Page 1

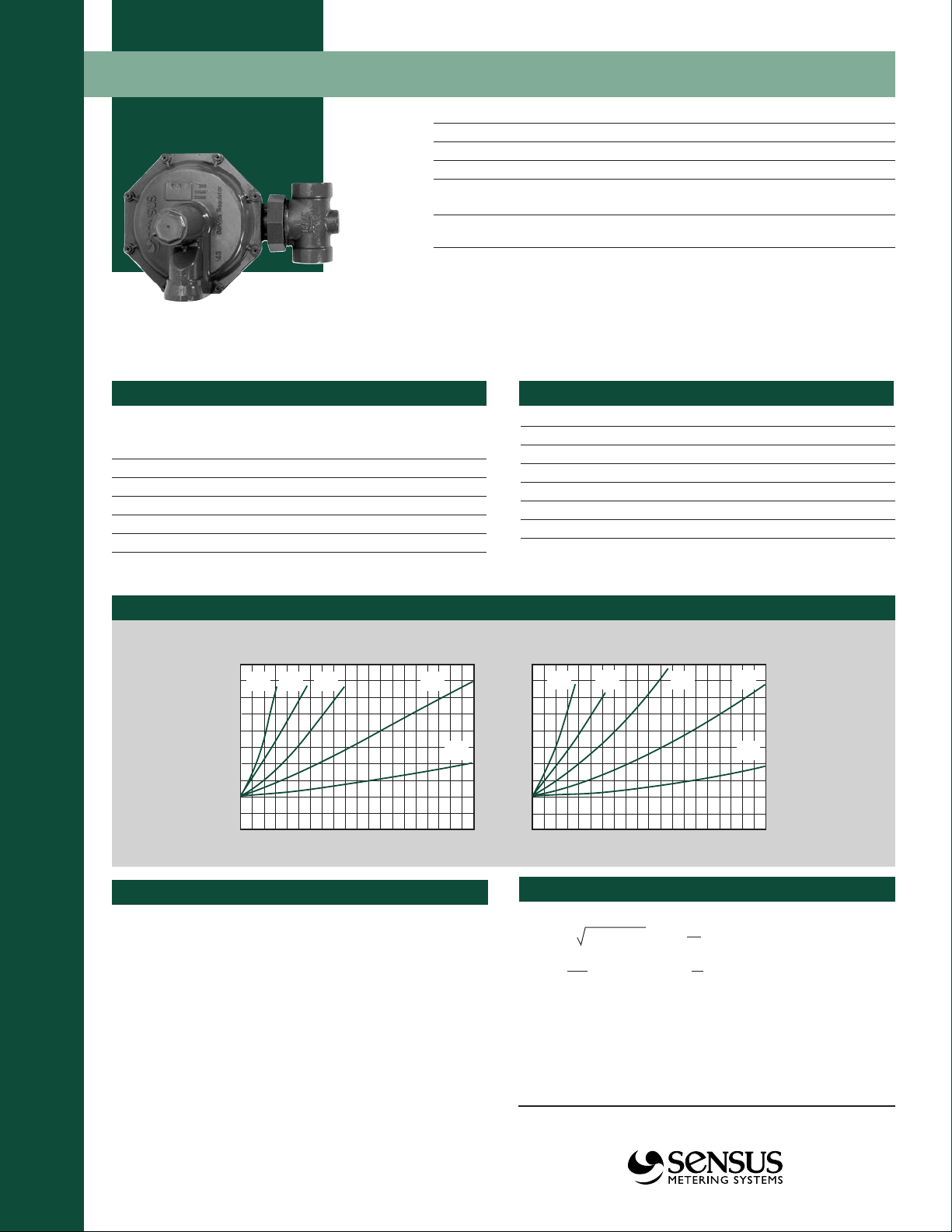

7" w.c. Set Point – Blue Spring

3/4" Vent – No Vent Piping

2

1

⁄

2

2

1

1

⁄

2

1

1

⁄

2

0

OUTLET PRESSURE – in psi.

0 10 20 30 40 50 60 70 80 90 100

INLET PRESSURE – in psi

3/8"

Orifice

5/16"

Orifice

1/4"

Orifice

3/16"

Orifice

1/8"

Orifice

21⁄

2

2

1

1

⁄

2

1

1

⁄

2

0

OUTLET PRESSURE – in psi.

7" w.c. Set Point – Blue Spring

1" Vent – No Vent Piping

INLET PRESSURE – in psi

0 10 20 30 40 50 60 70 80 90 100

3/8"

Orifice

5/16"

Orifice

1/4"

Orifice

3/16"

Orifice

1/8"

Orifice

Sensus Metering Systems

Model 143-80 Service Regulator

TD-1301

THE GAS INDUSTRY

Models:

Technical Data

143-80-1

143-80-2

143-80-2HP

Diaphragm: Nylon fabric reinforced Buna-N with full 26 in2effective area

Vent and Valve: Precision-fit polyethylene valve and seat, threaded 3/4" or 1" NPT

Operating Temperature: -20° F to 150° F (-28.9° C to 65.5° C)

Corrosion Protection: Cases dip primed chromate conversion coating, topcoat enamel

Internal Relief Valve: Set to relieve at approximately 7" w.c. above normal outlet pressure setting

Spring Ranges

Outlet Pressure Spring Spring

Ranges Color Part Number

1

3

⁄2" to 61⁄2" w.c. Red 143-62-021-15

1

5" to 8

⁄2" w.c. Blue 143-62-021-16

6" to 14" w.c. Green 143-62-021-17

12" to 28" w.c. Orange 143-62-021-18

1

⁄2psi to 2 psi Black & White 143-62-021-22

1

⁄2psi to 3 psi Cadmium* 173-62-021-02

2 to 6 psi Black* 139-16-021-01

*For high pressure model 143-80-2HP

Valve Body: Cast Iron, 125 psig Working Pressure Straight Body

Spring and Lower Case: Die-Cast Aluminum 3/4" x 3/4"

Orifice: Stainless Steel 3/4" x 1"

Fulcrum Pin: Aluminum or Brass 3/4" x 1-1/4"

Buna-N seat pad and fiberglass reinforced nylon stem

Valve Seat/Stem: One piece molded

Throat/Support/Stem Guide: Cast Aluminum

integral to lower case

1" x 1"

1" x 1-1/4"

Diaphragm Plate: Plated Steel 1-1/4" x 1-1/4"

Orifice and Maximum Inlet Pressure

Orifice Part Number Pressure

1

⁄8" aluminum 143-62-023-37 125 psig

3

⁄16" aluminum 143-63-023-40 125 psig

1

⁄4" aluminum 143-62-023-42 60 psig

5

⁄16" aluminum 143-62-023-43 40 psig

3

⁄8" aluminum 143-62-023-44 40 psig

1

⁄2" aluminum 143-62-023-45 20 psig

5

⁄8" aluminum 143-62-023-46 10 psig

Relief Valve Performance: Lever blocked with valve disc in the wide open position

Maximum Emergency Pressure

The maximum pressure that the model 143-80-1, 143-80-2

and 143-80-2HP regulator inlets may be subjected under abnormal

conditions without causing damage to the regulator is the stated

Maximum Inlet Pressure + 50 psi

Note: For the Low Pressure Cut Off version model 143-80-6 it is

Maximum Inlet Pressure + 10 psi. See bulletin TD-1301-L

The maximum pressure to which the 143-80 diaphragm case may

be subjected under abnormal conditions without causing damage

to the internal parts of the regulator is the set point + 3 psi.

If the outlet pressure exceeds this pressure, the regulator must

be removed from service and carefully inspected. Damaged or

otherwise unsatisfactory parts must be replaced before returning

the regulator to service. The maximum outlet pressure that can

be safely contained in the 143-80 diaphragm case is 10 psi

(safely means no leakage as well as no bursting).

Full Open Capacity

Use the following formula for the full open capacity:

1. Q = K P

KP

2.Q =

I

2P

...................... (for

O(PI–PO

) .... (for

Q=maximum capacity of the regulator

(in SCFH of 0.6 specific gravity natural gas).

K=the “K” factor, the regulator constant from the table below.

P

= absolute inlet pressure (psia).

I

P

= absolute outlet pressure (psia).

O

Orifice

K 820 520 292 206 132 74 33

5

1

"

8

⁄

P

I

less than 1.894)

P

O

P

I

greater than 1.894)

O

3

"

2

⁄

5

"

8

⁄

1

3

"

16

⁄

"

4

⁄

1

"

16

⁄

"

8

⁄

Page 2

B

C

A

D

E

F

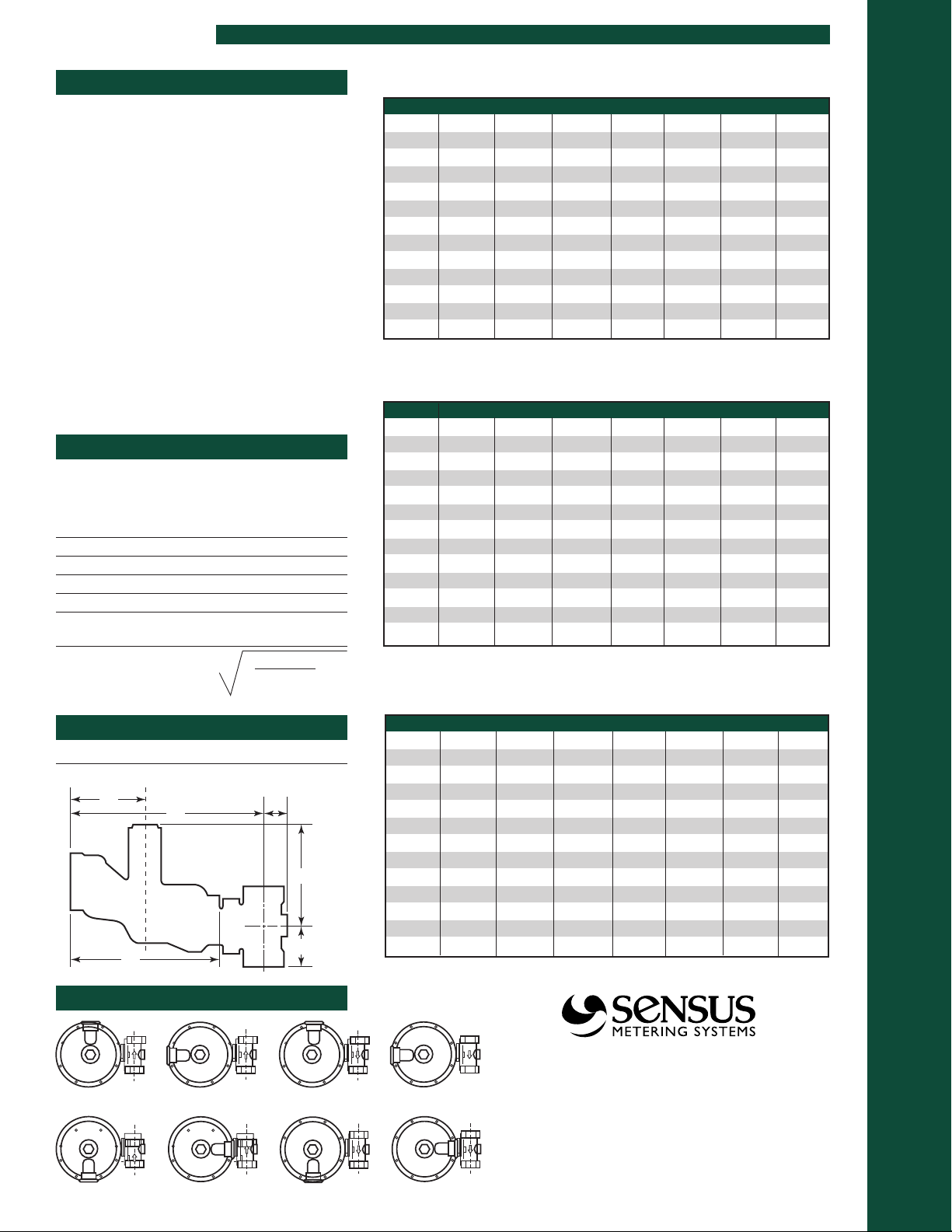

Model 143-80

Technical Data

Capacities

Flow capacities in SCFH natural gas

(0.6 specific gravity – 14.65 psia – 60°F)

Capacities are based on the following maximum

variations in outlet pressure:

Red and Blue Springs – 1" w.c. droop

Orange Spring – 3" w.c. droop

Green Spring – 2" w.c. droop

Black Spring – 10% droop

Note: The 1/2 psig, 1 psig and 2 psig inlet pressures

apply only to Red and Blue springs.

Note: The last capacity figure in each column

indicates the maximum capacity for each

orifice at recommended pressure within

the optimum performance range.

The performance data is based on normal testing at

70°F flowing temperature.

Changes in performance can occur at extreme low

flowing temperatures.

Other Gases

143-80 Regulators are mainly used on natural gas.

However, they perform equally well on LP gas, nitrogen, dry CO

Other Gases Correction Factor

Air (Specific Gravity 1.0) 0.77

Propane (Specific Gravity 1.53) 0.63

1350 BTU Propane Air Mix (1.20) 0.71

Nitrogen (Specific Gravity 0.97) 0.79

Dry Carbon Dioxide

(Specific Gravity 1.52) 0.63

For other non corrosive gases: 0.6

CORRECTION FACTOR = Specific Gravity

Regulator A B C D E F

143-80 9

2

, air and others.

of the Gas

Dimensions

3

⁄8"15⁄16"37⁄16"67⁄8"53⁄4"131⁄32"

Body Size 3/4" x 3/4"

Inlet Orifice

psig 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" 5/8"

1/2 ––––340450510

1–––480500510530

2––530560 570 580 600

3–420 600 620 630 650 670

5 250 560 700 720 730 770 790

7.5 310 700 840 860 880 900 900

10 370 830 950 970 1000 1020 1020

20 530 1200 1220 1240 1250 1270 –

40 860 1570 1330 1340 1450 – –

60 1200 1660 1520 ––––

80 1500 1710 –––––

125 1800 1900 –––––

Body Size 3/4" x 1" • 1" x 1"

Inlet Orifice

psig 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" 5/8"

1/2 ––––350460520

1–––480550600650

2––530700 840 880 780

3–420 650 870 1000 920 810

5 250 580 890 1120 1160 950 970

7.5 310 700 1140 1340 1270 1140 1060

10 370 840 1360 1500 1330 1200 1180

20 530 1230 2000 1600 1480 1400 –

40 860 1700 2000 1640 1900 – –

60 1200 1900 2000 ––––

80 1540 2000 – – – –

125 2100 2100 –––––

Body Size 3/4" x 1-1/4" • 1" x 1-1/4" • 1-1/4" x 1-1/4"

Inlet Orifice

psig 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" 5/8"

1/2 ––––350460520

1–––480550680760

2––530 700 840 1020 1030

3–420 650 870 1030 1200 1050

5 250 580 890 1180 1350 1490 1060

7.5 310 700 1140 1500 1610 1580 1060

10 370 840 1360 1700 1710 1800 1180

20 630 1230 1600 1800 1900 1900 –

40 860 1800 2200 1900 2000 – –

60 1200 2100 2400 ––––

80 1550 2200 –––––

125 2250 2400 –––––

Mounting Positions

6–12 POSITION 6 – 9 POSITION 12 – 12 POSITION 12 – 9 POSITION

6–6 POSITION 6 – 3 POSITION 12 – 6 POSITION 12 –3 POSITION

805 Liberty Boulevard

DuBois, PA 15801

800-375-8875

Fax: (814) 375-8460

www.sensus.com

(open “North America Gas”)

© Sensus Metering Systems 2006 Made in USA

09-06-Becken 50M

Loading...

Loading...