Page 1

Instruction manual for downdraft hood

Model codes: DD903BK & DD522BK

Contact Caple on 0117 938 7420 or for spare parts www.caple.co.uk

www.caple.co.uk

Page 2

Keep these instructions for use with the

appliance. If the appliance should be sold or

passed on to others, make sure that the

instructions are passed on with it. We thank

you for taking note of these suggestions

before installing and using the appliance.

They have been written for your personal

safety and the safety of others.

TO THE ATTENTION

OF THE USER

WARNING

●

Do not cook food over open flames (flambé)

or operate gas hobs without pots or pans on

them by the downdraft itself (the flames extracted

into the downdraft might damage the appliance).

●

Frying next to the appliance must be done

under constant supervision as hot oils and fats

may ignite. Respect the guidelines for cleaning

and replacement of grease filters. Accumulated

deposits of grease are a fire hazard.

●

This appliance must not be used near hobs

powered by wood or coal or in any case, over

hobs with power levels that could damage the

appliance.

Never use steam or high-pressure devices for

cleaning your hood (regulations regarding

electrical safety).

● Never use the cooker hood without the grease

lters.

Constantly seeking to improve our products,

we reserve the right to modify their technical,

functional, or aesthetic characteristics deriving

from their upgrading.

In the event a downdraft is installed with an

external motor, for normal downdraft operation,

it is necessary to use an external motor made by

the same manufacturer.

The air collected must not be conveyed into a

flue used for smoke or fumes from appliances

powered by anything other than electricity

(central heating systems, etc.). As far as

discharging exhaust air is concerned, please

follow the guidelines given by competent

authorities.

SAFTEY INSTRUCTIONS

These hoods have been designed for personal

use in the home. The appliance must be used by

adults. Make sure that the appliance is out of

reach of children and that they do not use it to

play with. Make sure that children do not operate

the controls.

●

When the appliance is delivered, check the

overall appearance of the packaging. Any

remarks should be written on the delivery note, of

which you keep a copy.

Your appliance is designed for normal domestic

use. It is not designed for commercial or industrial

use, or for purposes other than those for which it

was designed.

● Any consequences of or damage from incorrect

installation or incorrect use of the appliance will not

be covered by the manufacturer’s guarantee.

●

Do not ever change or try to change the

characteristics of this appliance. This would be a

danger. Repairs must be performed only by a

Caple approved engineer. Always disconnect the

hood before carrying out cleaning or maintenance

operations.

●

Adequately ventilate the room when a cooker

hood and other appliances, powered by energy

other than electricity, are used simultaneously, so

that the hood does not extract any combustion

fumes.

The DD903BK & DD522BK are designed so

they can be either externally ventilated or re

circulated.

2

•

There must be a minimum space of 50mm

between the edge of a gas hob and the

downdraft frame

Page 3

DESCRIPTION OF THE APPLIANCE ....................................................................................4

INSTALLING THE DOWNDRAFT...........................................................................................5

Grease filter removal, mounting the activated charcoal filter .................................................6

Electrical connection of the hood ..........................................................................................6

HOW THE DOWNDRAFT WORKS ........................................................................................8

CLEANING THE DOWNDRAFT.............................................................................................9

TROUBLESHOOTING............................................................................................................10

AFTER SALES SERVICE ......................................................................................................10

CONTENTS

3

Page 4

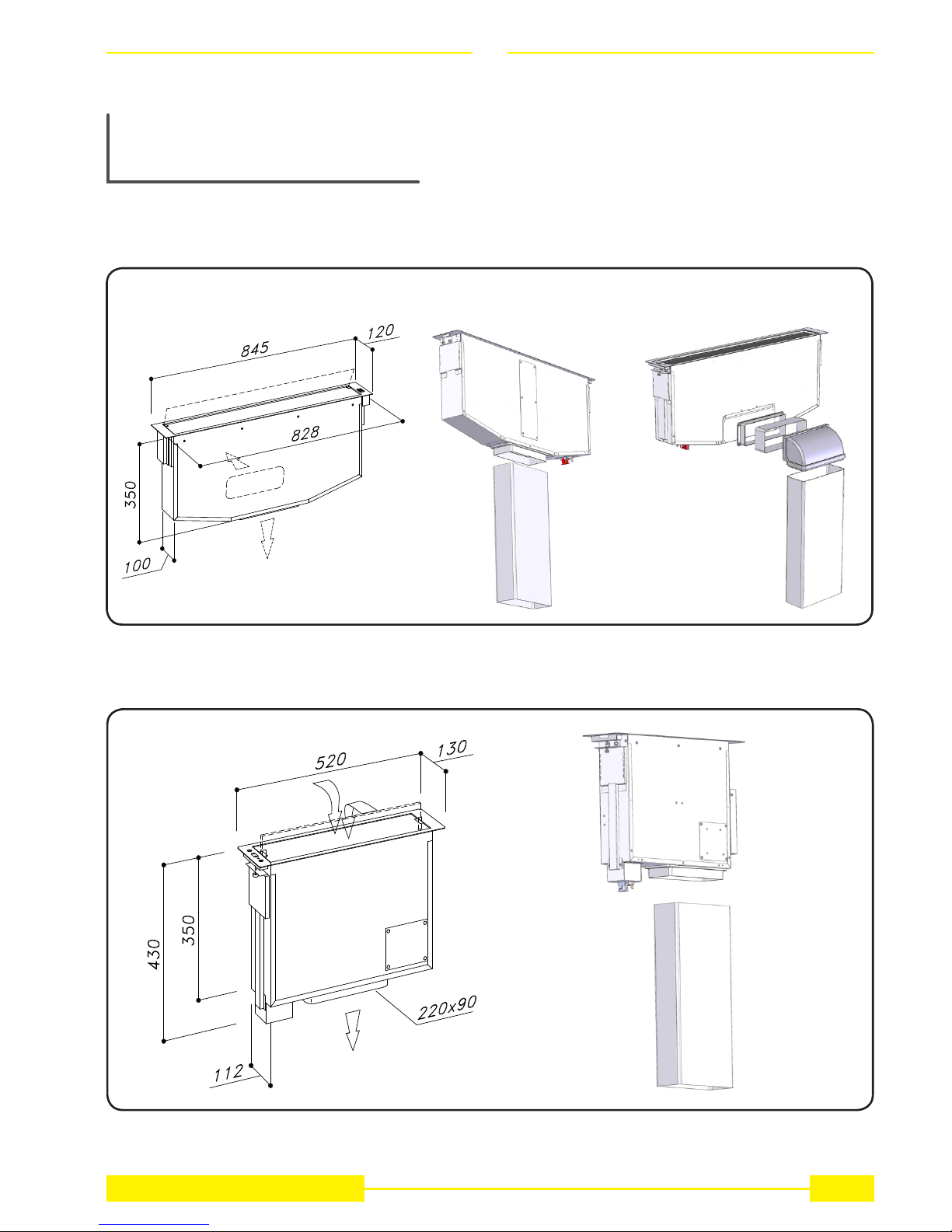

DESCRIPTION OF

THE APPLIANCE

BACK AIR OUTLET LOWER AIR OUTLET

DD903BK

DD522BK

4

Page 5

INSTALLING THE

DOWNDRAFT

1.

2.

3.

4.

Then tighten the screws manually, as in g.3,

to secure the product to the furniture.

Before tightening the screws, make sure

that the product is perfectly balanced. Pay

attention in order not to tighten the

screws too much.

For the DD522BK if the

structure of the cabinet does not allow to

use the brackets in figure 2, it is possible to

use the alternative brackets, as in figure 13.

If the Downdraft is equipped with external

motor, place the intake unit (external motor)

and settle the exhaust air duct. See the

installation diagram:

DDMEXT21 & DDMEXT30 - Figure 9 &11

DDMEXT28 - Figure 10 & 12

Then fit the air outlet ducts between the

external motor and the product. Select the air

outlet among the two available options and

fit the adaptor supplied with the appliance.

DD903BK: If you intend to use the rear air exit,

you will first have to remove the flange from

product, install the product in the furniture

then restore the flange as shown in fig. 4.

Place the metal box containing the electronic

components in an easily reachable area for

possible technical assistance operations, by

connecting the related connectors (g. 5).

If the product is equipped with external

motor, connect the motor unit cable to the

specific terminal board found in the plastic

box shown in fig. 6.

Power the downdraft.

After completing the installation and

connecting the appliance to the power

supply, activate the product as indicated in

the “HOW THE DOWNDRAFT WORKS”

section.

Place the charcoal filters, if the appliance

is used in the recirculating mode (charcoal

filters are supplied separately) behind the

grease filters (see fig. 7), and then settle the

front glass by sticking the magnets into the

specific seats.

Charcoal filters

DD903BK - CAP66CF x 2

DD522BK - CAP72CF x 1

5.

6.

7.

8.

9.

Before carrying out the appliance installation,

please check that all components are not

damaged, in such a case contact your retailer

and do not carry out any installation operation.

Furthermore, please read carefully all of the

following installation instructions.

●

Use an air exhausting pipe where the

maximum length does not exceed 5 meters.

● Limit the number of elbows in the piping, since

each elbow reduces the air capacity of 1 linear

meter. (Ex.: if you use no. 2 x 90° elbows, the

length of piping should not exceed 3 meters).

● Avoid abrupt direction changes.,

● Use a 150 mm. constant diameter pipe for

the whole length.

● Use piping approved by standards in force.

The manufacturer shall not be deemed

responsible for air capacity or noise problems

caused by failure to comply with the above

instructions and no warranty on the product

shall be provided.

Before making the hole, check that there are

no structural or other parts inside the cabinet,

where the appliance is to be placed, which

could hinder a proper installation.

Check that the dimensions of the product and

the ones of the hob are compatible with the

cabinet so that the installation can be carried

out properly.

Make a rectangular opening into the worktop

in the following sizes:

DD903BK: 102 x 832mm

DD522BK: 114 x 486mm

Fit the product in the opening, by inserting

it from above as shown in (fig. 1).

Secure the product inside the furniture by

using the specic brackets provided.

Proceed to the installation of the brackets in

the sides of the product, in the specic hooks,

as shown in g. 2.

5

Note: The Downdraft worktop cutout can be

connected to the hob cutout, but only for

electric hobs.

For gas hobs, a minimum 50mm gap must

be left beetween the edge of the gas hob

and the downdraft frame

Page 6

HOW TO USE THE DOWNDRAFT

This appliance is intended to extract cooking

fumes, greases and vapours. It has been

designed to work in either ventilation mode or in

recirculation mode.

Externally vented mode

The downdraft can be installed in this mode with

outside discharge of extracted air: in this case it is

necessary to connect the ducting channel to the

outside wall (ducting pipes are not supplied with

this product).

Recirculation mode

In case fumes and vapours cannot be extracted

outside, the appliance can be used in

recirculation mode.

CAUTION

Installation must comply with the regulations

in force regarding the ventilation of enclosed

environments. The use of discontinued ducts

is not allowed without the approval of a

qualified technician.

REMOVAL OF GREASE FILTER, AND

MOUNTING THE CHARCOAL FILTER

The assembly and disassembly of grease filters

and charcoal filters must be made with the

downdraft in the open position. For this,

actuate the opening of the glass as indicated by

the operation section.

Inhere the grease filters as shown in figure 7, in

the case the charcoal filters are necessary,

install these first as shown in figure 7.

Place the metal

box containing the electronic

components at a distance of no less than 65

cm from hobs or in any case, 65 cm from the

suctioning surface of the cookerhood.

ELECTRICAL CONNECTION

OF THE DOWNDRAFT

WARNING

We recommend installing the metal box

containing the electronic components at

least 10 cm above floor level and at a

suitable distance from all heat sources (e.g.

ovens and hobs).

NOTE

This appliance is fitted with an H05 VVF 3

conductor, 0.75 mm2 (neutral, phase, and

ground) power cord.

This can be connected up to a 220 - 240 V

monophase electrical network through a CEI

60083 approved power socket, which must

remain accessible after installation, in

compliance with installation regulations.

We decline any responsibility in case of

accidents caused by a lack of ground

connection or incorrect ground

connection. The appliance must be fed

through a differential protection device

(RCD), with a nominal residual current not

exceeding 30mA. If the power cord is

damaged, call the after-sales service to avoid

any risk.

CAUTION

After having replaced the filters, reinstall the

front stainless steel panel, otherwise the

Downdraft is not able to function.

WARNING

6

2 x CAP66CF charcoal filters are required for the

DD903BK

1 x CAP72CF charcoal filter is required for the

DD522BK.

these can be purchased directly from

www.caple.co.uk or by calling our sales office on

0117 938 1900

Clean air is then recycled back into the room via a

ventilation slot in the kitchen plinth.

Page 7

The downdraft connection to the electrica

nework must be carried out only by

professional and qualified technicians.

The downdraft must be connected to a

properly installed and suitable electrical

network. The electrical system must

comply with VDE0100 standard.

WARNING

If the downdraft presents any anomaly,

disconnect the appliance or remove the fuse

corresponding to the appliance power

disconnecting line.

DANGER

If the appliance has no plug or if the plug is not

easily accessible, then a device needs to be tted

to cut it off from the electric network; this device

must have an opening distance between contacts

on all poles of at least 3 mm.

ELECTRICAL CONNECTION

This appliance complies with the European

Directives 2014/35/EU (Low Voltage Directive)

and 2014/30/EU (Electromagnetic Compatibility).

NOTE

While installing the appliance and carrying

maintenance operation, make sure it is

disconnected from the electrical network or the fuses

are cut out or removed.

Check that:

• Power is enough.

• Feeder lines (mains) are in good conditions.

• The cables diameter complies with

installation regulations.

7

Page 8

Push button control panel (fig. 8)

A: 10 minutes timer, after which the motor is

turned off and the front is closed.

The setting of the function is signaled by

indicator(B) flashing.

B: The motor speed indicator.

The LED gives off four different colors, depending

on the set speed.

First speed color: WHITE

Second speed color: GREEN

Third speed color: BLUE

Fourth speed color: RED

C: The key is only active with open top (45° 90°).

For each selection of the function there is an

increase of the motor speed, up to the fourth

speed.

D: the key is only active with open top (45° 90°).

Each time

you select the function you have a

speed decrease of the motor, up to the first

speed.

E: When the product is switched off, the first

touch activates the top panel until it reaches the

intermediate opening of 45°.

As the intermediate opening is reached, the

motor is automatically set to the 2nd speed.

Another press will start full opening (90°) of

the top panel, maintaining the speed of the motor.

Another press will stop the motor and completely

close the top panel.

NOTE:

- When the top panel is opened at 45°, hold down

the E button for 3 seconds, the top panel will

close and the motor turns off.

- When the top panel is closed, hold down the E

button for 3 seconds, the top panels opens by 90°

and the motor is activated at the second speed.

Warning: The product DD522BK allows the

opening of the glass top only by 90° (no 45°

opening is possible).

HOW THE

DOWNDRAFT WORKS

TIMING

As a result of the new EU65 “Energy label” and

EU66 “ Ecodesign” regulations issued by the European Commission, which came into force as from

January 1st, 2015 , our products have been adapted to comply with these new requirements.

All of the models complying with the energy label

requirements, are equipped with new electronics

including a timer device for suction speeds control,

when the air capacity exceeds 650m³/h.

Internal motor models, with maximum air capacity

higher than 650m³/h, are equipped with a timer device that automatically switches the suction speed

from 4th to 3rd speed, after 6 minutes operation.

External motor models are equipped with remote

motors that , as for internal motor versions, include a timer device that switches down the suction

speed when it exceeds 650 m³/h. (See External

Motors Instructions)

Remote motors, whose air capacity exceeds

650m³/h at both 4th and 3rd speed, will have the

following by default timer control functions:

The suction speed is automatically switched from

4th to 2nd speed, after 6 minutes operation.

If the appliance is working at 3rd speed, it is automatically switched to 2nd speed, after 7 minutes

operation. Operation speeds can also be changed

during operation.

The energy consumption of the appliance in stand

– by mode is lower than 0.5W.

Other functions:

Automatic turn off:

After 4 hours of continuous operation from the last

setup, the appliance turns off automatically.

Grease lters saturation

After 30 hours of operation, the speed indicators

“B” will all flash simultaneously, signaling the

grease filters saturation. To reset this alarm, hold

the “TIMER” button down for at least 3 seconds,

while the extractable unit is open.

8

Fig.8

Page 9

Careful maintenance ensures proper operation and good performances over time.

CLEANING THE

DOWNDRAFT

The hood must be disconnected from the electrical network, both by unplugging the appliance

from the socket and activating the magnetic circuit breaker (safety cut-out), before removing the

metal grease lters. After cleaning operations, replace the metal grease lters as outlined in the

installation instructions.

CAUTION

MAINTENANCE HOW TO PROCEED?

ACCESSORY PRODUCTS TO

USE

Cleaning external

surfaces and

accessories

Do not use metallic scrubbers,

abrasive products, or hard brushes.

To clean the external surfaces of the

downdraft and the light housing

screen use only commercially

available household detergents

diluted in water. Then rinse with

clean water and dry with a soft cloth.

Grease filters

Activated charcoal

lter

After 30 hours of operation, the

downdraft will signal the grease filter

saturation. Saturation is indicated

by flashing RED color LED speed

indicator, when the cooker hood is

off. To reset, hold down the timer

button for at least 3 seconds,

while the hood is OFF.

In the recirculation mode, the

active charcoal filter must be

replaced periodically.

To remove the charcoal filter first of

all it is necessary to remove the

grease filter and then pull the

plastic key of the panel itself, in

order to disengage it from its seating.

Follow these steps in reverse order

to insert the active charcoal filter.

Replace the used charcoal filter on

an average of every six months.

The grease filters can be washed by

hand or in the dishwasher. These

filters need to be cleaned on a

regular basis, because otherwise

they may represent a fire risk.

Refit the grease filters and front

panel, making sure that they are

properly fitted at the sides so that

it does not cause the downdraft to

stop operating.

9

Page 10

TROUBLESHOOTING

PROBLEM SOLUTION

The downdraft

does not work...

The downdraft has

low performances...

The downdraft stops

in the middle of

operation.

Check that:

● There is not a power outage.

● A specic speed has actually been selected.

● The red reset key, found over the electrical system box, is pushed.

Check that:

● The motor speed selected is sufcient for the quantity of fumes and

vapors present in the room.

● The kitchen is ventilated well enough to allow air for intake.

●

The charcoal filter is not worn out.( recirculation mode only).

● The air outlet channel is free and compliant with paragraph no. 2.

● The non-return valves of the suctioning unit are free to rotate.

Check that:

● There is not a power outage.

● The omnipolar device has not tripped.

AFTER SALES SERVICE

Any maintenance operation on your appliance should be carried out by:

● Either your retailer;

●

Or another Caple approved engineer or similiar qualified person.

10

If a problem still persists and further assistance is required, please contact our Caple after sales

team on:

T - 0117 938 7420

E - service@caple.co.uk

Page 11

Fig. 1

Fig. 3

Fig. 4

Fig. 5

Fig. 2

11

Page 12

Fig. 7

Fig. 8

Fig. 9

Fig. 6

12

Page 13

Fig. 10

220X90

220X90

DDMEXT21

or

DDMEXT30

A

A

SEZIONE A-A

DD522BK with DDMEXT21 or DDMEXT30

Fig. 11

13

Page 14

A

A

SEZIONE A-A

SCALA 1 : 8

Fig. 13

14

Page 15

Page 16

Bristol

BS11 8DW

t: 0117 938 7420

e: service@caple.co.uk

www.caple.co.uk

Please keep this instruction manual for future reference

Caple Service

Fourth Way

Avonmouth

Loading...

Loading...