Page 1

Series 27100, 28000

Vertical DETECT-A-FIRE® Units

Installation Instructions

12.01.D

DESCRIPTION

DETECT-A-FIRE¨ thermal detectors are UL Listed, UL of

Canada available upon request, and FM Approved detection and release devices used with fire detection systems to

activate alarms and actuate extinguishing systems. This Rate

Compensated device combines the best features of both

fixed temperature and rate-of-rise detectors.

ELECTRICAL RA TING

tcatnoC

rebmuNledoM

nonoitarepO

erutarepmeT

esiR

*gnitaRlacirtcelE

)ylnOevitsiseR(

Effective: August 1999

02172

02082

12172

12082

*Although incandescent lamps are considered resistive, their inrush current is 10 - 15 times their steady current. Do not exceed ratings.

snepO

o

054(

)xaMF

sesolC

spmA0.5

spmA5.0

spmA0.5

spmA5.0

spmA0.2

spmA0.1

CAV521

CDV521

CAV521

CDV521

CDV42

CDV84

LOCATION

DETECT-A-FIRE® Units are precision temperature sensors.

They must be mounted in an area (normally a ceiling) so

that:

1. The detector spacing complies with both system requirements and requirements of the agency having local jurisdiction.

2. The thermal air path to the shell is not obstructed.

Spacing per UL, FM, and UL of Canada is shown in T able 1.

Distances given are for between units on smooth ceilings.

Distances from partitions or walls are half that shown. To

assure that all spacing requirements are met, consult the

authority having local jurisdiction.

MOUNTING

Detect-A-Fire units are not position sensitive. Horizontal and

vertical detectors refer to the most common mounting configuration for that unit. However, each type can be mounted

either horizontally or vertically depending on the application

and installation requirements.

Table 1.

o

F

0418-/7+050552kcalB

0618-/7+525252kcalB

0918-/7+050552etihW

0128-/7+520552etihW

5228-/7+520552etihW

57201±520552eulB

52301±050552deR

06301±520552deR

05451±520552neerG

00551±050552egnarO

00602±A/N0552egnarO

52752±A/N0552egnarO

o

gnitteS

F

ecnareloT

U

®

L

)teefni(SGNICAPS

roloC

gnidoC

Note: For clean agents and CO2 suppression systems,

ceiling spacing 20 ft. (6.1 meters) apart unless otherwise specified.

Not all units are suitable for all hazard location applications.

Refer to Table 2 and markings on the detector for hazardous location suitability .

1

Page 2

suodrazaH

noitacoL

spuorG,*IssalC

;DdnaC,B,A

spuorG,*IIssalC

GdnaF,E

spuorG,*IssalC

;DdnaC,B

spuorG,*IIssalC

GdnaF,E

*Division 1 and 2.

INSTALLATION

Table 2.

ledoM

rbmuN

3-02082

5-12082

0-02172

0-12172

0-12082

roFderiuqeRgnittiF

sgnitsiLCLU,LU

lavorppAMFdna

22-02172

02-12172

aotrotcetedtnuoM

nignittifdetsil-ylbatius

htiwecnadroca

edoCcirtcelElanoitaN

ytirohtualacolro/dna

.noitcidsirujgnivah

Series 28000 units are similar to Series 27100 units except

they have two 1/2-14 NPT threads for mounting.

The unit may be mounted as described above or may be

threaded into a 1/2-14 NPT tapped hole in the vessel wall or

threaded into a coupling brazed or welded to the vessel wall.

FIELD WIRING REQUIREMENT

Field wiring must be capable of withstanding the maximum

anticipated ambient temperature in the application.

FUNCTIONAL TEST

When used with automatic fire extinguishing systems first

disconnect the initiator/solenoid leads from the panel and

connect a 24 VDC bulb to initiator terminals in the control

unit. Heat the D-A-F units with a heat lamp or other convenient source. When the bulb in the control unit changes state,

remove heat source and allow D-A-F unit to cool. Reset control unit. Test lamp must change state and stay changed

after system is reset. Do not reconnect initiator/solenoid leads

until all D-A-F units have cooled below set point as indicated

by test lamp. When D-A-F units are used in other types of

systems, disconnect them from the system, connect a 24

VDC lamp and power source in series with the D-A-F units

and test with heat source as above. Make sure that contacts

have reset to normal condition before reconnecting to system circuit.

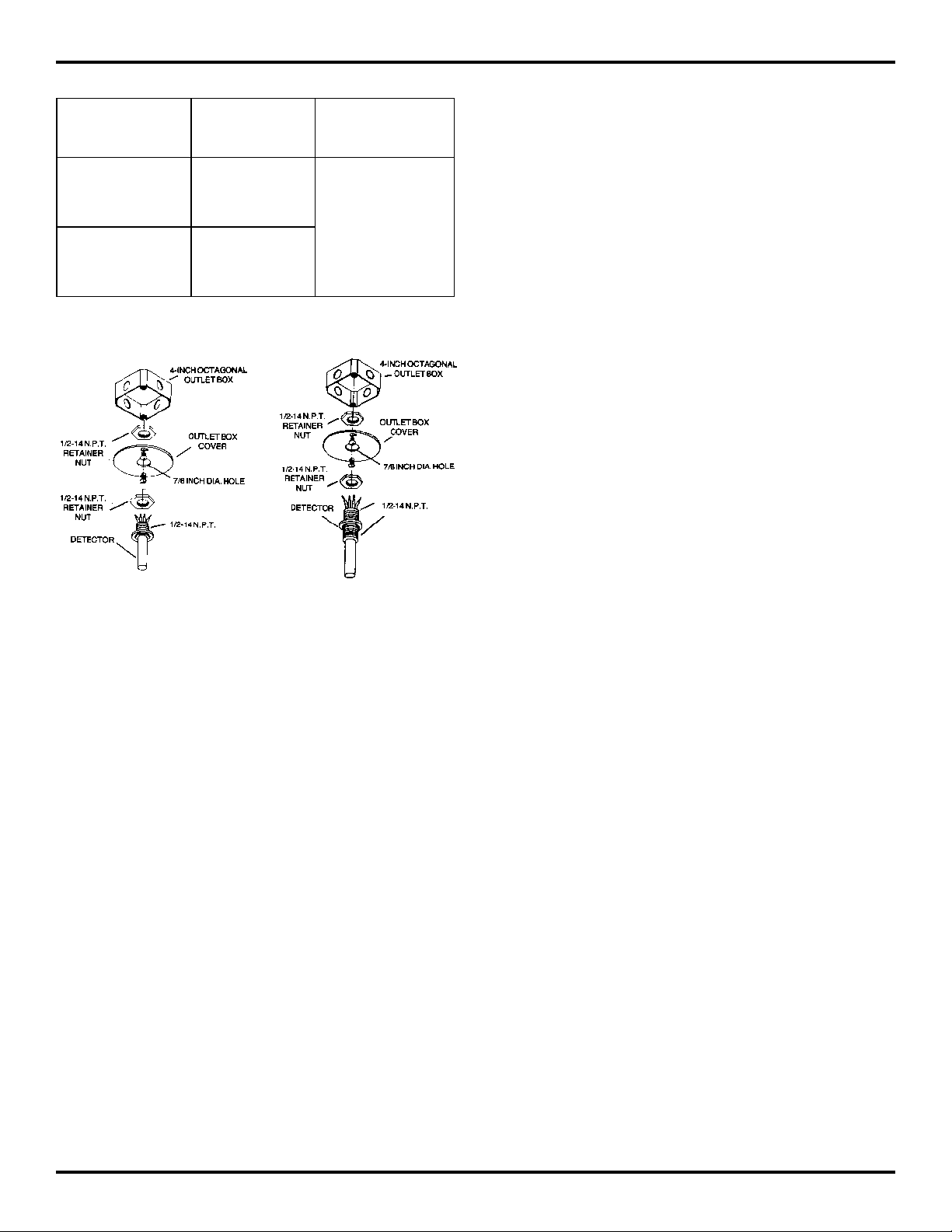

Figure 1

Figure 2

1. Kidde-Fenwal recommends that standard 4-inch octagonal outlet boxes be used to mount detectors.

2. Attach detector to outlet box cover through a 0.875 inch

diameter hole and using two 1/2-14 NPT retainer nuts

as indicated.

3. Connect system wiring to detector per Figure 3 and applicable electrical codes.

4. Ordinary Locations: The DETECT-A-FIRE Units are

to be installed in grounded metallic junction boxes only .

They are to be secured to the boxes using two lock

nuts, one on either side of the mounting plate. DETECTA-FIRE Units are not to be installed in non-metallic junction boxes.

5. Hazardous Locations: For Class I, Division 1 and 2

locations, install the DETECT-A-FIRE Unit in a listed

explosion-proof enclosure with a minimum thread engagement of five full turns. No non-conductive material

is to be placed on the threaded joint of the DETECT-AFIRE Unit or in the listed explosion-proof enclosure.

For Division 2 locations, assure that a protective ground

terminal is provided in the listed explosion-proof enclosure when flexible metal conduit is used.

6. Do not exceed a maximum torque without thread lubricant of 20 foot-pounds (27.1 Newton Meters).

2

Page 3

WARNING

!

1. In order to function properly, the sensing shell of the unit must remain free from paint, grease, oil, etc. Should such a

build up occur, do not, under any circumstances, attempt to remove it. Replace the unit.

2. Detectors mounted in an area subject to physical abuse or damage, other than above, must be suitably protected

without obstructing the thermal air path to the unit.

3. Do not install the unit where the shell would be physically damaged by sand, grain, rocks, etc.

4. Do not overtorque the unit when installing.

5. Any detector that has been abused or damaged must be replaced.

6. Consult the factory for special precautions necessary for outdoor use or moist environments.

ANY OF THE ABOVE COULD CHANGE THE FACTORY TEMPERATURE SETTING, WHICH MAY RESULT IN PROPERTY DAMAGE AND/ OR PERSONAL INJURY OR DEATH.

IT IS POSSIBLE FOR A UNIT TO HAVE BEEN ABUSED OR DAMAGED AND NOT DISPLA Y ANY OUTWARD INDICATION OF THE DAMAGE. ALL UNITS SHOULD BE TESTED PERIODICALL Y IN ACCORDANCE WITH NA TIONAL FIRE

PROTECTION ASSOCIATION REQUIREMENTS (72E) OR THE AGENCY HAVING LOCAL JURISDICTION.

Typical Fire Alarm System Method

Typical Security System Method

Figure 3. System Wiring

These instructions do not purport to cover all the details or variations in the equipment described, nor do they provide for every possible

contingency to be met in connection with installation, operation and maintenance. All specifications subject to change without notice. Should

further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purpose, the matter

should be referred to KIDDE-FENWAL, Inc., Ashland, Massachusetts.

3

Page 4

KIDDE-FENWAL, INC.

400 MAIN STREET,ASHLAND, MA 01721

TEL: (508) 881-2000 FAX: (508) 881-8920

www.fenwalfire.com

R

Protection Systems

This literature is provided for informational purposes only. KIDDE-FENWAL,INC. assumes no

responsibility for the product's suitability for a particular application. The product must be properly applied to work correctly.

If you need more information on this product, or if you have a particular problem or question,

R

contact KIDDE-FENWAL INC., Ashland, MA 01721. Telephone: (508) 881-2000

12.01.D 8/99 ©1999 Kidde-Fenwal, Inc. Printed in U.S.A. CP

Loading...

Loading...