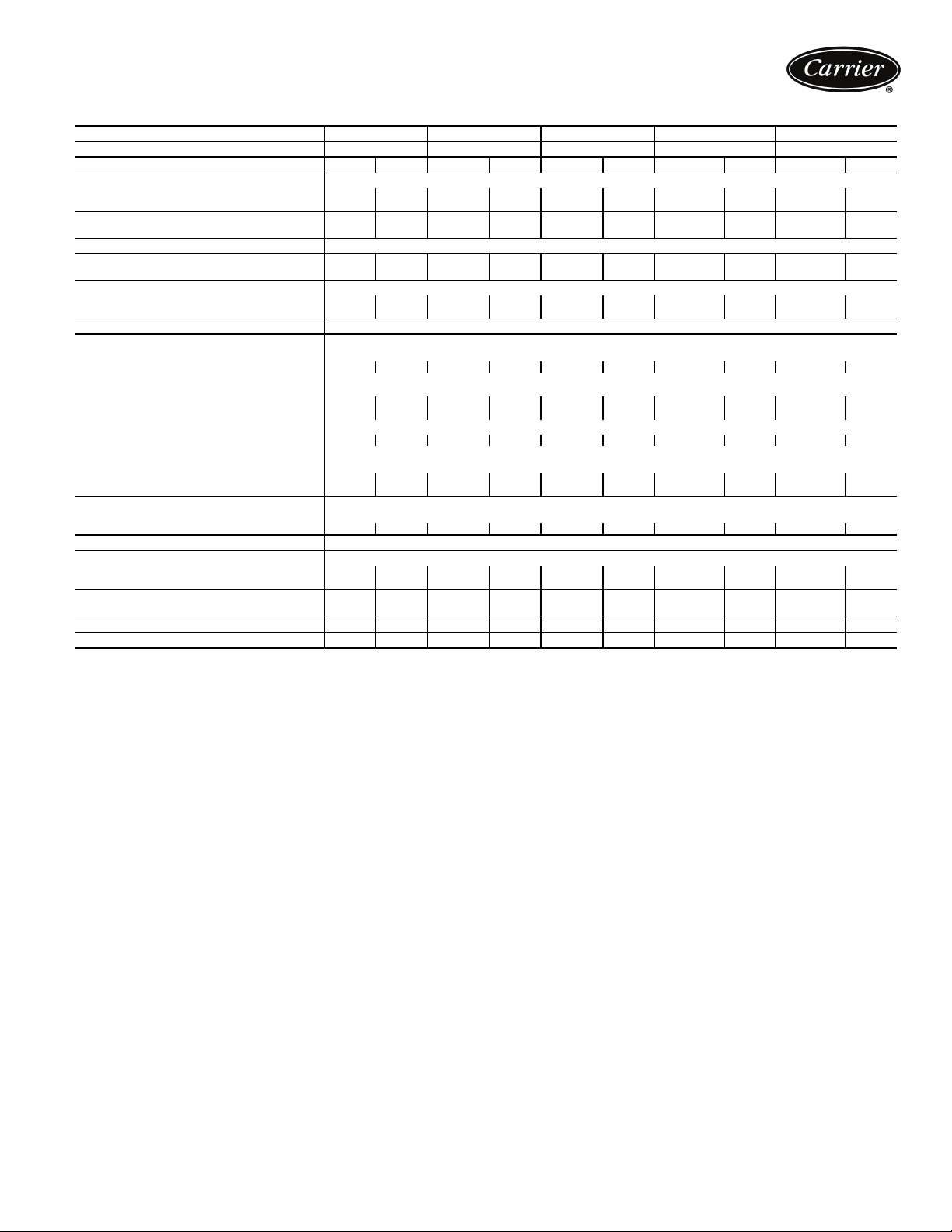

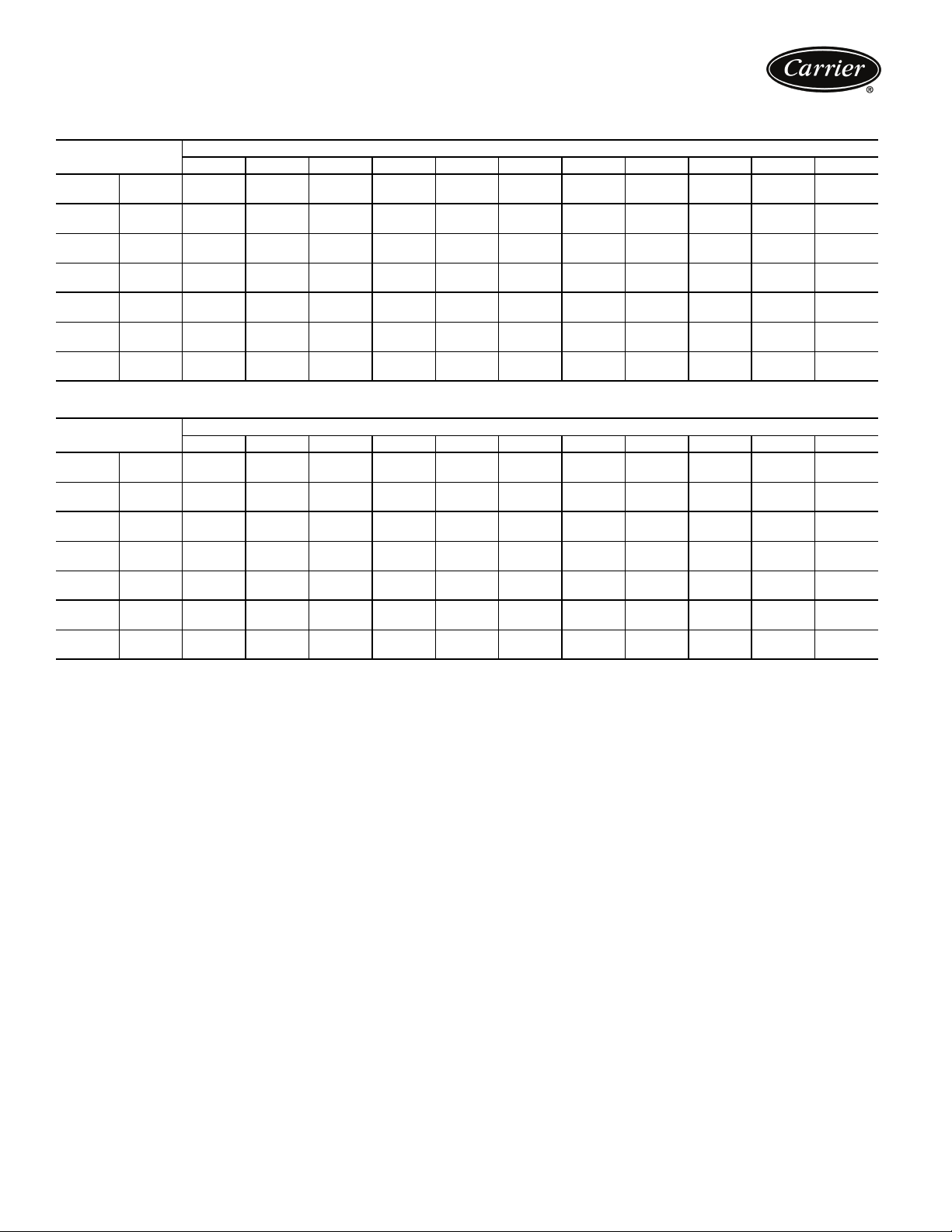

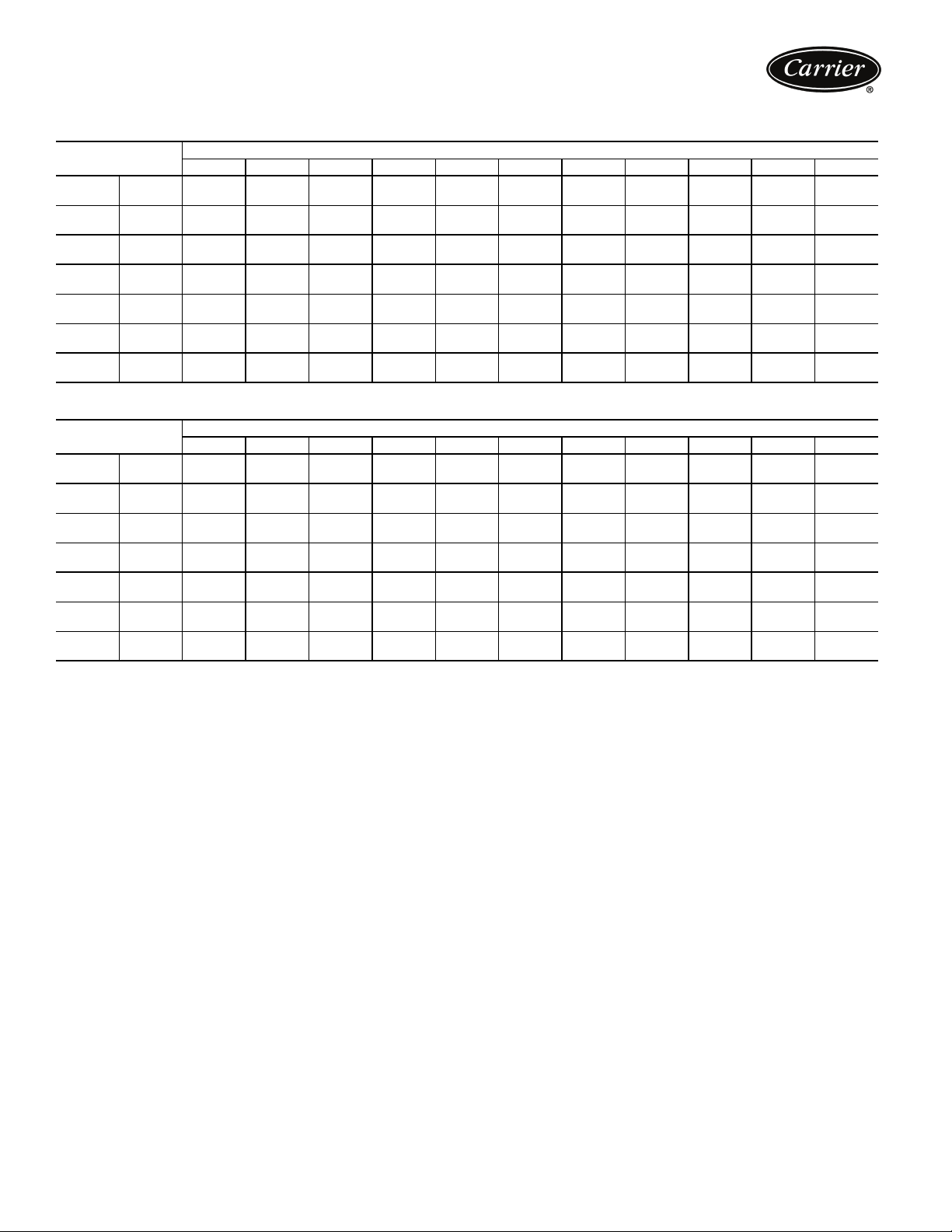

38AP025-050 UNITS — SI

NOMINAL CAPACITY 50/60 Hz (kW) 74/88 81/95 88/106 116/141 148/176

38AP UNIT SIZES 025 027 030 040 050

CIRCUIT Dual Single Dual Single Dual Single Dual Single Dual Single

OPERATING WEIGHTS (kg)

Standard 497 489 571 562 573 565 950 893 961 897

With Low Sound Option 513 505 587 579 590 582 974 917 986 921

APPROXIMATE REFRIGERANT CHARGE,

TYPICAL (kg)*

12.7 10.9 13.6 11.8 13.6 11.8 23.6 18.1 23.6 18.1

NITROGEN SHIPPING CHARGE 1.03 bar

COMPRESSOR

kW (Qty) (CKT A/CKT B)

CAPACITY STEPS

Standard 222222 4 3 4 3

Digital Option 22 22 22 22 22 22 44 33 44 33

8.2 (2) 8.2 (2) 9.7 (2) 9.7 (2) 11.2 (2) 11.2 (2) 7.5 (2)/

6.3 (2)

9.7 (3) 8.2 (2)/

9.7 (2)

11.2 (3)

CRANKCASE HEATER (W) (each compressor) 90

CONDENSER FANS

Standard Propeller Type - Direct Drive

Quantity 222222 3 3 3 3

r/s 19 (60 Hz), 16 (50 Hz)

Diameter (mm) 762

Total Watts (60 Hz) 3300 3300 3300 3300 3300 3300 4200 4200 4200 4200

Total Watts (50 Hz) 2750 2750 2750 2750 2750 2750 3500 3500 3500 3500

Low Noise

Quantity 222222 3 3 3 3

r/s

Diameter (mm) 762

Total Watts (60 Hz) 2750 2750 2750 2750 2750 2750 3500 3500 3500 3500

Total Watts (50 Hz) 2300 2300 2300 2300 2300 2300 2900 2900 2900 2900

CONDENSER COIL MCHX Type

No. Coils per Circuit 1

sq m 2.5 2.5 3.2 3.2 3.2 3.2 6.3 6.3 6.3 6.3

Shrouded Axial Fan - Direct Drive

14 (60 Hz), 12 (50 Hz)

TEMPERATURE RELIEF Fusible Plug on Liquid Lines of Each Circuit - 99 C

CONNECTIONS (in.) ODF (CKT A/CKT B)

Suction Line 1

Liquid Line

MAXIMUM HEIGHT FOR 1.7° C

SUBCOOLING (m)†

3

/8 / 13/815/813/8 / 13/815/813/8 / 13/815/

5

/8 / 5/

5

5

/

8

/8 / 5/

8

5

5

/

8

/8 / 5/

8

8

15/8 / 15/

8

7

5

/

/8 / 5/

8

21/

8

8

15/8 / 15/

8

7

/

8

5

/8 / 5/

8

8

23 23 23 23 23 23 23 23 23 23

21/

8

7

/

8

CAPACITY PER CIRCUIT (%) (CKT A/CKT B) 50/50 100 50/50 100 50/50 100 54/46 100 48/52 100

MINIMUM UNIT CAPACITY (%) 50 50 50 50 50 50 23 33 23 33

LEGEND

MCHX — Microchannel Heat Exchanger

ODF — Outside Diameter, Female

*Typical operating charge with 7.62 m of interconnecting piping. Operating charge

is approximate for maximum system capacity. Unit is factory supplied with nitrogen holding charge. Refrigerant charge for dual circuit units is the total for both

circuits.

†Maximum vertical separation between evaporator coil and condensing unit if con-

densing unit is below the evaporator.

NOTE: Refer to Loading Sequences tables in Application Data section on page 85

or contact Application Engineering for detailed capacity step data.

7

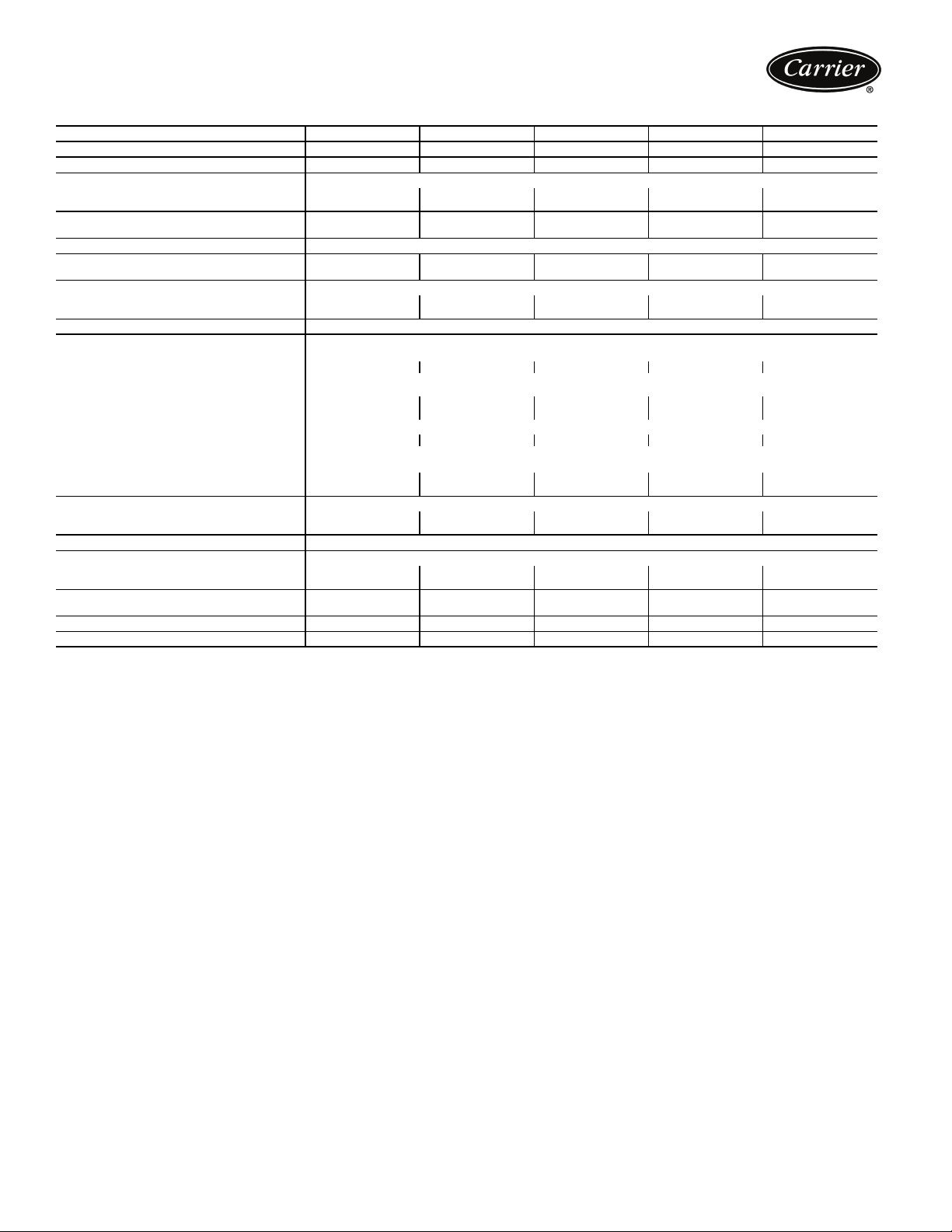

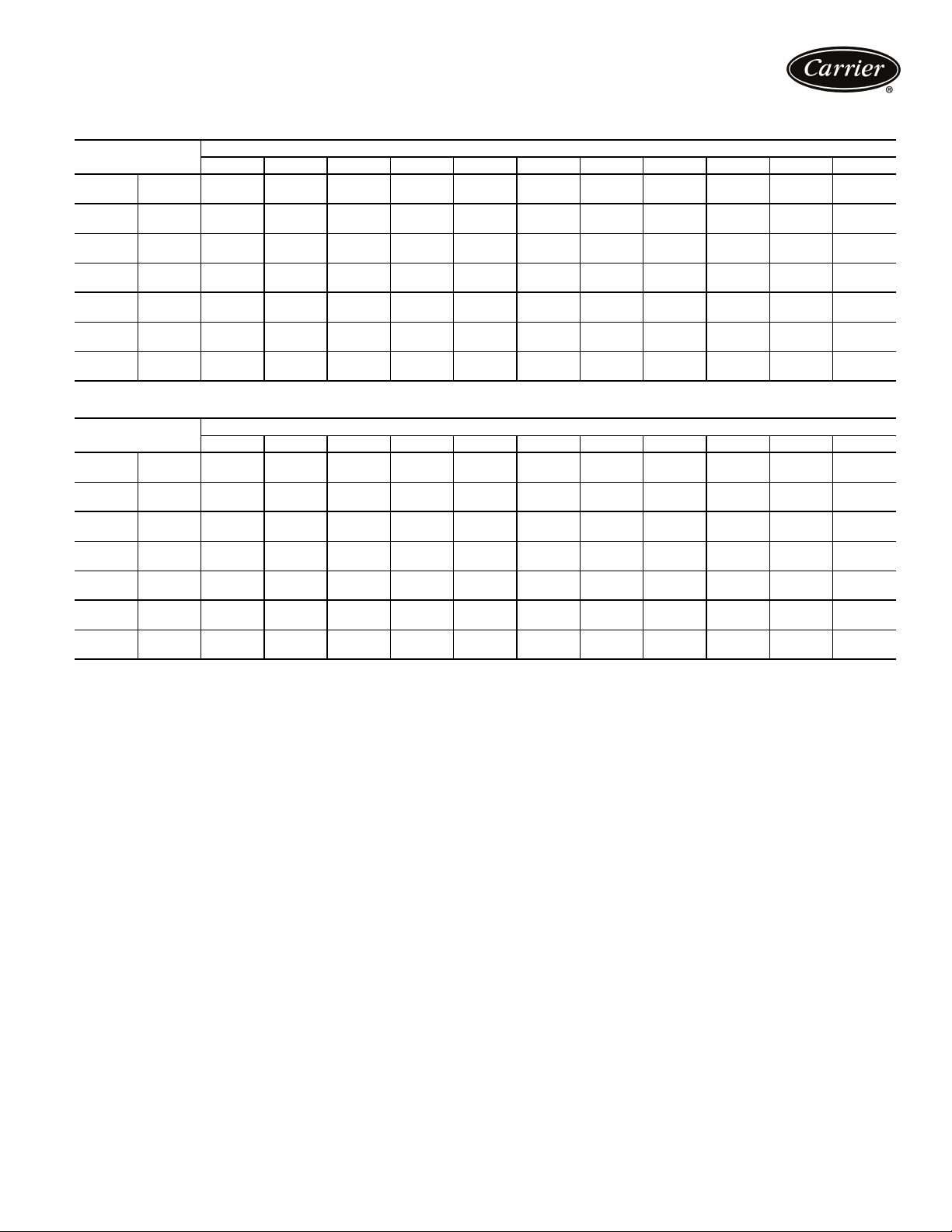

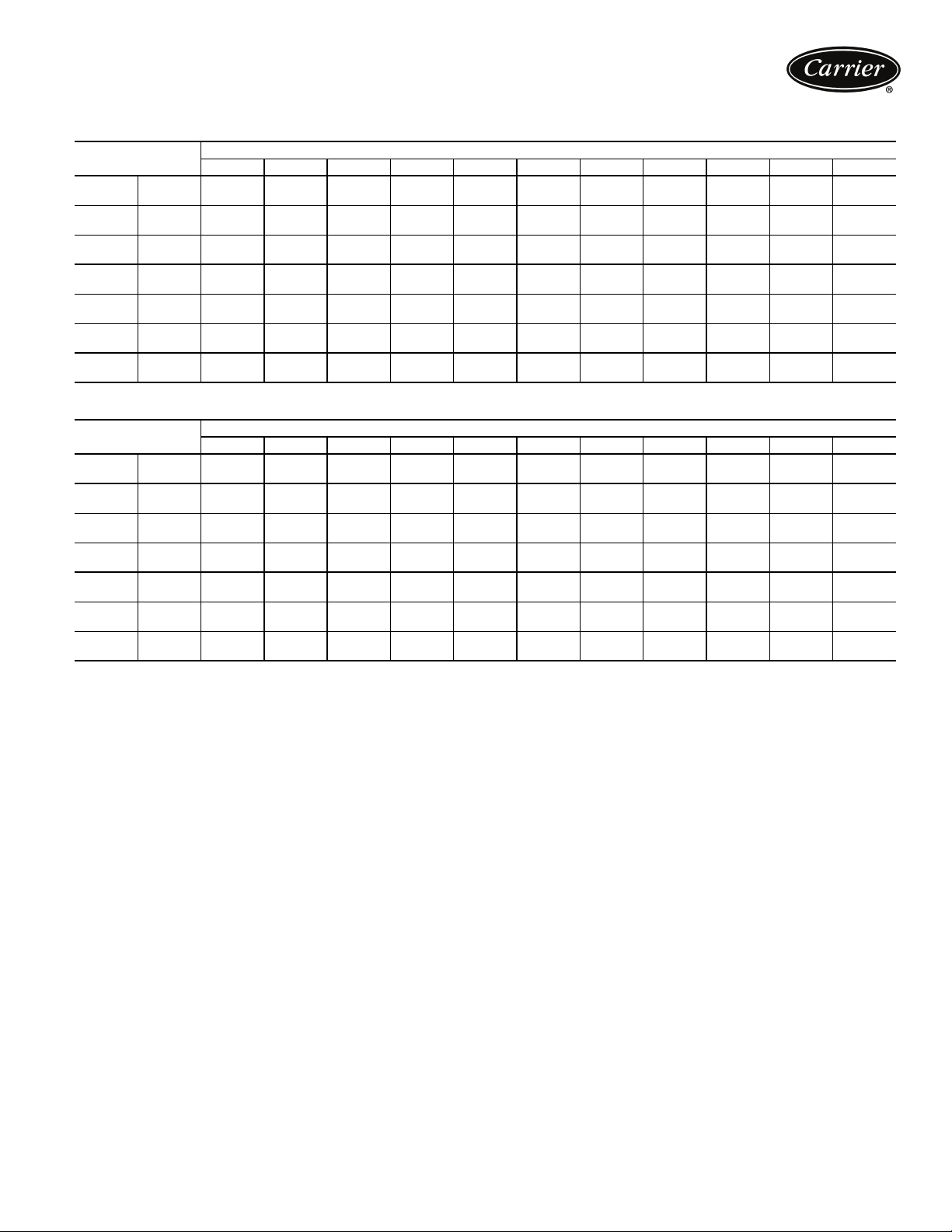

Physical data (cont)

38AP060-100 UNITS — SI

NOMINAL CAPACITY 50/60 Hz (kW) 176/211 204/246 236/281 264/317 292/352

38AP UNIT SIZES 060 070 080 090 100

CIRCUIT Dual Dual Dual Dual Dual

OPERATING WEIGHTS (kg)

Standard 1010 1111 1184 1286 1290

With Low Sound Option 1043 1144 1225 1335 1339

APPROXIMATE REFRIGERANT CHARGE,

TYPICAL (kg)*

27.2 31.8 35.4 43.5 45.4

NITROGEN SHIPPING CHARGE 1.03 bar

COMPRESSOR

kW (Qty) (CKT A/CKT B)

CAPACITY STEPS

Standard 45566

Digital Option 44 55 55 66 66

9.7 (2)/11.2 (2) 11.2 (2)/8.2 (3) 11.2 (2)/11.2 (3) 9.7 (3)/11.2 (3) 11.2 (3)/11.2 (3)

CRANKCASE HEATER (W) (each compressor) 90

CONDENSER FANS

Standard Propeller Type - Direct Drive

Quantity 44566

r/s 19 (60 Hz), 16 (50 Hz)

Diameter (mm) 762

Total Watts (60 Hz) 6200 6000 7500 9000 9000

Total Watts (50 Hz) 5150 5000 6250 7500 7500

Low Noise

Quantity 44566

r/s

Diameter (mm) 762

Total Watts (60 Hz) 5200 5000 6250 7500 7500

Total Watts (50 Hz) 4300 4150 5200 6250 6250

CONDENSER COIL MCHX Type

No. Coils per Circuit 1 2 2 - 3 3 - 3 3 - 3

sq m 6.3 9.3 11.6 13.9 13.9

Shrouded Axial Fan - Direct Drive

14 (60 Hz), 12 (50 Hz)

TEMPERATURE RELIEF Fusible Plug on Liquid Lines of Each Circuit - 99 C

CONNECTIONS (in.) ODF (CKT A/CKT B)

Suction Line 1

Liquid Line

MAXIMUM HEIGHT FOR 1.7° C

SUBCOOLING (m)†

5

/8 / 15/

5

/8 / 7/

8

8

15/8 / 21/

7

/8 / 7/

8

8

15/8 / 21/

7

/8 / 7/

8

8

21/8 / 21/

7

/8 / 7/

8

8

23 23 23 23 23

21/8 / 25/

7

/8 / 7/

8

8

CAPACITY PER CIRCUIT (%) (CKT A/CKT B) 46/54 47/53 40/60 46/54 50/50

MINIMUM UNIT CAPACITY (%) 23 24 20 15 17

LEGEND

MCHX — Microchannel Heat Exchanger

ODF — Outside Diameter, Female

*Typical operating charge with 7.62 m of interconnecting piping. Operating charge

is approximate for maximum system capacity. Unit is factory supplied with nitrogen holding charge. Refrigerant charge for dual circuit units is the total for both

circuits.

†Maximum vertical separation between evaporator coil and condensing unit if con-

densing unit is below the evaporator.

NOTE: Refer to Loading Sequences tables in Application Data section on page 85

or contact Application Engineering for detailed capacity step data.

8

–

–

Options and accessories

ITEM FACTORY-INSTALLED OPTION FIELD-INSTALLED ACCESSORY

Condenser Coil/Low Sound Options

E-Coated MCHX X

Low Sound Fan(s) X

Compressor Blankets X

Security Grilles/Hail Guards X

Vibration isolation pads X

Line Length Options

Long Line Length Check Valve XX

Ambient/Capacity Control/Interrupt Options

Digital Compressor* X

High Short Circuit Current Rating Interrupt X

Motormaster V Low Ambient Control X

Electrical Options

Non-Fused Disconnect X

Controls/Communications Options

Navigator™ Display X

Remote Enhanced Display X

Touch Pilot™ Display X

ComfortLink™ Controls with Scrolling Marquee Display Module X

EMM XX

BACnet Translator Control X

LON Translator Control X

Packaging Options

Bottom Skid X

Top Crate, Bag X

LEGEND *Digital compressors provide incremental unloading from full capacity

E-Coated — Epoxy Coating Applied to Entire Coil Assembly

EMM — Energy Management Module

LON — Local Operating Network

MCHX — Microchannel Heat Exchanger

down to a minimum value.

NOTES:

1. Std Interrupt - SCCR (short circuit current rating) (5K)

2. High Interrupt - SCCR 460-v and 380/415-v (65K), 208/230-v

(65K), 575-v (25K)

X

Factory-installed options

Novation® heat exchanger technology microchannel coil (aluminum fin/aluminum tube) condenser is

available for optimum durability. Novation heat exchangers

with microchannel coil technology are offered coated or

uncoated to match coil protection to site conditions. The

Carrier Electronic Catalog (E-Cat) can be used to determine whether or not corrosion protection is recommended

for particular applications in coastal/marine environments.

Following the input of the requested data, the E-Cat program output will advise the appropriate coil to be used.

Other factors described in "Selection Guide: Environmental

Corrosion Protection, Novation Heat Exchanger with Microchannel Coil Technology" catalog number 04-58104201 must also be considered to determine if corrosion protection is required.

Low sound fans provide a specially designed system of

fan propellers and stacks that reduce sound without reducing unit performance. The factory-installed fan option is

compatible with the Motormaster

Compressor blankets provide additional sound reduction when used with low sound fans. Blankets are available

only on units with the low sound fan.

Security grilles/hail guards consist of louvered, sheet

metal panels which securely fasten to the chiller and provide condenser coil protection against hail and physical

damage.

Long line length check valves are required for liquid

line installation on all linear line length applications

of more than 100 ft (30.5 m). For any 025-030 size

dual-circuit unit application where evaporator is located

higher than the condensing unit, check valves are required

for linear line length above 55 ft (16.8 m). The check valve

®

V option.

option prevents charge migration to compressor. Check

valves are also available as field-installed accessories.

Digital compressor control allows incremental unloading for a closer match to building load. Refer to Loading

Sequences tables in Application Data section on page 85.

High short circuit current rating interrupt provides a

short circuit current rating protection for the unit up to

65,000 A on 460-v, 380/415-v, and 208/230-v units or

25,000 A on 575-v units.

Motormaster

®

V low-ambient control provides con-

trol of outdoor-fan motor operation to maintain head pressure at low outdoor ambient temperatures down to 20 F

( 29 C) for 50 and 60 Hz units. Only one factory-installed

low ambient temperature kit per unit is required. This

option also requires field-installed wind baffles. The

Motormaster V low-ambient control is also available as a

field-installed accessory.

Non-fused disconnect includes factory-installed nonfused disconnect capability for power and control located

at the unit.

ComfortLink™ controls with scrolling marquee

display module is used for accessing condensing unit

information, reading sensor values, and testing the condensing unit. The marquee display is a 4-key, 4-character,

16-segment LED (light-emitting diode) display. Eleven

mode LEDs are located on the display as well as an Alarm

Status LED. The display shows all of the ComfortLink

control codes (with 60-character expandable clear language), plus set points, time of day, temperatures, pressures, and superheat. Additional information can be displayed all at once with the accessory Navigator™ display.

9

–

–

Options and accessories (cont)

Packaging options include bottom skid with standard

coil protection and bottom skid, top crate with bag. Standard coil protection is also included on all unit packaging.

Energy management module (EMM) provides energy

management capabilities to minimize condensing unit

energy consumption. The EMM is also available as a fieldinstalled accessory.

Field-installed accessories

Vibration isolation pads reduce vibration transmission

from the compressor through the floor and into the conditioned space. The neoprene isolator pads measure

thick (24 in. x 3 in.).

Long line length check valves are required for liquid

line installation on all linear line length applications

of more than 100 ft (30.5 m). For any 025-030 size dualcircuit unit application where evaporator is located higher

than the condensing unit, check valves are required for linear line length above 55 ft (16.8 m). The check valve option prevents charge migration to compressor. Check

valves are also available as a factory-installed option.

Motormaster

trol of outdoor-fan motor operation to maintain head pressure at low outdoor ambient temperatures down to 20 F

( 29 C) for 50 and 60 Hz units. Only one field-installed

low ambient temperature kit per unit is required. This accessory also requires field-installed wind baffles. The

Motormaster V low-ambient control is also available as a

factory-installed option.

®

V low-ambient control provides con-

1

/4 in.

Navigator™ display module provides a portable, hand

held display module for convenient access to unit status,

operation, configuration and troubleshooting diagnostics

capability. The 4-line, 80-character LCD (liquid crystal

display) display provides clear language information in

English, French, Spanish or Portuguese. The weatherproof

enclosure and industrial grade extension cord make the

Navigator module ideally suited for outdoor applications.

Magnets located on the back of the module allow

attachment of any sheet metal component for hands free

operation.

Energy management module provides energy

management capabilities to minimize condensing unit

energy consumption. The EMM is also available as a factory-installed option.

BACnet* translator control provides an interface between the unit and a BACnet Local Area Network (LAN,

i.e., MS/TP EIA-485).

LON (local operating network) translator control

provides an interface between the unit and a local operating network (i.e., LonWorks

Remote enhanced display accessory kit contains a remotely mounted 40-character per line, 16-line display panel for unit diagnostics.

Touch Pilot™ display is a cost-effective, touch-screen,

remote-mount device that can be used in lieu of the remote

enhanced display.

†

FT-10A ANSI/EIA-709.1).

*Sponsered by ASHRAE (American Society of Heating, Refrigerating

and Air Conditioning Engineers).

†Registered trademark of Echelon Corporation.

10

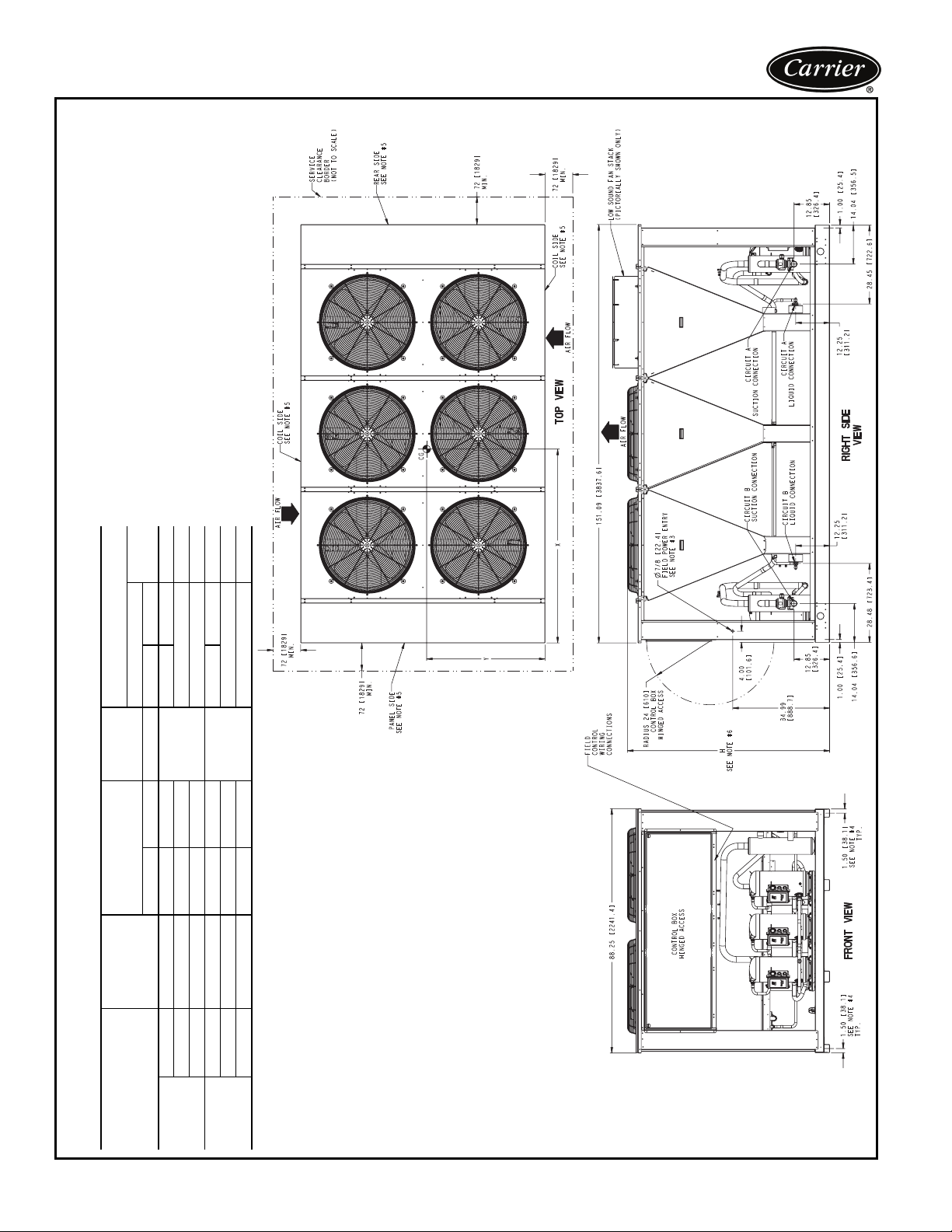

Dimensions

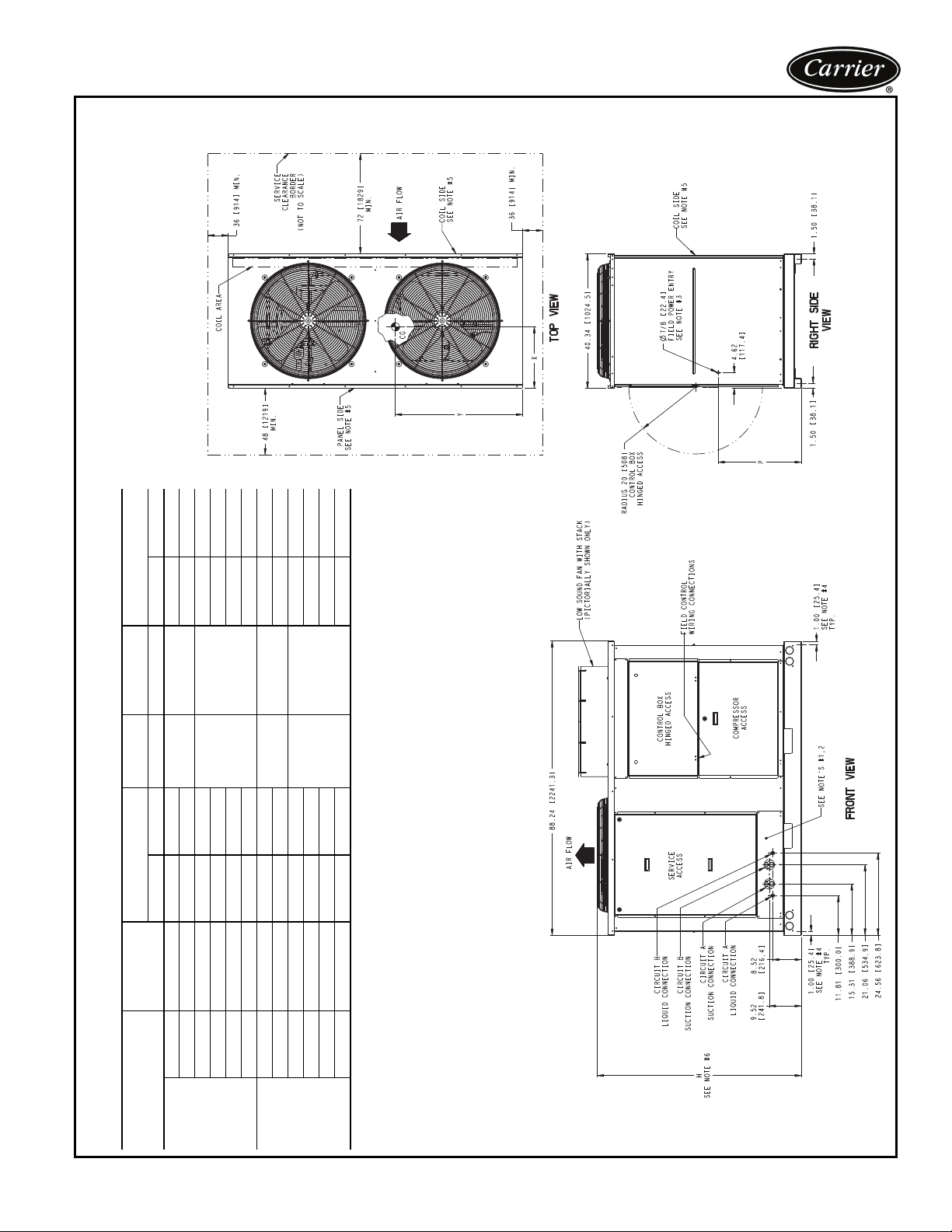

38AP UNITS, SIZES 025-030

UNIT

STANDARD

WEIGHT, lb (kg)

CENTER OF GRAVITY,

in. (mm)

HEIGHT,

in. (mm)

POWER ENTRY,

in. (mm)

SERVICE VALVE

CONNECTIONS, in. (mm)

X Y H P Suction Liquid

Standard

38APS025 1077 (489) 17.8 (452) 36.9 (937)

61.0 (1549) 24.9 (632)

1

5

/

8

(41)

5

/

8

(16)

38APD025 1095 (497) 17.8 (452) 37.0 (940) 1

3

/

8

(35)

5

/

8

(16)

38APS027 1240 (563) 18.2 (462) 37.6 (955)

73.1 (1857) 36.9 (937)

1

5

/

8

(41)

5

/

8

(16)

38APD027 1258 (571) 18.2 (462) 37.6 (955) 1

3

/

8

(35)

5

/

8

(16)

38APS030 1246 (565) 18.2 (462) 37.5 (953) 1

5

/

8

(41)

7

/

8

(22)

38APD030 1264 (573) 18.2 (462) 37.6 (955) 1

3

/

8

(35)

5

/

8

(16)

Low Sound

38APS025 1113 (505) 17.8 (452) 36.9 (937)

66.5 (1689) 24.9 (632)

1

5

/

8

(41)

5

/

8

(16)

38APD025 1131 (513) 17.8 (452) 37.0 (940) 1

3

/

8

(35)

5

/

8

(16)

38APS027 1276 (579) 18.2 (462) 37.6 (955)

78.6 (1996) 36.9 (937)

1

5

/

8

(41)

5

/

8

(16)

38APD027 1294 (587) 18.2 (462) 37.6 (955) 1

3

/

8

(35)

5

/

8

(16)

38APS030 1282 (582) 18.2 (462) 37.5 (953) 1

5

/

8

(41)

7

/

8

(22)

38APD030 1300 (590) 18.2 (462) 37.6 (955) 1

3

/

8

(35)

5

/

8

(16)

NOTES:

1. Be sure to use a wet rag to remove all valve cores before brazing field piping.

2. Do not cap or otherwise obstruct the liquid line temperature relief.

3. A

7

/

8

in. (22.4 mm) diameter hole is provided for locating field power wiring. Actual hole size

required depends on field wire sizing.

4. A 0.437 in. (11.1 mm) diameter hole is used for mounting unit.

5. Unit must have clearances as follows:

Top - Do not restrict.

Coil End - 72 in. (1829) from solid surface.

Panel Side - 48 in. (1219) per NEC (National Electrical Code).

6. Unit height dimension for standard and low sound unit with stack fan option.

7. Installation in a pit is not recommended.

8. Unit can be handled using the fork truck lift pockets.

9. Dimensions shown in inches (mm).

10. Weight does not include unit refrigerant charge.

a38-7101

11

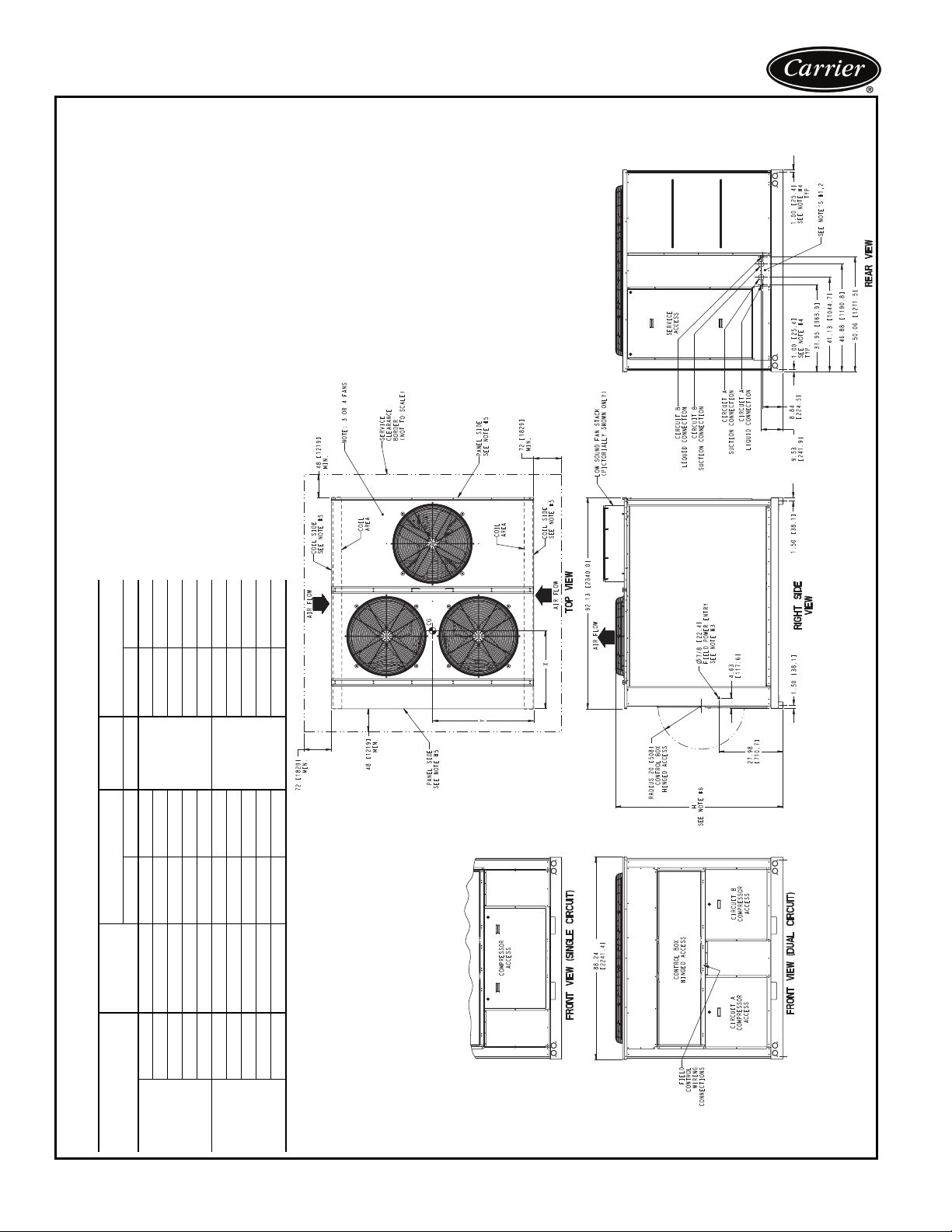

Dimensions (cont)

UNIT

STANDARD

WEIGHT, lb (kg)

CENTER OF GRAVITY,

in. (mm)

HEIGHT,

in. (mm)

SERVICE VALVE

CONNECTIONS, in. (mm)

X Y H Suction Liquid

Standard

38APS040 1968 (893) 35.0 (869) 44.0 (1118)

73.0 (1854)

2

1

/

8

(54)

7

/

8

(22)

38APD040 2094 (950) 33.7 (856) 44.1 (1120) 1

5

/

8

(41)

5

/

8

(16)

38APS050 1977 (897) 34.9 (886) 44.0 (1118) 2

1

/

8

(54)

7

/

8

(22)

38APD050 2120 (961) 33.4 (848) 44.1 (1120) 1

5

/

8

(41)

5

/

8

(16)

38APD060 2227 (1010) 34.4 (874) 44.1 (1120) 1

5

/

8

(41)

5

/

8

(16)

Low Sound

38APS040 2022 (917) 35.0 (869) 44.0 (1118)

78.5 (1994)

2

1

/

8

(54)

7

/

8

(22)

38APD040 2148 (974) 33.7 (856) 44.1 (1120) 1

5

/

8

(41)

5

/

8

(16)

38APS050 2031 (921) 34.9 (886) 44.0 (1118) 2

1

/

8

(54)

7

/

8

(22)

38APD050 2174 (986) 33.4 (848) 44.1 (1120) 1

5

/

8

(41)

5

/

8

(16)

38APD060 2299 (1043) 34.4 (874) 44.1 (1120) 1

5

/

8

(41)

5

/

8

(16)

38AP UNITS, SIZES 040-060

NOTES:

1. Be sure to use a wet rag to remove all valve cores before brazing field piping.

2. Do not cap or otherwise obstruct the liquid line temperature relief.

3. A

7

/

8

in. (22.4 mm) diameter hole is provided for locating field power wiring.

Actual hole size required depends on field wire sizing.

4. A 0.437 in. (11.1 mm) diameter hole is used for mounting unit.

5. Unit must have clearances as follows:

Top - Do not restrict.

Coil End - 72 in. (1829) from solid surface.

Panel Side - 48 in. (1219) per NEC (National Electrical Code).

6. Unit height dimension for standard and low sound unit with stack fan option.

7. Installation in a pit is not recommended.

8. Unit can be handled using the fork truck lift pockets.

9. Dimensions shown in inches (mm).

10. Sizes 040 and 050 units have 3 condenser fans. Size 060 units have 4 con-

denser fans.

11. Weight does not include unit refrigerant charge.

a38-7102

12

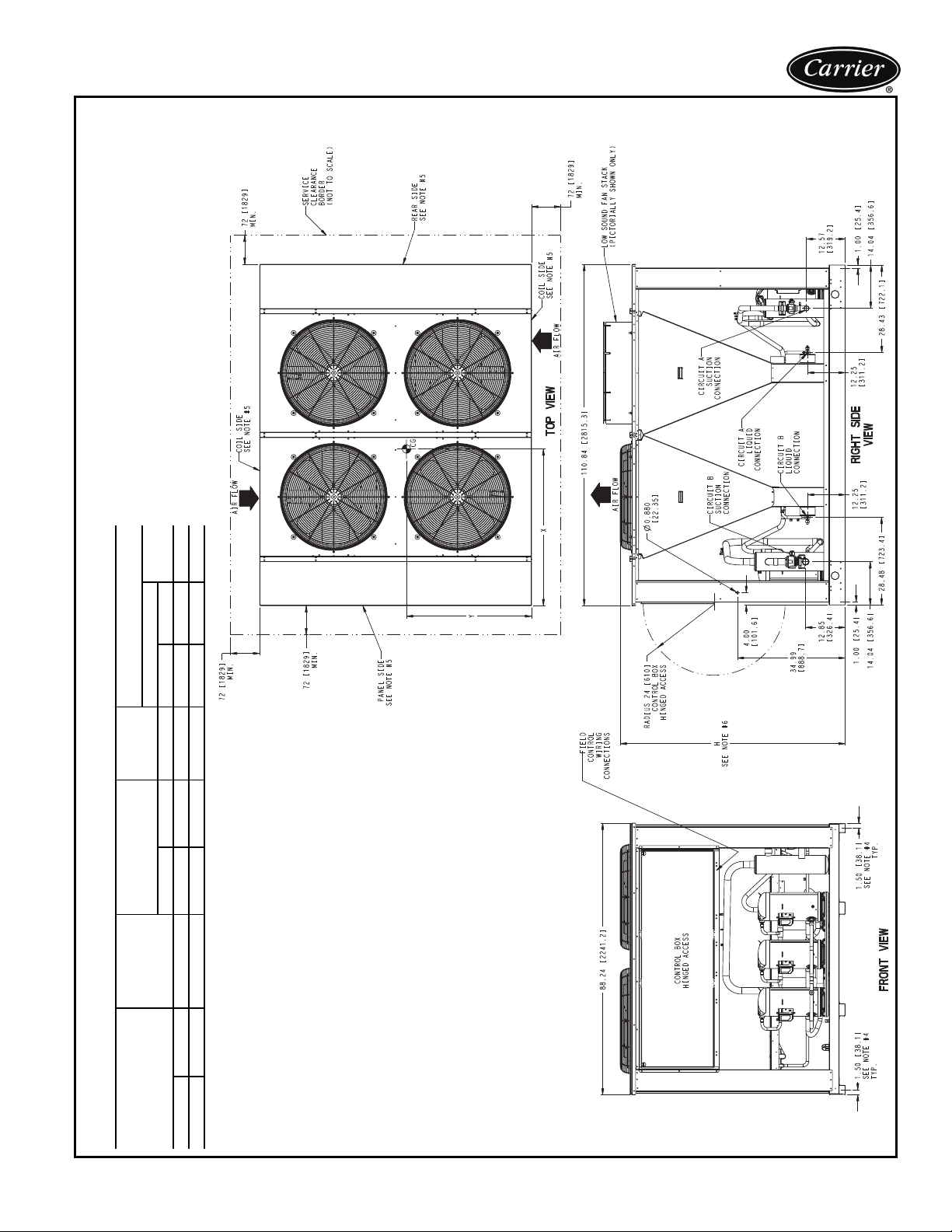

UNIT

STANDARD

WEIGHT, lb (kg)

CENTER OF GRAVITY,

in. (mm)

HEIGHT,

in. (mm)

SERVICE VALVE CONNECTIONS,

in. (mm)

Suction

Liquid

X Y H Circuit A Circuit B

Standard 38APD070 2450 (1111) 50.9 (1293) 40.6 (1031) 73.0 (1854) 2

1

/

8

(54) 1

5

/

8

(41)

7

/

8

(22)

Low Sound 38APD070 2522 (1144) 50.9 (1293) 40.6 (1031) 78.5 (1994) 2

1

/

8

(54) 1

5

/

8

(41)

7

/

8

(22)

38AP UNITS, SIZE 070

NOTES:

1. Be sure to use a wet rag to remove all valve cores before brazing field piping.

2. Do not cap or otherwise obstruct the liquid line temperature relief.

3. A

7

/

8

in. (22.4 mm) diameter hole is provided for locating field power wiring.

Actual hole size required depends on field wire sizing.

4. A 0.437 in. (11.1 mm) diameter hole is used for mounting unit.

5. Unit must have clearances as follows:

Top - Do not restrict.

Coil, Panel and Rear Side - 72 in. (1829) from solid surface.

6. Unit height dimension for standard and low sound unit with stack fan option.

7. Installation in a pit is not recommended.

8. Unit can be handled using crane. Refer to service installation instructions.

9. Dimensions shown in inches (mm).

10. Weight does not include unit refrigerant charge.

a38-7103

13

Dimensions (cont)

UNIT

STANDARD

WEIGHT, lb (kg)

CENTER OF GRAVITY,

in. (mm)

HEIGHT,

in. (mm)

SERVICE VALVE CONNECTIONS,

in. (mm)

Suction

Liquid

X Y H Circuit A Circuit B

Standard

38APD080 2610 (1184) 67.6 (1716) 40.2 (1020)

73.0 (1854)

2

1

/

8

(54) 1

5

/

8

(41)

7

/

8

(22)

38APD090 2835 (1286) 72.4 (1839) 43.3 (1099) 2

1

/

8

(54)

7

/

8

(22)

38APD100 2844 (1290) 72.6 (1844) 43.3 (1099) 2

1

/

8

(54)

7

/

8

(22)

Low Sound

38APD080 2700 (1225) 67.6 (1716) 40.2 (1020)

78.5 (1994)

2

1

/

8

(54) 1

5

/

8

(41)

7

/

8

(22)

38APD090 2943 (1335) 72.4 (1839) 43.3 (1099) 2

1

/

8

(54)

7

/

8

(22)

38APD100 2952 (1339) 72.6 (1844) 43.3 (1099) 2

1

/

8

(54)

7

/

8

(22)

38AP UNITS, SIZES 080-100

NOTES:

1. Be sure to use a wet rag to remove all valve cores before brazing field piping.

2. Do not cap or otherwise obstruct the liquid line temperature relief.

3. A

7

/

8

in. (22.4 mm) diameter hole is provided for locating field power wiring.

Actual hole size required depends on field wire sizing.

4. A 0.437 in. (11.1 mm) diameter hole is used for mounting unit.

5. Unit must have clearances as follows:

Top - Do not restrict.

Coil, Panel and Rear Side - 72 in. (1829) from solid surface.

6. Unit height dimension for standard and low sound unit with stack fan option.

7. Installation in a pit is not recommended.

8. Unit can be handled using crane. Refer to service installation instructions.

9. Dimensions shown in inches (mm).

10. Size 080 units have 5 condenser fans. Sizes 090 and 100 units have 6 con-

denser fans.

11. Weight does not include unit refrigerant charge.

a38-7104

14

–

Selection procedure

To select a 38AP stand-alone condensing unit:

Use Carrier's Commercial Split Builder program to select a

stand-alone outdoor unit from the Installation Configuration drop down menu and input the job requirements.

From the list presented, select a 38AP condensing

unit that is estimated to meet capacity requirements.

The 38APS single-circuit unit is offered in sizes 025-050

and the 38APD dual-circuit unit is offered in sizes 025-

100. After a 38AP unit is selected, the program will calculate the condensing unit performance.

To select 38AP systems:

For systems with one 40RU fan coil unit or

39 Series air handler — Use Carrier's Commercial

Split Builder program to select a combined 38AP outdoor

unit with matched 40RU indoor unit for sizes 025-030.

The AHUBuilder

38AP outdoor units with a matching 39 Series air handler

with direct-expansion (DX) coils. The 38APS single-circuit

unit is offered in sizes 025-050 and 38APD dual-circuit

unit is offered in sizes 025-100. Enter the software program and input the job requirements. From the list presented, select a 38AP condensing unit that is estimated to meet

capacity requirements. After selecting a 38AP unit, check

®

selection program is available to select

its performance with one or several DX coils. From the DX

coil list presented on the screen, match the 38AP with any

coil or all coils. The program calculates the combined performance of the condensing unit and each DX coil and

presents the resulting system capacities and operating temperatures. Matching thermostatic expansion valves and

nozzles for the DX coils are automatically selected and

displayed.

For systems with two air handlers — Use Carrier's

AHUBuilder

100 38AP outdoor unit to match with two 39 Series air

handlers with DX coils. For the first air handler, enter the

AHUBuilder selection program and input the job require-

ments. To choose a condensing unit, select the Specify

Your Own option. The program asks for condensing unit

capacities at 30 F ( 1.1 C) and 50 F (10 C) SST. See the

Condensing Unit Circuit Ratings tables on pages 20-29,

34-43, 48-57, and 62-71, and enter the capacities from

condenser circuit A or B (remember to use the correct air

temperature entering condenser column when locating the

circuit capacities). For the second air handler, repeat the

procedure to select the second DX coil for the condenser

circuit (A or B) not used in the first selection.

®

selection program to select one size 025-

15

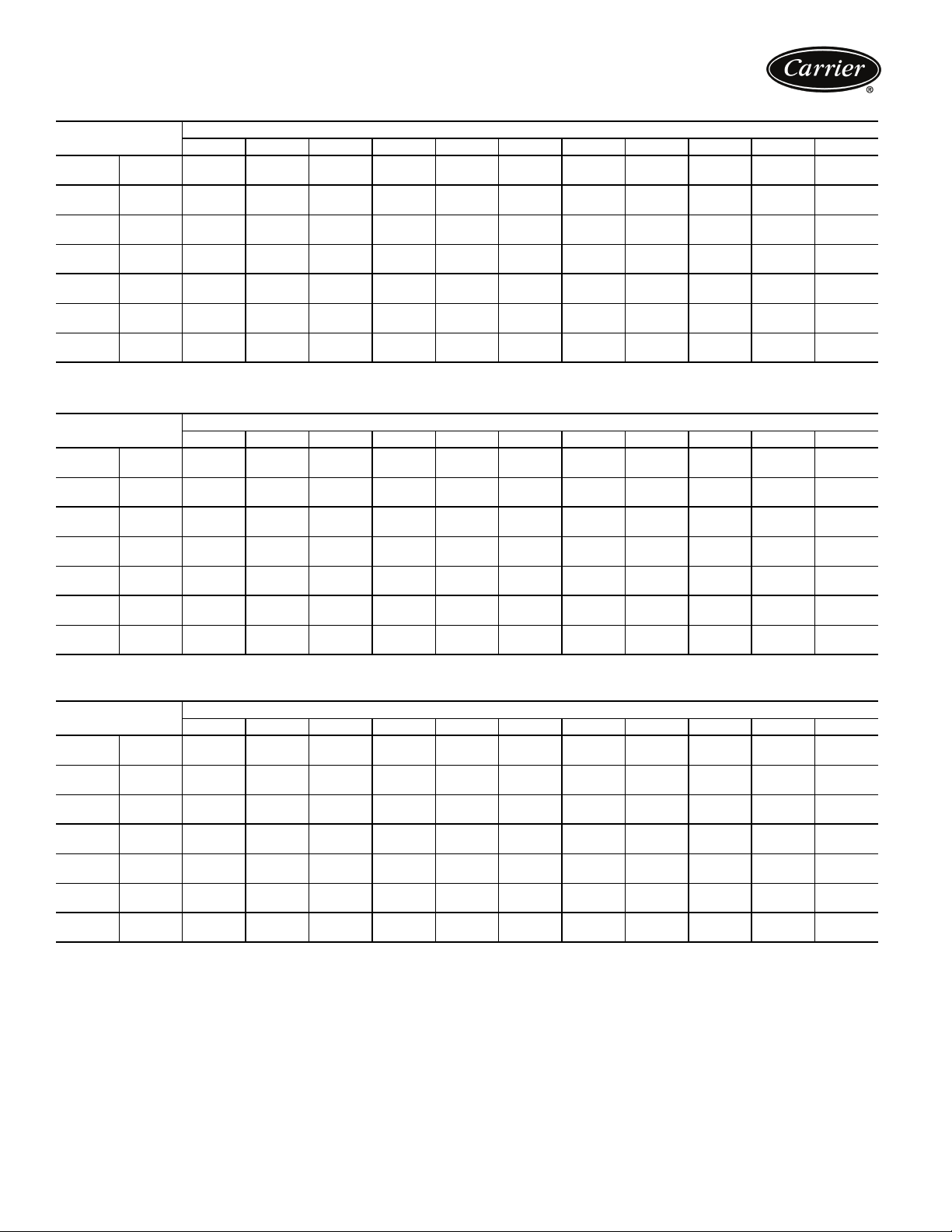

Performance data

38APD,APS025 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

20

25

30

35

40

45

50

20

25

30

35

40

45

50

SST (F)

TC 203.0 195.9 188.4 181.5 174.5 167.5 160.2 152.9 145.4 138.5 131.4

kW 16.7 17.7 18.8 19.8 20.9 21.9 23.0 24.1 25.2 26.2 27.3

TC 225.7 218.1 210.1 202.8 195.3 187.8 180.1 172.1 164.2 156.9 149.2

kW 17.0 18.1 19.2 20.2 21.3 22.4 23.5 24.7 25.8 26.8 27.9

TC 250.0 241.8 233.3 225.4 217.4 209.2 201.0 192.6 184.1 176.2 168.0

kW 17.2 18.4 19.6 20.6 21.7 22.8 24.0 25.1 26.3 27.4 28.5

TC 275.6 266.8 257.7 249.2 240.6 231.9 223.0 214.0 204.7 196.3 187.5

kW 17.5 18.6 19.9 20.9 22.0 23.2 24.3 25.5 26.8 27.8 29.0

TC 302.0 292.5 282.6 273.5 264.2 254.8 245.3 235.6 225.7 216.6 207.1

kW 18.1 19.2 20.5 21.6 22.8 23.8 25.0 26.2 27.5 28.6 29.8

TC 328.2 318.0 307.3 297.5 287.5 277.4 267.1 256.6 245.9 236.1 225.9

kW 18.1 19.2 20.5 21.6 22.8 23.8 25.0 26.2 27.5 28.6 29.8

TC 353.7 342.7 331.2 320.5 309.6 298.6 287.5 276.1 264.6 253.9 242.9

kW 18.4 19.6 20.9 21.9 23.0 24.2 25.4 26.6 27.8 28.9 30.1

70 80 85 90 95 100 105 110 115 120 125

CONDENSER ENTERING-AIR TEMPERATURE (F)

38APD,APS027 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

SST (F)

TC 232.0 225.0 217.7 210.9 204.0 197.0 190.0 182.8 175.5 168.7 161.7

kW 18.2 19.4 20.9 22.0 23.2 24.4 25.7 27.1 28.5 29.6 30.9

TC 256.5 248.9 241.0 233.5 226.0 218.5 210.8 202.9 195.1 187.7 180.0

kW 18.6 19.9 21.3 22.5 23.7 24.9 26.2 27.6 29.0 30.1 31.4

TC 282.5 274.2 265.6 257.5 249.3 241.0 232.6 224.2 215.5 207.4 199.1

kW 19.2 20.4 21.8 23.0 24.1 25.4 26.7 28.0 29.5 30.6 31.8

TC 309.6 300.5 291.1 282.3 273.4 264.4 255.2 245.9 236.4 227.6 218.5

kW 19.7 20.9 22.4 23.5 24.7 25.9 27.2 28.5 30.0 31.1 32.3

TC 336.9 327.1 316.8 307.3 297.6 287.8 277.9 267.8 257.5 248.0 238.1

kW 20.9 22.1 23.5 24.6 25.8 27.0 28.3 29.6 31.0 32.1 33.3

TC 364.2 353.5 342.4 332.0 318.6 310.8 300.0 289.0 277.9 267.5 256.8

kW 20.9 22.1 23.5 24.6 25.8 27.0 28.3 29.6 31.0 32.1 33.3

TC 391.3 379.6 367.6 356.2 344.7 333.1 321.4 309.5 297.4 286.1 274.4

kW 21.5 22.8 24.2 25.2 26.4 27.6 28.9 30.2 31.6 32.6 33.9

70 80 85 90 95 100 105 110 115 120 125

CONDENSER ENTERING-AIR TEMPERATURE (F)

38APD,APS030 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

SST (F)

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 270.2 262.2 253.9 246.1 238.2 230.3 222.1 213.9 205.6 197.9 189.8

kW 21.9 23.5 25.2 26.7 28.1 29.6 31.3 33.0 34.7 36.1 37.7

TC 298.8 290.1 281.1 272.6 264.1 255.4 246.6 237.8 228.7 220.3 211.5

kW 22.5 24.1 25.8 27.2 28.7 30.3 31.9 33.6 35.4 36.8 38.4

TC 328.8 319.4 309.6 300.5 291.2 281.9 272.5 262.8 253.0 243.9 234.5

kW 23.1 24.7 26.5 27.9 29.3 30.9 32.5 34.2 36.0 37.4 39.0

TC 359.8 349.6 339.0 329.2 319.2 309.1 298.8 288.4 277.8 268.0 257.8

kW 23.7 25.3 27.1 28.5 30.0 31.5 33.2 34.9 36.7 38.1 39.6

TC 390.7 379.8 368.5 358.0 347.4 336.7 325.7 314.5 303.1 292.7 281.8

kW 25.2 26.8 28.5 29.9 31.4 32.9 34.5 36.2 38.0 39.4 41.0

TC 421.2 409.6 397.6 386.5 373.5 363.7 352.1 340.2 328.1 317.0 305.4

kW 25.2 26.8 28.5 29.9 31.4 32.9 34.5 36.2 38.0 39.4 41.0

TC 452.0 439.6 426.8 414.8 402.6 390.3 377.9 365.3 352.2 340.3 327.9

kW 26.1 27.6 29.4 30.7 32.2 33.7 35.3 36.9 38.7 40.1 41.6

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

16

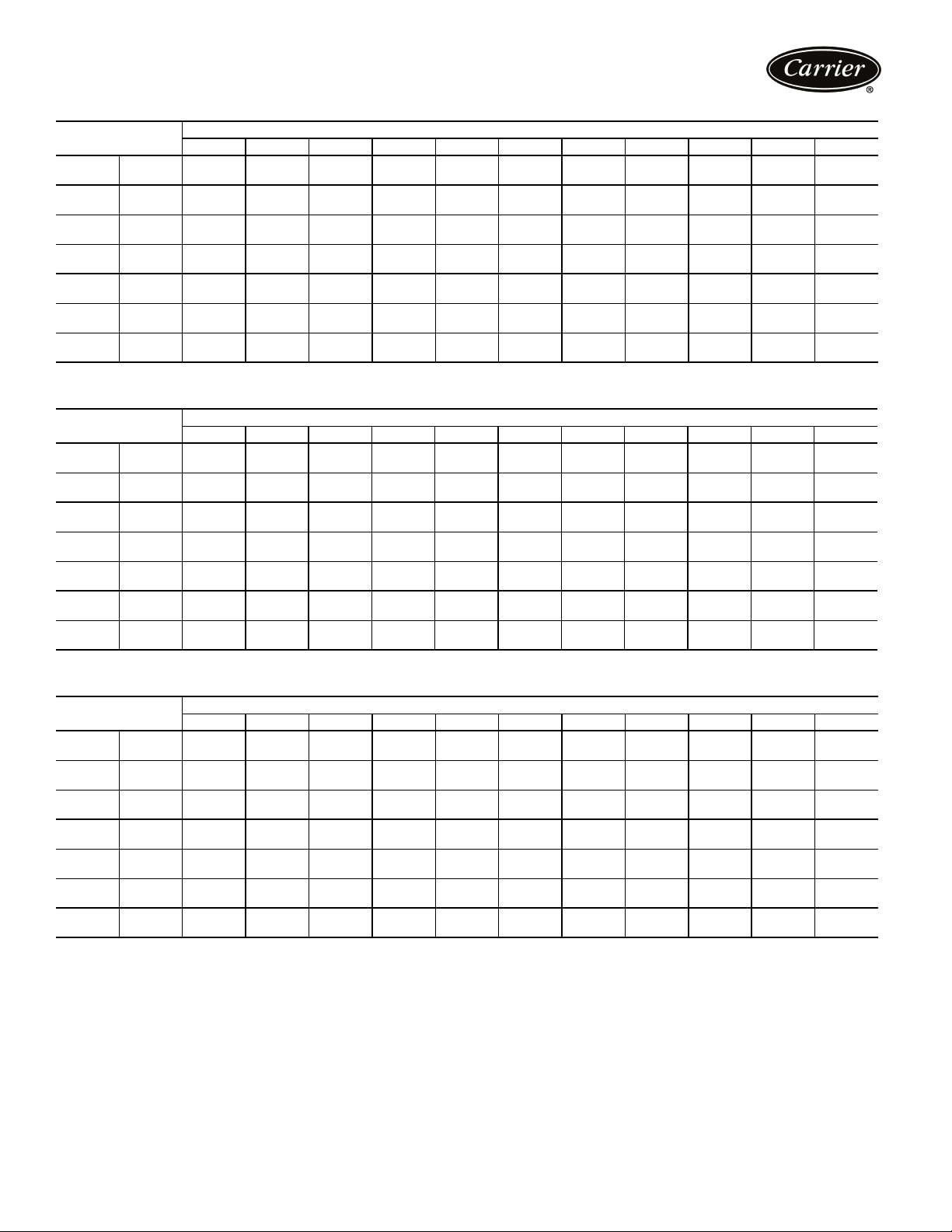

38APD040 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

20

25

30

35

40

45

50

20

25

30

35

40

45

50

SST (F)

TC 335.7 324.3 312.4 301.3 290.3 278.9 267.5 255.8 243.6 232.8 221.4

kW 26.2 28.1 30.1 31.9 33.7 35.6 37.6 39.6 41.6 43.4 45.3

TC 372.4 360.1 347.2 335.4 323.4 311.1 298.6 286.2 273.1 261.4 249.0

kW 26.6 28.6 30.7 32.5 34.4 36.3 38.3 40.4 42.5 44.3 46.2

TC 411.2 397.9 384.0 371.1 358.4 345.3 331.9 318.0 304.1 291.5 278.2

kW 27.1 29.1 31.3 33.1 35.0 37.0 39.0 41.1 43.3 45.1 47.1

TC 451.9 437.5 422.8 408.8 394.9 380.7 366.4 351.6 336.8 323.0 308.7

kW 27.6 29.7 31.9 33.7 35.6 37.7 39.7 41.9 44.1 45.9 47.9

TC 494.0 478.6 462.8 447.5 432.2 417.3 401.5 385.9 369.6 354.8 339.3

kW 28.8 30.8 33.1 34.9 36.5 38.9 41.0 43.2 45.4 47.3 49.4

TC 538.1 521.2 503.7 486.9 470.9 453.8 437.0 420.1 401.4 385.6 368.7

kW 28.8 30.8 33.1 34.9 36.5 38.9 41.0 43.2 45.4 47.3 49.4

TC 582.3 563.9 544.3 527.5 509.4 491.1 471.6 453.6 434.5 416.7 398.3

kW 29.4 31.5 33.7 35.6 37.6 39.6 41.7 43.9 46.1 48.0 50.1

70 80 85 90 95 100 105 110 115 120 125

CONDENSER ENTERING-AIR TEMPERATURE (F)

38APS040 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

SST (F)

TC 342.5 331.8 321.0 310.5 300.0 289.5 278.8 268.0 257.0 246.7 236.0

kW 25.9 27.7 29.8 31.4 33.2 35.0 36.9 38.9 41.0 42.6 44.5

TC 378.2 366.5 354.6 343.3 331.9 320.3 308.7 296.8 284.8 273.6 261.9

kW 26.6 28.4 30.5 32.2 33.9 35.7 37.6 39.6 41.7 43.4 45.2

TC 416.3 403.6 390.5 378.2 365.7 353.1 340.3 327.4 314.1 301.9 289.1

kW 27.3 29.2 31.3 33.0 34.7 36.5 38.4 40.4 42.5 44.2 46.0

TC 456.7 442.8 428.5 414.9 401.3 387.5 373.5 359.3 344.8 331.4 317.5

kW 28.2 30.1 32.1 33.8 35.5 37.4 39.3 41.3 43.4 45.0 46.9

TC 498.8 483.7 468.2 453.4 438.5 423.4 408.1 392.6 377.5 362.5 347.3

kW 29.1 30.9 33.0 34.7 36.4 38.3 40.2 42.2 44.3 45.9 47.8

TC 543.2 526.6 510.2 493.3 477.0 460.5 443.7 427.7 410.6 394.2 377.7

kW 30.1 31.9 34.0 35.7 37.4 39.2 41.1 43.1 45.2 46.9 48.7

TC 589.2 571.2 553.5 535.0 517.1 499.0 481.9 463.6 445.1 427.4 409.4

kW 31.1 33.0 35.1 36.7 38.4 40.2 42.2 44.2 46.2 47.9 49.7

70 80 85 90 95 100 105 110 115 120 125

CONDENSER ENTERING-AIR TEMPERATURE (F)

38APD050 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

SST (F)

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 433.0 418.5 403.0 389.1 375.2 361.3 347.3 331.8 314.7 302.2 287.6

kW 36.5 38.9 41.5 43.7 46.0 48.4 50.9 53.4 55.9 58.2 60.7

TC 478.5 463.0 446.8 431.7 417.0 401.9 385.8 370.6 353.2 339.0 323.5

kW 37.3 39.8 42.4 44.7 47.0 49.5 52.0 54.6 57.2 59.5 62.0

TC 526.4 509.8 492.9 476.6 460.3 444.3 426.8 410.3 393.4 377.2 360.6

kW 38.1 40.6 43.4 45.7 48.0 50.5 53.1 55.7 58.5 60.7 63.2

TC 578.9 560.6 541.3 524.3 506.7 488.5 469.7 450.8 432.5 414.8 396.5

kW 39.1 41.6 44.4 46.7 49.1 51.6 54.1 56.8 59.5 61.8 64.4

TC 632.1 612.3 591.1 572.6 553.4 534.0 514.4 493.3 472.0 453.7 433.8

kW 41.1 43.6 46.4 48.7 50.1 53.6 56.2 58.9 61.7 64.0 66.5

TC 686.6 665.0 642.1 622.2 600.2 580.1 556.8 534.9 513.9 492.5 471.0

kW 41.1 43.6 46.4 48.7 50.1 53.6 56.2 58.9 61.7 64.0 66.5

TC 740.3 717.1 693.4 670.7 648.0 624.2 600.4 578.3 553.9 531.1 507.9

kW 42.2 44.7 47.5 49.8 52.2 54.7 57.3 60.0 62.7 65.0 67.6

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

17

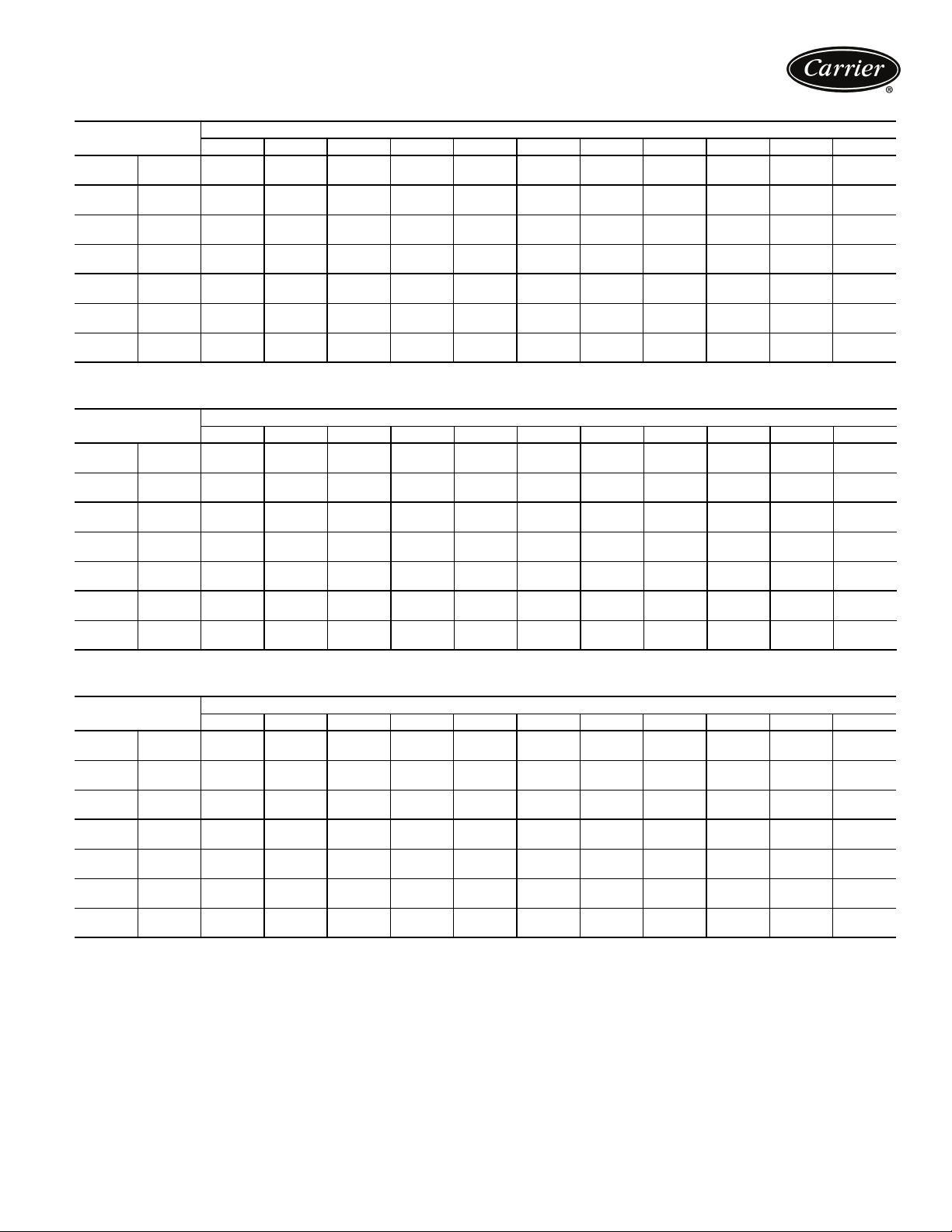

Performance data (cont)

38APS050 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

20

25

30

35

40

45

50

20

25

30

35

40

45

50

SST (F)

TC 411.1 398.1 386.4 369.8 359.0 346.1 333.0 319.8 306.3 293.5 280.4

kW 33.4 35.8 38.6 40.4 42.6 45.0 47.5 50.0 52.7 54.7 57.1

TC 451.7 438.1 424.4 409.0 398.0 387.2 367.2 355.8 341.6 325.9 311.1

kW 35.3 37.5 40.0 42.0 44.0 46.3 48.2 50.8 53.5 55.3 57.5

TC 503.7 486.6 471.0 453.0 435.0 417.0 399.0 381.2 371.3 349.9 332.8

kW 59.7 61.9 40.3 42.5 44.7 46.9 49.1 51.4 54.1 40.3 42.5

TC 551.1 534.3 516.6 500.6 484.4 469.0 451.0 433.9 415.9 400.3 383.6

kW 36.4 38.7 41.3 43.4 45.6 47.9 50.3 52.8 55.3 57.4 59.8

TC 602.4 584.3 565.4 548.0 530.1 512.1 495.3 476.6 455.5 439.4 421.3

kW 37.3 39.7 42.3 44.4 46.6 48.8 51.3 53.8 56.3 58.4 60.8

TC 656.0 636.0 614.8 596.9 577.5 556.4 536.3 515.7 496.6 476.6 456.7

kW 38.9 41.2 43.2 45.4 49.2 49.8 52.2 54.6 57.2 59.3 61.5

TC 710.1 688.0 665.3 644.2 623.1 599.6 577.5 556.3 533.4 511.8 489.8

kW 39.5 41.8 44.3 46.4 48.5 50.8 53.1 55.6 58.1 60.1 62.4

70 80 85 90 95 100 105 110 115 120 125

CONDENSER ENTERING-AIR TEMPERATURE (F)

38APD060 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

SST (F)

TC 492.7 478.8 459.7 453.8 440.6 424.6 410.4 394.7 379.9 368.0 354.2

kW 39.9 42.8 45.8 48.4 51.2 53.8 56.7 59.7 62.9 65.4 68.2

TC 551.7 535.5 517.9 505.1 485.4 472.8 456.4 438.7 421.5 406.7 390.6

kW 41.2 44.0 47.1 49.7 52.2 54.8 57.7 60.9 64.0 66.4 69.2

TC 607.4 589.8 570.0 555.1 536.5 520.8 503.6 486.0 462.4 448.6 431.0

kW 42.4 45.2 48.3 50.9 53.4 56.0 58.9 62.0 65.2 67.6 70.4

TC 653.4 636.1 609.0 605.5 591.5 573.3 546.6 532.6 511.7 498.2 481.0

kW 43.6 46.5 49.5 52.1 54.7 57.6 60.3 63.2 66.4 68.9 71.7

TC 701.2 684.4 649.2 660.0 645.0 623.4 602.6 581.2 559.3 550.1 533.3

kW 46.4 49.2 52.2 54.9 57.6 60.4 63.2 66.1 69.2 71.8 74.6

TC 760.6 742.3 705.5 712.8 700.1 679.5 648.7 631.8 606.0 596.1 577.8

kW 46.4 49.2 52.2 54.9 57.6 60.4 63.2 66.1 69.2 71.8 74.6

TC 835.2 813.2 776.2 779.4 754.4 728.7 704.3 678.9 654.7 637.2 615.3

kW 48.1 50.9 53.9 56.7 59.2 61.9 64.7 67.7 70.8 73.3 76.1

70 80 85 90 95 100 105 110 115 120 125

CONDENSER ENTERING-AIR TEMPERATURE (F)

38APD070 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

SST (F)

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 570.2 551.4 531.9 513.9 495.4 476.7 458.1 439.7 418.6 401.3 382.5

kW 48.0 51.2 54.6 57.5 60.6 63.7 67.0 70.3 73.7 76.7 79.9

TC 632.3 612.0 591.1 571.6 551.6 531.5 511.1 490.6 469.6 450.0 429.8

kW 49.2 52.5 56.0 59.0 62.1 65.3 68.7 72.1 75.6 78.6 81.9

TC 698.4 676.5 653.9 632.7 611.3 589.6 567.5 545.3 522.5 501.5 479.6

kW 50.5 53.9 57.5 60.5 63.6 66.9 70.3 73.8 77.4 80.5 83.8

TC 767.9 744.3 719.9 697.0 673.9 650.4 626.8 602.7 578.0 555.3 531.7

kW 51.9 55.3 59.0 62.0 65.2 68.5 72.0 75.5 79.2 82.2 85.6

TC 840.5 815.0 788.7 763.9 739.0 713.7 688.1 662.0 635.5 610.9 585.4

kW 54.9 58.3 62.1 65.2 67.6 71.8 75.3 78.9 82.7 85.7 89.2

TC 915.5 887.9 859.4 832.7 807.0 778.5 750.8 722.6 693.9 667.4 639.9

kW 54.9 58.3 62.1 65.2 67.6 71.8 75.3 78.9 82.7 85.7 89.2

TC 992.3 962.6 931.7 903.1 873.9 844.4 814.6 784.1 753.1 724.6 694.8

kW 56.6 60.1 63.8 66.9 70.1 73.5 77.0 80.6 84.4 87.5 90.9

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

18

38APD080 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

20

25

30

35

40

45

50

20

25

30

35

40

45

50

SST (F)

TC 678.1 657.5 636.1 616.1 596.0 575.4 554.5 533.2 512.3 492.1 471.4

kW 54.3 58.1 62.3 65.7 69.2 72.9 76.8 80.8 85.1 88.5 92.3

TC 748.4 726.0 701.8 681.9 659.9 637.7 614.5 592.1 568.1 547.1 524.8

kW 55.6 59.4 63.7 67.1 70.6 74.4 78.3 82.4 86.6 90.0 93.8

TC 824.8 800.2 775.3 750.3 726.6 702.5 677.3 652.6 626.9 603.1 578.5

kW 57.1 60.9 65.1 68.5 72.1 75.9 79.8 83.8 88.1 91.5 95.3

TC 902.7 876.5 848.6 823.9 794.7 779.3 744.6 725.6 686.9 667.4 641.3

kW 58.6 62.5 66.7 70.1 73.6 77.4 81.3 85.2 89.6 92.9 96.7

TC 985.7 957.2 924.6 903.7 877.6 836.6 820.3 778.4 761.5 729.3 700.8

kW 62.0 65.8 69.8 73.4 77.1 80.7 84.5 88.6 92.7 96.2 100.0

TC 1056.5 1026.9 984.8 974.7 936.0 917.5 885.5 854.6 805.0 789.7 760.1

kW 62.0 65.8 69.8 73.4 77.1 80.7 84.5 88.6 92.7 96.2 100.0

TC 1142.4 1109.6 1068.4 1046.7 1018.3 981.5 949.4 907.8 878.4 847.6 814.9

kW 63.9 67.7 71.6 75.3 79.0 82.5 86.4 90.2 94.3 97.8 101.6

70 80 85 90 95 100 105 110 115 120 125

CONDENSER ENTERING-AIR TEMPERATURE (F)

38APD090 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

SST (F)

TC 759.2 735.5 710.5 688.3 665.6 642.2 618.1 593.7 568.8 546.5 522.9

kW 59.8 64.2 68.9 72.9 77.0 81.3 85.8 90.3 95.0 99.0 103.4

TC 837.0 811.5 784.5 760.3 736.2 711.2 685.3 658.4 631.7 607.8 582.3

kW 60.9 65.3 70.1 74.1 78.2 82.6 87.1 91.7 96.5 100.5 104.9

TC 918.4 891.5 862.2 836.4 817.8 782.0 755.0 735.1 699.9 676.5 649.7

kW 62.1 66.5 71.4 75.4 79.4 83.8 88.3 92.8 97.9 101.8 106.2

TC 1011.8 981.5 945.3 925.6 888.2 867.5 826.8 805.8 762.7 739.0 708.7

kW 63.7 68.0 72.8 76.7 80.9 85.2 89.7 94.0 99.1 102.9 107.3

TC 1099.9 1067.2 1030.0 1005.9 974.9 930.2 908.9 863.6 842.0 805.8 773.1

kW 66.9 71.2 75.8 79.8 83.9 88.2 92.5 97.0 101.7 105.6 109.9

TC 1173.6 1140.2 1092.4 1078.8 1048.3 1016.3 973.9 936.6 900.1 872.9 839.5

kW 66.9 71.2 75.8 79.8 83.9 88.2 92.5 97.0 101.7 105.6 109.9

TC 1270.4 1232.1 1191.3 1153.5 1122.4 1086.0 1035.8 997.6 966.9 926.0 887.7

kW 68.8 73.1 77.6 81.6 85.8 89.9 94.0 98.5 103.3 107.1 111.3

70 80 85 90 95 100 105 110 115 120 125

CONDENSER ENTERING-AIR TEMPERATURE (F)

38APD100 CONDENSING UNIT RATINGS, 60 Hz ENGLISH

SST (F)

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 818.6 794.0 768.7 744.7 720.5 696.0 671.5 646.3 620.9 597.0 572.4

kW 65.7 70.4 75.6 79.7 84.0 88.6 93.3 98.3 103.5 107.6 112.3

TC 906.6 879.8 852.3 826.1 799.7 773.0 746.1 719.1 691.1 665.2 638.4

kW 67.6 72.3 77.5 81.7 86.0 90.6 95.4 100.4 105.6 109.7 114.4

TC 1001.0 971.8 941.7 913.3 884.5 855.6 826.2 796.3 766.2 737.9 708.6

kW 69.6 74.3 79.5 83.7 88.1 92.7 97.5 102.5 107.7 111.8 116.5

TC 1101.5 1069.6 1036.7 1005.8 974.6 942.9 910.9 878.5 845.4 814.6 782.7

kW 71.8 76.5 81.7 85.9 90.2 94.8 99.6 104.6 109.8 114.0 118.7

TC 1207.6 1172.8 1137.0 1103.4 1069.3 1034.9 1000.1 964.6 928.5 895.1 860.3

kW 76.4 81.0 86.2 90.4 94.7 99.3 104.1 109.0 114.3 118.4 123.1

TC 1315.3 1277.8 1241.6 1204.9 1152.0 1130.4 1092.3 1053.6 1014.0 977.7 940.2

kW 76.4 81.0 86.2 90.4 94.7 99.3 104.1 109.0 114.3 118.4 123.1

TC 1433.5 1392.2 1349.3 1309.4 1269.0 1228.0 1186.4 1144.2 1101.0 1061.4 1020.0

kW 78.9 83.6 88.7 92.8 97.2 101.7 106.4 111.4 116.6 120.7 125.3

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

19

Performance data (cont)

38APD025 CONDENSING UNIT CIRCUIT RATINGS, 60 Hz ENGLISH

CIRCUIT A

SST (F)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 101.5 97.9 94.2 90.8 87.3 83.7 80.1 76.4 72.7 69.3 65.7

kW 8.3 8.9 9.4 9.9 10.4 11.0 11.5 12.1 12.6 13.1 13.6

TC 112.9 109.0 105.0 101.4 97.7 93.9 90.0 86.1 82.1 78.4 74.6

kW 8.5 9.0 9.6 10.1 10.7 11.2 11.8 12.3 12.9 13.4 14.0

TC 125.0 120.9 116.6 112.7 108.7 104.6 100.5 96.3 92.0 88.1 84.0

kW 8.6 9.2 9.8 10.3 10.8 11.4 12.0 12.6 13.2 13.7 14.3

TC 137.8 133.4 128.8 124.6 120.3 115.9 111.5 107.0 102.4 98.2 93.8

kW 8.7 9.3 9.9 10.5 11.0 11.6 12.2 12.8 13.4 13.9 14.5

TC 151.0 146.2 141.3 136.7 132.1 127.4 122.7 117.8 112.8 108.3 103.6

kW 8.9 9.5 10.1 10.6 11.2 11.8 12.3 13.0 13.6 14.1 14.7

TC 164.1 159.0 153.7 148.8 143.8 138.7 133.5 128.3 123.0 118.1 112.9

kW 9.0 9.6 10.2 10.8 11.4 11.9 12.5 13.1 13.8 14.3 14.9

TC 176.9 171.3 165.6 160.2 154.8 149.3 143.7 138.1 132.3 127.0 121.4

kW 9.2 9.8 10.4 11.0 11.5 12.1 12.7 13.3 13.9 14.5 15.0

SST (F)

TC 101.5 97.9 94.2 90.8 87.3 83.7 80.1 76.4 72.7 69.3 65.7

kW 8.3 8.9 9.4 9.9 10.4 11.0 11.5 12.1 12.6 13.1 13.6

TC 112.9 109.0 105.0 101.4 97.7 93.9 90.0 86.1 82.1 78.4 74.6

kW 8.5 9.0 9.6 10.1 10.7 11.2 11.8 12.3 12.9 13.4 14.0

TC 125.0 120.9 116.6 112.7 108.7 104.6 100.5 96.3 92.0 88.1 84.0

kW 8.6 9.2 9.8 10.3 10.8 11.4 12.0 12.6 13.2 13.7 14.3

TC 137.8 133.4 128.8 124.6 120.3 115.9 111.5 107.0 102.4 98.2 93.8

kW 8.7 9.3 9.9 10.5 11.0 11.6 12.2 12.8 13.4 13.9 14.5

TC 151.0 146.2 141.3 136.7 132.1 127.4 122.7 117.8 112.8 108.3 103.6

kW 8.9 9.5 10.1 10.6 11.2 11.8 12.3 13.0 13.6 14.1 14.7

TC 164.1 159.0 153.7 148.8 143.8 138.7 133.5 128.3 123.0 118.1 112.9

kW 9.0 9.6 10.2 10.8 11.4 11.9 12.5 13.1 13.8 14.3 14.9

TC 176.9 171.3 165.6 160.2 154.8 149.3 143.7 138.1 132.3 127.0 121.4

kW 9.2 9.8 10.4 11.0 11.5 12.1 12.7 13.3 13.9 14.5 15.0

70 80 85 90 95 100 105 110 115 120 125

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

CONDENSER ENTERING-AIR TEMPERATURE (F)

CIRCUIT B

20

38APD027 CONDENSING UNIT CIRCUIT RATINGS, 60 Hz ENGLISH

CIRCUIT A

SST (F)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 116.1 112.6 109.0 105.6 102.1 98.7 95.1 91.5 87.9 84.5 81.0

kW 9.1 9.7 10.5 11.0 11.6 12.2 12.9 13.6 14.3 14.9 15.5

TC 128.5 124.7 120.7 117.0 113.3 109.5 105.7 101.7 97.8 94.1 90.3

kW 9.3 10.0 10.7 11.3 11.9 12.5 13.1 13.8 14.5 15.1 15.7

TC 141.7 137.5 133.2 129.2 125.1 121.0 116.8 112.6 108.2 104.3 100.1

kW 9.6 10.2 10.9 11.5 12.1 12.7 13.4 14.0 14.8 15.3 16.0

TC 155.5 151.0 146.2 141.9 137.5 132.9 128.4 123.7 119.0 114.7 110.1

kW 9.8 10.5 11.2 11.7 12.3 13.0 13.6 14.3 15.0 15.6 16.2

TC 169.5 164.6 159.5 154.7 149.9 145.1 140.1 135.1 130.0 125.3 120.3

kW 10.1 10.7 11.5 12.0 12.6 13.2 13.9 14.5 15.3 15.8 16.4

TC 183.5 178.1 172.6 167.5 159.3 156.9 151.6 146.1 140.6 135.5 130.1

kW 10.4 11.1 11.8 12.3 12.9 13.5 14.1 14.8 15.5 16.1 16.7

TC 197.3 191.5 185.6 180.0 174.3 168.5 162.7 156.8 150.8 145.2 139.4

kW 10.8 11.4 12.1 12.6 13.2 13.8 14.4 15.1 15.8 16.3 16.9

SST (F)

TC 115.9 112.4 108.7 105.3 101.9 98.4 94.8 91.2 87.6 84.2 80.7

kW 9.1 9.7 10.4 11.0 11.6 12.2 12.8 13.5 14.2 14.8 15.4

TC 128.0 124.2 120.3 116.5 112.8 109.0 105.1 101.2 97.2 93.5 89.7

kW 9.3 9.9 10.6 11.2 11.8 12.4 13.1 13.8 14.4 15.0 15.6

TC 140.9 136.7 132.4 128.3 124.2 120.0 115.8 111.6 107.2 103.2 99.0

kW 9.6 10.2 10.9 11.5 12.1 12.7 13.3 14.0 14.7 15.3 15.9

TC 154.2 149.6 144.9 140.4 136.0 131.4 126.8 122.1 117.4 113.0 108.4

kW 9.8 10.5 11.2 11.7 12.3 12.9 13.6 14.2 14.9 15.5 16.1

TC 167.5 162.5 157.3 152.6 147.7 142.8 137.8 132.7 127.5 122.8 117.8

kW 10.1 10.7 11.4 12.0 12.6 13.2 13.8 14.5 15.2 15.8 16.4

TC 180.8 175.3 169.8 164.5 159.3 153.8 148.4 142.9 137.3 132.0 126.6

kW 10.4 11.0 11.7 12.3 12.9 13.5 14.1 14.8 15.5 16.0 16.7

TC 193.9 188.0 182.0 176.2 170.4 164.6 158.7 152.7 146.6 140.9 135.0

kW 10.8 11.4 12.1 12.6 13.2 13.8 14.4 15.1 15.8 16.3 16.9

70 80 85 90 95 100 105 110 115 120 125

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

CONDENSER ENTERING-AIR TEMPERATURE (F)

CIRCUIT B

21

Performance data (cont)

38APD030 CONDENSING UNIT CIRCUIT RATINGS, 60 Hz ENGLISH

CIRCUIT A

SST (F)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 135.0 131.0 126.8 122.9 119.0 115.1 110.9 106.8 102.7 98.8 94.8

kW 10.9 11.7 12.6 13.3 14.0 14.7 15.6 16.4 17.3 18.0 18.8

TC 149.3 144.9 140.4 136.2 131.9 127.6 123.2 118.8 114.2 110.0 105.7

kW 11.2 12.0 12.8 13.5 14.3 15.1 15.9 16.7 17.6 18.3 19.1

TC 164.3 159.5 154.7 150.1 145.5 140.8 136.2 131.3 126.4 121.9 117.2

kW 11.5 12.3 13.1 13.8 14.6 15.4 16.2 17.0 17.9 18.6 19.4

TC 179.7 174.6 169.3 164.5 159.5 154.5 149.4 144.2 138.9 134.0 128.9

kW 11.8 12.6 13.5 14.2 14.9 15.7 16.5 17.3 18.2 18.9 19.7

TC 195.0 189.6 184.0 178.8 173.6 168.2 162.8 157.2 151.5 146.4 141.0

kW 12.1 12.9 13.8 14.5 15.2 16.0 16.8 17.7 18.5 19.2 20.0

TC 210.1 204.4 198.4 192.9 186.7 181.7 175.9 170.0 164.0 158.6 152.8

kW 12.5 13.3 14.2 14.9 15.6 16.4 17.2 18.0 18.9 19.6 20.3

TC 225.3 219.2 212.8 206.9 200.9 194.9 188.7 182.5 176.0 170.2 164.0

kW 13.0 13.7 14.6 15.3 16.0 16.7 17.5 18.3 19.2 19.9 20.7

SST (F)

TC 135.2 131.2 127.1 123.2 119.2 115.3 111.2 107.1 102.9 99.0 95.0

kW 11.0 11.8 12.7 13.4 14.1 14.9 15.7 16.6 17.5 18.2 18.9

TC 149.5 145.1 140.6 136.4 132.1 127.8 123.4 119.0 114.4 110.2 105.9

kW 11.3 12.1 13.0 13.7 14.4 15.2 16.0 16.9 17.8 18.5 19.3

TC 164.5 159.8 154.9 150.3 145.8 141.0 136.3 131.5 126.6 122.0 117.3

kW 11.6 12.4 13.3 14.0 14.8 15.5 16.3 17.2 18.1 18.8 19.6

TC 180.1 175.0 169.7 164.7 159.7 154.7 149.5 144.3 138.9 134.0 128.9

kW 12.0 12.8 13.6 14.4 15.1 15.9 16.7 17.5 18.4 19.1 19.9

TC 195.7 190.2 184.5 179.2 173.9 168.5 162.9 157.3 151.5 146.3 140.8

kW 12.3 13.1 14.0 14.7 15.4 16.2 17.0 17.9 18.8 19.5 20.3

TC 211.1 205.3 199.2 193.5 186.8 182.1 176.2 170.2 164.0 158.5 152.6

kW 12.7 13.5 14.4 15.1 15.8 16.6 17.4 18.2 19.1 19.8 20.6

TC 226.7 220.4 213.9 207.9 201.7 195.5 189.2 182.8 176.2 170.2 163.9

kW 13.1 13.9 14.8 15.5 16.2 17.0 17.8 18.6 19.5 20.2 21.0

70 80 85 90 95 100 105 110 115 120 125

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

CONDENSER ENTERING-AIR TEMPERATURE (F)

CIRCUIT B

22

38APD040 CONDENSING UNIT CIRCUIT RATINGS, 60 Hz ENGLISH

CIRCUIT A

SST (F)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 179.3 172.9 166.2 160.0 153.8 147.4 141.1 134.5 127.6 121.6 115.2

kW 14.5 15.4 16.4 17.3 18.3 19.2 20.2 21.2 22.2 23.1 24.1

TC 199.2 192.3 185.1 178.5 171.9 164.9 157.9 151.1 143.8 137.2 130.3

kW 14.7 15.7 16.8 17.7 18.7 19.7 20.7 21.7 22.8 23.7 24.7

TC 220.1 212.7 205.0 197.8 190.9 183.6 176.2 168.3 160.6 153.7 146.3

kW 15.0 16.1 17.2 18.1 19.1 20.1 21.2 22.2 23.3 24.3 25.3

TC 242.1 234.2 226.1 218.3 210.7 202.8 194.9 186.7 178.6 170.9 163.0

kW 15.3 16.4 17.5 18.5 19.5 20.5 21.6 22.7 23.8 24.8 25.9

TC 264.9 256.4 247.7 239.3 230.9 222.7 214.1 205.4 196.5 188.3 179.8

kW 15.6 16.7 17.9 18.9 19.9 20.9 22.0 23.2 24.3 25.3 26.4

TC 288.6 279.4 269.8 260.7 252.0 242.7 233.3 224.1 214.1 205.4 196.1

kW 16.0 17.1 18.2 19.2 20.1 21.3 22.4 23.6 24.7 25.7 26.8

TC 312.6 302.6 292.0 282.8 272.6 262.7 252.4 242.3 231.9 222.2 212.1

kW 16.4 17.5 18.6 19.6 20.7 21.7 22.8 24.0 25.2 26.2 27.3

SST (F)

TC 156.4 151.4 146.2 141.4 136.4 131.5 126.4 121.2 116.0 111.2 106.2

kW 11.7 12.7 13.7 14.6 15.5 16.4 17.4 18.4 19.4 20.3 21.2

TC 173.2 167.8 162.1 156.9 151.6 146.2 140.7 135.1 129.4 124.2 118.7

kW 11.9 12.9 13.9 14.8 15.7 16.6 17.6 18.6 19.7 20.6 21.5

TC 191.1 185.2 179.0 173.3 167.6 161.7 155.8 149.7 143.5 137.8 131.9

kW 12.1 13.1 14.1 15.0 15.9 16.9 17.9 18.9 20.0 20.8 21.8

TC 209.7 203.3 196.7 190.5 184.3 177.9 171.5 164.9 158.2 152.1 145.7

kW 12.3 13.3 14.4 15.2 16.2 17.1 18.1 19.2 20.2 21.1 22.1

TC 229.1 222.1 215.0 208.2 201.2 194.6 187.4 180.4 173.1 166.4 159.5

kW 12.5 13.5 14.6 15.5 16.4 17.3 18.3 19.4 20.5 21.4 22.3

TC 249.5 241.8 233.9 226.2 218.9 211.0 203.6 196.0 187.3 180.2 172.6

kW 12.8 13.8 14.8 15.7 16.4 17.6 18.6 19.6 20.7 21.6 22.6

TC 269.6 261.3 252.3 244.8 236.8 228.4 219.2 211.2 202.6 194.5 186.2

kW 13.0 14.0 15.1 16.0 16.9 17.8 18.8 19.9 21.0 21.8 22.8

70 80 85 90 95 100 105 110 115 120 125

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

CONDENSER ENTERING-AIR TEMPERATURE (F)

CIRCUIT B

23

Performance data (cont)

38APD050 CONDENSING UNIT CIRCUIT RATINGS, 60 Hz ENGLISH

CIRCUIT A

SST (F)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 204.3 196.8 188.6 181.6 174.6 167.9 160.7 152.5 143.0 137.1 129.7

kW 17.2 18.4 19.5 20.6 21.7 22.9 24.1 25.2 26.3 27.4 28.6

TC 225.8 218.0 209.8 202.2 195.0 187.5 179.5 172.1 162.6 155.9 148.1

kW 17.5 18.6 19.9 21.0 22.2 23.3 24.5 25.8 26.9 28.1 29.3

TC 248.7 240.5 232.3 224.1 216.1 208.3 199.7 191.7 183.2 175.3 167.1

kW 17.7 18.9 20.2 21.4 22.5 23.7 25.0 26.3 27.5 28.7 29.9

TC 274.0 265.1 255.8 247.4 238.8 230.1 220.7 211.6 203.0 194.2 185.3

kW 18.0 19.2 20.6 21.7 22.9 24.1 25.4 26.7 28.0 29.2 30.4

TC 300.0 290.4 280.0 271.2 261.9 252.5 242.9 232.5 222.4 213.4 203.8

kW 18.3 19.5 20.9 22.0 23.2 24.5 25.8 27.1 28.4 29.6 30.9

TC 326.5 316.1 305.2 295.4 285.0 275.1 264.1 253.5 243.3 233.0 222.7

kW 18.5 19.8 21.2 22.4 23.0 24.8 26.1 27.4 28.8 30.0 31.3

TC 353.2 342.0 330.4 319.6 309.1 297.2 285.8 274.9 263.2 252.3 241.1

kW 18.9 20.1 21.5 22.7 23.9 25.1 26.4 27.8 29.2 30.3 31.6

SST (F)

TC 228.8 221.7 214.4 207.5 200.6 193.5 186.6 179.3 171.8 165.1 158.0

kW 19.2 20.5 21.9 23.1 24.3 25.5 26.9 28.2 29.7 30.8 32.1

TC 252.7 245.0 236.9 229.5 222.0 214.4 206.4 198.6 190.6 183.2 175.4

kW 19.8 21.1 22.5 23.7 24.9 26.2 27.5 28.9 30.3 31.4 32.7

TC 277.7 269.3 260.6 252.5 244.2 236.0 227.1 218.5 210.3 201.9 193.5

kW 20.4 21.7 23.2 24.3 25.5 26.8 28.1 29.5 30.9 32.0 33.3

TC 304.9 295.5 285.5 276.9 267.8 258.4 248.9 239.3 229.5 220.6 211.2

kW 21.1 22.4 23.8 25.0 26.2 27.4 28.7 30.1 31.5 32.7 34.0

TC 332.1 321.9 311.1 301.4 291.5 281.4 271.6 260.8 249.6 240.2 230.0

kW 21.8 23.1 24.5 25.6 26.8 28.1 29.4 30.8 32.2 33.3 34.6

TC 360.1 348.9 336.9 326.8 315.2 304.9 292.7 281.4 270.6 259.5 248.3

kW 22.5 23.8 25.2 26.4 27.1 28.8 30.1 31.5 32.9 34.0 35.3

TC 387.1 375.1 363.0 351.1 338.9 327.0 314.6 303.4 290.6 278.8 266.8

kW 23.3 24.6 26.0 27.1 28.3 29.5 30.8 32.2 33.6 34.7 36.0

70 80 85 90 95 100 105 110 115 120 125

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

CONDENSER ENTERING-AIR TEMPERATURE (F)

CIRCUIT B

24

38APD060 CONDENSING UNIT CIRCUIT RATINGS, 60 Hz ENGLISH

CIRCUIT A

SST (F)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 230.8 224.0 216.3 211.1 202.8 197.5 189.2 183.8 175.0 169.1 162.2

kW 17.7 19.0 20.4 21.5 22.7 23.9 25.2 26.6 27.9 29.1 30.3

TC 254.9 247.4 239.3 233.3 224.3 218.4 210.8 203.7 194.1 187.9 180.5

kW 18.2 19.4 20.9 22.0 23.1 24.3 25.6 27.0 28.4 29.5 30.8

TC 279.8 271.7 263.2 254.9 248.6 240.2 232.4 224.3 214.1 207.6 199.5

kW 18.7 19.9 21.4 22.5 23.6 24.8 26.1 27.5 28.9 30.0 31.2

TC 305.4 296.8 287.3 279.2 272.5 264.1 251.3 245.4 236.5 227.9 219.3

kW 19.3 20.5 21.9 23.0 24.2 25.4 26.6 28.0 29.4 30.5 31.7

TC 327.4 318.9 305.8 303.9 296.6 286.7 277.2 267.4 257.4 251.0 242.5

kW 19.9 21.1 22.4 23.6 24.7 25.9 27.2 28.5 29.8 30.9 32.1

TC 352.5 343.7 329.6 327.4 321.6 312.1 298.1 290.3 280.0 273.2 264.4

kW 20.4 21.6 23.0 24.2 25.3 26.6 27.8 29.1 30.6 31.7 32.9

TC 392.7 381.1 366.6 362.7 343.5 337.3 321.5 313.8 298.4 288.5 276.9

kW 21.2 22.4 23.8 25.0 26.0 27.3 28.5 29.8 31.2 32.3 33.5

SST (F)

TC 261.8 254.9 243.4 242.8 237.7 227.2 221.3 211.0 204.9 198.9 191.9

kW 22.2 23.8 25.4 26.9 28.5 29.9 31.6 33.1 35.0 36.3 37.9

TC 296.8 288.1 278.6 271.8 261.1 254.4 245.6 235.0 227.4 218.8 210.1

kW 23.0 24.6 26.3 27.7 29.1 30.6 32.1 33.9 35.6 36.9 38.5

TC 327.6 318.0 306.8 300.2 287.9 280.5 271.3 261.7 248.3 241.1 231.4

kW 23.7 25.3 27.0 28.5 29.8 31.3 32.9 34.6 36.3 37.6 39.2

TC 347.9 339.3 321.6 326.4 319.0 309.2 295.3 287.2 275.1 270.3 261.7

kW 24.4 26.0 27.6 29.1 30.6 32.2 33.7 35.3 37.0 38.5 40.0

TC 373.7 365.4 343.5 356.2 348.4 336.7 325.4 313.8 302.0 299.1 290.8

kW 25.2 26.7 28.3 29.9 31.4 32.8 34.4 36.0 37.6 39.1 40.6

TC 408.1 398.6 375.9 385.4 378.6 367.3 350.5 341.6 326.0 322.8 313.4

kW 26.0 27.5 29.2 30.8 32.2 33.8 35.3 36.9 38.7 40.1 41.7

TC 442.4 432.0 409.6 416.7 410.9 391.3 382.8 365.1 356.2 348.7 338.3

kW 26.9 28.5 30.1 31.7 33.2 34.6 36.2 37.8 39.6 41.0 42.6

70 80 85 90 95 100 105 110 115 120 125

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

CONDENSER ENTERING-AIR TEMPERATURE (F)

CIRCUIT B

25

Performance data (cont)

38APD070 CONDENSING UNIT CIRCUIT RATINGS, 60 Hz ENGLISH

CIRCUIT A

SST (F)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

kW — Compressor Power

SST — Saturated Suction Temperature Entering Condensing Unit

TC — Gross Cooling Capacity (1000 Btuh)

NOTES:

1. Ratings are based on 15 F superheat and use of R-410A

refrigerant.

2. Ratings include suction line losses due to an accumulator.

3. Refer to Commercial Split Builder program for more detailed

information.

TC 303.5 292.7 281.5 271.2 260.6 249.9 239.1 228.0 216.8 206.4 195.6

kW 25.7 27.3 29.0 30.5 32.1 33.7 35.3 37.0 38.6 40.2 41.8

TC 336.8 325.2 313.3 302.1 290.8 279.4 267.8 256.0 243.9 232.8 221.3

kW 26.3 27.9 29.7 31.3 32.9 34.6 36.3 38.0 39.8 41.4 43.1

TC 371.9 359.5 346.7 334.8 322.7 310.4 298.0 285.3 272.5 260.6 248.2

kW 26.9 28.6 30.5 32.1 33.7 35.5 37.2 39.0 40.9 42.5 44.2

TC 408.6 395.3 381.6 368.8 355.8 342.7 329.4 315.8 302.0 289.3 276.0

kW 27.5 29.3 31.2 32.9 34.6 36.3 38.1 40.0 41.9 43.5 45.3

TC 446.6 432.4 417.7 403.9 390.0 375.9 361.7 347.1 332.3 318.6 304.4

kW 28.2 30.0 32.0 33.6 35.4 37.2 39.0 40.9 42.9 44.5 46.4

TC 485.6 470.3 454.5 439.7 425.4 409.7 394.3 378.7 362.8 348.1 332.9

kW 29.0 30.8 32.8 34.5 35.8 38.0 39.9 41.8 43.8 45.5 47.4

TC 525.2 508.8 491.9 476.1 460.0 443.8 427.4 410.6 393.6 377.8 361.5

kW 29.8 31.6 33.7 35.3 37.1 38.9 40.8 42.8 44.8 46.5 48.3

SST (F)

TC 266.6 258.7 250.4 242.8 234.7 226.8 219.0 211.7 201.9 194.9 186.9

kW 22.3 23.9 25.6 27.0 28.5 30.0 31.7 33.4 35.1 36.5 38.1

TC 295.5 286.8 277.9 269.4 260.8 252.1 243.3 234.6 225.7 217.2 208.5

kW 22.9 24.5 26.3 27.7 29.2 30.7 32.4 34.1 35.8 37.2 38.8

TC 326.5 317.0 307.2 297.9 288.7 279.2 269.5 260.0 250.0 240.9 231.3

kW 23.6 25.2 27.0 28.4 29.9 31.5 33.1 34.8 36.6 38.0 39.6

TC 359.3 348.9 338.3 328.2 318.0 307.7 297.4 286.8 276.0 266.0 255.7

kW 24.4 26.0 27.7 29.2 30.6 32.2 33.8 35.5 37.3 38.7 40.3

TC 393.9 382.6 371.0 360.0 348.9 337.8 326.4 314.9 303.2 292.3 281.0

kW 25.1 26.7 28.5 29.9 31.4 32.9 34.6 36.3 38.1 39.5 41.1

TC 429.9 417.6 404.9 393.0 381.6 368.9 356.5 343.9 331.1 319.3 307.0

kW 26.0 27.5 29.3 30.7 31.8 33.7 35.4 37.1 38.8 40.2 41.8

TC 467.1 453.7 439.8 427.0 413.9 400.6 387.2 373.5 359.6 346.7 333.4

kW 26.8 28.4 30.2 31.6 33.0 34.6 36.2 37.9 39.6 41.0 42.6

70 80 85 90 95 100 105 110 115 120 125

70 80 85 90 95 100 105 110 115 120 125

LEGEND

CONDENSER ENTERING-AIR TEMPERATURE (F)

CONDENSER ENTERING-AIR TEMPERATURE (F)

CIRCUIT B

26

38APD080 CONDENSING UNIT CIRCUIT RATINGS, 60 Hz ENGLISH

CIRCUIT A

SST (F)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

kW — Compressor Power