Page 1

CS10000 HVLP Spray System

CAPSpray

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

Owner’s Manual

Printed in the U. S. A.

Model No. 0295636

0201 © 2001 CAPSpray. All rights reserved. Form No. 0295640D

Page 2

Table of Contents

WARNING

CAUTION

WARNING

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Connecting the Spray System . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Spray Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety

This manual contains information that must be read and

understood before using the equipment. When you come to

an area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information will

follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information that should

be given special attention.

HAZARD: GENERAL — May cause property damage or

severe injury.

PREVENTION:

• Read all instructions and safety precautions before

operating any equipment.

• Comply with all appropriate local, state and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly Part 1910 of

the General Standards and Part 1926 of the Construction

Standard should be consulted.

• This equipment is designed to be used with authorized

parts only. When using this equipment with parts that do

not comply with the minimum specifications and safety

devices of the equipment manufacturer, the user assumes

all risks and liabilities.

• Check all hoses for cuts, leaks, abrasion or bulging of

cover, as well as damage or movement of couplings

before each use. If any of these conditions exist, replace

the hose immediately. Never repair a paint hose.

• Never aim the spray gun at any part of the body.

• Wear protective eyewear.

HAZARD: SKIN BURN INJURY— Heated parts can cause

severe skin burn injury.

PREVENTION:

• Quick-disconnect fittings on the hose and the spray gun

become hot during use. Avoid skin contact with any

quick-disconnect fittings when they are hot. Allow the

quick disconnect fittings to cool before disconnecting the

spray gun from the hose

• The compressor becomes hot during use. Allow the

compressor to cool before touching it.

HAZARD: HAZARDOUS VAPORS — Paints, solvents,

insecticides, and other materials may be

harmful if inhaled causing severe nausea,

fainting, or poisoning.

PREVENTION:

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled. Read all instructions with the

mask to insure that it will provide the necessary protection

against the inhalation of harmful vapors.

HAZARD: EXPLOSION — Compressed air has great force

and may cause injury.

PREVENTION:

• The maximum operating range of the unit is 125 PSI air

pressure.

• The pressure pot assembly is protected from overpressurizing by a safety valve. Pull the ring on the safety

valve occasionally to make sure that the valve operates

freely. The valve must be replaced if it does not operate

freely or if it does not release air when the ring is pulled.

• Never modify the pressure pot or the compressor.

• All accessories must be rated at or above 125 PSI. This

includes spray tips, guns, extensions, hoses, and other

tools.

HAZARD: EXPLOSION OR FIRE — Solvent and paint

fumes can explode or ignite causing property

damage and or severe injury.

PREVENTION:

• Exhaust and fresh air introduction must be provided to

keep the air within the spray area free from the

accumulation of flammable vapors.

• Keep the turbine at the maximum distance possible from

the spray area.

• Avoid all ignition sources such as static electricity sparks,

open flames, pilot lights, hot objects, cigarettes, and

sparks caused by connecting and disconnecting power

cords and operating light switches.

• Keep the motor away from spray area to avoid solvent

and paint fumes. Motor contains arcing parts which emit

sparks.

• Fire extinguishing equipment must be present and in

working order.

• The power cord must be connected to a grounded circuit.

• Follow the material and solvent manufacturer's safety

precautions and warnings.

Grounding Instructions

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

WARNING

Improper installation of the grounding plug can result in a

risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either flat blade terminal.

The wire with insulation having a green outer surface with or

without yellow stripes is the grounding wire and must be

connected to the grounding pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

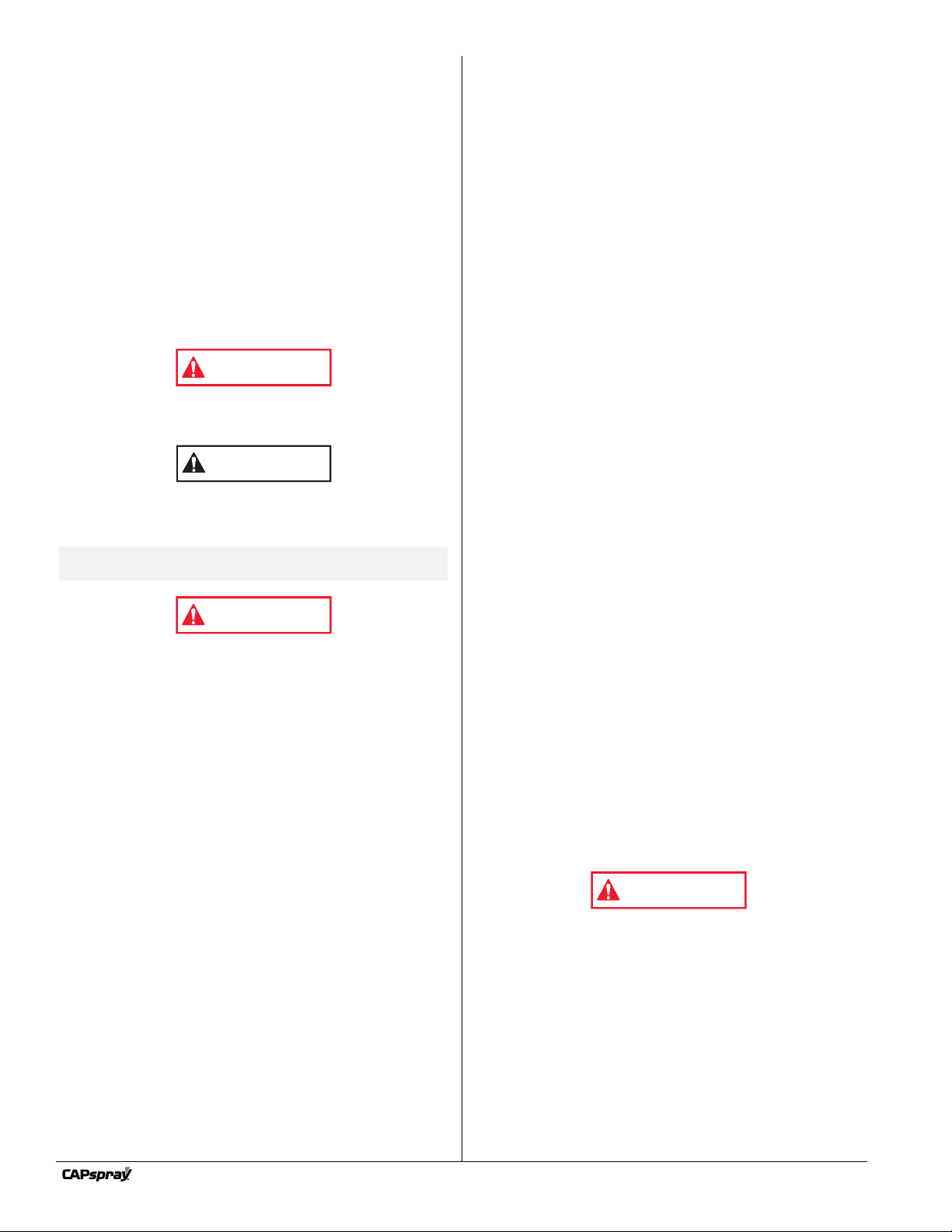

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below.

2 © CAPSpray. All rights reserved.

Page 3

Extension Cord Selection

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Pressure Pot Outlet

Material Hose

Air Hose

Spray Gun

Material

Inlet

Spray Gun

Air Inlet

Pressure Pot Air Inlet

Compressor Hose

If an extension cord is used, make sure that it is of the 3conductor type with NEMA connectors so a continuous

grounding circuit is provided from the tool to the power circuit

receptacle. Also, be sure that the conductor size is large

enough to prevent excessive voltage drop which will cause

loss of power and possible motor damage to the unit. A table

of recommended extension cord sizes is shown below.

If an extension cord is to be used outdoors, it must be marked

with the suffix W-A following the cord type designation. For

example, SJTW-A to indicate that it is acceptable for outdoor

use.

Use only a 3-wire extension cord that has a 3-blade grounding

plug and a 3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. A 14 or 12 gauge cord is

recommended.

NOTE: Do not use more than 100 feet of extension

cord. If you need to paint further than 100 feet

from your power source, use more paint hose,

not more extension cord. Shorter extension

cords will ensure maximum electrical power

for proper operation.

Setup

Connecting the Spray System

1. Make sure the ON/OFF lever on the pressure switch is on

the OFF position.

2. Connect the compressor hose from the lower storage tank

to the pressure pot air inlet.

NOTE: The hose features quick-disconnect fittings.

To use, pull back on the spring-loaded collar

of each fitting. Slide the hose fitting over the

correct connection and release the collar.

3. Thread the end of the material hose onto the pressure pot

material outlet and tighten.

4. Thread the other end of the material hose onto the spray

gun material inlet and tighten.

Introduction

The CS10000 HVLP spray system is designed for use as a

large capacity, fine finish spray painting tool. Components of

the spray system include a dual-head compressor, a cart, a

compressor air outlet, a pressure switch, a pressure pot, a

pressure pot air inlet, and a pressure pot material outlet.

Pressure Pot

Pressure Pot

Dual-Head

Compressor

Storage

Tanks

Cart

NOTE: The dual-head compressor can be used to

© CAPSpray. All rights reserved. 3

Pressure Pot

Air Inlet

supply air for other air-powered tools. A tee

fitting on the compressor air outlet allows the

installation of an additional regulator.

Material Outlet

(behind regulator)

Compressor

Air Outlet

Pressure Switch

5. Connect the air hose to compressor air outlet.

6. Thread the other end of the air hose onto the spray gun

air inlet and tighten.

Page 4

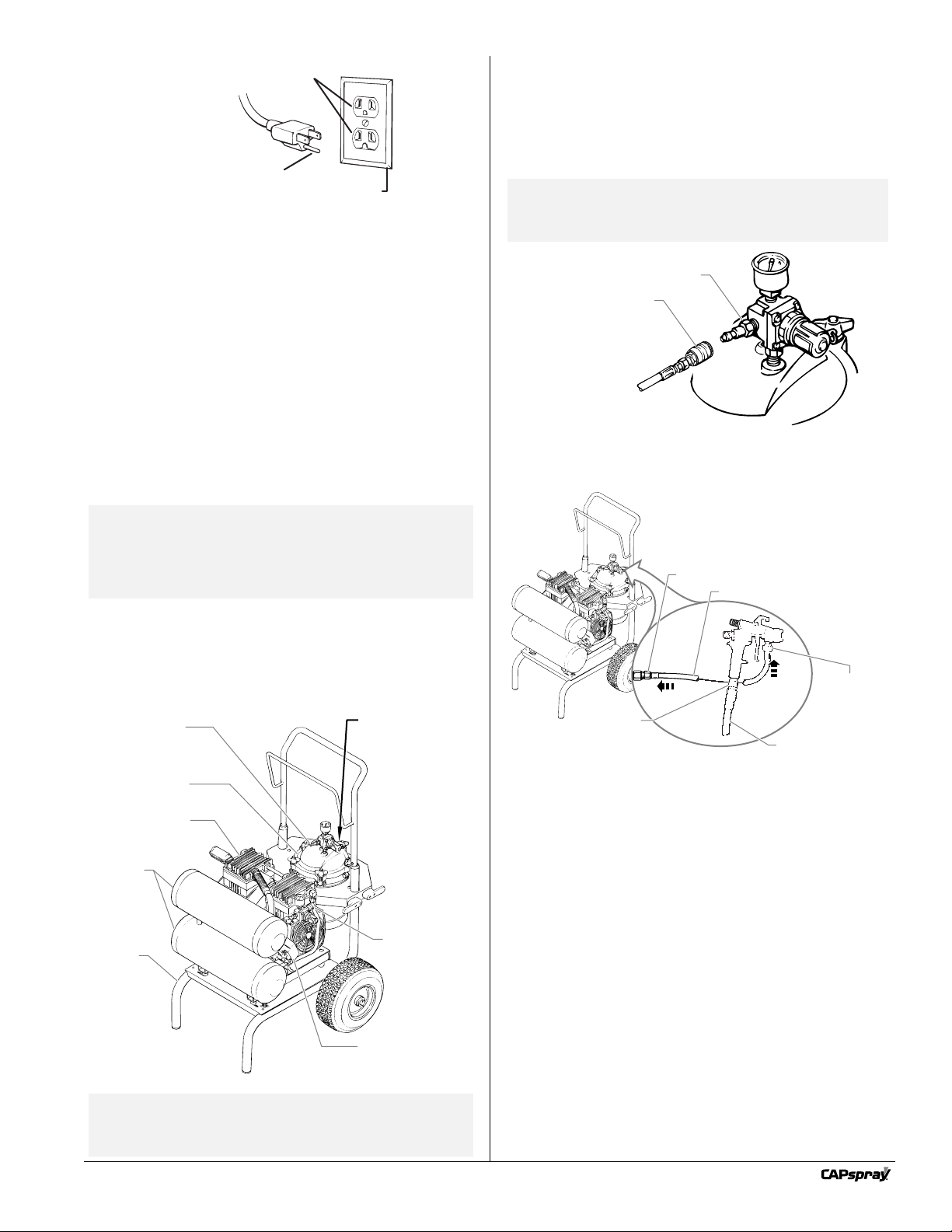

Operation

Compressor

Air Outlet

Pressure

Control Knob

Pressure Gauge

Cover

Groove

Seal

Locking Clamp

Pressure Pot

Pressure

Control Knob

Pot Liner

(optional)

Spraying Pressure Air Consumption

Pressure

Inside Cap

Compressor Pressure*

Air CFM

6 PSI 6.5 9

15

18

20

24

7.5

7.8

8

8.5

8 PSI

10 PSI

12 PSI

14 PSI

*The pressure at the compressor air outlet

when spraying gun.

Startup

1. Place the unit in a clean, dry and well-ventilated area.

The compressor should be located at least 12” from walls

or other obstructions that could interfere with the flow of

air.

2. Fill the pressure pot

with spray material.

3. Fasten the cover

securely onto the

pressure pot by

placing the five

locking clamps into

the cover grooves

and rotating each

clockwise until hand

tight. Be certain that

the seal is in place.

4. Plug in the power

cord for the

compressor.

5. Move the ON/OFF

lever on the pressure

switch to the ON

position to start the

compressor. Allow

the tank pressure to

build. When the

motor stops, the

compressor has

reached cut-out

pressure, and the

system is ready for

use.

6. Pull out the pressure

control knob on the

pressure pot and

turn it until the pressure pot pressure is set properly for

the type of material you are using.

• For thin materials, set to 8 PSI.

• For thicker materials, set to between 8 and 14 PSI.

7. Pull out the pressure control knob on the compressor air

outlet and turn it until the gun pressure is set properly for

the type of material you are using.(see spray chart for

reference).

Shutdown

1. Move the ON/OFF lever on the pressure switch to the

OFF position.

2. Allow the compressor to cool.

3. Drain the storage tanks (refer to compressor manual for

procedure).

Spray Charts

8. Practice spraying on a piece of scrap wood or cardboard

until you are satisfied with the pot pressure, gun air

pressure, spray pattern, and spray shape. The spray

pattern adjustments and spray shape selections are

described in your gun manual.

4 © CAPSpray. All rights reserved.

Page 5

Français

AVERTISSEMENT

DANGER: GÉNÉRAUX — Risques de dommages matériels et de

PRÉVENTION:

• Lire toutes les directives et mises en garde avant de faire

• Se conformer à tous les codes locaux, provinciaux et nationaux

• Les normes de sécurité adoptées par le gouvernement américain

• Cet équipement est conçu pour fonctionner avec les pièces

• On doit s'assurer que les tuyaux soient exempts de coupures, de

• On ne doit jamais orienter le pistolet vers une partie du corps.

DANGER: DANGER DE BRÛLURE — Les pièces chauffées

PRÉVENTION:

• Les raccords à dégagement rapide du tuyau flexible et du pistolet

• Le compresseur devient chaud à l'utilisation. Le laisser refroidir

DANGER: ÉMANATIONS DANGEREUSES — Les peintures, les

PRÉVENTION:

• Utiliser un masque ou un respirateur en présence de risques

DANGER: EXPLOSION — L'air comprimé est très puissant et

PREVENTION:

• L'ensemble réservoir est protégé contre la surpression par une

• Ne jamais modifier le réservoir sous pression ni le compresseur.

• Ne connecter aucun autre outil pneumatique au compresseur.

DANGER: D'EXPLOSION OU D'INCENDIE — Les émanations de

PRÉVENTION:

• On doit assurer la ventilation et l'introduction d'air neuf dans la

• Placer la turbine le plus loin possible de la zone de pulvérisation.

• Il faut éviter les sources de combustion comme l'électricité statique,

• Placer le moteur le plus loin possible de la zone de pulvérisation

• On doit avoir à portée de la main de l'équipement d'extinction en

• Le cordon d'alimentation doit être raccordé à un circuit mis à la

• S'assurer de suivre les directives en matière de sécurité et de lire

© CAPSpray. All rights reserved. 5

blessures graves.

fonctionner l'équipement, quel qu'il soit.

qui régissent la ventilation, la prévention des incendies et le

fonctionnement des dispositifs.

l'ont été en vertu de sa Occupational Safety and Health Act

(OSHA); ces normes, particulièrement les parties 1910 des

normes générales et 1926 des normes de construction, devraient

toujours être consultées.

autorisées seulement. Si on l'utilise avec des pièces non

conformes aux spécifications et exigences en matière de sécurité

du fabricant, on devra accepter les responsabilités et risques

inhérents.

fuites, d'abrasions ou de renflements et que les raccords ne

soient ni endommagés ni mal assujettis avant chaque usage. Le

cas échéant, il faut remplacer le tuyau sur le champ, en ne

tentant jamais de le réparer.

peuvent causer de graves brûlures cutanées.

peuvent s'échauffer en cours d'utilisation; il faut alors éviter les

contacts cutanés, en attendant que les raccords refroidissent avant

de séparer le pistolet du tuyau.

avant d'y toucher.

solvants, les insecticides et autres substances

peuvent être dangereuses si inhalées, entraînant de

graves nausées, des pertes de connaissance ou une

intoxication.

d'inhalation. Lire toutes les directives relatives au dispositif de

protection afin d'en assurer l'efficacité dans l'usage auquel il est

destiné.

peut provoquer des blessures.

soupape de sécurité. De temps en temps, tirer sur l'anneau de la

soupape de sécurité pour vérifier qu'elle fonctionne normalement.

Remplacer la soupape si elle ne fonctionne pas bien ou si elle ne

laisse pas passer l'air quand on tire sur l'anneau.

solvants et de peintures peuvent exploser ou

s'enflammer, entraînant des dommages matériels ou

des blessures graves.

zone de pulvérisation afin d'éviter les accumulations de vapeurs

inflammables.

les flammes nues, les veilleuses de bec de gaz, les objets chauds,

les cigarettes et les étincelles provoquées par la

connexion/déconnexion de cordon d'alimentation et la commutation

d'interrupteurs d'éclairage.

pour l'éloigner des vapeurs de solvant et de peinture. Le moteur

contient des pièces qui peuvent émettre des étincelles.

bon état de marche.

terre.

les mises en garde du fabricant des solvants et des produits

utilisés.

Español

ADVERTENCIA

PELIGRO: GENERAL — Puede causar daños en la propiedad o

PREVENCIÓN:

• Lea todas las instrucciones y advertencias de seguridad antes de

• Cumpla con todos los códigos locales, estatales y nacionales de

• Los Estándares de Seguridad del Gobierno de los Estados Unidos

• Este equipo está diseñado para usarse solamente con piezas

• Cada vez, antes de usarlo, revise todas las mangueras para ver

• Nunca apunte la pistola hacia alguna parte del cuerpo.

PELIGRO: QUEMADURA DE LA PIEL — Las piezas calientes

PREVENCIÓN:

• Las conexiones de desconexión rápida de la manguera y la

• El compresor se calienta durante el uso. Permita que el

PELIGRO: VAPORES PELIGROSOS — Las pinturas, solventes,

PREVENCIÓN:

• Use un respirador o una mascarilla siempre que exista el riesgo

PELIGRO: EXPLOSION — El aire comprimido tiene una gran

PREVENCION:

• El ensamble del tanque de presión está protegido con una

• Nunca modifique el tanque de presión o el compresor.

• Nunca conecte otras herramientas de aire al compresor.

PELIGRO: INCENDIO O EXPLOSIÓN — Los vapores de los

PREVENCIÓN:

• Se deberá contar con un escape y entrada de aire fresco para

• Mantenga la turbina a la máxima distancia posible del área de

• Evite que haya cualquier fuente de ignición como la electricidad

• Mantenga el motor alejado del área de pintado para evitar

• Debe haber equipo para extinción de incendios que además

• El cable de energía debe conectarse en un circuito que esté

• Siga las medidas de precaución y advertencias de seguridad del

lesiones severas.

hacer funcionar cualquier equipo.

ventilación, prevención de incendios y operación que rijan.

se han adoptado bajo el Decreto de Seguridad y Salud

Ocupacionales (OSHA por sus siglas en inglés). Deben consultarse

estos estándares, particularmente la parte 1910 de los Estándares

Generales y la parte 1926 de los Estándares de la Construcción.

autorizadas por el fabricante. Cuando se use este equipo con

piezas que no cumplan con las especificaciones mínimas ni con

las de los dispositivos de seguridad del fabricante de la bomba,

el usuario asumirá todos los riesgos y responsabilidades legales.

que no tengan cortadas, fugas, una cubierta desgastada por

abrasión o con abolladuras, así como uniones dañadas o que se

hayan movido. Si existiera cualquiera de estas condiciones,

reemplace la manguera inmediatamente. Nunca repare una

manguera de pintura.

pueden causar lesiones de quemadura de la piel

severas.

pistola de atomización se llegan a calentar mientras se usan.

Evite que la piel tenga contacto con las conexiones de

desconexión rápida cuando se calienten. Deje que las

conexiones de desconexión rápida se enfríen antes de

desconectar la pistola de atomización de la manguera.

compresor se enfríe antes de tocarlo.

insecticidas y otros materiales pueden ser peligrosos

si se inhalan; pueden causar náuseas, desmayos o

envenenamientos severos.

de poder inhalar los vapores. Lea las instrucciones de la

mascarilla para asegurarse de que proporcionará la protección

necesaria contra la inhalación de vapores dañinos.

fuerza y pudiera causar lesiones.

válvula de seguridad en caso de una sobre presurización.

Ocasionalmente jale la argolla de la válvula de seguridad para

asegurarse que la válvula opere libremente. En caso de no

operar con libertad o si la válvula no libera aire cuando se jala la

argolla, debe cambiarse.

solventes y pinturas pueden explotar o encenderse y

causar con esto daños en la propiedad y/o lesiones

severas.

mantener el aire del área de atomización libre de acumulaciones

de vapores inflamables.

pintado.

estática, llamas abiertas, flamas de pilotos, objetos calientes,

cigarros y chispas que provengan de conectar y desconectar

cables de energía e interruptores de luces que estén funcionando.

vapores de solvente y pintura. El motor contiene partes que al

arquear producen chispas.

funcione bien.

conectado a tierra.

fabricante del material y del solvente.

Page 6

Parts List

Main Assembly

NOTE: Refer to the air compressor

manual included with this

unit for air compressor

replacement parts.

8

2

9

10

11

12

13

14

From compressor

1

2

11

3

To gun

15

16

17

18

19

20

4

5

6

7

Item Part # Description Quantity

1 0295689 Air hose.....................................................1

2 0275696 Fitting, air, 1/4" male, quick connect.........2

3 0295691 Compressor...............................................1

4 ---------- Cart assembly (see separate listing) ........1

5 9820206 Washer......................................................4

6 9821503 Lock washer..............................................4

7 0295695 Screw ........................................................4

8 0275721 Check valve ..............................................1

9 0279427 Pressure gauge, 60 psi.............................1

10 0275693 Regulator...................................................2

11 05045 Fitting, 1/4” x 1/8”......................................1

Item

6 © CAPSpray. All rights reserved.

Part # Description Quantity

12 0277348 Hose, material (connects to gun)..............1

13 0295700 Relief valve ...............................................1

14 0295701 Fitting, fluid................................................1

15 0295702 Lid .............................................................1

16 0295703 Tube, pick up ............................................1

17 0508943 Pot gasket .................................................1

18 0275702 Pot liner.....................................................1

19 0279284 Pressure pot..............................................1

20 0295040 Pressure pot assembly

(Includes Items 8–11 and 13–19).....................1

21 0279647 Pot liner “Caution” label (not shown) ........1

Page 7

1

2

3

4

6

7

8

9

10

11

12

13

14

15

13

5

Cart Assembly

Item

1 0295611 Hole trim ...............................................1

2 0295725 Cart weldment, CS10000 .....................1

3 9885571 Plug.......................................................2

4 0508144 Handle ..................................................1

5 0295610 Roll pin..................................................2

6 9841504 Snap button ..........................................2

7 0295607 Sleeve...................................................2

8 0295609 Washer..................................................2

Part # Description Quantity

Item

9 0295608 Screw....................................................4

10 0509386 Washer..................................................4

11 0293357 Screw....................................................4

12 0279437 Cord wrap .............................................2

13 0294534 Spacer washer......................................4

14 0507379 Wheel....................................................2

15 9890104 Hub cap ................................................2

Part # Description Quantity

© CAPSpray. All rights reserved. 7

Page 8

Limited Warranty - High Volume, Low Pressure Spray Equipment

What Is Covered By This Warranty:

This product, manufactured by CAPspray, is warranted against defects in material and workmanship for one (1) year following

date of purchase if operated in accordance with CAPspray's printed recommendations and instructions.

Within the applicable warranty period, CAPspray will repair or replace, at our option, defective parts without charge if such parts

are returned with transportation charges prepaid to the nearest Authorized Service Center or to CAPspray Corporation, 1770

Fernbrook Lane, Minneapolis, MN 55447. If CAPspray is unable to repair this product as to conform to this Limited Warranty after

a reasonable number of attempts, CAPspray will provide, at our option, either a replacement for this product or a full refund of the

purchase price of this product. These remedies are the sole and exclusive remedies available for breach of express and implied

warranties.

What is Not Covered By This Warranty:

1. This Warranty does not cover any defects or damages caused by either:

a) the use or installation of repair or replacement parts or accessories not manufactured by CAPspray, or

b) repair performed by anyone other than a CAPspray Authorized Service Center.

2. The Warranty does not cover equipment and accessories supplied to CAPspray from an original equipment manufacturer,

including but not limited to: hoses, tips, or accessories. CAPspray will provide the purchaser with copies of the original

equipment manufacturer’s express warranties provided to CAPspray along with the name and address of the appropriate

manufacturer. In the case of the compressor, the manufacturer has extended the warranty — first year for parts and service,

second year on parts only.

3. This Warranty does not cover damage or defects caused by or related to abrasion, corrosion, abuse, misuse, negligence,

accident, normal wear, faulty installation or tampering in a manner which impairs normal operation.

Limitation of Remedies:

IN NO CASE SHALL CAPSPRAY BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OR LOSS,

INCLUDING TRANSPORTATION COSTS, WHETHER SUCH DAMAGES ARE BASED UPON A BREACH OF EXPRESS OR

IMPLIED WARRANTIES, BREACH OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL THEORY.

Disclaimer Of Implied Warranties:

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABlLlTY AND FITNESS FOR A PARTICULAR PURPOSE.

No Ability To Transfer:

This warranty is extended to the original purchaser only and is not transferable.

Your Rights Under State Law:

Some states do not allow limitations on how long an implied warranty lasts or the exclusion of incidental or consequential

damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Patents

These products are covered by one or more of the following U.S. patents:

5,423,395 D322,790 5,181,832 D338,208 5,174,610 5,550,336 D365,569

5,556,255 5,639,222 5,702,131 5,558,492 5,573,371 5,772,711

SprayTECH 30-Day Satisfaction Guarantee

If, within a 30-day period from the date of purchase, you are not totally satisfied with a SprayTECH/CAPSpray unit, you

may return it for full credit toward another SprayTECH or CAPSpray product of equal or greater value.

8 © CAPSpray. All rights reserved.

Loading...

Loading...