Page 1

Contact Caple on 0117 938 7420 or for spare parts www.caple.co.uk

Downdraft induction hob

instruction manual

DD935BK

Page 2

Instruction manual DD935BK

Please keep this instruction manual for future reference

CONTENTS

WARNINGS 3

SAFETY WARNINGS 3

ENVIRONMENTAL PROTECTION 7

INSTALLATION INSTRUCTIONS 8

POSITIONING 8

VENTILATION 8

INSTALLATION 10

ELECTRICAL CONNECTIONS 12

COOKWARE 16

HOB INSTRUCTIONS 17

DOWNDRAFT INSTRUCTIONS 23

CLEANING AND MAINTENANCE 25

TROUBLESHOOTING 26

2

Page 3

Instruction manual DD935BK

Please keep this instruction manual for future reference

WARNINGS

- Keep these instructions for use with the appliance. If the

appliance should be sold or passed on to others, make

sure that the instructions are passed on with it. We

thank you for taking note of these suggestions before

installing and using the appliance. They have been

written for your personal safety and the safety of others.

- This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

SAFETY WARNINGS

- Use the appliance only in household situations for the

preparation and warming of food. All other types of use

are not permitted.

- Children under 8 years of age must be kept away from

the appliance unless they are under constant supervision.

- Children 8 years and older must only be allowed to use

the appliance if they have been given supervision or

instruction concerning use of the appliance in a safe way

and understand the hazards involved.

- Children shall not play with the appliance.

3

Page 4

Instruction manual DD935BK

Please keep this instruction manual for future reference

- Cleaning and user maintenance shall not be made by

children without supervision.

- Installation, repair and maintenance work should only be

performed by an authorised service technician. Work by

unqualified persons could be dangerous for the user.

RISK OF ELECTRIC SHOCK!

- If the appliance is defective or chipped, cracked or

broken in any way, immediately switch it off and do not

continue to use it. Disconnect it from the electrical power

supply.

WARNING

- If the supply cord of the appliance is damaged, it must

be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard

- The appliance and its accessible parts become hot during

use. Care should be taken to avoid touching heating

elements.

- Unattended cooking on a hob with fat or oil can be

dangerous and may result in fire. NEVER try to extinguish

a fire with water, but switch off the appliance and then

cover flame e.g. with a lid or a fire blanket.

- The hob is hot during use and remains so for some time

after being switched off. The risk of burns remains until

the residual heat indicators have gone out.

4

Page 5

Instruction manual DD935BK

Please keep this instruction manual for future reference

CAUTION

- The cooking process has to be supervised. A short term

cooking process has to be supervised continuously.

DANGER OF FIRE

- Do not store items on the cooking surfaces! Metallic

objects such as knives, forks, spoons and lids should not

be placed on the hob surface since they can become hot.

- Always switch the cooking zones off after use!

- The appliance is not intended to be operated by means

of an external timer or separate remote-control system.

SAFETY INSTRUCTIONS

- When the appliance is delivered, check the overall

appearance of the packaging. Any remarks should be

written on the delivery note, of which you keep a copy

- Your appliance is designed for normal domestic use. It

is not designed for commercial or industrial use, or for

purposes other than those for which it was designed.

- Any consequences of or damage from incorrect

installation or incorrect use of the appliance will not be

covered by the manufacturer’s guarantee.

- Do not ever change or try to change the characteristics

of this appliance. This would be a danger. Repairs must

be performed only by an authorised technician. Always

5

Page 6

Instruction manual DD935BK

Please keep this instruction manual for future reference

disconnect the hood before carrying out cleaning or

maintenance operations.

- Adequately ventilate the room when a extractor

and other appliances, powered by energy other than

electricity, are used simultaneously, so that the extractor

does not suck any combustion fumes

- Never use steam or high-pressure devices for cleaning

your appliance (regulations regarding electrical safety).

- Never use the extractor without the grease filters

6

Page 7

Instruction manual DD935BK

Please keep this instruction manual for future reference

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed of with household waste. Please

recycle where facilities exist. Check with your Local Authority or retailer for recycling

advice. This appliance is marked according to the European directive on Waste

Electrical and Electronic Equipment (WEEE).

By ensuring this product is disposed of correctly, you will help prevent potential

negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. The symbol

on the product indicates that this product may not be treated as household waste.

Instead it shall be handed over to the applicable collection point for the recycling of

electrical and electronic equipment. Disposal must be carried out in accordance with

local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this

product, please contact your local council, your household waste disposal service or

the retailer where you purchased the product

CE DECLARATIONS OF CONFORMITY

This appliance has been manufactured to the strictest standards and complies

with all applicable legislation, Low Voltage Directive (LVD) and Electromagnetic

Compatibility (EMC).

7

Page 8

Instruction manual DD935BK

Please keep this instruction manual for future reference

INSTALLATION INSTRUCTIONS

These instructions are for qualified personnel and are a guide for the installation

process, regulations and maintenance in accordance with the law and current

standards.

Before securing the hob to the worktop, ensure the downdraft has been assembled

as per the ‘Downdraft Assembly’ instructions on page 10.

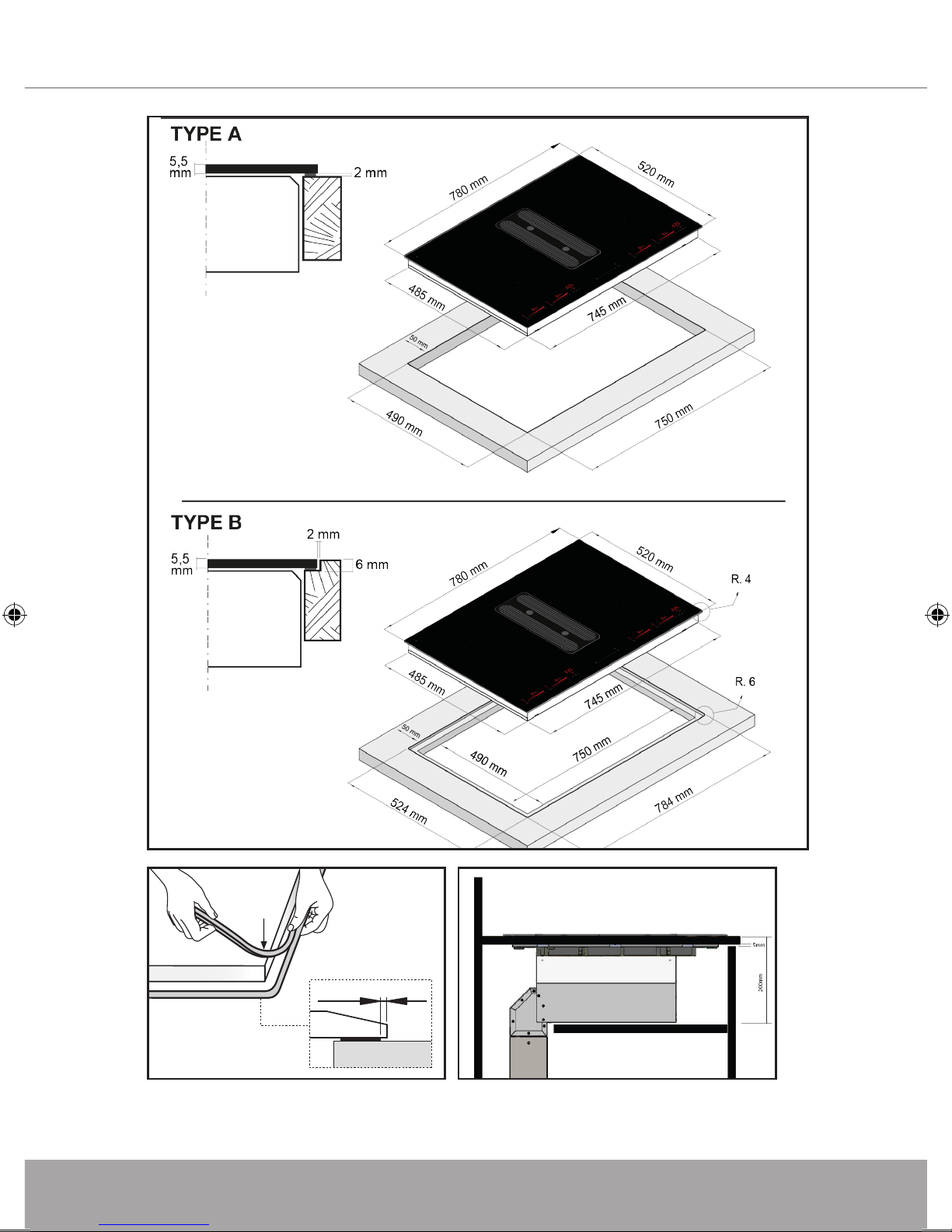

POSITIONING

The hob is designed for either an inset or flush mounted installation, the way it is

illustrated in Fig.1. Apply the sealing strip (Fig.2) along the whole perimeter (for

dimensions of the cut out see Fig.1). Fix the hob into place with 4 fixing brackets,

keeping in mind the depth of the work surface (Fig.4).

If the lower part of the appliance is accessible after installation via the unit it is

installed in, it is necessary to mount a separating panel as shown in Fig. 4, keeping

in mind the distances stated.

VENTILATION

To ensure adequate ventilation, a 5mm gap below the worktop on the front edge

(see fig.3), should be applied.

If the product is being recirculated, a 5mm ventilation slot will also need to

be included in the kitchen plinth around the entire perimeter of the island.

Alternatively a vent grill can be installed onto the plinth in line with where the

motor has been installed to allow the clean air to escape back into the room.

8

Page 9

Instruction manual DD935BK

Please keep this instruction manual for future reference

min. 50 mm

50

mm

20 mm

3

- INSET

- FLUSH MOUNTED

Fig.1

~ 2 mm

Fig.2

Fig.3

9

Page 10

Instruction manual DD935BK

A

B

A

4

Fig.4

A

B

min 10 max 30 mm

B

min 30 max 50 mm

DOWNDRAFT ASSEMBLY

1. Before carrying out the downdraft installation, please check that all components

are not damaged, in such a case contact your retailer and do not carry out any

installation operation.

- Use solid 150mm ducting whose maximum length does not exceed 5 meters

- Limit the number of elbows in the ducting, since each elbow reduces the air

capacity of 1 linear meter. (E.g. if you use no. 2 x 90° elbows, the length of

ducting should not exceed 3 meters).

- Avoid abrupt direction changes.

- Use a 150mm constant diameter or a similar section ducting for the whole length.

- Use ducting approved by relevant standards in force. The manufacturer shall

not be held liable for air capacity or noise problems due to non-observance of

aforementioned instructions and no warranty will be provided in such a case.

10

Page 11

Instruction manual DD935BK

2. Place the upturned hob on a suitable surface, making sure the glass is protected

from scratches.

Take the ‘filtering chamber ‘out of the packaging and install it as shown in fig. 5.

The ‘filtering chamber’ metal hooks shall be inserted in their suitable slots found

on the hob rear side, as shown in fig. 6.

After fitting the ‘filtering chamber’ to the hob,fasten it using the metric screw

provided with the appliance, which shall be installed as shown in fig. 7.

3. Fit the hob into the cabinet, as shown on page 8-10.

Take the motor unit out of the packaging, fix the metal joint on it using the screws

provided with the appliance, as shown in fig. 8.

After installing the hob, place the motor unit immediately under the hob, as

shown in fig. 9.

In order to install the motor unit in such a way as it can touch the floor , make a

410mm X 410mm opening in the cabinet floor (see fig.17).

Then place the two metal telescopic conduits into the motor unit air inlet (figure

10), and fix them using the screws supplied with appliance.

Lift the internal metal conduit until it reaches the ‘filtering chamber’ and fix it using

the screws supplied with appliance (fig.11).

Seal the air flow opening with the adhesive tape provided with the appliance, as

shown in figure 12.

Connect the ducting to the motor unit. You can use the air outlet on the right

or left side of the motor unit, according to the needs of the kitchen: remove the

four screws fixing the outlet flange and replace it with the metal lid placed on the

opposite side.

The air outlet which is not going to be used must always be covered and closed

with the metal lid.

Another two plastic flanges are provided with the appliance to connect different

section ducts.

Flanges provided have the following sections:

230x80 mm

220x90mm

218x55mm (recommended for recirculating mode installation only).

11

Page 12

Instruction manual DD935BK

Fit the two grease filters into their housing, by passing them through the hob

central opening, see fig. 13.

Fit the metal grid in order to close the hob central opening, as shown in fig. 14.

Place the wiring box near the appliance, in order to connect the flat cable to the

corresponding flat cable of the touch - control panel.

Connect the motor unit cable to the terminal block found inside the plastic black

box, see fig. 15B.

5

7

6

8

12

Page 13

Instruction manual DD935BK

9

10

11

13

12

14

13

Page 14

Instruction manual DD935BK

A

B

A

B

A

B

min 10 max 30 mm

min 30 max 50 mm

15

17

16

14

brown

L1

2 x 220-240 V~

220-240 V~

3x1,5mm

blue earth

N

Fig.18

2

Page 15

Instruction manual DD935BK

Please keep this instruction manual for future reference

ELECTRICAL CONNECTIONS (FIG.18)

Before making the electrical connections, check that:

- The system ratings meet the ratings indicated on the identification plate fixed on

the lower part of the worktop;

- The fuse rating for this appliance is 40amp.

- The system is fitted with efficient ground wires in accordance with the laws and

current standards.

Grounding is mandatory by law. If the domestic appliance is not supplied with a

cable, use material suitable for the absorption value indicated on the identification

plate and the operating temperature. An omnipolar switch must be installed with

a minimum 3 mm opening between the contacts and appropriate for the load

indicated on the plate and in accordance with current standards (the yellow/green

ground conductor must not be disconnected by a switch). When the appliance has

been installed, the omnipolar switch must be easily accessible.

WARNING

Place the metal box containing the electronic components at a distance of no less

than 65 cm from the suctioning surface of the cooker hood.

Connecting the product to the mains electricity must be carried out by technically

qualified personnel. The product must be connected to an electrical system correctly

designed and installed. The electrical system must comply with VDE0100 standard.

NOTE

We recommend installing the metal box containing the electronic components at

least 10 cm above floor level and at a suitable distance from all heat sources (e.g.

oven sides or hob).

CAUTION

This appliance is fitted with an H05 VVF 3 conductor, 0.75 mm2 (neutral, phase,

and ground) power cord. This can be connected up to a 220 - 240 V mono-phase

electrical network through a CEI 60083 approved power socket, which must remain

accessible after installation, in compliance with installation regulations. We decline

any responsibility in case of accidents caused by a lack of ground connection or

incorrect ground connection. The appliance must be fed through a differential

protection device (RCD), with a nominal residual current not exceeding 30mA. If the

power cord is damaged, call the after-sales service to avoid any risk.

15

Page 16

Instruction manual DD935BK

Please keep this instruction manual for future reference

COOKWARE

Induction

A

B

The use of appropriate cookware is an essential factor for induction cooking. Check

that your pots are suitable for the induction system. Only ferromagnetic cookware

made of the following materials is suitable for induction hobs:

- Enameled steel

- Cast iron

- Induction-capable stainless steel cookware.

To determine whether the cookware is suitable, check whether the base of the

pot or pan attracts a magnet. There are other induction-capable pots and pans

whose bases are not completely ferromagnetic. To get good cooking results, we

recommend that the dimension of the ferromagnetic area of the cookware match

the size of the burner. We advise cookware having a flat base (Fig.6A). This way you

can use the power optimally.

Do not use cookware with a rough base to avoid scratching the surface of the hob.

A very important factor in induction cooking is the dimension of the pot compared

to the plate used. The cooking zones allow the use of cookware with bases of

various diameters. It is, however, preferable to use the appropriate cooking zone for

the dimension of the pot.

16

Page 17

Instruction manual DD935BK

Please keep this instruction manual for future reference

HOB INSTRUCTIONS

G

D

H

B A C

F

I

E

D

F

E

min

Induction

A

B

The appliance is operated using the control panel sensor keys. Functions are

controlled by touching the sensor keys and confirmed by displays and acoustic

signals. Touch the sensor keys from above, without covering other sensor keys.

TOUCH CONTROLS

A. On/Off key

B. Lock key

C. Pause key

D. Cooking Zone Power Slidebar

E. Programs key

F. Cooking zone Display

G. Timer [+] key

H. Timer [-] key

I. Timer display

FAN

A. On/Off key

B. Fan speed slidebar

C. Fan speed display

D. Timer Key

17

Page 18

Instruction manual DD935BK

Please keep this instruction manual for future reference

SWITCHING THE APPLIANCE ON

G

D

H

B A C

F

I

E

D

F

E

min

7

Induction

A

B

6

Press the On-Off key to switch the hob on. All the displays relative to the cooking

zones switch on in the «0» standby position. The control unit remains active for 10

seconds. If no cooking zone is selected within this time, the appliance switches off

automatically.

SWITCHING A COOKING ZONE ON

Select the desired cooking zone and press or slide on the corresponding slidebar

(D). The power of the single cooking zone can be adjusted in 9 different positions

and will be shown on the relative luminous display with a level from “1” to “9”.

Slide right on the slidebar to increase the power level, slide left to decrease it.

BRIDGE ZONES -

This function allows you to combine the front cooking zone to the rear cooking

zone to create one large zone (zone 1+2 and 3+4, Fig. 8).

Pay attention in placing the

8

( A) Max. 3700 W 16A

( B) Max. 3700 W 16A

cookware in the correct position

on the cooking zones. To

activate the Bridge function press

simultaneously on both Sliderbars

Octa 220x184

Max.

2100 W

P: 3700 W

Octa 220x184

Max.

2100 W

P: 3700 W

of the two adjacent cooking zones.

The bridge luminous symbol

- will appear on the side of

the two cooking zones display

indicating that the function is

active. Now it is possible to set the

heat level of the bridge zone.

NOTE: the settings of the bridge zone are only enabled by the front cooking zone

Octa 220x184

Max.

2100 W

P: 3700 W

Octa 220x184

Max.

2100 W

P: 3700 W

slidebar and sensor keys. To disable the Bridge function press simultaneously on

both Sliderbars of the two adjacent cooking zones. The bridge illuminated symbol

- turns off.

18

Page 19

Instruction manual DD935BK

Please keep this instruction manual for future reference

POT DETECTION

Each induction cooking zone has a pot detection minimum limit, which varies

according to the material of the cookware being used. For this reason, you should

choose the cooking zone which is most suitable for the diameter of the cookware

you are going to use.

If the symbol appears on the cooking zone display, it means that:

- The cookware used is not suitable for induction cooking.

- The cookware diameter is smaller than the one allowed by the hob.

- No cookware is on the cooking zone.

RESIDUAL HEAT H

If the temperature of the cooking zone is still high (over 50°C) after it has been

switched off, the relative display will indicate the symbol H (residual heat).

The symbol will stay on even when the appliance is switched off and will only

switch off when the burn risk in no longer present.

POWER BOOST (QUICK HEATING) P

This program further reduces the cooking time of a certain cooking zone, by

bringing the temperature to the maximum heat level for 10 minutes.

At the end of this timeframe, the cooking zone heat level will automatically go back

to level 9. The use of this function is recommended for heating large quantities of

liquids (e.g. water to cook pasta) or food in a very short time.

To activate this program slide to the far right on the slidebar until the P symbol

appears on the cooking zone display.

AUTOMATIC WARM-UP R

All cooking zones are equipped with an “automatic warm up” function. This

feature sets the cooking zone to the highest heat level for a certain period of time

and then automatically switches back to the cooking setting that was originally set.

The length of time that the automatic warm up function operates depends on the

heat setting selected. To activate the “automatic warm up” function on a cooking

zone place your finger on the slidebar at the desired heat level an hold the position

for 3 seconds until the symbol R, alternating with the selected heat level, appears

on the cooking area display.

19

Page 20

Instruction manual DD935BK

Please keep this instruction manual for future reference

SPECIAL PROGRAMS

The cooktop has three special programs that have already been set to perform

special cooking operations.

Bake

The ‘‘Bake’’ program sets the heat temperature of the selected cooking zone

at 42°C to melt chocolate, butter or the like. To activate this program press the

Programs key once. The Bake LED lights up besides the cooking zone

display.

Keep Warm

The ‘‘Keep Warm’’ program sets the heat temperature of the selected cooking

zone at 70°C to keep food warm. To activate this program press the Programs key

twice. The Keep Warm LED lights up besides the cooking zone display.

Boil Control

The ‘‘Boil Control’’ program sets the heat temperature of the selected cooking

zone at 94°C to bring to a boil slowly preparing sauces or soups and stews. To

activate this program press the Programs key three times, the Boil Control LED

lights up besides the cooking zone display.

TIMER

This function allows you to set the time from 1 minute to 1 hour and 59 minutes

for the automatic switch off of a cooking zone.

Timer Display

From 1 minute to 9 1.00 , 2.00 ... 9.00

From 10 minutes to 59 0.10, 0.15 ... 0.59

From 1 hour to 1hr 59minutes 1.00, 1.10 ... 1.59

Switch on a cooking zone by sliding on the slidebar to adjust the heat level. To

activate the timer press simultaneously the “+“ and “-“ keys on the timer area until

the clock symbol lights up beside the cooking zone display, then set the desired

time using the timer “+“ and “-“ keys within 5 seconds. Wait for 5 seconds for the

automatic confirmation. The time countdown will start on the timer display.

20

Page 21

Instruction manual DD935BK

Please keep this instruction manual for future reference

When time elapses the cooking zone will automatically switch off, the timer display

will show a flashing “000” and an acoustic signal will be heard. Press the “+“ or

“-“ key on the timer area to stop the signals. To disable the timer of a cooking

zone press repeatedly and simultaneously the “+“ and “-“ keys on the timer area

until the clock symbol lights up beside the display of the desired cooking zone,

press again the timer “+“ and “-“ keys simultaneously, then bring the timer value

back to “000” by using the timer “-“ key. Wait for 5 seconds for the automatic

confirmation. The clock symbol beside the cooking zone display goes off.

EGG TIMER/REMINDER

When no cooking zone is active it is possible to set an acoustic reminder which

stays active after switching the appliance off. When the Egg timer/Reminder

function is active, the Timer function cannot be selected.

To enable this function press simultaneously the timer “+“ and “-“ keys. The clock

symbol lights up below the timer display. Set the time, ranging from 1 minute to 1

hour and 59 minutes, by pressing the “+“ and “-“ keys. Wait for 5 seconds for the

automatic confirmation. The time countdown will be shown on the timer display.

When time elapses the display will show a flashing “000” and an acoustic signal will

be heard. Press the “+“ and “-“ key on the timer area to stop the signals.

To disable the Egg timer/Reminder function press simultaneously the timer “+“

and “-“ keys. The clock symbol lights up below the timer display. Bring the timer

value back to “000” by using the “-“ key. Wait for 5 seconds for the automatic

confirmation. The clock symbol beside the timer display goes off.

PAUSE

II

When at least one cooking zone is operating it is possible to momentarily pause

the appliance switching off the cooking zones. To enable this function press the

Pause key. The relative led lights up and all the cooking zone displays show the

symbol “

II

“. Previously programmed timers will be stopped. The pause can last for

maximum 10 minutes. If this status is not terminated within this time the appliance

switches off. To disable the Pause function press the Pause key and slide right on

the flashing slidebar within 10 seconds.

RECALL

When the appliance has been switched off by mistake it is possible to quickly recall

the previously active settings by pressing the On - Off key within 5 seconds, then

pressing the Pause key within another 5 seconds. If the recall function is available

the relative led will be flashing when the appliance is switched on again.

21

Page 22

Instruction manual DD935BK

Please keep this instruction manual for future reference

CONTROL LOCK

Controls can be locked in order to prevent any risk of unintentional changes to the

settings (children, cleaning operations, etc.). To activate this function press the Lock

key. The relative led will light up. The function remains active when the appliance

is switched off and on again. To disable the Control Lock function simply press the

Lock key. The relative led will go off.

CHILD SAFETY LOCK “L”

This function serves the purpose of preventing children from switching on the

appliance even accidentally or intentionally. The Child safety lock can only be

activated within 10 seconds from the switching on of the appliance, with all the

cooking zones off. To activate this function press simoultaneously the Lock key and

the Pause key, then again the Control Lock key. The symbol “L” will appear on all

displays to confirm your selection and the relative led will light up. When the Child

safety lock is enabled you can switch the appliance off. The Child safety lock is still

enabled when the appliance is switched on again.

To unlock the appliance permanently, press simoultaneously the Lock key and

the Pause key, then again the Pause key. In this case the Child safety lock won’t

be enabled when the appliance is switched on again.

To unlock the appliance temporarily press simoultaneously the Lock key and

the Pause key. In this case the Child safety lock will still be active each time the

appliance is switched on again.

SWITCHING A COOKING ZONE OFF

To switch a cooking zone off bring its level back to “0” by sliding left on the

corresponding slidebar.

SWITCHING THE APPLIANCE OFF

To turn off the hob entirely hold down the On - Off key.

SAFETY SWITCH

The appliance has a safety switch that automatically switches off the cooking zones

when they have been operating for a certain amount of time at a given power level.

22

Page 23

Instruction manual DD935BK

Please keep this instruction manual for future reference

POWER LEVEL OPERATING

TIME

LIMIT (hours)

1-2 6

POWER MANAGEMENT

All cooking zones are connected to one phase. The

phase has a maximum electricity loading of 3700

W/230V (fig. 8).

3-4 5

5 4

The function divides the heat level between

cooking zones and activates when the total

electricity loading of the cooking zones exceeds

6-7-8-9 1.5

3700 W. The function decreases the heat level to

the other cooking zones. The heat setting display

of the reduced zones changes between two levels

DOWNDRAFT INSTRUCTIONS

Turning the Fan ON/OFF

Press the On - Off key to turn the fan on. This will automatically set at level 2.

To turn off the fan, press the On - Off key.

Increasing/decreasing the fan speed

To increase the speed slide to the right on the slide-bar. To decrease the speed slide

to the left on the slide-bar. The LEDs in the fan speed display will show which speed

the fan is set to.

Timer

Press the Timer key to set a 10 minute timer. The LED on the fan speed display will

flash to show this has been set. once the 10 minutes are up, the fan will turn off

automatically.

Automatic turn off

After 4 hours of continuously working, the appliance turns off automatically.

Grease filters saturation

Press a total of 30 hours of operation, the speed indicators will all flash

simultaneously, signalling the grease filters saturation. Clean the filters either by

hand with warm soapy water, and leave to dry, or clean in the dishwasher. Once

clean and re inserted, reset the function by pressing the “TIMER” key for at least 3

seconds whilst the appliance is switched off.

23

Page 24

Instruction manual DD935BK

Timing

As a result of the EU65 “Energy label” and EU66 “ Ecodesign” regulations issued

by the European Commission, which came into force as from January 1st, 2015 ,

our products have been adapted to comply with these new requirements. All of

the models complying with the energy label requirements, are equipped with new

electronics including a timer device for suction speeds control, when the air capacity

exceeds 650m³/h. Internal motor models, with maximum air capacity higher than

650m³/h, are equipped with a timer device that automatically switches the suction

speed from 4th to 3rd speed, after 6 minutes operation. External motor models

are equipped with remote motors that, as for internal motor versions, include a

timer device that switches down the suction speed when it exceeds 650 m3/h.

(See External Motors Instructions). Remote motors, whose air capacity exceeds

650m³/h at both 4th and 3rd speed, will have the following by default timer control

functions: The suction speed is automatically switched from 4th to 2nd speed, after

6 minutes operation. If the appliance is working at 3rd speed, it is automatically

switched to 2nd speed, after 7 minutes operation. Operation speeds can still be

changed during operation. The energy consumption of the appliance in standby

mode is lower than 0.5W.

24

Page 25

Instruction manual DD935BK

CLEANING AND MAINTENANCE (HOB)

Remove any residues of food and drops of grease from the cooking surface by

using a glass scraper or similar. Clean the heated area as thoroughly as possible

using suitable products, and a cloth/ paper, then rinse with water and dry with a

clean cloth. Using the scraper immediately remove any fragments of aluminium and

plastic material that have unintentionally melted on the heated cooking area, or

residues of sugar or food with a high sugar content. In this way, any damage to the

hob surface can be prevented. Under no circumstances should abrasive sponges, or

corrosive chemical detergents, such as oven sprays or stain removers, be used.

WARNING:

STEAM CLEANERS MUST NOT BE USED.

CLEANING AND MAINTENANCE (DOWNDRAFT)

Careful maintenance ensures proper operation and good performances over time.

Grease filters can be washed by hand or in the dishwasher.

Grease filters shall be cleaned depending on use, at least once every two months.

The charcoal filters shall be replaced depending on use, at least once every six

months.

To buy replacement charcoal filters (CAP76CF), visit www.caple.co.uk.

Use only tepid water and neutral detergents to clean the appliance; the use of

products containing abrasive substances shall be avoided.

25

Page 26

Instruction manual DD935BK

TROUBLESHOOTING

Problem Possible cause Remedy

You cannot activate

or operate the

appliance.

The hob deactivates.

Residual heat

indicator does not

come on.

The appliance is not connected to an

electrical supply or it is connected

incorrectly.

The fuse has released / tripped

It’s been more than 10 seconds from

switching on the appliance.

2 or more keys pressed at the same

time.

Pause function operates.

There is water or fat stains

on the control panel.

You put something on the

sensor key ON-OFF.

The zone is not hot because

it operated only for a short

time.

Check if the appliance is correctly

connected to the electrical supply.

Refer to “Electrical connections” chapter.

Make sure that the fuse is the cause of the

malfunction. If the fuse releases again and

again, contact a qualified electrician.

Activate the appliance again and

set the heat setting in less than 10 seconds.

Touch only one sensor key.

Refer to “Using the hob”

chapter.

Clean the control panel.

Remove the object from the sensor

key.

If the zone operated sufficiently

long to be hot contact an

Authorised Service Centre.

Automatic Warm Up

function does not

operate.

The heat setting

changes between

two levels.

The sensor keys

become hot.

- comes on.

L comes on.

comes on.

The zone is hot.

The highest heat setting is

set.

Power management

function operates.

The cookware is too large

or you put it too near to the

controls.

Safety Switch operates.

The Child Lock function

operates.

Water or cooking utensils

above the control panel.

Let the zone become sufficiently

cool.

The highest heat setting has the

same power as the function.

Refer to “Using the hob”

chapter.

Put large cookware on the rear

zones if possible.

Deactivate the appliance and

activate it again.

Refer to “Using the hob”

4 chapter.

Remove the objects from the

control panel.

26

Page 27

Instruction manual DD935BK

Problem Possible cause Remedy

comes on.

E and a number

come on.

E2 comes on.

E21 comes on.

There is no cookware on

the zone.

The cookware is incorrect.

The dimension of the

bottom of the cookware is

too small for the zone.

The cookware does not

cover the cooking zone.

There is an error in the

appliance.

The induction coils are

overheated.

The appliance is

overheated. The cooling

fan might be blocked.

Put cookware on the zone.

Use the correct cookware. Refer

to “Induction Cooking” chapter.

Use cookware with correct

dimensions. Refer to “Induction

Cooking” chapter.

Cover the cooking zone fully.

Disconnect the appliance from

the electrical supply for some

time. Disconnect the fuse from

the electrical system of the house.

Connect it again. If comes on

again, contact an Authorised

7 Service Centre.

Allow the appliance to cool down.

Allow the appliance to cool down.

Check if objects block the cooling

fan. If comes on again, contact an

Authorised Service Centre.

E31 comes on. Incorrect data configuration.

None or faulty communication

E47 comes on.

U400 comes on.

E22, E20, E36, E5,

E6 or E9 comes on.

between control panel and induction

coils.

Control Panel is wrongly

connected.

An internal component

of the appliance needs

replacing.

New configuration needed.

Contact an Authorised Service Centre.

Ensure that connection cable

is plugged on correctly and

functional.

Connect to correct mains voltage.

Contact Caple service

If you cannot find a solution to the problem yourself, contact Caple service.

Provide the model and serial number from the rating plate.

Telephone : 0117 938 1900

Email : service@caple.co.uk

27

Page 28

Instruction manual DD935BK

Please keep this instruction manual for future reference

Caple Service

Fourth Way

Avonmouth

Bristol

BS11 8DW

t: 0117 938 7420

e: service@caple.co.uk

www.caple.co.uk

V1 - 20112017

28

Loading...

Loading...