Page 1

Instruction manual for wall chimney hoods

Model codes: ZC920 / ZC620

Contact Caple on 0844 800 3830 or for spare parts www.4caple.co.uk

Page 2

IMPORTANT SAFETY INFORMATION

IMPORTANT SAFETY INFORMATION

**Read the complete manual carefully before installation**

**Read the complete manual carefully before installation**

Intended for Domestic Kitchen Use Only

Intended for Domestic Kitchen Use Only

Warnings:

Warnings:

TO REDUCE HE ISK F IRE LECTRICAL HOCK R ERSONAL NJURY LEASE

TO REDUCE HE ISK F IRE LECTRICAL HOCK R ERSONAL NJURY LEASE

BSERVE HE OLLOWING

BSERVE HE OLLOWING

OTF

OTF

1 Installation and electrical work must be done by a qualified person in accordance with all

1 Installation and electrical work must be done by a qualified person in accordance with all

.

.

applicable codes and standards

applicable codes and standards

2 If the power cord is damaged it must be replaced by the manufacturer its service

2 If the power cord is damaged it must be replaced by the manufacturer its service

., ,

., ,

agent or a similarly qualified person to avoid a hazard Any modifications that may be

agent or a similarly qualified person to avoid a hazard Any modifications that may be

required to the electrical system for the installation of the cooker hood must only be

required to the electrical system for the installation of the cooker hood must only be

made by qualified electricians

made by qualified electricians

3 Before servicing or cleaning unit switch the power off at the service panel Lock panel

3 Before servicing or cleaning unit switch the power off at the service panel Lock panel

., .

., .

to prevent power from being switched on accidentally

to prevent power from being switched on accidentally

4 Use this unit only in the manner intended by the manufacturer

4 Use this unit only in the manner intended by the manufacturer

. .

. .

5 Sufficient air is needed for combustion and exhausting of gases through the chimney of

5 Sufficient air is needed for combustion and exhausting of gases through the chimney of

.

.

fuel burning equipment to prevent back drafting Follow the heating equipment

fuel burning equipment to prevent back drafting Follow the heating equipment

manufacturer's guidelines with safety standards and the local authorities code

manufacturer's guidelines with safety standards and the local authorities code

6 When cutting or drilling into the wall or ceiling be careful not to damage existing

6 When cutting or drilling into the wall or ceiling be careful not to damage existing

.,

.,

electrical wiring and other hidden utilities

electrical wiring and other hidden utilities

TR OF E S OP I P

TR OF E S OP I P

,,

,,

:

:

.

.

.

.

.

.

.

.

,.

,.

.

.

7 Ducted fans must always be vented to the outdoors

7 Ducted fans must always be vented to the outdoors

..

..

8 To reduce the risk of fire use only metal ductwork

8 To reduce the risk of fire use only metal ductwork

.,.

.,.

9 This unit must be earthed

9 This unit must be earthed

..

..

TO REDUCE HE ISK F ANGE OP REASE IRE

TO REDUCE HE ISK F ANGE OP REASE IRE

1 Never leave surface units unattended at high settings Boil overs cause smoke and

1 Never leave surface units unattended at high settings Boil overs cause smoke and

..-

..-

greasy spillovers that may ignite Heat oils slowly on low or medium settings

greasy spillovers that may ignite Heat oils slowly on low or medium settings

2 Always turn the hood ON when cooking at high heat

2 Always turn the hood ON when cooking at high heat

..

..

3 Clean ventilating fans frequently Grease should not be allowed to accumulate on fan or

3 Clean ventilating fans frequently Grease should not be allowed to accumulate on fan or

..

..

filter

filter

4 Use correct pan size Always use cookware appropriate for the size of the surface

4 Use correct pan size Always use cookware appropriate for the size of the surface

..

..

element

element

TR OAR TG F

TR OAR TG F

..

..

.

.

.

.

:

:

Page 3

WARNING

TO REDUCE THE RICK OF INJURY TO PERSONS IN THE EVENT OF A GREASE FIRE

OBSERVE THE FOLLOWING,:

1 SMOTHER FLAMES with a close fitting lid cookie sheet or metal tray and then turn off

.-,,

the burner If the flames do not go out immediately evacuate and call the fire

department

2 NEVER PICK UP A FLAMING PAN You may be burned

..–.

3 DO NOT USE WATER including wet dishcloths or towels a violent steam explosion will

., –

result

4 Use an extinguisher ONLY if

.:

.,

.

.

You know you have a Class ABC extinguisher and you know how to operate it

Thefireissmallandcontainedintheareawhereitstarted

The fire department is being called

Youcanfightthefirewithyourbacktoanexit

.

.

.

.

CAUTION

1 To reduce the risk of fire and to properly exhaust air be sure to duct air outside

.,.

Do not vent exhaust air into spaces within walls or ceiling or into attics crawl

spaces or garages

2 Take care when using cleaning agents or detergents

..

3.

Avoid using food products that produce flames under the cooker hood.

4. The cooker hood must only be used for the exhaust of cooking fumes in home kitchens.

The manufacturer disclaims all liability for any other use of the appliance.

5. Two installers are recommended because of the large size and weight of this hood.

6. Use with approved cord-connection kit only.

7. Please read specification label on product for further information and requirements.

.

,

Page 4

INSTALLATION INSTRUCTIONS

Before You Start...

1. Read this manual carefully and completely.

2. The cooker hoods conform to related appliances standards. Please check your local building codes for any

additional requirements.

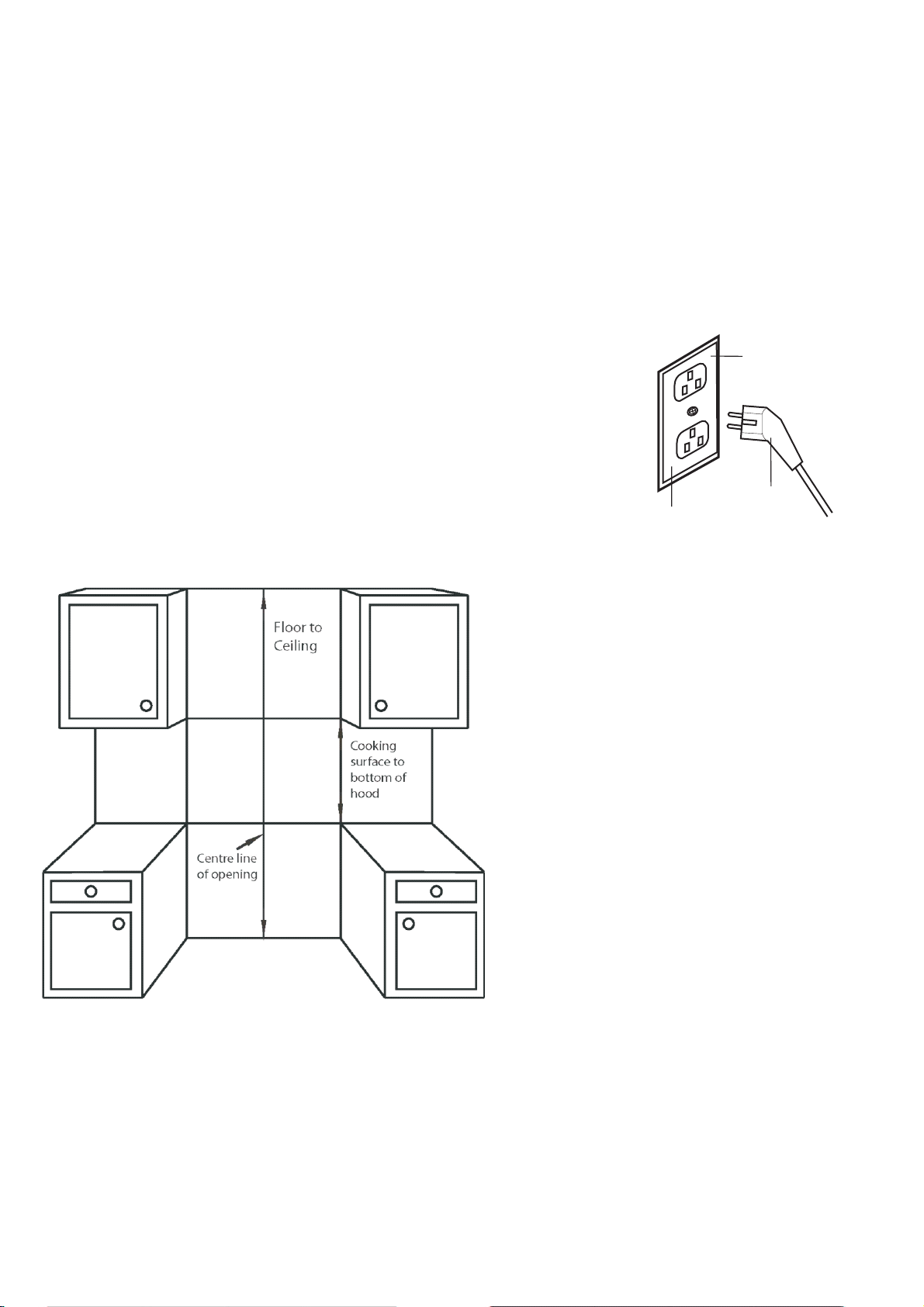

3. The appliance has been manufactured as class I, therefore earthed connection is necessary. The cooker hood

must be installed so that the plug is easily accessible.

Earthed

Outlet Box

Planning Your Installation

Earthed Plug

Earthed

Outlet

1. Measure the floor to ceiling height. This hood

can be installed on walls between 8” and 9” tall.

2. Find the centre point of your opening. Mark a

plumb line through this point from ceiling to your

range/cook-top.

3. Check your range/cook-top User Manual for the

minimum distance above your cooking surface.

The minimum distance between any element or

flame height and the nearest combustible surface

is 61cm (24”).

4. Decided where the ductwork will run between

the hood and the outside. Short, straight duct runs

will provide the most air flow.

5. If a recirculating kit is necessary, you may

purchase one through your dealer.

Unpacking

Remove the packaging with the product in place. Cut off the packing ribbons and carefully cut open the packaging

(do not cut too deeply), remove the packaging. Check that the product is free from transport damage. Any damage

shall be reported immediately to the carrier or retailer. Damage, faults and missing parts must be reported

immediately to the retailer

Page 5

Installing the Ductwork

1. Plan where the ductwork will run between the hood and the outside. The

hoods exhaust vertically but can be ducted to the rear behind the chimney

duct through an outside wall or vertically up through the ceiling to the

roof. A short straight duct run will produce the most air flow. Length and

elbows will reduce the efficiency of the blower.

2. Install a roof or wall cap. Connect a 6” round metal duct to the cap and

work backwards toward the hood. Ensure joints are completely sealed

with duct tape.

Fixing to the Wall

1. Before mounting the hood, plug in and test all functions for correct

operation.

2. Remove the filters from the bottom of the hood to prevent damage during

the installation.

to roof cap

decorative

chimney duct

to wall cap

hood

210

20

3. With assistance, hold the hood temporary in position ensuring the bottom

is above the minimum clearance for the cooking surface. Mark on the

wall the holes for the two mounting screws.

4. Drill the holes (A) at the distances indicated. Use the appropriate screws

and screw anchors for your wall type (e.g. reinforced concrete, drywall,

etc.). If necessary, prepare back wall with cross framing for secure

installation.

5. Mount the hood on the wall screws. Align it in a horizontal position

relative to cabinets. When the hood has been adjusted, secure unit by

tightening screws (A).

Connect a 6” aluminum duct tube (not included) to the exhaust piece

6.

using duct tape on all seals. (C)

Fixing the Decorative Chimney

Flu

1

.

Carefully losen but do not separate the telescopic chimney duct pieces.

230

A

C

2

.

Arrange the electrical power supply within the dimensions of the

decorative chimney duct.

3

.

Adjust the width of the support bracket to match the upper duct. Fix it

to the ceiling using the screws (B) so that it is centered in line with your

hood and at a distance from the ceiling indicated.

Page 6

Installing Guideline

Wall Mounted-

1200~1700mm

650~700mm

Duct-out

Note: The above installation guideline for references only, please contact your local dealer

for a installation service.

Leveling Device

When mounting the hood on the wall,the level can be adjusted by turning the two screws on the motor

housing.

Page 7

INSTALLATION ALTERNATIVES

The cooker hood can be installed in the following ways:

Circulating indoor air (A)

Outdoor venting (B)

A

REMEMBER!

B

The distance between the top of the hob and the lowest part of the cooker

hood must be at least 65 cm.

If a two-part connection tube is used, the lower section must sit outside the

upper sec tion.

Do not connect the cooker hood exhaust to a duct used to circulate hot air or

vent steam from another appliance.

Always use protective gloves when installing the appliance!

Page 8

USE AND CARE INSTRUCTIONS

Operations

1. For optimum performance in removing cooking odors, it is recommended that you turn on your cooker hood

prior to cooking and you leave it operating for 15 minutes after cooking.

2. Clean the surfaces of the cooker hood regularly using a non-abrasive detergent.

3. The anti-grease filters capture the grease particles suspended in the air. They will accumulate grease and dirt

depending on the frequency of the use of your range/cook top.

4. In order to prevent a fire hazard, it is recommended that you clean the aluminum filter at least every 2 months

WARNINGS: Do not attempt to remove the filters while the Cooker Hood is

operating.

Disconnect the electrical plug prior to any maintenance.

This appliance is not intended for use by young children or infirm persons without

supervision.

There should be adequate ventilation in the room when the Cooker Hood is used at

the same time as other fuel burning appliances.

DESCRIPTION OF THE CONTROLS

Electronic Control.

1

1

Touch

Touch

Touch 3 seconds

2

Touch

Touch

Touch 3 seconds

3

Touch

3

2

Low speed setting

Off

Medium speed setting

Off

High speed setting

Delay off timer 5 min.

Delay off timer 5 min.

Touch

Touch 3 seconds

Off

Delay off timer 5 min.

Page 9

CARE AND CLEANING

General

Regular maintenance is required to ensure that the

cooker hood functions properly. This is especially true

of the grease and charcoal filters.

Clean the fan and other surfaces of the cooker hood

regularly with a cloth dipped in denatured alcohol or a

non-abrasive liquid cleaner.

The charcoal filter cleans the circulating air in the

room. Such filters cannot be cleaned or recycled and

must be replaced at least every four months. The speed

at which the charcoal filter becomes saturated depends

on how often the fan is used, the type of food that is

cooked and how often the grease filter is cleaned.

To prevent the risk of fire and to ensure that the cooker

hood functions properly, the grease filter must always

be cleaned as instructed below when the display

indicates the need or at least every two months.

Cleaning the grease filter

Remove the flter from the cooker hood and clean it in a

solution of water and neutral cleaning liquid. Leave the

flter to soak in the solution for a while.

Replacing the charcoal filter (standard

hood)

Replace the charcoal filter (standard hood) as

follows:

Remove the grease filter.

Squeeze the clips on the charcoal filter a pull the

charcoal filter back to remove it.

Replacing the charcoal filter (for hood

with sloping surface)

1. Press the middle of the right edge of the glass cover

to open it

Rinse thoroughly with hot water and leave the filter

-

to dry.

The filter can also be cleaned in a dishwasher. The

-

color of the grease filter may change after a few

washes. This is normal.

NB:

If you clean the grease flter in the

dishwasher: load only the grease flter

and no other ite ms as foo d parti cles from

dishes can fas ten in th e filter.

Page 10

Emptying and cleaning the fat collector (For these fitted with a fat collector)

The fan is fitted with a fat collector that collects fat from the fan blades and fan housing.

1. Remove the grease f ilt er and the charcoal filt er (if fitted).

2. Remove the fat collector and clean it in warm water with washing up liquid. It can

also be cleaned in a dishwasher.

DO NOT le t dirt build up on th e hood

DO NOT use steel wool or steel brushes to clean the hood

DO NOT leave salt solutions, disinfectants, bleaches or cleaning compounds on

the hoo d for any length of t ime a s they may damage t he stainless st eel . Rinse

after u se with clean wat er an d wipe dry with a cle an cloth.

Replacing th e bulbs

Depending on your model of hood, there are two possible types of lighting, halogen and LED. The illumination

is designed for use during cooking and not for prolonged general illumination of your kitchen. Prolonged use of

the lights may reduce the life time of the bulbs.

WARNING: Do not touch or change light bulbs while the hood is

operating. Wait until the bulb has cooled before removing.

Use only the same bulbs as the original specification. Replacement lights are available through the dealers.

Halogen and LED Lights.

With the grease filter removed, from inside the hood press the light fixture out of its mounting bracket. Unplug

the light from the wiring harness. Avoid direct contact between the lense and your hands.

Replace the damaged lamp by reversing the steps. Snap in place.

Replace the bulbs as follows:

1. Lift up and remove the light fitting with a screwdriver or other suitable tool.

Page 11

2. Remove the blown halogen bulb (if the fan has 4 bulbs = 10W, 2 bulbs = 20W). Remember that the bulb can

be hot!

3. Insert the new halogen bulb.

If you touch the halogen bulb with your bare hands this may reduce its service life. Always use a glove or a cloth

to avoid direct contact.

NB:

The light is only meant for use during cooking and not for illuminating the surroundings for longer periods. If

the light is used for longer periods, this will considerably shorten the burn time of the bulbs.

Recycling

This appliance complies with European Community directive 2002/96/EC, Waste Electrical and Electronic

Equipment (WEEE). By ensuring that this product is recycled responsibly, the user helps prevent possible

negative impact on the environment.

NB:

Dispose of this product responsibly. Irresponsible disposal can result in negative environmental impact or

personal injury.'

Under no circumstances may this extractor fan be disposed of as household waste. It must be taken to a recycling

centre for electrical and electronic equipment.

This product must be disposed of in accordance with local legislation.

For more information on disposal, recycling and reuse of this product, contact your local authority, your

household waste collection service or the store where you purchased the product

For reliable service and original parts:

Tel 0844 800 3830

:

Website www caple co uk

:. ..

Page 12

Hood Size:

300

300

320

320

560 1050~

60

500

3

2

1

600

560-1050

60

500

900

Page 13

Trouble Shooting Guide

Problem

Hood doesn't turn on.

Poor Airflow

Hood is vibrating

Motor running but no

air flow

Motor stops after a few

minutes

Possible Reason Solution

No electrical supply.

Power cord is damaged

Aluminum grease filters clogged

Charcoal filters clogged.

Re-circulating mode only.

Hood is not secured in place

Butterfly valve jammed.

High temperature safety device

activated.

The hood is installed too near the

cooking surface.

Check the plug is connected.

Check the main switch is turned

on.

Contact your service technician

Clean the filters and replace

when dry.

Replace the charcoal filters.

Check the installation of hood.

Tighten mounting screws.

Contact your service technician

The kitchen is not sufficiently

ventilated.

The hood must be at least

61cm (24”) from the stove

Strong cooking smell.

Oil dripping onto stove.

Whirring sound

Lights are working but

fan isn't

Fan is working but lights

are not

Fan speed too low

Charcoal filters not installed.

Aluminum grease filter saturated.

Something in contact with fan blade.

Use one of the higher settings.

In re-circulating mode, charcoal

filters must be installed.

Wash the aluminum grease

filters

Contact your service technician

Contact your service technician

Contact your service technician

GUARANTEE AND SERVICE!

Before booking a service call,read the Trouble Shooting Guide above , for more information on

guarantee and service conditions, please contact local dealer.

Loading...

Loading...