Page 1

DELHI INDUSTRIES INC.

Figure 1: DELHI 200 SERIES

DESCRIPTION

UNPACKING

GENERAL SAFETY INSTRUCTIONS

INSTALLATION

NOTE: Check the interior of the blower housing. It should be clean and free of debris.

Maximum HP Ratings and Shaft Details

200 SERIES - INLINE DUCT BLOWERS

OPERATION INSTRUCTIONS AND PARTS MANUAL

MODELS: 207, 209, 210, 212, 215, 218

instructions

DELHI

200

Series

Blowers

are

designed

asaquiet

and

efficient

indoor

Once

the

packaging

has

been

removed

inspect

the

unit

carefully.

Check

for

loose,

missing,

or

damaged

parts.

Rotate

the

Blower

must

be

electrically

grounded.

This

canbeaccomplished

by

using

a

separate

ground

wire

Do

not

put

hands

nearorallow

loose

and

hanging

clothing

tobenear

belts,

pulleys,

or

blower

wheel

Read installation and operation instructions carefully before attempting to install, operate or service DELHI 200 SERIES

BLOWERS. Failure to comply with instructions could result in personal injury and/or property damage. Retain

for future reference.

inline duct blower for heating, air conditioning and ventilation systems.

These forward curved, double inlet blowers are enclosed in a sturdy steel

cabinet c/w reinforcing rails which are suitable for hanging bolts in

applications where suspended overhead duct work is required. Motor,

drive installations and servicing may be completed through access doors

located on either side of the cabinet.

Prelubricated ball bearings, motor platform and a dynamically balanced

wheel are standard equipment. Operating temperature range is -65 to 250

deg. F.

Model No.

207

209

210

215

218

wheel by hand to ensure the wheel spins freely. Tighten all set screws.

1

2

3

4

5

Always disconnect power source before working on or near a motor or its connected load. Lock the

power disconnect in the open position and tag to prevent unauthorized application of power.

Follow all local and national electrical and safety codes.

connected to the bare metal of blower frame, or other suitable means.

Ensure that the power source conforms to the requirements of your equipment.

while the unit is running.

Max. H.P. Shaft Dia.

3/4

1-1/2

1-1/2 keyway

3

5

3/4

3/4

1

1212

1

1

Shaft End

keyway3/4

keyway

keyway

keyway

keyway

1

DELHI INDUSTRIES INC., 523 JAMES ST., DELHI, ONTARIO, CANADA N4B 2Z3 PH:(519)582-2440 FX:(519)582-0581

SE-22-4

Rotate the blower wheel by hand. It should not rub against the housing inlet. If rubbing occurs, loosen

the set screws on the wheel hub and shift the wheel to obtain clearance. Retighten all set screws.

JULY 1999

Page 2

DELHI INDUSTRIES INC.

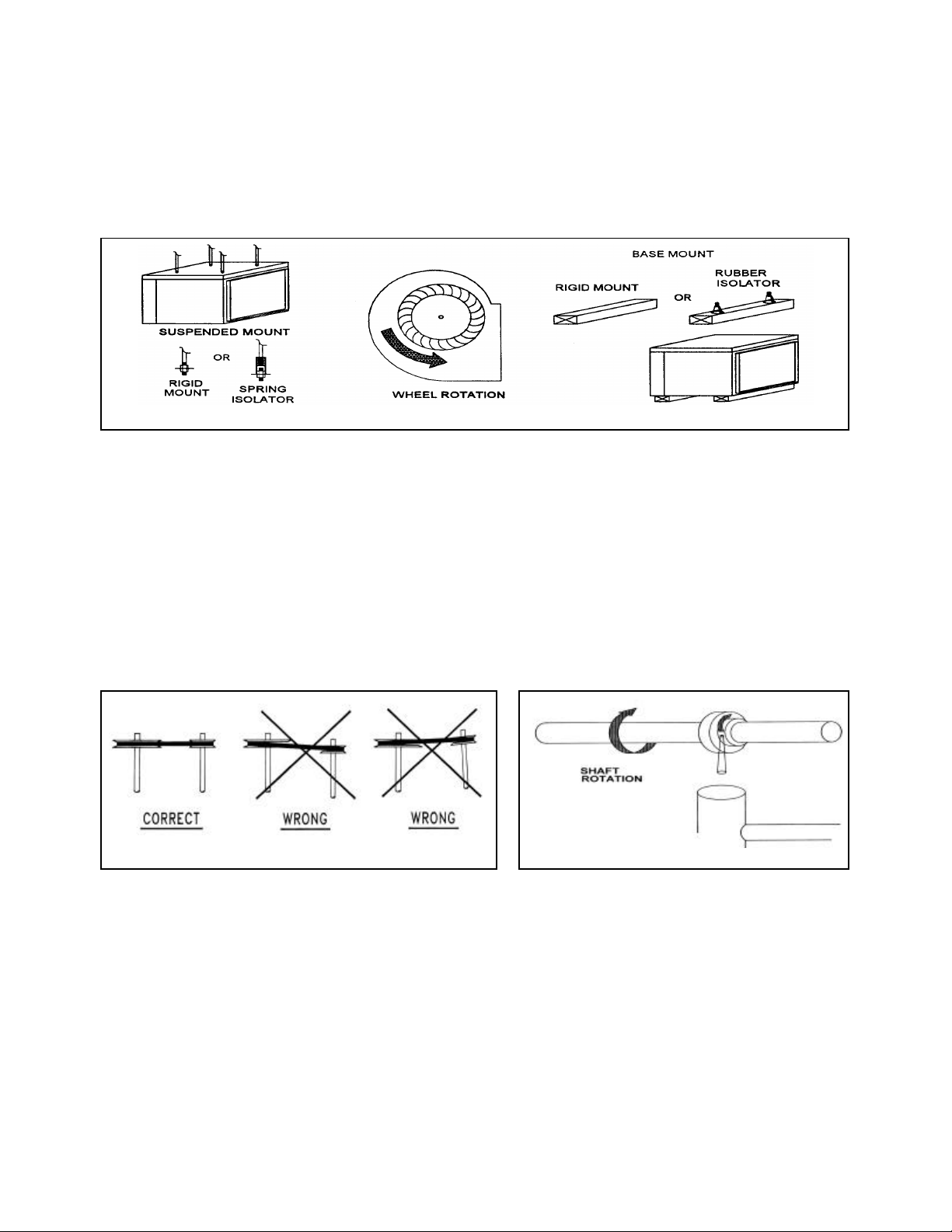

Suspension Mounting:

Base Mounting:

NOTE: Pulley alignment may change when adjusting variable pitch pulleys.

With

the

motor

adjusting

boltinits

minimum

position

install

theVbelt

within

the

sheave

grooves.

Adjust

belt

tension

by

turning

the

motor

adjustment

hook

bolt.

Ideal

belt

tension

is

the

lowest

proper

Suspend

the

unit

using

4

threaded

rods

through

the

four

(4)

7/8"

clearance

holes

located

at

the

top

Secure

the

unit

through

the

four

internal

(4)

7/8"

clearance

holes

toasolid

base.

Ensure

unit

is

Mount

the

blower

sheave

on

the

blower

shaft

and

tighten

its

set

screw

securely

on

the

keyofthe

Mount

the

motor

sheave

on

the

motor

shaft.

Leave

some

clearance

between

the

pulley

and

the

NOTE:

Flexible

inlet

and

outlet

duct

collars

are

recommended

to

minimize

vibration

WARNING:

A

GROUND

WIRE

MUST

BE

CONNECTED

FROM

THE

MOTOR

HOUSING

TO

A

2

of the unit or by means of an angle iron cradle (supplied by others) under the unit.

Figure 2: Installation Method

level. Complete installation of inlet and outlet ducts.

transmission.

3

shaft. (See Table 1 for Drive Data)

4

motor end bell. Tighten the set screws on the key of the motor shaft.

5

Slide the square head bolts into the channel provided in the motor bracket. Place the motor into

position, finger tighten the nuts to temporarily secure the motor. Attach the motor adjustment (belt

tension) assembly.

6

Slide the motor within the motor bracket to ensure proper pulley alignment (see Figure 3). A

straight edge across the face of the driven pulley should be parallel to the belt once proper

alignment has been achieved. Tighten the nuts on the motor base to anchor the motor position

within the bracket.

Figure 3: Pulley Alignment Figure 4: Bearing Replacement

7

tension at which the belt will not slip during start up. A rule of thumb suggests that 3/4" of deflection

mid span under medium finger pressure (2-3 lbs.) for every foot of span is approximately

belt tension. Lock the motor adjustment (belt tension) assembly once proper belt tension has been

achieved.

WARNING: EXCESSIVE BELT TENSION IS THE MOST FREQUENT CAUSE OF BEARING

WEAR AND RESULTING NOISE

8

Before connecting the motor to the electrical supply, check the electrical characteristics and wiring

instructions as indicated on the motor nameplate or inside the conduit box cover to ensure proper

voltage and phase. Make your electrical connections.

SUITABLE ELECTRICAL GROUND

SS-22-4

JULY 1999

Page 3

DELHI INDUSTRIES INC.

207

209

210

212

215

218

Pulley

Pulley

Range

48 FRAME

48 FRAME

FRAME

FRAME

FRAME

FRAME

OPERATION

MAINTENANCE

WARNING: DISCONNECT POWER SUPPLY BEFORE SERVICING THE BLOWER

After

electrical

connections

are

completed,

energize

the

unit

momentarily

and

ensure

that

the

rotation

of

the

wheel

is

correct

(see

Figure

2).

With

the

air

system

in

full

operation,

all

ducts

attached

and

top

cover

in

place,

measure

current

inputtothe

motor

and

ensure

thatitis

less

Inspect V-belts for wear and proper tension. If it is necessary to replace one belt on a multiple belt drive, replace all the belts with a matched

Table 1: Drive Table

NOTE TO CONVERT:

A) 48 FRAME TO 56/143T/145T FRAME ADD 1" TO BELT LENGTH

B) 56/143T/145T FRAME TO 182T/184T FRAME ADD 2" TO BELT LENGTH

C) 4L TO B BELTS SUBTRACT 3" FROM THE BELT LENGTH

(eg.: 4L48 EQUIVALENT TO A B45 - RPM WILL VARY SLIGHTLY)

Motor Blower RPM 56T/143T/145T 56T/143T/145T 56T/143T/145T 182T/184T

12 282 - 431 - - - - - - - - - 4L55 4L59 - - -

3-1/4" 10 340 - 519 - - - 4L45 4L48 4L51 4L55 - - -

9 379 - 578 4L40 4L44 4L46 4L49 4L54 - - -

3/4 HP 8 427 - 652 4L38 4L42 4L44 4L48 4L52 - - -

MAX. 7 490 - 749 4L36 4L40 4L42 4L46 - - - - - -

6 575 - 878 4L34 4L38 4L41 4L44 - - - - - -

5 696 - 1062 4L33 4L36 4L39 4L43 - - - - - BK160H 252 - 309 - - - - - - - - - - - - 4L65 4L47

BK140H 310 - 356 - - - - - - - - - - - - 4L61 4L67

BK130H 357 - 386 - - - - - - - - - - - - 4L60 4L65

BK120H 387 - 421 - - - - - - 4L50 4L53 4L58 B61

IVL34 BK110H 422 - 464 - - - 4L45 4L48 4L52 4L56 B59

BK100H 465 - 515 - - - 4L43 4L46 4L50 4L54 B57

BK90H 516 - 579 4L38 4L41 4L44 4L48 4L52 B55

BK80H 580 - 663 4L36 4L39 4L42 4L46 4L51 B54

BK70H 664 - 773 4L34 4L38 4L41 4L44 4L49 B52

BK60H 774 - 963 4L32 4L36 4L39 4L43 B45 B50

BK50H 964 - 1203 4L31 4L35 4L38 4L41 B43 - - -

BK40H 1204 - 1504 4L29 4L34 B34 B38 - - - - - BK130H 491 - 543 - - - - - - - - - - - - B59 B64

BK120H 544 - 592 - - - - - - 4L52 4L56 B57 B63

BK110H 593 - 648 - - - 4L47 4L50 4L54 B56 B61

BK100H 649 - 716 - - - 4L45 4L48 4L53 B54 B59

IVP44 BK90H 717 - 802 4L39 4L43 4L46 4L51 B52 B57

BK80H 803 - 911 4L37 4L41 4L44 4L49 B49 B55

BK70H 912 - 1053 4L35 4L39 4L42 4L47 B47 B53

BK60H 1054 - 1281 4L34 4L38 B39 B43 B47 - - -

1

Apply full power.

2

than the rated full load motor amperage.

Proper adjustment to the belt tension is critical for quiet efficient operation.

3

1

Inspect and tighten all bearing collar and wheel set screws after the first 50 to 100 hours of operation and periodically thereafter.

Follow motor manufacturer's instructions for motor lubrication. Remove any excess lubrication.

2

Check the drives.

3

a. Tighten set screws on sheaves, wheel and bearing locking collars.

b. Check belt tension and alignment.

c. Replace cracked or worn belts.

Check wiring to be sure it is secure and well insulated.

4

Blower bearings are permanently lubricated and require no further lubrication.

5

6

set. Do not use belt dressing.

7

Clean the blower wheel periodically. Material build up on the blades can cause wheel imbalance which may result in wheel or bearing

failure.

8

To reinstall replacement ball bearings press the locking collar against the inner ring of the bearing and turn in the direction of the shaft

rotation until engaged. Insert a drift pin into the pin hole and tap lightly to set. Tighten set screw on locking collar firmly (see Figure 4).

Should further service to the blower be necessary, refer to the exploded view illustration. (See Figure 5).

9

SE-22-4

JULY 1999

Page 4

DELHI INDUSTRIES INC.

DELHI INDUSTRIES INC. WARRANTY

Delhi Air Moving Products are guaranteed for a period of one year against manufacturing defects in material and

workmanship when operating under normal conditions. Liability is limited to the replacement of defective parts. Labour

and transportation costs are not included.

SE-22-4 JULY 1999

Loading...

Loading...