Page 1

Model code: DD911BK DD911SS

DD911WH DD120BK

Instruction manual for downdraft hood

Contact Caple on 0117 938 7420 or for spare parts www.caple.co.uk

Page 2

Page 3

3

Environmental protection

The symbol on the product or on its packaging indicates that this product may not be treated as household waste. Instead it shall be handed over to the applicable collection point for the recycling of

electrical and electronic equipment. By ensuring this product is disposed of correctly, you will help

prevent poten-tial negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For more detailed information

about recycling of this product, please contact your local city office, your household waste disposal

service or the shop where you purchased the product. This appliance is marked according to the

European directive 2002/96/EC on waste electrical and electronic equipment (WEEE).

CE Declarations of Conformity

This appliance has been manufactured to the strictest standards and complies with all applicable

legislation, Low Voltage Directive (LVD) and Electromagnetic Compatibility Directive (EMC).

Page 4

4

Notes for the user

This product is designed to work in both ducted

and recirculated mode, which ever is preferred

for you installation.

Saftey instructions

These hoods have been designed for personal

use in the home. The appliance must be used

by adults. Make sure that the appliance is out of

reach of children and that they do not use it to

play with. Make sure that children do not operate

the controls.

• When the appliance is delivered, check the

overall appearance of the packaging.

Any remarks should be written on the

delivery coupon, of which you keep a copy.

Your appliance is designed for normal

domestic use. It is not designed for

commercial or industrial use, or for purposes

other than those for which it was designed.

• Anyconsequencesofordamagefromincorrect installation or incorrect use of the appliance will not be covered by the manufacturer’s guarantee.

• Donoteverchangeortrytochangethechar-

acteristics of this appliance. This would be a

danger. Repairs must be performed only by

an authorised technician.

Always disconnect the hood before carrying

out cleaning or maintenance operations.

• Adequatelyventilatetheroomwhenacooker

hoodand other appliances, powered by energy other than electricity, are used simultaneously, so that the hood does not suck anycombustion fumes.

•

Do not cook food over open flames (flambé)

or operate gas hobs without pots

or pans on

them while using the hood (the flames may get

sucked into the hood causing damage the

appliance).

•

Fryingundertheappliancemustbedone

under constant supervision as hot oils and

fats may ignite.

Respect the guidelines for cleaning and

replacement of grease filters. Accumulated

deposits of grease are a fire hazard.

•

This appliance must notbe with over cook

tops powered by wood or coal or in any case,

with cook tops with power levels that could

damage the appliance.

Never use steam or high pressure devices

for cleaning your hood (regulations regarding

electrical safety).

•

Neverusethecookerhoodwithoutthegrease

filters fitted.

• The minimum distance between the Downdraft (closed) and the surface above it must

be at least 400 mm.

•

Whenhandlingthedowndraft,neverputyour

hands in the field of action of the extractable

unit. Keep your hands clear of moving parts.

We are constantly seeking to improve our

products, we reserve the right to modify their

technical, functional, or aesthetic

characteristics deriving from their upgrading.

In the case of the version with external

motor, for normal downdraft operation, it is

necessary to use a external motor made by

Caple.

The air collected must not be conveyed into a

flue used for smoke or fumes from

appliances powered by anything other than

electricity (central heating systems, etc.). As

far as discharging exhaust air is concerned,

please follow the guidelines given by

competent authorities.

WARNING

Keep these instructions for use with the

appliance. If the appliance should be sold

or passed on to others, make sure that the

instructions are passed on with it. We

thank you for taking note of these

suggestions before installing and using the

appliance. They have been written for your

personal safety and the safety of others.

•

Page 5

5

Contents

Dimensions 6

Installing the extractor 7

Grease filter removal, installing the activated charcoal filter

8

9

10

12

13

Electrical connection

How the downdraft works

Cleaning the extractor

Troubleshooting

Aftersales service 13

Page 6

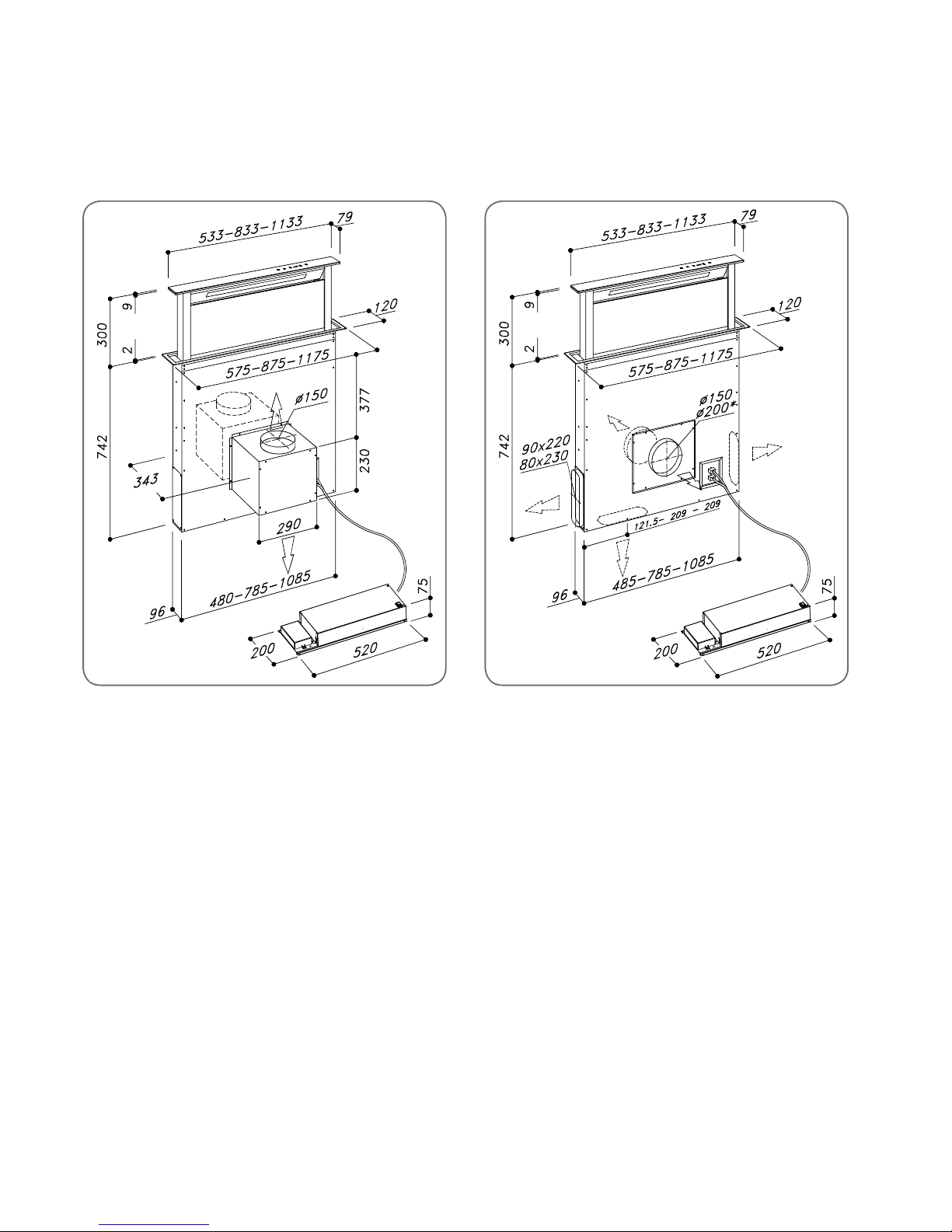

6

Dimensions

INC

Page 7

7

Installing the extractor

1. Before carrying out the appliance installa-

tion, please check that all components are

not damaged, in such a case contact your

retailer and do not carry out any installation

operation.

Before the installation of the Downdraft,

please remove the safety piece you can see

in the picture (Fig. 1). Furthermore, please

read carefully all of the following installation

instructions.

• Useanairexhaustingpipewhosemaximum length does not exceed 5 meters.

•

Limitthenumberofelbowsinthepiping,

since each elbow reduces the air capacity of 1 linear meter. (eg. if you use no. 2 x

90 ° elbows, the length of piping should

not exceed 3 meters).

• Avoidabruptdirectionchanges.,

•

Use a 150 mm. constant diameter rigid

ducting pipe for the whole length.

• Use piping approved by standards in

force.

The manufacturer shall not be deemed responsible for air capacity or noise problems

caused by failure to comply with the above

instructions and no warranty on the product

shall be provided.

2. Before making the hole, check that there are

no structural or other parts inside the cabinet, where the appliance is to be placed,

which could hinder a proper installation.

Check that the dimensions of the Downdraft

and the ones of the cook top are compatible

with the cabinet so that the installation can

be carried out properly.

3.

Make a rectangular opening, 842 x 100 mm

in size, in the back of the cook top for the

90cm model, 1142 x 100 mm for the 1200

model and 542 x 100 mm for the 60 cm

model.

4. Put the Downdraft in the opening, inserting it

from above as shown in (Fig. 2).

5. Fix the downdraft inside the cabinet, using

the special fixing brackets supplied with the

product (Fig. 3).

Insert the brackets in the lower side of the

downdraft (Fig. 3), in such a way that there

is a 2 mm distance between the lower side

of bracket and the bottom of the cabinet

(Fig. 3).

This distance will allow the traction to be positioned downwards of the product, at the

moment of fixing, in order to have the stainless steel trim perfectly adhering with the

work surface. Before inserting the screws,

please make sure that the appliance is perfectly perpendicular with the work surface.

6.

Once the installation is complete and after

connecting the appliance to the mains

power, lift up the downdraft and remove the

door block (Fig. 4); then open the door

(Fig. 5) and fit the filters in place (Fig. 6). In

the ver-sion of the Downdraft equipped with

internal motor, install the power unit

orienting the air outlet to the desired

position, either downwards or upwards

(Fig. 7). The motor can be installed either on

the front or rear side of the downdraft After

having installed the motor, connect the air

ducts.

7.

For versions with an external motor, place

the external motor in a suitable area and fit

the exhaust ducting as illustrated. Then fit

the air outlet ducts between the external

motor and the downdraft. Select an air outlet

from the five possibilities (Fig. 9) and fit the

union supplied with the appliance.

8. Place the metal box with the electronic com-

ponents in an easily reachable area for eventual technical assistance operations. (Fig.

9), connecting the three connectors (9 pole

connector for the actuator control and the

safety control, 4 pole connector for neon

lamp turn on and push-button connector)

(Fig. 10).

Page 8

WARNING

Before connecting the air exhaust hose,

make sure that the non-return valves

can move freely.

CAUTION

Installation must comply with the regula-

tions in force regarding the ventilation of

enclosed environments. In particular, dis-

charged air must not be conveyed into a

duct used for fumes discharge or discharge

from appliances using gas

or other combustible materials. The use of

discontinued ducts is not allowed without

the approval of a qualified technician.

WARNING

After having replaced the filters, reinstall

the front stainless steel panel, otherwise

the Downdraft is not function.

9. For external motors, connect the motor unit

cable to the relevant connector on the

electrical components box.

10. Power up the cookerhood.

How to use the extractor

This appliance is intended to suck cooking

fumes, greases and some steam. It has been

designed to work in both ducted mode, with

outside evacuation, and recirculating mode.

Outside - ducted version

The cooker hood can be mounted in the version

with outside discharge of extracted air: in this

case it is necessary to connect the exhausting

channel/ducting to the outside (exhausting

pipes are not supplied with this product.)

Check for a non-return valve blockage

In case of outside air discharge installation, fit a

non-return valve to prevent wind and back air

from entering.

Recirculating mode

In case fumes and vapour cannot be evacuated

outside, the appliance can be used in the

recirculating mode.

Activated charcoal filters are required for

this type of cooker hood (code: CAP43CF).

Air recycled through the charcoal filters is

recirculated into the kitchen, thanks to a duct

conveying the air on one side of the cabinet

(Fig. 11).

Removing the grease filter and

installing the charcoal filter

The removal and fitting of the grease and carcoal

filters need to be carried out with the downdraft in

the open position. To open the downdraft, push

the

key. Then remove the front panel, push-

ing the upper part of each side at the same time.

The panel will rotate forwards to make it possible

to access the grease filters (Fig. 6). Remove the

grease filters to access the carbon filters (Fig.

12). The replacement of the charcoal filters has

to be carried out accordingly to the effective use

of the Downdraft, and in any case at least once

every 6 months.

CAUTION

Installation must comply with the regulations in force regarding the ventilation of

enclosed environments. In particular, discharged air must not be conveyed into a

duct used for fumes discharge or discharge

from appliances using gas

or other combustible materials. The use of

discontinued ducts is not allowed without

the approval of a qualified technician.

WARNING

After having replaced the filters, reinstall

the front stainless steel panel, otherwise

the Downdraft is not function.

Recirculating mode

In case fumes and vapour cannot be evacuated

outside, the appliance can be used in the

recirculating mode.

Activated charcoal filters are required for

this type of cooker hood (code: CAP43CF).

Air recycled through the charcoal filters is

recirculated into the kitchen, thanks to a duct

conveying the air on one side of the cabinet

(Fig. 11).

Removing the grease filter and

installing the charcoal filter

The removal and fitting of the grease and carcoal

filters need to be carried out with the downdraft in

the open position. To open the downdraft, push

the

key. Then remove the front panel, push-

ing the upper part of each side at the same time.

The panel will rotate forwards to make it possible

to access the grease filters (Fig. 6). Remove the

grease filters to access the carbon filters (Fig.

12). The replacement of the charcoal filters has

to be carried out accordingly to the effective use

of the Downdraft, and in any case at least once

every 6 months.

8

WARNING

Before connecting the air exhaust hose,

make sure that the non-return valves

can move freely.

CAUTION

Installation must comply with the regula-

tions in force regarding the ventilation of

enclosed environments. In particular, dis-

charged air must not be conveyed into a

duct used for fumes discharge or discharge

from appliances using gas

or other combustible materials. The use of

discontinued ducts is not allowed without

the approval of a qualified technician.

WARNING

After having replaced the filters, reinstall

the front stainless steel panel, otherwise

the Downdraft is not function.

9. For external motors, connect the motor unit

cable to the relevant connector on the

electrical components box.

10. Power up the cookerhood.

How to use the extractor

This appliance is intended to suck cooking

fumes, greases and some steam. It has been

designed to work in both ducted mode, with

outside evacuation, and recirculating mode.

Outside - ducted version

The cooker hood can be mounted in the version

with outside discharge of extracted air: in this

case it is necessary to connect the exhausting

channel/ducting to the outside (exhausting

pipes are not supplied with this product.)

Check for a non-return valve blockage

In case of outside air discharge installation, fit a

non-return valve to prevent wind and back air

from entering.

Recirculating mode

In case fumes and vapour cannot be evacuated

outside, the appliance can be used in the

recirculating mode.

Activated charcoal filters are required for

this type of cooker hood (code: CAP43CF).

Air recycled through the charcoal filters is

recirculated into the kitchen, thanks to a duct

conveying the air on one side of the cabinet

(Fig. 11).

Removing the grease filter and

installing the charcoal filter

The removal and fitting of the grease and carcoal

filters need to be carried out with the downdraft in

the open position. To open the downdraft, push

the

key. Then remove the front panel, push-

ing the upper part of each side at the same time.

The panel will rotate forwards to make it possible

to access the grease filters (Fig. 6). Remove the

grease filters to access the carbon filters (Fig.

12). The replacement of the charcoal filters has

to be carried out accordingly to the effective use

of the Downdraft, and in any case at least once

every 6 months.

9. Connnect the internal or external

motors cable to the terminal board found

inside the plastic box of the downdraft

wiring. Ensure you respect the power

cables wiring colours when perfoming the

electrical connection

Page 9

9

Electrical connection

If the appliance has no plug or if the plug is not

easily accessible, then a device needs to be fitted to cut it off from the electric network; this

device must have an opening distance between

contacts on all poles of at least 3 mm.

Electrical connection

While installing the appliance and carrying maintenance operation, make sure it is disconnected

from the electrical network or the fuses are cut

out or removed.

Check that:

• Powerisenough.

• Feeder lines (mains) are in good condi-

tion.

•

Thecablediametercomplieswithinstal-

lation regulations.

WARNING

Place the

metal box containing the electronic components at a distance of no

less than 65 cm from gas operated hobs or

in any case, 65 cm from the suctioning

surface of the cooker hood.

NOTE

We recommend installing the metal box

containing the electronic components at

least 10 cm above floor level and at a suitable distance from all heat sources (e.g. oven

sides or cook top).

CAUTION

This appliance is fitted with an H05 VVF 3

conductor, 0.75 mm2 (neutral, phase, and

ground) power cord.

This can be connected up to a 220 - 240 V

mono-phase electrical network through a

CEI 60083 approved power socket, which

must remain accessible after installation, in

compliance with installation regulations.

We decline any responsibility in case of accidents caused by a lack of ground connection or incorrect ground connection. The

appliance must be fed through a differential protection device (RCD), with a nominal

residual current not exceeding 30mA. If

the power cord is damaged, call the Caple

Service to avoid any risk.

WARNING

The downdraft connection to the electrical

network must be carried out only by professional and qualified technicians.

The downdraft must be connected to a

properly installed and suitable electrical

network.

The electrical system must comply with

VDE0100 standard.

DANGER

If the cooker hood presents any anomaly,

disconnect the appliance or remove the

fuse corresponding to the appliance power

disconnecting line.

NOTE

This appliance complies with the European

Directives 2006/95/EC (Low Voltage Directive) and 2004/108/EC (Electromagnetic

Compatibility).

Page 10

10

MODEL DD911

A: Light ON/OFF key

The light switches on and off only when the

carriage is fully OPEN.

Pressing this button with the carriage closed

will cause the carriage to open and then the

light will switch on .

The button also serves to switch off the light

if it is on.

B:

ON/OFF key

This starts the extraction carriage upward

movement and when it is fully open, it sets the

second extraction speed.

With the carriage open: it switches off the motor and if on, the light; then it retracts the extraction carriage.

C:

(-) Key

This reduces the speed of the extractor motor

from the 4th speed until the motor switch-

es off, without closing the pull-out carriage.

D:

Indicators

•

This signals the speed setting, by only

the relevant LED switching on.(see

'Timing' on pg 11 for further information)

• This signals that all filters have been saturated by all LEDs switching on.

E:

(+) Key

This increases the speed of the extractor motor, from 1st to 4th speed, without moving the

extractor panel.

F:

Timer

10 min after setting, it serves to stop the extractor motor, close the carriage and switch

the lights off, if they are on. The set function is

signalled by the flashing LEDs “D” for the set

speed. The timer can be cancelled by pressing the key again.

Other functions:

Automatic turn off:

After 4 hours of continuous working from

the last function selection, the appliance

turns off and closes automatically.

Grease filters saturation:

After 30 hours of working, the speed indicators “D” will all flash simultaneously, signaling

the grease filters saturation.

To reset this alarm, hold down the “TIMER”

button for at least 3 seconds, while the carriage is open.

Calibration:

The cooker hood carries out its self

calibration every 3 complete cycles of its

extractable unit.

By pushing the “TIMER” key 6 times consecutively (MAX break between one push and the

other is 3 sec.) all the leds will flash and the

calibration will be reset.

After the next 3 cycles the downdraft will carry

out its self

calibration.

Stand-by:

When the extractable unit is closed and the

light is switched off, the control panel,

after

6 seconds, activates the stand-by

function, reducing the brightness of the leds.

This function can be stopped by pressing ON/

OFF or LIGHT key.

How the downdraft works

Page 11

11

Security saftey system:

If there is an obstacle while the extractable

unit is closing, the Downdraft stops closing

and rises again thanks to a security system.

WARNING

This operation has to be carried out by

a specialised technician.

TIMING

As a result of the new EU65 “Energy label”

and EU66 “ Ecodesign” regulations issued

by the European Commission, which came

into force as from January 1st, 2015 , our

products have been adapted to comply

with these new requirements. All of the

models complying with the energy label

requirements, are equipped with new

electronics including a timer device for

suction speed control, when the air

capacity exceeds 650m³/h. Internal motor

models, with maximum air capacity higher

than 650m³/h, are equipped with a timer

device that automatically switches the suction speed from 4th to 3rd speed, after 6

minutes operation. External motor models

are equipped with remote motors that as

with internal motor versions, include a

timer device that switches down the

suction speed when it exceeds 650 m³/h.

(See External Motors Instructions ) Remote motors, whose air capacity exceeds

650m³/h at both 4th and 3rd speed , will

have the following by default timer control

functions: The suction speed is automatically switched from 4th to 2nd speed, after

6 minutes operation. If the appliance is

working at 3rd speed, it is automatically

switched to 2nd speed after 7 minutes

operation. Operation speeds can also be

changed during operation. The energy

consumption of the appliance in stand – by

mode is lower than 0.5W.

Page 12

12

Careful maintenance ensures the correct operation and optimal performance.

MAINTENANCE HOW TO PROCEED?

ACCESSORY PRODUCTS TO

USE

External surfaces and

accessories

Do not use metallic

scrubbers,

abrasive products, or hard brushes.

To clean the external surfaces of the

cookerhood and the light housing

screen use only commercially available household detergents diluted

in water. Then rinse with clean water

and dry with a soft cloth.

Active charcoal filter

with extractable

unit open

After 30 hours of operation, the

downdraft will signal the grease filter

saturation.

The saturation is signaled by the

blinking of the 4 central leds.

To reset, hold down the timer button

for at least 3 seconds, while the

carriage is open.

The grease filters can be washed by

hand or in the dishwasher. These filters need to be cleaned on a regular

basis, because otherwise they may

represent a fire risk.

Refit the grease filters and front

panel, making sure that the panis

properly fitted at the sides so that it

it does not cause the downdraft to

stop operating.

Active charcoal filter

In

the recirculation mode, the

active charcoal filter must be

replaced periodically.

To remove the charcoal filter first of all

it is necessary to remove the grease

filter and then pull the plastic key of

the panel itself, in order to disengage

it from its seating.

Follow these steps in reverse order to

insert the active charcoal filter.

Replace the used charcoal filter on

an average of every six months.

Cl

eaning the extractor

CAUTION

The hood must be disconnected from the electrical network, both by unplugging the appliance

from the socket and activating the magnetic circuit breaker (safety cut-out), before removing

the metal grease filters. After cleaning operations, replace the metal grease filters as outlined

in the installation instructions.

Page 13

13

PROBLEM SOLUTION

The cooker hood

does not work

Check that:

• Thereisnotapoweroutage.

• Aspecificspeedhasactuallybeenselected.

• The9poleconnectionisinsertedproperly.

• Theredresetkey,foundovertheelectricalsystembox,ispushed.

• Makesurethatthewiresofthe9poleconnectionareinsertedprop-

erly in the connector itself (during the connection phase, an excessive

pressure could bend the contacts).

The cooker hood has

low performance

Check that:

• Themotorspeed selected issufficientforthequantityoffumes and

vapors present in the room.

• Thekitchenisventilatedwellenoughtoallowairforintake.

• Thecharcoalfilterisnotwornout.(filteringversioncookerhood).

• Theairoutletchannelisfreeandcompliantwithparagraphno.2.

• Thenon-returnvalvesofthesuctioningunitarefreetorotate.

The cooker hood

stops in the middle of

operation

Check that:

• Thereisnotapoweroutage.

• Theomnipolardevicehasnottripped.

Any maintenance operation on your appliance should be carried out by:

• Either your retailer;

• Or another qualified professional technician, authorised for Caple appliances.

Tro

ubleshooting

Aftersales service

NOTE

When

calling,

please mention the appliance details (Type Fig. 13a and equipment Fig. 13b and

production date Fig. 13c).

This information is stated on the rating label and the production date label is placed on the lower

side of the downdraft.

You can contact Caple Service by telephone on 0117 938 7420 or by email service@caple.co.uk

Page 14

14

Page 15

15

Images

Page 16

16

2 mm

2

6

3

4

5

1

Page 17

17

9

8

7

10

11

12

Page 18

18

10/09

90002103999

N

220 - 240V - 50 HZ

ATTUATORE 12Vcc 68W

MAX 68W

TYPE

FSEE

EQUIPMENT

S - 002 - EM_TC X22 - Q3 - X0

90002002001

A

C

B

13

14

Page 19

Page 20

Caple

Fourth Way

Avonmouth

Bristol

BS11 8DW

www.caple.co.uk

90002422415 - GM 02/12

Serial number

90002422911 - GM 04/15

Loading...

Loading...