TM

EVO™

Spray Application

Operator Manual

150300-010 Rev. A | Revised 01/2019 | ©2019 Capstan Ag Systems, Inc.

TM

Thank you for your business!

At CapstanAG, our goal is to redefine the way people do their chemical application. Our PWM

control systems have been setting the bar for maximum productivity for more than 20 years.

Our focus on performance, support, and education have dramatically changed the landscape of

agricultural chemical application.

CapstanAG specializes in creating proprietary systems for the agricultural industry, primarily

focusing on chemical and fertilizer applications. Our inventive process involves research,

engineering, design, and lab and field testing.

Service Contact Information

If a problem occurs with your system that cannot be corrected with the information in this

manual, please contact your dealer for service and technical assistance. If further assistance is

needed, contact CapstanAG.

System Purchased: _____________________________________

Dealer: ______________________________________________

Contact: _____________________________________________

Phone: _______________________________________________

Address: _____________________________________________

City,State/Province, Zip: ________________________________

Factory Service/Repairs

CapstanAG

4225 S.W. Kirklawn Ave. | Topeka, KS 66609

Hours: 8:00 a.m. to 4:00 p.m. CST

Toll-free number: (855) 628-7722 | Fax: (785) 232-7799

E-mail: prodsupport@capstanag.com | Online: www.CapstanAG.com

©2019 Capstan Ag Systems, Inc. All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmited, in any form or by means electronic, mechanical, photocopying, or otherwise, without prior written

permission of Capstan Ag Systems, Inc.

TM

Contents

Chapter 1: Introduction.................................................................................... 5

This Manual.................................................................................................................................................5

System Identification...................................................................................................................................5

Chapter 2: Safety............................................................................................... 7

Signal Words............................................................................................................................................... 7

Emergency Safety........................................................................................................................................7

Pressurized Fluid Lines...............................................................................................................................7

Personal Protective Equipment................................................................................................................... 7

Battery Safety.............................................................................................................................................. 7

Chemical Safety...........................................................................................................................................8

Chapter 3: Warranty.........................................................................................9

Limited Warranty.........................................................................................................................................9

Contents

Chapter 4: Installation.................................................................................... 11

Before System Installation........................................................................................................................11

Tip Selection and Capacities.....................................................................................................................11

Nozzle Types and Component Identification............................................................................................12

7-Watt—15 Series Coil Components............................................................................................12

12-Watt—24 Series Coil Components..........................................................................................13

Assemble the Nozzle Valves.....................................................................................................................14

Move the Spray Tube Mount (Nozzle Valve Interference).......................................................... 15

Install the Nozzle Harnesses and Smart Drivers...................................................................................... 16

Install the Power to CAN X Harness....................................................................................................... 17

Install the Pressure Transmitter Module................................................................................................... 17

Install the Pressure Sensor Adapter Harness................................................................................ 18

Install the Boom Signal Transmitter Module........................................................................................... 18

Install the Shutoff Adapter............................................................................................................18

Install the CAN Bus Extension Harness...................................................................................................19

Install the CAN Terminator...................................................................................................................... 21

Install the Pressure Sensor (Optional)...................................................................................................... 21

Install the Cab Display..............................................................................................................................22

Install the Display Harness and CAN Bus Extension Harness.....................................................22

Install the Power Harness......................................................................................................................... 23

Chapter 5: Setup.............................................................................................. 25

Cab Display............................................................................................................................................... 25

Screen Descriptions...................................................................................................................................26

Advanced Menu.............................................................................................................................28

Driver Module LED Identification........................................................................................................... 32

Start the Cab Display................................................................................................................................ 33

©

2019 Capstan Ag Systems, Inc. iii EVO Spray

Shutdown the Cab Display....................................................................................................................... 33

Change the Units of Measure................................................................................................................... 34

Do the Odd/Even Test...............................................................................................................................35

Nozzle Speed Ranges................................................................................................................................36

US Measurements Nozzle Speed Ranges..................................................................................... 36

Metric Nozzle Speed Ranges........................................................................................................ 44

Chapter 6: Operation...................................................................................... 51

Start the Cab Display................................................................................................................................ 51

Shutdown the Cab Display....................................................................................................................... 51

Manual Mode Operation........................................................................................................................... 51

Shutdown the Cab Display....................................................................................................................... 53

Chapter 7: Maintenance..................................................................................55

Service the System....................................................................................................................................55

Jump Start, Weld On, or Charge the Machine..............................................................................55

Inspect the System.................................................................................................................................... 55

Clean the System.......................................................................................................................................55

Storage of the System............................................................................................................................... 55

Winterize for Storage.................................................................................................................... 55

Recommended Guidelines for Maintenance/Service................................................................................56

Baseline Evaluation Process..................................................................................................................... 56

Nozzle Valves............................................................................................................................................ 56

Clean the Nozzle Valve(s).............................................................................................................57

Plunger Seal Inspection.................................................................................................................58

Chapter 8: Schematics.....................................................................................61

System Layout...........................................................................................................................................61

Display Harness.........................................................................................................................................62

Power Harness...........................................................................................................................................63

Power Extension Harness..........................................................................................................................64

CAN Bus Extension Harness.................................................................................................................... 65

Power to CAN X Harness........................................................................................................................ 66

Nozzle Harness..........................................................................................................................................68

Chapter 9: Troubleshooting............................................................................ 71

Troubleshooting Charts............................................................................................................................. 71

Interchangeable Components.................................................................................................................... 76

Coil Test.....................................................................................................................................................76

Battery Voltage Test..................................................................................................................................77

Do a Check of the System Load Capacity............................................................................................... 78

Pressure Sensor Signal Test...................................................................................................................... 79

Power to the Pressure Sensor Input Test..................................................................................................80

Index........................................................................................................................................81

TM

Chapter 1: Introduction

This Manual

This manual includes operation, maintenance, and installation information for the system you purchased.

Make sure that all personnel have read this manual and that they thoroughly understand the safe and correct

operation and maintenance procedures. Failure to do so could result in personal injury or equipment damage.

This manual should be considered a permanent part of your system and should remain with the system at all

times and when you sell it.

Right and left sides of the system are determined by facing the direction of forward travel of the machine on

which the system is installed.

The information, screenshots, and other illustrations were correct at the time of publication. Changes can occur

without notice.

This manual contains important information on how to safely and correctly install, operate, and maintain

CapstanAG products. These instructions will help keep personnel safe, reduce downtime, and increase the

reliability and life of the equipment, its components, and related systems.

Review the safety information in the Original Equipment Manufacturer (OEM) agricultural equipment

manual(s).

Introduction

Follow the instructions (in this manual) and in the OEM agricultural equipment manual(s) for each step, to

make sure that work conditions in and around the OEM equipment are safe.

It is important for all individuals working with chemicals to understand the potential risks, necessary safety

precautions, and proper response in the event of accidental contact.

Review the OEM agricultural equipment manual(s) for chemical safety information.

Read, understand, and review the procedures in this manual and OEM agricultural equipment manual(s). Use

the Safety Data Sheets (SDS) and the required Personal Protective Equipment (PPE) for hazardous chemicals.

Please keep this manual and all enclosed documentation in an accessible location known to all operators,

installation, and maintenance personnel.

If you do not understand the CapstanAG equipment after reading this manual, please obtain the proper training

before working with equipment, to make sure that your own safety, as well as your co-workers’ safety, is

maintained.

Do not attempt to operate any equipment or system until you completely understand why, when, and how it

operates. If you are uncertain after studying this manual, please contact CapstanAG.

System Identification

Write the system name, serial number, and other information down in the Service Contact Information on

the inside cover of this manual. Your dealer will use these numbers when you order parts. File a copy of the

identification numbers in a secure place off the machine.

If you are not the original owner of this machine, it is in your interest to contact your local CapstanAG dealer

to inform them of this unit's serial number. Providing this information will help CapstanAG notify you of any

issues or product improvements.

©

2019 Capstan Ag Systems, Inc. 5 EVO Spray

TM

Introduction

©

2019 Capstan Ag Systems, Inc. 6 EVO Spray

TM

Chapter 2: Safety

Signal Words

DANGER: Indicates an imminent hazard which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations, typically for machine components that, for

functional purposes, cannot be guarded.

Warning: Indicates a potential hazard which, if not avoided, could result in death or serious injury, and

includes hazards that are exposed when guards are removed. It may also be used to alert against unsafe

practices.

CAUTION: Indicates a potential hazard which, if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Important: This is used to draw attention to specific information that is necessary for the operation, setup, or

service of the system.

Note: This is used for additional information that can help understand or operate the system.

Safety

Emergency Safety

Fire extinguishing systems must meet the applicable OSHA requirements, and all users of portable/fixed fire

suppression equipment must know the types, limitations, and proper uses of this equipment; including hazards

involved with incipient stage firefighting.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone.

Know the location of fire extinguishers and first aid kits and how to use them.

Inspect the fire extinguisher and service the fire extinguisher regularly.

Follow the recommendations on the instructions plate.

Very small fires can be put out (extinguished) with a fire extinguisher. Use an appropriate method to extinguish

a fire (water for paper fires, and chemical extinguishers for electrical or chemical fires.

Pressurized Fluid Lines

Do not heat by welding, soldering, or using a torch near pressurized fluid lines or other flammable materials.

Pressurized lines can accidentally burst when too much heat is present.

Personal Protective Equipment

Wear close-fitting clothing and the correct personal protective equipment (PPE) for the job. See the

manufacturer’s manual or other information for correct PPE.

Battery Safety

Use the procedure in the appropriate agricultural equipment manual for connecting, disconnecting, and jumpstarting the machine’s battery.

Keep sparks and flames away from the battery. Battery gas can explode and cause serious injury. Do not smoke

in the battery charging area.

Remove jewelry, which might make electrical contact and create sparks.

©

2019 Capstan Ag Systems, Inc. 7 EVO Spray

TM

Chemical Safety

Chemicals used in agricultural applications can be harmful to your health and/or the environment if not used

correctly. Always follow all label directions for effective, safe, and legal use of agricultural chemicals.

Safety

©

2019 Capstan Ag Systems, Inc. 8 EVO Spray

TM

Chapter 3: Warranty

Limited Warranty

What does the Limited Warranty cover?

The ultimate purchaser/user (“you”), by acceptance of seller Capstan Ag Systems, Inc.’s, (“our,” “we,” or “us”)

product, assume all risk and liability of the consequences of any use or misuse by you, your employees, or

others.

All replacement components furnished under this warranty, but shipped before the failed component is returned

for evaluation, will be invoiced in the usual manner and warranty adjustments will be made after the component

claimed to be defective has been returned to and inspected and deemed defective by us at our factory.

Upon determining that a component has failed under warranty, the repaired component or replacement

component, furnished under this warranty, will be shipped at our expense, to your location. We will credit you

an amount equal to the incoming freight you paid. We shall not be responsible for installation costs. (You shall

be responsible for all customs and brokerage fees for all international transactions.)

If the component does not prove to be defective, you shall be liable for all freight, inspection and handling

costs. In no event will any claim for labor or incidental or consequential damages be allowed for removing or

replacing a defective product. Warranty will be denied on any component which has been subject to misuse,

abuse, accidents, or alterations, or to improper or negligent use, maintenance, storage or transportation and

handling.

Warranty

Our liability under this warranty, or for any loss or damage to the components whether the claim is based

on contract or negligence, shall not, in any case, exceed the purchase price of the components and upon the

expiration of the warranty period all such liability shall terminate. The foregoing shall constitute your exclusive

remedy and our exclusive liability.

The terms of this warranty do not in any way extend to any product which was not manufactured by us or one of

our affiliates.

While necessary maintenance or repairs on your Capstan Ag Systems, Inc. product can be performed by

any company, we recommend that you use only authorized Capstan Ag Systems, Inc. dealers. Improper or

incorrectly performed maintenance or repair voids this warranty.

The foregoing warranty is exclusive and is in lieu of all other warranties expressed or implied. We shall not be

liable for any incidental or consequential damages resulting from any breach of warranty.

Your exclusive remedy for breach of warranty shall be repair or replacement of defective component(s):

Provided, if the component(s) are incapable of being repaired or replaced, your exclusive remedy shall be credit

issued, but such credit shall not exceed the purchase price of the components.

On any claim of any kind, including negligence, our liability for any loss or damage arising out of, or from the

design, manufacture, sale, delivery, resale, installation, technical direction of installation, inspection, repair,

operation of use of any products shall in no case exceed the purchase price allocable to the components.

In no event, whether as a result of breach of contract or warranty or alleged negligence, shall we be liable for

incidental or consequential damages, including, but not limited to: personal injury, loss of profits or revenue,

loss of use of equipment or any associated equipment, cost of capital, cost of substitute equipment, facilities or

services, downtime costs, environmental damage, crop losses, or claims of customers of you for such damages.

What is the period of coverage?

We warrant to you, that our products are free from defects in material and workmanship in normal use and

service for a period of one year from date of purchase.

©

2019 Capstan Ag Systems, Inc. 9 EVO Spray

TM

How do you get service?

Our obligation under this warranty shall be limited to the repairing or replacing at our option, the component

which our inspection discloses to be defective, free of charge, return freight paid by us, provided you: (i) Notify

us of defect within thirty (30) days of failure; (ii) Return the defective component to us, freight prepaid; (iii)

Complete the Owner Registration Form and returned it to us; and (iv) Establish that the product has been

properly installed, maintained and operated in accordance with our instructions or instructions contained in our

operations or maintenance manuals and within the limits of normal usage.

Any claim for breach of our warranty must be in writing addressed to us and must set forth the alleged defect

in sufficient detail to permit its easy identification by us. All breach of warranty claims must be made within

thirty (30) days after expiration of the warranty period which is applicable to the defective product. Any breach

of warranty claim not timely made will not be honored by us and will be of no force and effect. Any component

that needs to be repaired or evaluated for warranty has to be authorized before return. Contact the factory

(785-232-4477) to get a Return Materials Authorization (RMA #). This helps to track the part coming into the

factory for repair or replacement.

Before returning any component to the factory, clean the component as well as possible to remove any dirt or

chemical residue. Components received at the factory that are not clean, will be returned and warranty denied.

After receiving your RMA #, package the part, making sure to include the RMA #, your name, customer’s

name, your address and phone number and description of problems or failure. Then ship to:

Warranty

Capstan Ag Systems, Inc.

Attn: Warranty/Repair

4225 SW Kirklawn Ave.

Topeka, KS 66609

Phone: (785) 232-4477

Fax: (785) 232-7799

Hours: 8 a.m. - 4:30 pm CST

How does state law relate to this Limited Warranty?

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not

apply to you.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

1

1

Rev. Date 7/15/2014

©

2019 Capstan Ag Systems, Inc. 10 EVO Spray

TM

Chapter 4: Installation

Before System Installation

Before assembly and installation, read the installation information carefully. Make sure that you have all of the

parts in the kits. Read all of the instructions in this document, the system operator manual, and the machine

manuals. The system operator manual includes information on operation, adjustments, troubleshooting, and

maintenance.

For further assistance contact your CapstanAG representative.

Tip Selection and Capacities

Installation

Fig. 1:

When selecting the correct tips:

• Always use 110° spray angle tips and maintain the boom height of at least 24 in (61 cm). If 80° spray

angle tips are used, maintain the boom height of at least 36 in (91 cm).

• The tip selection chart, in the operation section of this manual, describes the speed ranges that can be

expected when operating with a rate controller at various rates and pressures.

•

To use the chart, select the application rate (1).

•

Move down the column to the desired speed range (2).

•

Select a tip (3) that provides the boom pressure you wish to spray (4).

©

2019 Capstan Ag Systems, Inc. 11 EVO Spray

TM

Nozzle Types and Component Identification

Important: Make sure that you have the correct nozzles and components for your system.

7-Watt—15 Series Coil Components

Installation

Fig. 2:

Item Description Arag High

Flow Part

Number

1 7-Watt Coil Assembly 116189-111 116189-111 116189-111 116189-111

2 Plunger Assembly 716009-114 716009-114 716009-114 716009-114

3 Inner-valve O-ring 715022-204 715022-204 715022-204 715022-204

4 Flybody 116182-201 116182-001 116186-001 116188-001

5 FlyBody Stem (Tip) O-ring 715022-211 715022-210 715022-210 715022-210

6 Nozzle Body FlyBody O-

ring

©

2019 Capstan Ag Systems, Inc. 12 EVO Spray

715022-212 715022-205 715022-202 715022-206

Arag Part

Number

Tee Jet Part

Number

Wilger Part

Number

TM

12-Watt—24 Series Coil Components

Installation

Fig. 3:

Item Description Arag High

Flow Part

Arag Part

Number

Tee Jet Part

Number

Wilger Part

Number

Number

1 12-Watt Coil Assembly 116189-111 625147-011 625147-011 625147-011

2 Plunger Assembly 716009-114 716009-114 716009-114 716009-114

3 Inner-valve O-Ring 715022-204 715022-204 715022-204 715022-204

4 Flybody 116182-201 116182-002 116186-002 116188-002

5 FlyBody Stem (Tip) O-ring 715022-211 715022-210 715022-210 715022-210

6 Nozzle Body FlyBody O-

715022-212 715022-205 715022-202 715022-206

ring

©

2019 Capstan Ag Systems, Inc. 13 EVO Spray

TM

Assemble the Nozzle Valves

1.

Remove the drip check valve and diaphragm cap from each nozzle body.

Installation

Fig. 4:

2.

Install the O-rings (1) onto the flybody nozzle assembly (2).

3.

Install the nozzle valve assembly onto the nozzle body (3).

4.

Tighten the flybody (4) until the coil housing does not spin.

The nozzle valves only need to be snug to prevent leakage.

5.

Install and tighten the spray tip to a port (5) on the nozzle body.

6.

Repeat steps 1 to 5 for all nozzle valve assemblies.

©

2019 Capstan Ag Systems, Inc. 14 EVO Spray

TM

Move the Spray Tube Mount (Nozzle Valve Interference)

Installation

Fig. 5:

If a spray tube mount (1) prevents nozzle valve installation:

1.

Loosen the spray tube mount bolts (2).

2.

Slide the spray tube mount away from the nozzle valve assembly (3) until the nozzle valve assembly can be

properly installed.

3.

Tighten the spray tube mount bolts.

©

2019 Capstan Ag Systems, Inc. 15 EVO Spray

TM

Install the Nozzle Harnesses and Smart Drivers

Installation

Fig. 6:

Each nozzle harness will have a smart driver already installed.

1.

Put the smart drivers in serial number order with the lowest number to the left side of the machine.

The smart driver serial number (1) is shown on the front of the smart driver.

2.

Route the nozzle harnesses along the boom with the smart driver toward the center of the machine.

Make sure that there is enough slack in the harnesses to raise and lower the booms and to avoid pinch points

at the boom fold and pivot points.

3.

Use cable ties to attach the smart driver and the nozzle harnesses to the machine.

©

2019 Capstan Ag Systems, Inc. 16 EVO Spray

TM

Install the Power to CAN X Harness

Installation

Fig. 7:

1.

Install the power to CAN X harness at the center of the machine.

2.

Use cable ties to attach the harness to the machine.

Install the Pressure Transmitter Module

Fig. 8:

1.

Install the pressure transmitter module (1) to the pressure connector (2) on the power to CAN X harness.

2.

Use cable ties to attach the module to the machine.

©

2019 Capstan Ag Systems, Inc. 17 EVO Spray

TM

Install the Pressure Sensor Adapter Harness

1.

Connect one end of the pressure sensor adapter harness to the pressure transmitter module.

2.

Route the harness to the pressure sensor.

3.

Connect the other end of the harness to the pressure sensor.

Install the Boom Signal Transmitter Module

Installation

Fig. 9:

1.

Install the boom signal transmitter module (1) to the shutoff connector (2) on the power to CAN X harness.

2.

Use cable ties to attach the module to the machine.

Install the Shutoff Adapter

1.

Install one end of the shutoff adapter into the boom signal transmitter module.

2.

Route and connect the other ends of the shutoff adapter as necessary.

©

2019 Capstan Ag Systems, Inc. 18 EVO Spray

TM

Install the CAN Bus Extension Harness

Installation

Fig. 10:

1.

Connect the CAN Bus extension harness (1), of the correct length, to the left boom/left truck connector (2)

on the power to CAN X harness.

2.

Connect the other end of the CAN Bus harness to the smart driver module (3) closest to the center left side

of the machine.

3.

Connect another CAN Bus harness (4), of the correct length, to the other port (5) on the smart driver at the

center left side of the machine.

4.

Route the CAN Bus harness to the next smart driver (6) to the left.

5.

Connect the other end of the harness to the next smart driver.

6.

Continue installing CAN Bus harnesses, of the correct length, until you get to the last smart driver on the left

of the machine.

©

2019 Capstan Ag Systems, Inc. 19 EVO Spray

TM

Fig. 11:

7.

Connect the CAN Bus extension harness (1), of the correct length, to the right boom/right truck connector

(2) on the power to CAN X harness.

8.

Connect the other end of the CAN Bus harness to the smart driver module (3) closest to the center right side

of the machine.

9.

Connect another CAN Bus harness (4), of the correct length, to the other port (5) on the smart driver at the

center right side of the machine.

10.

Route the CAN Bus harness to the next smart driver (6) to the right.

11.

Connect the other end of the harness to the next smart driver.

12.

Continue installing CAN Bus harnesses, of the correct length, until you get to the last smart driver on the

right of the machine.

Installation

©

2019 Capstan Ag Systems, Inc. 20 EVO Spray

TM

Install the CAN Terminator

Installation

Fig. 12:

1.

On the left most smart driver, install a CAN terminator (1) into the open CAN port (2).

2.

On the right most smart driver, install a CAN terminator into the open CAN port.

Install the Pressure Sensor (Optional)

The use of a CapstanAG pressure sensor is optional. The EVO Spray system is designed to integrate with the

existing boom pressure sensor on the machine.

1.

If you want to use the Capstan AG pressure sensor, remove the existing machine pressure sensor from the

boom manifold.

2.

Install the tee fitting and other hardware with sealant tape.

3.

Vertically install the new pressure sensor with sealant tape.

Note: If you must install the pressure sensor horizontally make sure that there is an angle to it to keep liquid

from settling inside the pressure sensor.

Important: Do not over-tighten the pressure sensor when installing into plastic tee fittings.

4.

Install the existing machine pressure sensor with sealant tape.

©

2019 Capstan Ag Systems, Inc. 21 EVO Spray

TM

Install the Cab Display

Installation

Fig. 13:

Mount the cab display (1) in the cab of the machine with the hardware (2) supplied with the kit.

Make sure that the cab display is within view and reach of the operator.

Install the Display Harness and CAN Bus Extension Harness

Fig. 14:

1.

Install one end of the display harness (1) into the connector at the back of the cab display (2).

2.

Route the display harness to the back of the cab of the machine.

3.

Connect the GPS connector (3) to the GPS source.

©

2019 Capstan Ag Systems, Inc. 22 EVO Spray

TM

4.

At the back of the cab, connect the display harness to the CAN Bus extension harness (4).

5.

Route the CAN Bus extension harness to the power to CAN X harness at the back of the machine.

6.

Connect the other end of the CAN Bus extension harness to the display connector (5) on the power to CAN

X harness.

Install the Power Harness

1.

Connect one end of the power harness to the power to CAN X harness.

2.

Route the power harness to the battery.

3.

Connect the battery harness positive (+) red cable to the positive terminal of the battery.

4.

Connect the battery harness negative (-) black cable to the battery ground terminal.

Installation

©

2019 Capstan Ag Systems, Inc. 23 EVO Spray

TM

Installation

©

2019 Capstan Ag Systems, Inc. 24 EVO Spray

TM

Chapter 5: Setup

Cab Display

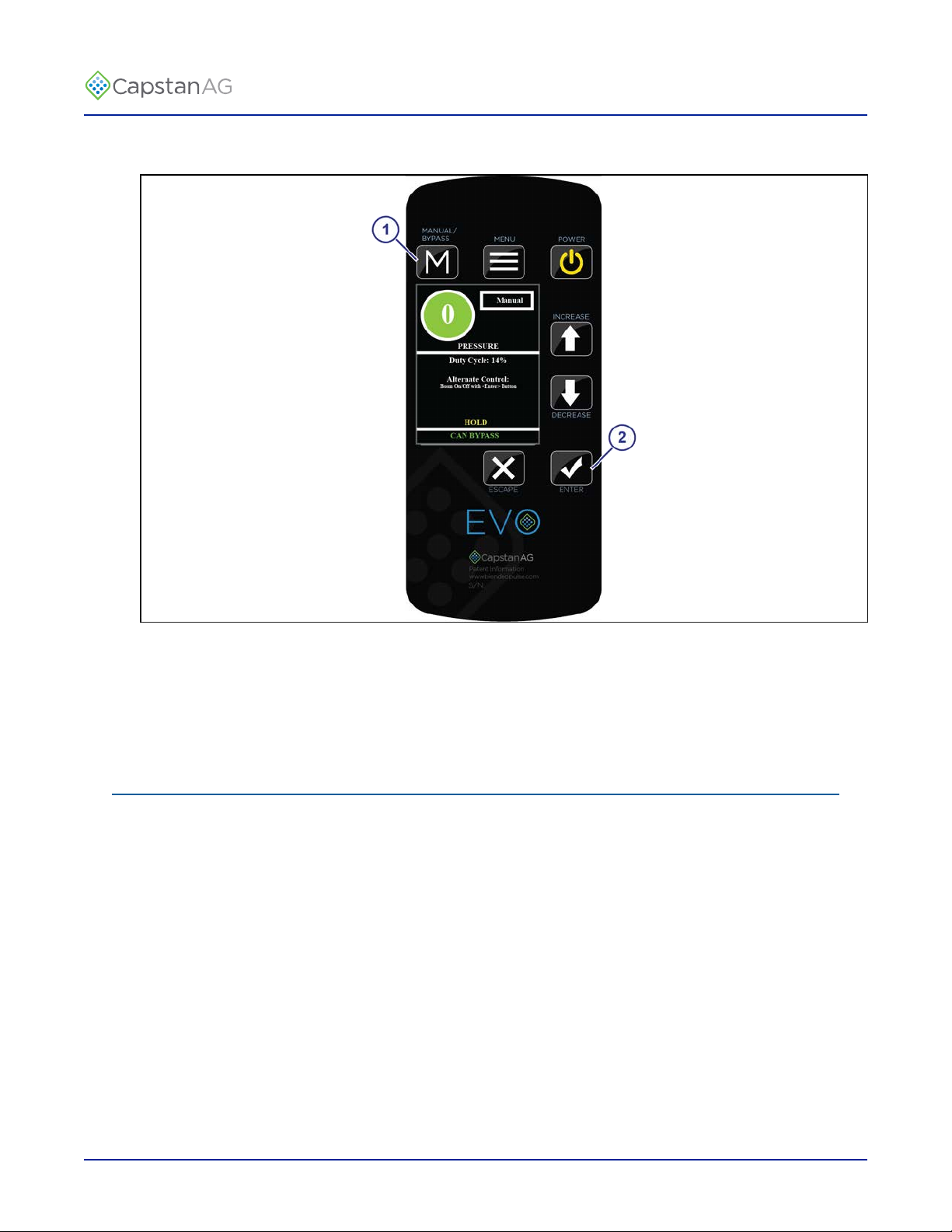

Setup

Fig. 15:

The cab display has seven buttons to navigate and control the system. A screen on the cab display shows

immediate information and gives access to the menu items.

(1)

(2)

(3)

(4)

(5)

(6)

POWER Button—Press to turn on or off the display

MENU Button—Press to see the Main Menu screen

INCREASE and DECREASE Buttons—Press to move through the menu items

ENTER Button—Press to accept changes or go to the next screen

ESCAPE Button—Press to cancel or go back to the previous screen.

MANUAL/BYPASS Button—Press to use the manual operation or bypass mode.

©

2019 Capstan Ag Systems, Inc. 25 EVO Spray

TM

Screen Descriptions

Setup

Fig. 16:

Main Menu

The Main Menu screen (1) includes this information:

1.

Backlight

2.

Alarm Volume

3.

Turn Compensation

4.

Rate Sync

5.

Pressure Increment

6.

Advanced Menu

Backlight

The Change Backlight screen (2) gives choices of the brightness of the LCD screen and light behind the keypad

for low light conditions.

Range: 1 to 5 (Dimmest to Brightest)

When selections 1 or 2 are active (low ambient light conditions) the keypad buttons become back-lit.

Alarm Volume

The Change Alarm Volume screen (3) let you change the volume level of the alarm.

To silence the alarm, select Off.

Range: Off to 5 (Quiet to Loudest)

©

2019 Capstan Ag Systems, Inc. 26 EVO Spray

TM

Turn Compensation

The Turn Compensation screen (4) lets you turn the feature on or off.

Range: Enabled or Disabled

Rate Sync

The Rate Sync screen (5) lets you turn the feature on or off.

Range: On or Off

When the feature is on the range is 5 Hz to 10 Hz.

Rate Sync™ uses real time speed change to determine the proper duty cycle for the appropriate boom section. It

is used to make the system react faster to speed changes.

Setup

Note: A 5 Hz GPS connection is required for Rate Sync™ to operate properly. If a 5 Hz GPS signal is not

available, the Rate Sync

™

feature should be set to Off.

Rate Sync™ turned off disables speed change corrections. GPS connection is not needed with the Rate Sync

feature set to Off.

Pressure Increment

The Pressure Increment screen (7) lets you change pressure increment per toggle of the INCREASE or

DECREASE button.

Range: 1 to 10

™

©

2019 Capstan Ag Systems, Inc. 27 EVO Spray

TM

Advanced Menu

The Advanced Menu screens include this information:

Setup

Fig. 17:

System Gain

The System Gain screen (1) lets you make changes to the system pressure control.

Range: 1 to 20

System Gain is the first pressure control parameter in the display menu system. System Gain changes the total

response of system according to the same ratio between the individual P Gain and I Gain values. It is the first

menu item to utilize when tuning the pressure control.

Increasing the System Gain makes the system react faster to pressure changes.

Decreasing the System Gain makes system react slower to pressure changes.

P Gain

The P Gain screen (2) lets you change the value.

Range: 2.00 to 8.5

P (Proportional) gain is the second pressure tuning parameter in the display menu. Proportional gain determines

the initial speed at which display drives the duty cycle toward the target value. Stabilize an oscillating system by

selecting a lower number. Speed up a sluggish system by selecting a higher number.

©

2019 Capstan Ag Systems, Inc. 28 EVO Spray

TM

I Gain

The I Gain screen (3) lets you change the value.

Range: 0.05 to 0.35

I (Integral) Gain, the third pressure tuning parameter in the display, determines the acceleration driving duty

cycle to the target value. To stabilize an oscillating system, use a lower number. To speed up a sluggish system,

use a higher number.

Run/Hold Delay

The Run/Hold Delay screen (4) lets you change the delay when the display starts at a preset value (50% or the

last known duty cycle) allowing the rate controller to stabilize before making larger pressure control changes.

Range: 0 to 6

When the boom is turned on and the run/hold signal is returned, the display will begin to control pressure by

first resuming the pulsing at the previous duty cycle before the boom was shutoff.

The Hold will show in the Diagnostics area on the main operating screen, to alert the operator that the

initialization delay has been activated.

The start-up delay time is equal to the run/hold delay time. This allows the flow control system to resume

control and attain rate stability. Once the delay period has elapsed, the display will resume pressure control.

Setup

The diagnostic readout area will read Hold and count down the seconds to alert the operator that the Run/Hold

Delay has been activated. When the hold count down is finished, the display will read Run in diagnostics area.

At this point, the display is controlling pressure once again.

Low Pressure Shutoff

The Low Pressure Shutoff screen (5) lets you change when the system turns off the nozzle valves when the

pressure decreases.

Range: Off or 8 psi

This feature is intended to duplicate the effect of the nozzle drip checks found on sprayers. To alert the operator

that the low pressure shutoff feature has been activated, low PSI shutoff will appear in the diagnostic readout

area.

When the pressure rises above 12 PSI again, the display will pulse at 50% duty cycle for the start-up delay

period and then will resume pressure control.

When set to Off, the display will maintain a minimum duty cycle percentage, equal to the pulse frequency,

regardless of either low or zero pressure.

Pwm Frequency

The Pwm Frequency screen (6) lets you change the value.

Range: 3 to 30 Hz

CapstanAG does not recommend pulse frequencies slower than 10 Hz in sprayer applications.

©

2019 Capstan Ag Systems, Inc. 29 EVO Spray

TM

Setup

Fig. 18:

Units

The Units screen (1) lets you change the units of measure.

Range: US, SI

Nozzle Spacing

The Nozzle Spacing screen (2) lets you change the system nozzle spacing.

Range: 10 to 40

Module Location

The Module Location screen (3) lets you see smart driver module location and information and change the

order if necessary.

To change the order follow the prompts on the display.

Note: The smart driver module location must be correct for the sections to operate in the correct order.

Section Size

The Section Size screen (4) lets you change the number of nozzles per section.

The correct number of nozzles for each section must be entered manually for the system to operate correctly.

This feature lets the nozzles on a specific section turn on, and for accurate turn compensation.

Note: The section size programming must be done after doing the module location setup.

Low Flow Menu

The Low Flow Menu (5) is for use with the John Deere R Series Sprayers only. See a CapstanAG representative

for more information.

©

2019 Capstan Ag Systems, Inc. 30 EVO Spray

TM

Setup

Fig. 19:

Pressure Sensor Menu

Select the Pressure Sensor Menu (1) to see the Pressure Sensor screen (2).

Sensor Offset

The Sensor Offset screen (3) lets you manipulate this setting if a difference in the pressure is noticed across

separate pressure sensors, such as between the display pressure reading and the rate controller pressure display

from a secondary pressure sensor.

Range: -10 to 10

Note: The system requires a greater quality pressure sensor relative to pressure sensors which only report a

screen value. In most cases, the adjustment will be correcting the value to the least accurate sensor.

Sensor volt min

The Sensor volt min screen (4) lets you change the minimum voltage of the pressure sensor.

Range: 0.5 to 1.0

If you are using a CapstanAG™ pressure sensor leave the default value of 0.5. Change the value as needed if

you are using another type of pressure sensor.

Sensor volt max

The Sensor volt max screen (5) lets you change the maximum voltage of the pressure sensor.

Range: 4.5 to 5.0

Sensor pressure max

The Sensor pressure max screen (6) lets you change the maximum pressure of the pressure sensor.

Range: 50 to 250

©

2019 Capstan Ag Systems, Inc. 31 EVO Spray

TM

Diagnostics

Fig. 20:

The Diagnostics screen (1) shows system information that is useful for troubleshooting and/or diagnostics.

Odd/Even test is the one menu line a person can enter and utilize in this Diagnostic page. Do the Odd/Even Test

for setup and troubleshooting.

Setup

Driver Module LED Identification

Fig. 21:

The system will have several smart driver modules (1). Each module has 3 LEDs:

(2)

(3)

Green—Power

Solid Illumination—12 V

Blue—CAN

Blinking Illumination—5 Hz

(4)

©

2019 Capstan Ag Systems, Inc. 32 EVO Spray

Red—Duty Cycle/Frequency Feedback

Blinking Illumination—5 Hz

TM

The system will have one pressure transmitter module (5) and one boom signal transmitter module (6). Each

module has 3 LEDs:

Setup

(7)

(8)

(9)

Green—Power

Solid Illumination—12 V

Blue—CAN

Blinking Illumination—5 Hz

Red—Feedback Information

Blinking Illumination—5 Hz

Start the Cab Display

Fig. 22:

1.

Start the machine.

2.

Press the POWER button (1) on the cab display.

3.

Set the desired pressure on the cab display.

4.

Start the rate controller, if necessary.

5.

Make sure that the rate settings are correct on the rate controller.

6.

Turn on the boom sections to spray.

Shutdown the Cab Display

1.

Turn off the boom sections.

2.

Press the POWER button on the cab display.

3.

Turn off the machine.

©

2019 Capstan Ag Systems, Inc. 33 EVO Spray

TM

Change the Units of Measure

Setup

Fig. 23:

1.

Press the MENU button (1).

2.

Use the UP or DOWN arrow buttons (2) to select Advanced Menu (3) from the Main Menu.

3.

Press the ENTER button (4).

4.

Use the UP or DOWN arrow buttons to select Units (5) from the Advanced Menu.

5.

Press the ENTER button.

6.

Use the UP or DOWN arrow buttons to select the desired units of measure (6) on the Units screen.

7.

When the desired unit of measure is highlighted, press the ENTER button.

©

2019 Capstan Ag Systems, Inc. 34 EVO Spray

TM

Do the Odd/Even Test

Testing with Odd/Even test will actuate only the odd valves then only the even valves.

Setup

Fig. 24:

1.

Press the MENU button (1).

2.

Use the UP or DOWN arrow buttons (2) to select Advanced Menu (3) from the Main Menu.

3.

Press the ENTER button (4).

4.

Use the UP or DOWN arrow buttons to select Diagnostics (5) from the Advanced Menu.

5.

Press the ENTER button.

6.

Use the UP or DOWN arrow buttons to select Odd/Even Test (6) from the Diagnostics screen.

7.

Press the ENTER button.

8.

Use the UP or DOWN arrow buttons to select Odd (7) from the Selection list on the Odd/Even Test screen.

9.

Press the ENTER button.

10.

Make sure that all of the odd nozzles are operating.

Note: If two adjacent nozzles are pulsing, one nozzle must be moved to skip a connector on the harness.

11.

Use the UP or DOWN arrow buttons to select Even (8) from the Selection list on the Odd/Even Test

screen.

12.

Press the ENTER button.

13.

Make sure that all of the even nozzles are operating.

Note: If two adjacent nozzles are pulsing, one nozzle must be moved to skip a connector on the harness.

14.

Use the UP or DOWN arrow buttons to select Disabled (9) from the Selection list on the Odd/Even Test

screen.

15.

Press the ESCAPE button (10) to exit the Odd/Even Test screen.

©

2019 Capstan Ag Systems, Inc. 35 EVO Spray

TM

Nozzle Speed Ranges

US Measurements Nozzle Speed Ranges

Nozzle Spacing—15 in

Setup

©

2019 Capstan Ag Systems, Inc. 36 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 37 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 38 EVO Spray

TM

Nozzle Spacing—20 in

Setup

©

2019 Capstan Ag Systems, Inc. 39 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 40 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 41 EVO Spray

TM

Blended Pulse™ Droplet Classification Table-US Measurements

Setup

©

2019 Capstan Ag Systems, Inc. 42 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 43 EVO Spray

TM

Metric Nozzle Speed Ranges

Nozzle Spacing—38 cm

Setup

©

2019 Capstan Ag Systems, Inc. 44 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 45 EVO Spray

TM

Nozzle Spacing—50 cm

Setup

©

2019 Capstan Ag Systems, Inc. 46 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 47 EVO Spray

TM

Blended Pulse™ Droplet Classification Table-Metric

Setup

©

2019 Capstan Ag Systems, Inc. 48 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 49 EVO Spray

TM

Setup

©

2019 Capstan Ag Systems, Inc. 50 EVO Spray

TM

Chapter 6: Operation

Start the Cab Display

Operation

Fig. 25:

1.

Start the machine.

2.

Press the POWER button (1) on the cab display.

3.

Set the desired pressure on the cab display.

4.

Start the rate controller, if necessary.

5.

Make sure that the rate settings are correct on the rate controller.

6.

Turn on the boom sections to spray.

Shutdown the Cab Display

1.

Turn off the boom sections.

2.

Press the POWER button on the cab display.

3.

Turn off the machine.

Manual Mode Operation

Manual mode is usually used for troubleshooting purposes, should the operator encounter rate or pressure

instability issues while spraying. Switching to manual mode could allow the operator to finish a field or job

before contacting the dealer to solve the problem.

Manual mode will keep the nozzle valves at a constant duty cycle, which is useful when optimizing rate

controller tuning.

©

2019 Capstan Ag Systems, Inc. 51 EVO Spray

TM

Operation

Fig. 26:

Press the MANUAL/BYPASS button (1) to enter manual mode operation.

Use the UP or DOWN arrows (2) to control the nozzle duty cycle, regardless of the pressure sensor reading or

target pressure set point.

©

2019 Capstan Ag Systems, Inc. 52 EVO Spray

TM

ByPass Mode

Operation

Fig. 27:

To enter into bypass mode, press and hold the MANUAL/BYPASS (1).

Press the ENTER button (2) to turn the booms on and off.

ByPass Mode provides a way to continue operation without CAN Communication.

Shutdown the Cab Display

1.

Turn off the boom sections.

2.

Press the POWER button on the cab display.

3.

Turn off the machine.

©

2019 Capstan Ag Systems, Inc. 53 EVO Spray

TM

Operation

©

2019 Capstan Ag Systems, Inc. 54 EVO Spray

TM

Chapter 7: Maintenance

Service the System

CAUTION: Before operation or service to the system, read and understand the machine’s operator

manual and the system operator manual. Chemical residue may be present on/in the OEM equipment.

Use the correct personal protective equipment.

Before servicing the system or plumbing components, release the pressure and empty any product from the

system and liquid delivery lines.

Jump Start, Weld On, or Charge the Machine

If jump starting the machine, make sure that you trip the circuit breaker to prevent damage to the system.

If charging the machine’s batteries or welding on the machine, trip the circuit breaker.

Inspect the System

• Inspect the hoses for cuts, nicks, or abrasions before each use. Replace any damaged hoses immediately.

• Make sure that the strainers are clean.

• Make sure that all hoses and wiring are secure.

• Do a check for loose hoses, mounting hardware, and other components. Tighten if necessary.

• Do a check for damaged or missing decals. Replace if necessary.

Maintenance

Clean the System

• Thoroughly clean the system after each use.

• Avoid high-pressure spray when cleaning the spray system components, valves, and wiring connectors.

Storage of the System

Thoroughly clean the implement and the system before any long storage.

Winterize for Storage

Do not use fertilizer to winterize! The use of fertilizer to winterize will cause internal damage to the nozzle

valves.

Thoroughly clean the spray system before winter storage.

Flush the spray system with clean water.

Winterize the spray system with RV antifreeze for winter storage. Proper winterizing of the machine with a

CapstanAG system installed on it is essential. Make sure that the booms are completely full of antifreeze at

100% strength and that the solenoids are pulsed (sprayed) for a few minutes to make sure that the antifreeze

remaining in the solenoids is at full strength.

©

2019 Capstan Ag Systems, Inc. 55 EVO Spray

TM

Recommended Guidelines for Maintenance/Service

When servicing a system, CapstanAG recommends doing these:

• Do the baseline service checks and verify the original setup values in this manual.

• Identify individual performance problems. Evaluate possible causes and corrections for performance

issues.

• Troubleshoot individual components and replace if needed.

Important: The primary service tool will be a multimeter that can measure voltage and resistance (ohms).

Baseline Evaluation Process

1.

Make sure that the voltage readings are correct.

2.

Do a visual check of all wire connections, harnesses, and connectors. Make sure that there are no loose,

broken, or damaged parts.

3.

Make sure that the correct tip size is used for the application.

4.

Make sure that the liquid product plumbing and the strainer(s) are clean.

5.

Do a like component swap test to see if the failure follows the component.

6.

Repair or replace any damaged components.

7.

Do the system tests.

Maintenance

See the system testing information in this manual.

Nozzle Valves

Plugged nozzle valves can be classified into two categories:

• Plunger blockage

• Plunger stuck

Plunger blockage results when larger debris catches between the orifice and plunger seal. This is the smallest

flow passage within the nozzle valve.

Stuck plungers result when smaller debris collects around the barrel of the plunger and binds the plunger in

place. Symptoms of a blocked or stuck plunger are:

• Constant application

• Leaking when the nozzle is shut off

• No application

Note: Pinched or split O-rings will also cause nozzles to drip when shutoff.

Note: Operating a plugged nozzle valve for extended periods of time may result in a nozzle valve coil failure.

Immediately clean any plugged nozzle valves.

©

2019 Capstan Ag Systems, Inc. 56 EVO Spray

TM

Clean the Nozzle Valve(s)

Warning: Chemical residues may be present in the agricultural equipment. Always use the proper

personal equipment to avoid personal injury.

1.

Release pressure from the system before servicing.

2.

Clean the system before installation or service of the fittings, hoses, valves, or nozzles.

Fig. 28:

3.

Use pliers around the flybody (1) to hold the assembly with the coil harness facing the ground.

4.

Rotate the coil (2) counter-clockwise to remove the coil from the valve body.

5.

Remove the plunger (3) from the coil.

6.

Inspect the O-ring (4) on the coil.

7.

Inspect the O-rings (5) on the flybody.

8.

Wash the nozzle valve components to remove any debris.

9.

Inspect the plunger for wear or damage.

10.

If there is wear or damage to the plunger, replace the plunger.

11.

Inspect the flybody.

Make sure that the orifice is not plugged with debris, worn, or damaged.

12.

If there is wear or damage to the orifice, replace the flybody.

13.

Wash the nozzle body components to remove any debris.

Maintenance

Important: Do not use brake cleaner. Brake cleaner can damage the seal.

Important: During installation, apply 40 lbf in of torque to the coil when it threads into the valve body to

properly seat the O-ring.

©

2019 Capstan Ag Systems, Inc. 57 EVO Spray

TM

Plunger Seal Inspection

Maintenance

Fig. 29:

After extended use, the plunger seal will wear a groove (1) where the seal impacts the hard orifice seat. Replace

plunger if worn or damaged.

As the groove deepens the pressure capacity of the valve will decrease until the pressure capacity interferes with

the operating pressure of the system.

The result is erratic pulsing, often described as “flickering.” The system will operate normally at lower

pressures until replacement parts can be installed. High operating pressures and abrasive chemicals will

accelerate the wear of the plunger seal material.

©

2019 Capstan Ag Systems, Inc. 58 EVO Spray

TM

Fig. 30:

Maintenance

When replacement of the plunger is necessary, make sure that you have the correct plunger:

(1)

(2)

(3)

Standard Flow—4 slots on the outside

Standard Flow—2 slots on the outside

Heavy Flow—The spring (4) on the plunger has a larger diameter than the spring on the standard

valve plunger.

Make sure that the plunger seats are still smooth and not pitted.

(1)

(2)

A plunger seat on a new valve body

Examples of a worn plunger seat on a valve body

©

2019 Capstan Ag Systems, Inc. 59 EVO Spray

TM

Maintenance

©

2019 Capstan Ag Systems, Inc. 60 EVO Spray

TM

Chapter 8: Schematics

System Layout

Schematics

Fig. 31:

Callout Description Callout Description

(1)

(2)

(3)

(4)

(5)

(6)

(7)

©

2019 Capstan Ag Systems, Inc. 61 EVO Spray

Power to CAN X Harness

CAN Bus Extension Harness

Display Harness

Cab Display

Power Harness

Pressure Transmitter Module

Pressure Sensor Adapter Harness

(8)

(9)

(10)

(11)

(12)

(13)

(14)

Boom Signal Transmitter Module

CAN Bus Extension Harness (Plug to

Plug)

Smart Driver Module

CAN Terminator

Nozzle Harness

Nozzle Valve Assembly

Boom Shutoff Adapter

TM

Display Harness

Fig. 32:

Table: Display Connector (1) Pinout—12-pin DT Plug

Pin Description Color Pin Description Color

1 Power with Fuse Red 7 GPS Rx Black/White

2 Ground Black 8 Plug

Schematics

3 Synch Blue 9 GPS Ground Blue/White

4 CAN Hi Yellow 10 Plug

5 CAN Lo Green 11 Plug

6 AI Ground Brown 12 Plug

5 A Fuse (2).

Table: GPS Connector (3) Pinout—DB9 Male Connector

Pin Description Color Pin Description Color

1 6

2 GPS Rx Black/White 7

3 8

4 9

5 GPS Ground Blue/White

Table: CAN Extension Harness Connector (4) Pinout—6-pin DT Receptacle

Pin Description Color Pin Description Color

1 Power Red 4 CAN Hi Yellow

2 Ground Black 5 CAN Lo Green

3 Synch Blue 6 AI Ground Brown

©

2019 Capstan Ag Systems, Inc. 62 EVO Spray

TM

Power Harness

Fig. 33:

Schematics

(1)

(2)

(3)

Battery Power Positive (+) Ring Terminal

20 A Fuse

Battery Ground Negative (-) Ring Terminal

Table: Power Harness Connector (4) Pinout—4-pin WP Shroud

Pin Description Color Pin Description Color

A Power Red C Ground Black

B Power Red D Ground Black

©

2019 Capstan Ag Systems, Inc. 63 EVO Spray

TM

Power Extension Harness

Fig. 34:

Table: Power Harness Connector (1) Pinout—4-pin WP Tower

Pin Description Color Pin Description Color

A Power Red C Ground Black

B Power Red D Ground Black

Table: Power to CAN Extension Harness Connector (2) Pinout—4-pin WP Shroud

Schematics

Pin Description Color Pin Description Color

A Power Red C Ground Black

B Power Red D Ground Black

©

2019 Capstan Ag Systems, Inc. 64 EVO Spray

TM

CAN Bus Extension Harness

Fig. 35:

Table: Extension Connector (1) Pinout—6-pin DT Receptacle

Pin Description Color Pin Description Color

1 Power Red 4 CAN Hi Yellow

2 Ground Black 5 CAN Lo Green

3 Synch Blue 6 AI Ground Brown

Table: Extension Connector (1) Pinout—6-pin DT Receptacle

Schematics

Pin Description Color Pin Description Color

1 Power Red 4 CAN Hi Yellow

2 Ground Black 5 CAN Lo Green

3 Synch Blue 6 AI Ground Brown

©

2019 Capstan Ag Systems, Inc. 65 EVO Spray

TM

Power to CAN X Harness

Schematics

Fig. 36:

Table: PSI Module/Right Trunk Connector (1)—6-pin DT Plug

Pin Description Color Pin Description Color

1 Power (Right) Red 4 CAN Hi Yellow

2 Ground (Right) Black 5 CAN Lo Green

3 Synch Blue 6 AI Ground Brown

Table: Section Shutoff Module/Right Trunk Connector (2)—6-pin DT Plug

Pin Description Color Pin Description Color

1 Power (Right) Red 4 CAN Hi Yellow

2 Ground (Right) Black 5 CAN Lo Green

3 Synch Blue 6 AI Ground Brown

Table: Right Boom/Right Trunk Connector (3)—6-pin DT Receptacle

Pin Description Color Pin Description Color

1 Power (Right) Red 4 CAN Hi Yellow

2 Ground (Right) Black 5 CAN Lo Green

3 Synch Blue 6 AI Ground Brown

©

2019 Capstan Ag Systems, Inc. 66 EVO Spray

TM

Table: Left Boom/Left Trunk Connector (4)—6-pin DT Receptacle

Pin Description Color Pin Description Color

1 Power (Left) Red 4 CAN Hi Yellow

2 Ground (Left) Black 5 CAN Lo Green

3 Synch Blue 6 AI Ground Brown

Table: Display/Left Trunk Connector (5)—6-pin DT Receptacle

Pin Description Color Pin Description Color

1 Power (Left) Red 4 CAN Hi Yellow

2 Ground (Left) Black 5 CAN Lo Green

3 Synch Blue 6 AI Ground Brown

Table: Power Harness Connector (6) Pinout—4-pin WP Tower

Pin Description Color Pin Description Color

Schematics

A Power (Left) Red C Ground (Left) Black

B Power (Right) Red D Ground (Right) Black

©

2019 Capstan Ag Systems, Inc. 67 EVO Spray

TM

Nozzle Harness

Fig. 37:

The nozzle harnesses can have two, four, or eight connectors for the nozzles.

Note: A four nozzle harness is shown.

Table: Smart Valve Driver Connector (1) Pinout—3-pin WP Tower

Pin Description Color Pin Description Color

A Power Red C Odd White

Schematics

B Even Green

Table: Nozzle Valve Connector (2) Pinout—2-pin WP Shroud

Pin Description Color Pin Description Color

A Power Red B Odd White

Table: Nozzle Valve Connector (3) Pinout—2-pin WP Shroud

Pin Description Color Pin Description Color

A Power Red B Even Green

Table: Nozzle Harness Connector (4) Pinout—3-pin WP Shroud

Pin Description Color Pin Description Color

A Power Red C Odd White

B Even Green

©

2019 Capstan Ag Systems, Inc. 68 EVO Spray

TM

Schematics

Fig. 38:

When necessary there is a 1x20 nozzle harness available that can be connected to the end of the other nozzle

harnesses.

Table: Nozzle Harness Connector (1) Pinout—3-pin WP Tower

Pin Description Color Pin Description Color

A Power Red C Odd White

Table: Nozzle Valve Connector (2) Pinout—2-pin WP Shroud

Pin Description Color Pin Description Color

A Power Red B Odd White

©

2019 Capstan Ag Systems, Inc. 69 EVO Spray

TM

Schematics

©

2019 Capstan Ag Systems, Inc. 70 EVO Spray

TM

Chapter 9: Troubleshooting

Troubleshooting Charts

When troubleshooting the EVO™ system start with these:

1.

Use the battery harness fuses to isolate half of the system. This will help focus on the half of the system

that has the issue. The fuse located on the left trunk corresponds to the power to CAN X harness left trunk

connections.

2.

When there is a CAN issue, isolate half of the system to start looking for the issue by disconnecting the left

or right trunk connection.

3.

Once the side of the system has been determined (left or right trunk), use the daisy chain of CAN extension

harnesses to finish isolating the issue. Disconnect the connections except for the center module and harness.

Start connecting the modules back together one at a time until the error shows again. When the error shows

again, you have found the section with the problem.

Problem Cause Correction

Troubleshooting

CAN Bypass Mode The CAN Bus is experiencing issues. This

is an alternative control mode that allows

the operator to use manual PWM spray

mode to complete the current job before

locating and solving the issue.

CAN Bus Off The CAN Bus is experiencing issues.

Follow the on-screen prompts to utilize an

alternate PWM spray mode to complete

the current job before locating and solving

the issue.

No CAN: Alt Control The CAN Bus is experiencing issues. This

is an alternative control mode that allows

the operator to use manual PWM spray

mode to complete the current job before

locating and solving the issue.

No Bm Sig Module The boom signal transmitter module is not

on the CAN Bus.

Use the LEDs on the system modules to

locate the area of the issue.

Find and repair the CAN issue.

Use the LEDs on the system modules to

locate the area of the issue.

Find and repair the CAN issue.

Connect the modules and set up system.No CAN Modules Modules are not on the CAN Bus.

Use the LEDs on the system modules to

locate the area of the issue.

Use the LEDs on the system modules to

locate the area of the issue.

Find and repair the CAN issue.

Connect the boom signal transmitter

module.

Find and repair wiring issue.

No Bm Sig: Alt

Control

©

2019 Capstan Ag Systems, Inc. 71 EVO Spray

The boom signal transmitter module is not

on the CAN Bus. This is an alternative

control mode that allows the operator to

use manual PWM spray mode to complete

the current job before locating and solving

the issue.

Connect the boom signal transmitter

module.

Find and repair wiring issue.

TM

Problem Cause Correction

Troubleshooting

No Psi Trans Module The pressure transmitter module is not on

the CAN Bus.

Connect the pressure transmitter

module.

Find and repair wiring issue. Use the

LEDs on the system modules to locate

the area of the issue.

No Pump Module Pump Module is not on the CAN Bus. The pressure transmitter module is

plugged. Find and repair the CAN

issue. Use the LEDs on the system

modules to locate the area of the issue.

Missing Sm Driver

Mod

One of the smart driver modules is not on

the CAN Bus.

Connect the smart driver module.

Go to the system setup screen and make

sure the information is correct.

Use the LEDs on the system modules to

locate the area of the issue.

Find and repair the CAN issue.

CAN Bus Error The CAN Bus is experiencing issues.

Find and repair the CAN issue.

Follow the on-screen prompts to use an

alternate PWM spray mode to complete

the current job before locating and solving

the issue.

New Sm Driver Mod A new smart driver module has been

connected to the system.

Do the module location and section size

setup procedures.

Sm Driver Init Smart Driver Module initialization Do the module location and section size

setup procedures.

Pressure Sensor Fail The pressure sensor is experiencing issues. Find the pressure sensor error and

repair or replace as needed

Pressure Sensor 2 Fail The pressure sensor is experiencing issues. Find the pressure sensor error and

repair or replace as needed

The tank is empty. Fill the tankLow Pressure

The nozzle valves are closed to keep pump

from running dry.

Increase the pressure above 12 psi and

error will clear

Maximum Duty Shows when the maximum duty cycle value is experienced

Minimum Duty Shows when the minimum duty cycle value is experienced.

Low Flow Control Incorrect low flow threshold Do a check of the low flow threshold

and adjust as needed

©

2019 Capstan Ag Systems, Inc. 72 EVO Spray

TM

Problem Cause Correction

Troubleshooting

No GPS Signal

GPS messages are being received but are

empty

Wait for the GPS antenna to acquire

satellites

Faulty GPS antenna Replace the GPS antenna

Faulty GPS receiver Replace the GPS receiver

Incorrect GPS settings Wait 10 seconds while the GPS verifies

itself. Change GPS receiver baud rate

setting 19200 to 115200

No GPS VTG Incorrect GPS settings Change the VTG message rate to at

least 10 Hz on the GPS receiver

Note: 5 Hz will work for this system if

your antenna cannot export 10 Hz.

No GPS GGA Incorrect GPS settings Change the GGA message rate to at

least 10 Hz on the GPS receiver

Note: 5 Hz will work for this system if

your antenna cannot export 10 Hz.

Sync Line Fail An issue has occurred with the Sync line

(pin 3 in your 6p DT connection points).

Find the Sync Line failure by separating

left and right trunk issue(s). Then

disconnecting the daisy chained CAN

extension harness connections until the

issue is found.

Sm Driver Mod Error The smart driver module is experiencing

issues.

Find the smart driver module error

by seperating the left and right trunk

issue(s). Then disconnecting the

daisy chained CAN extension harness

connections until the issue is found.

©

2019 Capstan Ag Systems, Inc. 73 EVO Spray

TM

Problem Cause Correction

Troubleshooting

Under application of

product.

Over application

Plugged nozzle valves. Clean or replace the nozzle valves.

Plugged filter(s). Clean or replace the filter(s).

Filter(s) not installed correctly. Check all filters for correct installation.

Plugged, kinked, or collapsed

hoses.

Product supply valve not fully

Do a check of all the hoses and replace as

needed.

Open the supply valve fully.

open.

Outrunning system capability. Slow down.

Incorrect rate settings. Do a check of the rate settings and adjust as

necessary.

Incorrect calibration settings. Do a check of the calibration settings and

adjust as necessary.

Faulty radar. Replace the radar.

Poor GPS satellite signal. Verify that the GPS is working correctly.

Flow meter cal # incorrect. Do a check of the flow meter calibration.

Faulty module. Replace the module.

Worn nozzle valves. Replace the nozzle valves.

Rate instability

Rate instability continued

Speed too slow. Increase the speed.

Incorrect rate settings. Do a check of the rate settings and adjust as

necessary.

Incorrect calibration settings. Do a check of the calibration settings and

adjust as necessary.

Flow meter cal # incorrect. Do a check of the flow meter calibration.

Faulty flow meter module. Repair or replace the flow meter module.

Faulty rate controller. Replace the rate controller.

Faulty module. Do a check of the module and replace if

needed.

Faulty speed sensor reading. Do a check of the radar and replace if

needed.

Collapsed supply hose. Replace the supply hose.

Strainer(s) plugged. Do a check of the strainer(s) and clean if

needed.

Incorrect valve calibration

settings.

Do a check of the valve calibration settings,

and adjust as necessary (See the rate

controller’s manual).

Faulty rate controller. Replace the rate controller.

Low voltage to rate controller. Do a test of the voltage and repair as needed.

©

2019 Capstan Ag Systems, Inc. 74 EVO Spray

TM

Problem Cause Correction

Troubleshooting

Single nozzle leaks when

shutoff.

Single nozzle valve

operates erratically.

Orifice is lodged with debris. Clean the nozzle valve.

O-ring pinched or broken. Replace the O-ring.

Orifice is worn or damaged. Replace the valve body.

Plunger is lodged with debris. Clean the nozzle valve.

Plunger is worn or damaged. Replace the plunger.

Nozzle valve is faulty. Service the nozzle valve.

©

2019 Capstan Ag Systems, Inc. 75 EVO Spray

TM

Interchangeable Components

The system includes a number of multiple parts:

• Nozzle valves

• Boom and extension harnesses

• Electronic control modules

When troubleshooting failed components, it can be helpful to replace the failed part with a working part at

another location. If the problem follows the failed part to the new location, repair or replace the failed part.

If the problem does not follow the failed part, then the problem is likely elsewhere in the system, and other

troubleshooting means may be followed.

Note: Use caution when interchanging failed components as in rare cases the failed component may cause

other components to fail at the new location.

Coil Test

Coil failures are often the result of two factors:

• Extended valve use with a plugged nozzle

• Extended use in corrosive environments

Troubleshooting

Recommendation: Clean any plugged nozzle valves immediately.

Recommendation: Rinse the inside of the booms, and wash the outside of the coils with clean water as often

as practical.

Use a voltmeter to measure the ohms of resistance across pins A and B on the coil connector.

Notice:

Correct resistance is:

• 7-watt coils resistance—21 ohms to 23.5 ohms

• 12-watt coils resistance—10 ohms to 11.5 ohms

If correct resistance is not found:

• Clean the connector terminals and retest

• Replace the coil

©

2019 Capstan Ag Systems, Inc. 76 EVO Spray

TM

Battery Voltage Test

Troubleshooting

Fig. 39:

Disconnect the display harness (12-pin connector) on the back of the cab display.

• With the engine of the machine running, use a voltmeter to observe that there is a 13.5 VDC between pin

1 and pin 2.

• With the engine of the machine off, there is a 12.0 VDC between pin 1 and pin 2.

Make sure that the polarity is accurate by looking at the positive voltage when the red (positive) probe is

connected to pin 1, and the black (negative) probe is connected to pin 2.

If there is no voltage present between pin 1 and pin 2, do a check of:

• The 5 A in-line Fuse on the pin 1 battery wire.

• The 2 (20 A fuses) located next to the battery connection point.

• The system battery harness connections.

• The condition of the battery and the alternator.

©

2019 Capstan Ag Systems, Inc. 77 EVO Spray

TM

Do a Check of the System Load Capacity

1.

Start the engine of the machine.

2.

Turn on the cab display and all of the boom sections.

3.

Turn on all of the electrical loads, including the air conditioning, foam marker monitors, etc.

4.

See what the voltage readout on the cab display is on the Diagnostics screen.