Page 1

CS8100 Spray System

Owner’s Manual • Notice d’utilisation • Manual del Propietario

Model No. 0277030

CAPSpray

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

0800 © 2000 SprayTECH Corporation. All rights reserved.Form No. 0277747E

EnglishFrançaisEspañol

Page 2

Table of Contents

Safety ...................................................................................2–3

Grounding Instructions ..........................................................3

Service .....................................................................................3

Introduction .............................................................................3

Using an HVLP Spray System ............................................3-4

Setup .....................................................................................3

Dual Filtration System ...........................................................4

Maintenance ............................................................................4

Cleaning/Replacing Filters.....................................................4

Replacing a Fuse ..................................................................4

Troubleshooting......................................................................5

Parts List..........................................................................14–15

Français ...................................................................................6

Español ..................................................................................10

Warranty.................................................................................16

Safety

This manual contains information that must be read and

understood before using the equipment. When you come to

an area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

WARNING

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information will

follow.

CAUTION

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information that should

be given special attention.

WARNING

HAZARD: EXPLOSION OR FIRE - Solvent and paint fumes

can explode or ignite. Severe injury and/or

property damage can occur.

PREVENTION:

• Provide extensive exhaust and fresh air introduction to

keep the air within the spray area free from accumulation

of flammable vapors.

• Avoid all ignition sources such as static electric sparks,

open flames, pilot lights, and hot objects. Connecting or

disconnecting power cords or working light switches can

make sparks.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Place turbine at a minimum of 3 feet (preferably more)

into a separate, well ventilated room from the spray object

or at least 20 feet from the spray object in a well

ventilated area. Flammable vapors are often heavier than

air. Floor area must be extremely well ventilated. The

turbine contains arcing parts that emit spark and can

ignite vapors.

• Use only Wagner HVLP hose.

• Follow the material and solvent manufacturer's warnings

and instructions.

• Use extreme caution when using materials with a

flashpoint below 70° F (21° C). Flashpoint is the

temperature that a fluid can produce enough vapors to

ignite.

• Plastic can cause static sparks. Never hang plastic to

enclose a spray area. Do not use plastic drop cloths

when spraying flammable materials.

English

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

MATERIALS - Will cause severe injury or

property damage.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as

mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

insecticides, and other materials can be

harmful if inhaled or come in contact with the

body. Vapors can cause severe nausea,

fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read

all instructions supplied with the mask to be sure it will

provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating

manufacturer.

HAZARD: SKIN BURN INJURY — Heated parts can cause

severe skin burn injury.

PREVENTION:

• Quick disconnect fittings on the hose and spray gun

become hot during use. Avoid skin contact with quick

disconnect fittings when they are hot. Allow quick

disconnect fittings to cool before disconnecting the spray

gun from the hose.

HAZARD: GENERAL - This product can cause severe

injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before

operating equipment.

• Always disconnect the motor from the power supply

before working on the equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards should be consulted.

• Use only manufacturer authorized parts. User assumes

all risks and liabilities when using parts that do not meet

the minimum specifications and safety devices of the

manufacturer.

• Power cord must be connected to a grounded circuit.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a hose. Replace it with an

identical replacement hose.

• All hoses, swivels, guns, and accessories must be

pressure rated at or above 10PSI/ 0,69 BAR.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

• Never aim spray gun at any part of the body.

2 © SprayTECH Corporation. All rights reserved.

Page 3

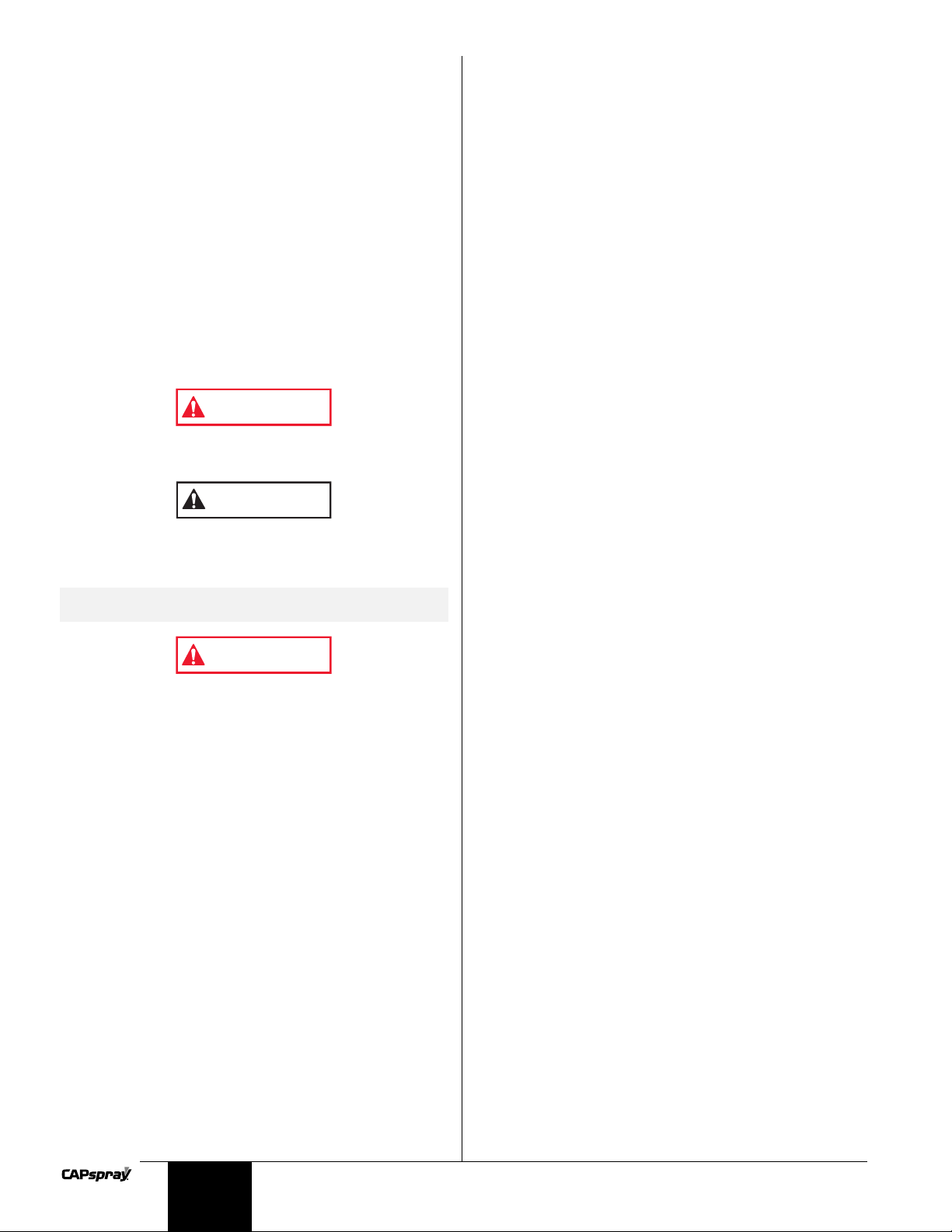

Grounding Instructions

CAUTION

Grounded Outlet

Grounding Pin

Tab for

Grounding Screw

Adapter

Metal Screw

Cover for grounded outlet box

WARNING

Cup Holder

Fuse

Filter

Warning

Light

Power Switch

Power Cord

Filter

Filter (in end

of filter can)

Air Hose

Air Outlet

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER — Improper installation of the grounding plug can

result in a risk of electric shock. If repair or replacement of the

cord or plug is necessary, do not connect the green grounding

wire to either flat blade terminal. The wire with insulation

having a green outer surface with or without yellow stripes is

the grounding wire and must be connected to the grounding

pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. A

temporary adapter which looks like the adapter illustrated in

the figure below may be used to connect this plug to a 2 pole

receptacle as shown if a properly grounded outlet is not

available.

The temporary adapter should be used only until a properly

grounded outlet as shown below can be installed by a qualified

electrician. The green colored rigid ear, lug, or the grounding

wire extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held in place

by a metal screw.

Introduction

This High Volume/Low Pressure (HVLP) spray system is

designed for applying coatings to surfaces that can be sprayed

faster than brushing or rolling and are too small for traditional

airless sprayers. Components of this system include a power

switch, a power cord, a filter warning light, a replaceable fuse,

a dual filtration system, a cup holder, an air hose, and an air

outlet.

With this HVLP spray system, you can achieve the highest

quality professional finish possible with little or no preparation

or setup time. Please review all the information contained in

this manual before operating the system.

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the

plug on the product. Make sure your extension cord is in

good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your

product will draw. For lengths less than 25 feet, No. 16

AWG extension cords should be used. Between 25 feet

and 50 feet, the minimum gauge is 14 AWG. An

undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. If an extension cord is

to be used outdoors, it must be marked with the suffix WA after the cord type designation. For example, a

designation of SJTW-A would indicate that the cord would

be appropriate for outdoor use.

Service

Should your spray system need service during the warranty

period, return your unit and the proof of purchase to the

distributor where it was purchased. At our option, the unit will

be repaired or replaced. In a continued commitment to

improve quality, we reserve the right to make component or

design changes when necessary.

© SprayTECH Corporation. All rights reserved. 3

Using an HVLP Spray System

Refer to the following information to operate and understand

your HVLP spray system.

Setup

Use the following procedure to set up your HVLP spray system

for operation.

1. Plug the turbine power cord into a grounded, 3-slot

receptacle.

Keep the turbine at the maximum possible distance from

the spray area to safeguard against explosion or fire that

may be caused by sparking electrical parts.

2. Prepare your spray gun for operation. Refer to your spray

gun manual for material preparation, setup, and spraying

information.

3. Attach the air hose to the air outlet on the turbine.

4. Attach the air hose to the air inlet on your spray gun.

5. Turn on the turbine and begin spraying.

English

Page 4

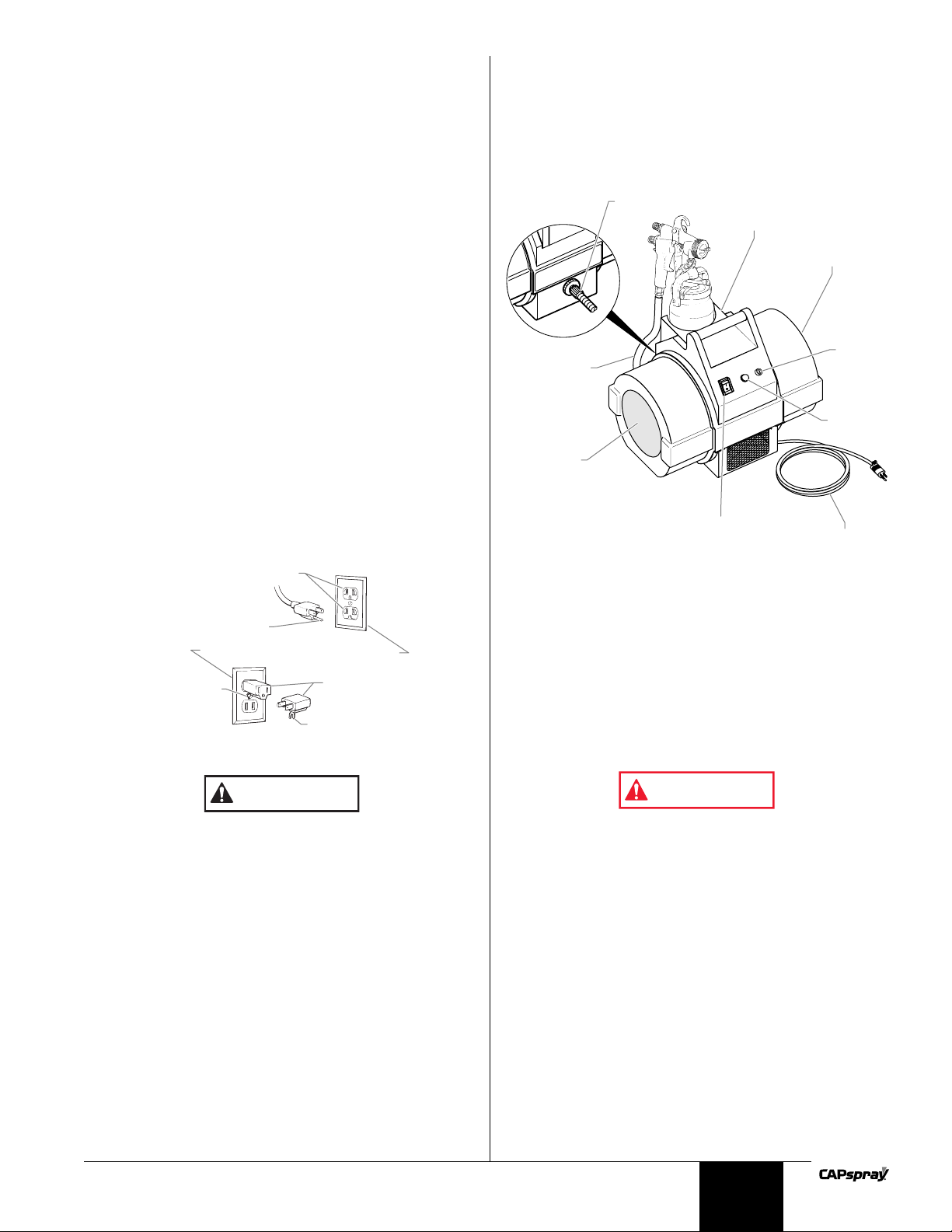

Dual Filtration System

Cooling Air Discharge

Cooling Air

Intake

Atomizing Air

Intake

Atomizing Air

Discharge

Cooling Air Filter

Two-Stage Atomizing

Air Filter

(green side facing

the turbine)

The turbine has two different air filters— one for atomizing air

and one for cooling air. The atomizing air filter is a two-stage,

fine mesh filter designed to trap particles that may damage

your finish. The atomizing air is discharged through the nozzle

of the spray gun where it atomizes the coating material. The

cooling air filter is a coarse mesh filter designed to allow the

proper amount of air flow through the turbine for cooling

purposes. Cooling air is exhausted through the cooling air

discharge on the front of the turbine.

Filter Warning System

The filter warning system on your turbine consists of a red filter

warning light on the front control panel and an air flow switch

inside the turbine. When the air flow switch does not detect

the appropriate amount of air flowing through the turbine, the

filter warning light will come on to indicate that it is time to

clean or change the filters.

NOTE: The filter warning system does not shut down

the turbine.

CAUTION

Clean filters regularly. Clogged filters can cause excessive

heat and possibly damage the turbine.

Maintenance

Use the following procedures to keep your HVLP spray system

running properly.

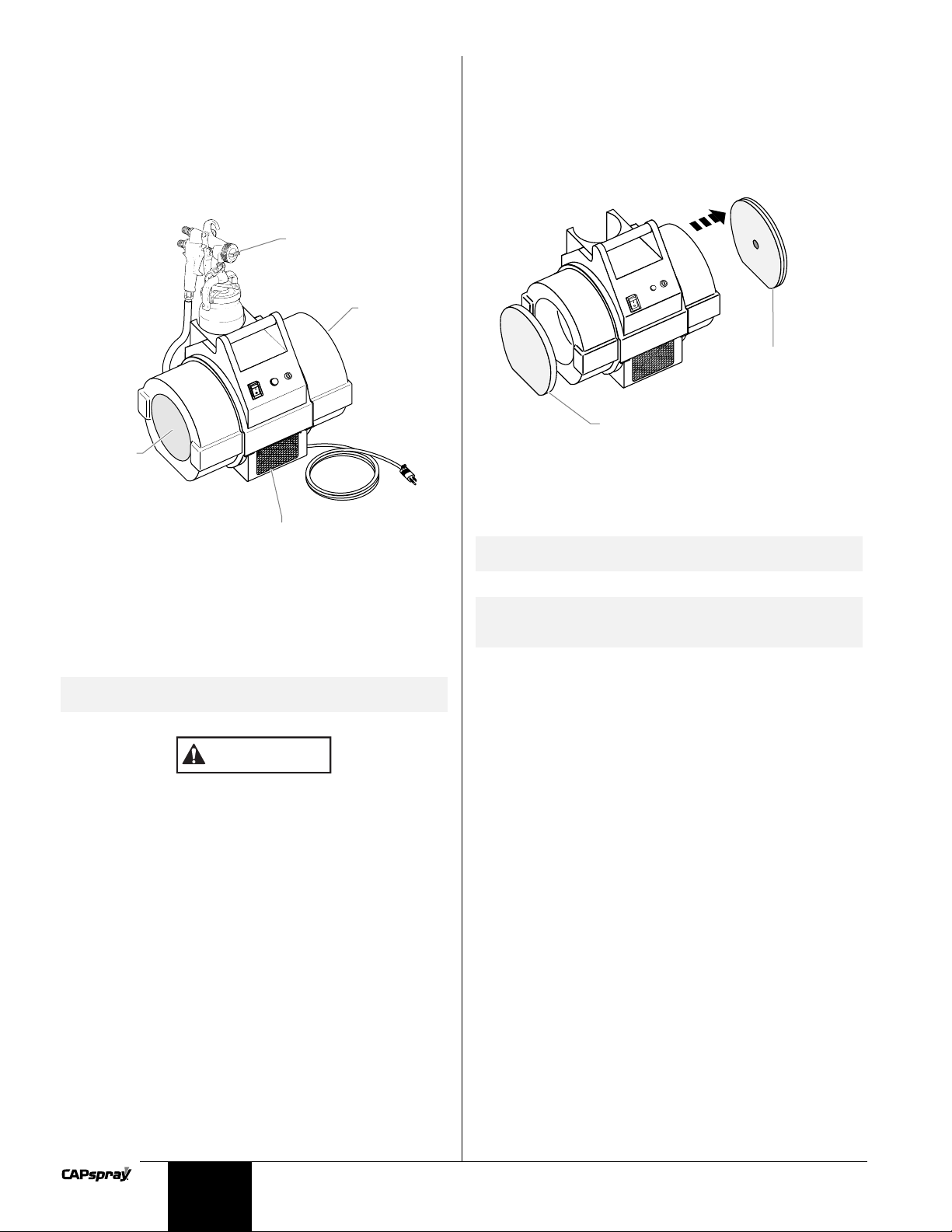

Cleaning/Replacing the Filters

1. Remove each filter by grabbing them and pulling them

straight out of the filter cans on the turbine. This will not

damage the filters.

2. Clean the filters. Either tap the filters to knock out the

contaminants or use pressurized air to blow out the

contaminants. For material that is not blown or knocked

loose easily, soak the filters in soapy water or mineral

spirits. Allow the filters to dry completely before placing

them back in the turbine.

NOTE: Do not use highly flammable solvents, such as

lacquer thinner, to clean the filters

3. Insert each filter back into its corresponding filter can.

NOTE: The two-stage, atomizing air filter must be

placed in the filter can labeled “2-Stage Filter”

with the green side facing the turbine.

After several cleanings, it may become necessary to replace

the filters. Refer to the parts list near the end of this manual

for the filter replacement kit part number.

Replacing a Fuse

1. Remove the fuse holder cover using a flathead screw

driver. Push the screwdriver into the cover and turn the

cover counterclockwise

2. Pull the old fuse out of the fuse holder cover.

3. Place the new fuse inside the fuse holder cover.

4. Place the new fuse and the fuse holder cover into the fuse

holder. Turn the fuse holder cover clockwise with the

flathead screwdriver to lock it into position.

English

4 © SprayTECH Corporation. All rights reserved.

Page 5

Problem

Restricted air flow or no air

flow

Troubleshooting

Cause

1. Air flow adjustment knob on the spray

gun is turned off

2. Air filters are clogged

Solution

1. Adjust the air flow adjustment knob

2. Clean or replace the filters

Filter warning light is on

The turbine has no power

Excessive arcing/sparking in

the turbine

1. Air filters are clogged

1. No power at the power supply

2. The fuse is blown

3. Worn turbine brushes

1. Worn turbine brushes

2. Damaged commutator

Patents

These products may be covered under one or more of the following U.S. patents:

5,702,131 5,655,714 5,639,222 5,573,371 5,558,492 5,556,255 5,550,336

5,423,395 5,284,301 5,183,207 5,174,610 D365,569 5,078,323 5,078,322

5,074,467 5,050,804 B1 5,772,711 D331,095 D321,926

1. Clean or replace the filters

1. Check the power supply

2. Check and replace the fuse

3. Have the brushes replaced at an authorized

CAPSpray service center

1. Have the brushes replaced at an authorized

CAPSpray service center

2. Replace the turbine (contact a CAPSpray

service technician)

© SprayTECH Corporation. All rights reserved. 5

English

Page 6

Table Des Matiéres

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

Sécurité ................................................................................6–7

Instructions de mise à la terre...............................................7

Entretien et Réparations ........................................................7

Introduction .............................................................................7

Utilisation d'un système de vaporisation HVLP..................7-8

Préparation ............................................................................7

Système de double filtration..................................................8

Maintenance ............................................................................8

Nettoyage/remplacement des filtres......................................8

Remplacement d'un fusible ...................................................8

Recherche des pannes...........................................................9

Liste de pièces ................................................................14–15

Garantie..................................................................................16

Sécurité

Le présent manuel comprend des renseignements devant être

lus attentivement avant toute utilisation de l'appareil. Lorsque

l'un des symboles suivants apparaît, il est recommandé d'être

particulièrement attentif et de tenir compte des mesures de

sécurité indiquées.

Ce symbole indique un danger potentiel pouvant causer des

blessures graves ou même mortelles. Des renseignements

importants sur la sécurité sont également indiqués.

Ce symbole indique un danger potentiel pouvant causer des

blessures corporelles ou des dommages à l'équipement. Des

renseignements importants sur la façon de prévenir tout

dommage à l'équipement ou toute blessure corporelle mineure

sont également indiqués.

NOTA : Les remarques donnent des renseignements

importants requérant une attention particulière.

DANGER: RISQUES D'EXPLOSION OU D'INCENDIE - Les

vapeurs dégagées par le solvant ou la peinture

sont explosives et inflammables et peuvent causer

des corporels sérieux ou dommages matériels.

MESURES PRÉVENTIVES:

• Veiller à éviter toute accumulation de vapeurs

inflammables en vous assurant que la zone où la

pulvérisation a lieu est suffisamment ventilée.

• Veiller à éviter la présence de toute source incandescente

telle qu'étincelle électrostatique, flamme nue, flammepilote, objet brûlant, cigarette et étincelle provenant du

branchement ou du débranchement d'un cordon

d'alimentation électrique ou d'un commutateur.

• Ne pas fumer dans la zone d’épandage.

• Toujours avoir un extincteur en état de fonctionner à

portée de la main.

• Placer la pompe à une distance d’au moins un mètre (3

pi) (on recommande d’ailleurs une plus grande distance)

de l’objet qui doit être vaporisé dans une pièce séparée

bien aérée, ou à une distance d’au moins six mètres (20

pi) de celui-ci dans une zone bien aérée. Les vapeurs

inflammables sont souvent plus lourdes que l’air. Le

plancher doit être extrêmement bien aéré. La pompe

contient des pièces pouvant créer des étincelles et

enflammer les vapeurs présentes dans l’air.

• Employer seulement Wagner HVLP tuyau.

• Se conformer aux consignes et recommandations de

sécurité du fabricant du solvant ou du produit.

• S’entourer de toutes les précautions possibles lorsqu’on

utilise des produits ayant un point d’éclair inférieur à 21

°C (70 °F). Le point d’éclair d’un fluide est la température

à laquelle les vapeurs émanant du fluide peuvent

s’enflammer au contact d’une flamme ou d’une étincelle.

• Le plastique peut être une source d’étincelles provoquées

par l’électricité statique. Ne jamais utiliser une couverture

en plastique pour fermer une zone d’épandage ni utiliser

des toiles de protection en plastique lors de la

pulvérisation de matières inflammables.

DANGER: RISQUES D'EXPLOSION PAR INCOMPATIBILITÉ

DES MATÉRIAUX - Peuvent être à l'origine de

corporels sérieux ou dommages matériels.

MESURES PRÉVENTIVES:

• Ne pas utiliser de matériaux contenant des agents de

blanchiment ou du chlore.

• Ne pas utiliser des solvants à base d’hydrocarbure

halogéné tels que l’agent anticryptogamique, le chlorure

de méthylène et le trichloro-éthane-1,1,1. Ces produits ne

sont pas compatibles avec l’aluminium

• Communiquer avec votre fournisseur de revêtement pour

connaître la compatibilité du matériau avec l’aluminium.

DANGER: VAPEURS NOCIVES – la peinture, les solvants,

les insecticides et autres matériaux peuvent

être nocifs lorsqu’ils sont inhalés ou en contact

avec le corps. Les vapeurs peuvent causer une

nausée importante, des évanouissements ou

un empoisonnement.

MESURES PRÉVENTIVES:

• Utiliser un respirateur ou un masque chaque fois qu'il y a

des risques d'inhalation de vapeurs. Lire attentivement

toutes les instructions se rapportant au masque pour

vérifier que celui-ci vous assure une protection suffisante

contre les vapeurs toxiques.

• Porter des lunettes de protection.

• Porter des vêtements de protection, conformément aux

directives du fabricant de revêtement.

DANGER: DANGER DE BRÛLURE — Les pièces chauffées

peuvent causer de graves brûlures cutanées.

PRÉVENTION:

• Les raccords à dégagement rapide du tuyau flexible et du

pistolet peuvent s'échauffer en cours d'utilisation; il faut alors

éviter les contacts cutanés, en attendant que les raccords

refroidissent avant de séparer le pistolet du tuyau.

DANGER: GÉNÉRALITÉS - Peut causer des dommages

matériels ou corporels sérieux.

MESURES PRÉVENTIVES:

• Avant d'utiliser tout équipement, lire attentivement toutes

les instructions et les consignes de sécurité

• Toujours débrancher le moteur de l’alimentation électrique

avant d’effectuer des travaux sur l’appareil.

• Se conformer à la législation locale, provinciale ou fédérale

pour tout ce qui concerne la ventilation, la prévention des

incendies et les conditions générales d'utilisation.

• Les normes de sécurité du Gouvernement américain sont

régies par le Occupational Safety and Health Act (OSHA).

Il est important de consulter ces normes, en particulier la

section 1910 sur le normes générales et la section 1926

sur les des normes de la construction.

• N’utiliser que les pièces autorisées par le fabricant.

L’utilisateur assume tous les risques et responsabilités

lorsqu’il utilise des pièces qui ne sont pas conformes aux

caractéristiques techniques minimales ainsi qu’aux

dispositifs de sécurité du fabricant.

• Le cordon d’alimentation doit être raccordé à un circuit

mis à la terre.

• Vérifier, avant toute utilisation, que les flexibles ne

présentent pas d'entaille ou de fuite, que le couvercle ne

soit pas gonflé et que les raccords ne soient pas

endommagés. Si le flexible a subi l'un des dommages

précités, remplacez-le immédiatement. Ne jamais réparer

un flexible d'alimentation. Le remplacer avec un flexible

identique de remplacement.

• Tout flexible, raccord orientable, pistolet et accessoire

utilisé avec cet appareil doit pouvoir fonctionner à une

pression égale ou supérieure à 10 lb/po2 / 0,69 BAR.

• Ne jamais pulvériser lorsqu'il vente.

Français

6 © SprayTECH Corporation. Tous droits réservés.

Page 7

• Porter des vêtements pour protéger la peau et les

ATTENTION

Prise de terre

Goupille de mise la terre

Patte pour

vis de mise

la terre

Adapteur

Vis m tallique

Couvercle du bo tier de prise de terre

AVERTISSEMENT

Support de godet

Fusible

Lampe

témoin

de filtre

Interrupteur

Câble

d'alimentation

Filtre

Filtre (à l'extrémité

du carter de filtre)

Boyau

pour l'air

Sortie d'air

cheveux contre tout contact avec la peinture.

• NE JAMAIS diriger le pistolet vers une quelconque partie

du corps.

Instructions de mise à la terre

Cet appareil doit être mis à la terre. La mise à la terre réduit

les risques d'électrocution lors d'un court-circuit en permettant

au courant de s'écouler par le fil de mise à la terre. Cet

appareil est muni d'un cordon électrique avec fil de mise à la

terre ainsi que d'une fiche de terre. La fiche doit être branchée

sur une prise installée correctement et mise à la terre

conformément à la réglementation et aux codes en vigueur.

DANGER — Une prise de terre mal branchée peut être à

l'origine d'électrocutions. S'il s'avère nécessaire de réparer ou

de remplacer le cordon électrique ou la fiche, ne pas brancher le

fil vert de mise à la terre sur l'une ou l'autre des bornes à broche

plate. Le fil recouvert d'un isolant vert avec ou sans rayures

jaunes est le fil de mise à la terre et doit être branché sur la

broche de mise à la terre.

Si vous ne comprenez pas les instructions de mise à la terre

ou si vous n'êtes pas sûr que l'appareil est correctement mis à

la terre, contactez un électricien agréé. Ne pas modifier la

fiche d'origine. Si la prise ne convient pas à la fiche, faites

installer la prise adéquate par un électricien agréé.

Cet appareil est conçu pour un tension normale de 120 V et

est muni d'une fiche de mise à la terre semblable à celle de

l'illustration ci-dessous. Un adaptateur temporaire semblable à

celui illustré à la figure ci-dessous, peut être utilisé pour

raccorder cette fiche dans une prise bipolaire, tel qu’illustré,

lorsqu’une prise de courant avec contact de mise à la terre

n’est pas disponible.

L’adaptateur temporaire doit être utilisé seulement jusqu’à ce

qu’une prise de courant avec contact de mise à la terre, tel

qu’illustré ci-dessous, puisse être installée par un électricien

qualifié. L’oreillette de fixation rigide de couleur verte ou le fil

de mise à la terre raccordé à l’adaptateur doit être mis à la

terre en permanence, par l’entremise d’un composant

quelconque, tel qu’une boîte de sortie. Lorsque l’adaptateur

est utilisé, il doit être tenu en place au moyen d’une vis

métallique.

Entretien et Réparations

Si le système requiert de l'entretien ou des réparations

pendant la période de la garantie, on doit le retourner,

accompagné d'une preuve d'achat, au distributeur chez qui on

l'a acheté. Il sera alors, selon le choix du fabricant, réparé ou

remplacé. Dans le cadre de son engagement perpétuel

envers l'amélioration de la qualité, nous réservons le droit de

modifier les composants ou la conception de ses produits si

elle le juge nécessaire.

Introduction

Ce système de vaporisation "High Volume/Low Pressure

(HVLP) (volume élevé/basse pression) est conçu pour

l'application de revêtements sur des surfaces qui peuvent être

peintes plus rapidement qu'avec un pinceau ou un rouleau et

qui sont trop petites pour permettre l'utilisation des

vaporisateurs sans air traditionnels. Le système comprend les

composants suivants : un interrupteur d'alimentation, un câble

d'alimentation, une lampe témoin de filtre, un fusible

remplaçable, un système de double filtration, un support de

godet, un boyau pour l'air et une sortie d'air.

Utiliser uniquement une rallonge à trois fils munie d'une

fiche de terre dans une prise secteur mise à la terre

correspondant au type de fiche de l'appareil. S'assurer

que votre rallonge est en bon état. Lorsque vous utilisez

une rallonge, assurez-vous qu'elle soit d'un calibre

suffisant pour supporter l'intensité du courant requise par

l'appareil. Pour des longueurs moins que 25 pieds, No.

16 AWG rallonge devraient être employées. Entre 25 et 50

pieds, de calibre minimum est 14 AWG. Une rallonge trop

mince entraîne une chute de tension, une diminution de

l'intensité et une surchauffe. Si vous devez utiliser une

rallonge à l’extérieur, celle-ci doit comprendre la marque

W-A après la désignation indiquant le type de cordon. Par

exemple, la désignation SJTW-A indique que le cordon est

conçu pour être utilisé à l’extérieur.

© SprayTECH Corporation. Tous droits réservés. 7

Grâce à ce système HVLP, il est possible d'obtenir une très

haute qualité professionnelle avec peu de préparation et de

temps de réglage. Veuillez SVP consulter toutes les

informations contenues dans ce manuel avant de faire

fonctionner le système.

Utilisation d'un système de vaporisation HVLP

Se reporter aux informations suivantes pour faire fonctionner et

bien assimiler le système de vaporisation HVLP.

Préparation

Utiliser la procédure suivante pour préparer à faire fonctionner

le système de vaporisation HVLP.

1. Brancher le câble d'alimentation de la turbine dans une

prise électrique à 3 broches équipée d'une mise à la terre.

Maintenir la turbine aussi éloignée que possible de la

zone de vaporisation, de manière à éviter tout incendie ou

explosion provoqué par les pièces produisant des

étincelles.

Français

Page 8

2. Préparer à faire fonctionner le pistolet de vaporisation. Se

Echappement air de refroidissement

Entrée air de

refroidissement

Entrée air

d'atomisation

Echappement air

d'atomisation

Filtre d'air de refroidissement

Filtre d'air d'atomisation

à deux étages

(côté vert faisant

face à la turbine)

reporter au manuel du pistolet de vaporisation pour les

informations concernant la préparation de l'équipement, le

réglage et la vaporisation.

3. Raccorder le boyau pour l'air à la sortie d'air de la turbine.

4. Raccorder le boyau pour l'air à l'entrée d'air du pistolet de

vaporisation.

5. Mettre en marche la turbine et commencer à vaporiser.

Système de double filtration

La turbine comporte deux filtres à air différents — un pour

l'atomisation de l'air et l'autre pour le refroidissement de l'air.

Le filtre à air pour l'atomisation est un filtre à mailles fin à deux

étages conçu pour piéger les particules néfastes à la qualité

de la finition. L'air d'atomisation est évacué à travers la buse

du pistolet de vaporisation où il atomise le matériau du

revêtement. Le filtre à air pour le refroidissement est un filtre à

mailles grossier conçu pour permettre un débit d'air de

refroidissement approprié à travers la turbine. L'air de

refroidissement est évacué par l'échappement d'air de

refroidissement situé à l'avant de la turbine.

Système d'avertissement de filtre

Le système d'avertissement du filtre de la turbine comporte

une lampe témoin de filtre rouge sur le panneau de

commande frontal et un commutateur de débit d'air à l'intérieur

de la turbine. Lorsque le commutateur de débit d'air ne détecte

pas le débit d'air approprié devant circuler à travers la turbine,

la lampe témoin s'allume pour indiquer qu'il est temps de

nettoyer ou de changer les filtres.

NOTA: Le système d'avertissement du filtre n'arrête

pas le fonctionnement de la turbine.

ATTENTION

Maintenance

Utiliser la procédure suivante pour maintenir votre pistolet de

vaporisation HVLP en bon état de fonctionnement.

Nettoyage/remplacement des filtres

1. Retirer chaque filtre en le saisissant et en le retirant du

carter sur la turbine. Cette opération n'endommage pas

les filtres.

2. Nettoyer les filtres. Donner des petits coups sur les filtres

pour évacuer les contaminants ou utiliser de l'air

comprimé pour les chasser. Pour les matières qui ne sont

pas évacuées facilement, tremper les filtres dans de l'eau

savonneuse ou dans de l'essence minérale. Laisser

sécher complètement les filtres avant de les remonter

dans la turbine.

NOTA: Pour nettoyer les filtres, ne pas utiliser de

solvants hautement inflammable tels que les

diluants à peinture-laque.

3. Remonter chaque filtre dans son carter correspondant.

NOTA: Le filtre d'atomisation à deux étages doit être

monté dans le carter de filtre portant l'étiquette

"2-Stage Filter" (Filtre à deux étages), avec le

côté vert faisant face à la turbine.

Après plusieurs nettoyages, il peut devenir nécessaire de

remplacer les filtres. Se reporter à la liste de pièces à la fin de

ce manuel pour la référence de l'ensemble de remplacement

de filtre.

Remplacement d'un fusible

1. Retirer le couvercle du support fusible en utilisant un

tournevis plat. Pousser le tournevis dans le couvercle et

tourner celui-ci dans le sens anti-horaire.

2. Retirer le fusible endommagé du couvercle du support

fusible.

3. Monter le nouveau fusible dans le couvercle du support

fusible.

4. Monter le nouveau fusible et le couvercle du support

fusible dans le support fusible. Tourner le couvercle du

support fusible dans le sens horaire avec le tournevis plat

pour le verrouiller dans sa position.

Nettoyer régulièrement les filtres. Les filtres engorgés

peuvent engendrer une surchauffe et peut-être

endommager l'unité.

Français

8 © SprayTECH Corporation. Tous droits réservés.

Page 9

Problème

Débit d'air restreint ou aucun

débit d'air

Recherche des pannes

Cause

1. Le bouton de réglage de débit d'air sur

le pistolet de vaporisation est fermé

2. Les filtres à air sont colmatés

Solution

1. Ajuster le bouton de réglage de débit d'air

2. Nettoyer ou remplacer les filtres

La lampe témoin de filtre est

allumée

La turbine n'a pas de

puissance

Production excessive d'arcs

électriques/étincelles dans la

turbine

1. Les filtres à air sont colmatés

1. Pas d'alimentation électrique

2. Le fusible est brûlé

3. Les balais de la turbine sont usés

1. Les balais de la turbine sont usés

2. Le commutateur est endommagé

1. Nettoyer ou remplacer les filtres

1. Vérifier l'alimentation électrique

2. Vérifier et remplacer le fusible si nécessaire

3. Faire remplacer les balais par un centre de

1. Faire remplacer les balais par un centre de

2. Remplacer la turbine (contacter un

Brevets

Ces produits peuvent être protégés par un ou plusieurs des brevets (U.S.A.) suivants :

5,702,131 5,655,714 5,639,222 5,573,371 5,558,492 5,556,255 5,550,336

5,423,395 5,284,301 5,183,207 5,174,610 D365,569 5,078,323 5,078,322

5,074,467 5,050,804 B1 5,772,711 D331,095 D321,926

service agréé CAPSpray

service agréé CAPSpray

technicien CAPSpray)

© SprayTECH Corporation. All rights reserved. 9

Français

Page 10

Idice

PRECAUCION

ADVERTENCIA

Seguridad.........................................................................10–11

Instrucciones para conectar a tierra ....................................11

Servicio ..................................................................................11

Introducción...........................................................................11

Cómo Usar un Sistema de Atomización HVLP...............11–12

Preperación..........................................................................11

Sistema Doble de Filtration .................................................12

Mantenimiento.......................................................................12

Limpieza/Cambio de Filtros.................................................12

Cambiando un Fusible ........................................................12

Solución de Problemas ........................................................13

Lista de Partes ................................................................14–15

Garantia..................................................................................16

Seguridad

Este manual contiene información que debe leer y comprender

antes de usar el equipo. Cuando se encuentre con uno de los

siguientes símbolos, asegúrese de observar sus indicaciones

de seguridad.

Este símbolo indica la existencia de un peligro potencial que

puede causar lesiones graves o la muerte. Después del

mismo se incluye información de seguridad importante.

Este símbolo indica la existencia de un peligro potencial para

usted o el equipo. Después del mismo se incluye información

importante que indica la forma de evitar daños al equipo o la

forma de prevenir lesiones menores.

NOTA: los avisos contienen información importante,

présteles especial atención.

ADVERTENCIA

PELIGRO: EXPLOSIÓN O INCENDIO - Los vapores de

solventes y pintura pueden explotar o

incendiarse, causando con esto lesiones

severas y/o daños en la propiedad.

PARA PREVENIR:

• Debe proveerse un escape y aire fresco para hacer que el

aire que está dentro del área de atomización se mantenga

libre de acumulaciones de vapores inflamables.

• Evite todas las fuentes de ignición como son las chispas

electrostáticas, llamas abiertas, flamas de piloto, objetos

calientes, cigarros, y chispas que se generan al conectar

y desconectar las extensiones o de apagadores de luz

que estén funcionando.

• No fume en la zona de trabajo.

• Debe haber un equipo para extinguir incendios

permanentemente y en buenas condiciones.

• Coloque la bomba a un mínimo de 1 m (de preferencia

más) en una habitación aparte, bien ventilada, alejada del

objeto que va a pintar o a por lo menos 6 m de dicho

objeto, en una zona bien ventilada. Los gases

inflamables a menudo son más pesados que el aire. La

zona del piso debe tener la debida ventilación. La bomba

contiene piezas que forman arcos que emiten chispas y

pueden encender los gases.

• Use solamente Wagner HVLP mangueras.

• Siga las advertencias y avisos de seguridad del fabricante

de los materiales y solventes.

• Tenga muchísimo cuidado al usar materiales cuyo punto de

ignición sea inferior a 70° F (21° C). El punto de ignición

es la temperatura a la cual pueden encenderse los vapores

emanados por un fluido al exponerlos a llamas o chispas.

• El plástico puede causar chispas estáticas. Nunca

cuelgue plástico en las ventanas ni en las puertas del

área donde va a pintar. No utilice plástico para proteger

el piso cuando pinte materiales inflamables.

• Cuando enjuague el equipo utilice la presión más baja posible.

Español

PELIGRO: PELIGRO DE EXPLOSIÓN DEBIDO A

MATERIALES INCOMPATIBLES - Podría

causar lesiones severas o daños en la

propiedad.

PARA PREVENIR:

• No utilice materiales que contengan blanqueador o cloro.

• No use solventes con hidrocarburos halogenados, tales como

productos para eliminar el moho, cloruro de metileno y 1,1,1 tricloroetano. Estos no son compatibles con el aluminio.

• Comuníquese con el proveedor del producto para obtener

información de compatibilidad con materiales de aluminio.

PELIGRO: GASES PELIGROSOS - Las pinturas, solventes,

insecticidas y otros materiales pueden ser

perjudiciales si se inhalan o entran en contacto

con el cuerpo. Los gases pueden causar

náusea, desmayos o envenenamiento graves.

PARA PREVENIR:

• Use una mascarilla respiratoria o careta siempre que

exista la posibilidad de que se puedan inhalar vapores.

Lea todas las intrucciones que vengan con la careta para

estar seguro de que se tendrá la protección necesaria

contra la inhalación de vapores dañinos.

• Use gafas protectoras.

• Use ropa de protección, según lo requiera el fabricante

del producto.

PELIGRO: QUEMADURA DE LA PIEL — Las piezas

calientes pueden causar lesiones de

quemadura de la piel severas.

PARA PREVENIR:

• Las conexiones de desconexión rápida de la manguera y

la pistola de atomización se llegan a calentar mientras se

usan. Evite que la piel tenga contacto con las conexiones

de desconexión rápida cuando se calienten. Deje que las

conexiones de desconexión rápida se enfríen antes de

desconectar la pistola de atomización de la manguera.

PELIGRO: GENERAL - Puede causar daños en la

propiedad o lesiones severas.

PARA PREVENIR:

• Lea todas las instrucciones y advertencias de seguridad

antes de hacer funcionar cualquier equipo.

• Desconecte siempre el motor del suministro eléctrico

antes de dar servicio al equipo.

• Observe todos los códigos locales, estatales y nacionales

apropiados que rigen las medidas de ventilación,

prevención de incendios y operación.

• Los Estándares de Seguridad del Gobierno de los

Estados Unidos se han adoptado bajo el Acta de

Seguridad y Salud Ocupacionales (OSHA por sus siglas

en inglés). Deben consultarse estos estándares,

particularmente la parte 1910 de los Estándares

Generales y la parte 1926 de los Estándares de la

Construcción.

• Utilice únicamente piezas autorizadas por el fabricante.

El usuario asume todos los riesgos y responsabilidades si

usa piezas que no cumplen con las especificaciones

mínimas y dispositivos de seguridad del fabricante.

• El cable de alimentación debe enchufarse a un circuito

aterrado.

• Antes de usarla cada vez, revise todas las mangueras

para ver que no tengan cortadas, fugas, una cubierta

desgastada por abrasión o con abolladuras, así como

uniones dañadas o que se hayan movido. Si existiera

cualquiera de estas condiciones, reemplace la manguera

inmediatamente. No repare nunca una manguera.

Reemplazar lo con una manguera idéntica de reemplazo.

• Todas las mangueras, soportes giratorios, pistolas y

accesorios que se usen con esta unidad deben tener una

capacidad de presión de 10 lb/pulg2 o mayor.

• No atomice en días con viento.

• Use ropa que evite el contacto de la pintura con la piel y

el cabello.

• NO dirija NUNCA la punta de la pistola hacia alguna parte

del cuerpo.

10 © SprayTECH Corporation. Todos los derechos reservados.

Page 11

ADVERTENCIA

Porta Latas

Fusible

Luz de

Advertencia

del Filtro

Switch de Potencia

Cable de Energa

Filtro

Filtro (en el extremo

de la lata del filtro)

Manguera

de Aire

Salida de Aire

Instrucciones para conectar a tierra

PRECAUCION

Tomacorriente aterrado

Terminal de tierra

Lengueta

del tornillo

de conexi n a tierra

Adaptador

Tornillo met lico

Tapa de la caja del tomacorriente aterrado

Este producto se debe conectar a tierra. En caso de que

ocurra un corto circuito, la conexión a tierra reduce el riesgo

de choque eléctrico al proporcionar un alambre de escape

para la corriente eléctrica. Este producto está equipado con

un cable que tiene un alambre de conexión a tierra con un

enchufe de conexión a tierra apropiado. El enchufe se debe

enchufar en una toma de corriente que se haya instalado y

conectado a tierra debidamente, de acuerdo con todos los

códigos y estatutos locales.

PELIGRO — Una instalación inapropiada del enchufe de

conexión a tierra puede dar como resultado el que exista un

riesgo de choque eléctrico. Si es necesario reparar o

reemplazar el cable o el enchufe, no conecte el alambre de

conexión a tierra a ninguno de los terminales de hoja planos. El

alambre con aislamiento que tiene la superficie exterior de color

verde con franjas amarillas o sin ellas es el alambre de conexión

a tierra que debe conectarse al conector de conexión a tierra.

Verifique con un electricista o técnico de servicio calificado si

las instrucciones para conectar a tierra no le han quedado

completamente claras, o si duda que el producto haya

quedado conectado a tierra de manera apropiada. No

modifique el enchufe que se proporciona. Si el enchufe no

entra en la toma de corriente, pídale a un electricista calificado

que instale la toma apropiada.

Este producto está diseñado para usarse en un circuito de 120

voltios nominales y el enchufe de conexión a tierra que tiene

se parece al enchufe que se ilustra a continuación. Si no

dispone de una toma de corriente con conexión a tierra, puede

usar un adaptador temporal que se asemeja al adaptador

ilustrado en la figura a continuación, para conectar este

enchufe en un receptáculo de 2 polos como se muestra.

El adaptador temporal solamente se debe utilizar hasta que un

electricista calificado instale debidamente una toma de

corriente con conexión a tierra. La patilla verde o alambre de

conexión a tierra que se extiende desde el adaptador se debe

conectar a tierra permanente, tal como la tapa de una caja de

distribución conectada a tierra. Cuando use el adaptador, debe

mantenerlo en su lugar con un tornillo metálico.

Servicio

Si su pistola necesitara recibir servicio durante el periodo de

garantía, devuelva la pieza y la prueba de compra al

distribuidor donde la compró. Nosotros decidiremos si la

reparamos o la reemplazamos. Por el compromiso continuo

que se tiene de mejorar la calidad, nosotros reservamos el

derecho de hacer cambios de componentes o diseño cuando

sea necesario.

Introducción

Este sistema de atomización Alto Volumen/Baja Presión (HVLP)

está diseñado para aplicar recubrimientos a superficies que

pueden pintarse más rápidamente que con brocha o rodillo y que

son demasiado pequeñas para los tradicionales atomizadores

sin aire. Los componentes de este sistema incluyen un switch de

potencia, cable de energía, luz de advertencia del filtro, fusible

reemplazable, sistema doble de filtración, un porta latas, una

manguera de aire y una salida de aire.

Use solamente extensiones trifilares que tengan un

enchufe de conexión a tierra de 3 hojas y un receptáculo

de triple ranura que acepte el enchufe del producto.

Asegúrese de que su extensión esté en buenas

condiciones. Cuando use una extensión, asegúrese de

usar una que sea lo suficientemente resistente como para

soportar la corriente que descargue su producto. Para

longitudes menos de 25 los pies, usan únicos un No. 16

AWG cable de extensión. Entre 25 y 50 pies, el calibre

mínimo es 14 AWG. Un cable de un tamaño menor

causará una caída de voltage en la línea que dará como

resultado una pérdida de energía y un sobrecalenta|ôento.

Si se utiliza un cable de extensión en el exterior, tiene que

estar marcado con el sufijo W-A después de la

designación del tipo de cable. Por ejemplo, SJTW-A para

indicar que el cable es apropiado para uso en exteriores.

© SprayTECH Corporation. Todos los derechos reservados. 11

Con este sistema de atomización HVLP, usted puede lograr un

acabado profesional de la mayor calidad con poco o nada de

tiempo de preparación. Por favor revise toda la información en

este manual antes de usar el sistema.

Cómo Usar un Sistema de Atomización HVLP

Consulte la siguiente Información para operar y entender su

sistema de atomización HVLP.

Preparación

Use el siguente procedimiento para preparar su sistema de

atomización HVLP para operación.

1. Conecte el cable de potencia de la turbina en un contacto

aterrizado de 3-ranuras.

Mantenga la tubina a la máxima distancia posible del área

de pintado para salvaguardar contra la posibilidad de

explosión o incendio causado por partes eléctricas

generando chispa.

2. Prepare su pistola atomizadora para operación.Consulte

el manual de su pistola atomizadora para preperación del

material, e información de preperación y atomización.

3. Conecte la manguera de aire a la salida de aire en la

turbina.

4. Conecte la manguera de aire a la entrada de aire en su

pistola atomizadora.

5. Encienda la turbina y comience a pintar.

Español

Page 12

Sistema Doble de Filtración

PRECAUCION

Filtro de Aire de Enfriamiento

Filtro Atomizador

de Aire de Dos Etapas

(lado verde hacia

la turbina)

La turbina tiene dos filtros de aire diferentes - uno para

atomizar el aire y el otro para enfriar el aire. El filtro de

atomización es un filtro de dos etapas, con tamiz de malla fina

diseñado para atrapar las particulas que pudieran dañar su

acabado. El aire atomizado se descarga a través de la

boquilla de la pistola de aire donde atomiza el material de

recubrimiento. El filtro de enfriamiento es de malla gruesa

diseñado para permitir el paso del flujo adecuado de aire a

través de la turbina para enfriarlo. El aire de enfriamiento es

ventilado a través de la descarga de aire de enfriamiento al

frente de la turbina.

Descarga de Aire

Atomizado

Admisión de Aire

de Atomización

Admisión

de Aire de

Enfriamiento

Descarga de Aire de Enfriamiento

Sistema de Advertencia de Filtro

El sistema de advertencia de filtro en su turbina consiste de

una luz roja de advertencia del filtro en el tablero de control

delantero y un switch de flujo de aire dentro de la turbina.

Cuando el switch de flujo de aire no detecta el flujo adecuado

de aire pasando por la turbina, se enciende la luz de

advertencia para indicar la necesidad de limpiar o cambiar los

filtros.

NOTA: El sistema de advertencia de filtro no apaga la

turbina.

Limpie los filtros regularmente. Los filtros tapados

pueden causar un calor excesivo y posiblemente que la

unidad se dañe.

Mantenimiento

Use los siguientes procedimientos para que su sistema de

atomización HVLP trabaje correctamente.

Limpiando/Cambiando los Filtros

1. Quite cada filtro sujetándolo y jalándolo de la lata portafiltro en la turbina. Los filtros no se dañan con esta

operación.

2. Limpie los filtros. Puede sacudir los filtros para sacar los

contaminantes o usar aire comprimido para sopletear los

contaminantes. Para material pegado difícil de separar,

sumerja los filtros en agua jabonosa o espíritus minerales.

Permita que los filtros se sequen completemente antes de

volverlos a colocar en la turbina.

NOTA: No use solventes inflamables, tales como

adelgazador de laca, para limpiar los filtros.

3. Inserte cada filtro nuevamente en su lata de filtro

correspondinte.

NOTA: El filtro de aire atomizado de dos-etapas debe

colorcarse en la lata de filtro marcada “2-Stage

Filter” con el lado verde hacia la turbina.

Después de varias limpiezas, pudiera ser necesario reponer

los filtros. Consulte la lista de partes al final de este manual

para el número de parte de los juegos de filtros de repuesto.

Cambiando un Fusible

1. Quite la tapa porta-fusible usando un desarmador plano.

Inserte el desarmador en la tapa y gire la tapa hacia la

izquierda.

2. Jale el fusible fundido de la tapa del porta-fusible.

3. Ponga el fusible nuevo dentro de la tapa del porta-fusible.

4. Coloque el fusible nuevo y la tapa del porta-fusible en el

porta-fusible.Gire la tapa del porta-fusible hacia la

derecha con el desarmador plano para regresar a su

posición cerrada.

Español

12 © SprayTECH Corporation. Todos los derechos reservados.

Page 13

Problema

Flujo restringido de aire o

ningún flujo

Solución de Problemas

Causa

1. Está cerrada la perrila de ajuste de

flujo en la pistola atomizadora

2. Los filtros de aire están tapados

Solución

1. Ajuste la perilla de ajuste de flujo de aire

2. Limpie o reponga los filtros

La luz de advertencia del filtro

está encendida

La turbina no tiene energía

Arqueo/chispas excesivas en

la turbina

1. Los filtros de aire están tapados

1. No hay energía en la fuente de poder

2. El fusible se fundió

3. Los cepillos de la turbina están

desgastados

1. Los cepillos de la turbina están

desgastados

2. Conmutador dañado

Patentes

Estos productos podrían ser protegidos por una de las siguientes patentes (U.S.A.):

5,702,131 5,655,714 5,639,222 5,573,371 5,558,492 5,556,255 5,550,336

5,423,395 5,284,301 5,183,207 5,174,610 D365,569 5,078,323 5,078,322

5,074,467 5,050,804 B1 5,772,711 D331,095 D321,926

1. Limpie o reponga los filtros

1. Revise la fuente de poder

2. Revise y cambie el fusible

3. Mande cambiar los cepillos en un centro de

servicio autorizado CAPSpra

1. Mande cambiar los cepillos en un centro de

servicio autorizado CAPSpray

2. Cambie la turbina (consulte un técnico de

servicio CAPSpray

)

© SprayTECH Corporation. All rights reserved. 13

Español

Page 14

• The turbine motor can be damaged if not serviced properly. Have the brushes (Kit P/N 0277918) checked for wear

PRECAUCION

ATTENTION

CAUTION

by an authorized service center every 400 hours.

• Clean filters regularly. When the filter warning light comes on, it is time to clean the filters. Clogged filters cam

cause excessive heat and possibly damage the unit.

• For additional troubleshooting information, see the manual that came with your gun.

• Le moteur de la turbine peut être endommagé si on n'en effectue pas l'entretien approprié. Faire vérifier l'usure des

brosses (N/P 0277918) par un centre d'entretien autorisé à toutes les 400 heures d'utilisation.

• Nettoyer régulièrement les filtres. Si le voyant lumineux s'allume, c'est qu'il est temps d'y voir. Les filtres engorgés

peuvent engendrer une surchauffe et peut-être endommager l'unité.

• Pour obtenir de plus amples renseignements en matière de diagnostic des anomalies, consulter le manuel

accompagnant le pistolet.

• El motor de la turbina se puede dañar si no se le da servicio de manera apropiada. Pida a un centro de servicio

autorizado que verifique el desgaste de las brochas (Juego N/P 0277918) cada 400 horas.

• Limpie los filtros regularmente. Cuando la luz de advertencia se encienda, significará que es tiempo de limpiar los

filtros. Los filtros tapados pueden causar un calor excesivo y posiblemente que la unidad se dañe.

• Vea el manual que viene con la pistola para consultar la información de detección de problemas adicional.

15

40

39

38

1

2

3

4

5

41

10

37

36

35

34

33

32

31

11

12

30

13

14

16

29

28

17

27

24

25

26

19

18

42

43

6

7

8

9

15

20

21

18

22

17

23

16

English

Français Español

14 © SprayTECH Corporation. All rights reserved.

Page 15

English

Item Part No. Description Quantity

1 0277316 Ring, air outlet retaining . . . . . . . . . . . . . . .1

2 0277439 Air outlet pipe . . . . . . . . . . . . . . . . . . . . . .1

3 9803103 Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4 0277443 Bleeder box cover . . . . . . . . . . . . . . . . . . .1

5 0277442 Bleeder box base . . . . . . . . . . . . . . . . . . . .1

6 0277397 Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7 0277402 Foam Tape . . . . . . . . . . . . . . . . . . . . . . . .2

8 0277455 Bottom housing, US . . . . . . . . . . . . . . . . . .1

9 0090628 Foot Pad . . . . . . . . . . . . . . . . . . . . . . . . . .4

10 9802222 Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

11 0277383 Vent plate . . . . . . . . . . . . . . . . . . . . . . . . .1

12 9800319 Screw, hex soc hd cap 1/4-20 x .75 . . . . . .4

13 0276363 Strain relief . . . . . . . . . . . . . . . . . . . . . . . .1

14 0277471 Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15 0293395 Screw, 8-32 x 3/8 Taptite . . . . . . . . . . . . .12

16 0277366 Filter can, large . . . . . . . . . . . . . . . . . . . . .2

17 0279937 Filter replacement kit . . . . . . . . . . . . . . . . .1

18 0277367 Filter screen . . . . . . . . . . . . . . . . . . . . . . . .2

19 0277371 Fan noise foam . . . . . . . . . . . . . . . . . . . . .1

20 0277369 Can cover . . . . . . . . . . . . . . . . . . . . . . . . .1

21 0277396 Can mount foot . . . . . . . . . . . . . . . . . . . . .6

22 0276598 Foam disk . . . . . . . . . . . . . . . . . . . . . . . . .1

23 0277501 Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Français

Article

No de pièce Description Quantité

1 0277316 Anneau, retenue de la sortie d'air . . . . . .1

2 0277439 Tuyau de sortie d'air . . . . . . . . . . . . . . . .1

3 9803103 Vis . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4 0277443 Couvercle de boîte de purge . . . . . . . . .1

5 0277442 Base de boîte de purge . . . . . . . . . . . . .1

6 0277397 Cale . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7 0277402 Bande de mousse . . . . . . . . . . . . . . . . .2

8 0277455 Boîtier inférieur, US . . . . . . . . . . . . . . . .1

9 0090628 Coupelles . . . . . . . . . . . . . . . . . . . . . . .4

10 9802222 Vis . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

11 0277383 Plaque de ventilation . . . . . . . . . . . . . . .1

12 9800319 Vis d'assemblage à tête cylindrique

à six pans (1/4-20 x .75) . . . . . . . . . . . .4

13 0276363 Détendeur . . . . . . . . . . . . . . . . . . . . . . .1

14 0277471 Cordon . . . . . . . . . . . . . . . . . . . . . . . . .1

15 0293395 Vis Taptite (8-32 x 3/8) . . . . . . . . . . . . .12

16 0277366 Carters de filtre, grand . . . . . . . . . . . . . .2

17 0279937 L'équipement de remplacement

de filtre . . . . . . . . . . . . . . . . . . . . . . . . .1

18 0277367 Crépines . . . . . . . . . . . . . . . . . . . . . . . .2

19 0277371 Mousses d'insonorisation . . . . . . . . . . . .1

20 0277369 Couvercle de carter . . . . . . . . . . . . . . . .1

21 0277396 Bases de montage de carter . . . . . . . . .6

22 0276598 Disque de mousse . . . . . . . . . . . . . . . . .1

Item Part No. Description Quantity

24 0277368 Foam Insert . . . . . . . . . . . . . . . . . . . . . . . .1

25 0277159 Silencer assembly . . . . . . . . . . . . . . . . . . .1

26 0279466 Foam disk . . . . . . . . . . . . . . . . . . . . . . . . .1

27 0277370 Can cover . . . . . . . . . . . . . . . . . . . . . . . . .1

28 0279415 Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

29 0277937 Turbine assembly, 3-stage, 120V . . . . . . . .1

30 0276511 Exhaust hose fitting . . . . . . . . . . . . . . . . . .1

31 9881911 Exhaust hose . . . . . . . . . . . . . . . . . . . . . . .1

32 9803104 Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

33 0277500 Cup holder . . . . . . . . . . . . . . . . . . . . . . . . .1

34 0275476 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

35 0295225 Warning light assembly, 120V . . . . . . . . . .1

36 0269112 Fuse holder . . . . . . . . . . . . . . . . . . . . . . . .1

37 0275710 Fuse, slow blow, 15 amp . . . . . . . . . . . . . .1

38 0277381 Top housing . . . . . . . . . . . . . . . . . . . . . . . .1

39 0277389 Foam Tape . . . . . . . . . . . . . . . . . . . . . . . .2

40 0277380 Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

41 0277372 Foam Tape . . . . . . . . . . . . . . . . . . . . . . . .2

42 0277472 Air flow switch . . . . . . . . . . . . . . . . . . . . . .1

43 0277475 Air flow tube . . . . . . . . . . . . . . . . . . . . . . .1

44 0277337 Air hose (not pictured) . . . . . . . . . . . . . . . .1

45 0275625 Quick disconnect fitting (not pictured) . . . . .1

Article

No de pièce Description Quantité

23 0277501 Attache . . . . . . . . . . . . . . . . . . . . . . . . .1

24 0277368 Mousses d'insonorisation . . . . . . . . . . . .1

25 0277159 Silencieux . . . . . . . . . . . . . . . . . . . . . . .1

26 0279466 Disque de mousse . . . . . . . . . . . . . . . . .1

27 0277370 Couvercle de carter . . . . . . . . . . . . . . . .1

28 0279415 Ressort . . . . . . . . . . . . . . . . . . . . . . . . .6

29 0277937 Turbine en trois pièces, 120 V . . . . . . . .1

30 0276511 Raccord de tuyau d'échappement . . . . .1

31 9881911 Tuyau d'échappement . . . . . . . . . . . . . .1

32 9803104 Vis . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

33 0277500 Porte-godet . . . . . . . . . . . . . . . . . . . . . .1

34 0275476 Commutateur . . . . . . . . . . . . . . . . . . . . .1

35 0295225 Voyant lumineux, 120 V . . . . . . . . . . . . .1

36 0269112 Porte-fusible . . . . . . . . . . . . . . . . . . . . .1

37 0275710 Fusible, le coup lent, 15 A . . . . . . . . . . .1

38 0277381 Boîtier supérieur . . . . . . . . . . . . . . . . . .1

39 0277389 Bande de mousse . . . . . . . . . . . . . . . . .2

40 0277380 Poignée . . . . . . . . . . . . . . . . . . . . . . . . .1

41 0277372 Bande de mousse . . . . . . . . . . . . . . . . .2

42 0277472 Sélecteur d'aération . . . . . . . . . . . . . . . .1

43 0277475 Tube d'aération . . . . . . . . . . . . . . . . . . .1

44 0277337 Boyau pour l'air (pas d'illustration) . . . . .1

45 0275625 Raccord rapide (pas d'illustration) . . . . .1

Español

Renglón No.

1 0277316 Anillo, retén de la salida de aire . . . . .1

2 0277439 Tubo de salida de aire . . . . . . . . . . . .1

3 9803103 Tornillo . . . . . . . . . . . . . . . . . . . . . . . .2

4 0277443 Cubierta de la caja del purgador . . . . .1

5 0277442 Base de la caja del purgador . . . . . . .1

6 0277397 Amortiguador . . . . . . . . . . . . . . . . . . .1

7 0277402 Cinta de espuma . . . . . . . . . . . . . . . .2

8 0277455 Caja del fondo, US . . . . . . . . . . . . . . .1

9 0090628 Amortiguador de la base . . . . . . . . . .4

10 9802222 Tornillo . . . . . . . . . . . . . . . . . . . . . . . .4

11 0277383 Placa de ventilación . . . . . . . . . . . . . .1

12 9800319 Tornillo, cabeza de cavidad

13 0276363 Desbloqueador . . . . . . . . . . . . . . . . . .1

14 0277471 Cordón . . . . . . . . . . . . . . . . . . . . . . . .1

15 0293395 Tornillo, Taptite 8-32x3/8 . . . . . . . . . .12

16 0277366 Recipiente del filtro, grande . . . . . . . .2

17 0279937 El conjunto de reemplazo de filtro . . . .1

18 0277367 Pantalla del filtro . . . . . . . . . . . . . . . .2

19 0277371 Espuma contra ruido de ventilador . . . . .1

20 0277369 Cubierta del recipiente . . . . . . . . . . . .1

21 0277396 Base de montaje del recipiente . . . . .6

22 0276598 Disco de espuma . . . . . . . . . . . . . . . .1

23 0277501 Soporte . . . . . . . . . . . . . . . . . . . . . . .1

© SprayTECH Corporation. All rights reserved. 15

Pieza No.

Descripción Cantidad

hexagonal 1/4-20 x .75 . . . . . . . . . . . .4

Renglón No.

24 0277368 Espuma contra ruido de ventilador . . . . .1

25 0277159 Conjunto del silenciador . . . . . . . . . . .1

26 0279466 Disco de espuma . . . . . . . . . . . . . . . .1

27 0277370 Cubierta del recipiente . . . . . . . . . . . .1

28 0279415 Resorte . . . . . . . . . . . . . . . . . . . . . . .6

29 0277937 Conjunto de la turbina, 3-fases, 120v . . . .1

30 0276511 Adaptador de la manguera de escape . . .1

31 9881911 Manguera de escape . . . . . . . . . . . . .1

32 9803104 Tornillo . . . . . . . . . . . . . . . . . . . . . . . .6

33 0277500 Sostén del depósito . . . . . . . . . . . . . .1

34 0275476 Interruptor . . . . . . . . . . . . . . . . . . . . .1

35 0295225 Conjunto de la luz de advertencia . . . .1

36 0269112 Portafusible . . . . . . . . . . . . . . . . . . . .1

37 0275710 Fusible, el golpe lento, 15 amperios . .1

38 0277381 Caja superior . . . . . . . . . . . . . . . . . . .1

39 0277389 Cinta de espuma . . . . . . . . . . . . . . . .2

40 0277380 Manubrio . . . . . . . . . . . . . . . . . . . . . .1

41 0277372 Cinta de espuma . . . . . . . . . . . . . . . .2

42 0277472 Interruptor del flujo de aire . . . . . . . . .1

43 0277475 Tubo del flujo de aire . . . . . . . . . . . . .1

44 0277337 Manguera de aire (no se muestra) . . .1

45 0275625 Accesorio de desconexión rápida

Español

Pieza No.

Descripción Cantidad

(no se muestra) . . . . . . . . . . . . . . . . .1

EnglishFrançais

Page 16

What Is Covered By This Warranty:

Limited Warranty — High Volume/Low Pressure Spray Equipment

This product, manufactured by CAPspray, is warranted against defects in material and workmanship for one (1) year following date of purchase if operated in

accordance with CAPspray's printed recommendations and instructions.

Within the applicable warranty period, CAPspray will repair or replace, at our option, defective parts without charge if such parts are returned with transportation

charges prepaid to the nearest Authorized Service Center or to CAPspray Corporation, 1770 Fernbrook Lane, Minneapolis, MN 55447. If CAPspray is unable to repair

this product as to conform to this Limited Warranty after a reasonable number of attempts, CAPspray will provide, at our option, either a replacement for this product

or a full refund of the purchase price of this product. These remedies are the sole and exclusive remedies available for breach of express and implied warranties.

What is Not Covered By This Warranty:

1. This Waranty does not cover any defects or damages caused by either:

a) the use or installation of repair or replacement parts or accessories not manufactured by CAPspray, or

b) repair performed by anyone other than a CAPspray Authorized Service Center.

2. The Warranty does not cover equipment and accessories supplied to CAPspray from an original equipment manufacturer, including but not limited to: hoses,

tips, or accessories. CAPspray will provide the purchaser with copies of the original equipment manufacturer’s express warranties provided to CAPspray along

with the name and address of the appropriate manufacturer.

3. This Warranty does not cover damage or defects caused by or related to abrasion, corrosion, abuse, misuse, negligence, accident, normal wear, faulty

installation, or tampering in a manner which impairs normal operation.

Limitation of Remedies:

IN NO CASE SHALL CAPSPRAY BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OR LOSS, INCLUDING TRANSPORTATION

COSTS, WHETHER SUCH DAMAGES ARE BASED UPON A BREACH OF EXPRESS OR IMPLIED WARRANTIES, BREACH OF CONTRACT, NEGLIGENCE,

STRICT TORT, OR ANY OTHER LEGAL THEORY.

Disclaimer Of Implied Warranties:

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABlLlTY AND FITNESS FOR A PARTICULAR PURPOSE.

No Ability To Transfer:

This warranty is extended to the original purchaser only and is not transferable.

Your Rights Under State Law:

Some states do not allow limitations on how long an implied warranty lasts or the exclusion of incidental or consequential damages, so the above limitation and

exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Ce qui est couvert par la présente garantie :

Ce produit, fabriqué par CAPspray, est garanti contre tout vice de matières et toute malfaçon pendant un (1) an suivant la date d'achat, lorsqu'il est utilisé

conformément aux recommandations et directives imprimées de CAPspray.

Pendant la période de la dite garantie, CAPspray réparera ou remplacera, à son choix, les pièces défectueuses sans frais si ces dernières sont envoyées, port payé,

au centre d'entretien autorisé le plus près, ou directement chez elle, au 1770 Fernbrook Lane, Minneapolis, MN 55447 (É.-U.). Si CAPspray ne peut, après un

nombre raisonnable de tentatives, réparer le produit de manière à ce qu'il soit conforme à la présente garantie limitée, elle devra, à son choix, remplacer le produit ou

en rembourser le prix d'achat. Seuls les recours exclusifs qui précèdent sont offerts en cas de violation des garanties expresses et implicites.

Ce qui n'est pas couvert par la présente garantie :

1. La présente garantie ne couvre pas les défauts ou dommages entraînés par :

a) l'utilisation ou l'installation de pièces ou d'accessoires de rechange ou de réparation n'étant pas fabriqués par CAPspray;

b) les réparations effectuées par qui que ce soit d'autre qu'un centre d'entretien autorisé par CAPspray.

2. La présente garantie ne couvre pas l'équipement et les accessoires fournis à CAPspray par un fabricant de matériel original (OEM) incluant ,sans toutefois s'y

limiter, les tuyaux flexibles et les embouts. CAPspray fournira à l'acheteur un exemplaire des garanties expresses offertes par le fabricant, de même que le nom

et l'adresse de ce dernier.

3. La présente garantie ne couvre pas les défauts ou les dommages découlant de l'abrasion, de la corrosion, de l'usage abusif, de l'emploi incorrect, de

négligence, d'accidents, de l'usure normale, d'une installation fautive ou d'une intervention non autorisée susceptible de nuire au fonctionnement normal de

l'équipement.

Limitation des recours :

CAPSPRAY NE PEUT EN AUCUN CAS ÊTRE TENUE RESPONSABLE DE TOUT DOMMAGE OU DE TOUTE PERTE DE NATURE INDIRECTE, SPÉCIALE OU

CONSÉCUTIVE, INCLUANT LES FRAIS DE TRANSPORT, QUE CES PERTES OU DOMMAGES SOIENT FONDÉS SUR UNE VIOLATION DES GARANTIES

EXPRESSES ET IMPLICITES, UNE RUPTURE DE CONTRAT, DE LA NÉGLIGENCE, UN DÉLIT CIVIL OU TOUTE AUTRE THÉORIE JURIDIQUE.

Stipulation d'exonération de garanties implicites :

LES GARANTIES PRÉCÉDENTES REMPLACENT TOUTE AUTRE GARANTIE, EXPRESSE OU IMPLICITE, INCLUANT, SANS TOUTEFOIS S'Y LIMITER, LES

GARANTIES IMPLICITE DE VENDABILITÉ ET DE CONVENANCE À UNE DESTINATION PARTICULIÈRE.

Aucune possibilité de transfert :

La présente garantie est offerte à L'acheteur original seulement et n'est pas transférable.

Droits en vertu de lois locales :

Certains états ou provinces ne permettant pas la limitation de la durée de garanties implicites ou l'exclusion de dommages indirects ou consécutifs, les limitations et

exclusions ci-dessus pourraient ne pas s'appliquer à l'acheteur. Si la présente garantie lui accorde des droits particuliers, l'acheteur pourrait en disposer d'autres en

vertu de lois variant entre provinces et états.

Garantía Limitada — Equipo de atomización de alto volumen y baja presión

Lo que está cubierto por esta garantía:

Este producto, fabricado por CAPspray, está garantizado por un (1) año a partir de la fecha de compra, contra los defectos de material y mano de obra que haya

cuando se utilice de acuerdo con las recomendaciones e instrucciones impresas de CAPspray.

Dentro del período de garantía con validez, CAPspray reparará o reemplazará, a opción nuestra y sin cargo, las piezas defectuosas si dichas piezas se devuelven,

con el costo de transportación pagado de antemano, al Centro de Servicio Autorizado más cercano o a CAPspray Corporation, 1770 Fernbrook Lane, Minneapolis,

MN 55447. Si CAPspray es incapaz de reparar este producto conforme se establece en esta Garantía Limitada después de un número razonable de intentos,

CAPspray proporcionará, a opción nuestra, ya sea un repuesto de este producto o bien el reembolso total del precio de compra de este producto. Estos remedios

son los únicos y exclusivos remedios de que se dispone cuando se violen las garantías expresas o implícitas.

Lo que no está cubierto por esta garantía:

1. Esta garantía no cubre ningún defecto o daño que haya surgido a causa de:

a) usar o instalar piezas de reparación o reemplazo o accesorios que no haya fabricado CAPspray, o

b) una reparación realizada por alguien que no pertenezca al Centro de Servicio Autorizado de CAPspray.

2. La garantía no cubre el equipo ni los accesorios que se le hayan suministrado a CAPspray a través de un fabricante de equipo original, que incluyen sin quedar

limitados a ser sólo estos: mangueras, boquillas o accesorios. CAPspray le proporcionará al comprador copias de las garantías expresas del fabricante del

equipo que se le hayan proporcionado, junto con el nombre y dirección del fabricante apropiado.

3. Esta garantía no cubre los daños ni defectos que hayan sido causados por la abrasión, corrosión, abuso, uso erróneo, negligencia, accidentes, desgaste

normal, una instalación defectuosa o una alteración por la que se impida el funcionamiento normal, o que tengan relación con éstos.

Limitación de remedios:

CAPSPRAY NO SE HARÁ RESPONSABLE EN NINGÚN CASO DE LA PÉRDIDA NI DE NINGÚN DAÑO, INCIDENTAL, ESPECIAL O DE CONSECUENCIA,

INCLUYENDO LOS COSTOS DE TRANSPORTACIÓN, SI LOS DAÑOS SE ORIGINAN POR VIOLAR LAS GARANTÍAS EXPRESAS O IMPLÍCITAS, VIOLAR EL

CONTRATO, NEGLIGENCIA, ESTRICTO PERJUICIO O CUALQUIER OTRA TEORÍA LEGAL.

Renuncia de garantías implícitas:

LAS GARANTÍAS ANTERIORMENTE MENCIONADAS SON EN LUGAR DE TODAS LAS DEMÁS GARANTÍAS, EXPRESAS O IMPLÍCITAS, QUE INCLUYEN SIN

QUEDAR LIMITADAS A SER SÓLO LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E IDONEIDAD PARA UN PROPÓSITO PARTICULAR.

Sin posibilidad de ser transferida:

Esta garantía se le extiende al comprador original solamente y no es transferible.

Sus derechos bajo la ley estatal:

Algunos estados no permiten limitaciones en cuanto a la duración de una garantía implícita o la exclusión de daños incidentales o de consecuencia, de manera que

la limitación y exclusión anteriores podrían no ser válidas para usted. Esta garantía le concede derechos legales específicos, pero podría tener derecho a otros, los

que varían de estado a estado.

Garantie Limitée — Équipement pulvérisateur à volume élevé et à basse pression

Page 17

Loading...

Loading...